Page 1

1

www.fairchildsemi.com

FM93CS06 Rev. C.1

FM93CS06 (MICROWIRE Bus Interface) 256-Bit Serial EEPROM

with Data Protect and Sequential Read

July 2000

© 2000 Fairchild Semiconductor International

FM93CS06

(MICROWIRE™ Bus Interface) 256-Bit Serial EEPROM

with Data Protect and Sequential Read

General Description

FM93CS06 is a 256-bit CMOS non-volatile EEPROM organized

as 16 x 16-bit array. This device features MICROWIRE interface

which is a 4-wire serial bus with chipselect (CS), clock (SK), data

input (DI) and data output (DO) signals. This interface is compatible to many of standard Microcontrollers and Microprocessors.

FM93CS06 offers programmable write protection to the memory

array using a special register called Protect Register. Selected

memory locations can be protected against write by programming

this Protect Register with the address of the first memory location

to be protected (all locations greater than or equal to this first

address are then protected from further change). Additionally, this

address can be “permanently locked” into the device, making all

future attempts to change data impossible. In addition this device

features “sequential read”, by which, entire memory can be read

in one cycle instead of multiple single byte read cycles. There are

10 instructions implemented on the FM93CS06, 5 of which are for

memory operations and the remaining 5 are for Protect Register

operations. This device is fabricated using Fairchild Semiconductor floating-gate CMOS process for high reliability, high endurance

and low power consumption.

“LZ” and “L” versions of FM93CS06 offer very low standby current

making them suitable for low power applications. This device is offered

in both SO and TSSOP packages for small space considerations.

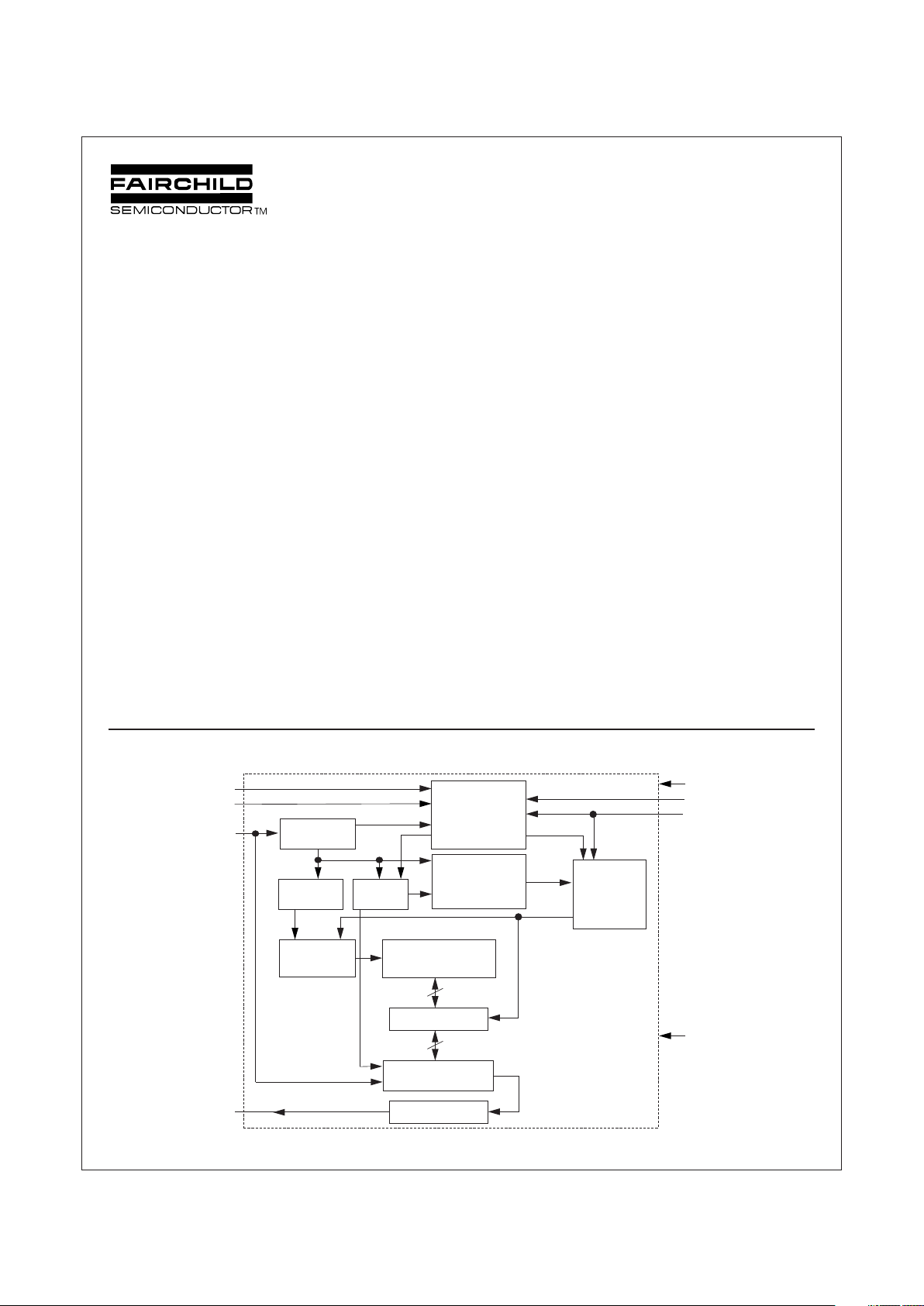

Functional Diagram

Features

■ Wide VCC 2.7V - 5.5V

■ Programmable write protection

■ Sequential register read

■ Typical active current of 200µA

10µA standby current typical

1µA standby current typical (L)

0.1µA standby current typical (LZ)

■ No Erase instruction required before Write instruction

■ Self timed write cycle

■ Device status during programming cycles

■ 40 year data retention

■ Endurance: 1,000,000 data changes

■ Packages available: 8-pin SO, 8-pin DIP, 8-pin TSSOP

INSTRUCTION

DECODER

CONTROL LOGIC

AND CLOCK

GENERATORS

COMPARATOR

AND

WRITE ENABLE

HIGH VOLTAGE

GENERATOR

AND

PROGRAM

TIMER

INSTRUCTION

REGISTER

ADDRESS

REGISTER

PROTECT

REGISTER

EEPROM ARRAY

READ/WRITE AMPS

DATA IN/OUT REGISTER

16 BITS

DECODER

16

16

DATA OUT BUFFER

PRE

PE

CS

SK

DI

DO

V

SS

V

CC

Page 2

2

www.fairchildsemi.com

FM93CS06 Rev. C.1

FM93CS06 (MICROWIRE Bus Interface) 256-Bit Serial EEPROM

with Data Protect and Sequential Read

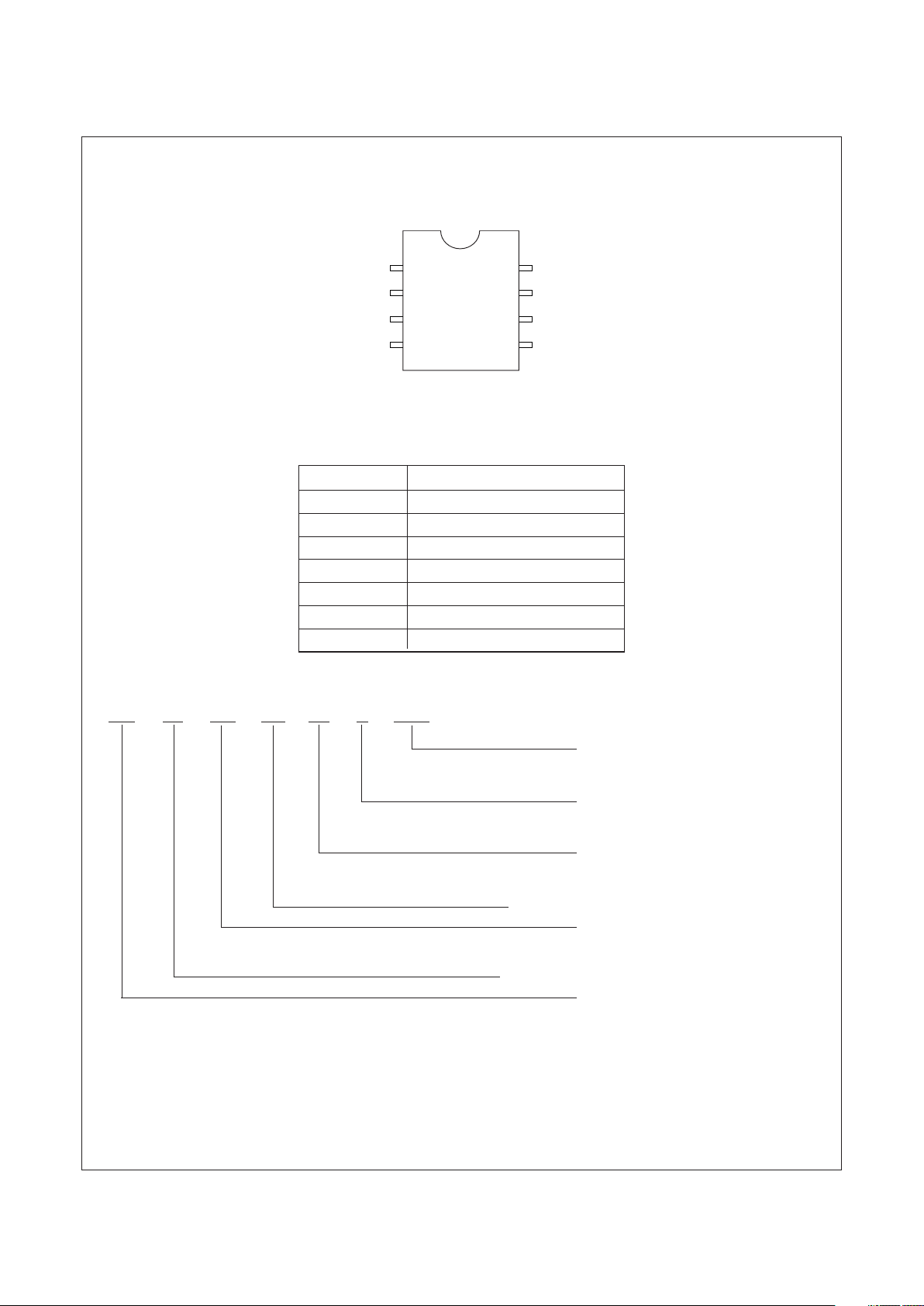

Connection Diagram

Dual-In-Line Package (N)

8–Pin SO (M8) and 8–Pin TSSOP (MT8)

Top View

Package Number

N08E, M08A and MTC08

Pin Names

CS Chip Select

SK Serial Data Clock

DI Serial Data Input

DO Serial Data Output

GND Ground

PE Program Enable

PRE Protect Register Enable

V

CC

Power Supply

Ordering Information

FM 93 CS XX LZ E XXX Letter Description

Package N 8-pin DIP

M8 8-pin SO

MT8 8-pin TSSOP

Temp. Range None 0 to 70°C

V -40 to +125°C

E -40 to +85°C

Voltage Operating Range Blank 4.5V to 5.5V

L 2.7V to 5.5V

LZ 2.7V to 5.5V and

<1µA Standby Current

Density 06 256 bits

C CMOS

CS Data protect and sequential

read

Interface 93 MICROWIRE

Fairchild Memory Prefix

V

CC

PE

GND

CS

SK

DI

DO

1

2

3

4

8

7

6

5

PRE

Page 3

3

www.fairchildsemi.com

FM93CS06 Rev. C.1

FM93CS06 (MICROWIRE Bus Interface) 256-Bit Serial EEPROM

with Data Protect and Sequential Read

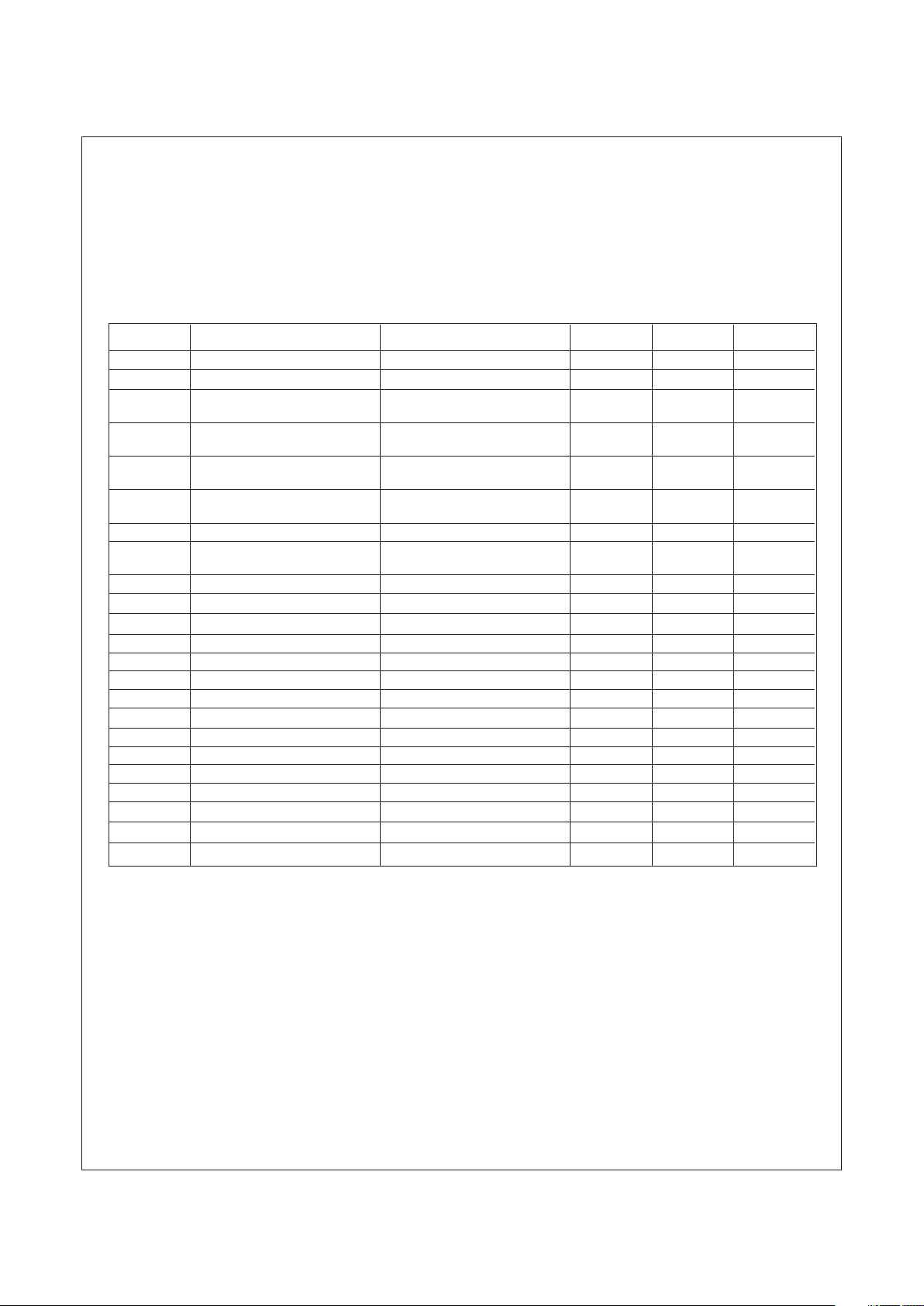

Absolute Maximum Ratings (Note 1)

Ambient Storage Temperature -65°C to +150°C

All Input or Output Voltages +6.5V to -0.3V

with Respect to Ground

Lead Temperature

(Soldering, 10 sec.) +300°C

ESD rating 2000V

Operating Conditions

Ambient Operating Temperature

FM93CS06 0°C to +70°C

FM93CS06E -40°C to +85°C

FM93CS06V -40°C to +125°C

Power Supply (V

CC

) 4.5V to 5.5V

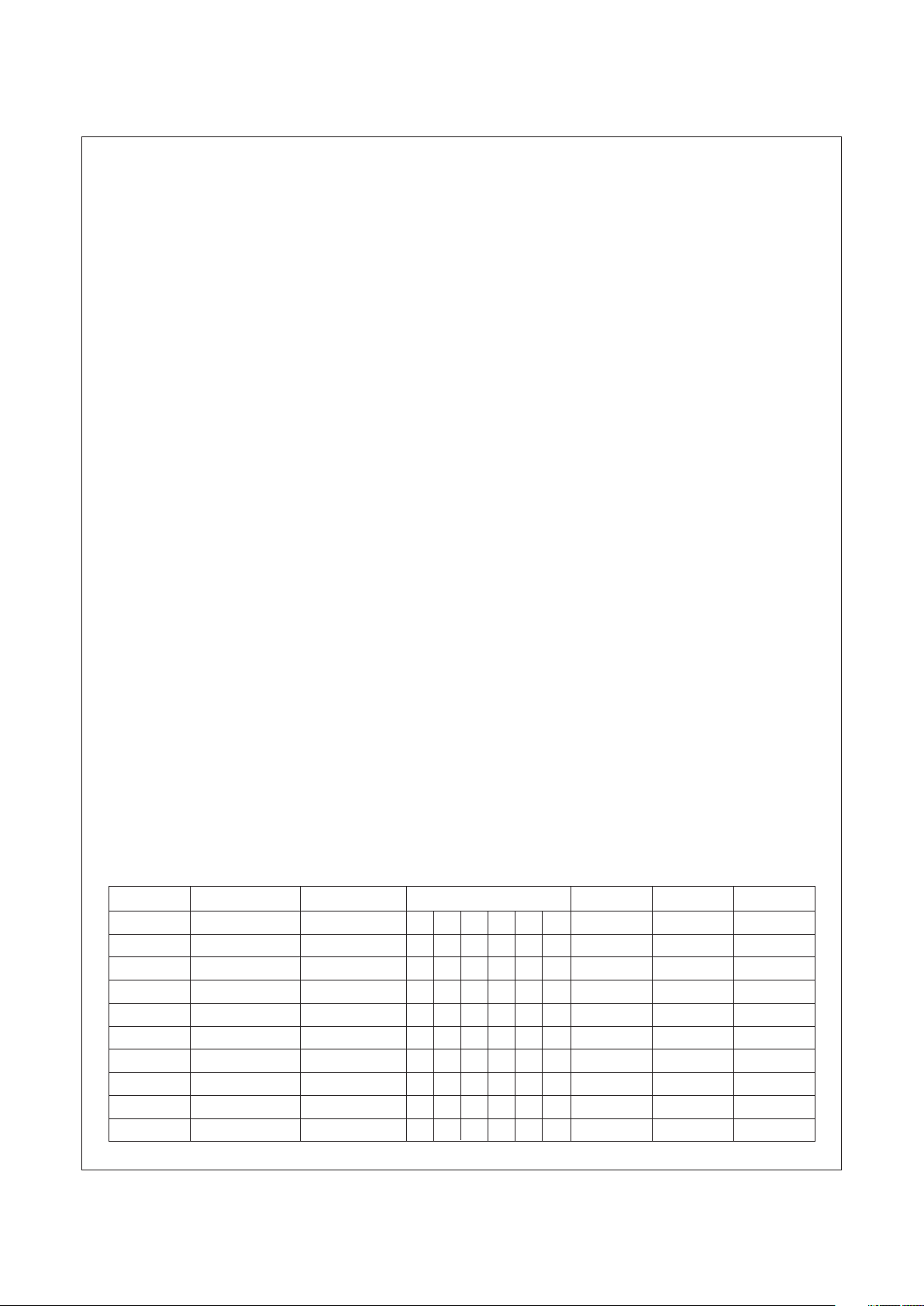

DC and AC Electrical Characteristics V

CC

= 4.5V to 5.5V unless otherwise specified

Symbol Parameter Conditions Min Max Units

I

CCA

Operating Current CS = VIH, SK=1.0 MHz 1 mA

I

CCS

Standby Current CS = V

IL

50 µA

I

IL

Input Leakage VIN = 0V to V

CC

±-1 µA

I

OL

Output Leakage (Note 2)

V

IL

Input Low Voltage -0.1 0.8 V

V

IH

Input High Voltage 2 VCC +1

V

OL1

Output Low Voltage IOL = 2.1 mA 0.4 V

V

OH1

Output High Voltage IOH = -400 µA 2.4

V

OL2

Output Low Voltage IOL = 10 µA 0.2 V

V

OH2

Output High Voltage IOH = -10 µAV

CC

- 0.2

f

SK

SK Clock Frequency (Note 3) 1 MHz

t

SKH

SK High Time 0°C to +70°C 250 ns

-40°C to +125°C 300

t

SKL

SK Low Time 250 ns

t

CS

Minimum CS Low Time (Note 4) 250 ns

t

CSS

CS Setup Time 50 ns

t

PRES

PRE Setup Time 50 ns

t

DH

DO Hold Time 70 ns

t

PES

PE Setup Time 50 ns

t

DIS

DI Setup Time 100 ns

t

CSH

CS Hold Time 0 ns

t

PEH

PE Hold Time 250 ns

t

PREH

PRE Hold Time 50 ns

t

DIH

DI Hold Time 20 ns

t

PD

Output Delay 500 ns

t

SV

CS to Status Valid 500 ns

t

DF

CS to DO in Hi-Z CS = V

IL

100 ns

t

WP

Write Cycle Time 10 ms

Page 4

4

www.fairchildsemi.com

FM93CS06 Rev. C.1

FM93CS06 (MICROWIRE Bus Interface) 256-Bit Serial EEPROM

with Data Protect and Sequential Read

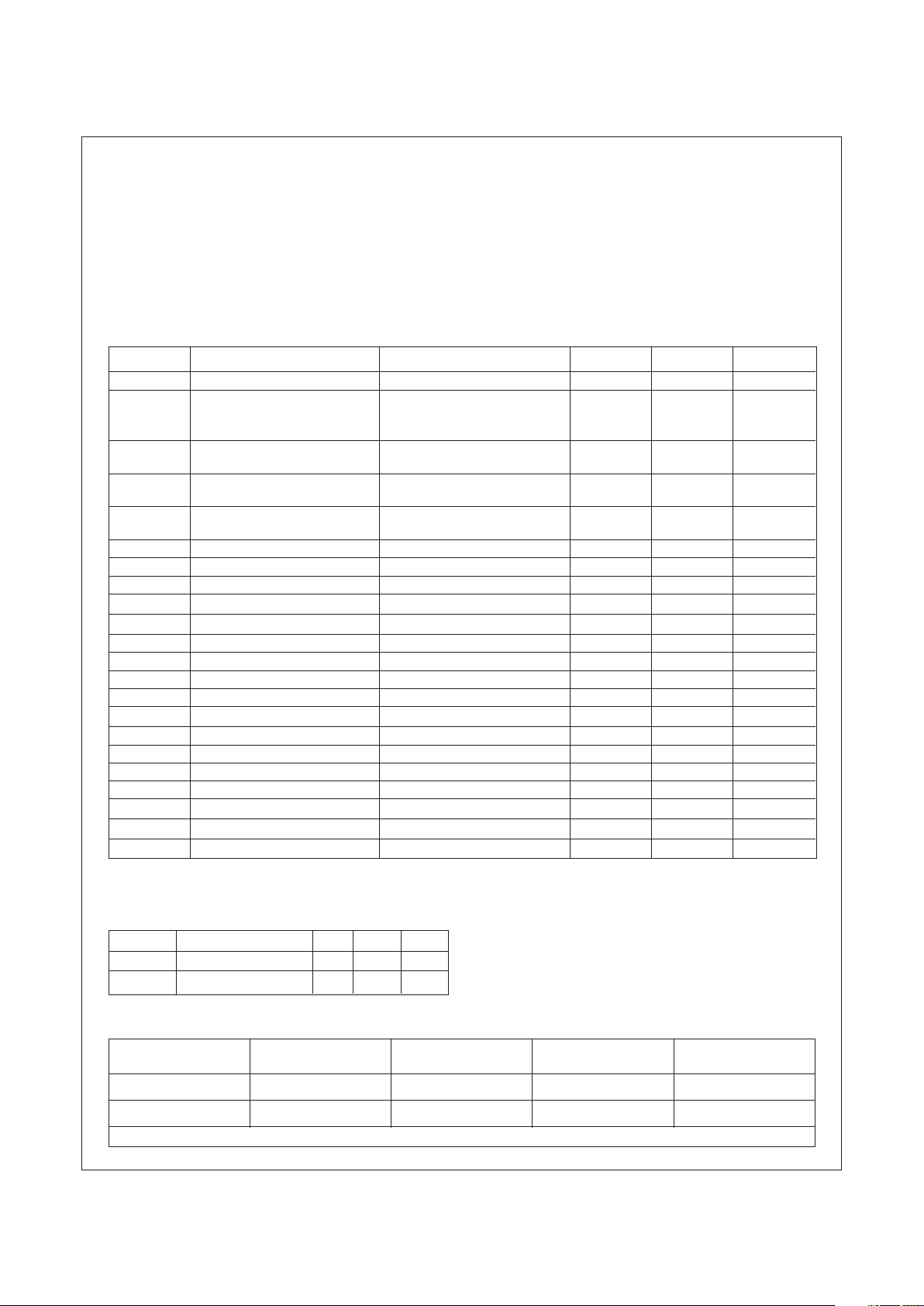

Absolute Maximum Ratings (Note 1)

Ambient Storage Temperature -65°C to +150°C

All Input or Output Voltages +6.5V to -0.3V

with Respect to Ground

Lead Temperature

(Soldering, 10 sec.) +300°C

ESD rating 2000V

Operating Conditions

Ambient Operating Temperature

FM93CS06L/LZ 0°C to +70°C

FM93CS06LE/LZE -40°C to +85°C

FM93CS06LV/LZV -40°C to +125°C

Power Supply (V

CC

) 2.7V to 5.5V

DC and AC Electrical Characteristics V

CC

= 2.7V to 4.5V unless otherwise specified. Refer to

page 3 for V

CC

= 4.5V to 5.5V.

Symbol Parameter Conditions Min Max Units

I

CCA

Operating Current CS = VIH, SK= 250 KHz 1 mA

I

CCS

Standby Current CS = V

IL

L 10 µA

LZ (2.7V to 4.5V) 1 µA

I

IL

Input Leakage VIN = 0V to V

CC

±1 µA

I

OL

Output Leakage (Note 2)

V

IL

Input Low Voltage -0.1 0.15V

CC

V

V

IH

Input High Voltage 0.8V

CC

VCC +1

V

OL

Output Low Voltage IOL = 10µA 0.1V

CC

V

V

OH

Output High Voltage IOH = -10µA 0.9V

CC

f

SK

SK Clock Frequency (Note 3) 0 250 KHz

t

SKH

SK High Time 1 µs

t

SKL

SK Low Time 1 µs

t

CS

Minimum CS Low Time (Note 4) 1 µs

t

CSS

CS Setup Time 0.2 µs

t

PRES

PRE Setup Time 50 ns

t

DH

DO Hold Time 70 ns

t

PES

PE Setup Time 50 ns

t

DIS

DI Setup Time 0.4 µs

t

CSH

CS Hold Time 0 ns

t

PEH

PE Hold Time 250 ns

t

PREH

PRE Hold Time 50 ns

t

DIH

DI Hold Time 0.4 µs

t

PD

Output Delay 2 µs

t

SV

CS to Status Valid 1 µs

t

DF

CS to DO in Hi-Z CS = V

IL

0.4 µs

t

WP

Write Cycle Time 15 ms

Capacitance TA = 25°C, f = 1 MHz or 250

KHz(Note 5)

Symbol Test Typ Max Units

C

OUT

Output Capacitance 5 pF

C

IN

Input Capacitance 5 pF

Note 1: Stress above those listed under “Absolute Maximum Ratings” may cause permanent damage

to the device. This is a stress rating only and functional operation of the device at these or any other

conditions above those indicated in the operational sections of the specification is not implied. Exposure

to absolute maximum rating conditions for extended periods may affect device reliability.

Note 2: Typical leakage values are in the 20nA range.

Note 3: The shortest allowable SK clock period = 1/f

SK

(as shown under the fSK parameter). Maximum

SK clock speed (minimum SK period) is determined by the interaction of several AC parameters stated

in the datasheet. Within this SK period, both t

SKH

and t

SKL

limits must be observed. Therefore, it is not

allowable to set 1/fSK = t

SKHminimum

+ t

SKLminimum

for shorter SK cycle time operation.

Note 4: CS (Chip Select) must be brought low (to V

IL

) for an interval of tCS in order to reset all internal

device registers (device reset) prior to beginning another opcode cycle. (This is shown in the opcode

diagram on the following page.)

Note 5: This parameter is periodically sampled and not 100% tested.

AC Test Conditions

VCC Range VIL/V

IH

VIL/V

IH

VOL/V

OH

IOL/I

OH

Input Levels Timing Level Timing Level

2.7V ≤ VCC ≤ 5.5V 0.3V/1.8V 1.0V 0.8V/1.5V ±10µA

(Extended Voltage Levels)

4.5V ≤ VCC ≤ 5.5V 0.4V/2.4V 1.0V/2.0V 0.4V/2.4V 2.1mA/-0.4mA

(TTL Levels)

Output Load: 1 TTL Gate (CL = 100 pF)

Page 5

5

www.fairchildsemi.com

FM93CS06 Rev. C.1

FM93CS06 (MICROWIRE Bus Interface) 256-Bit Serial EEPROM

with Data Protect and Sequential Read

Pin Description

Chip Select (CS)

This is an active high input pin to FM93CS06 EEPROM (the device)

and is generated by a master that is controlling the device. A high

level on this pin selects the device and a low level deselects the

device. All serial communications with the device is enabled only

when this pin is held high. However this pin cannot be permanently

tied high, as a rising edge on this signal is required to reset the

internal state-machine to accept a new cycle and a falling edge to

initiate an internal programming after a write cycle. All activity on the

SK, DI and DO pins are ignored while CS is held low.

Serial Clock (SK)

This is an input pin to the device and is generated by the master that

is controlling the device. This is a clock signal that synchronizes the

communication between a master and the device. All input information (DI) to the device is latched on the rising edge of this clock input,

while output data (DO) from the device is driven from the rising edge

of this clock input. This pin is gated by CS signal.

Serial Input (DI)

This is an input pin to the device and is generated by the master

that is controlling the device. The master transfers Input information (Start bit, Opcode bits, Array addresses and Data) serially via

this pin into the device. This Input information is latched on the

rising edge of the SCK. This pin is gated by CS signal.

Serial Output (DO)

This is an output pin from the device and is used to transfer Output

data via this pin to the controlling master. Output data is serially

shifted out on this pin from the rising edge of the SCK. This pin is

active only when the device is selected.

Protect Register Enable (PRE)

This is an active high input pin to the device and is used to

distinguish operations to memory array and operations to Protect

Register. When this pin is held low, operations to the memory

array are enabled. When this pin is held high, operations to the

Protect Register are enabled. This pin operates in conjunction

with PE pin. Refer Table1 for functional matrix of this pin for

various operations.

Program Enable (PE)

This is an active high input pin to the device and is used to enable

operations, that are write in nature, to the memory array and to the

Protect register. When this pin is held high, operations that are

“write” in nature are enabled. When this pin is held low, operations

that are “write” in nature are disabled. This pin operates in

conjunction with PRE pin. Refer Table1 for functional matrix of this

pin for various operations.

Microwire Interface

A typical communication on the Microwire bus is made through the

CS, SK, DI and DO signals. To facilitate various operations on the

Memory array and on the Protect Register, a set of 10 instructions

are implemented on FM93CS06. The format of each instruction is

listed in Table 1.

Instruction

Each of the above 10 instructions is explained under individual

instruction descriptions.

Start Bit

This is a 1-bit field and is the first bit that is clocked into the device

when a Microwire cycle starts. This bit has to be “1” for a valid cycle

to begin. Any number of preceding “0” can be clocked into the

device before clocking a “1”.

Opcode

This is a 2-bit field and should immediately follow the start bit.

These two bits (along with PRE, PE signals and 2 MSB of address

field) select a particular instruction to be executed.

Address Field

This is a 6-bit field and should immediately follow the Opcode bits.

In FM93CS06, only the LSB 4 bits are used for address decoding

during READ, WRITE and PRWRITE instructions. During these

instructions (READ, WRITE and PRWRITE), the MSB 2 bits are

"don't care" (can be 0 or 1). During all other instructions (with the

exception of PRREAD), the MSB 2 bits are used to decode

instruction (along with Opcode bits, PRE and PE signals).

Data Field

This is a 16-bit field and should immediately follow the Address

bits. Only the WRITE and WRALL instructions require this field.

D15 (MSB) is clocked first and D0 (LSB) is clocked last (both

during writes as well as reads).

TABLE 1. Instruction set

Instruction Start Bit Opcode Field Address Field Data Field PRE Pin PE Pin

READ 1 10 X X A3 A2 A1 A0 0 X

WEN 1 00 1 1XXXX 0 1

WRITE 1 01 X X A3 A2 A1 A0 D15-D0 0 1

WRALL 1 00 0 1 XXXX D15-D0 0 1

WDS 1 00 0 0XXXX 0 X

PRREAD 1 10 X X XXXX 1 X

PREN 1 00 1 1 XXXX 1 1

PRCLEAR 1 11 111111 1 1

PRWRITE 1 01 X X A3 A2 A1 A0 1 1

PRDS 1 00 000000 1 1

Page 6

6

www.fairchildsemi.com

FM93CS06 Rev. C.1

FM93CS06 (MICROWIRE Bus Interface) 256-Bit Serial EEPROM

with Data Protect and Sequential Read

Functional Description

A typical Microwire cycle starts by first selecting the device

(bringing the CS signal high). Once the device is selected, a valid

Start bit (“1”) should be issued to properly recognize the cycle.

Following this, the 2-bit opcode of appropriate instruction should

be issued. After the opcode bits, the 6-bit address information

should be issued. For certain instructions, some (or all) of these

6 bits are don’t care values (can be “0” or “1”), but they should still

be issued. Following the address information, depending on the

instruction (WRITE and WRALL), 16-Bit data is issued. Otherwise, depending on the instruction (READ and PRREAD), the

device starts to drive the output data on the DO line. Other

instructions perform certain control functions and do not deal with

data bits. The Microwire cycle ends when the CS signal is brought

low. However during certain instructions, falling edge of the CS

signal initiates an internal cycle (Programming), and the device

remains busy till the completion of the internal cycle. Each of the

10 instructions is explained in detail in the following sections.

Memory Instructions

Following five instructions, READ, WEN, WRITE, WRALL and

WDS are specific to operations intended for memory array. The

PRE pin should be held low during these instructions.

1) Read and Sequential Read (READ)

READ instruction allows data to be read from a selected location

in the memory array. Input information (Start bit, Opcode and

Address) for this instruction should be issued as listed under

Table1. Upon receiving a valid input information, decoding of the

opcode and the address is made, followed by data transfer from

the selected memory location into a 16-bit serial-out shift register.

This 16-bit data is then shifted out on the DO pin. D15 bit (MSB)

is shifted out first and D0 bit (LSB) is shifted out last. A dummy-bit

(logical 0) precedes this 16-bit data output string. Output data

changes are initiated on the rising edge of the SK clock. After

reading the 16-bit data, the CS signal can be brought low to end

the Read cycle. The PRE pin should be held low during this cycle.

Refer

Read cycle diagram

.

This device also offers “sequential memory read” operation to

allow reading of data from the additional memory locations instead

of just one location. It is started in the same manner as normal read

but the cycle is continued to read further data (instead of terminating after reading the first 16-bit data). After providing 16-bit data,

the device automatically increments the address pointer to the

next location and continues to provide the data from that location.

Any number of locations can be read out in this manner, however,

after reading out from the last location, the address pointer points

back to the first location. If the cycle is continued further, data will

be read from this first location onward. In this mode of read, the

dummy-bit is present only when the very first data is read (like

normal read cycle) and is not present on subsequent data reads.

The PRE pin should be held low during this cycle. Refer

Sequen-

tial Read cycle diagram

.

2) Write Enable (WEN)

When VCC is applied to the part, it “powers up” in the Write Disable

(WDS) state. Therefore, all programming operations (for both

memory array and Protect Register) must be preceded by a Write

Enable (WEN) instruction. Once a Write Enable instruction is

executed, programming remains enabled until a Write Disable

(WDS) instruction is executed or VCC is completely removed from

the part. Input information (Start bit, Opcode and Address) for this

WEN instruction should be issued as listed under Table1. The

device becomes write-enabled at the end of this cycle when the

CS signal is brought low. The PRE pin should be held low during

this cycle. Execution of a READ instruction is independent of WEN

instruction. Refer

Write Enable cycle diagram.

3) Write (WRITE)

WRITE instruction allows write operation to a specified location in

the memory with a specified data. This instruction is valid only

when the following are true:

■ Device is write-enabled (Refer WEN instruction)

■ Address of the write location is not write-protected

■ PE pin is held high during this cycle

■ PRE pin should be held low during this cycle

Input information (Start bit, Opcode, Address and Data) for this

WRITE instruction should be issued as listed under Table1. After

inputting the last bit of data (D0 bit), CS signal must be brought low

before the next rising edge of the SK clock. This falling edge of the

CS initiates the self-timed programming cycle. It takes t

WP

time

(Refer appropriate DC and AC Electrical Characteristics table) for

the internal programming cycle to finish. During this time, the

device remains busy and is not ready for another instruction.

The status of the internal programming cycle can be polled at any

time by bringing the CS signal high again, after tCS interval. When

CS signal is high, the DO pin indicates the READY/BUSY status

of the chip. DO = logical 0 indicates that the programming is still

in progress. DO = logical 1 indicates that the programming is

finished and the device is ready for another instruction. It is not

required to provide the SK clock during this status polling. While

the device is busy, it is recommended that no new instruction be

issued. Refer

Write cycle diagram.

It is also recommended to follow this instruction (after the device

becomes READY) with a Write Disable (WDS) instruction to

safeguard data against corruption due to spurious noise, inadvertent writes etc.

4) Write All (WRALL)

Write all (WRALL) instruction is similar to the Write instruction

except that WRALL instruction will simultaneously program all

memory locations with the data pattern specified in the instruction.

This instruction is valid only when the following are true:

■ Protect Register has been cleared (Refer PRCLEAR

instruction)

■ Device is write-enabled (Refer WEN instruction)

■ PE pin is held high during this cycle

■ PRE pin should be held low during this cycle

Input information (Start bit, Opcode, Address and Data) for this

WRALL instruction should be issued as listed under Table1. After

inputting the last bit of data (D0 bit), CS signal must be brought low

before the next rising edge of the SK clock. This falling edge of the

CS initiates the self-timed programming cycle. It takes tWP time

(Refer appropriate DC and AC Electrical Characteristics table) for

the internal programming cycle to finish. During this time, the

device remains busy and is not ready for another instruction.

Status of the internal programming can be polled as described

under WRITE instruction description. While the device is busy, it

is recommended that no new instruction be issued. Refer

Write All

cycle diagram.

Page 7

7

www.fairchildsemi.com

FM93CS06 Rev. C.1

FM93CS06 (MICROWIRE Bus Interface) 256-Bit Serial EEPROM

with Data Protect and Sequential Read

5) Write Disable (WDS)

Write Disable (WDS) instruction disables all programming operations and is recommended to follow all programming operations.

Executing this instruction after a valid write instruction would

protect against accidental data disturb due to spurious noise,

glitches, inadvertent writes etc. Input information (Start bit, Opcode

and Address) for this WDS instruction should be issued as listed

under Table1. The device becomes write-disabled at the end of

this cycle when the CS signal is brought low. Execution of a READ

instruction is independent of WDS instruction. Refer

Write Disable

cycle diagram.

Protect Register Instructions

Following five instructions, PRREAD, PREN, PRCLEAR,

PRWRITE and PRDS are specific to operations intended for

Protect Register. The PRE pin should be held high during these

instructions.

1) Protect Register Read (PRREAD)

This instruction reads the content of the internal Protect Register.

Content of this register is 6-bit wide and is the starting address of

the “write-protected” section of the memory array. All memory

locations greater than or equal to this address are write-protected.

Input information (Start bit, Opcode and Address) for this PRREAD

instruction should be issued as listed under Table1. Upon receiving a valid input information, decoding of the opcode and the

address is made, followed by data transfer (address information)

from the Protect Register. This 6-bit data is then shifted out on the

DO pin with the MSB first and the LSB last. Like the READ

instruction a dummy-bit (logical 0) precedes this 6-bit data output

string. Output data changes are initiated on the rising edge of the

SK clock. After reading the 6-bit data, the CS signal can be

brought low to end the PRREAD cycle. The PRE pin should be

held high during this cycle. Refer

Protect Register Read cycle

diagram.

Though the content of this register is 6-bit wide, only the last 4 bits

(LSB) are valid for FM93CS06 device.

2) Protect Register Enable (PREN)

This instruction is required to enable PRCLEAR, PRWRITE and

PRDS instructions and should be executed prior to executing

PRCLEAR, PRWRITE and PRDS instructions. However, this

PREN instruction is enabled (valid) only the following are true

■ Device is write-enabled (Refer WEN instruction)

■ PE pin is held high during this cycle

■ PRE pin is held high during this cycle

Input information (Start bit, Opcode and Address) for this PREN

instruction should be issued as listed under Table1. The Protect

Register becomes enabled for PRCLEAR, PRWRITE and PRDS

instructions at the end of this cycle when the CS signal is brought

low. Note that this PREN instruction must immediately precede

a PRCLEAR, PRWRITE or PRDS instruction. In other words, no

other instruction should be executed between a PREN instruction

and a PRCLEAR, PRWRITE or PRDS instruction. Refer

Protect

Register Enable cycle diagram.

3) Protect Register Clear (PRCLEAR)

This instruction clears the content of the Protect register and

therefore enables write operations (WRITE or WRALL) to all

memory locations. Executing this instruction will program the

content of the Protect Register with a pattern of all 1s. However,

in this case, WRITE operation to the last memory address

(0x001111) is still enabled. PRCLEAR instruction is enabled

(valid) only when the following are true:

■ PREN instruction was executed immediately prior to

PRCLEAR instruction

■ PE pin is held high during this cycle

■ PRE pin is held high during this cycle

Input information (Start bit, Opcode and Address) for this PRCLEAR

instruction should be issued as listed under Table1. After inputting

the last bit of address (A0 bit), CS signal must be brought low

before the next rising edge of the SK clock. This falling edge of the

CS initiates the self-timed clear cycle. It takes tWP time (Refer

appropriate DC and AC Electrical Characteristics table) for the

internal clear cycle to finish. During this time, the device remains

busy and is not ready for another instruction. Status of the internal

programming can be polled as described under WRITE instruction

description. While the device is busy, it is recommended that no

new instruction be issued. Refer

Protect Register Clear cycle

diagram.

4) Protect Register Write (PRWRITE)

This instruction is used to write the starting address of the memory

section to be write-protected into the Protect register. After the

execution of PRWRITE instruction, all memory locations greater

than or equal to this address are write-protected. PRWRITE

instruction is enabled (valid) only the following are true:

■ PRCLEAR instruction was executed first (to clear the Protect

Register)

■ PREN instruction was executed immediately prior to

PRWRITE instruction

■ PE pin is held high during this cycle

■ PRE pin is held high during this cycle

Input information (Start bit, Opcode and Address) for this PRWRITE

instruction should be issued as listed under Table1. After inputting

the last bit of address (A0 bit), CS signal must be brought low

before the next rising edge of the SK clock. This falling edge of the

CS initiates the self-timed programming cycle. It takes tWP time

(Refer appropriate DC and AC Electrical Characteristics table) for

the internal programming cycle to finish. During this time, the

device remains busy and is not ready for another instruction.

Status of the internal programming can be polled as described

under WRITE instruction description. While the device is busy, it

is recommended that no new instruction be issued. Refer

Protect

Register Write cycle diagram.

5) Protect Register Disable (PRDS)

Unlike all other instructions, this instruction is a one-time-only

instruction which when executed permanently write-protects

the Protect Register and renders it unalterable in the future. This

instruction is useful to safeguard vital data (typically read only

data) in the memory against any possible corruption. PRDS

instruction is enabled (valid) only the following are true:

■ PREN instruction was executed immediately prior to PRDS

instruction

■ PE pin is held high during this cycle

■ PRE pin is held high during this cycle

Page 8

8

www.fairchildsemi.com

FM93CS06 Rev. C.1

FM93CS06 (MICROWIRE Bus Interface) 256-Bit Serial EEPROM

with Data Protect and Sequential Read

Input information (Start bit, Opcode and Address) for this PRDS

instruction should be issued as listed under Table1. After inputting

the last bit of address (A0 bit), CS signal must be brought low

before the next rising edge of the SK clock. This falling edge of the

CS initiates the self-timed programming cycle. It takes tWP time

(Refer appropriate DC and AC Electrical Characteristics table) for

the internal programming cycle to finish. During this time, the

device remains busy and is not ready for another instruction.

Status of the internal programming can be polled as described

under WRITE instruction description. While the device is busy, it

is recommended that no new instruction be issued. The Protect

Register is permanently write-protected at the end of this cycle.

Refer

Protect Register Disable cycle diagram.

Clearing of Ready/Busy status

When programming is in progress, the Data-Out pin will display

the programming status as either BUSY (low) or READY (high)

when CS is brought high (DO output will be tri-stated when CS is

low). To restate, during programming, the CS pin may be brought

high and low any number of times to view the programming status

without affecting the programming operation. Once programming

is completed (Output in READY state), the output is ‘cleared’

(returned to normal tri-state condition) by clocking in a Start Bit.

After the Start Bit is clocked in, the output will return to a tri-stated

condition. When clocked in, this Start Bit can be the first bit in a

command string, or CS can be brought low again to reset all

internal circuits. Refer

Clearing Ready Status

diagram.

Related Document

Application Note: AN758 - Using Fairchild’s MICROWIRE™ EEPROM.

Page 9

9

www.fairchildsemi.com

FM93CS06 Rev. C.1

FM93CS06 (MICROWIRE Bus Interface) 256-Bit Serial EEPROM

with Data Protect and Sequential Read

t

CSS

SYNCHRONOUS DATA TIMING

CS

SK

PRE

PE

DI

DO (Data Read)

DO (Status Read)

Valid Status

t

PRES

t

PES

t

DIStDIH

t

PD

t

DH

t

SV

t

SKH

t

SKL

t

CSH

t

PREH

t

PEH

t

DF

t

DF

t

PD

Valid

Input

Valid

Input

Valid

Output

Valid

Output

CS

SK

DI

DO

High - Z

Dummy

Bit

1 1 0 A5 A4 A1 A0

PRE

0

D15 D1 D0

t

CS

NORMAL READ CYCLE (READ)

Address

Bits(6)

Start

Bit

Opcode

Bits(2)

93CS06:

Address bits pattern -> x-x-A3-A2-A1-A0; (x -> Don't Care, can be 0 or 1); (A3-A0 -> User defined)

PE

Timing Diagrams

CS

SK

DI

DO

High - Z

Dummy

Bit

Data(n)

1 1 0 A5 A0

PRE

0

D15 D0

D15 D0 D15 D0

t

CS

SEQUENTIAL READ CYCLE (PRE = 0; PE = X)

Data(n+1) Data(n+2)

Address

Bits(6)

Start

Bit

Opcode

Bits(2)

93CS06:

Address bits pattern -> x-x-A3-A2-A1-A0; (x -> Don't Care, can be 0 or 1); (A3-A0 -> User defined)

Page 10

10

www.fairchildsemi.com

FM93CS06 Rev. C.1

FM93CS06 (MICROWIRE Bus Interface) 256-Bit Serial EEPROM

with Data Protect and Sequential Read

Timing Diagrams (Continued)

Address

Bits(6)

CS

PE

SK

DI

DO

High - Z

WRITE DISABLE CYCLE (WDS)

Start

Bit

93CS06:

Address bits pattern -> 0-0-x-x-x-x; (x -> Don't Care, can be 0 or 1)

Opcode

Bits(2)

1 0 0 A5 A4 A1 A0

PRE

t

CS

Address

Bits(6)

Data

Bits(16)

CS

PE

SK

DI

DO

High - Z

t

CS

WRITE CYCLE (WRITE)

Start

Bit

93CS06:

Address bits pattern -> x-x-A3-A2-A1-A0; (x -> Don't Care, can be 0 or 1); (A3-A0 -> User defined)

Data bits pattern -> User defined

Opcode

Bits(2)

1 0 1 A5 A4 A1 A0 D15 D14 D1 D0

PRE

Busy

Ready

t

WP

Address

Bits(6)

CS

PE

SK

DI

DO

High - Z

WRITE ENABLE CYCLE (WEN)

Start

Bit

93CS06:

Address bits pattern -> 1-1-x-x-x-x; (x -> Don't Care, can be 0 or 1)

Opcode

Bits(2)

1 0 0 A5 A4 A1 A0

PRE

t

CS

Page 11

11

www.fairchildsemi.com

FM93CS06 Rev. C.1

FM93CS06 (MICROWIRE Bus Interface) 256-Bit Serial EEPROM

with Data Protect and Sequential Read

Timing Diagrams (Continued)

CS

SK

DI

DO

High - Z

Dummy

Bit

1 1 0 A5 A4 A1 A0

PRE

PE

0

D5 D1 D0

t

CS

PROTECT REGISTER READ CYCLE (PRREAD)

Address

Bits(6)

Start

Bit

Opcode

Bits(2)

93CS06:

Address bits pattern -> x-x-x-x-x-x; (x -> Don't Care, can be 0 or 1)

Of the 6-bit output data(D5-D0), only D3 to D0 are valid and they correspond to A3 to A0 respectively.

Address

Bits(6)

CS

PE

SK

DI

DO

High - Z

PROTECT REGISTER ENABLE CYCLE (PREN)

Start

Bit

93CS06:

Address bits pattern -> 1-1-x-x-x-x; (x -> Don't Care, can be 0 or 1)

Opcode

Bits(2)

1 0 0 A5 A4 A1 A0

PRE

t

CS

Address

Bits(6)

Data

Bits(16)

CS

PE

SK

DI

DO

High - Z

t

CS

WRITE ALL CYCLE (WRALL)

Start

Bit

93CS06:

Address bits pattern -> 0-1-x-x-x-x; (x -> Don't Care, can be 0 or 1)

Data bits pattern -> User defined

Opcode

Bits(2)

1 0 0 A5 A4 A1 A0 D15 D14 D1 D0

PRE

Busy

Ready

t

WP

Page 12

12

www.fairchildsemi.com

FM93CS06 Rev. C.1

FM93CS06 (MICROWIRE Bus Interface) 256-Bit Serial EEPROM

with Data Protect and Sequential Read

Timing Diagrams (Continued)

Address

Bits(6)

CS

PE

SK

DI

DO

High - Z

t

CS

PROTECT REGISTER WRITE CYCLE (PRWRITE)

Start

Bit

93CS06:

Address bits pattern -> x-x-A3-A2-A1-A0; (x -> Don't Care, can be 0 or 1); (A3-A0 -> User defined)

Opcode

Bits(2)

1 0 1 A5 A4 A1 A0

PRE

Busy

Ready

t

WP

Address

Bits(6)

CS

PE

SK

DI

DO

High - Z

t

CS

PROTECT REGISTER DISABLE CYCLE (PRDS)

Start

Bit

93CS06:

Address bits pattern -> 0-0-0-0-0-0

Opcode

Bits(2)

1 0 0 A5 A4 A1 A0

PRE

Busy

Ready

t

WP

Address

Bits(6)

CS

PE

SK

DI

DO

High - Z

t

CS

PROTECT REGISTER CLEAR CYCLE (PRCLEAR)

Start

Bit

93CS06:

Address bits pattern -> 1-1-1-1-1-1

Opcode

Bits(2)

1 1 1 A5 A4 A1 A0

PRE

Busy

Ready

t

WP

Page 13

13

www.fairchildsemi.com

FM93CS06 Rev. C.1

FM93CS06 (MICROWIRE Bus Interface) 256-Bit Serial EEPROM

with Data Protect and Sequential Read

Timing Diagrams (Continued)

CS

PE

SK

DI

DO

High - Z High - Z

CLEARING READY STATUS

Start

Bit

Note: This Start bit can also be part of a next instruction. Hence the cycle

can be continued(instead of getting terminated, as shown) as if a new

instruction is being issued.

PRE

Busy

Ready

Page 14

14

www.fairchildsemi.com

FM93CS06 Rev. C.1

FM93CS06 (MICROWIRE Bus Interface) 256-Bit Serial EEPROM

with Data Protect and Sequential Read

Molded Package, Small Outline, 0.15 Wide, 8-Lead (M8)

Package Number M08A

Physical Dimensions inches (millimeters) unless otherwise noted

1234

8765

0.189 - 0.197

(4.800 - 5.004)

0.228 - 0.244

(5.791 - 6.198)

Lead #1

IDENT

Seating

Plane

0.004 - 0.010

(0.102 - 0.254)

0.014 - 0.020

(0.356 - 0.508)

0.014

(0.356)

Typ.

0.053 - 0.069

(1.346 - 1.753)

0.050

(1.270)

Typ

0.016 - 0.050

(0.406 - 1.270)

Typ. All Leads

8¡ Max, Typ.

All leads

0.150 - 0.157

(3.810 - 3.988)

0.0075 - 0.0098

(0.190 - 0.249)

Typ. All Leads

0.004

(0.102)

All lead tips

0.010 - 0.020

(0.254 - 0.508)

x 45¡

Page 15

15

www.fairchildsemi.com

FM93CS06 Rev. C.1

FM93CS06 (MICROWIRE Bus Interface) 256-Bit Serial EEPROM

with Data Protect and Sequential Read

8-Pin Molded TSSOP, JEDEC (MT8)

Package Number MTC08

Physical Dimensions inches (millimeters) unless otherwise noted

0.114 - 0.122

(2.90 - 3.10)

0.123 - 0.128

(3.13 - 3.30)

0.246 - 0.256

(6.25 - 6.5)

14

85

0.169 - 0.177

(4.30 - 4.50)

(7.72) Typ

(4.16) Typ

(1.78) Typ

(0.42) Typ

(0.65) Typ

0.002 - 0.006

(0.05 - 0.15)

0.0256 (0.65)

Typ.

0.0433

(1.1)

Max

0.0075 - 0.0118

(0.19 - 0.30)

Pin #1 IDENT

0.0035 - 0.0079

0¡-8¡

0.020 - 0.028

(0.50 - 0.70)

0.0075 - 0.0098

(0.19 - 0.25)

Seating

plane

Gage

plane

See detail A

Notes: Unless otherwise specified

1. Reference JEDEC registration MO153. Variation AA. Dated 7/93

Land pattern recommendation

DETAIL A

Typ. Scale: 40X

Page 16

16

www.fairchildsemi.com

FM93CS06 Rev. C.1

FM93CS06 (MICROWIRE Bus Interface) 256-Bit Serial EEPROM

with Data Protect and Sequential Read

Physical Dimensions inches (millimeters) unless otherwise noted

Molded Dual-In-Line Package (N)

Package Number N08E

0.373 - 0.400

(9.474 - 10.16)

0.092

(2.337)

DIA

+

1234

8765

0.250 - 0.005

(6.35 ± 0.127)

87

0.032 ± 0.005

(0.813 ± 0.127)

Pin #1

Option 2

RAD

1

0.145 - 0.200

(3.683 - 5.080)

0.130 ± 0.005

(3.302 ± 0.127)

0.125 - 0.140

(3.175 - 3.556)

0.020

(0.508)

Min

0.018 ± 0.003

(0.457 ± 0.076)

90° ± 4°

Typ

0.100 ± 0.010

(2.540 ± 0.254)

0.040

(1.016)

0.039

(0.991)

Typ.

20° ± 1°

0.065

(1.651)

0.050

(1.270)

0.060

(1.524)

Pin #1 IDENT

Option 1

0.280

MIN

0.300 - 0.320

(7.62 - 8.128)

0.030

(0.762)

MAX

0.125

(3.175)

DIA

NOM

0.009 - 0.015

(0.229 - 0.381)

0.045 ± 0.015

(1.143 ± 0.381)

0.325

+0.040

-0.015

8.255

+1.016

-0.381

95° ± 5°

0.090

(2.286)

(7.112)

IDENT

Fairchild does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and Fairchild reserves the right at any time without notice to change said circuitry and specifications.

Life Support Policy

Fairchild's products are not authorized for use as critical components in life support devices or systems without the express written

approval of the President of Fairchild Semiconductor Corporation. As used herein:

1. Life support devices or systems are devices or systems which,

(a) are intended for surgical implant into the body, or (b) support

or sustain life, and whose failure to perform, when properly

used in accordance with instructions for use provided in the

labeling, can be reasonably expected to result in a significant

injury to the user.

2. A critical component is any component of a life support device

or system whose failure to perform can be reasonably expected to cause the failure of the life support device or system,

or to affect its safety or effectiveness.

Fairchild Semiconductor Fairchild Semiconductor Fairchild Semiconductor Fairchild Semiconductor

Americas Europe Hong Kong Japan Ltd.

Customer Response Center Fax: +44 (0) 1793-856858 8/F, Room 808, Empire Centre 4F, Natsume Bldg.

Tel. 1-888-522-5372 Deutsch Tel: +49 (0) 8141-6102-0 68 Mody Road, Tsimshatsui East 2-18-6, Yushima, Bunkyo-ku

English Tel: +44 (0) 1793-856856 Kowloon. Hong Kong Tokyo, 113-0034 Japan

Français Tel: +33 (0) 1-6930-3696 Tel; +852-2722-8338 Tel: 81-3-3818-8840

Italiano Tel: +39 (0) 2-249111-1 Fax: +852-2722-8383 Fax: 81-3-3818-8841

Loading...

Loading...