Page 1

EL7571C

Programmable PWM Controller

EL7571C

Features

• Pentium® II Compatible

• 5 bit DAC Controlled Output Voltage

• Greater than 90% Efficiency

• 4.5V to 12.6V Input Range

• Dual NMOS Power FET Drivers

• Fixed frequency, Current Mode

Control

• Adjustable Oscillator with External

Sync. Capability

• Synchronous Switching

• Internal Soft-Start

• User Adjustable Slope

Compensation

• Pulse by Pulse Current Limiting

• 1% Typical Output Accuracy

• Power Good Signal

• Output Power Down

• Over Voltage Protection

Applications

• Pentium® II Voltage Regulation

Modules (VRMs)

• PC Motherboards

• DC/DC Converters

• GTL Bus Termination

• Secondary Regulation

Ordering Information

Part No Temp. Range Package Outline #

EL7571C 0°C to +70°C 20-Pin SO MDP0027

General Description

The EL7571C is a flexible, high efficiency, current mode, PWM step

down controller. It incorporates five bit DAC adjustable output voltage

control which conforms to the Intel Voltage Regulation Module (VRM)

Specification for Pentium® II and Pentium® Pro class processors. The

controller employs synchronous rectification to deliver efficiencies

greater than 90% over a wide range of supply voltages and load conditions. The on-board oscillator frequency is externally adjustable, or may

be slaved to a system clock, allowing optimization of RFI performance in

critical applications. In single supply operation, the high side FET driver

supports boot-strapped operation. For maximum flexibility, system operation is possible from either a 5V rail, a single 12V rail, or dual supply

rails with the controller operating from 12V and the power FETs from

5V.

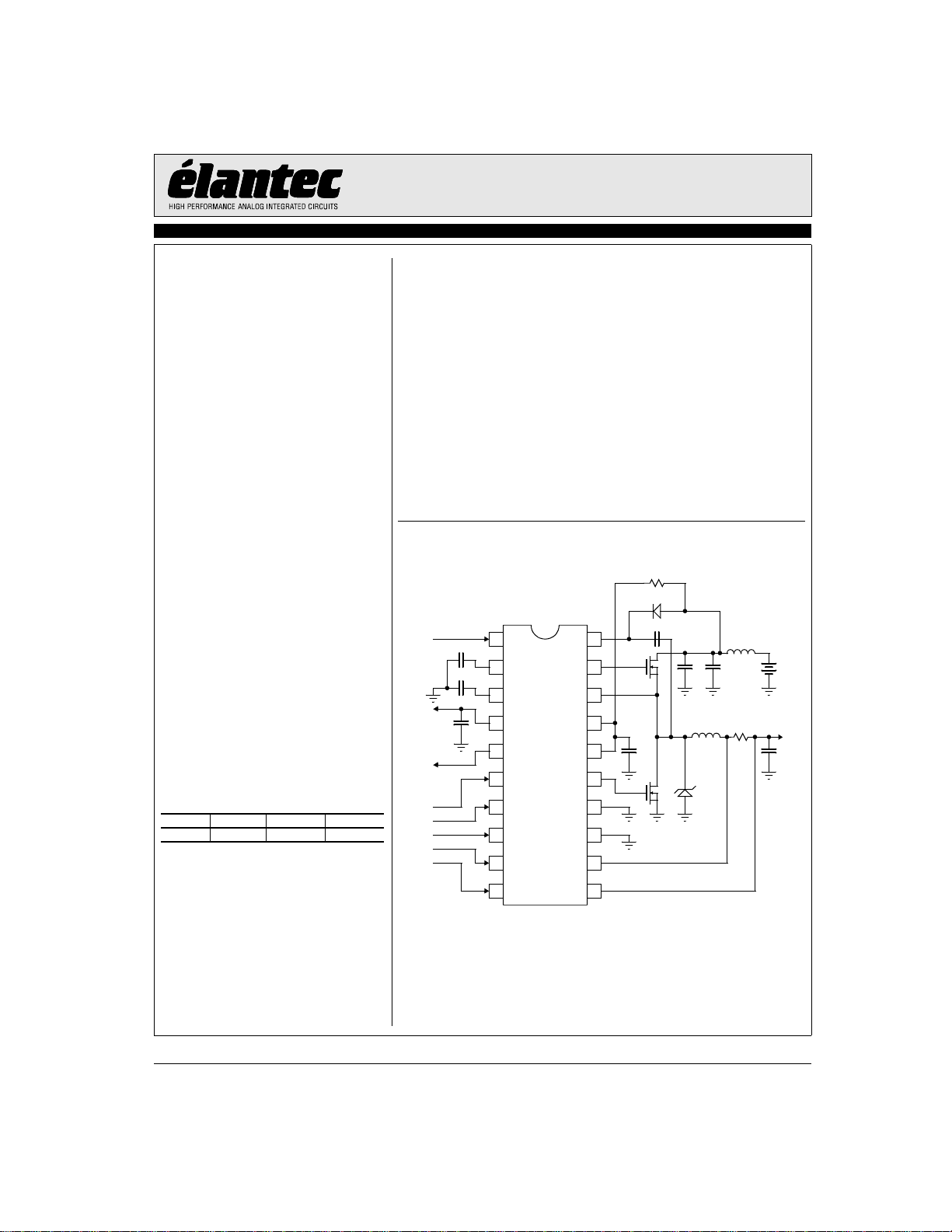

Connection Diagram

R2

5Ω

D1

ENABLE

1.4V

POWER

GOOD

Voltage

(VID

(0:4))

1

2

3

4

5

6

7

8

9

OTEN

CSLOPE

COSC

REF

PWRGD

VIDO

VID1

VID2

VID3

C3 240pF

C3 240pF

C3

0.1µF

I.D.

VH1

HSD

VIN

VINP

LSD

GNDP

GND

20

19

18

LX

17

16

15

14

13

12

CS

C6 0.1µF

Q1

C7

1µF

Q2 D2

1.5µH

C8

1µFC11000µF

x3

L1

5.1µH

L2

4.5V

to

12.6V

V

OUT

1.3V to

3.5V

R2

C2

5Ω

1000µF

x6

10

VID4

Q1, Q2: Siliconix, Si4410, x2

C1: Sanyo, 16MV 1000GX, 1000µF x3

C2: Sanyo, 6MV 1000GX, 1000µF x6

L1: Pulse Engineering, PE-53700, 5.1µH

L2: Micrometals, T30-26, 7T AWG #20, 1.5µH

R1: Dale, WSL-25-12, 15mΩ, x2

D1: BAV99

D2: IR, 32CTQ030

Note: All information contained in this data sheet has been carefully checked and is believed to be accurate as of the date of publication; however, this data sheet cannot be a “controlled document”. Current revisions, if any, to these

specifications are maintained at the factory and are available upon your request. We recommend checking the revision level before finalization of your design documentation.

© 2001 Elantec Semiconductor, Inc.

11

FB

April 24, 2001

Page 2

EL7571C

Programmable PWM Controller

EL7571C

Absolute Maximum Ratings (T

Supply Voltage: -0.5V to 14V

Input Pin Voltage: -.03 below Ground, +0.3 above Supply

VHI -0.5V to 27V

Storage Temperature Range: 65°C to +150°C

= 25°C)

A

Operating Temperature Range: 0°C to +70°C

Operating Junction Temperature: 125°C

Peak Output Current: 3A

Power Dissipation: SO20 500mW

Important Note:

All parameters having Min/Max specifications are guaranteed. Typ values are for information purposes only. Unless otherwise noted, all tests are at the

specified temperature and are pulsed tests, therefore: TJ = TC = TA.

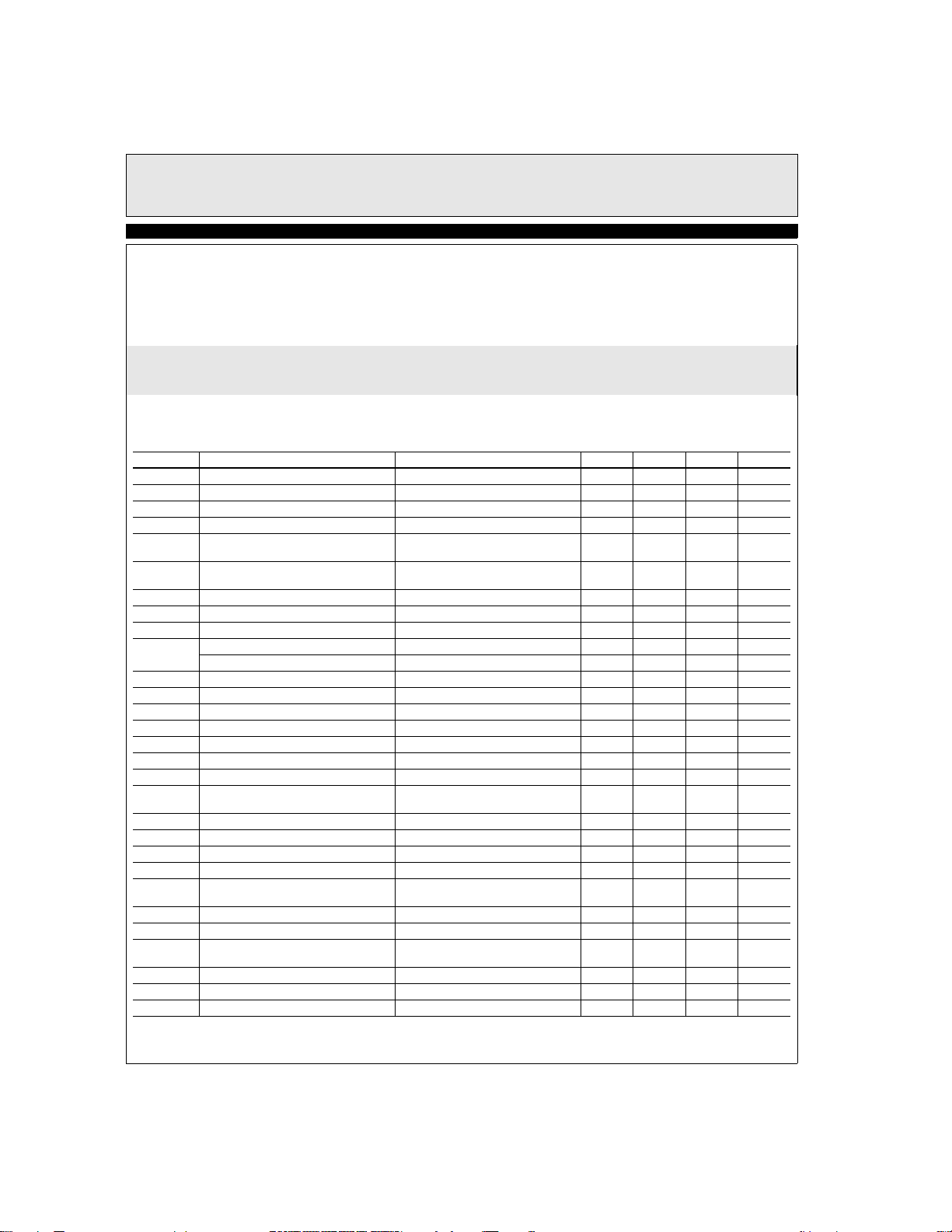

DC Electrical Characteristics

TA = 25°C, VIN = 5V, C

Parameter Description Condition Min Typ Max Unit

V

IN

V

UVLO HI

V

UVLO LO

V

OUT RANGE

V

OUT 1

V

OUT 2

V

REF

V

ILIM

V

IREV

V

OUT PG

V

OVP

V

OTEN LO

V

OTEN HI

V

ID LO

V

ID HI

V

OSC

V

PWRGD LO

R

DS ON

R

FB

R

CS

I

VIN

I

VIN DIS

I

SOURCE/SINK

I

RAMP

I

OSC CHARGE

I

OSC

DISCHARGE

I

REFMAX

I

VID

I

OTEN

= 330pF, C

OSC

SLOPE

= 390pF, R

= 7.5mΩ unless otherwise specified.

SENSE

Input Voltage Range 4.5 12.6 V

Input Under Voltage Lock out Upper Limit Positive going input voltage 3.6 4 4.4 V

Input Under Voltage Lock out Lower Limit Negative going input voltage 3.15 3.5 3.85 V

Output Voltage Range See VID table 1.3 3.5 V

Steady State Output Voltage Accuracy, VID =

10111

Steady State Output Voltage Accuracy, VID =

00101

IL = 6.5A, V

IL = 6.5A, V

= 2.8V 2.74 2.82 2.90 V

OUT

=1.8V 1.74 1.81 1.9 V

OUT

Reference Voltage 1.396 1.41 1.424 V

Current Limit Voltage V

Current Reversal Threshold V

Output Voltage Power Good Lower Level V

= (VCS-VFB) 125 154 185 mV

ILIM

= (VCS-VFB) -40 -5 20 mV

IREV

= 2.05V -18 -14 -10 %

OUT

Output Voltage Power Good Upper Level 8 12 16 %

Over-Voltage Protection Threshold +9 +13 +17 %

Power Down Input Low Level VIN = -10uA 1.5 V

Power Down Input High Level (VIN-1.5) V

Voltage I.D. Input Low Level 1.5 V

Voltage I.D. Input High Level (VIN-1.5) V

Oscillator Voltage Swing 0.85 V

Power Good Output Low Level I

HSD, LSD Switch On-Resistance VIN, V

= 1mA 0.5 V

OUT

INP

LX) = 12V

= 12V, I

= 100mA, (VHI-

OUT

4.8 6 Ω

FB Input Impedance 9.5 kΩ

CS Input Impedance 115 kΩ

Quiescent Supply Current V

Supply Current in Output Disable Mode V

Peak Driver Output Current VIN,V

C

Ramp Current High Side Switch Active 8.5 14 20 µA

SLOPE

Oscillator Charge Current 1.2>V

Oscillator Discharge Current 1.2>V

>(VIN-0.5)V 1.2 2 mA

OTEN

<1.5V 0.76 1 mA

OTEN

= 12V, Measured at HSD, LSD,

INP

(VHI-LX) = 12V

>0.35V 50 µA

OSC

>0.35V 2 mA

OSC

2.5 A

VREF Output Current 25 µA

VID Input Pull up Current 3 5 7 µA

OTEN Input Pull up Current 3 5 7 µA

P-P

2

Page 3

EL7571C

Programmable PWM Controller

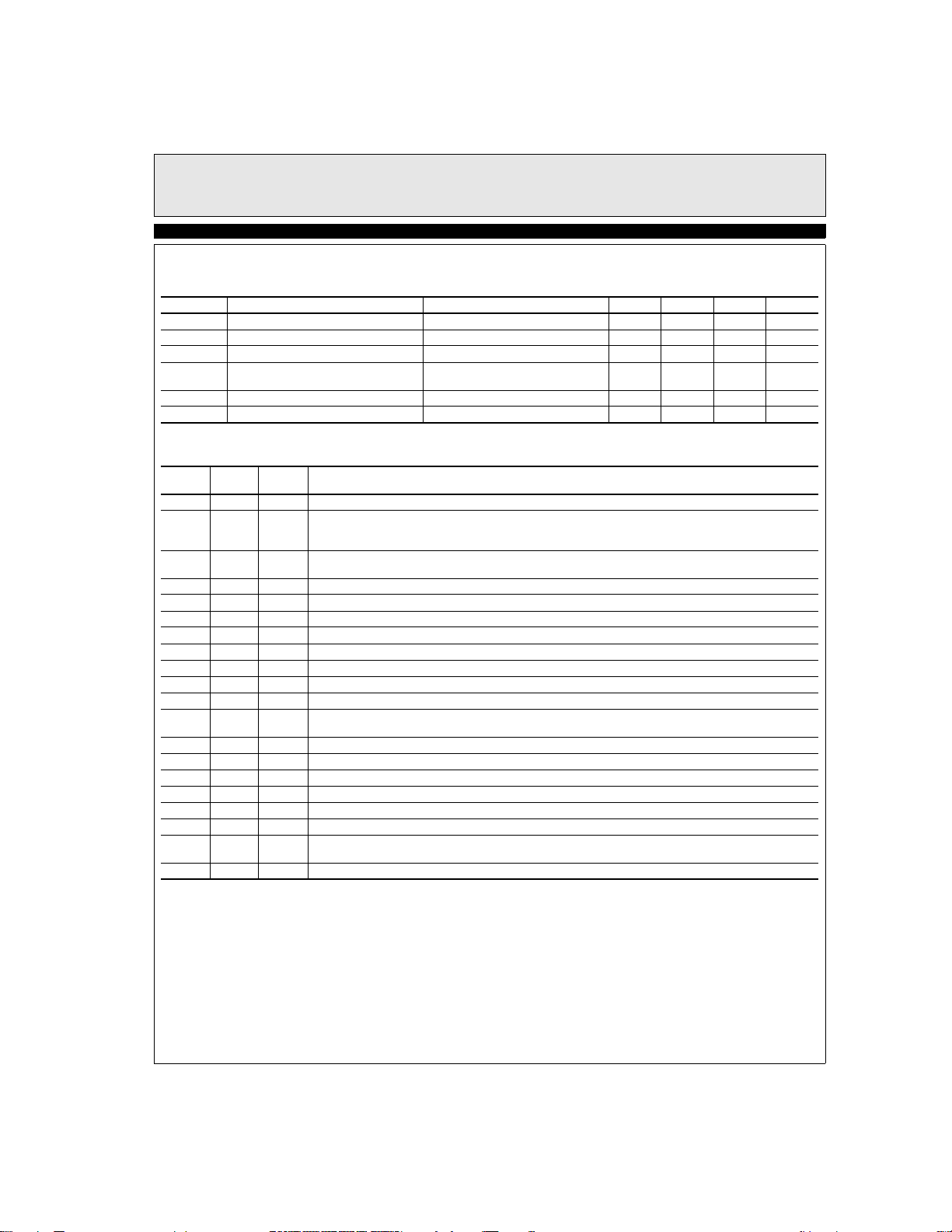

AC Electrical Characteristics

TA = 25°C, VIN = 5V, C

Parameter Description Conditions Min Typ Max Unit

f

OSC

f

CLK

t

OTEN

t

SYNC

T

START

D

MAX

Pin Descriptions

Pin No.

1. Pin designators: I = Input, O = Output, S = Supply

Pin

Name

1 OTEN I Chip enable input, internal pull up (5mA typical). Active high.

2 CSLOPE I With a capacitor attached from CSLOPE to GND, generates the voltage ramp compensation for the PWM current mode con-

3 COSC I Multi-function pin: with a timing capacitor attached, sets the internal oscillator rate fS (kHz) = 57/C

4 REF O Band gap reference output. Decouple to GND with 0.1uF.

5 PWRGD O Power good, open drain output. Set low whenever the output voltage is not within ±13% of the programmed value.

6 VID0 I Bit 0 of the output voltage select DAC. Internal pull up sets input high when not driven.

7 VID1 I Bit 1 of the output voltage select DAC. Internal pull up sets input high when not driven.

8 VID2 I Bit 2 of the output voltage select DAC. Internal pull up sets input high when not driven.

9 VID3 I Bit 3 of the output voltage select DAC. Internal pull up sets input high when not driven.

10 VID4 I Bit 4 of the output voltage select DAC. Internal pull up sets input high when not driven.

11 FB I Voltage regulation feedback input. Tie to V

12 CS I Current sense. Current feedback input of PWM controller and over current capacitor input. Current limit threshold set at

13 GND S Ground

14 GNDP S Power ground for low side FET driver. Tie to GND for normal operation.

15 LSD O Low side gate drive output.

16 VINP S Input supply voltage for low side FET driver. Tie to VIN for normal operation.

17 VIN S Input supply voltage for control unit.

18 LX S Negative supply input for high side FET driver.

19 HSD O High side gate drive output. Driver ground referenced to LX. Driver supply may be bootstrapped to enhance low controller

20 VH1 S Positive supply input for high side FET driver.

= 330pF, C

OSC

Nominal Oscillator Frequency C

Clock Frequency 50 500 1000 kHz

Shutdown Delay V

Oscillator Sync. Pulse Width Oscillator i/p (COSC) driven with HCMOS

Soft-start Period V

Maximum Duty Cycle 97 %

Pin

[1]

Type

= 390pF unless otherwise specified.

SLOPE

= 330pF 140 190 240 kHz

OSC

>1.5V 100 ns

OTEN

gate

= 3.5V 100/f

OUT

Function

troller. Slope rate is determined by an internal 14uA pull up and the C

the termination of the high side cycle.

low for a duration t

+154mV with respect to FB. Connect sense resistor between CS and FB for normal operation.

input voltage operation.

synchronizes device to an external clock.

SYNC

for normal operation.

OUT

20 800 ns

capacitor value. VC

SLOPE

CLK

SLOPE

OSC

is reset to ground at

(µF); when pulsed

EL7571C

us

3

Page 4

EL7571C

Programmable PWM Controller

EL7571C

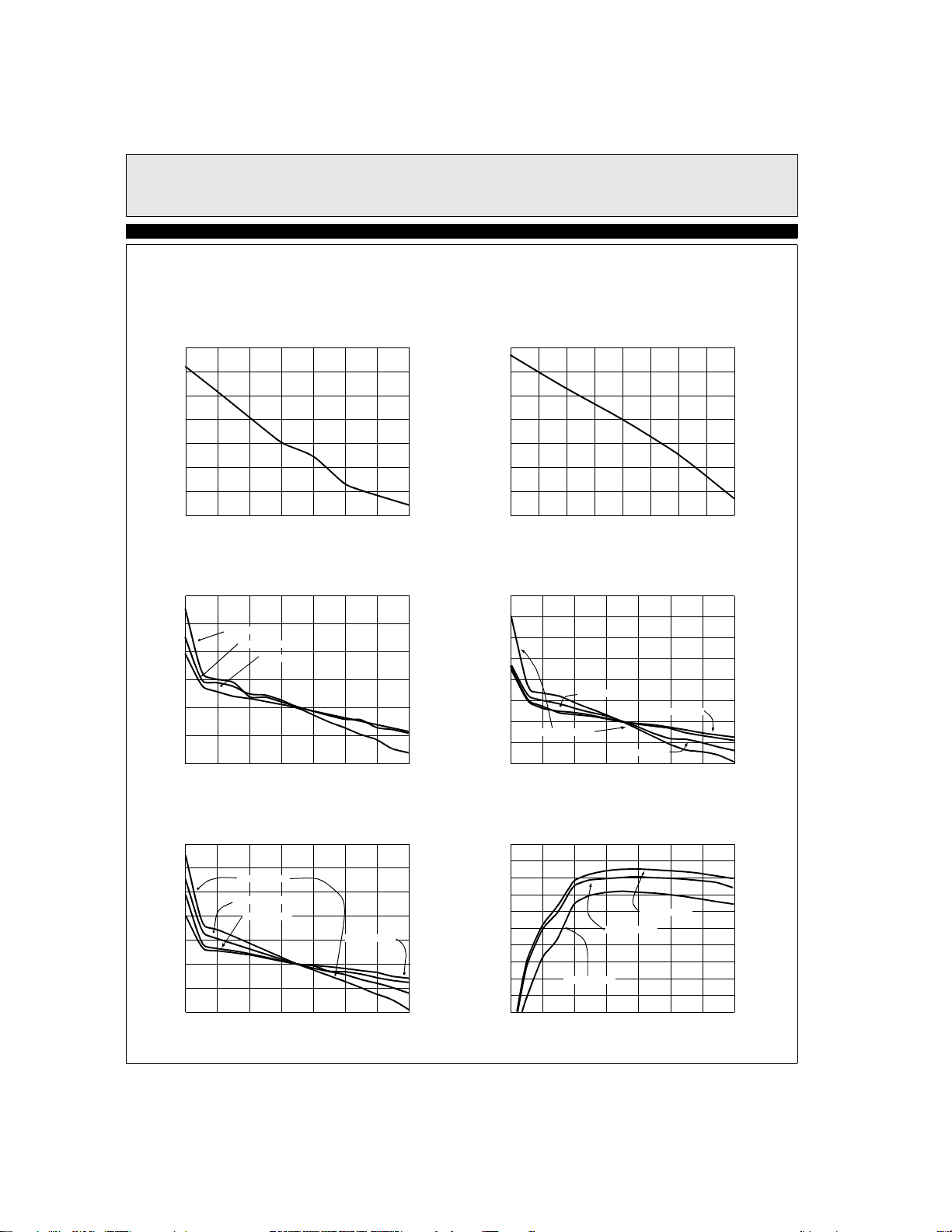

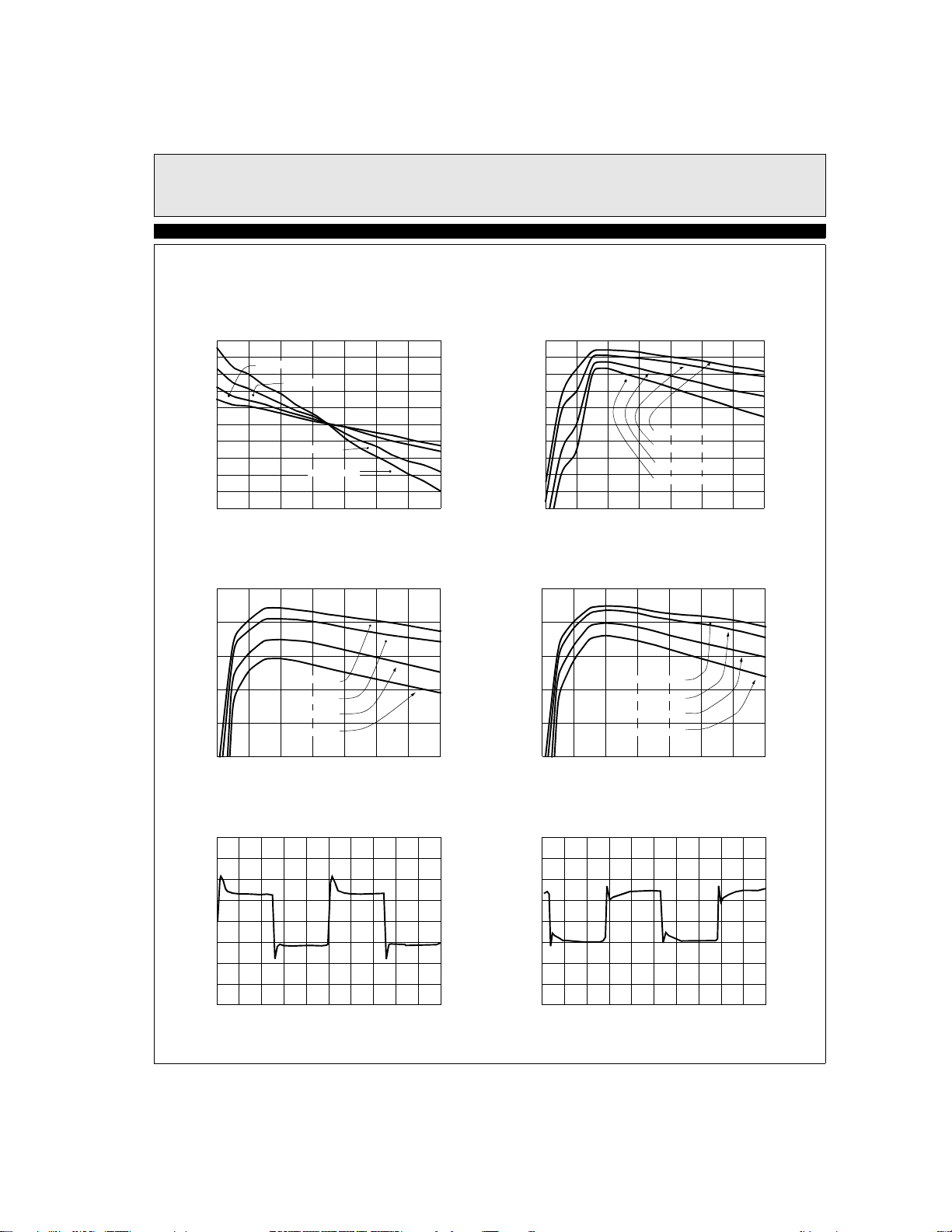

Typical Performance Curves

+12V Supply Sync Line Regulation

0.004

0.003

0.002

0.001

0

Line Regulation (%)

-0.001

-0.002

-0.003

13.5 10.011.5 11.0 10.513.0 12.5 12.0

+12V Supply Sync Load Regulation

0.04

0.03

0.02

0.01

0

Load Regulation (%)

-0.01

-0.02

V

= 1.8V

OUT

V

= 2.1V

OUT

V

0 1 3 5 11 1397

OUT

VIN (V)

= 2.8V

I

OUT

5V Supply Line Regulation

0.30

0.20

0.10

0.00

-0.10

Line Regulation (%)

-0.20

-0.30

-0.40

5.50 4.505.005.25 4.75

VRM +5V Supply +12V Controller Sync w/o

Schottky Load Regulation

6.00

5.00

4.00

3.00

2.00

1.00

Load Regulation (%)

0

V

-1.00

-2.00

(A)

OUT

0 1 3 5 11 1397

= 1.3V

VIN (V)

V

= 2.8V

OUT

V

= 3.5V

OUT

V

= 1.8V

OUT

I

(A)

OUT

+5V Supply Non-Sync Load Regulation

5.00

4.00

3.00

2.00

1.00

Load Regulation (%)

0

-1.00

-2.00

0 1 3 5 11 1397

V

= 1.3V

OUT

V

= 1.8V

OUT

V

= 2.8V

OUT

+12V Supply Sync Efficiency

1.0

0.9

0.8

V

= 3.5V

OUT

I

(A)

OUT

0.7

Efficiency (%)

0.6

0.5

0 1 3 5 11 1397

V

= 1.8V

OUT

V

= 3.5V

OUT

V

= 2.8V

OUT

I

(A)

OUT

4

Page 5

Typical Performance Curves

EL7571C

EL7571C

Programmable PWM Controller

+5V Supply Sync with Schottky Load

2.5

V

= 3.5V

1.5

0.5

0

-0.5

Load Regulation (%)

-1.5

-2.5

0

1.0

0.9

0.8

0.7

Efficiency (%)

0.6

0.5

0 1 3 5 11 1397 0 1 3 5 11 1397

OUT

V

= 2.8V

OUT

V

= 1.8V

OUT

V

= 1.3V

OUT

1 3 5 11 1397

I

(A)

OUT

+5V Supply Non-Sync VRM Efficiency

V

= 3.5V

OUT

V

= 2.8V

OUT

V

= 1.8V

OUT

V

= 1.3V

OUT

I

(A)

OUT

+5V Supply +12V Controller Sync w/o Schottky

VRM Efficiency

1.0

0.9

0.8

0.7

Efficiency (X)

0.6

0.5

0.02

1.02 3.04 5.04 11.04 13.049.047.04

+5V Supply Sync with Schottky VRM Efficiency

1.0

0.9

0.8

0.7

Efficiency (%)

0.6

0.5

V

= 3.5V

OUT

V

= 1.8V

OUT

V

= 2.8V

OUT

V

= 1.3V

OUT

I

(A)

OUT

V

= 3.5V

OUT

V

= 2.8V

OUT

V

= 1.8V

OUT

V

= 1.3V

OUT

I

(A)

OUT

12V Transient Response

1

5V Non-sync Transient Response

1

5

Page 6

EL7571C

Programmable PWM Controller

EL7571C

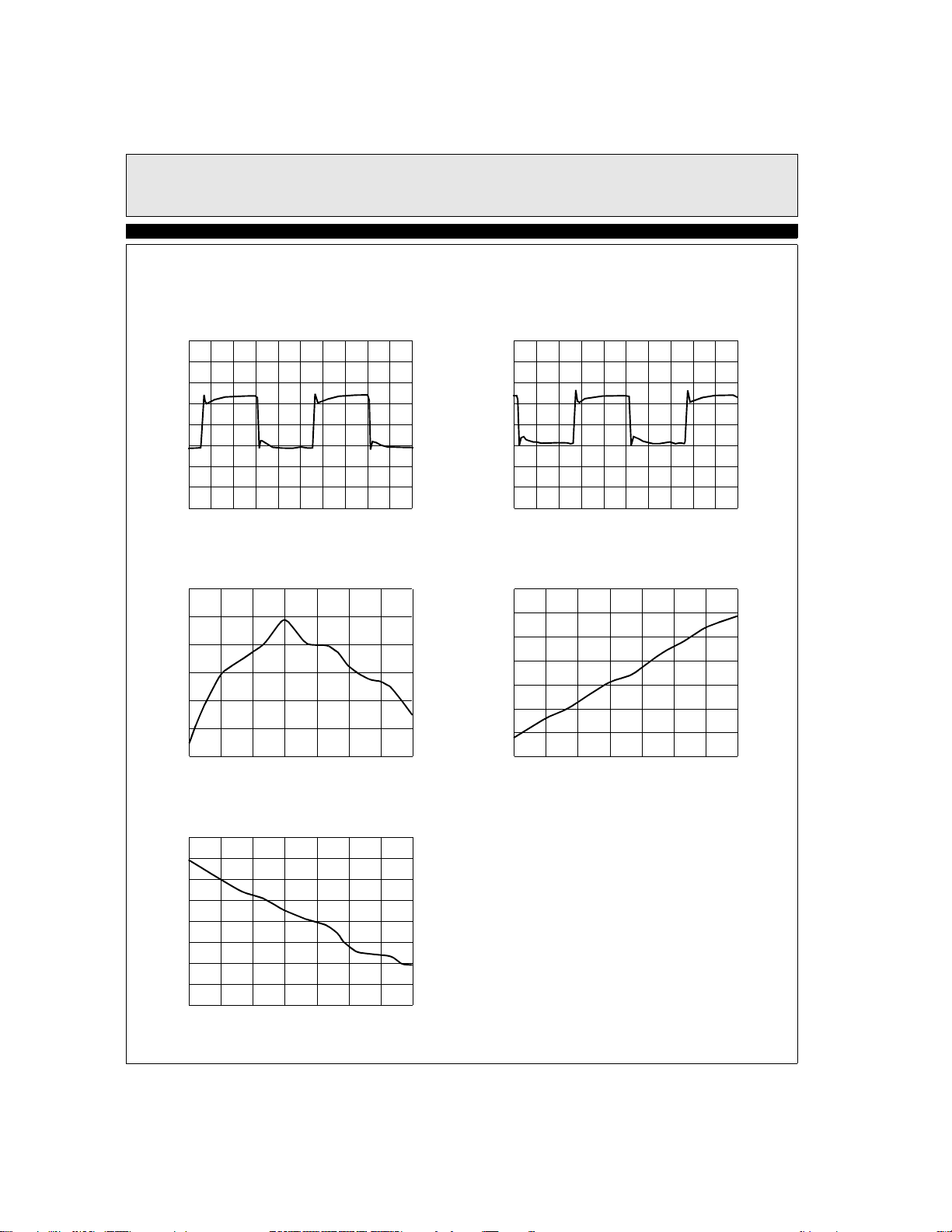

Typical Performance Curves

5V Sync Transient Response

1

Efficiency vs Temperature

92.6

92.5

92.4

92.2

Efficiency (%)

92.0

91.8

91.6

-45 6015 30 45-30 -15 0

Temperature (°C)

5V Input 12V Controller Transient Response

1

V

vs Temperature

REF

1.425

1.420

1.415

1.410

(V)

REF

1.405

V

1.400

1.395

1.390

-45 6015 30 45-30 -15 0

Temperature (°C)

Frequency vs Temperature

280

270

260

250

240

230

Frequency (KHz)

220

210

200

-45 6015 30 45-30 -15 0

Temperature (°C)

6

Page 7

Applications Information

Circuit Description

EL7571C

EL7571C

Programmable PWM Controller

General

The EL7571C is a fixed frequency, current mode, pulse

width modulated (PWM) controller with an integrated

high precision reference and a 5 bit Digital-to-Analog

Converter (DAC). The device incorporates all the active

circuitry required to implement a synchronous step

down (buck) converter which conforms to the Intel Pentium® II VRM specification. Complementary switching

outputs are provided to drive dual NMOS power FET’s

in either synchronous or non-synchronous configurations, enabling the user to realize a variety of high

efficiency and low cost converters.

Reference

A precision, temperature compensated band gap reference forms the basis of the EL7571C. The reference is

trimmed during manufacturing and provides 1% set

point accuracy for the overall regulator. AC rejection of

the reference is optimized using an external bypass

capacitor C

REF

.

Main Loop

A current mode PWM control loop is implemented in

the EL7571C (see block diagram). This configuration

employs dual feedback loops which provide both output

voltage and current feedback to the controller. The

resulting system offers several advantages over tradititional voltage control systems, including simpler loop

design, pulse by pulse current limiting, rapid response to

line variaion and good load step response. Current feedback is performed by sensing voltage across an external

shunt resistor. Selection of the shunt resistance value

sets the level of current feedback and thereby the load

regulation and current limit levels. Consequently, operation over a wide range of output currents is possible. The

reference output is fed to a 5 bit DAC with step weighing conforming to the Intel VRM Specification. Each

DAC input includes an internal current pull up which

directly interfaces to the VID output of a Pentium® II

class microprocessor. The heart of the controller is a triple-input direct summing differential comparator, which

sums voltage feedback, current feedback and compen-

sating ramp signals together. The relative gains of the

comparator input stages are weighed. The ratio of voltage feedback to current feedback to compensating ramp

defines the load regulation and open loop voltage gain

for the system, respectively. The compensating ramp is

required to maintain large system signal system stability

for PWM duty cycles greater than 50%. Compensation

ramp amplitude is user adjustable and is set with a single

external capacitor (CSLOPE). The ramp voltage is

ground referenced and is reset to ground whenever the

high side drive signal is low. In operation, the DAC output voltage is compared to the regulator output, which

has been internally attenuated. The resulting error voltage is compared with the compensating ramp and

current feedback voltage. PWM duty cycle is adjusted

by the comparator output such that the combined comparator input sums to zero. A weighted comparator

scheme enhances system operation over traditional voltage error amplifier loops by providing cycle-by-cycle

adjustment of the PWM output voltage, eliminating the

need for error amplifier compensation. The dominant

pole in the loop is defined by the output capacitance and

equivalent load resistance, the effect of the output inductor having been canceled due to the current feedback. An

output enable (OUTEN) input allows the regulator output to be disabled by an external logic control signal.

Auxiliary Comparators

The current feedback signal is monitored by two additional comparators which set the operating limits for the

main inductor current. An over current comparator terminates the PWM cycle independently of the main

summing comparator output whenever the voltage

across the sense resistor exceeds 154mV. For a 7.5mΩ

resistor this corresponds to a nominal 20A current limit.

Since output current is continuously monitored, cycleby-cycle current limiting results. A second comparator

senses inductor current reverse flow. The low side drive

signal is terminated when the sense resistor voltage is

less than -5mV, corresponding to a nominal reverse cur-

rent of -0.67A, for a 7.5mΩ sense resistor. Additionally,

under fault conditions, with the regulator output over-

7

Page 8

EL7571C

Programmable PWM Controller

EL7571C

voltage, inductor current is prevented from ramping to a

high level in the reverse direction. This prevents the parasitic boost action of the local power supply when the

fault is removed and potential damage to circuitry connected to the local supply.

Oscillator

A system clock is generated by an internal relaxation

oscillator. Operating frequency is simple to adjust using

a single external capacitor C

discharge current in the oscillator is well defined and

sets the maximum duty cycle for the system at around

96%.

. The ratio of charge to

OSC

Soft-start

During start-up, potentially large currents can flow into

the regulator output capacitors due to the fast rate of

change of output voltage caused during start-up,

although peak inrush current will be limited by the over

current comparator. However an additionally internal

switch capacitor soft-start circuit controls the rate of

change of output voltage during start-up by overriding

the voltage feedback input of the main summing comparator, limiting the start-up ramp to around 1ms under

typical operating conditions. The soft-start ramp is reset

whenever the output enable (OUTEN) is reset or whenever the controller supply falls below 3.5V.

Watchdog

A system watchdog monitors the condition of the controller supply and the integrity of the generated output

voltage. Modern logic level power FET’s rapidly

increase in resistivity (Rdson) as their gate drive is

reduced below 5V. To prevent thermal damage to the

power FET’s under load, with a reduced supply voltage,

the system watchdog monitors the controller supply

(VIN) and disables both PWM outputs (HSD, LSD)

when the supply voltage drops below 3.5V. When the

supply voltage is increased above 4V the watchdog initiates a soft-start ramp and enables PWM operation. The

difference between enable and disable thresholds introduces hysteresis into the circuit operation, preventing

start-up oscillation. In addition, output voltage is also

monitored by the watchdog. As called out by the Intel

Pentium® II VRM specification, the watchdog power

good output (PWRGD) is set low whenever the output

voltage differs from it’s selected value by more than

±13%. PWRGD is an open drain output. A third watchdog function disables PWM output switching during

over-voltage fault conditions, displaying both external

FET drives, whenever the output voltage is greater than

13% of its selected value, thereby anticipating reverse

inductor current ramping and conforming to the VRM

over-voltage specification, which requires the regulator

output to be disabled during fault conditions. Switching

is enabled after the fault condition is removed.

Output Drivers

Complementary control signals developed by the PWM

control loop are fed to dual NMOS power FET drivers

via a level shift circuit. Each driver is capable of delivering nominal peak output currents of 2A at 12V. To

prevent shoot-through in the external FET’s, each driver

is disabled until the gate voltage of the complementary

power FET has fallen to less than 1V. Supply connections for both drivers are independent, allowing the

controller to be configured with a boot-strapped high

side drive. Employing this technique a single supply

voltage may be used for both power FET’s and controller. Alternatively, the application may be simplified

using dual supply rails with the power FET’s connected

to a secondary supply voltage below the controller’s,

typically 12V and 5V. For applications where efficiency

is less important than cost, applications can be further

simplified by replacing the low side power FET with a

Schottky diode, resulting in non-synchronous operation.

Applications Information

The EL7571C is designed to meet the Intel 5 bit VRM

specification. Refer to the VID decode table for the controller output voltage range.

The EL7571C may be used in a number converter topologies. The trade-off between efficiency, cost, circuit

complexity, line input noise, transient response and

availability of input supply voltages will determine

which converter topology is suitable for a given applica-

8

Page 9

EL7571C

Programmable PWM Controller

tion. The following table lists some of the differences

between the various configurations:

Converter Topologies

Topology Diagram Efficiency Cost Complexity Input Noise

5V only Non-synchronous figure 1 92% low low high good

5V only Synchronous figure 2 95% higher higher high good

5V &12V Non-synchronous figure 3 92% lowest lowest high good

5V & 12V Synchronous figure 4 95% high high high good

12V only Synchronous Connection

Diagram

92% highest highest high best

Transient

Response

EL7571C

Circuit schematics and Bills of Material (BOMs) for the

various topologies are provided at the end of this data

sheet. If your application requirements differ from the

included samples, the following design guide lines

should be used to select the key component values.

Refer to the front page connection diagram for component locations.

Output Inductor, L

1

Two key converter requirements are used to determine

inductor value:

• I

- minimum output current; the current level at

MIN

which the converter enters the discontinuous mode of

operation (refer to Elantec application note #18 for a

detailed discussion of discontinuous mode)

• I

- maximum output current

MAX

Although many factors influence the choice of the

inductor value, including efficiency, transient response

and ripple current, one practical way of sizing the inductor is to select a value which maintains continuous mode

operation, i.e. inductor current positive for all conditions. This is desirable to optimize load regulation and

light load transient response. When the minimum inductor ripple current just reaches zero and with the mean

ripple current set to I

twice I

, independent of duty cycle. The minimum

MAX

, peak inductor ripple current is

MIN

inductor value is given by:

L

1MIN

V(

-----------------------------------------------------

INVOUT

1

PEAK

) TON×–

V(

---------------------------------------------------------==

VINFSW2 I

INVOUT

) V

×–

OUT

×××

MIN

where:

I

= peak ripple current

PEAK

T

= top switch on time

ON

VIN = input voltage

FSW = switching frequency

V

= output voltage

OUT

I

= minimum load

MIN

Since inductance value tends to decrease with current,

ripple current will generally be greater than 21

MIN

higher output current.

Once the minimum output inductance is determined, an

off the shelf inductor with current rating greater than the

maximum DC output required can be selected. Pulse

Engineering and Coil Craft are two manufactures of

high current inductors. For converter designers who

want to design their own high current inductors, for

experimental purposes or to further reduce costs, we recommend the Micrometals Powered Iron Cores data

sheet and applications note as a good reference and starting point.

Current Sense Resistor, R

1

Inductor current is monitored indirectly via a low value

resistor R1. The voltage developed across the current

sense resistor is used to set the maximum operating current, the current reversal threshold and the system load

regulation. To ensure reliable system operation it is

important to sense the actual voltage drop across the

resistor. Accordingly a four wire Kelvin connection

should be made to the controller current sense inputs.

at

9

Page 10

EL7571C

Programmable PWM Controller

EL7571C

There are two criteria for selecting the resistor value and

type. Firstly, the minimum value is limited by the maximum output current. The EL7571C current limit

capacitor has a typical threshold of 154mV, 125mV

minimum. When the voltage across the sense resistor

exceeds this threshold, the conduction cycle of the top

switch terminates immediately, providing pulse by pulse

current limiting. A resistor value must be selected which

guarantees operation under maximum load. That is:

V

OCMIN

R

---------------------=

1

1

MAX

where:

V

I

= minimum over current voltage threshold

OCMIN

= maximum output current

MAX

Secondly, since the load current passes directly through

the sense resistor, its power rating must be sufficient to

handle the power dissipated during maximum load (current limit) conditions. Thus:

OUTMAX

2

R

×=

1

PD1

where:

PD = power dissipated in current sense resistor

PD must be less than the power rating of the current

sense resistor. High current applications may require

parallel sense resistors to dissipate sufficient power.

Current Sense Resistor Table below lists some popular

current sense resistors: the WLS-2512 series of Power

Metal Strip Resistors from Dale Electronics, OARS

series Iron Alloy resistor from IRC, and Copper Magnanin (CuNi) wire resistor from Mills Resistors. Mother

board copper trace is not recommended because of its

high temperature coefficient and low power dissipation.

The trade-off between the different types of resistors are

cost, space, packaging and performance. Although

Power Metal Strip Resistors are relatively expensive,

they are available in surface mount packaging with

tighter tolerances. Consequently, less board space is

used to achieve a more accurate current sense. Alternatively, Magnanin copper wire has looser tolerance and

higher parasitic inductance. This results in a less current

sense but at a much lower cost. Metal track on the PCB

can also be used as current sense resistor. The trade-offs

are ±30% tolerance and ±4000 ppm temperature coefficient. Ultimately, the selection of the type of current

sense element must be made on an application by application basis.

Bill of Materials

Manufacturer Part No. Tolerance

Dale WSL 2512 ±1% ±75ppm 1 W 402-563-6506 402-563-6418

IRC OARS Series ±5% ±20ppm 1W - 5W 800-472-6467 800-472-3282

Mills Resistor MRS1367-TBA ±10% ±20ppm 1.2W 916-422-5461 906-422-1409

PCB Trace Resistor ±30% ±4000ppm 50A/in (1oz Cu)

Input Capacitor, C

1

In a buck converter, where the output current is greater

than 10A, significant demand is placed on the input

capacitor. Under steady state operation, the high side

FET conducts only when it is switched “on” and conducts zero current when it is turned “off”. The result is a

current square wave drawn from the input supply. Most

of this input ripple current is supplied from the input

capacitor C1. The current flow through C1’s equivalent

series resistance (ESR) can heat up the capacitor and

Temperature

Coefficient Power Rating Phone No. Fax No.

cause premature failure. Maximum input ripple current

occurs when the duty cycle is 50%, a current of Iout/2

RMS.

Worst case power dissipation is:

P

D

•=

-------------

2

ESR

IN

2

I

OUT

where:

ERSIN = input capacitor ESR

10

Page 11

EL7571C

Programmable PWM Controller

EL7571C

For safe and reliable operation, PD must be less than the

capacitor’s data sheet rating.

Input Inductor, L

2

The input inductor (L2) isolates switching noise from

the input supply line by diverting buck converter input

ripple current into the input capacitor. Buck regulators

generate high levels of input ripple current because the

load is connected directly to the supply through the top

switch every cycle, chopping the input current between

the load current and zero, in proportion to the duty cycle.

The input inductor is critical in high current applications

where the ripple current is similarly high. An exclusively large input inductor degrades the converter’s load

transient response by limiting the maximum rate of

change of current at the converter input. A 1.5µH input

inductor is sufficient in most applications.

Output Capacitor, C

2

During steady state operation, output ripple current is

much less than the input ripple current since current flow

is continuous, either via the top switch or the bottom

switch. Consequently, output capacitor power dissipation is less of a concern than the input capacitor’s.

However, low ESR is still required for applications with

very low output ripple voltage or transient response

requirements. Output ripple voltage is given by:

V

RIPIRIP

ESR

×=

OUT

where:

I

= output ripple current

RIP

ESR

= output capacitor ESR

OUT

During a transient response, the output voltage spike is

determined by the ESR and the equivalent series inductance (ESL) of the output capacitor in addition to the rate

of change and magnitude of the load current step. The

output voltage transient is given by:

∆V

ESR

=

OUT

OUT∆IOUT

ESL

d

i

×+×

----

d

t

where:

ESR

= output capacitor ESR

OUT

ESL = output capacitor ESL

∆I

= output current step

OUT

di/dt = rate of change of output current

Power MOSFET, Q1 and Q2

The EL7571C incorporates a boot-strap gate drive

scheme to allow the usage of N-channel MOSFETs. Nchannel MOSFETs are preferred because of their relative low cost and low on resistance. The largest amount

of the power loss occurs in the power MOSFETs, thus

low on resistance should be the primary characteristic

when selecting power MOSFETs. In the boot-strap gate

drive scheme, the gate drive voltage can only go as high

as the supply voltage, therefore in a 5V system, the

MOSFETs must be logic level type, Vgs<4.5V. In addition to on resistance and gate to source threshold, the

gate to source capacitance is also very important. In the

region when the output current is low (below5A),

switching loss is the dominant factor. Switching loss is

determined by:

2

PCV

where:

C is the gate to source capacitance of the MOSFET

V is the supply voltage

F is the switching frequency

Another undesirable reason for a large MOSFET gate to

source capacitance is that the on resistance of the MOSFET driver can not supply the peak current required to

turn the MOSFET on and off fast. This results in additional MOSFET conduction loss. As frequency

increases, this loss also increases which leads to more

power loss and lower efficiency.

Finally, the MOSFET must be able to conduct the maximum current and handle the power dissipation.

The EL7571C is designed to boot-strap to 12V for 12V

only input converters. In this application, logic level

MOSFETs are not required.

Table below lists a few popular MOSFETs and their critical specifications.

F××=

11

Page 12

EL7571C

Programmable PWM Controller

EL7571C

Manufacturer Model Vgs Ron (max) Cgs ID VDS Package

MegaMos Mi4410 4.5V 20mΩ 6.4nF ±10A 30V SO-8

MegaMos Mip30N03A 4.5V 22mΩ 6.3nF ±15A 30V TO-220

Siliconix Si4410 4.5V 20mΩ 4.3nF ±10A 30V SO-8

Fuji 2SK1388 4V 37mΩ ±17.5A TO-220

IR IRF3205S 4 8mΩ 17nF (max) ±98A 55V D2Pak

Motorola MTB75N05HD 4 7mΩ 7.1nF ±75A 50V TO-220

Skottky Diode, D2

In the non-synchronous scheme a flyback diode is

required to provide a current path to the output when the

high side power MOSFET, Q1, is switched off. The critical criteria for selecting D2 is that it must have low

forward voltage drop. The product of forward voltage

drop and condition current is a primary source of power

dissipation in the convertor. The Schottky diode selected

is the International Rectifier 32CTQ030 which has 0.4V

of forward voltage drop at 15A.

12

Page 13

Block Diagram

ENABLE

In

Regulation

EL7571C

EL7571C

Programmable PWM Controller

12.6V

Reference

4V

UVLO HI

+

-

UVLO LOW

+

-

3.5V

Oscillator

0.1µF

DAC

Ramp Control

C

S

+

-

+

-

Current Reversal

+

-

+

-

+

∑

-

+

Soft

Start

ENABLE

PWM

Control Logic

INP

V

HI

HSD

0.1µF

LX

5.1µH L

LSD

GNDPGND

V

1

7.5mΩ C

OUT

2

6mF

1.5µH

L

2

3mF4.5V to

VID

(0:4)

240pF

220pF

C

VINOTEN REF FB PWRGD V

1

C

SLOPE

C

OSC

13

Page 14

EL7571C

Programmable PWM Controller

EL7571C

Voltage ID Code Output Voltage Settings

V

ID4

0 1 1 1 1 1.3

0 1 1 1 0 1.35

0 1 1 0 1 1.4

0 1 1 0 0 1.45

0 1 0 1 1 1.5

0 1 0 1 0 1.55

0 1 0 0 1 1.6

0 1 0 0 0 1.65

0 0 1 1 1 1.7

0 0 1 1 0 1.75

0 0 1 0 1 1.8

0 0 1 0 0 1.85

0 0 0 1 1 1.9

0 0 0 1 0 1.95

0 0 0 0 1 2.0

0 0 0 0 0 2.05

1 1 1 1 1 0, No CPU

1 1 1 1 0 2.1

1 1 1 0 1 2.2

1 1 1 0 0 2.3

1 1 0 1 1 2.4

1 1 0 1 0 2.5

1 1 0 0 1 2.6

1 1 0 0 0 2.7

1 0 1 1 1 2.8

1 0 1 1 0 2.9

1 0 1 0 1 3.0

1 0 1 0 0 3.1

1 0 0 1 1 3.2

1 0 0 1 0 3.3

1 0 0 0 1 3.4

1 0 0 0 0 3.5

V

ID3

V

ID2

V

ID1

V

ID0

V

OUT

Application Circuits

To assist the evaluation of EL7571C, several VRM

applications have been developed. These are described

in the converter topologies table earlier in the data sheet.

The demo board can be configured to operate with either

a 5V or 12V controller supply, using a 5V FET supply.

14

Page 15

Programmable PWM Controller

5V Input, Boot-Strapped Non-Synchronous DC:DC Converter

5Ω

D1R2

Q1

C7

0.1µF

0.1µF

D2

C6

C8

1µF

L1 R1

5.1µH

C1

1000µF

x3

1µH

L2

7.5mΩ

ENABLE OTEN

1.4V

0.1µF

POWER

GOOD

1

240pF

2

220pF

3

4

5

6

CSLOPE

COSC

REF

PWRGD

C3

C4

C5

VH1

HSD

V1H

VINP

LSDVIDO

20

19

18

LX

17

16

15

EL7571C

5V

VOUT

C2

1000µ

F

EL7571C

GNDP

GND

14

13

CS

12

FB

11

Voltage

LD.

(VID(0:4))

7

VID1

VID2

8

VID3

9

10

VID4

EL7571C 5V VRM Bill of Materials - 5V Non Sync Solution

Component Manufacturer Part Number Value Unit

C1 Sanyo 6MV1000GX 1000µF 3

C2 Sanyo 6MV1000GX 1000µF 6

C3 Chip Capacitors 240pf 1

C4 Chip Capacitors 220pf 1

C5, C6 Chip Capacitors 0.1µF 2

C7, C8 Chip Capacitors 1µF 2

D1 GI Schotty diode SS12GICT-ND 1

IC1 Elantec EL7571CM 1

L1 Pulse Engineering PE-53700 5.1µH 1

L2 Micrometals T30-26,7T AWG #20 1µH 1

R1 DALE WSL-2512 15mΩ 2

R2 Chip Resistor 5Ω 1

D2 IR IR32CTQ030 1

Q1 Siliconix Si4410 2

15

Page 16

EL7571C

Programmable PWM Controller

EL7571C

5V Input Boot-Strapped Synchronous DC:DC Converter

5Ω

R2

D1

Q1

C7

0.1µF

C6

0.1µF

C8

1µF

D2

Q2

ENABLE OTEN

1.4V

0.1µF

POWER

GOOD

1

240pF

2

220pF

3

4

5

6

7

CSLOPE

COSC

REF

PWRGD

VID1

C3

C4

C5

VH1

HSD

V1H

VINP

LSDVIDO

GNDP

20

19

18

LX

17

16

15

14

C1

1000µF

x3

L1 R1

5.1µH

1.5µH

L2

7.5mΩ

5V

VOUT

C2

1000µ

F

Voltage

LD.

(VID(0:4))

VID2

8

VID3

9

10

VID4

GND

13

CS

12

11

FB

EL7571C 5V VRM Bill of Materials - 5V Non Sync Solution

Component Manufacturer Part Number Value Unit

C1 Sanyo 6MV1000GX 1000µF 3

C2 Sanyo 6MV1000GX 1000µF 6

C3 Chip Capacitors 240pf 1

C4 Chip Capacitors 220pf 1

C5, C6 Chip Capacitors 0.1µF 2

C7, C8 Chip Capacitors 1µF 2

D1 GI Schotty diode SS12GICT-ND 1

IC1 Elantec EL7571CM 1

L1 Pulse Engineering PE-53700 5.1µH 1

L2 Micrometals T30-26,7T AWG #20 1µH 1

R1 DALE WSL-2512 15mΩ 2

R2 Chip Resistor 5Ω 1

D2 IR IR32CTQ030 1

Q1, Q2 Siliconix Si4410 2 each

16

Page 17

5V Input, 12V Controller, Non-Sync Solution

ENABLE OTEN

1.4V

0.1µF

POWER

GOOD

1

220pF

2

220pF

3

4

5

6

7

CSLOPE

COSC

REF

PWRGD

VID1

C3

C4

C5

VH1

HSD

V1H

VINP

LSDVIDO

GNDP

20

19

18

LX

17

16

15

14

Q1

C7

0.1µF

Q2

EL7571C

Programmable PWM Controller

12V

5Ω

R2

1µH

L2

C1

C8

1µF

L1 R1

5.1µH

1000µF

x3

7.5mΩ

5V

VOUT

C2

1000µ

F

EL7571C

Voltage

LD.

(VID(0:4))

VID2

8

VID3

9

10

VID4

GND

13

CS

12

11

FB

EL7571C 5V VRM Bill of Materials - 5V Non Sync Solution

Component Manufacturer Part Number Value Unit

C1 Sanyo 6MV1000GX 1000µF 3

C2 Sanyo 6MV1000GX 1000µF 6

C3 Chip Capacitors 240pF 1

C4 Chip Capacitors 220pF 1

C5 Chip Capacitors 0.1µF 1

C7, C8 Chip Capacitors 1µF 2

IC1 Elantec EL7571CM 1

L1 Pulse Engineering PE-53700 5.1µH 1

L2 Micrometals T30-26,7T AWG #20 1µH 1

R1 DALE WSL-2512 15mΩ 2

R2 Chip Resistor 5Ω 1

D2 IR IR32CTQ030 1

Q1 Siliconix Si4410 2

17

Page 18

EL7571C

Programmable PWM Controller

EL7571C

5V Input, 12V Controller, Synchronous DC:DC Converter

D2

C8

1µF

L1 R1

5.1µH

12V

C1

1000µF

x3

1.5µH

L2

7.5mΩ

5V

VOUT

C2

1000µ

F

ENABLE OTEN

1.4V

0.1µF

POWER

GOOD

Voltage

LD.

(VID(0:4))

1

330pF

2

330pF

3

4

5

6

7

8

9

10

CSLOPE

COSC

REF

PWRGD

VID1

VID2

VID3

VID4

C3

C4

C5

VH1

HSD

V1H

VINP

LSDVIDO

GNDP

GND

C6

20

19

18

LX

17

16

15

14

13

CS

12

11

FB

0.1µF

Q1

C7

0.1µF

EL7571C 5V VRM Bill of Materials - 5V Input, 12V Controller Sync Solution

Component Manufacturer Part Number Value Unit

C1 Sanyo 6MV1000GX 1000µF 3

C2 Sanyo 6MV1000GX 1000µF 6

C3 Chip Capacitors 330pf 1

C4 Chip Capacitors 330pf 1

C5, C6 Chip Capacitors 0.1µF 2

C7, C8 Chip Capacitors 1µF 2

IC1 Elantec EL7571CM 1

L1 Pulse Engineering PE-53700 5.1µH 1

L2 Micrometals T30-26,7T AWG #20 1µH 1

R1 DALE WSL-2512 15mΩ 2

D2 IR IR32CTQ030 1

Q1, Q2 Siliconix Si4410 2 each

18

Page 19

PCB Layout Considerations

EL7571C

EL7571C

Programmable PWM Controller

1. Place the power MOSFET’s as close to the controller as possible. Failure to do so will cause

large amounts of ringing due to the parasitic

inductance of the copper trace. Additionally, the

parasitic capacitance of the trace will weaken the

effective gate drive. High frequency switching

noise may also couple to other control lines.

2. Always place the by-pass capacitors (0.1µF and

1µF) as close to the EL7571C as possible. Long

lead lengths will lessen the effectiveness.

3. Separate the power ground (input capacitor

ground and ground connections of the Schottky

diode and the power MOSFET’s) and signal

grounds (ground pins of the by-pass capacitors

and ground terminals of the EL7571C). This will

isolate the highly noisy switching ground from

the very sensitive signal ground.

4. Connect the power and signal grounds at the output capacitors. Output capacitor ground is the

quietest point in the converter and should be

used as the reference ground.

5. The power MOSFET’s output inductor and

Schottky diode should be grouped together to

contain high switching noise in the smallest area.

6. Current sense traces running from pin 11 and pin

12 to the current sense resistor should run parallel and close to each other and be Kelvin

connected (no high current flow). In high current

applications performance can be improved by

connecting low Pass filter (typical values 4.7Ω,

0.1µF) between the sense resistor and the IC

inputs.

19

Page 20

EL7571C

Programmable PWM Controller

EL7571C

Layout Example

To demonstrate the points discussed above, below

shows two reference layouts - a synchronous 5V only

VRM layout and a synchronous 5V only PC board lay-

out. Both layouts can be modified to any application

circuit configuration shown on this data sheet. Gerber

files of the layouts are available from the factory.

Top Layer Silkscreen

Bottom Layer Silkscreen

20

Page 21

Top Layer Metal

EL7571C

EL7571C

Programmable PWM Controller

Bottom Layer Metal

Top Layer Silkscreen

21

Page 22

EL7571C

Programmable PWM Controller

EL7571C

Top Layer Metal

Bottom Layer Metal

22

Page 23

EL7571C

Programmable PWM Controller

EL7571C

General Disclaimer

Specifications contained in this data sheet are in effect as of the publication date shown. Elantec, Inc. reserves the right to make changes in the circuitry or specifications contained herein at any time without notice. Elantec, Inc. assumes no responsibility for the use of any circuits described

herein and makes no representations that they are free from patent infringement.

WARNING - Life Support Policy

Elantec, Inc. products are not authorized for and should not be used

within Life Support Systems without the specific written consent of

Elantec, Inc. Life Support systems are equipment intended to sup-

Elantec Semiconductor, Inc.

675 Trade Zone Blvd.

Milpitas, CA 95035

Telephone: (408) 945-1323

(888) ELANTEC

Fax: (408) 945-9305

European Office: 44-118-977-6020

Japan Technical Center: 81-45-682-5820

port or sustain life and whose failure to perform when properly used

in accordance with instructions provided can be reasonably

expected to result in significant personal injury or death. Users contemplating application of Elantec, Inc. Products in Life Support

Systems are requested to contact Elantec, Inc. factory headquarters

to establish suitable terms & conditions for these applications. Elantec, Inc.’s warranty is limited to replacement of defective

components and does not cover injury to persons or property or

other consequential damages.

April 24, 2001

23

Printed in U.S.A.

Loading...

Loading...