Page 1

ELH0101/883/8508901/2YX December 1994 Rev H

ELH0101/883/8508901/2YX

Power Operational Amplifier

Note: All information contained in this data sheet has been carefully checked and is believed to be accurate as of the date of publication; however, this data sheet cannot be a ‘‘controlled document’’. Current revisions, if any, to these

specifications are maintained at the factory and are available upon your request. We recommend checking the revision level before finalization of your design documentation. Patent pending.

©

1985 Elantec, Inc.

Features

# 5A peak, 2A continuous output

current

# 10 V/ms slew rate

# 300 kHz power bandwidth

# 850 mW standby power (

g

15V

supplies)

# 300 pA input bias current

# Virtually no crossover distortion

# 2 ms settling time to 0.01%

# 5 MHz gain bandwidth

# MIL-STD-883 devices 100%

manufactured in U.S.A.

Ordering Information

Part No. Temp. Range Package Outline

Ý

ELH0101AK/883Bb55§Ctoa125§C TO-3 MDP0003

ELH0101K/883Bb55§Ctoa125§C TO-3 MDP0003

8508901YX and 8508902YX are the SMD

versions of this device.

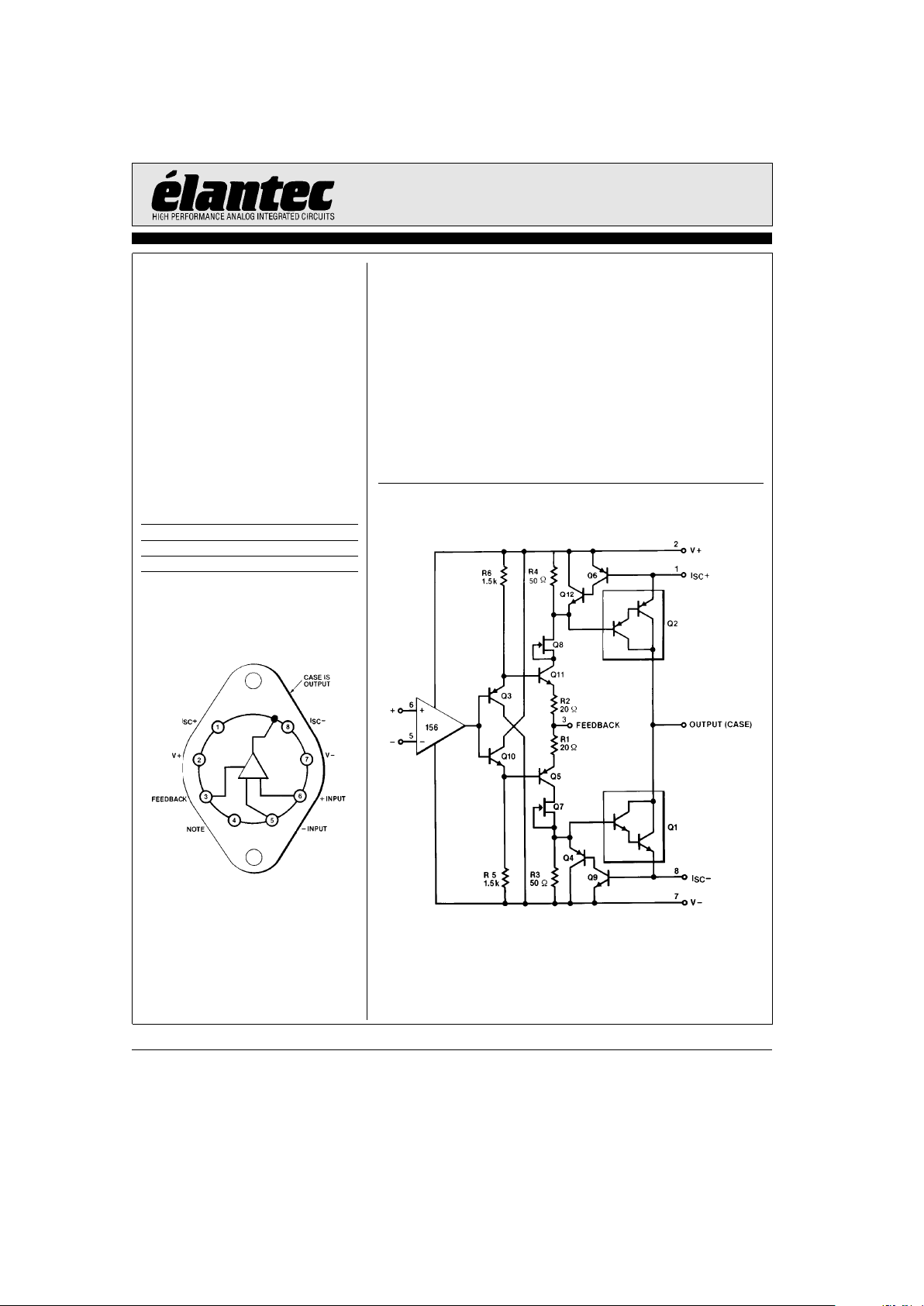

Connection Diagram

0101– 1

Top View

Note: Electrically connected internally.

No connection should be made to pin.

General Description

The ELH0101 is a wideband power operational amplifier featuring FET inputs, internal compensation, virtually no crossover

distortion, and rapid settling time. These features make the

ELH0101 an ideal choice for DC or AC servo amplifiers, deflection yoke drivers, programmable power supplies, and disk head

positioner amplifiers.

Elantec facilities comply with MIL-I-45208A and other applicable quality specifications. Elantec’s Military devices are 100%

fabricated and assembled in our rigidly controlled, ultra-clean

facilities in Milpitas, California. For additional information on

Elantec’s Quality and Reliability Assurance policy and procedures request brochure QRA-1.

Equivalent Schematic

0101– 2

TABWIDE

Page 2

ELH0101/883/8508901/2YX

Power Operational Amplifier

Absolute Maximum Ratings

V

S

Supply Voltage

ELH0101, ELH0101A

g

22V

P

D

Power Dissipation at T

A

e

25§C5W

Derate linearly at 25

§

C/W

to zero at 150

§

C

P

D

Power Dissipation at T

C

e

25§C 62W

Derate linearly at 2

§

C/W

to zero at 150

§

C

Differential Input Voltage

ELH0101, ELH0101A

g

40V but

k

g

V

S

VINInput Voltage Range

ELH0101, ELH0101A

g

20V but

k

g

V

S

Peak Output Current (50 ms pulse) 5A

Output Short Circuit Duration

(within rated power dissipation,

R

SC

e

0.35X,T

A

e

25§C) Continuous

T

A

Operating Temperature Range:

ELH0101, ELH0101A

b

55§Ctoa125§C

T

J

Maximum Junction Temperature 150§C

T

ST

Storage Temperature

b

65§Ctoa150§C

Lead Temperature

(Soldering, 10 seconds) 300

§

C

Important Note:

All parameters having Min/Max specifications are guaranteed. The Test Level column indicates the specific device testing actually

performed during production and Quality inspection. Elantec performs most electrical tests using modern high-speed automatic test

equipment, specifically the LTX77 Series system. Unless otherwise noted, all tests are pulsed tests, therefore T

J

e

T

C

e

TA.

Test Level Test Procedure

I 100% production tested and QA sample tested per QA test plan QCX0002.

II 100% production tested at T

A

e

25§C and QA sample tested at T

A

e

25§C,

T

MAX

and T

MIN

per QA test plan QCX0002.

III QA sample tested per QA test plan QCX0002.

IV Parameter is guaranteed (but not tested) by Design and Characterization Data.

V Parameter is typical value at T

A

e

25§C for information purposes only.

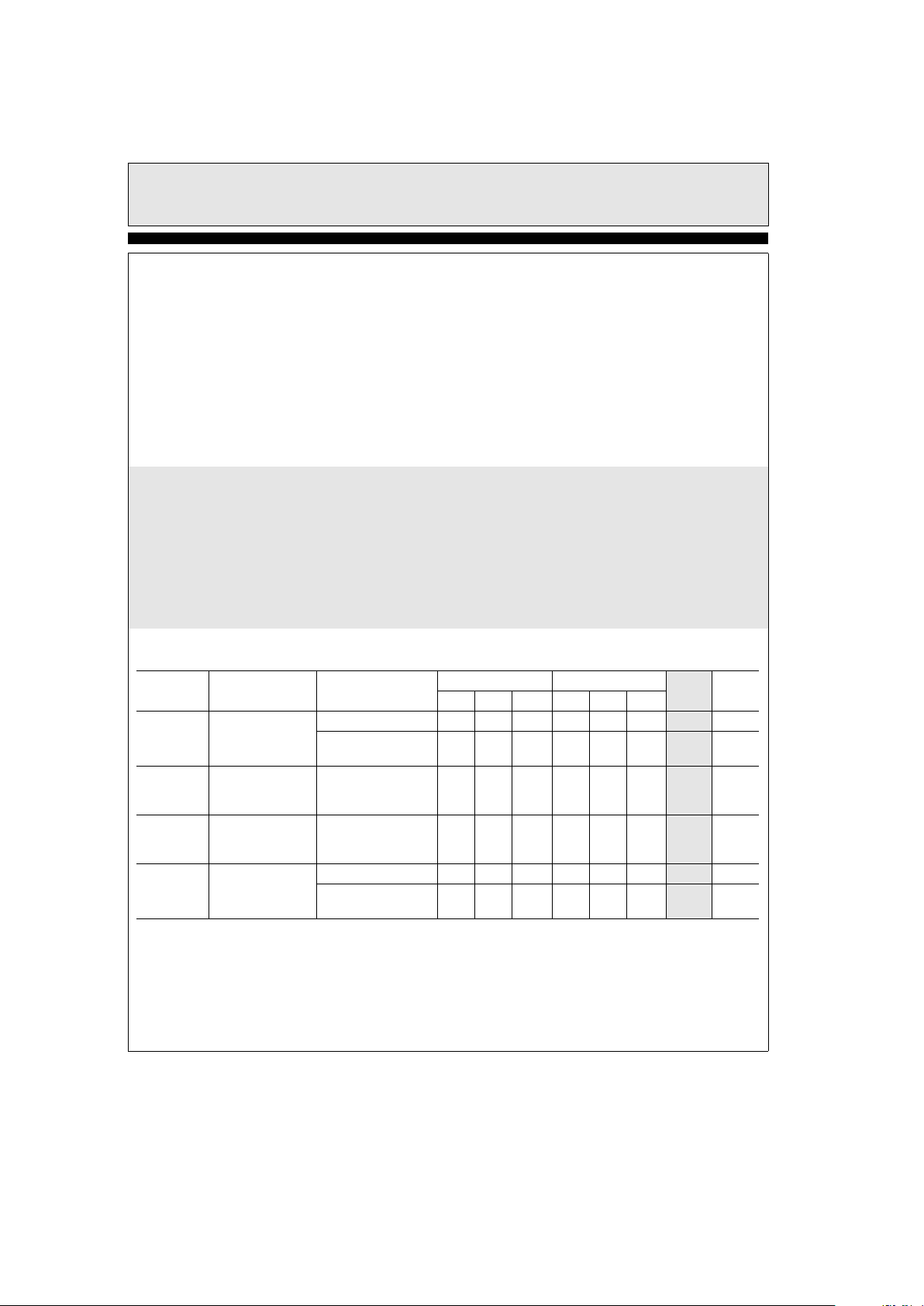

DC Electrical Characteristics

(Note 1) V

S

e

g

15V, T

A

e

25§C, V

CM

e

0V

Parameter Description Test Conditions

ELH0101 ELH0101A

Level

Test

Units

Min Typ Max Min Typ Max

V

OS

Input Offset 1 10 1 3 I mV

Voltage

T

MIN

s

T

A

s

T

MAX

,

15 7 I mV

ELH0101

DVOS/DPDChange in Input (Note 2)

Offset Voltage with 150 150 V mV/W

Dissipated Power

DVOS/DT Change in Input

Offset Voltage with 10 10 V mV/

§

C

Temperature

I

B

Input Bias Current 1,000 300 I pA

T

A

s

T

MAX

,

1,000 300 I nA

ELH0101

2

TDis 2.3in

Page 3

ELH0101/883/8508901/2YX

Power Operational Amplifier

DC Electrical Characteristics

(Note 1) V

S

e

g

15V, T

A

e

25§C, V

CM

e

0V Ð Contd.

Parameter Description Test Conditions

ELH0101 ELH0101A

Level

Test

Units

Min Typ Max Min Typ Max

I

OS

Input Offset 250 75 I pA

Current

T

A

s

T

MAX

,

250 75 I nA

ELH0101, A

A

VOL

Large Signal V

O

e

g

10V, R

L

e

10X

50 200 50 200 I V/mV

Voltage Gain

V

O

Output Voltage R

SC

e

0X,A

V

e

1,

g

11.7g12.5

g

11.7g12.5 I V

Swing R

L

e

100X (Note 3)

R

SC

e

0X,A

V

e

1,

g11g

11.6

g11g

11.6 I V

R

L

e

10X (Note 3)

R

SC

e

0X,A

V

e

1,

g

10.5g11

g

10.5g11 I V

R

L

e

5X (Note 3)

CMRR Common-Mode V

IN

e

g

10V

85 100 85 100 I dB

Rejection Ratio

PSRR Power Supply

g

5VsV

S

s

g

15V 85 100 85 100 I dB

Rejection Ratio

a

5VsVS(a)

s

a

15V,

80 110 80 110 I dB

V

S

(b)eb15V

b

5VtVS(b)

t

b

15V,

80 95 80 95 I dB

VS(a)ea15V

I

S

Supply Current 28 35 28 35 I mA

AC Electrical Characteristics

V

S

e

g

15V, T

A

e

T

C

e

T

J

e

25§C

Parameter Description Test Conditions

ELH0101 ELH0101A

Level

Test

Units

Min Typ Max Min Typ Max

e

n

Equivalent Input fe1 kHz

25 25 V nV/

0

Hz

Noise Voltage

C

IN

Input Capacitance fe1 MHz 3 3 V pF

PBW Power Bandwidth, R

L

e

10X,A

V

e

1

300 300 V kHz

b

3dB

SR Slew Rate R

L

e

10X,A

V

e

1

7.5 10 7.5 10 I Vms

ELH0101AK

tr,t

f

Small Signal Rise R

L

e

10X,A

V

e

1

200 200 V ns

or Fall Time

Small Signal R

L

e

10X,A

V

e

1

10 10 V %

Overshoot

3

TDis 3.5inTDis 2.2in

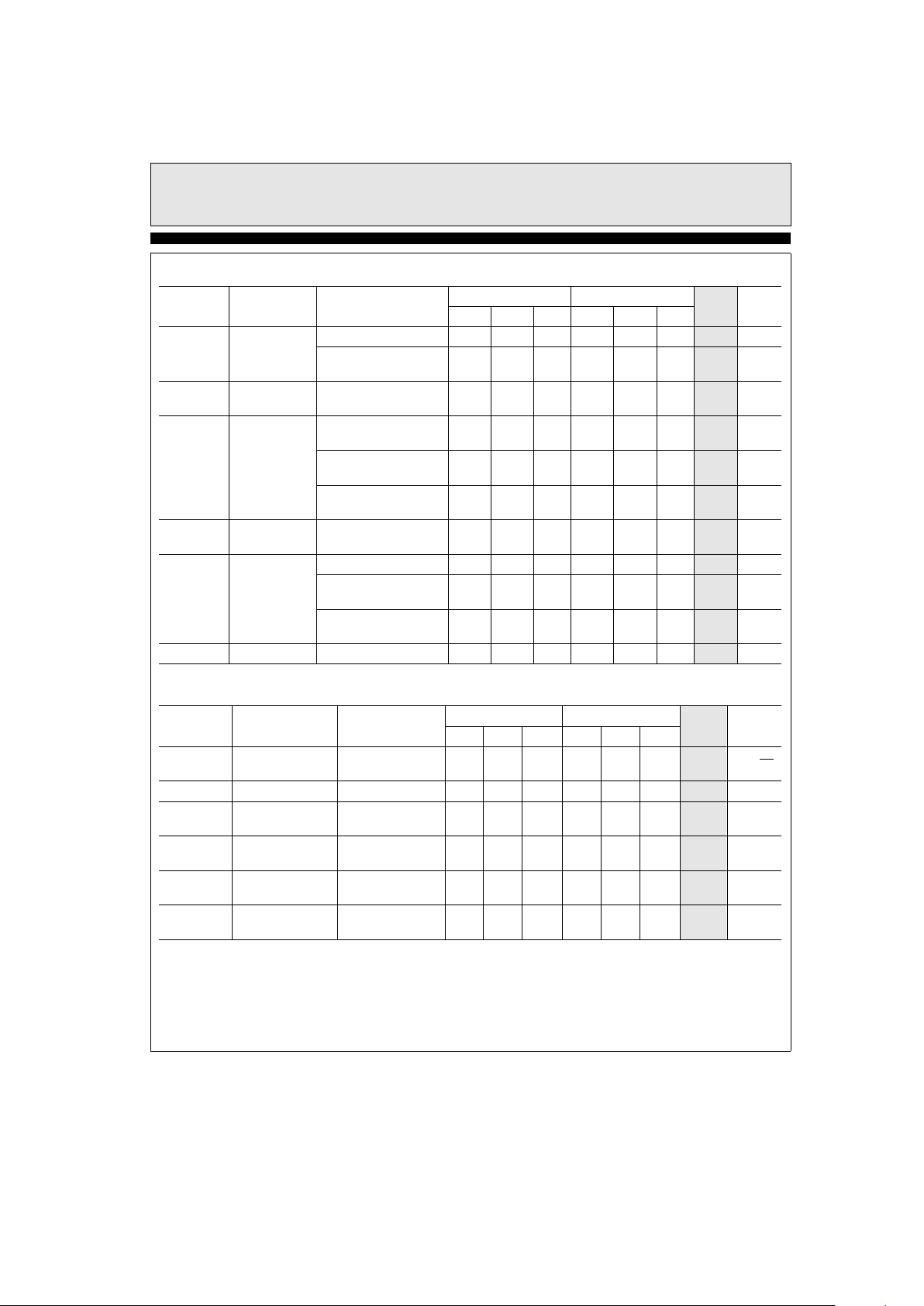

Page 4

ELH0101/883/8508901/2YX

Power Operational Amplifier

AC Electrical Characteristics

V

S

e

g

15V, T

A

e

T

C

e

T

J

e

25§C Ð Contd.

Parameter Description Test Conditions

ELH0101 ELH0101A

Level

Test

Units

Min Typ Max Min Typ Max

GBW Gain-Bandwidth R

L

e %

,A

V

e

1

4 5 4 5 I MHz

Product ELH0101AK

t

S

Large Signal

Settling Time R

L

e %

,A

V

e

12 2Vms

(0.01%)

THD Total Harmonic fe1 kHz, P

O

e

0.5W,

0.008 0.008 V %

Distortion R

L

e

10X

Note 1: Specification is at T

A

e

25§C. Actual values at operating temperature may differ from the T

A

e

25§C value. When supply

voltages are

g

15V, quiescent operating junction temperature will rise approximately 20§C without heatsinking. Accordingly,

V

OS

may change 0.5 mV and IBand IOSwill change significantly during warm-ups. Refer to IBvs. temperature and power

dissipation graphs for expected values.

Note 2: Change in offset voltage with dissipated power is due entirely to average device temperature rise and not to differential

thermal feedback effects. Test is performed without any heatsink.

Note 3: At light loads, the output swing may be limited by the second stage rather than the output stage. See the application section

under ‘‘Output swing enhancement’’ for hints on how to obtain extended operation. R

SC

is the current sense resistor.

4

TDis 1.5in

Page 5

ELH0101/883/8508901/2YX

Power Operational Amplifier

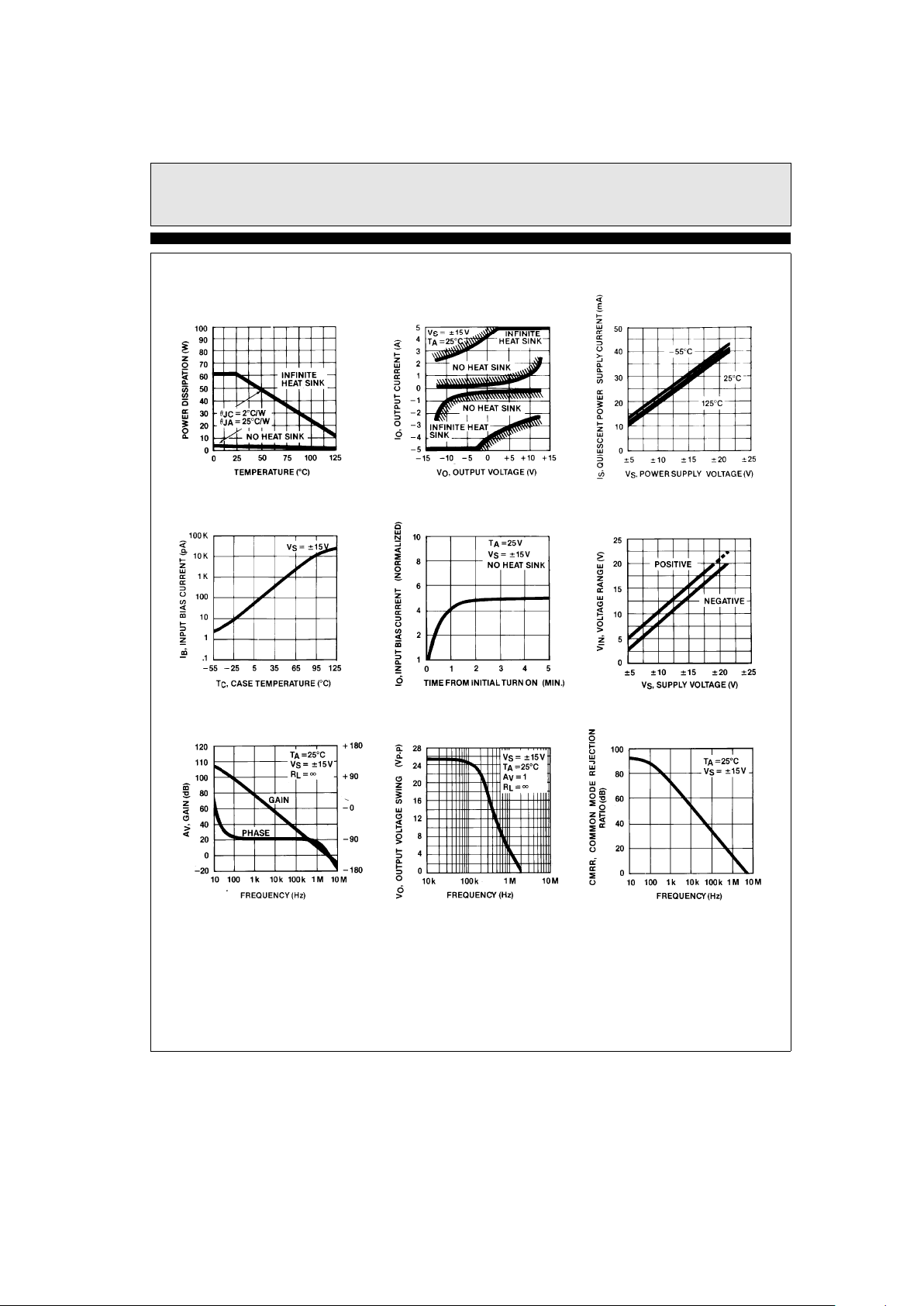

Typical Performance Curves

Power Dissipation

Safe Operating Area Current

Quiescent Power Supply

Input Bias Current Warm-up

Input Bias Current After

Voltage Range

Input Common-Mode

Frequency Response

Open-Loop Small Signal

Frequency

Output Voltage Swing vs

Ratio vs Frequency

Common-Mode Rejection

0101– 3

5

Page 6

ELH0101/883/8508901/2YX

Power Operational Amplifier

Typical Performance Curves

Ð Contd.

Ratio vs Frequency

Power Supply Rejection

Settling Time vs Frequency

Total Harmonic Distortion

vs Gain

Total Harmonic Distortion

Voltage

Equivalent Input Noise

Swing Enhancement

Output Voltage Swing with

Load Resistance

Output Voltage Swing vs

Resistance

Open-Loop Output

Resistance vs Frequency

Open-Loop Output

0101– 4

6

Page 7

ELH0101/883/8508901/2YX

Power Operational Amplifier

Typical Performance Curves

Ð Contd.

0101– 5

Typical Applications

High Power Voltage Follower

0101– 6

High Power Voltage Follower

with Swing Enhancement

0101– 7

Restricting Outputs to Positive Voltage Only

0101– 8

Generating a Split Supply

from a Single Voltage Supply

0101– 9

7

Page 8

ELH0101/883/8508901/2YX

Power Operational Amplifier

Typical Applications

Ð Contd.

g

5tog35 Power Source or Sink

0101– 10

CRT Deflection Yoke Driver

0101– 11

DC Servo Amplifier

0101– 12

High Current Source/Sink

0101– 13

8

Page 9

ELH0101/883/8508901/2YX

Power Operational Amplifier

Applications Information

Input Voltages

The ELH0101 operational amplifier contains

JFET input devices which exhibit high reverse

breakdown voltages from gate to source or drain.

This eliminates the need for input clamp diodes,

so that high differential input voltages may be

applied without a large increase in input current.

However, neither input voltage should be allowed

to exceed the negative supply as the resultant

high current flow may destroy the unit.

Exceeding the negative common-mode limit on

either input will cause a reversal of the phase to

the output and force the amplifier output to the

corresponding high or low state. Exceeding the

negative common-mode limit on both inputs will

force the amplifier output to a high state. In neither case does a latch occur since raising the input back within the common-mode range again

puts the input stage and thus the amplifier in a

normal operating mode.

Exceeding the positive common-mode limit on a

single input will not change the phase of the output, however; if both inputs exceed the limit, the

output of the amplifier will be forced to a high

state.

These amplifiers will operate with the commonmode input voltage equal to the positive supply.

In fact, the common-mode voltage may exceed

the positive supply by approximately 100 mV, independent of supply voltage and over the full operating temperature range. The positive supply

may therefore be used as a reference on an input

as, for example, in a supply current monitor and/

or limiter.

With the ELH0101 there is a temptation to remove the bias current compensation resistor normally used on the non-inverting input of a summing amplifier. Direct connection of the inputs

to ground or a low-impedance voltage source is

not recommended with supply voltages greater

than 3V. The potential problem involves loss of

one supply which can cause excessive current in

the second supply. Destruction of the IC could

result if the current to the inputs of the device is

not limited to less than 100 mA or if there is

much more than 1 mF bypass on the supply bus.

Although difficulties can be largely avoided by

installing clamp diodes across the supply lines on

every PC board, a conservative design would include enough resistance in the input lead to limit

current to 10 mA if the input lead is pulled to

either supply by internal currents. This precaution is by no means limited to the ELH0101.

Layout Considerations

When working with circuitry capable of resolving

picoampere level signals, leakage currents in circuitry external to the op amp can significantly

degrade performance. High quality insulation is a

must (Kel-F and Teflon rate high). Proper cleaning of all insulating surfaces to remove fluxes and

other residues is also required. This includes the

IC package as well as sockets and printed circuit

boards. When operating in high humidity environments or near 0

§

C, some form of surface coating may be necessary to provide a moisture barrier.

The effects of board leakage can be minimized by

encircling the input circuitry with a conductive

guard ring operated at a potential close to that of

the inputs.

Electrostatic shielding of high impedance circuitry is advisable.

Error voltages can also be generated in the external circuitry. Thermocouples formed between dissimilar metals can cause hundreds of microvolts

of error in the presence of temperature gradients.

Since the ELH0101 can deliver large output currents, careful attention should be paid to power

supply, power supply bypassing and load currents. Incorrect grounding of signal inputs and

load can cause significant errors.

9

Page 10

ELH0101/883/8508901/2YX

Power Operational Amplifier

Applications Information

Ð Contd.

Every attempt should be made to achieve a single point ground system as shown in the figure

below.

0101– 14

Bypass capacitor CBXshould be used if the lead

lengths of bypass capacitors C

B

are long. If a single point ground system is not possible, keep signal, load, and power supply from intermingling

as much as possible. For further information on

proper grounding techniques refer to ‘‘Grounding

and Shielding Techniques in Instrumentation’’

by Morrison, and ‘‘Noise Reduction Techniques

in Electronic Systems’’ by Ott (both published

by John Wiley and Sons).

Leads or PC board traces to the supply pins,

short circuit current limit pins, and the output

pin must be substantial enough to handle the

high currents that the ELH0101 is capable of

producing.

Short Circuit Current Limiting

Should current limiting of the output not be necessary, SC

a

should be shorted to Vaand SC

b

should be shorted to Vb. Remember that the

short circuit current limit is dependent upon the

total resistance seen between the supply and current limit pins. This total resistance includes the

desired resistor plus leads, PC Board traces, and

solder joints.* Assuming a zero TCR current limit resistor, typical temperature coefficient of the

short circuit will be approximately 0.3%.

Thermal Resistance

The thermal resistance between two points of a

conductive system is expressed as:

i

12

e

T

1

b

T

2

P

D

§

C/W (1)

where subscript order indicates the direction of

heat flow. A simplified heat transfer circuit for a

cased semiconductor and heatsink system is

shown in the figure below.

The circuit is valid only if the system is in thermal equilibrium (constant heat flow) and there

are, indeed, single specific temperatures, T

J,TC

,

and T

S

, (no temperature distribution in junction,

case, or heatsink). Nevertheless, this is a reasonable approximation of actual performance.

0101– 15

*Short circuit current will be limited to approximately

0.6

RSC

.

The junction-to-case thermal resistance, iJC,

specified in the data sheet depends upon the material and size of the package, die size and thickness, and quality of the die bond to the case or

lead frame. The case-to-heatsink thermal resistance, i

CS

, depends on the mounting of the device

to the heatsink and upon the area and quality of

the contact surface. Typical i

CS

for a TO-3 pack-

age is 0.5

§

C/W to 0.7§C/W, and 0.3§C/W to

0.5

§

C/W using silicone grease.

The heatsink to ambient thermal resistance, i

SA

,

depends on the quality of the heatsink and the

ambient conditions.

10

Page 11

ELH0101/883/8508901/2YX

Power Operational Amplifier

Application Information

Ð Contd.

Cooling is normally required to maintain the

worst case operating junction temperature, T

J

,of

the device below the specified maximum value,

T

J(MAX).TJ

can be calculated from known oper-

ating conditions. Rewriting equation (1), we find:

i

JA

e

T

J

b

T

A

P

D

§

C/W

T

J

e

T

A

a

PDi

JA

§

C

Where: P

D

e

(V

S

b

V

OUT)IOUT

a

l

V

g

(Vb)lI

Q

i

JA

e

i

JC

a

i

CS

a

iSAand

V

S

e

Supply Voltage

i

JC

for the ELH0101 is typically 2§C/W.

Stability and Compensation

As with most amplifiers, care should be taken

with lead dress, component placement and supply decoupling in order to ensure stability. For

example, resistors from the output to an input

should be placed with the body close to the input

to minimize ‘‘pickup’’ and maximize the frequency of the feedback pole by minimizing the capacitance from the input to ground.

A feedback pole is created when the feedback

around any amplifier is resistive. The parallel resistance and capacitance from the input of the

device (usually the inverting input) to AC

ground set the frequency of the pole. In many

instances the frequency of this pole is much

greater than the expected 3 dB frequency of the

closed loop gain and consequently there is negligible effect on stability margin. However, if the

feedback pole is less than approximately six

times the expected 3 dB frequency, a lead capacitor should be placed from the output to the input

of the op amp. The value of the added capacitor

should be such that the RC time constant of this

capacitor and the resistance it parallels is greater

than or equal to the original feedback pole time

constant.

Some inductive loads may cause output stage oscillation. A 0.01 mF ceramic capacitor in series

with a 10X resistor from the output to ground

will usually remedy this situation.

0101– 16

Capacitive loads may be compensated for by traditional techniques. (See ‘‘Operational Amplifiers: Theory and Practice’’ by Roberge, published

by Wiley.)

0101– 17

A similar but alternative technique may be used

for the ELH0101.

0101– 18

11

Page 12

ELH0101/883/8508901/2YX

Power Operational Amplifier

Output Swing Enhancement

When the feedback pin is connected directly to

the output, the output voltage swing is limited

by the driver stage and not by output saturation.

Output swing can be increased by taking gain in

the output stage as shown below in the High

Power Voltage Follower with Swing Enhancement. Whenever gain is taken in the output

stage, either the output stage, or the entire op

amp must be appropriately compensated to account for the additional loop gain.

Output Resistance

The open-loop output resistance of the ELH0101

is a function of the load current. No-load output

resistance is approximately 10X. This decreases

to under an X for load currents exceeding

100 mA.

Burn-In Circuit

0101– 19

12

Page 13

ELH0101/883/8508901/2YX

Power Operational Amplifier

ELH0101 Macromodel

* Connections:ainput

*

l

b

Input

*

ll

V

a

*

lll

Isc

a

*

llll

Feedback

*

lllll

V

b

*

llllll

Isc

b

*

lllllll

Output

*

llllllll

*em0101 6 5213784

.subckt buffer 21 2 1 3 7 8 4

* Resistors

r132710

r2 26 3 10

r3 30 7 50

r422350

r5 29 7 2K

r62222K

r7 27 28 10

r8 24 26 10

* Transistors

q14308qnd

d1 8 4 dclamp

q24231qpd

d2 4 1 dclamp

q372122qp

q4 23 22 24 qn

q5 21 21 26 qn

q62312qp

q722129qn

q8 27 27 21 qn

q9 30 29 28 qp

q103087qn

*Models

.model qpd pnp (is

e

88.013eb12 ikfe5A tfe32nS vafe50V cjee45pF cjce60pF

a

xtbe2.1 bfe12000 nee4 isee1eb10)

.model qnd npn (is

e

88.013eb12 ikfe5A tfe32nS vafe50V cjee45pF cjce60pF

a

xtbe2.1 bfe12000 nee4 isce1eb10)

.model dclamp d (is

e

10eb28 tte100nS)

13

TABWIDE

TDis 5.2in

Page 14

ELH0101/883/8508901/2YX

Power Operational Amplifier

ELH0101 Macromodel

Ð Contd.

.model qp pnp (ise10eb15 xtie3ege1.11V vafe91V bfe200 nee2.321 isee6.2fA

a

ikfe500mA xtbe2.1 bre3.3 nce2 cjce14.6pF vjce0.75V mjce0.3333 fce0.5 cjee20pF

a

vjee0.75V mjee0.3333 tre29nS tfe0.4nS itfe0.4 vtfe10 xtfe2rbe10)

.model qn npn (is

e3eb

15 xtie3ege1.11V vafe151V bfe220 nee1.541 isee14fA

a

ikfe500mA xtbe2.1 bre6nce2 cjce14.6pF vjce0.75V mjce0.3333 fce0.5 cjee26pF

a

vjee0.75V mjee0.3333 tre51nS tfe0.4nS itfe0.6 vtfe1.7 xtfe2rbe10)

.ends buffer

* lf156 Subcircuit

* Connections:

a

Input

*

l

b

Input

*

ll

V

a

*

lll

V

b

*

llll

Output

*

lllll

.subckt lf156 6 52721

*Input Stage

vcm2 40 7 2

rd1 40 80 1.06K

rd2 40 90 1.06K

j1 80 102 12 jm1

j2 90 103 12 jm2

cin 5 6 4pF

rg1 5 102 2

rg2 6 103 2

* CM Clamp

dcm1 107 103 dm4

dcm2 105 107 dm4

vcmc 105 7 4V

ecmp 106 7 103 7 1

rcmp 107 106 10K

dcm3 109 102 dm4

dcm4 105 109 dm4

ecmn 108 2 102 2 1

rcmn 109 108 10K

cl 80 90 15pF

iss 2 12 0.48mA

gosit 2 12 90 80 2.4e

b

4

* Intermediate Stage

gcm 0 88 12 0 9.425e

b

9

ga 88 0 80 90 9.425e

b

4

r2 88 0 100K

c2 91 88 30pF

gb 91 0 88 0 28.6

ro2 91 0 74

14

TABWIDE

TDis 5.8in

Page 15

ELH0101/883/8508901/2YX

Power Operational Amplifier

ELH0101 Macromodel

Ð Contd.

* Output Stage

rso 91 21 1

ecl 18 0 91 21 20.69

gcl0882001

rcl 20 0 1K

d1 18 20 dm1

d2 20 18 dm1

d3a 131 70 dm3

d3b 13 131 dm3

gpl0887021

vc 13 21 3.1552V

rpla 2 70 10K

rplb 2 131 100K

d4a 60 141 dm3

d4b 141 14 dm3

gnl0886071

ve 21 14 3.1552V

rnla 60 7 10K

rnlb 141 7 100K

ip 2 7 4.52mA

dsub 7 2 dm2

* Models

.model jm1 pjf (is

e

3.15eb11 betae9.2528eb4 vtoeb1.0)

.model jm2 pjf (is

e

2.85eb11 betae9.2528eb4 vtoeb0.999)

.model dm1 d (is

e

1.0eb15)

.model dm2 d (is

e

8.0eb16 bve52.8)

.model dm3 d (is

e

1.0eb16)

.model dm4 d (is

e

1.0eb9)

ends lf156

* lf156 model courtesy of Linear Technology Corp.

15

TDis 3.9in

Page 16

ELH0101/883/8508901/2YXDecember 1994 Rev H

ELH0101/883/8508901/2YX

Power Operational Amplifier

ELH0101 Macromodel

Ð Contd.

0101– 20

General Disclaimer

Specifications contained in this data sheet are in effect as of the publication date shown. Elantec, Inc. reserves the right to make changes

in the circuitry or specifications contained herein at any time without notice. Elantec, Inc. assumes no responsibility for the use of any

circuits described herein and makes no representations that they are free from patent infringement.

Elantec, Inc.

1996 Tarob Court

Milpitas, CA 95035

Telephone: (408) 945-1323

(800) 333-6314

Fax: (408) 945-9305

European Office: 44-71-482-4596

WARNING Ð Life Support Policy

Elantec, Inc. products are not authorized for and should not be

used within Life Support Systems without the specific written

consent of Elantec, Inc. Life Support systems are equipment intended to support or sustain life and whose failure to perform

when properly used in accordance with instructions provided can

be reasonably expected to result in significant personal injury or

death. Users contemplating application of Elantec, Inc. products

in Life Support Systems are requested to contact Elantec, Inc.

factory headquarters to establish suitable terms & conditions for

these applications. Elantec, Inc.’s warranty is limited to replacement of defective components and does not cover injury to persons or property or other consequential damages.

Printed in U.S.A.16

Loading...

Loading...