Page 1

®

ESDA6V1BC6

Application Specific Discretes

A.S.D.

APPLICATIONS

Where transient overvoltage protection in ESD

sensitive equipment is required, such as :

COMPUTERS

■

PRINTERS

■

COMMUNICATION SYSTEMS

■

VIDEO EQUIPMENT

■

Thisdeviceisparticularlyadaptedtotheprotection

of symmetrical signals.

DESCRIPTION

The ESDA6V1BC6 is a monolithic array designed

to protect up to 4 lines in a bidirectional way

against ESD transients.

The device is ideal for situations where board

space is at a premium.

FEATURES

■ 4 BIDIRECTIONAL TRANSIL FUNCTIONS

■

ESD PROTECTION FOR DATA, SIGNAL AND

BUS

V

CC

■

STAND OFF VOLTAGE RANGE: ± 5 V MIN.

■

LOW LEAKAGE CURRENT < 1 µA

■

PEAK PULSE POWER ( 8/20)=80W

SUPPRESSOR FOR ESD PROTECTION

QUAD BIDIRECTIONAL TRANSIL

SOT23-6L (SC-74)

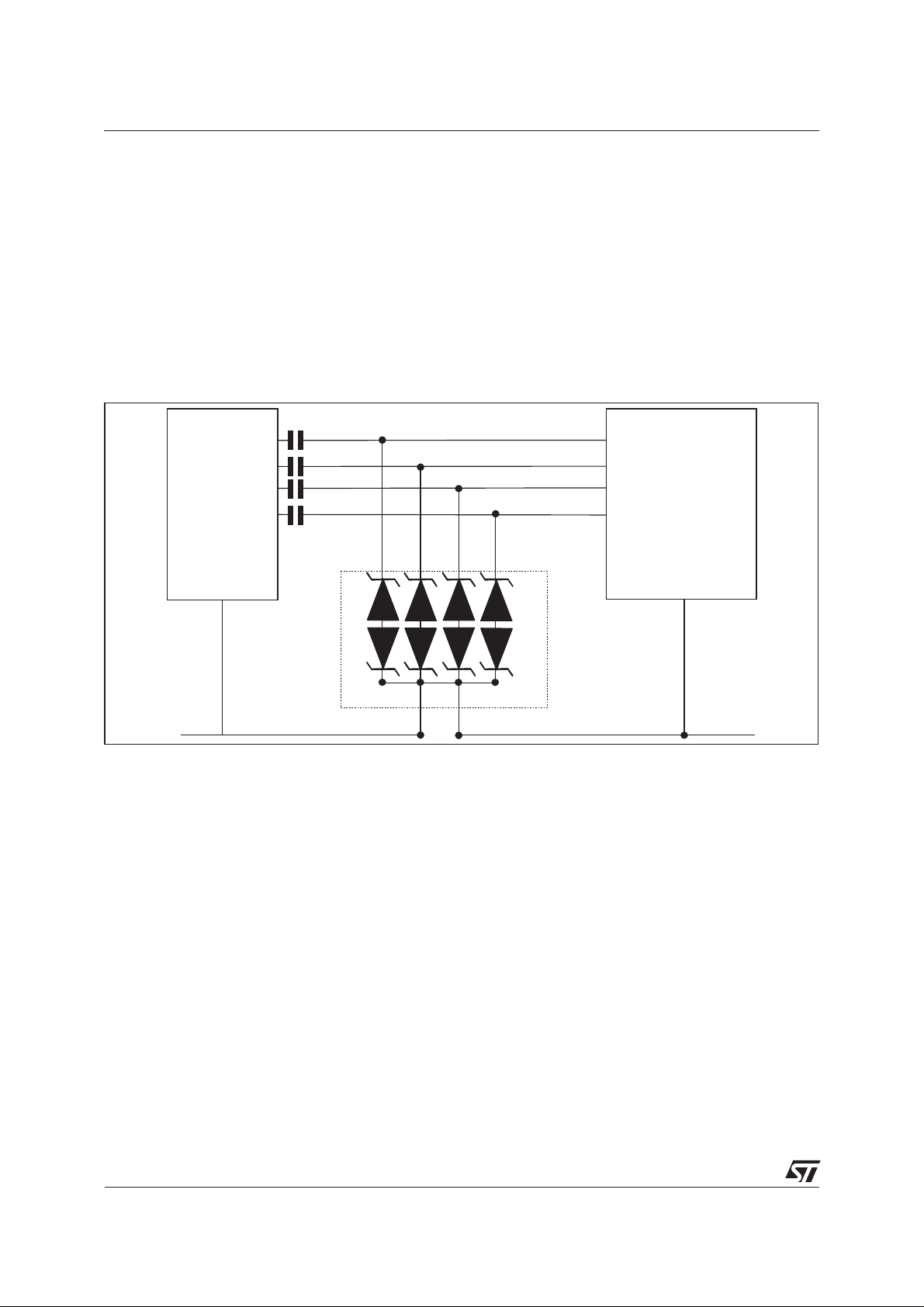

FUNCTIONAL DIAGRAM

SOT23-6L

1

2

3

6

5

4

BENEFITS

■

High ESD protection level : up to 25 kV

■

High integration

■

Suitable for high density boards

COMPLIES WITH THE FOLLOWING STANDARDS:

- IEC61000-4-2: 15 kV (air discharge)

8 kV (contact discharge)

- MIL STD 883C-Method 3015-6: class3

(human body model)

January 2002 - Ed: 1C

1/6

Page 2

ESDA6V1BC6

1. ESD protection by ESDA6V1BC6

With the focus of lowering the operation levels, the problem of malfunction caused by the environment is

critical. Electrostatic discharge (ESD) is a major cause of failure in electronic system.

Transient Voltage Suppressors are an ideal choice for ESD protection and have proven capable in

suppressing ESD events. They are capable of clamping the incoming transient to a low enough level such

that damage to the protected semiconductor is prevented.

Surface mount TVS arrays offer the best choice for minimal lead inductance.

They serve as parallel protection elements, connected between the signal line to ground. As the transient

risesabove the operating voltageofthe device, theTVSarray becomes a lowimpedance path diverting the

transient current to ground.

Bidirectional protection for 0V biased signals.

DRIVER

CONNECTOR

The ESDA6V1BC6 array is the ideal product for use as board level protection of ESD sensitive

semiconductor components.

The tiny SOT23-6L package allows design flexibility in the design of “crowded” boards where the space

saving is at a premium. This enables to shorten the routing and can contribute to improve ESD

performance.

2. Circuit Board Layout

Circuit board layout is a critical design step in the suppression of ESD induced transients. The following

guidelines are recommended :

■

The ESDA6V1BC6 should be placed as near as possible to the input terminals or connectors.

■

Minimise the path length between the ESD suppressor and the protected device

■

Minimise all conductive loops, including power and ground loops

■

The ESD transient return path to ground should be kept as short as possible.

■

Use ground planes whenever possible.

2/6

Page 3

ESDA6V1BC6

ABSOLUTE MAXIMUM RATINGS (T

amb

= 25°C)

Symbol Test conditions Value Unit

V

PP

P

PP

T

j

T

stg

T

L

T

op

Note 1: Variation of parameters is given by curves.

ELECTRICAL CHARACTERISTICS (T

Symbol Parameter

V

RM

V

BR

V

CL

I

RM

ESD discharge - MILSTD 883C - Method 3015-6

IEC61000-4-2 air discharge

IEC61000-4-2 contact discharge

Peak pulse power (8/20µs)

Junction temperature

Storage temperature range

Lead solder temperature (10 second duration)

Operating temperature range (note 1)

= 25°C)

amb

Stand-off voltage

Breakdown voltage

Clamping voltage

V

V

CL

Leakage current

BR

25

15

8

80 W

150 °C

-55 to +150 °C

260 °C

-40 to +125 °C

I

V

RM

I

RM

kV

V

I

PP

C

Rd

Peak pulse current

Capacitance

Dynamic resistance

Type

ESDA6V1BC6

Note 1 : Square pulse, Ipp = 3A, tp=2.5µs.

V

@IRIRM@V

BR

Rd

RM

I

PP

Rd αTC

min. max. max. typ. max. typ.

note 1 0V bias

-4

VVmAµAV Ω 10

/°C pF

6.181151.35 3 20

3/6

Page 4

ESDA6V1BC6

Fig. 1: Peak power dissipation versus initial

junction temperature.

Ppp[Tj initial]/Pp p [T j in itia l= 2 5 °C]

1.1

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0.0

0 25 50 75 100 125 150 175

Tj initial(°C)

Fig. 3: Clamping voltage versus peak pulse

current (Tj initial = 25 °C).

Rectangular waveform tp = 2.5 µs.

Ipp(A)

20.0

tp=2.5µs

10.0

1.0

0.1

0 5 10 15 20 25 30 35 40

Vcl(V)

Fig. 2: Peakpulse power versus exponential pulse

duration (Tj initial = 25 °C).

Ppp(W)

500

100

10

1 10 100

tp(µs)

Fig. 4: Capacitance versus reverse applied

voltage (typical values).

C(pF)

22

21

20

19

18

17

16

15

14

13

12

11

10

012345678

VR(V)

F=1MHz

Vosc=30mV

Fig. 5: Relative variation of leakage current versus

junction temperature (typical values).

IR[Tj] / IR[Tj=25°C ]

500

100

10

1

25 50 75 100 125 150

4/6

Tj(°C)

Page 5

ORDER CODE

ESD ARRAY

ESDA6V1BC6

ESDA 6V1 B C6

PACKAGE:

C6: SOT23-6L (SC-74)

PACKAGE MECHANICAL DATA

SOT23-6L

E

e

D

e

C

θ

H

A1

L

b

V min.

BR

A

A2

Bidirectional

REF. DIMENSIONS

Millimeters Inches

Min. Typ. Max. Min. Typ. Max.

A 0.90 1.45 0.035 0.057

A1 0 0.10 0 0.004

A2 0.90 1.30 0.035 0.0512

b 0.35 0.50 0.0137 0.02

c 0.09 0.20 0.004 0.008

D 2.80 3.00 0.11 0.118

E 1.50 1.75 0.059 0.0689

e 0.95 0.0374

H 2.60 3.00 0.102 0.118

L 0.10 0.60 0.004 0.024

θ 10° 10°

FOOTPRINT

3.50

0.138

2.30

0.090

mm

inch

0.95

0.037

0.60

0.024

1.10

0.043

1.20

0.047

MARKING

Type Marking

ESDA6V1BC6 BS55

Packaging: Standard packaging is tape and reel.

5/6

Page 6

ESDA6V1BC6

Informationfurnished is believed tobe accurate and reliable.However, STMicroelectronics assumes noresponsibility for the consequencesof

useof such informationnor for any infringementof patents or other rights of thirdparties which may result from its use.No license is grantedby

implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject to

change without notice. This publication supersedes and replaces all information previously supplied.

STMicroelectronics products are not authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics

© 2002 STMicroelectronics - Printed in Italy - All rights reserved.

STMicroelectronics GROUP OF COMPANIES

Australia - Brazil - Canada - China - Finland - France - Germany

Hong Kong - India - Israel - Italy - Japan - Malaysia - Malta - Morocco - Singapore

Spain - Sweden - Switzerland - United Kingdom - United States.

http://www.st.com

6/6

Loading...

Loading...