Page 1

®

ESDA6V1P6

Application Specific Discretes

A.S.D.

MAIN APPLICATIONS

Where transient overvoltage protection in ESD

sensitive equipment is required, such as :

Computers

■

Printers

■

Communication systems and cellular phones

■

Video equipment

■

Thisdeviceisparticularlyadpatedto the protection

of symmetrical signals.

FEATURES

4UNIDIRECTIONAL TRANSIL™ FUNCTIONS.

■

■ BREAKDOWN VOLTAGE V

■ LOW LEAKAGE CURRENT < 500 nA

VERY SMALL PCB AREA < 2.6 mm

■

DESCRIPTION

The ESDA6V1P6 is a monolithic array designed to

protect up to 4 lines against ESD transients.

This device is ideal for applications where board

space saving is required.

= 6.1V MIN

BR

2

QUAD TRANSIL™ ARRAY

FOR ESD PROTECTION

SOT-666

FUNCTIONAL DIAGRAM

1

6

BENEFITS

■

High ESD protection level.

■

High integration.

■

Suitable for high density boards.

COMPLIESWITH THE FOLLOWING STANDARDS:

■

IEC61000-4-2 level 4: 15 kV (air discharge)

8kV (contact discharge)

■

MIL STD 883E-Method 3015-7: class 3

25kV HBM (Human Body Model)

January 2003 - Ed: 2

2

3

5

4

1/8

Page 2

ESDA6V1P6

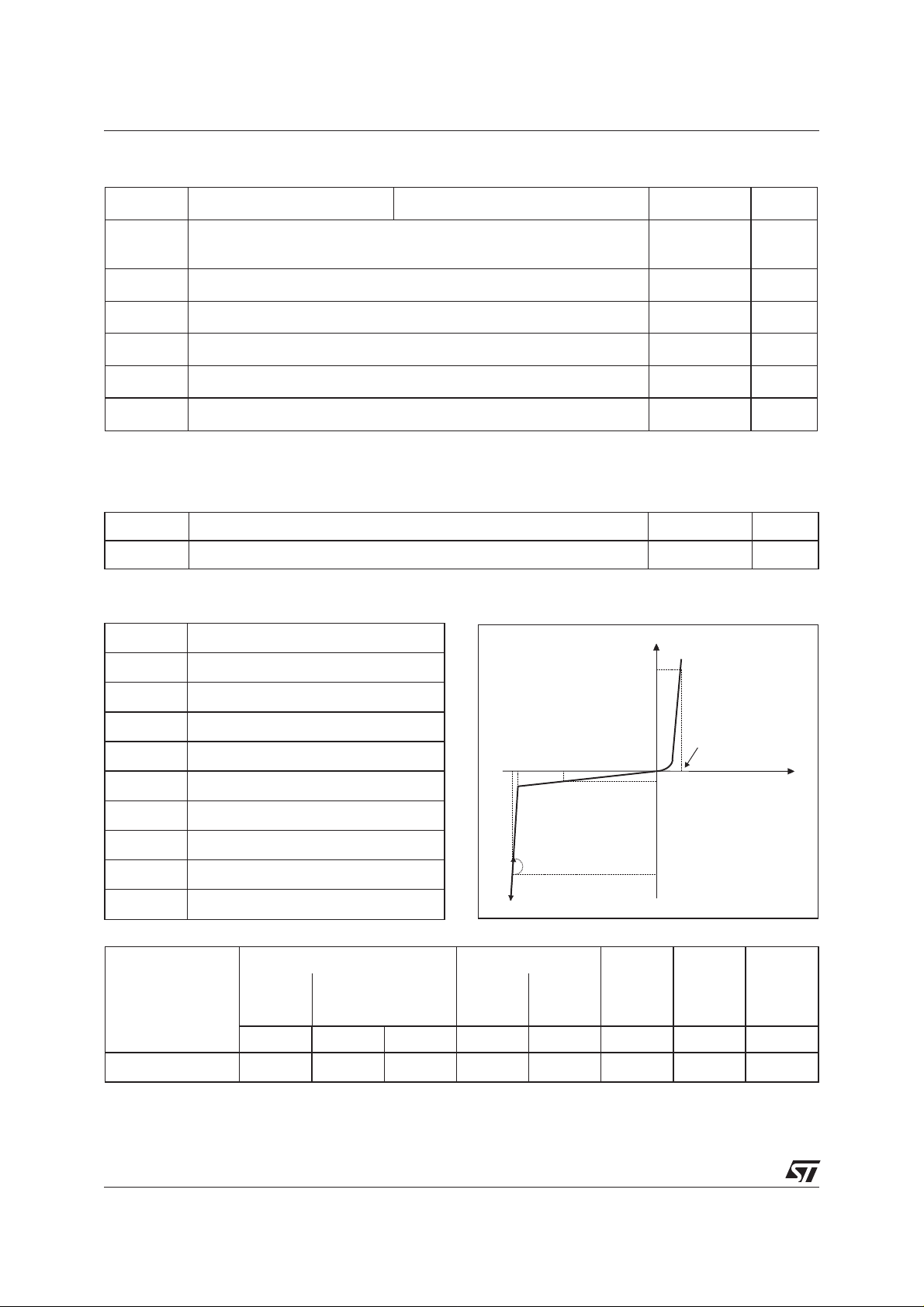

ABSOLUTE RATINGS (T

amb

= 25°C)

Symbol Parameter Test conditions Value Unit

V

PP

P

PP

T

j

T

stg

T

L

T

op

Note 1: for a surge greater than the maximum values, the diode will fail in short-circuit.

ESD discharge - IEC61000-4-2 air discharge

IEC61000-4-2 contact discharge

Peak pulse power (8/20 µs) (see note 1) Tjinitial = Tamb

Junction temperature

Storage temperature range

Maximum lead temperature for soldering during 10s at 5mm for case

Operating temperature range

±15

±8

150 W

125 °C

-55to+150 °C

260 °C

-40to+150 °C

THERMAL RESISTANCES

Symbol Parameter Value Unit

R

th(j-a)

ELECTRICAL CHARACTERISTICS (T

Junction to ambient on printed circuit on recommended pad layout

= 25°C)

amb

220 °C/W

kV

Symbol Parameter

V

RM

V

BR

V

CL

I

RM

I

PP

αT

V

F

C

R

d

Types V

ESDA6V1P6

Stand-off voltage

Breakdown voltage

Clamping voltage

Leakage current

Peak pulse current

Voltage tempature coefficient

Forward voltage drop

Capacitance per line

Dynamic resistance

BR

min. max. max. typ. max. typ.

VVmAµAV

6.1 7.2 1 0.5 3 1.5 4.5 70

@I

R

V

CLVBRVRM

Slope: 1/R

IRM@V

RM

I

I

F

V

F

I

RM

d

I

PP

Rd αTC

@0V

Ω10

-4

/°C pF

V

2/8

Page 3

ESDA6V1P6

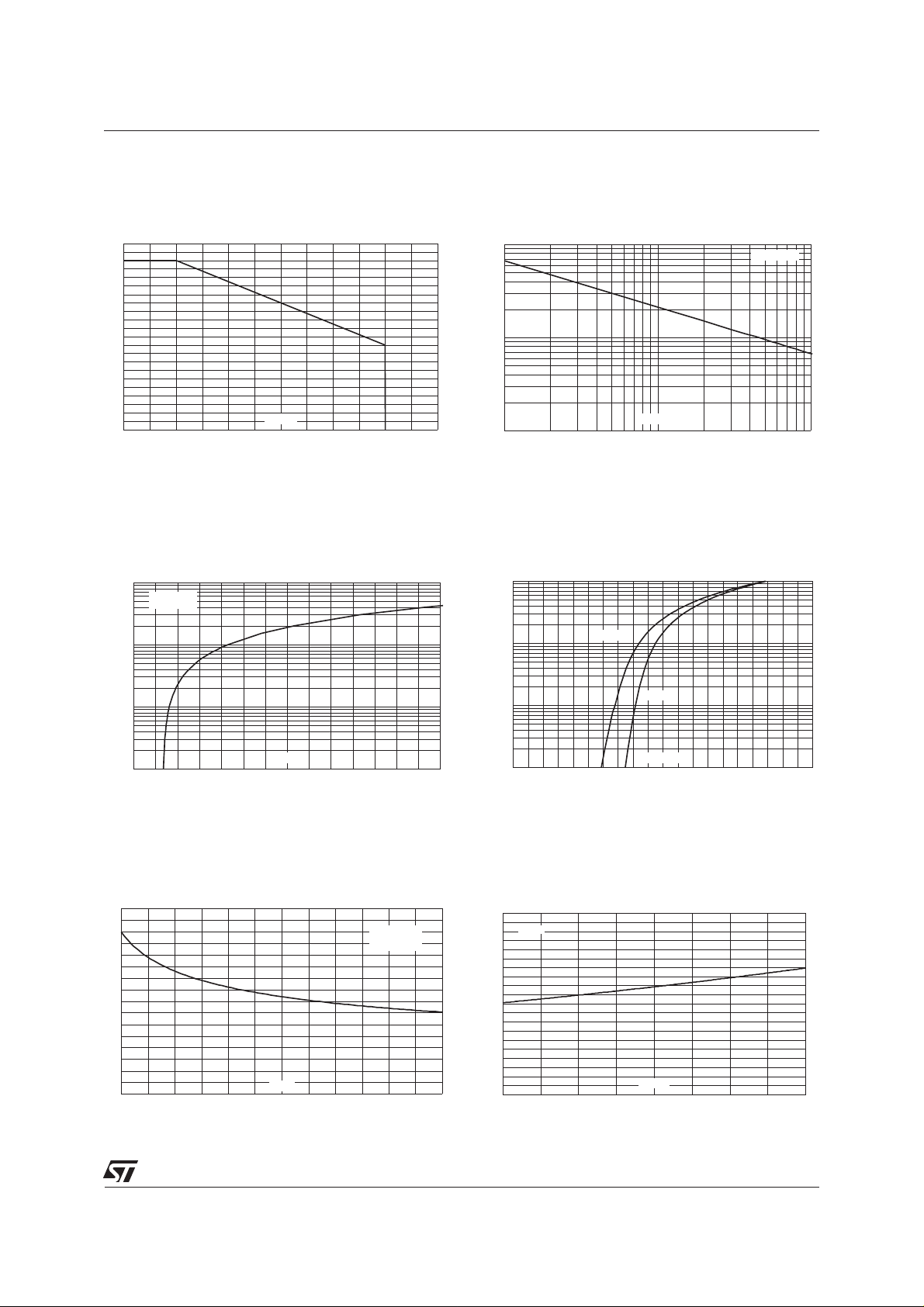

Fig. 1: Relative variation of peak pulse power

versus initial junction temperature.

P [T initial] / P [T initial=25°C)

PP j PP j

1.1

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0.0

0 25 50 75 100 125 150

T (°C)

j

Fig. 3: Clamping voltage versus peak pulse

current (typical values, rectangular waveform).

I (A)

PP

100.0

t =2.5µs

p

T initial=25°C

j

Fig. 2:Peak pulse power versusexponentialpulse

duration.

P (W)

PP

1000

100

T (µs)

10

1 10 100

p

T initial=25°C

j

Fig. 4: Forward voltage drop versus peak forward

current (typical values).

I (A)

FM

1.E+00

10.0

1.0

V (V)

0.1

0 10203040506070

CL

Fig. 5: Junction capacitance versus reverse

voltage applied (typical values).

C(pF)

80

70

60

50

40

30

20

10

0

0123456

V (V)

R

F=1MHz

V =30mV

OSC RMS

T=25°C

j

T=125°C

1.E-01

1.E-02

1.E-03

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0

j

T=25°C

j

V (V)

FM

Fig. 6: Relative variation of leakage current versus

junction temperature (typical values).

I [T ] / I [T =25°C]

Rj Rj

2.0

V =3V

R

1.8

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0.0

25 50 75 100 125

T (°C)

j

3/8

Page 4

ESDA6V1P6

TECHNICAL INFORMATION

1. ESD protection by ESDA6V1P6

Fig. A1: Application example.

With the focus of lowering the operation levels, the

problemofmalfunction caused by theenvironment

is critical. Electrostatic discharge (ESD) is a major

cause of failure in electronic systems.

I/O2

I/O1

As a transient voltage suppressor, ESDA6V1P6 is

an ideal choice for ESD protection by suppressing

ESD events. It is capable of clamping the

Connector

incoming transient to a low enough level such that

any damage is prevented on the device protected

by ESDA6V1P6.

ESDA6V1P6 serves as a parallel protection

elements, connected between the signal line and

ground. As the transient rises above the operating

voltage of the device, the ESDA6V1P6 becomesa

low impedance path diverting the transient current

to ground.

The clamping voltage is given by the following formula:

=VBR+Rd.I

V

CL

PP

As shown in figure A2, the ESD strikes are clamped by the transient voltage suppressor.

Fig. A2: ESD clamping behavior.

I/O4

I/O3

IC

to be

protected

R

G

V

G

I

PP

R

d

V(i/o)

V

BR

R

LOAD

Device

to be

ESD surge ESD6V1P6

Tohave a good approximationofthe remaining voltages atboth Vi/o side, weprovidethe typical dynamical

resistance value R

we have:

The results ofthecalculationdone V

= 1.5Ω (typ.) give:

R

d

This confirms the very low remaining voltage across the device to be protected. It is also important to note

that in this approximation the parasitic inductance effect was not taken into account. This could be a few

tenths of volts during a few ns at the Vi/o side.

. By taking into account the following hypothesis:

d

R

Vi o V R

()

= 8kV, RG= 330Ω(IEC61000-4-2 standard), VBR= 6.4V (typ.)and

G

V i o Volts

()

and R

G>Rd

/ =+×

load>Rd

BR d

/.=42 8

V

R

g

g

protected

4/8

Page 5

ESDA6V1P6

Fig. A3: ESD test board.

± 15kV ESD

Air discharge

V(i/o)

Fig. A5: Remaining voltage during ESD surge.

Fig. A4: ESD test configuration.

I/O1, I/O2, I/O3 or I/O4

± 15kV ESD

Air discharge

GND

V(i/o)

a: Response in the positive way b: Response in the negative way

2. Crosstalk behavior

Fig. A6: Crosstalk phenomenon

RG1

G1

V

RG2

VG2

DRIVERS RECEIVERS

Line 1

Line 2

R

L1

R

L2

αβ

αβ

V+ V

1G1 12G2

V+ V

2G2 21G1

5/8

Page 6

ESDA6V1P6

Thecrosstalkphenomena are due to the coupling between 2lines.Coupling factors ( β12 or β21 ) increase

whenthe gap across linesdecreases, particularly insilicondice. In theexample above, the expectedsignal

on load R

signal represents the effect of the crosstalk phenomenon of the line 1 on the line 2. This phenomenon has

to be taken into account when the drivers impose fast digital data or high frequency analog signals. The

perturbed line will be more affected if it works with low voltage signal or high load impedance (few kΩ)

is α2VG2, in facttherealvoltageatthis point has got an extra value β21VG2. This partoftheV

L2

G1

Fig. A7: Analog crosstalk test configuration.

I/O1

I/O4

unloaded

GND

50Ω

Port 2

VG

50Ω

Port 1

Fig. A9: Digital crosstalk test configuration.

I/O1

unloaded

Fig. A8: Typical analog crosstalk response.

I/O1

I/O4

unloaded

GND

50Ω

Port 2

VG

50Ω

Port 1

Fig. A10: Typical digital crosstalk response.

0 - 5V

pulse generator

F= 100KHz

R

t = 20ns

6/8

G1

V

GND

β21 G1V

crosstalk

V

β

21 G1

unloaded

I/O4

Page 7

ESDA6V1P6

3. PCB layout recommendations

As ESD is a fast event, the di/dt caused by this surge is about 30A/ns (risetime=1ns, Ipeak=30A), that

means each nH causes an overvoltage of 30V.

Thus, the circuit board layout is a critical design step in the suppression of ESD induced transients by

reducing parasitic inductances. To ensure that, the following guidelines are recommended :

The ESDA6V1P6 should be placed as close as possible to the input terminals or connectors.

■

The path length between the ESD suppressor and the protected line should be minimized.

■

All conductive loops, including power and ground loops should be minimized.

■

The ESD transient return path to ground should be kept as short as possible.

■

The connections from the ground pins to the ground plane should be the shortest possible.

■

4. Comparison with varistors

Varistors TRANSIL™

Leakage current

Protection efficiency

Ageing

Low leakage current for Transil™ device

Improve the autonomy of portable equipments as mobile

■

Better efficiency in terms of ESD protection by using Transil™ device

■ Varistors are bidirectional devices and so are not suitable to protect sensitive ICs, because they will be

submitted to high voltages in the negative way.

■ Ratio V

■

Less dispersion in terms of V

CL/VBR

lower for Transil™ device

BR

No ageing phenomena regarding ESD events with Transil™ device

■

Higher efficiency in terms of ESD protection

-- +++

-- ++

-- ++

ORDER CODE

ESDA 6V1 P6

ESD ARRAY

V min

BR

Ordering type Marking Package Weight Base qty Delivery mode

ESDA6V1P6 B SOT-666 2.9 mg. 3000 Tape & reel

PACKAGE:SOT-666

7/8

Page 8

ESDA6V1P6

PACKAGE MECHANICAL DATA

SOT-666

DIMENSIONS

bp

D

A

FOOT PRINT (in millimeters)

0.36

REF.

Millimeters Inches

Min. Max. Min. Max.

A 0.50 0.60 0.020 0.024

bp 0.17 0.27 0.007 0.011

e1

e

E

c 0.08 0.18 0.003 0.007

D 1.50 1.70 0.060 0.067

E 1.10 1.30 0.043 0.051

e 1.00 0.040

e1 0.50 0.020

Lp

He

U

He 1.50 1.70 0.059 0.067

Lp 0.10 0.30 0.004 0.012

0.30

0.84

0.20 0.20

Informationfurnished is believed to beaccurateand reliable. However, STMicroelectronics assumesno responsibility for the consequencesof

useof such information norforany infringement of patentsor other rights of thirdparties which may resultfromits use. No licenseis granted by

implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject to

change without notice. This publication supersedes and replaces all information previously supplied.

STMicroelectronics products are not authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

0.62

2.30

The ST logo is a registered trademark of STMicroelectronics

© 2003 STMicroelectronics - Printed in Italy - All rights reserved.

STMicroelectronics GROUP OF COMPANIES

Australia - Brazil - Canada - China - Finland - France - Germany

Hong Kong - India - Israel - Italy - Japan - Malaysia - Malta - Morocco - Singapore

Spain - Sweden - Switzerland - United Kingdom - United States.

http://www.st.com

8/8

Loading...

Loading...