Page 1

Product Preview

FM3808

256Kb Bytewide FRAM w/Real-Time Clock

Features

256K bit Ferroelectric NonVolatile RAM

• Organized as 32,752 x 8 bits

• High Endurance 100 Billion (10

• 10 year Data Retention

• NoDelay™ Writes

• 70 ns Access Time/ 130 ns Cycle Time

• Built-in Low V

Protection

DD

Real-Time Clock/Calendar Function

• Clock Registers in Top 16 bytes of Address Space

• Backup Power from External Capacitor or Battery

• Tracks Seconds through Centuries in BCD Format

• Tracks Leap Years through 2099

• Runs from a 32.768 kHz Timekeeping Crystal

Description

The FM3808 combines a 256Kb FRAM array with a

real-time clock and a system supervisor function. The

timekeeping function is driven by a user supplied

32.768 kHz crystal. It maintains time and date

settings in the a bsence of system power through the

user’s choice of backup power source – either

capacitor or battery. In either case data in the memory

array does not depend on the backup source, it

remains nonvolatile in FRAM. In addition to

timekeeping, the FM3808 includes a system

supervisor to manage low V

a watchdog timer function. A programmable interrupt

output pin allows the user to select the supervisor

functions and the polarity of the signal.

Both the FRAM array and the timekeeping function

are accessed through the memory interface. The

upper 16-address locations of the memory space are

allocated to the timekeeping registers rather than to

memory. The FRAM array provides data retention

for 10 years in the absence of system power, and is

not dependent on the backup power source used for

the clock. This eliminates system concerns over data

loss in a traditional battery-backed RAM solution. In

addition, clock and supervisor control settings are

implemented in FRAM rather than battery-backed

RAM, making them more dependable. The FM3808

offers guaranteed operation over an industrial

temperature range of -40°C to +85°C.

DD

11

) Read/Writes

power conditions and

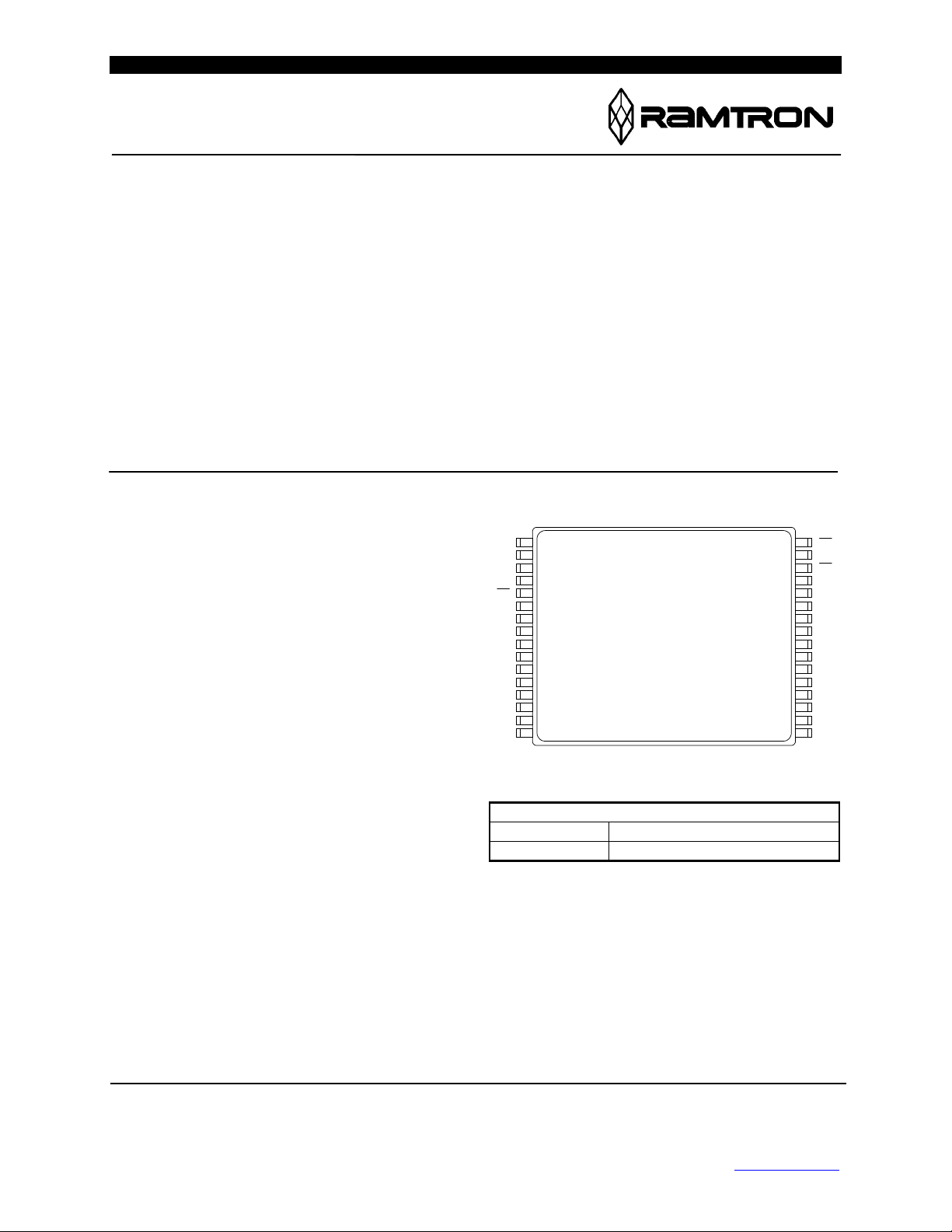

Pin Configuration

A11

A9

A8

A13

WE

VBAK

INT

VDD

X1

X2

A14

A12

A7

A6

A5

A4 A3

FM3808-70-T 70 ns access, 32-pin TSOP

FM3808DK DIP module development kit

Documentation for the DIP module development kit is

provided separately.

System Supervisor Function

• Programmable Clock/Calendar Alarm

• Programmable Watchdog Timer

• Programmable Power Supply Monitor

• Interrupt Output - Programmable active high/low

• Control Settings Inherently NonVolatile

• Generates either Processor Reset or Interrupt

Low Power Operation

• 5V Operation for Memory and Clock Interface

• Backup Voltage as low as 2.5V

• 25 mA I

• 1 µA I

Active Current

DD

Clock Backup Current

BAK

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

OE

A10

CE

DQ7

DQ6

DQ5

DQ4

DQ3

VSS

DQ2

DQ1

DQ0

A0

A1

A2

Ordering Information

This is a product under development. Characteristic data and other

specifications are design goals. Ramtron reserves the right to change 1850 Ramtron Drive, Colorado Springs, CO 80921

or discontinue the product without notice. (800) 545-FRAM, (719) 481-7000, FAX (719) 481-7058

Rev 0.2

Sept 2001 Page 1 of 27

Ramtron International Corporation

www.ramtron.com

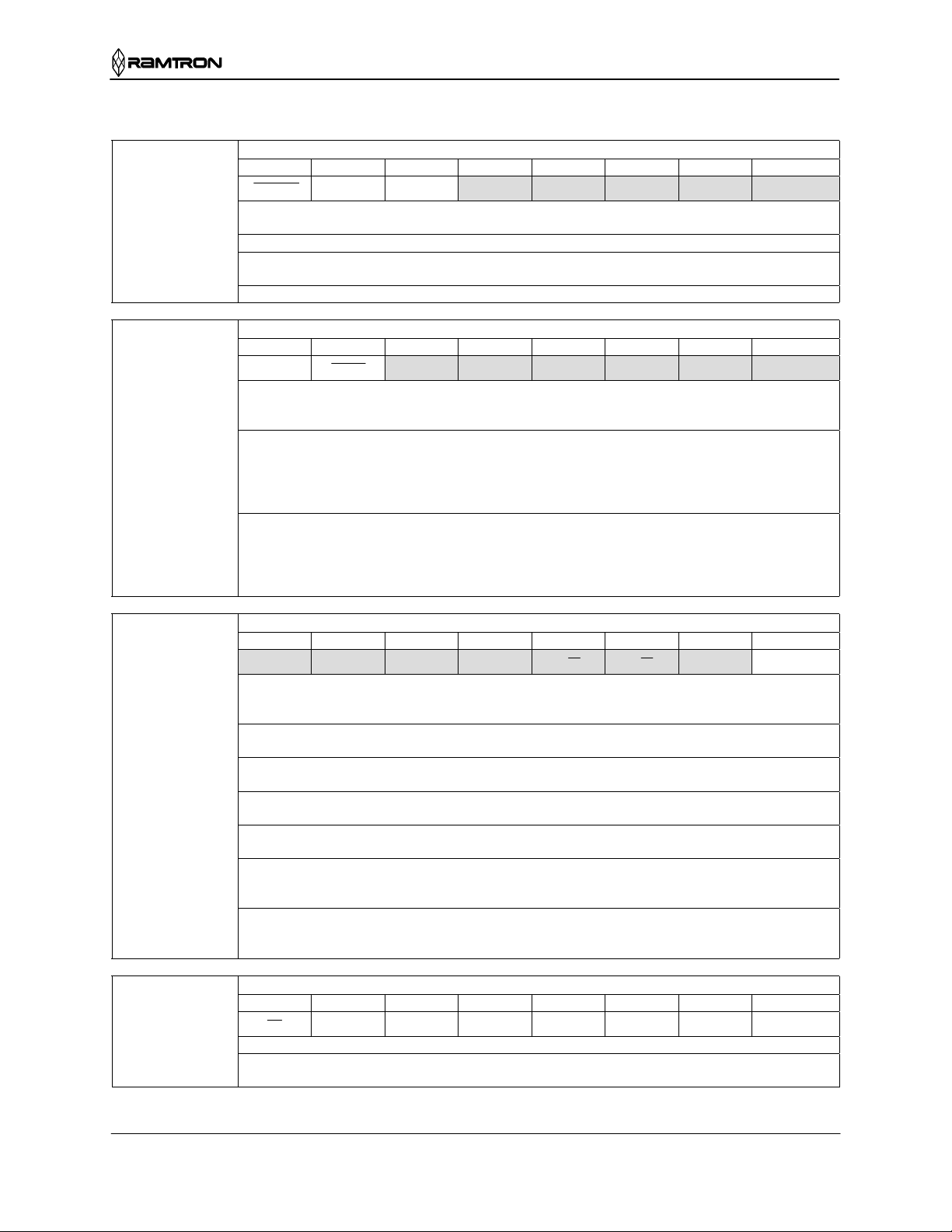

Page 2

FM3808

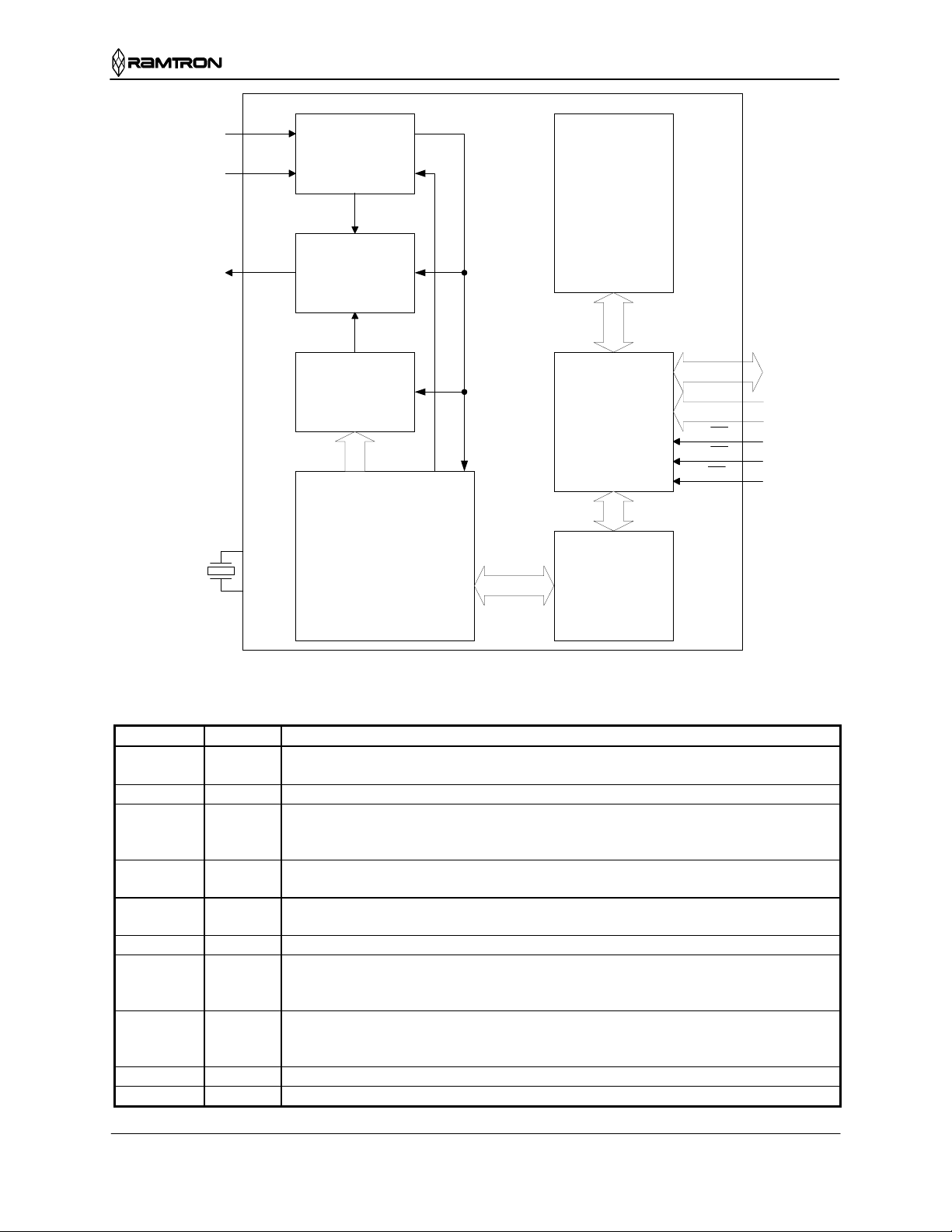

Switched

VDD

VBAK

System Supervisor

Low VDD monitor/

Watchdog timer

power

32.768

kHz

INT

X1

X2

Watchdog

Interrupt Control

Logic

Alarm

Clock/Calendar

timebase

FRAM Array

32,752x8

Address Decoder/

Bus Interface

16 Clock/Calendar

Registers

Data

Address

CE

OE

WE

Figure 1. Block Diagram

Pin Description

Pin Name I/O Pin Description

A0-A14 Input Address: The 15 address inputs select one of 32,752 bytes in the FRAM array or one of

16 bytes in the clock/calendar. The address is latched on the falling edge of /CE.

DQ(7:0) I/O Data: Bi-directional 8-bit data bus for accessing the FRAM array and clock.

/CE Input Chip Enable: The active low /CE input selects the device. The falling edge of /CE

internally latches the address. Address changes that occur after /CE has transitioned

low are ignored until the next falling edge occurs.

/OE Input Output Enable: The active low /OE input enables the data output buffers during read

cycles. Deasserting /OE high causes the DQ pins to tri-state.

/WE Input Write Enable: T he active low /WE low enables data on the DQ pins to be written to the

address location latched by the falling edge of /CE.

X1, X2 Input Connect 32.768 kHz crystal.

INT Output Interrupt output: This output can be programmed to respond to the clock alarm, the

watchdog timer, and the power monitor. It is programmable to either active high

(push/pull) or active low (open-drain).

V

Supply Backup Supply Voltage: This supply is used to maintain power for the clock. It must

BAK

remain between 2.5V and V

battery. Current is drawn from V

-0.3V. Typically it is supplied by either a capacitor or a

DD

when VDD is below the V

BAK

voltage.

BAK

VDD Supply Supply Voltage: 5V

VSS Supply Ground.

Rev 0.2

Sept 2001 Page 2 of 27

Page 3

FM3808

y

g

g

Functional Truth Table

/CE /WE /OE Function

H X X Standby/Precharge

!

X X Latch Address

L H L Read

L L X Write

Overview

The FM3808 integrates three complementary but

distinct functions under a common interface in a

single package. First, is the 32Kx8 FRAM memory

block (minus 16 bytes), second is the real-time

clock/calendar, and third is the system supervisor.

The functions are integrated to enhance their

individual performance, so that each provides better

capability than three similar stand-alone devices. All

functions use the same bytewide address/data

interface and are memory mapped. Special functions

including the clock and supervisor are controlled by

registers that reside in the top of the combined

memory map. The register map is described below,

followed by a detailed description of each functional

block.

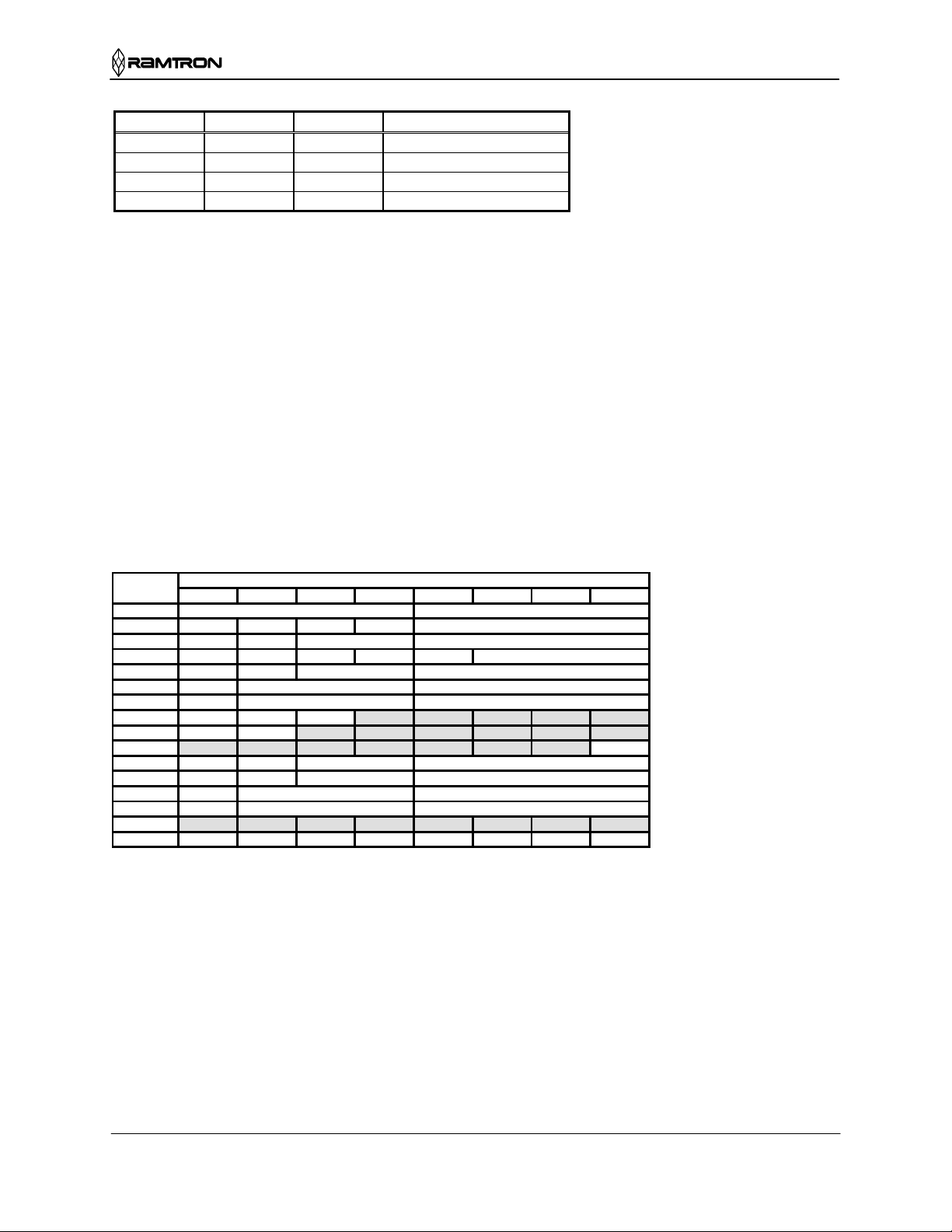

Register Map

The interface to clock and supervisor functions is via

16 address locations at the top of the address space.

The registers contain timekeeping data, control bits,

or information flags. A short description of each

register follows. Detailed descriptions of each

function follow the register summary.

Register Map Summary Table

Address

7FFFh 10 years years

7FFEh

7FFDh

7FFCh

7FFBh

7FFAh

7FF9h

7FF8h

7FF7h

7FF6h

7FF5h

7FF4h

7FF3h

7FF2h

7FF1h

7FF0h

D7 D6 D5 D4 D3 D2 D1 D0 Function Range

00010 mo

00

00000

00

0

0

/OSCEN reserved reserved CALS CAL3 CAL2 CAL1 CAL0 Control-NV

WDS /WDW WDT5 WDT4 WDT3 WDT2 WDT1 WDT0 Watchdo

WIE AIE PFE ABE H/L P/L VINT reserved Interrupts

/Match 0

/Match 0

/Match

/Match

WDF AF PF CF TST CAL W R Fla

Alarm 10 minutes Alarm minutes

Alarm 10 seconds Alarm seconds

10 date date

10 hours hours

10 minutes minutes

10 seconds seconds

Alarm 10 date Alarm date

Alarm 10 hours hours

Data

months

day

Years 00-99

Month 1-12

Date 1-31

Da

Hours 0-23

Minutes 0-59

Seconds 0-59

Alarm Date 1-31

Alarm Hours 0-23

Alarm Minutes 0-59

Alarm Seconds 0-59

User-NV

s/Control

1-7

Note that the shaded bits are implemented in FRAM and therefore are nonvolatile even without backup power.

Rev 0.2

Sept 2001 Page 3 of 27

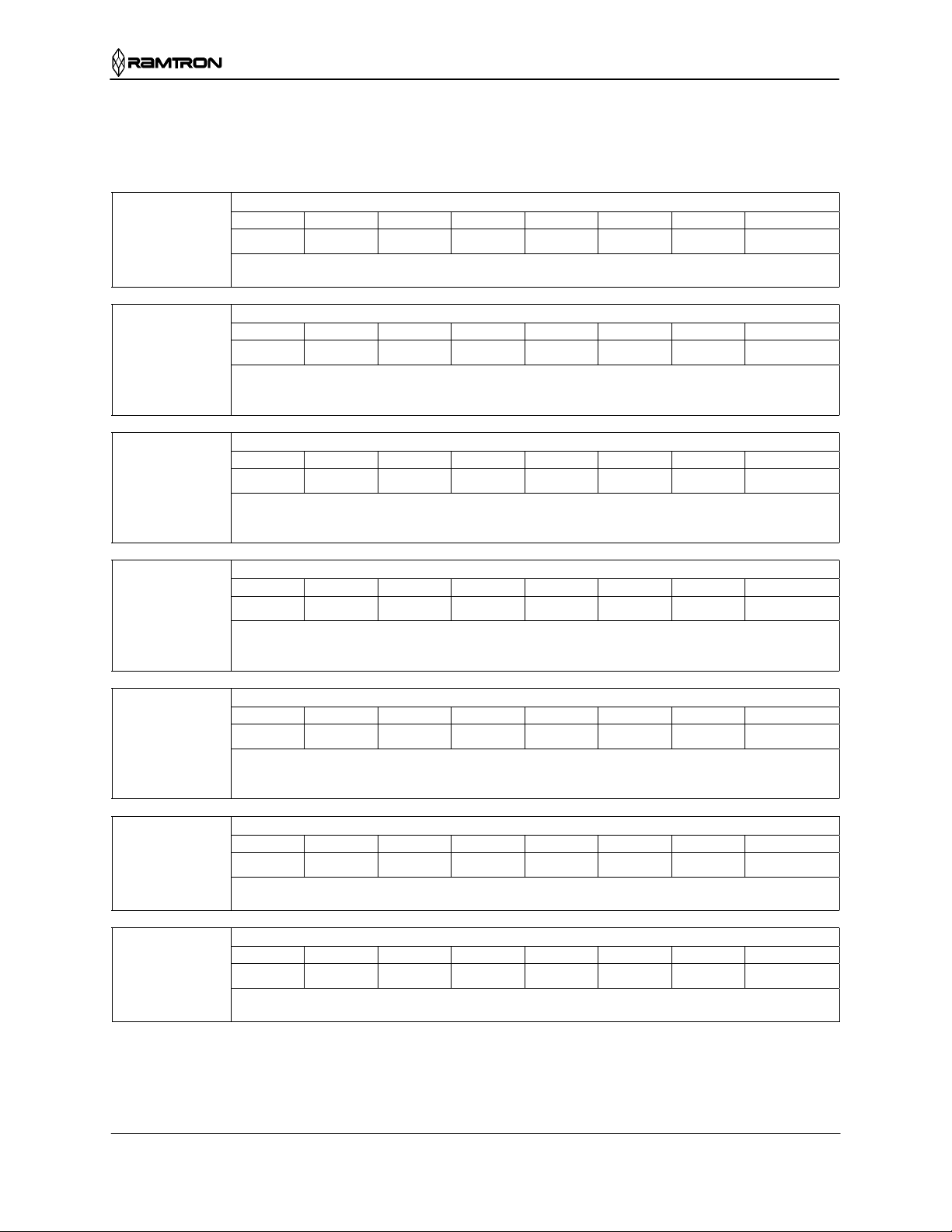

Page 4

FM3808

Table 1. Register Map

Address Description

7FFFh

Contains the lower two BCD digits of the year. Lower nibble contains the value for years; upper nibble

7FFEh

Contains the BCD digits for the month. Lower nibble contains the lower digit and operates from 0 to 9;

7FFDh

Contains the BCD digits for the date of the month. Lower nibble contains the lower digit and operates

7FFCh

Lower nibble contains a value that correlates to day of the week. Day of the week is a ring counter that

7FFBh

Contains the BCD value of hours in 24-hour format. Lower nibble contains the lower digit and operates

7FFAh

Contains the BCD value of minutes. Lower nibble contains the lower digit and operates from 0 to 9;

7FF9h

Contains the BCD value of seconds. Lower nibble contains the lower digit and operates from 0 to 9;

Timekeeping – Years

D7 D6 D5 D4 D3 D2 D1 D0

10 year.3 10 year.2 10 year.1 10 year.0 Year.3 Year.2 Year.1 Year.0

contains the value for 10s of years. Each nibble operates from 0 to 9. The range for the register is 0-99.

Timekeeping – Months

D7 D6 D5 D4 D3 D2 D1 D0

0 0 0 10 Month Month.3 Month.2 Month.1 Month.0

upper nibble (one bit) contains the upper digit and operates from 0 to 1. The range for the register is 1-

12.

Timekeeping – Date of the month

D7 D6 D5 D4 D3 D2 D1 D0

0 0 10 date.1 10 date.0 Date.3 Date.2 Date.1 Date.0

from 0 to 9; upper nibble contains the upper digit and operates from 0 to 3. The range for the register is

1-31.

Timekeeping – Day of the week

D7 D6 D5 D4 D3 D2 D1 D0

0 0 0 0 0 Day.2 Day.1 Day.0

counts from 1 to 7 then returns to 1. The user must assign meaning to the day value, as the day is not

integrated with the date.

Timekeeping – Hours

D7 D6 D5 D4 D3 D2 D1 D0

0 0 10 hours.1 10 hours.0 Hours.3 Hours2 Hours.1 Hours.0

from 0 to 9; upper nibble (two bits) contains the upper digit and operates from 0 to 2. The range for the

register is 0-23.

Timekeeping – Minutes

D7 D6 D5 D4 D3 D2 D1 D0

0 10 min.2 10 min.1 10 min.0 Min.3 Min.2 Min.1 Min.0

upper nibble contains the upper minutes digit and operates from 0 to 5. The range for the register is 0-59.

Timekeeping – Seconds

D7 D6 D5 D4 D3 D2 D1 D0

0 10 sec.2 10 sec.1 10 sec.0 Seconds.3 Seconds.2 Seconds.1 Seconds.0

upper nibble contains the upper digit and operates from 0 to 5. The range for the register is 0-59.

Rev 0.2

Sept 2001 Page 4 of 27

Page 5

FM3808

Address Description

7FF8h

/OSCEN /Oscillator Enable. When set to 1, the oscillator is halted. When set to 0, the oscillator runs. Disabling

Reserved Do not use. Should remain set to 0.

CALS Calibration sign. Determines if the calibration adjustment is applied as an addition to or as a subtraction

CAL.3-0 These four bits control the calibration of the clock. These bits are implemented in FRAM.

7FF7h

WDS Watchdog Strobe. Setting this bit to 1 reloads and restarts the watchdog timer. Setting the bit to 0 has no

/WDW Watchdog Write Enable. Setting this bit to 1 masks the watchdog timeout value (WDT.5-0) so it cannot

WDT.5-0 Watchdog Timeout selection. The watchdog timer interval is selected by the 6-bit value in this register.

7FF6h

WIE Watchdog Interrupt Enable. When set to 1 and a watchdog timeout occurs, the watchdog timer drives

AIE Alarm Interrupt Enable. When set to 1, the alarm match drives the interrupt pin as well as the AF flag.

PFE Power-fail Interrupt Enable. When set to 1, the power-fail monitor drives the pin as well as the PF flag.

ABE Alarm Battery-backup Enable. When set to 1, the alarm interrupt (as controlled by AIE) will function

H/L High/Low. When set to a 1, the Interrupt pin is push/pull active high. When set to a 0, the interrupt pin

P/L Pulse/Level. When set to a 1, the interrupt pin is driven active (determined by H/L) by an interrupt

VINT Voltage Interrupt. Selects the voltage on VDD that generates a power-fail flag. When set to a 1, the flag

7FF5h

Contains t he alarm value for the date of the month and the mask bit to select or deselect the date value.

/M

Control-Nonvolatile

D7 D6 D5 D4 D3 D2 D1 D0

OSCEN Reserved Reserved CALS CAL.3 CAL.2 CAL.1 CAL.0

the oscillator can save battery power during storage. On a no battery power up, this bit is set to 1.

from the time-base. This bit is implemented in FRAM. Calibration is explained below

Watchdog Timer

D7 D6 D5 D4 D3 D2 D1 D0

WDS WDW

affect. The bit is cleared automatically once the watchdog timer is reset. The WDS bit is write only.

Reading it always will return a 0.

be written. This allows the user to strobe the watchdog without disturbing the timeout value. Setting this

bit to 0 allows bits 5-0 to be written on the next write to the Watchdog register. The new value will be

loaded on the next internal watchdog clock after the write cycle is complete. This function is explained

in more detail in the watchdog Timer section below.

It represents a multiplier of the 32 Hz count (31.25 ms). The minimum range or timeout value is 31.25

ms (a setting of 1) and the maximum timeout is 2 seconds (setting of 3Fh). Setting the watchdog timer

register to 0 disables the timer. These bits can be written only if the /WDW bit was cleared to 0 on a

previous cycle.

Interrupts

D7 D6 D5 D4 D3 D2 D1 D0

WIE AIE PFE ABE H/L P/L VINT Reserved

the interrupt pin as well as the WDF flag. When set to 0, the watchdog timeout affects only the WDF

flag.

When set to 0, the alarm match only affects the AF flag.

When set to 0, the power-fail monitor affects only the PF flag.

even in battery backup mode. When set to 0, the alarm will occur only when VDD>VLO.

is open drain active low.

source for approximately 200 ms. When set to a 0, the interrupt pin is driven to an active level (as set by

H/L) until the flag register is read.

occurs at 4.75V. When set to 0 the flag occurs at 4.6V. The interrupt pin is enabled by the PFE bit,

otherwise only an internal flag is set.

Alarm – Date of the month

D7 D6 D5 D4 D3 D2 D1 D0

M 0 10 date.1 10 date.0 Date.3 Date.2 Date.1 Date.0

Match. Setting this bit to 0 causes the date value to be used in the alarm match. Setting this bit to 1

causes the match circuit to ignore the date value.

WDT.5 WDT.4 WDT.3 WDT.2 WDT.1 WDT.0

Rev 0.2

Sept 2001 Page 5 of 27

Page 6

FM3808

Address Description

7FF4h

Contains the alarm value for the hours and the mask bit to select or deselect the hours value.

/M Match. Setting this bit to 0 causes the hours value to be used in the alarm match. Setting this bit to 1

7FF3h

Contains t he alarm value for the minutes and th e mask bi t to select or deselect the minutes value

/M Match. Setting this bit to 0 causes the minutes value to be used in the alarm match. Setting this bit to 1

7FF2h

Contains the alarm value for the seconds and the mask bit to select or deselect the minutes value.

/M Match. Setting this bit to 0 causes the seconds value to be used in the alarm match. Setting this bit to1

7FF1h

This register is an uncommitted nonvolatile register. The user register is not manipulated by the real-

7FF0h

WDF Watchdog Timer Flag. This bit is set to 1 when the watchdog timer is allowed to reach 0 without being

AF Alarm Flag. This bit is set to 1 when the time and date match the values stored in the alarm registers

PF Power-fail Flag. This bit is set to 1 when power falls below the power-fail interrupt threshold VINT. It

CF Cen t ury Overflow Flag. This bit is set to a 1 when the values in the years register overflows from 99 to

TST Invokes factory test mode. Users should always set this bit to 0.

CAL Calibration Mode. When set to 1, the clock enters calibration mode. When CAL is set to 0, the clock

W Write Time. Setting the W bit to 1 freezes updates of the timekeeping registers. The user can then write

R Read Time. Setting the R bit to 1 copies a static image of the timekeeping registers and places them in a

Alarm – Hours

D7 D6 D5 D4 D3 D2 D1 D0

M 0 10 hours.1 10 hours.0 Hours.3 Hours2 Hours.1 Hours.0

causes the match circuit to ignore the hours value.

Alarm – Minutes

D7 D6 D5 D4 D3 D2 D1 D0

M 10 min.2

causes the match circuit to ignore the minutes value.

Alarm – Seconds

D7 D6 D5 D4 D3 D2 D1 D0

M 10 sec.2 10 sec.1 10 sec.0 Seconds.3 Seconds.2 Seconds.1 Seconds.0

causes the match circuit to ignore the seconds value.

User-NonVolatile

D7 D6 D5 D4 D3 D2 D1 D0

time clock other than to provide nonvolatile storage of the contents.

Flags/Control

D7 D6 D5 D4 D3 D2 D1 D0

WDF AF PF CF TST CAL W R

reset by the user. It is cleared to 0 when the Flag register is read. It is read-only for the user.

with the match bit(s) = 0. It is cleared when the Flag register is read. It is read -only for the user.

is cleared to 0 when the Fl ag register is read. It is read-only for the user.

00. This indicates a new century, such as going from 1999 to 2000 or 2099 to 2100. The user should

record the new century information as needed. This bit is cleared to 0 when the Flag register is read. It is

read-only for the user.

operates normally.

them with updated values. Setting the W bit to 0 causes the contents of the time registers to be

transferred to the timekeeping counters. This bit affects registers xF, xE, xD, xC, xB, xA, and x9.

holding register. The user can then read them without concerns over changing values causing system

errors. The R bit going from 0 to 1 causes the timekeeping capture, so the bit must be returned to 0 prior

to reading again . This bit affects registers xF, xE, xD, xC, xB, xA, and x9.

10 min.1 10 min.0 Min.3 Min.2 Min.1 Min.0

Rev 0.2

Sept 2001 Page 6 of 27

Page 7

FM3808

Real-time Clock Operation

The real-time clock (RTC) consists of an oscillator, a

divider, and a register system to access the

information. It divides down the 32.768 kHz timebase to provide the user timekeeping resolution of

one second (1Hz). Static registers provide the user

with read/write access to the time values. The

synchronization of these registers with the timekeeper

core is performed using R and W bits in register

7FF0h.

Setting the R bit from 0 to 1 causes a transfer of the

timekeeping information to holding registers that can

be read by the user. If a timekeeper update is in

progress when the R is set, the update will be

completed prior to loading the registers. Another

update cannot be performed unless the R bit is first

cleared to 0 again.

Setting the W bit causes the timekeeper to freeze

updates. Clearing it to 0 causes the values in the time

registers to be written into the timekeeper core. Users

should be sure not to load invalid values, such as FFh

to any of the timekeeping registers.

Updates to the timekeeping core occur continuously

except when frozen. A diagram of the timekeeping

core is shown below.

Backup Power

The real-time clock/calendar is intended for

permanently powered operation. When primary

system power fails, the voltage on V

When it crosses the voltage on the V

will drop.

DD

supply pin,

BAK

the clock power will switch to the backup power

supply V

. The supervisor function, described

BAK

below, controls the switchover process as part of a

more complete power management circ uit.

The clock uses very little current which maximizes

battery life. Although a backup batter y may be used

with the FM3808, the key advantage to combining a

clock function with FRAM is that the configuration

data (shaded regsiter bits in Table 2) is nonvolatile

and does not require a battery backup power source.

Therefore, it is more practical to use a capacitor as a

backup energy source than a battery-backed

RAM/clock combo. With the FM3808, the user has

the choice of using a battery or a capacitor as the

backup source. Some of the parameters used in the

capacitor vs. battery decision include the expected

duration of power outages, the difficulty of resetting

the time if lost, and the cost tradeoff of using a small

battery versus a capacitor.

The following functions are powered from the backup

power source when V

DD

< V

(backup mode) :

BAK

• Clock/calendar core

• Alarm interrupt/comparator

• INT pin driver (determined by ABE & AIE

bits); active low only

• Flags connected to related functions

The following functions are not powered and are

disabled when V

< VLO :

DD

• User interface

• Watchdog timer

• Power monitor & band-gap (V

< ≈ 2.0V)

DD

• Flags connected to related functions

• All FRAM access & updates

• Calibration operation

• INT driver if active high is programmed

Rev 0.2

Sept 2001 Page 7 of 27

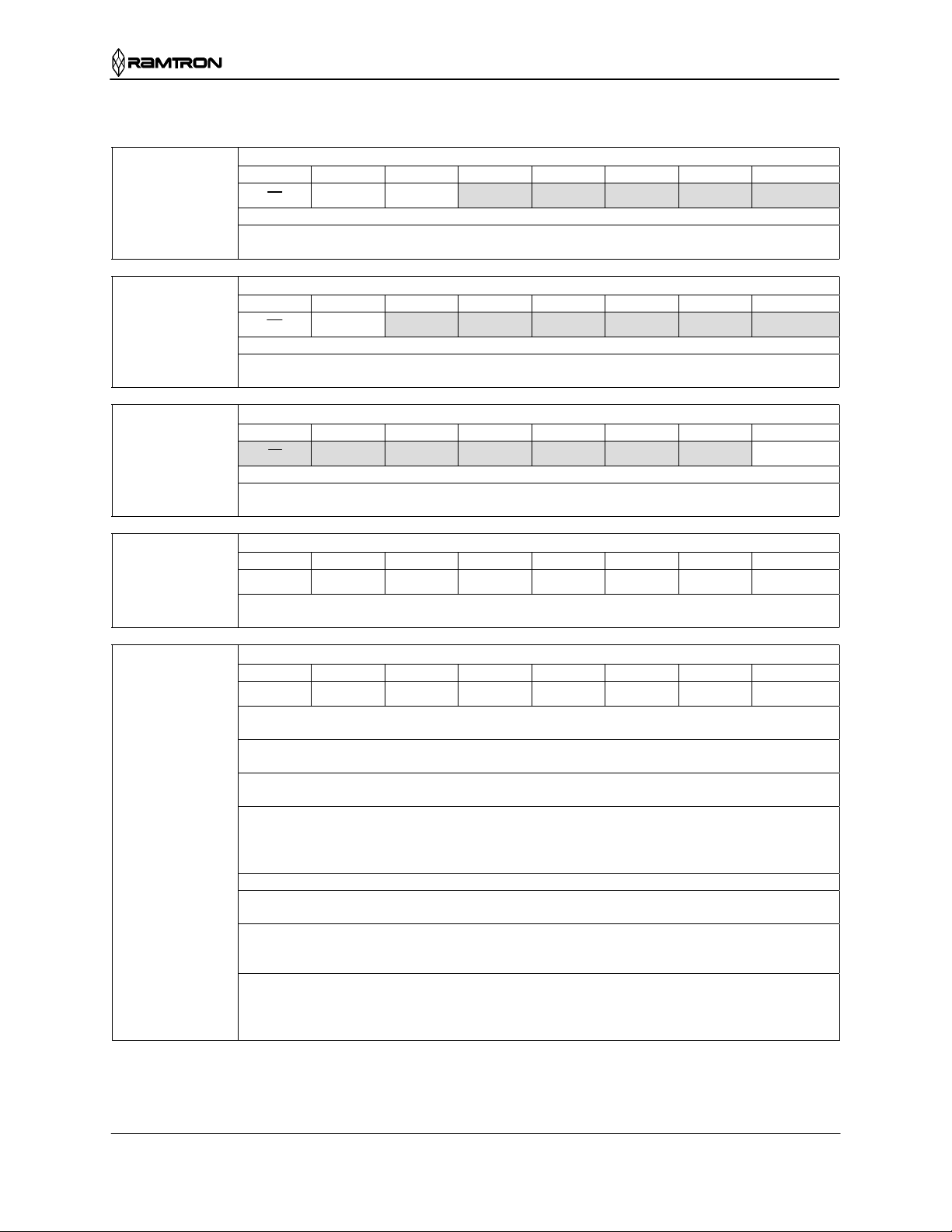

Page 8

FM3808

32 Hz

512 Hz

W

32.768 kHz

crystal

CF

Years

8 bits

Months

5 bits

Date

6 bits

Days

3 bits

User Interface Registers

Figure 2. Real-time Clock Core Block Diagram

Calibration

When the CAL bit in register 7FF0.2 is set to 1, the

clock enters calibration mode. Interrupts are disabled

in CAL mode. Calibration operates by applying a

digital correction to the counter based on the

frequency error. In CAL mode, the INT pin is driven

with a 512 Hz nominal square wave. Any measured

deviation from 512 Hz is converted into an error in

ppm. This error corresponds to a correction value that

must then be written by the user into the calibration

register 7FF8h. The correction factors are listed in the

Table 2.

Positive ppm errors require a negative adjustment that

removes pulses. Negative ppm errors require a

positive correction that adds pulses. Positive ppm

adjustments have the CALS bit set to 1, where as

negative ppm adjustments have CALS = 0. After

calibration, the clock will have a maximum error of

Oscillator

Hours

6 bits

Clock

Divider

1 Hz

Minutes

7 bits

Update

Logic

Seconds

7 bits

± 4.34 ppm or ± 0.19 minutes per month at the

calibrated temperature.

The calibration setting is nonvolatile and is stored in

7FF8.4-0. This value only can be written when the

CAL bit is set to a 1. To exit calibration mode, the

user should clear the CAL bit to a 0.

When the calibration mode is entered, the user can

measure the frequency error on the INT pin. This

error expressed in ppm translates directly into

timekeeping error. An offsetting calibration

adjustment corrects this error. However, the

correction is applied by adding or removing pulses on

a periodic basis. Therefore, the correction will not

appear on the 512 Hz output. The calibration

correction must be applied using the values shown in

Table 2. The timekeeping accuracy can be verified by

comparing the FM3808 time to a reference source.

R

Rev 0.2

Sept 2001 Page 8 of 27

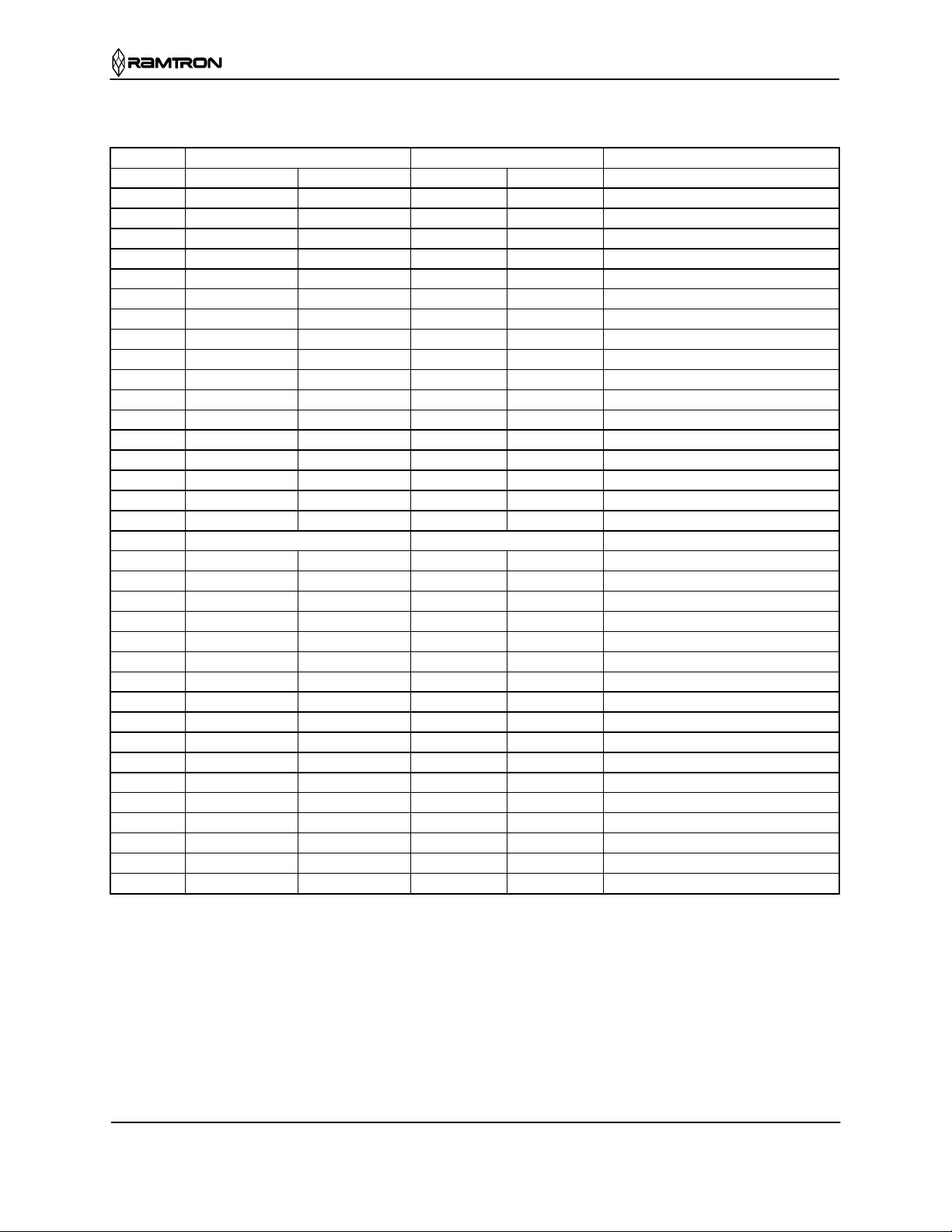

Page 9

FM3808

Table 2. Calibration Adjustments

Measured Frequency Range Error Range (ppm)

Min Max Min Max Program Calibration D4-D0

0 512.0000 511.9978 0 4.34 00000b

1 511.9978 511.9933 4.35 13.02 10001b

2 511.9933 511.9889 13.03 21.70 10010b

3 511.9889 511.9844 21.71 30.38 10011b

4 511.9844 511.9800 30.39 39.06 10100b

5 511.9800 511.9756 39.07 47.74 10101b

6 511.9756 511.9711 47.75 56.42 10110b

7 511.9711 511.9667 56.43 65.10 10111b

8 511.9667 511.9622 65.11 73.78 11000b

9 511.9622 511.9578 73.79 82.46 11001b

10 511.9578 511.9533 82.47 91.14 11010b

11 511.9533 511.9489 91.15 99.82 11011b

12 511.9489 511.9444 99.83 108.50 11100b

13 511.9444 511.9400 108.51 117.18 11101b

14 511.9400 511.9356 117.19 125.86 11110b

15 511.9356 511.9311 125.87 134.54 11111b

Measured Frequency Range Error Range (ppm)

Min Max Min Max Program Calibration D4-D0

0 512.0000 512.0022 0 4.34 00000b

1 512.0022 512.0067 4.35 13.02 00001b

2 512.0067 512.0111 13.03 21.70 00010b

3 512.0111 512.0156 21.71 30.38 00011b

4 512.0156 512.0200 30.39 39.06 00100b

5 512.0200 512.0244 39.07 47.74 00101b

6 512.0244 512.0289 47.75 56.42 00110b

7 512.0289 512.0333 56.43 65.10 00111b

8 512.0333 512.0378 65.11 73.78 01000b

9 512.0378 512.0422 73.79 82.46 01001b

10 512.0422 512.0467 82.47 91.14 01010b

11 512.0467 512.0511 91.15 99.82 01011b

12 512.0511 512.0556 99.83 108.50 01100b

13 512.0556 512.0600 108.51 117.18 01101b

14 512.0600 512.0644 117.19 125.86 01110b

15 512.0644 512.0689 125.87 134.54 01111b

Rev 0.2

Sept 2001 Page 9 of 27

Page 10

FM3808

Supervisor Operation

The Supervisor function includes a clock/calendar

alarm, a watchdog timer, and a power monitor. A

programmable interrupt pin provides maximum

functionality to permit the host processor to benefit

from the supervisor functions. It is designed to allow

either reset or interrupt capability to the external

processor ho st.

Alarm

The alarm function compares user-programmed

values to the corresponding time of day values. When

a match occurs, the alarm event occurs. The alarm

offers an internal flag bit and an optional external

interrupt.

There are four alarm match values. They are date of

the month, hours, minutes, and seconds. The match

select bits determine if a value is used in the alarm

match selection. Setting the match select bit to ‘0’

indicates that the corresponding value should be used

in the match process.

Depending on the match select bits, the alarm can

occur as specifically as one particular second on one

day of the month, or as frequently as once per second

continuously. Each match select bit is contained in

the MSB of the match value register. The match

select bits work in concert as shown in the table

below. Selecting none of the match bits (all ‘1’s)

indicates that no match is required. The alarm occurs

every second. Setting the match select bit for seconds

to ‘0’ causes the logic to match the seconds alarm

value to the current time of day. Since a match will

occur for only one value per minute, the alarm occurs

once per minute. Likewise setting the seconds and

minutes match select bits causes an exact match of

these values. Thus, an alarm will occur once per hour.

Setting seconds, minutes, and hours causes a match

once per day. Lastly, selecting all match-values

causes an exact time and date match. Selecting other

bit combinations will not produce meaningful results,

however the alarm circuit should follow the functions

described.

The alarm event can be detected by the user in two

ways. First, the AF flag bit in the register 7FF0.6 will

indicate that a match has occurred. The AF bit will be

set to 1 when a valid match occurs. Reading the flag

register clears the alarm flag bit (and all others).

Second, a hardware interrupt pin will be provided.

The interrupt function is described below.

Alarm Match Bits

Seconds Minutes Hours Date Alarm condition

1 1 1 1 No match required = alarm 1/second

0 1 1 1 Alarm when seconds match, = alarm 1/minute

0 0 1 1 Alarm when seconds, minutes match, = alarm 1/hour

0 0 0 1 Alarm when seconds, minutes, hours match, = alarm 1/day

0 0 0 0 Alarm when seconds, minutes, hours, date match, = alarm 1/month

Rev 0.2

Sept 2001 Page 10 of 27

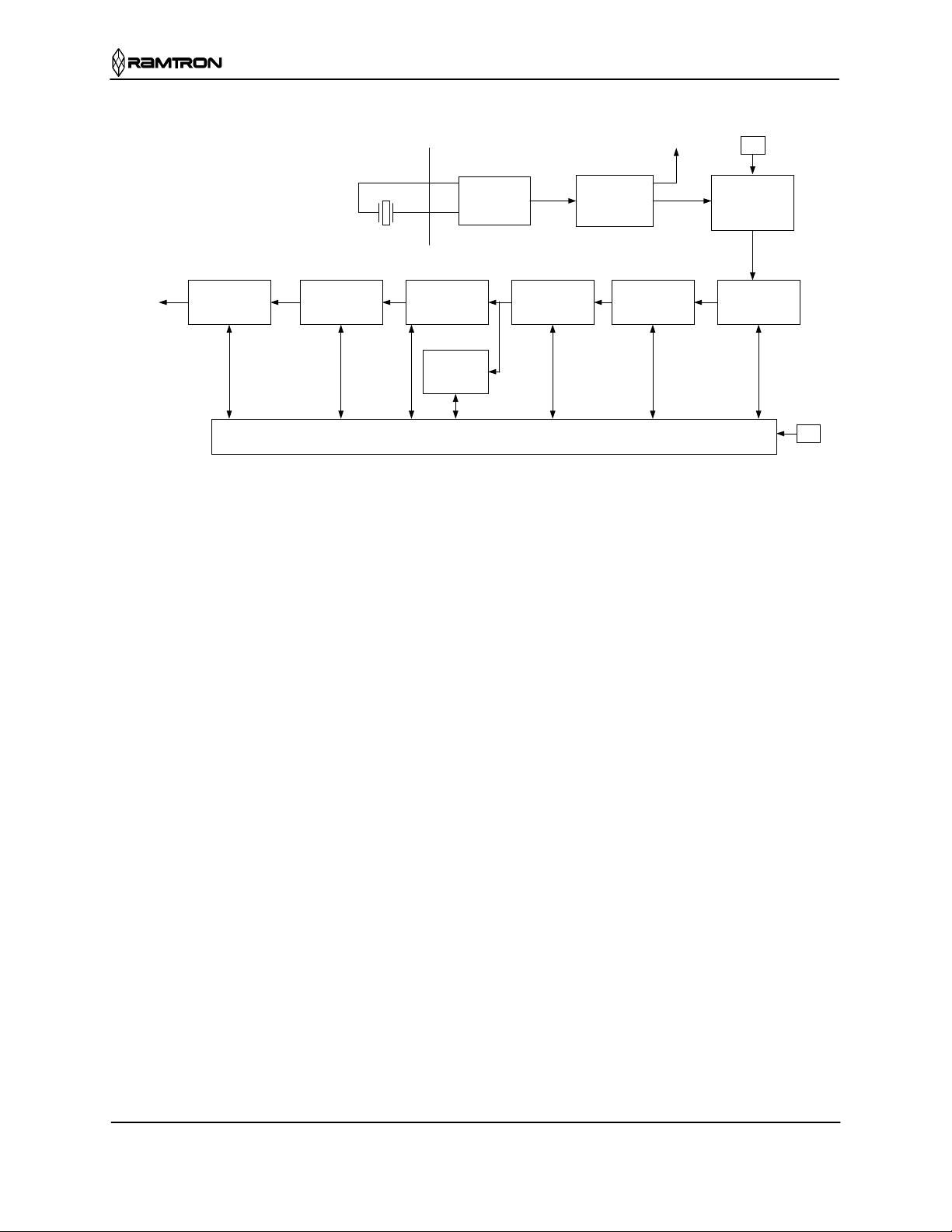

Page 11

FM3808

Watchdog Timer

The Watchd og timer is a free running down counter

that uses the 32 Hz clock (31.25 ms) derived from the

crystal oscillator. The oscillator must be running

(/OSCEN=0) for the watchdog to function. It begins

counting down from the value loaded in the

Watchdog timer register (7FF7h).

The counter consists of a loadable register and a free

running counter. On power up, the watchd og timeout

value in 7FF7h is loaded into the counter load

register. Counting begins on power up and restarts

from the loadable value any time the Watchdog

Strobe (WDS – 7FF7.7) WDS bit is set to 1. The

counter is compared to terminal value of 0. If the

counter reaches this value, it causes an internal flag

and an optional interrupt output (see interrupts

below). The user can prevent the timeout interrupt by

setting WDS bit to 1 prior to the counter reaching 0.

This causes the counter to be reloaded with the

watchdog timeout value and to be restarted. As long

as the user sets the WDS bit prior to the counter

reaching the terminal value, the interrupt and flag

never occurs.

New timeout values can be written by setting the

watchdog write bit (/WDW – 7FF7.6) to 0. When the

/WDW bit is 0 (from a previous operation), new

writes to the watchdog timeout value 7FF7.5-0 allow

the timeout value to be modified. When /WDW is a 1,

then writes to bits 7FF7.4-0 will be ignored. The

/WDW function allows a user to set the WDS bit

without concern that the watchdog timer value will be

modified. A logical diagram of the watchdog timer is

shown below. Note that setting the watchdog timeout

value to 0 would be otherwise meaningless and

therefore disables the watchdog function.

The output of the watchdog timer is a flag bit (WDF

– 7FF0.7) that is set if the watchdog is allowed to

timeout. The flag is set upon a watchdog timeout and

cleared when the flag register is read by the user. The

user can also enable an optional interrupt source to

drive the interrupt pin if the watchdog timeout occurs.

The interrupt function is described below.

Oscillator

32.768 kHz

Clock

Divider

1 Hz

32 Hz

7FF0.7

WDF

WDS

WDW

Counter

Zero

Compare

Load Register

QD

Q

7FF7.5-0

Watchdog

write to

register

Watchdog

register

Figure 3. Watchdog Timer Block Diagram

Rev 0.2

Sept 2001 Page 11 of 27

Page 12

FM3808

Power Monitor

The FM3808 provides a power management scheme

with either power-fail interrupt or processor-reset

capability. It also controls the internal switch to

backup power for the timekeeper and protects the

memor y from l ow-V

access. The power monitor is

DD

based on an internal band-gap reference circuit that

compares the incoming V

to various thresholds.

DD

The power monitor compares V

The first is an interrupt threshold (V

to three thresholds.

DD

), which can be

INT

selected between two levels as shown below. When

V

drops below the programmed V

DD

level, the

INT

event will set the power fail flag (PF – 7FF0.5). It

also can drive the interrupt pin as described in the

interrupt section below. The interrupt level selection

is controlled via the voltage interrupt bit (V

INT

–

7FF6.1) as follows.

Power fail V

INT

4.6V 0

4.75V 1

If the power monitor is used to reset the external

processor, then the lower threshold is more likely to

be used. If the power monitor is providing an early

warning interrupt, then either may be suitable

depending on expected slew rates and the amount of

data to be saved on power failure.

below V

begin to draw power from V

event may be above or below the V

depending on whether a battery or capacitor backup is

used.

To conserve the life of the backup source, the power

monitor circuit is only operated from V

has dropped too low for the monitor to work, it ceases

operation. However, the power monitor will

reenergize as V

after the band-gap energizes, the reverse sequence

will occur. As soon as the band gap is functional, it

will re-assert both selections for switch over and

power fail. As the V

will be removed, allowing memory access and

operating the clock from V

V

, the power-fail condition will be removed. Note

INT

that the PF flag will not be cleared until the flag

register is read.

The following figure illustrates the various events

tracked by the power monitor.

VDD

VINT VINT

VLO VLO

VBAK

. When switchover occurs, the clock will

BAK

rather than VDD. This

BAK

or VLO level

INT

. When VDD

DD

rises on power-up. On power-up,

DD

rises further, the switchover

DD

. As the VDD rises above

DD

BG BG

VBAK

The second threshold is the low V

This level, which is called V

writes to the FRAM array, which may result in lost

data. At this time, access to the memory array and

clock registers will be blocked until V

V

. VLO is always below V

LO

V

, inputs will be ignored. On power up, the chip

LO

enable input will be ignored while V

but must be inactive (high) when V

level.

The third threshold is the switch of the internal supply

from V

to V

DD

for the timekeeper. This

BAK

switchover will occur at the level when V

memor y lock out.

DD

, prevents low voltage

LO

rises above

DD

. When VDD is below

INT

is below VLO,

DD

reaches the VLO

DD

crosses

DD

Figure 4. Power Monitor Events

In the diagram, BG is the voltage at which the bandgap will function. This voltage is not precisely

specified but is well below the range of operation for

the memory or other circuits. On power down, the

band-gap will monitor V

allows a brownout to occur where V

as long as possible. This

DD

returns to a

DD

proper level prior to the band-gap failing. Since the

band-gap runs only from V

, it does not reduce the

DD

life of the backup source.

Rev 0.2

Sept 2001 Page 12 of 27

Page 13

FM3808

Interrupts

The supervisor was designed to serve diverse

applications. Its sophistication is managed by the

interrupt block, which makes this functionality

available to the host system. The interrupt block is

capable of providing interrupt or reset conditions, and

even can power up a system at a preprogrammed

time. The function is described as an interrupt, even

though the output may be used as a reset source.

The supervisor provides three potential interrupt

sources. They include the watchdog timer, the power

monitor, and the clock/calendar alarm. Each can be

individually enabled and assigned to drive the single

INT pin. In addition, each has a flag bit associated

with it so that the host processor can determine the

cause of the interrupt.

Some of the sources have additional control bits that

determine functional behavior. In addition, the pin

interrupt occurs. A functional diagram of the interrupt

logic is shown below.

As shown, the three interrupts each have a source and

an enable. Both the source and the enable must be

active (true high) in order to generate an interrupt

output. Only one source is necessary to drive the pin.

The user can identify the source by reading the flag

register, which contains the flags associated with each

source. All flags are cleared to 0 when the register is

read. The cycle must be a complete read cycle,

otherwise the flags will not be cleared if the /WE

signal goes low. The power monitor has two

programmable settings that are explained above in the

power monitor section.

Once an interrupt source is active, the pin driver

determines the behavior of the output pad. It has two

programmable settings as shown below. Pin driver

control bits are located in the Interrupts register

7FF6h.3-2.

driver has three bits that specify its behavior when an

WDF

Watchdog

Timer

WIE

VDD

P/L

PF

Power

Monitor

PFE

Pin

Driver

INT

VINT

H/L

ABE

AF

Clock

Alarm

AIE

Figure 5. Interrupt Block Diagram

According to the programming selections, the pin can

be driven in the backup mode for an alarm interrupt

or not. In addition, the pin can be active low (opendrain) or active high (push-pull) driver. If

programmed for operation during backup mode, it

can only be active low. Lastly, the pin can provide a

one-shot function so that the active condition is a

pulse, or a level operation. In one-shot mode, the

pulse width is fixed at approximately 200 ms. This

mode is intended to reset a host microcontroller. In

level mode, the pin goes to its active polarity until the

Rev 0.2

Sept 2001 Page 13 of 27

Flag register is read by the user. This mode is

intended to be used as an interrupt to a host

microcontroller. The control bits are summarized as

follows.

Watchdog Interrupt Enable

- WIE. When set to 1, the

watchdog timer drives the interrupt pin as well as an

internal flag when a watchdog timeout occurs. When

set to 0, the watchdog timer affects only the internal

flag.

Page 14

FM3808

Alarm Interrupt Enable – AIE. When set to 1, the

alarm match drives the interrupt pin as well as an

internal flag. When set to 0, the alarm match only

affects the internal flag.

Power-fail Interrupt Enable

- PFE. When set to 1, the

power-fail monitor drives the pin as well as an

internal flag. When set to 0, the power-fail monitor

affects only the internal flag.

Alarm Battery-backup Enable

- ABE. When set to 1,

the clock alarm interrupt (as controlled by AIE) will

function even in battery backup mode. When set to 0,

the alarm will occur only when V

> VLO. AIE

DD

should only be set when the interrupt pin is

programmed for active low operation. In addition, it

only functions with the clock alarm, not the

watchdog. If enabled, the power monitor will drive

the interrupt during all normal V

conditions

DD

regardless of the ABE bit. The application for ABE is

intended for power control, where a system powers

up at a predetermined time. Depending on the

application, it may require dedicating the INT pin to

this function.

High/Low

– H/L. When set to a 1, the INT pin is

active high ( push-pull). The INT pin can drive high

only when V

DD>VLO

. When set to a 0, the interrupt

pin is active low (open-drain). It can function as a

pull down even in battery backup mode.

Pulse/Level

– P/L. When set to a 1, the INT pin is

driven (by an interrupt source) for approximately 200

ms. When P/L is set to a 0, the interrupt pin is driven

high or low (as set by H/L) until the flag register is

read.

When an enabled interrupt source activates the INT

pin, an external host can read the flag register to

determine the cause. One or more flags may be set

when the register is read, however all will be cleared

when the register is read. If the INT pin is

programmed for level mode, then the condition will

clear and the INT pin will return to its inactive state.

If the pin is programmed for pulsed operation, then

reading the flag also will clear the flag and the pin.

The pulse will not complete its specified duration if

the flag register is read. Of course, if the INT pin is

used to reset the host, then the flag register would not

be read during an active pulse. Care should be taken

in reading the flags as a new source may occur after

the pin goes active but before the register is read.

During a power-on reset with no battery, the interrupt

register is automatically loaded with the value 24h.

This causes power fail interrupt to be enabled with an

active low pulse.

Rev 0.2

Sept 2001 Page 14 of 27

Page 15

FM3808

FRAM Memory Operation

The memory array is logically organized as 32,768 x

8 with the upper 16 bytes disabled and allocated to

the RTC. It is accessed using an industry standard

SRAM-type parallel interface. It is virtually identical

to the 32Kx8 FM1808 in function. The memory array

in the FM3808 is inherently nonvolatile via its unique

ferroelectric process. All data written to the part is

immediately nonvolatile with no delay. Functional

operation of the FRAM memory is similar to SRAM

type devices. The major operating difference between

the FRAM array and an SRAM (besides nonvolatile

storage) is that the FM3808 latches the address on the

falling edge o f / C E.

Users access 32,752 memory locations each with 8

data bits through a parallel interface. The complete

15-bit address specifies each of 32,768 bytes

uniquely, with the upper 16 locations allocated to

timekeeping functions. Internally, the memory array

is organized into 32 blocks of 8Kb each. The 5 mostsignificant address lines decode one of 32 blocks.

This blo ck segmentation has no effect on o peration,

however the user may wish to group data into blocks

by its endurance requirements as explained in a later

section.

The access and cycle time are the same for read and

write memory operations. Writes occur immediately

at the end of the access with no delay. A precharge

operation, where /CE goes inactive, is a part of every

memory cycle. Thus unlike SRAM, the access and

cycle times are not equal.

The FM3808 is designed to operate in a manner very

similar to other bytewide memory products. For users

familiar with BBSRAM, the performance is

comparable but the bytewide interface operates in a

slightly different manner as described below. For

users familiar with EEPROM, the obvious differences

result from the higher write-performance of FRAM

technology including NoDelay writes and much

higher write-endur ance.

Read Operation

A read o peration begins on the fal ling edge of /CE.

At this time, the address bits are latched and a

memory cycle is initiated. Once started, a full

memory cycle will be completed internally even if the

/CE is taken inactive. Data becomes available on the

bus after the access time has been satisfied.

After the address has been latched, the address value

may be changed upon satisfying the hold time

parameter. Unlike an SRAM, changing address values

will have no effect on the memory operation after the

The FM3808 will drive the data bus when /OE is

asserted low. If /OE is asserted after the memory

access time has been satisfied, the data bus will be

driven with valid data. If /OE is asserted prior to

completion of the memory access, the data bus will

not be driven until valid data is available. This feature

minimizes supply current in the system by eliminating

transients due to invalid data. When /OE is inactive,

the data bus will remain tri-stated.

Write Operation

Writes occur in the FM3808 in the same time interval

as reads. The FM3808 supports both /CE and /WE

controlled write cycles. In all cases, the address is

latched on the falling edge of /CE.

In a /CE controlled write, the /WE signal is asserted

prior to beginning the memory cycle. That is, /WE is

low when /CE falls. In this case, the part begins the

memory cycle as a write. The FM3808 will not drive

the data bus regardless of the state of /OE.

In a /WE controlled write, the memory cycle begins

on the falling edge of /CE. The /WE signal falls after

the falling edge of /CE. Therefore, the memory cycle

begins as a read. The data bus will be driven

according to the state of /OE until /WE falls. The

timing of both /CE and /WE controlled write cycles is

shown in the electrical specifications.

Write access to the array begins asynchronously after

the memory cycle is initiated. The write access

terminates on the rising edge of /WE or /CE,

whichever is first. Data set-up time, as shown in the

electrical specifications, indicates the interval during

which data cannot change prior to the end of the write

access.

Unlike other truly nonvolatile memory technologies,

there is no write delay with FRAM. Since the read

and write access times of the underlying memory are

the same, the user experiences no delay through the

bus. The entire memory operation occurs in a single

bus cycle. Therefore, any operation including read or

write can occur immediately following a write. Data

polling, a technique used with EEPROMs to

determine if a write is complete, is unnecessary.

Precharge Operation

The precharge operation is an internal condition

where the state of the memory is prepared for a new

access. All memory cycles consist of a memory

access and a precharge. The precharge is user

initiated by taking the /CE signal high or inactive. It

must remain high for at least the minimum precharge

timing specification. The user dictates the beginning

address is latched.

Rev 0.2

Sept 2001 Page 15 of 27

Page 16

FM3808

FFFFh

of this operation since a precharge will not begin until

/CE rises. Ho wever, the de vice has a maximum /CE

low time specification that must be satisfied.

Memory Architecture

FRAM memory internally operates with a read and

restore mechanism similar to a DRAM. Therefore

each cycle (read or write) involves a change of state.

The memory architecture is based on an array of rows

and columns. Each access causes an endurance cycle

Block 31

Block 31

Block 30

Block 30

Block 29

Block 29

Block 28

Block 28

FFFFh

FC00h

FC00h

FBFFh

FBFFh

F800h

F800h

F7FFh

F7FFh

F400h

F400h

F3FFh

F3FFh

F000h

F000h

for an entire row (4 bytes). The memory array is

divided into 32 blocks, each 1Kx8. The 5-upper

address lines decode the block selection as shown in

Figure 6. Data targeted for significantly different

numbers of cycles should be located in separate

blocks since memory rows do not extend across block

boundaries.

Each block of 1Kx8 consists of 256 rows and 4

column address locations. The address lines A0-A7

decode row selection and A8-A9 lines decode column

selection. This scheme facilitates a relatively uniform

distribution of cycles across the rows of a block. By

Block 3

Block 3

Block 2

Block 2

Block 1

Block 1

Block 0

Block 0

0FFFh

0FFFh

0C00h

0C00h

0BFFh

0BFFh

0800h

0800h

07FFh

07FFh

0400h

0400h

03FFh

03FFh

0000h

0000h

allowing the address LSBs to decode row selection,

the user avoids applying multiple cycles to the same

row when accessing sequential data. For example,

256 bytes can be accessed sequentially without

accessing the same row twice. In this example, one

cycle would be applied to each row. An entire block

of 1Kx8 can be read or written with only four cycles

applied to each row. Figure 7 illustrates the

Figure 6. Address Blocks

A

9-A8

11b

Block 4

A14-A10

00100b

organization within a memory block.

10b

Row 0

Row 1

Row 2

01b

Row 3

Row 252

Row 253

Row 254

Row 255

00b

02h 03h

00h FFh

A0-A7

Figure 7. Row and Column Organization

01h

FCh

FDh

FEh

Rev 0.2

Sept 2001 Page 16 of 27

Page 17

FM3808

FRAM Design Considerations

When designing with FRAM for the first time, users

of SRAM will recognize a few minor differences.

First, bytewide FRAM memories latch each address

on the falling edge of chip enable. This allows the

address bus to change after starting the memory

access. Since every access latches the memory

address on the falling edge of /CE, users should not

ground it as they might with SRAM.

Users that are modifying existing designs to use

FRAM should examine the hardware address

decoders. Decoders should be modified to qualify

addresses with an address valid signal if they do not

already. In many cases, this is the only change

required. Systems that drive chip enable active, then

inactive for each valid address may need no

modifications. An example of the target signal

relationships are shown in Figure 8. Also shown is a

common SRAM signal relationship that will not

work

for the FM3808.

Valid Memory Signaling Relationship

FRAM

signaling

CE

Address

Data

Address 1 Address 2

Data 1 Data 2

Invalid Memory Signaling Relationship

SRAM

signaling

CE

Address

Data

Address 1

Data 1

Figure 8. Memory Address Relationships

Address 2

Data 2

Rev 0.2

Sept 2001 Page 17 of 27

Page 18

FM3808

Real-time Clock Design Considerations

The principal design issues in using the real time

clock are selection and specification of backup

energy source and the selection of the timekeeping

crystal. Selection of the backup source is primarily a

choice between a capacitor and a battery, and the

specifications needed for each. Selection of the

crystal is based on mechanical (surface mount versus

through-hole) considerations and the characteristic

capacitance. Each topic is discussed briefly.

Backup Power Source

The FM3808 is designed to accommodate either a

battery or a capacitor as a backup power source.

Unlike SRAM-based timekeepers that depend on the

battery to make data nonvolatile, the FM3808 is

unrestricted. Data stored in FRAM is not dependent

on the backup battery in any way. This means that

capacitor backup, which should be less expensive, is

a option. Selection of a capacitor is determined by the

expected duration of power outage where

timekeeping must be maintained, and the practical

difficulty in resetting the time should it be lost. If the

time is relatively easy to reset, or a typical power loss

is only a brownout, the capacitor may be a good, cost

effective choice. In addition, portable systems that

use a battery for primary power are good candidates

for capacitor backup. If the time is very difficult to

reset, or the power outage may be longer than a

capacitor can supply, then a small battery is best.

Each system and application can be evaluated for the

difficulty in setting the time. However, the expected

backup times for several capacitor choices are

illustrated below. These figures cannot be used as

guarantees due to the unknown leakage characteristic s

in external components, but they provide guidelines

for realistic expectations about capacitor use. In the

5V Supply

scenario using capacitor backup, the charging circuit

must also be considered. A typical representation is

shown below.

The backup times are based on a starting backup

voltage (fully char ged) of 4 .7V and minimum backup

voltage of 2.5V. A 0.3V forward drop from 5.0V

VDD might be expected from a schottky-diode. Note

the graph, which shows approximate backup current

as a function of backup voltage. Thus, the higher

voltages at the beginning of discharge provide less

incremental backup time than the lower voltages near

the end of discharge. However, the total backup time

depends on the capacitor size and the maximum, fully

charged volt age.

One important note about capacitor backup is that the

times are incremental. Each time power is restored

the capacitor is fully recharged. Rather than

examining the cumulative time without power in the

system over a 10-year period, the capacitor design is

only concerned with the maximum time without

power for one outage.

If the times available for a capacitor are not

sufficient, then a battery is the best selection. Most

users opt for a 3V lithium coin. Note that with nonrechargeable batteries, the reservoir is not replenished

so the critical parameter is the total time without

power during the useful life of a system. For 1 year

without power (total) during a 10-year system life, the

battery capacity must be at least 9.25 mAhr. For 5

years without power during a 10-year period, it

becomes 46 mA*hr.

x

1

VDD

Schottky

Diode

Capacitor Size Backup Time

x

2

FM3808

VBAK

Backup Capacitor or

Super/Golden Cap

100 µF 3 minutes

1000 µF 30 minutes

10000 µF 5.1 hours

0.47 F (super cap) 240 hours

Figure 9. Capacitor Backup Circuit

Rev 0.2

Sept 2001 Page 18 of 27

Page 19

FM3808

IBAK vs VBAK

2.5E-06

2.0E-06

1.5E-06

IBAK

1.0E-06

5.0E-07

0.0E+00

4.7 4.5 4.25 4 3.75 3.5 3.25 3 2.75 2.5

VBAK

Figure 10. Backup Current vs. Voltage

Crystal Selection

The second passive component needed for the RTC

function is the timekeeping crystal. A 32.768 kHz

time-base is required, and the FM3808 is designed to

accept a low cost crystal. The major parameters

associated with the crystal are timekeeping accuracy

and backup current. The FM3808 is designed to

accept a crystal with a characteristic capacitance of 6

pF. Deviations from this specification will lead to

different accuracy and IBAK from the specified

IBAK may go up or down from the specified value as

a function of the capacitive load.

The timekeeping accuracy is also a strong function of

the operating temperature due to errors in crystal

frequency. Temperature behavior of timekeeping

crystals is well known and it follows a curve like the

one shown below. The specific crystal manufacturer

should be consulted for the behavior of their specific

device. Note the error in frequency ppm. One ppm is

roughly 2.6 seconds per month in timekeeping error.

values. Though accuracy is unlikely to improve, the

0

-20

-40

-60

-80

-100

Error ppm

-120

-140

-160

-180

-200

-45

-35

-25

-15

5

-5

Ambient Temperature

15

C

25

35

45

55

65

75

85

Figure 11. Typical Crystal Error vs. Temperature

Rev 0.2

Sept 2001 Page 19 of 27

Page 20

FM3808

Electrical Specifications

Absolute Maximum Rat ing s

Symbol Description Ratings

VDD Power Supply Voltage with respect to VSS -1.0V to +7.0V

VIN Voltage on any signal pin with respect to VSS -1.0V to +7.0V and

V

< VDD+1.0V

IN

T

Storage temperature

STG

T

Lead temperature (Soldering, 10 seconds)

LEAD

Stresses above those listed under Absolute Maximum Ratings may cause permanent damage to the device.

This is a stress rating only, and the functional operation of the device at these or any other conditions above

those listed in the operational section of this specification is not implied. Exposure to absolute maximum

ratings conditions for extended periods may affect device reliability.

DC Operating Conditions (T

= -40° C to + 85° C, VDD = 4.5V to 5.5V unless otherwise specified)

A

Symbol Parameter Min Typ Max Units Notes

VDD Power Supply Voltage 4.5 5.0 5.5 V

V

VDD Voltage that activates INT pin 4.6

INT

4.45

V

Clock Backup Voltage 2.5 3.0 VDD V

BAK

VLO VDD Lockout Voltage 4.3 4.5 V 11

VSW VDD Voltage that causes switch to V

V

BAK

VBG VDD Voltage for active Power Monitor 2.3 V 5

IDD V

I

Standby Current - TTL 500

SB1

I

Standby Current - CMOS 150

SB2

I

Clock backup current 0.9 1.0

BAK

Supply Current - Active 10 25 mA 1

DD

ILI Input Leakage Current 10

ILO Output Leakage Current 10

VIH Input High Voltage 2.0 VDD + 0.5 V

VIL Input Low Voltage -0.5 0.8 V

VOH Output High Voltage 2.4 V 10

VOL Output Low Voltage 0.4 V 9

V

Output Low Voltage (INT pin)

OLB

Device in backup mode (V

DD<VBAK

)

0.7 V 12

Notes

VDD = 5.5V, /CE cycling at minimum cycle time. All inputs at CMOS levels, all outputs unloaded.

1.

2.

Voltage for V

3.

V

= 3.0V, VDD < V

BAK

4.

VSW occurs when VDD drops below V

rather than from V

5.

Signals controlled by the power monitor (such as the INT output) are active.

6.

VDD = 5.5V, /CE at VIH, All inputs at TTL levels, all outputs u nloaded .

7.

VDD = 5.5V, /CE at VIH, All inputs at CMOS levels, all outputs unloaded.

8.

VIN, V

9.

10.

11.

12.

OUT

IOL = 4.2 mA.

IOH = -2.0 mA.

Memory and register access is blocked when VDD < VLO

VDD=0, V

depends on selection of V

INT

between VDD and VSS.

= 3.0V, IOL = 4.2 mA

BAK

; oscillator running.

BAK

. VSW is not otherwise used for control signals or functions.

DD

control bit.

INT

. VSW is also the point at which the timekeeper draws current from the V

BAK

-40°C to + 85°C

300° C

4.75

4.6

V 4

BAK

V

V

µA

µA

µA

µA

µA

BAK

2

6

7

3

8

8

pin,

Rev 0.2

Sept 2001 Page 20 of 27

Page 21

FM3808

Read Cycle AC Parameters (T

= -40° C to + 85° C, VDD = 4.5V to 5.5V unless otherwise specified)

A

Symbol Parameter Min Max Units Notes

tCE Chip Enable Access Time ( to data valid) 70 ns

tCA Chip Enable Active Time 70 10,000 ns

tRC Read Cycle Time 130 ns

tPC Precharge Time 60 ns

tAS Address Setup Time 0 ns

tAH Address Hold Time 10 ns

tOE Output Enable Access Time 10 ns

tHZ Chip Enable to Output High-Z 15 ns 1

t

Output Enable to Output High-Z 15 ns 1

OHZ

Write Cycle AC Parameters (T

= -40° C to + 85° C, VDD = 4.5V to 5.5V unless otherwise specified)

A

Symbol Parameter Min Max Units Notes

tCA Chip Enable Active Time 70 10,000 ns

tCW Chip Enable to Write High 70 ns

tWC Write Cycle Time 130 ns

tPC Precharge Time 60 ns

tAS Address Setup Time 0 ns

tAH Address Hold Time 10 ns

tWP Write Enable Pulse Width 30 ns

tDS Data Setup 30 ns

tDH Data Hold 0 ns

tWZ Write Enable Low to Output High Z 15 ns 1

tWX Write Enable High to Output Driven 10 ns 1

tHZ Chip Enable to Output High-Z 15 ns 1

tWS Write Setup 0 ns 2

tWH Write Hold 0 ns 2

Notes

1 This parameter is periodically sampled and not 100% tested.

2 The relationship between /CE and /WE determines if a /CE- or /WE-controlled write occurs. There is no timing

specification associated with this relationship.

Power Cycle Timing (T

= -40° C to + 85° C)

A

Symbol Parameter Min Max Units Notes

t

INT signal active after V

INT

100 ns 1,2

INT

tPD Last Access Complete to VLO 0 ns 1,3

tRI VLO to inputs recognized on power-up 1

tR Rise time of VDD from VBG to VLO 100

tF Fall time of VDD from VLO to VBG 100

µs

µs

µs

1,4

1,5

1,5

Notes

1 This parameter is periodically sampled and not 100% tested.

2 If power monitor is programmed to generate INT.

3 Access is blocked at V

may be useful in accomplishing th is.

4 Failing to satisfy tRI may result in the first access b eing ign ored. Failure to raise /CE to a h igh level p rior to VDD>VLO may

result in improper operation.

5 Slew rate for proper transition between the locked-out condition and normal operation.

. The last access should be complete prior to reaching VLO. The early warning power fail interrupt

LO

Rev 0.2

Sept 2001 Page 21 of 27

Page 22

FM3808

Supervisor AC Parameters (T

= -40° C to + 85° C, VDD = 4.5V to 5.5V unless otherwise specified)

A

Symbol Parameter Min Typ Max Units Notes

t

INT output pulse width 150 200 300 ms 1

IPU

t

Flag register access to INT pin clear - 100 ns 2

FCO

Notes

1 P/L = 1; pulse mode.

2 P/L= 0; level mode. From the end of the access where th e flag regi st er is read and the flag cleared.

Data Retention (

VDD = 4.5V to 5.5V unless otherwise specified)

Parameter Min Units Notes

Data Retention 10 Years 1

Notes

1. The relationship between retention, temperature, and the associated reliability

level will be characterized separately.

Capacitance

(TA = 25° C, f=1.0 MHz, VDD = 5V)

Symbol Parameter Max Units Notes

CIO Input/output capacitance (DQ) 8 pF 1

CI Input capacitance 6 pF 1

C

X1, X2 Crystal pin capacitance 12 pF 1, 2

XTAL

Notes

1 This parameter is periodically sampled and not 100% tested.

2 The crystal attached to the X1/X2 pins must be rated as 6pF max.

AC Test Conditions Equivalent AC Load Circuit

Input Pulse Levels 0 to 3V

Input rise and fall times 10 ns

1.3V

Input and output timing levels 1.5V

3300

Ω

Output

50 pF

Rev 0.2

Sept 2001 Page 22 of 27

Page 23

FM3808

Timing Diagrams

CE

t

t

AH

AS

A0-14

t

OE

OE

DQ0-7

t

RC

t

CA

t

PC

t

OHZ

t

CE

t

HZ

Read Cycle Timing

t

WC

t

CA

t

PC

CE

t

t

AH

AS

A0-14

t

WS

t

WH

WE

OE

DQ0-7

t

DS

t

DH

Write Cycle Timing - /CE Controlled Timing

Rev 0.2

Sept 2001 Page 23 of 27

Page 24

FM3808

t

WC

t

CA

t

PC

CE

t

t

AH

AS

A0-14

t

WH

WE

t

WS

t

WP

OE

t

WZ

t

WX

DQ0-7

out

t

t

DS

DH

DQ0-7

in

Write Cycle Timing - /WE Controlled Timing

Rev 0.2

Sept 2001 Page 24 of 27

Page 25

FM3808

Picture assumes VSW < VINT

VDD

t

F

VINT

VLO VLO

VSW

VBG

t

INT

t

R

VINT

VSW

VBG

t

FCO

t

IPU

INT

t

PD

t

RI

Inputs

CE

Power Cycle Timing

INT

source

occurs

INT

source

occurs

P/L=1 P/L=0

t

IPU

INT

t

FCO

CE

INT source

flag cleared

INT Pin Timing

Rev 0.2

Sept 2001 Page 25 of 27

Page 26

FM3808

Mechanical Drawing

32-pin TSOP (JEDEC MO-142 BA)

All dimensions in millimeters

13.30-13.55

11.70-11.90

1

2

3

7.90-8.10

1.20

max

0.50

typ

0.17-0.27

typ

0.95-1.05

0.05-0.15

13.30-13.55

R 0.08 min

R 0.08-0.20

°°

0.50-0.70

0 - 5

Rev 0.2

Sept 2001 Page 26 of 27

Page 27

FM3808

Revision History

Revision Date Summary of Changes

0.1 Dec 19, 2000 Initial Release

0.2 Sept 19, 2001 Changed ISB spec, redefined crystal capacitance specs, data retention

temperature condition. General cleanup.

Rev 0.2

Sept 2001 Page 27 of 27

Loading...

Loading...