Page 1

(3.3V,

EL7562C - Preliminary

Monolithic 2 Amp DC:DC Step-down Regulator

EL7562C - Preliminary

Features

• Integrated synchronous MOSFETs

and current mode controller

• 2A continuous output current

• Up to 95% efficiency

• 4.5V to 5.5V input voltage

• Adjustable output from 1V to 3.8V

• Cycle-by-cycle current limit

• Precision reference

• ±0.5% load and line regulation

• Adjustable switching frequency to

1MHz

• Oscillator synchronization

possible

• Internal soft start

• Over temperature protection

• Under voltage lockout

• 16-pin QSOP package

Applications

• DSP, CPU Core and IO Supplies

• Logic/Bus Supplies

• Portable Equipment

• DC:DC Converter Modules

• GTL + Bus Power Supply

Ordering Information

Part No Package Tape & Reel Outline #

EL7562CU 16-Pin QSOP - MDP0040

General Description

The EL7562C is an integrated, synchronous step-down regulator with

output voltage adjustable from 1.0V to 3.8V. It is capable of delivering

2A continuous current at up to 95% efficiency. The EL7562C operates

at a constant frequency pulse width modulation (PWM) mode, making

external synchronization possible. Patented on-chip resistorless current sensing enables current mode control, which provides cycle-bycycle current limiting, over-current protection, and excellent step load

response. The EL7562C is available in a fused-lead 16-pin QSOP

package. With proper external components, the whole converter fits

into a less than 0.5 in2 area. The minimal external components and

small size make this EL7562C ideal for desktop and portable

applications.

The EL7562C is specified for operation over the -40°C to +85°C temperature range.

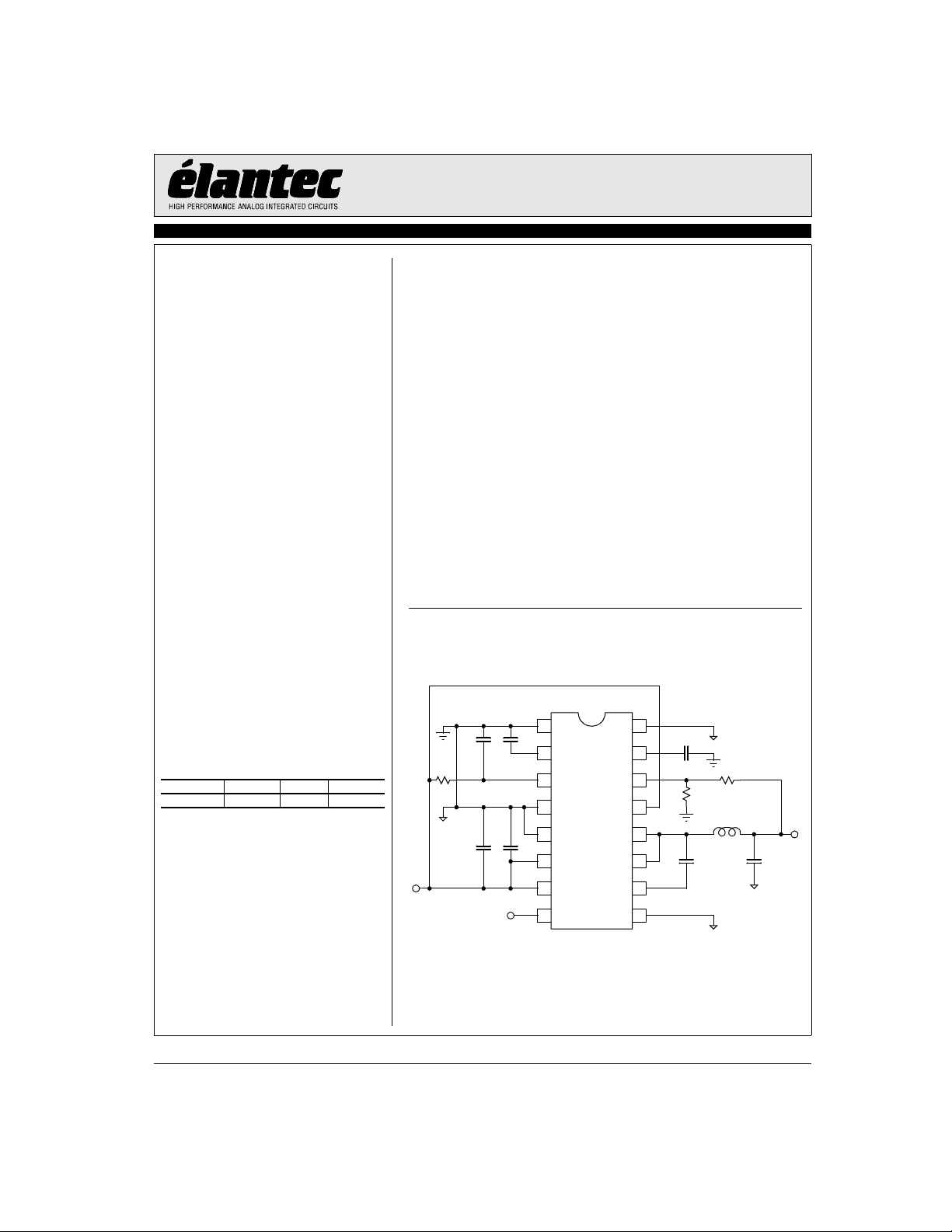

Typical Application Diagram

V

5.5V)

1

C3C

4

0.1µF 270pF

R

3

39Ω

C1C

2

100µF 0.1µF

IN

SGND

2

COSC

3

VDD

4

PGND

5

PGND

6

VIN

7

VIN

8 9

EN

PGND

VREF

VDRV

VHI

PGND

16

15

14

FB

13

12

LX

11

LX

10

C

0.1µF

5

R

1

1kΩ

C

6

0.1µF

R

2.37k

L

4.7µF

2

1

C

7

100µF

2A)

V

O

October 25, 2001

Manufactured under U.S. Patent No. 57,323,974

Note: All information contained in this data sheet has been carefully checked and is believed to be accurate as of the date of publication; however, this data sheet cannot be a “controlled document”. Current revisions, if any, to these

specifications are maintained at the factory and are available upon your request. We recommend checking the revision level before finalization of your design documentation.

© 2001 Elantec Semiconductor, Inc.

Page 2

EL7562C - Preliminary

Monolithic 2 Amp DC:DC Step-down Regulator

Absolute Maximum Ratings (T

Supply Voltage between VIN or VDD and GND +6.5V

VLX Voltage VIN +0.3V

Input Voltage GND -0.3V, VDD +0.3V

VHI Voltage GND -0.3V, V

EL7562C - Preliminary

= 25°C)

A

LX

Storage Temperature -65°C to +150°C

Operating Ambient Temperature -40°C to +85°C

Operating Junction Temperature +135°C

+6V

Important Note:

All parameters having Min/Max specifications are guaranteed. Typ values are for information purposes only. Unless otherwise noted, all tests are at the

specified temperature and are pulsed tests, therefore: TJ = TC = TA.

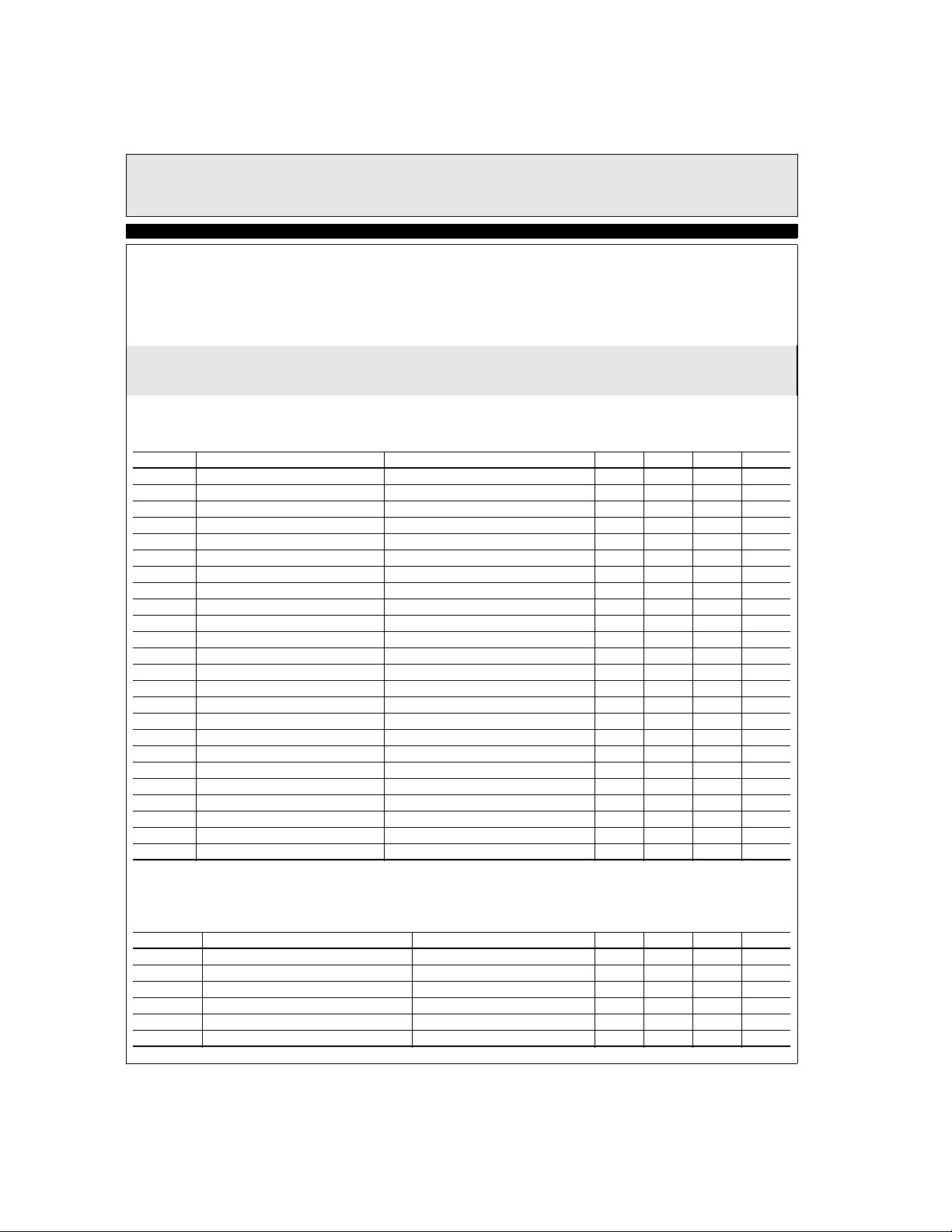

DC Characteristics

V

= V

= 5V, TA = TJ = 25°C, C

DD

IN

Parameter Description Conditions Min Typ Max Unit

V

REF

V

REFTC

V

REFLOAD

V

RAMP

I

OSC_CHG

I

OSC_DIS

I

VDD+VDRVVDD+VDRV

I

VDD_OFF

V

DD_OFF

V

DD_ON

T

OT

T

HYS

I

LEAK

I

LMAX

R

DSON

R

DSONTC

V

FB

V

FB_LINE

V

FB_LOAD

V

FB_TC

I

FB

V

EN_HI

V

EN_LO

I

EN

Reference Accuracy 1.24 1.26 1.28 V

Reference Temperature Coefficient 50 ppm/°C

Reference Load Regulation 0 < I

Oscillator Ramp Amplitude 1.15 V

Oscillator Charge Current 0.1V < V

Oscillator Discharge Current 0.1V < V

Supply Current VEN = 4V, F

V

Standby Current EN = 0 1 1.5 mA

DD

VDD for Shutdown 3.5 3.9 V

VDD for Startup 3.95 4.35 V

Over Temperature Threshold 135 °C

Over Temperature Hysteresis 20 °C

Internal FET Leakage Current EN = 0, LX = 5V (low FET), LX = 0V (high FET) 10 µA

Peak Current Limit 3 A

FET On Resistance Wafer level test only 60 120 mΩ

R

Tempco 0.2 mΩ/°C

DSON

Output Initial Accuracy I

Output Line Regulation V

Output Load Regulation 0.1A < I

Output Temperature Stability -40°C < TA < 85°C, I

Feedback Input Pull Up Current V

EN Input High Level 3.2 4 V

EN Input Low Level 1 V

Enable Pull Up Current VEN = 0 -4 -2.5 µA

= 1.2nF, unless otherwise specified.

OSC

LOAD

IN

FB

< 50µA -1 %

REF

< 1.25V 200 µA

OSC

< 1.25V 8 mA

OSC

= 120kHz 2 3.5 5 mA

OSC

= 0A 0.960 0.975 0.99 V

= 5V, ∆V

= 10%, I

IN

< 1A 0.5 %

LOAD

= 0A 0.5 %

LOAD

= 0.5A ±1 %

LOAD

= 0V 100 200 nA

Closed Loop AC Electrical Characteristics

VS = V

= 5V, TA = TJ = 25°C, C

IN

Parameter Description Conditions Min Typ Max Unit

F

OSC

t

SYNC

M

t

BRM

t

LEB

D

SS

MAX

Oscillator Initial Accuracy 105 117 130 kHz

Minimum Oscillator Sync Width 25 ns

Soft Start Slope 0.5 V/ms

FET Break Before Make Delay 15 ns

High Side FET Minimum On Time 150 ns

Maximum Duty Cycle 95 %

= 1.2nF, unless otherwise specified.

OSC

2

Page 3

EL7562C - Preliminary

Monolithic 2 Amp DC:DC Step-down Regulator

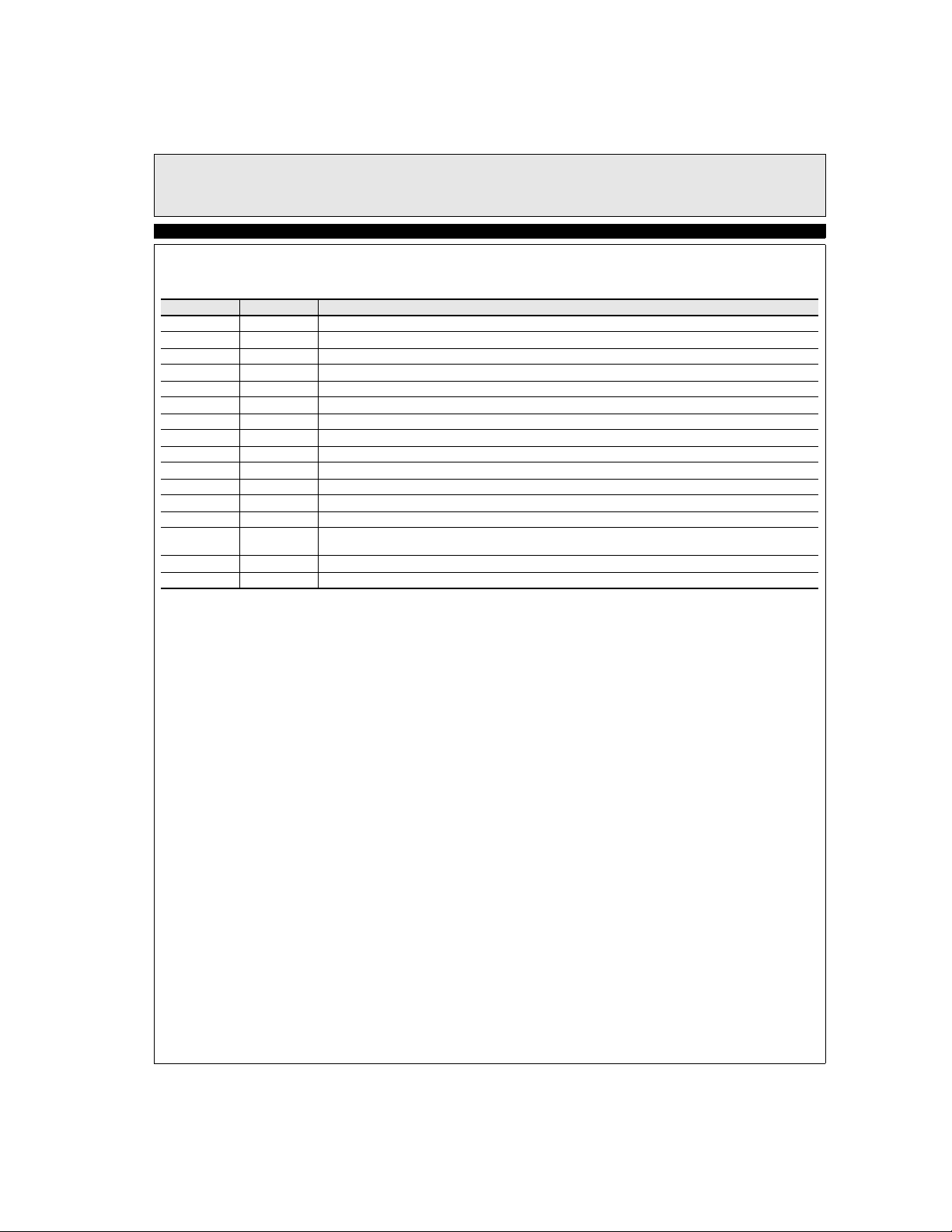

Pin Descriptions

Pin Number Pin Name Pin Function

1 SGND Control circuit negative supply.

2 COSC Oscillator timing capacitor. FOSC can be approximated by: FOSC (kHz) = 0.1843/COSC, COSC in µF.

3 VDD Control circuit positive supply.

4 PGND Ground return of the regulator. Connected to the source of the low-side synchronous NMOS power FET.

5 PGND Ground return of the regulator. Connected to the source of the low-side synchronous NMOS power FET.

6 VIN Power supply input of the regulator. Connected to the drain of the high-side NMOS power FET.

7 VIN Power supply input of the regulator. Connected to the drain of the high-side NMOS power FET.

8 EN Chip Enable, active high. A 2µA internal pull-up current enables the device if the pin is left open.

9 PGND Ground return of the regulator.

10 VHI Positive supply of the high-side driver.

11 LX Inductor drive pin. High current digital output whose average voltage equals the regulator output voltage.

12 LX Inductor drive pin. High current digital output whose average voltage equals the regulator output voltage.

13 VDRV Positive supply of the low-side driver and input voltage for the high-side boot strap.

14 FB Voltage feedback input. Connected to an external resistor divider between VOUT and GND. A 125nA pull-up current

15 VREF Bandgap reference bypass capacitor. Typically 0.1µF to GND.

16 PGND Ground return of the regulator.

forces VOUT to VS in the event that FB is floating.

EL7562C - Preliminary

3

Page 4

EL7562C - Preliminary

Monolithic 2 Amp DC:DC Step-down Regulator

Typical Performance Curves

Efficiency vs I

EL7562C - Preliminary

VIN=5V

100

95

90

85

80

75

Efficiency (%)

70

65

60

0.1 1 2

Efficiency vs I

VO=3.3V

100

95

90

85

80

75

Efficiency (%)

70

65

60

0 0.5 1 1.5 2

VIN=4.5V

VIN=5.5V

O

VO=1.8V

Load Current IO (A)

O

VIN=5V

Load Current IO (A)

VO=2.5V

VO=1.5V

VO=1.2V

FS=500kHz

L=Coilcraft DO3316P-472

VO=3.3V

Power Loss vs I

Power Loss vs I

VIN=5V

VIN=5V

0.7

0.7

0.6

0.6

0.5

0.5

0.4

0.4

0.3

0.3

Power Loss (W)

Power Loss (W)

0.2

0.2

0.1

0.1

0

0

0 0.5 1 1.5 2

0 0.5 1 1.5 2

Load Regulation

VO=3.3V

0.8

0.6

0.4

0.2

0

Output Voltage (%)

-0.2

-0.4

-0.6

0 0.5 1 1.5 2

O

O

VO=1.8V

Load Current IO (A)

Load Current IO (A)

VIN=5.5V

VIN=5V

Load Current IO (A)

VO=3.3V

VO=2.5V

VO=1.2V

VO=1.5V

VIN=4.5V

Line Regulation

VO=3.3V

0.6

0.4

IO=0.1A

0.2

0

(%)

O

V

-0.2

-0.4

-0.6

4.5 4.7 5.1 5.3 5.5

IO=1A

IO=2A

4.9

VIN (V)

V

vs Temperature

REF

1.258

1.256

1.254

1.252

(V)

1.25

REF

V

1.248

1.246

1.244

1.242

-40 10 60 110 160

Temperature (°C)

4

Page 5

Typical Performance Curves

EL7562C - Preliminary

EL7562C - Preliminary

Monolithic 2 Amp DC:DC Step-down Regulator

Oscillator Frequency vs Temperature

390

385

380

375

370

Oscillator Frequency (kHz)

365

360

-40 10 60 110 160

Temperature (°C)

Switching Frequency vs C

1400

1200

1000

800

(kHz)

S

600

F

400

200

0

0 400 600 800 1000

200

OSC

C

(pF)

OSC

Input Current vs Temperature

(Enable connected to GND)

0.96

0.94

0.92

0.9

0.88

0.86

Input Current (A)

0.84

0.82

0.8

-40 10 60 110 160

Temperature (°C)

VIN=5.5V

VIN=4.5VVIN=5V

5

Page 6

EL7562C - Preliminary

Monolithic 2 Amp DC:DC Step-down Regulator

Block Diagram

EL7562C - Preliminary

VREF COSC

270pF0.1µF

Junction

Temperature

Controlle

VDD

SGND

r Supply

FB

39Ω

0.1µF

EN

Voltage

Reference

PWM

Controller

Current

Sense

Oscillator

Drivers

Power

FET

Power

FET

VDRV

VHI

VIN

PGND

0.1µF

4.7µH

100µF

2370Ω

1kΩ

V

OUT

6

Page 7

Applications Information

EL7562C - Preliminary

EL7562C - Preliminary

Monolithic 2 Amp DC:DC Step-down Regulator

Circuit Description

General

The EL7562C is a fixed frequency, current mode controlled DC:DC converter with integrated N-channel

power MOSFETs and a high precision reference. The

device incorporates all the active circuitry required to

implement a cost effective, user-programmable 2A synchronous step-down regulator suitable for use in DSP

core power supplies.

Theory of Operation

The EL7562C is composed of 5 major blocks:

1. PWM Controller

2. NMOS Power FETs and Drive Circuitry

3. Bandgap Reference

4. Oscillator

5. Thermal Shut-down

PWM Controller

The EL7562C regulates output voltage through the use

of current-mode controlled pulse width modulation. The

three main elements in a PWM controller are the feedback loop and reference, a pulse width modulator whose

duty cycle is controlled by the feedback error signal, and

a filter which averages the logic level modulator output.

In a step-down (buck) converter, the feedback loop

forces the time-averaged output of the modulator to

equal the desired output voltage. Unlike pure voltagemode control systems, current-mode control utilizes

dual feedback loops to provide both output voltage and

inductor current information to the controller. The voltage loop minimizes DC and transient errors in the output

voltage by adjusting the PWM duty-cycle in response to

changes in line or load conditions. Since the output voltage is equal to the time-averaged of the modulator

output, the relatively large LC time constant found in

power supply applications generally results in low bandwidth and poor transient response. By directly

monitoring changes in inductor current via a series sense

resistor the controller's response time is not entirely lim-

ited by the output LC filter and can react more quickly to

changes in line and load conditions. This feed-forward

characteristic also simplifies AC loop compensation

since it adds a zero to the overall loop response. Through

proper selection of the current-feedback to voltage-feedback ratio the overall loop response will approach a onepole system. The resulting system offers several advantages over traditional voltage control systems, including

simpler loop compensation, pulse by pulse current limiting, rapid response to line variation and good load step

response.

The heart of the controller is an input direct summing

comparator which sum voltage feedback, current feedback, slope compensation ramp and power tracking

signals together. Slope compensation is required to prevent system instability that occurs in current-mode

topologies operating at duty-cycles greater than 50%

and is also used to define the open-loop gain of the overall system. The slope compensation is fixed internally

and optimized for 500mA inductor ripple current. The

power tracking will not contribute any input to the comparator steady-state operation. Current feedback is

measured by the patented sensing scheme that senses the

inductor current flowing through the high-side switch

whenever it is conducting. At the beginning of each

oscillator period the high-side NMOS switch is turned

on. The comparator inputs are gated off for a minimum

period of time of about 150ns (LEB) after the high-side

switch is turned on to allow the system to settle. The

Leading Edge Blanking (LEB) period prevents the

detection of erroneous voltages at the comparator inputs

due to switching noise. If the inductor current exceeds

the maximum current limit (ILMAX) a secondary overcurrent comparator will terminate the high-side switch

on time. If ILMAX has not been reached, the feedback

voltage FB derived from the regulator output voltage

VOUT is then compared to the internal feedback reference voltage. The resultant error voltage is summed with

the current feedback and slope compensation ramp. The

high-side switch remains on until all four comparator

inputs have summed to zero, at which time the high-side

switch is turned off and the low-side switch is turned on.

However, the maximum on-duty ratio of the high-side

switch is limited to 95%. In order to eliminate cross-con-

7

Page 8

EL7562C - Preliminary

Monolithic 2 Amp DC:DC Step-down Regulator

duction of the high-side and low-side switches a 15ns

break-before-make delay is incorporated in the switch

drive circuitry. The output enable (EN) input allows the

regulator output to be disabled by an external logic control signal.

EL7562C - Preliminary

Output Voltage Setting

In general:

R

2

V

OUT

0.975V 1

------

+

×=

R

1

However, due to the relatively low open loop gain of the

system, gain errors will occur as the output voltage and

loop-gain is changed. This is shown in the performance

curves. A 100nA pull-up current from FB to VDD forces

VOUT to GND in the event that FB is floating.

NMOS Power FETs and Drive Circuitry

The EL7562C integrates low on-resistance (60mΩ)

NMOS FETs to achieve high efficiency at 2A. In order

to use an NMOS switch for the high-side drive it is necessary to drive the gate voltage above the source voltage

(LX). This is accomplished by bootstrapping the VHI

pin above the LX voltage with an external capacitor

CVHI and internal switch and diode. When the low-side

switch is turned on and the LX voltage is close to GND

potential, capacitor CVHI is charged through internal

switch to VDRV, typically 5V. At the beginning of the

next cycle the high-side switch turns on and the LX pins

begin to rise from GND to VIN potential. As the LX pin

rises the positive plate of capacitor CVHI follows and

eventually reaches a value of VDRV+VIN, typically

10V, for VDRV=VIN=5V. This voltage is then level

shifted and used to drive the gate of the high-side FET,

via the VHI pin. A value of 0.1µF for CVHI is

recommended.

Reference

A 1.5% temperature compensated bandgap reference is

integrated in the EL7562C. The external VREF capacitor acts as the dominant pole of the amplifier and can be

increased in size to maximize transient noise rejection.

A value of 0.1µF is recommended.

Oscillator

The system clock is generated by an internal relaxation

oscillator with a maximum duty-cycle of approximately

95%. Operating frequency can be adjusted through the

COSC pin or can be driven by an external source. If the

oscillator is driven by an external source care must be

taken in selecting the ramp amplitude. Since CSLOPE

value is derived from the COSC ramp, changes to COSC

ramp will change the CSLOPE compensation ramp

which determine the open-loop gain of the system.

When external synchronization is required, always

choose C

such that the free-running frequency is at

OSC

least 20% lower than that of sync source to accommodate component and temperature variations. Figure 1

shows a typical connection.

1 16

2

3

6

7

8

EL7562C

15

14

11

10

9

External

Oscillator

BAT54S100pF

Figure 1. Oscillator Synchronization

Thermal Shut-down

An internal temperature sensor continuously monitors

die temperature. In the event that die temperature

exceeds the thermal trip-point, the system is in fault state

and will be shut down. The upper and low trip-points are

set to 135°C and 115°C respectively.

8

Page 9

Start-up Delay

A capacitor can be added to the EN pin to delay the converter start-up (Figure 2) by utilizing the pull-up current.

The delay time is approximately:

t

ms() 1200 C µF()×=

d

1 16

EL7562C - Preliminary

EL7562C - Preliminary

Monolithic 2 Amp DC:DC Step-down Regulator

2

3

6

7

C

8

EL7562C

15

14

11

10

9

Figure 2. Start-up Delay

Layout Considerations

The layout is very important for the converter to function properly. Power Ground ( ) and Signal Ground (---)

should be separated to ensure that the high pulse current

in the Power Ground never interferes with the sensitive

signals connected to Signal Ground. They should only

be connected at one point (normally at the negative side

of either the input or output capacitor.)

The trace connected to pin 14 (FB) is the most sensitive

trace. It needs to be as short as possible and in a “quiet”

place, preferably between PGND or SGND traces.

V

OUT

t

d

TIME

V

IN

V

O

In addition, the bypass capacitor connected to the VDD

pin needs to be as close to the pin as possible.

The heat of the chip is mainly dissipated through the

PGND pins. Maximizing the copper area around these

pins is preferable. In addition, a solid ground plane is

always helpful for the EMI performance.

The demo board is a good example of layout based on

these principles. Please refer to the EL7562C Application Brief for the layout.

9

Page 10

EL7562C - Preliminary

Monolithic 2 Amp DC:DC Step-down Regulator

EL7562C - Preliminary

General Disclaimer

Specifications contained in this data sheet are in effect as of the publication date shown. Elantec, Inc. reserves the right to make changes in the circuitry or specifications contained herein at any time without notice. Elantec, Inc. assumes no responsibility for the use of any circuits described

herein and makes no representations that they are free from patent infringement.

WARNING - Life Support Policy

Elantec, Inc. products are not authorized for and should not be used

within Life Support Systems without the specific written consent of

Elantec, Inc. Life Support systems are equipment intended to sup-

Elantec Semiconductor, Inc.

675 Trade Zone Blvd.

Milpitas, CA 95035

Telephone: (408) 945-1323

(888) ELANTEC

Fax: (408) 945-9305

European Office: +44-118-977-6020

Japan Technical Center: +81-45-682-5820

port or sustain life and whose failure to perform when properly used

in accordance with instructions provided can be reasonably

expected to result in significant personal injury or death. Users contemplating application of Elantec, Inc. Products in Life Support

Systems are requested to contact Elantec, Inc. factory headquarters

to establish suitable terms & conditions for these applications. Elantec, Inc.’s warranty is limited to replacement of defective

components and does not cover injury to persons or property or

other consequential damages.

October 25, 2001

10

Printed in U.S.A.

Loading...

Loading...