Page 1

EL7556BC

Integrated Adjustable 6 Amp Synchronous Switcher

EL7556BC

Features

• EL7556C/EL7556AC Pincompatible

• Improved temperature and voltage

ranges

• 6A continuous load current

• Precision internal 1% reference

• 1.0V to 3.8V output voltage

• Internal power MOSFETs

• >90% efficiency

• Synchronous switching

• Adjustable slope compensation

• Over-temperature indicator

• Pulse-by-pulse current limiting

• Operates up to 1MHz

• 1.5% typical output accuracy

• Adjustable oscillator with sync

• Remote enable/disable

• Intel P54- and P55-compatible

• VCC2DET interface

• Internal soft-start

Applications

• PC motherboards

• Local high power CPU supplies

• 5V to 1.0V DC:DC conversion

• Portable electronics/instruments

• P54 and P55 regulators

• GTL+ Bus power supply

Ordering Information

Part No Package

EL7556BCM 28-Pin SO - MDP0027

EL7556BCM-T13 28-Pin SO 13” MDP0027

Tape &

Reel Outline #

General Description

The EL7556BC is an adjustable synchronous DC:DC switching regulator optimized for a 5V input and 1.0V-3.8V output. By combining

integrated NMOS power FETS with a fused-lead package, the

EL7556BC can supply up to 6A continuous output current without the

use of external power devices or discrete heat sinks, thereby minimizing design effort and overall system cost.

On-chip resistorless current sensing is used to achieve stable, highly

efficient, current-mode control. The EL7556BC also incorporates the

VCC2DET function to directly interface with the Intel P54 and P55

microprocessors. Depending on the state of VCC2DET, the output

voltage is internally preset to 3.5V or a user-adjustable voltage using

two external resistors. In both internal and external feedback modes

the active-high PWRGD output indicates when the regulator output is

within ±10% of the programmed voltage. An on-board sensor monitors die temperature (OT) for over-temperature conditions and can be

connected directly to OUTEN to provide automatic thermal shutdown.

Adjustable oscillator frequency and slope compensation allow added

flexibility in overall system design.

The EL7556BC is available in a 28-pin SO package and is specified

for operation over the full -40°C to +85°C temperature range.

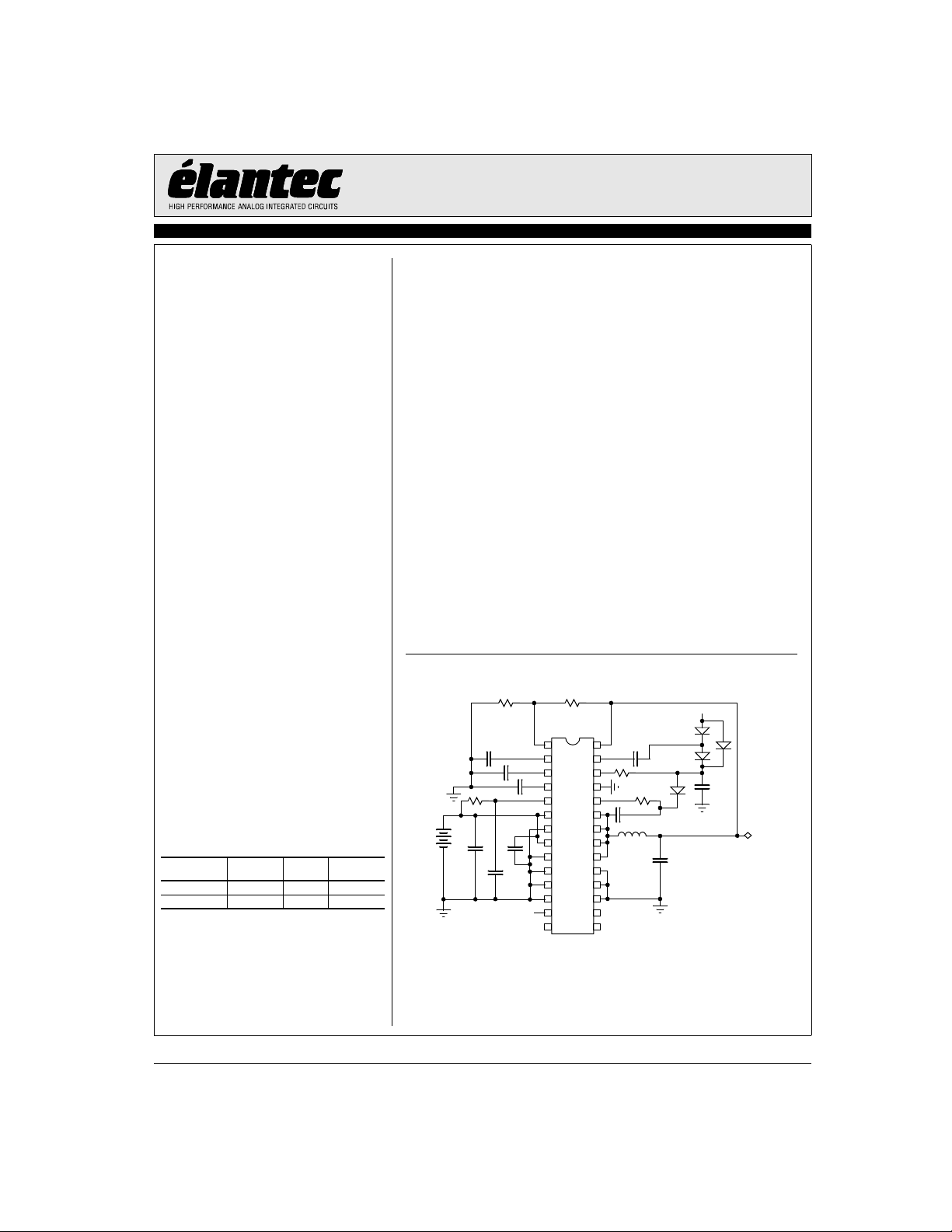

Connection Diagram

C4

R5

5.1Ω

C9

V

IN

660µF

C3

1µF

C12 - 1µF

C3, C4, C5, C6, C7 C8 - ceramic

C5, C11 - ceramic or tantalum

C9 - Sprague 293D337X96R3 2X330µF

C10 - Sprague 293D337X96R3 3X330µF

L1 - Pulse Engineering, PE-53681

D1-D4: BAT54S fast diode

D4 Required for EL7556ACM Only

Manufactured under U.S. Patents No. 5,723,974 and No. 5,793,126

R4 R3

100Ω 150Ω

0.1µF

C7

Connect to VSSP for

external feedback

1

2

39pF

3

C8

220pF

4

5

6

7

C12

8

1µF

9

10

11

12

13

FB1

CREF

C2V

CSLOPE

VSS

COSC

VDD

VIN

VSSP

VIN

VSSP

VSSP

VSSP

VSSP

VSSP

TEST

VSSP

VCC2DET

PWRGD

OUTEN

EL7556BC

28

FB2

CP

VHI

LX

LX

LX

LX

OT

C 5

27

1µF

R1

26

20Ω

25

R6

24

39.2Ω

C 6

23

0.1µF

22

L1

2.5µH

21

20

19

18

17

16

1514

V

IN

D3

D2

D4*

(Optional)

D1

C11

0.22µF

V

OUT =

C10

1mF

1V*(1+R3/R4)

October 5, 2001

Note: All information contained in this data sheet has been carefully checked and is believed to be accurate as of the date of publication; however, this data sheet cannot be a “controlled document”. Current revisions, if any, to these

specifications are maintained at the factory and are available upon your request. We recommend checking the revision level before finalization of your design documentation.

© 2001 Elantec Semiconductor, Inc.

Page 2

EL7556BC

Integrated Adjustable 6 Amp Synchronous Switcher

EL7556BC

Absolute Maximum Ratings (T

Storage Temperature Range -65°C to +150°C

Supply (VIN) 6.0V

Ambient Operating Temperature -40°C to +85°C

= 25°C)

A

Output Pins -0.3V below GND, +0.3V above VDD

Operating Junction Temperature 135°C

Peak Output Current 9A

Important Note:

All parameters having Min/Max specifications are guaranteed. Typ values are for information purposes only. Unless otherwise noted, all tests are at the

specified temperature and are pulsed tests, therefore: TJ = TC = TA.

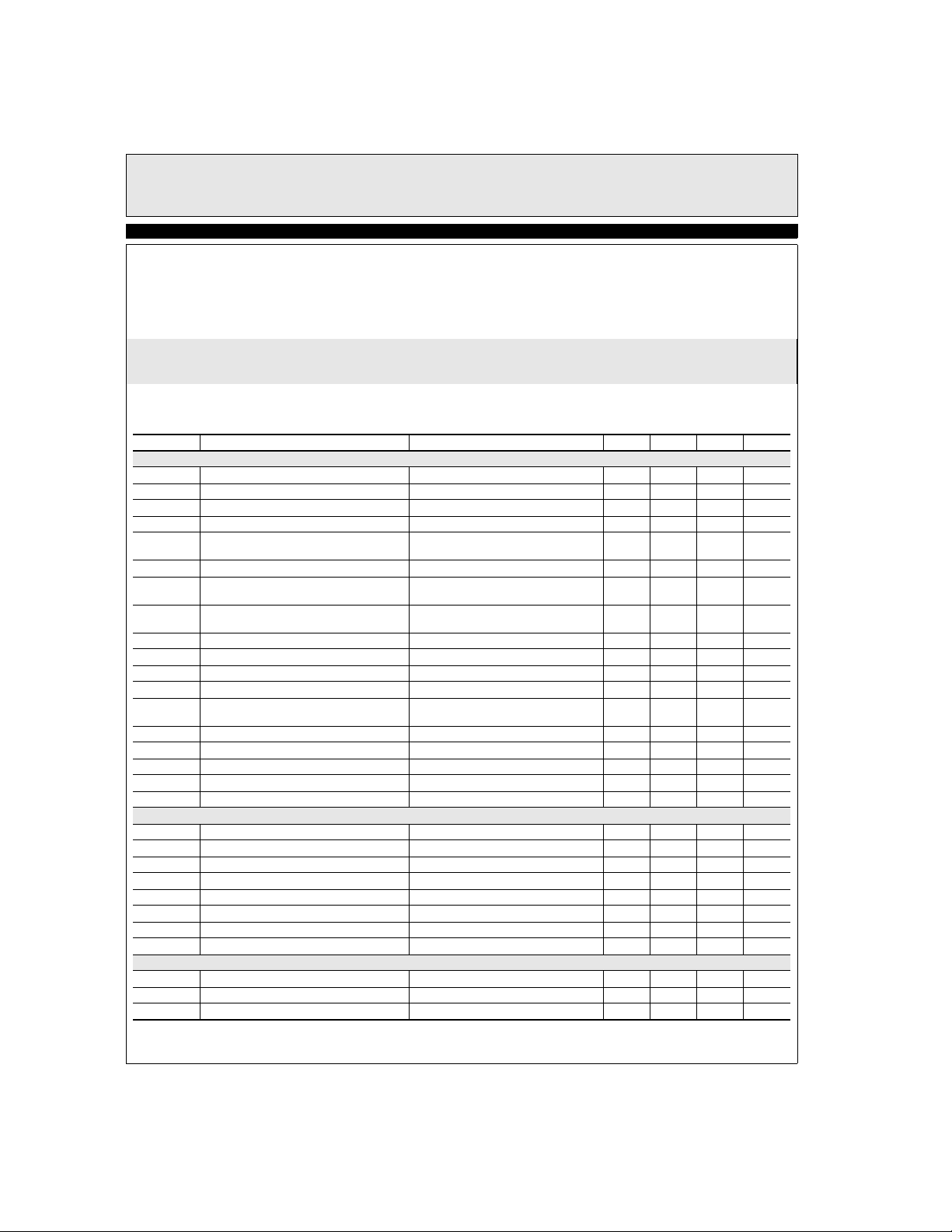

Electrical Characteristics

V

= VIN = 5V, C

DD

Parameter Description Conditions Min Typ Max Unit

General

I

DD

I

DDOFF

I

VIN

V

OUT1

V

OUT2

V

OUTLINE

V

OUTLOAD

R

SHORT

I

I MAX

V

OUTTC

T

OT

T

HYS

V

PWRGD

V

DDOFF

V

DDON

V

HYS

M

SS

D

MAX

Controller - Inputs

I

PUP

I

CSLOPE

I

FB1

R

OT

V

IH

V

IL

VOH

PWGD

V

OL PWGD

Controller - Reference

V

REF

V

REFTC

V

REFLOAD

= 1nF, C

OSC

VDD Supply Current OUTEN = 4V, F

= 470pF, TA = 25°C unless otherwise specified.

SLOPE

= 120kHz 11 25 mA

OSC

VDD Standby Current OUTEN = 0 0.1 mA

V

No Load Current OUTEN = 0 3 5 mA

IN

Output Initial Accuracy VCC2DET = 4V, IL = 3A (See Fig. 1) 3.450 3.500 3.550 V

Output Initial Accuracy VCC2DET = 0V, IL = 3A R

100Ω (See Fig. 1)

= 150Ω, R

3

=

2.450 2.500 2.550 V

4

Output line Regulation VDD = 5V, ±10% -1 1 %

Output Load Regulation 0A<I

Short Circuit Load Resistance IL = 6A, Prior to Continuous Application of

<6A, Relative to IL = 3A. Continu-

LOAD

ous Mode of Operation (See Fig.1)

R

. OUTEN Connected to OT.

SHORT

-1 1 %

100 mΩ

Current Limit 9 A

Output Tempco -40°C<TA<85°C ±1 %

Over Temperature Threshold 135 °C

Over Temperature Hysteresis 40 °C

Power Good Threshold Relative to Programmed

Output Voltage

VCC2SEL = 4V, V

= 3.50V ±6 ±10 ±14 %

OUT

Minimum VDD for Shutdown 3.15 V

Maximum VDD for Startup 4.15 V

Input Hysteresis V

HYS

= V

DDON-VDDOFF

0.5 V

Soft start slope 7 V/mS

Maximum duty cycle 96 %

VCC2DET, OUTEN Pull Up Current VCC2DET, OUTEN = 0 10 14 18 µA

Cslope Charging Current 23 28.5 34 µA

FB1 Input Pull Up Current 2 µA

Over Temperature Pull Up Resistance OT = 0V 30 40 50 kΩ

VCC2DET, OUTEN Input High 4 V

VCC2DET, OUTEN Input Low 0.8 V

Powergood Drive High I

Powergood Drive Low I

Reference Accuracy I

= 1mA 3.5 V

LOAD

= -1mA 1.0 V

LOAD

= 0 1.247 1.260 1.273 V

REF

Reference Voltage Tempco 50 ppm/ºC

Reference Load Regulation 0<I

<100µA 0.5 0.5 %/ºC

LOAD

2

Page 3

EL7556BC

Integrated Adjustable 6 Amp Synchronous Switcher

Electrical Characteristics

V

= VIN = 5V, C

DD

Parameter Description Conditions Min Typ Max Unit

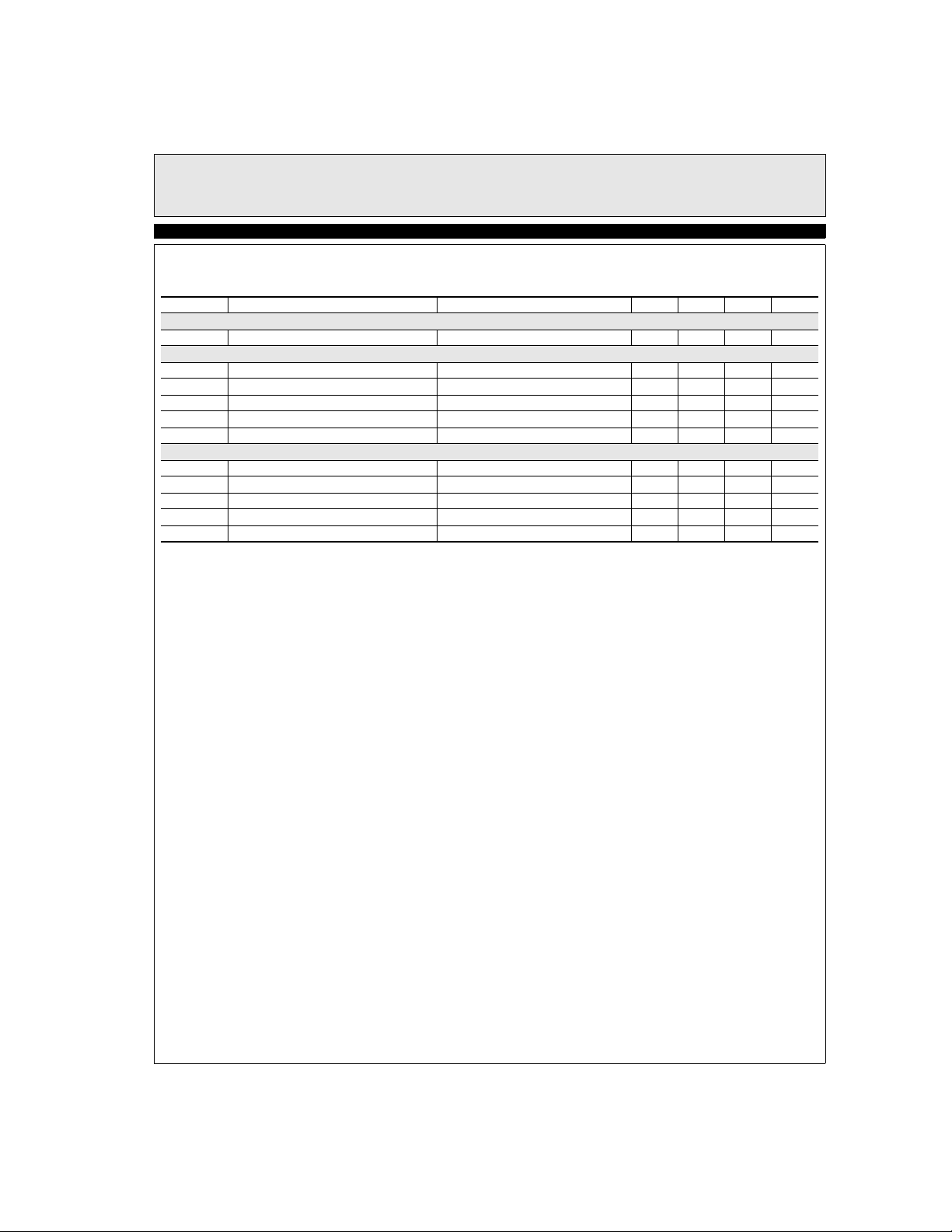

Controller - Doubler

V

C2V

Controller - Oscillator

F

RAMP

I

OSC CHG

I

OSC DIS

F

OSC

t

SYNC

Power - FET

I

LEAK

R

DSON

R

DSONTC

t

BRM

t

LEB

= 1nF, C

OSC

Voltage Doubler Output V

Oscillator Ramp Amplitude 1.2 V

Oscillator Charge Current 0.2V<V

Oscillator Discharge Current 0.2V<V

Oscillator initial accuracy 100 120 140 kHz

Minimum oscillator sync width 50 ns

LX Output Leakage to VSS LX = 0V 100 µA

Composite FET Resistance 18 30 mΩ

R

Tempco 0.1 mΩ/ºC

DSON

FET break before make delay 10 ns

High side FET minimum on time (LEB) 140 ns

= 470pF, TA = 25°C unless otherwise specified.

SLOPE

DD

= 5V, I

= 10mA 7.5 8.1 8.7 V

LOAD

<1.4V 150 µA

OSC

<1.4V 5 mA

OSC

EL7556BC

3

Page 4

EL7556BC

Integrated Adjustable 6 Amp Synchronous Switcher

EL7556BC

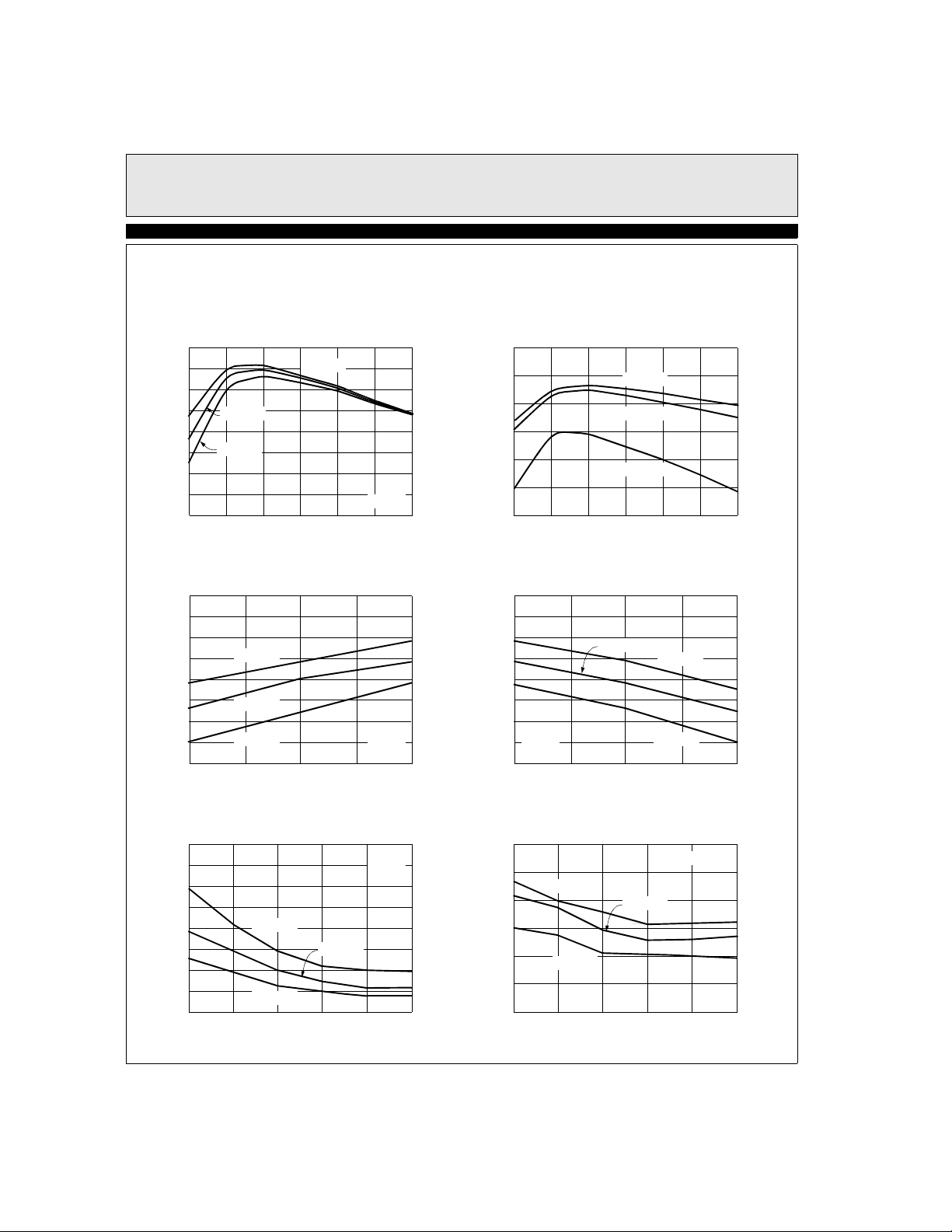

Typical Performance Curves

Efficiency vs I

VDD=VIN=5.0V (±10%)

96

94

LOAD

(V

=3.5V)

OUT

VDD=4.5V

92

90

VDD=5V

88

VDD=5.5V

86

Efficiency (%)

84

82

80

0.5 1.5 2.5 3.5 4.5 5.5

Line Regulation (C

SLOPE

I

OUT

=100pF)

(A)

3.54

3.53

3.52

I

=0.5A

3.51

(V)

3.50

OUT

V

3.49

OUT

I

OUT

=3A

3.48

I

=6A

3.47

3.46

4.5 5.0 5.5

OUT

VIN (V)

TA=25°C

TA=25°C

Efficiency vs I

(VDD=5.0V)

LOAD

100

95

90

VCC=3.5V

VCC=2.5V

85

Efficiency (%)

80

VCC=1V

75

6.5

70

0.5

1.5

Load Regulation (C

2.5 3.5 4.5 6.0

I

(A)

OUT

=100pF)

SLOPE

5.5

3.54

3.53

3.52

3.51

(V)

3.50

OUT

V

3.49

VIN=5V

VIN=5.5V

3.48

OUT

VIN=4.5V

(A)

3.47

TA=25°C

3.46

0.5 3.0 6.0

I

Line Regulation vs C

VDD=VIN=5.0V ±10%

0.8

0.7

0.6

0.5

(±) (%)

0.4

OUT

0.3

∆V

0.2

0.1

0.0

50 75

(I

=3A)

SLOPE

OUT

TA=25°C

V

=3.5A

OUT

V

=2.5A

OUT

V

=1A

OUT

100 125 150 175

C

(pF)

SLOPE

Load Regulation vs C

I

=3A, +3A, -2.5A

OUT

0.6

SLOPE (VIN

=5.0V)

TA=25°C

0.5

V

=3.5A

0.4

(±) (%)

0.3

OUT

∆V

0.2

OUT

V

=2.5A

OUT

V

=1A

OUT

0.1

0.0

50 75 100 125 150 175

C

SLOPE

(pF)

4

Page 5

Typical Performance Curves

EL7556BC

EL7556BC

Integrated Adjustable 6 Amp Synchronous Switcher

Line Regulation vs C

VIN=VDD=5.0V ±10%

0.8

0.7

0.6

0.5

(±) (%)

0.4

OUT

0.3

∆V

0.2

0.1

0.0

50 75

V

(VIN=5.0V, I

1.5

1.0

0.5

0.0

-0.5

(±) (%)

-1.0

OUT

∆V

-1.5

-2.0

-2.5

-3.0

50 75

OUT

SLOPE

TA=25°C

Load Regulation vs C

I

=3A, +3A, -2.5A

OUT

0.8

0.7

SLOPE

TA=25°C

0.6

0.5

I

=6A

OUT

I

=0.5A

OUT

(±) (%)

0.4

OUT

0.3

∆V

0.2

VIN=4.5V

VIN=5.5VVIN=5V

0.1

0.0

50 75

V

Variation vs Programmed Output

OUT

1.5

Voltage [V

IDEAL

=(1+R3/R4)]

100 125 150 175

C

(pF)

SLOPE

vs C

SLOPE

100 125 150 175

C

(pF)

SLOPE

=0.5A)

LOAD

TA=25°C

1.0

C

V

=1V

OUT

V

=2.5V

OUT

V

=3.5V

OUT

TA=25°C

100 125 150 175

C

(pF)

SLOPE

0.5

(%)

OUT

0.0

-0.5

Deviation in V

-1.0

Loop Gain Induced Error

-1.5

1.0 1.5

S

L

O

P

E

=

1

C

0

O

0

S

p

C

=

F

2

2

0

p

F

2.0 2.5 3.0 4.0

V

(V)

IDEAL

3.5

F

520

510

500

490

480

470

vs Temperature

OSC

VDD=4.5V

VDD=5.5V

VDD=5V

F

vs C

OSC

OSC

1000

TA=25°C

1000

(kHz)

100

OSC

F

(kHz)

OSC

F

10

460

1

10

C

(pF)

OSC

100k100 1k

450

20

0

40 60 80 140

100

120

Temperature (°C)

5

Page 6

EL7556BC

Integrated Adjustable 6 Amp Synchronous Switcher

EL7556BC

Typical Performance Curves

I(VDD) + I(VIN) vs F

60

TA=25°C

OUTEN=V

50

40

30

(mA)

Q

I

20

10

0

200 1000400 600 800 200 1000400 600 800

I(VDD) vs F

50

TA=25°C

45

OUTEN=V

40

35

30

25

(mA)

DD

I

20

15

10

5

0

200 1000400 600 800

OSC

OSC

DD

DD

VDD=5.5V

VDD=4.5V

F

(kHz)

OSC

VDD=5.5V

VDD=4.5V

F

(kHz)

OSC

VDD=5V

Continuous ModeDiscontinuous Mode

VDD=5V

(mA)

VIN

I

IN

(mA) + IV

DD

I

I(VIN) vs F

16

TA=25°C

14

OUTEN=V

12

10

8

6

4

2

0

IDD + IVIN vs F

2.0

1.5

1.0

10

OSC

DD

F

(kHz)

OSC

OSC

VDD=5.5V

VDD=4.5V

100 100

F

(kHz)

OSC

VDD=5.5V

VDD=5V

VDD=4.5V

Continuous ModeDiscontinuous Mode

VDD=5V

40

30

20

(mA))

Q

I

10

Power On Reset

TA=25°C

OUTEN=V

0

2.5

DD

3.0

3.5 4.5 5.0

VDD(V)

Minimum Output Voltage vs F

2.3

TJ=120°C

2.1

F

=500k

OSC

4.0

1.9

1.7

(V)

1.5

OUT

V

1.3

1.1

0.9

0.7

OSC

VDD=5.5V

VDD=5V

VDD=4.5V

F

(kHz)

OSC

6

Page 7

Typical Performance Curves

EL7556BC

EL7556BC

Integrated Adjustable 6 Amp Synchronous Switcher

ΘJA vs Cu Area

41

39

37

35

33

(°C/W)

JA

Θ

31

29

27

25

0.00 3.00

R

vs Temperature

DSON

38

36

34

32

30

(m Ω)

28

DSON

R

26

24

22

20

0

Board with no

Components

Board with

Inductor

Bare Cu Area (in2)

Temperature (°C)

Maximum I

7556 Demo Board (31°C/W)

8.0

7.5

7.0

6.5

(A)

6.0

LOAD

I

5.5

5.0

4.5

OUTEN connected to OT

6.004.002.001.00 5.00

125755025 100

4.0

25 50

vs Temperature

LOAD

4535

TA (°C)

100 LFPM

Still Air

55

70604030 65

7

Page 8

EL7556BC

Integrated Adjustable 6 Amp Synchronous Switcher

EL7556BC

Pin Descriptions

I = Input, O = Output, S = Supply

Pin Number Pin Name Pin Type Function

1 FB1 I Voltage feedback pin for the buck regulator. Active when VCC2DET is logic low. Normally connected to exter-

2 CREF I Bandgap reference bypass capacitor. Typically 0.1µF to VSS.

3 CSLOPE I Slope compensation capacitor. Ramp width corresponds to LX duty cycle. C

4 COSC I Oscillator timing capacitor. F

5 VDD S Power Supply for PWM control circuitry. Normally the same potential as VIN.

6 VIN S Power supply for the buck regulator. Connected to the drain of the high-side NMOS FET.

7 VSSP S Ground return for the buck regulator. Connected to the source of the low-side synchronous NMOS FET.

8 VIN S Same as pin 6.

9 VSSP S Same as pin 7.

10 VSSP S Same as pin 7.

11 VSSP S Same as pin 7.

12 VSSP S Same as pin 7.

13 VCC2DET I VCC2DET interface logic input. When driven to logic 1 V

14 OUTEN I The switching regulator output is enabled when logic 1. The reference voltage output operates whenever the

15 OT O Over temperature indicator. Normally high. Pulls low when die temperature exceeds 135°C, returns to the high

16 PWRGD O Power good window comparator output. Logic 1 when regulator output is within ±10% of programmed voltage.

17 TEST I Test pin. Must be connected to VSSP in normal operation.

18 VSSP S Same as pin 7.

19 VSSP S Same as pin 7.

20 LX O Inductor drive pin. High current switching output whose average voltage equals the regulator output voltage.

21 LX O Same as pin 20.

22 LX O Same as pin 20.

23 LX O Same as pin 20.

24 VHI I Gate drive to high-side driver. Bootstrapped from LX with a 0.1µF capacitor.

25 VSS S Ground return for the control circuitry.

26 C2V I Connected to voltage doubler output. Supplies gate drive to the low-side driver.

27 CP O Drives the negative side of charge pump capacitor at one-half the oscillator frequency F

28 FB2 I Voltage feedback pin. Active when VCC2DET is logic 1. Internally preset to V

nal resistor divider between VOUT and GND. A 2µA pull-up current forces VOUT to VSS in the event that

FB1is floating and VCC2DET is inadvertently connected to GND.

1:1.5.

(Hz) can be approximated by: F

OSC

FB1 to determine V

power supply is qualified (VDD>VPOR) regardless of the state of this pin.

state when die temperature has cooled to 100°C.

OUT

: V

= 1.0V*(1+R3/R4).

OUT

to C

SLOPE

(Hz) = 0.0001/C

OSC

= 3.500V. When driven to logic 0 the PWM uses

OUT

OUT

ratio is normally

OSC

. C

OSC

.

OSC

= 3.5V.

OSC

in Farads.

8

Page 9

Block Diagram

EL7556BC

EL7556BC

Integrated Adjustable 6 Amp Synchronous Switcher

Pin 25

PWRGD, Pin 16

CP, Pin 27

C2V, Pin 26

VHI, Pin 24

VDD and VIN,

Pin 5,6,8

LX, Pin 20-23

VSSP, Pin 9-12,

18-19

+

-

SS,

OT, Pin 15

V

V2X

-+-

2-1 MUX

Zero Cross Detect

Q

DELAY

LEB T

-

+

Current

-

+

+

1.26V

Q

R

S

PWM

-

+

Current Limit

Σ

VDD

-

+

4V

S

FF

R

SS

C

SS

R

S

UVLO

-

+

VDD

Over Temp Sensor

R

-

+

FB1, Pin1

FB2, Pin 28

VCCDET, Pin 13

CSLOPE, Pin 3

CREF, Pin 27

OUTEN, Pin 14

COSC, Pin 4

9

Page 10

EL7556BC

Integrated Adjustable 6 Amp Synchronous Switcher

EL7556BC

Applications Information

Circuit Description

General

The EL7556BC is a fixed frequency, current mode controlled DC:DC converter with integrated N-channel

power MOSFETS and a high precision reference. The

device incorporates all of the active circuitry required to

implement a cost effective, user-programmable 6A synchronous buck converter suitable for use in CPU power

supplies. By combining fused-lead packaging technology with an efficient synchronous switching

architecture, high power outputs (21W) can be realized

without the use of discrete external heat sinks.

Theory of Operation

The EL7556BC is composed of 7 major blocks:

1. PWM Controller

2. Output Voltage Mode Select

3. NMOS Power FETS and Drive Circuitry

4. Bandgap Reference

5. Oscillator

6. Temperature Sensor

7. Power Good and Power On Reset

PWM Controller

The EL7556BC regulates output voltage through the use

of current-mode controlled pulse width modulation. The

three main elements in a PWM controller are the feedback loop and reference, a pulse width modulator whose

duty cycle is controlled by the feedback error signal, and

a filter which averages the logic level modulator output.

In a step-down (buck) converter, the feedback loop

forces the time-averaged output of the modulator to

equal the desired output voltage. Unlike pure voltagemode control systems current-mode control utilizes dual

feedback loops to provide both output voltage and

inductor current information to the controller. The voltage loop minimizes DC and transient errors in the output

voltage by adjusting the PWM duty-cycle in response to

changes in line or load conditions. Since the output voltage is equal to the time-average of the modulator output

the relatively large LC time constants found in power

supply applications generally results in low bandwidth

and poor transient response. By directly monitoring

changes in inductor current via a series sense resistor the

controller’s response time is not entirely limited by the

output LC filter and can react more quickly to changes in

line or load conditions. This feed-forward characteristic

also simplifies AC loop compensation since it adds a

zero to the overall loop response. Through proper selection of the current-feedback to voltage-feedback ratio,

the overall loop response will approach a one pole system. The resulting system offers several advantages over

traditional voltage control systems, including simpler

loop compensation, pulse by pulse current limiting,

rapid response to line variation and good load step

response.

The heart of the controller is a triple-input direct summing comparator which sums voltage feedback, current

feedback and slope compensating ramp signals together.

Slope compensation is required to prevent system instability which occurs in current-mode topologies

operating at duty-cycles greater than 50% and is also

used to define the open-loop gain of the overall system.

The compensation ramp amplitude is user adjustable and

is set using a single external capacitor (CSLOPE). Each

comparator input is weighted and determines the load

and line regulation characteristics of the system. Current

feedback is measured by sensing the inductor current

flowing through the high-side switch whenever it is conducting. At the beginning of each oscillator period the

high-side NMOS switch is turned on and CSLOPE

ramps positively from its reset state (VREF potential).

The comparator inputs are gated off for a minimum

period of time (LEB) after the high-side switch is turned

on to allow the system to settle. The Leading Edge

Blanking (LEB) period prevents the detection of erroneous voltages at the comparator inputs due to switching

noise. When programming low regulator output voltages

the LEB delay will limit the maximum operating frequency of the circuit since the LEB will result in a

minimum duty-cycle regardless of the PWM error voltage. This relationship is shown in the performance

curves. If the inductor current exceeds the maximum

current limit (I

), a secondary over-current com-

LMAX

10

Page 11

EL7556BC

Integrated Adjustable 6 Amp Synchronous Switcher

EL7556BC

parator will terminate the high-side switch. If I

LMAX

has not been reached, the regulator output voltage is then

compared to the reference voltage VREF. The resultant

error voltage is summed with the current feedback and

slope compensation ramp. The high-side switch remains

on until all three comparator inputs have summed to

zero, at which time the high-side switch is turned off and

the low-side switch is turned on. In order to eliminate

cross-conduction of the high-side and low-side switches

a 10ns break-before-make delay is incorporated in the

switch driver circuitry. In the continuous mode of operation the low-side switch will remain on until the end of

the oscillator period. In order to improve the low current

efficiency of the EL7556BC, a zero-crossing comparator

senses when the inductor transitions through zero. Turning off the low-side switch at zero inductor current

prevents forward conduction through the internal clamping diodes (LX to VSSP) when the low-side switch turns

off, reducing power dissipation. The output enable

(OUTEN) input allows the regulator output to be disabled by an external logic control signal.

Output Voltage Mode Select

The VCC2DET multiplexes the FB1 and FB2 pins to the

PWM controller. A logic 1 on VCC2DET selects the

FB2 input and forces the output voltage to the internally

programmed value of 3.50V. A logic zero on VCC2DET

selects FB1 and allows the output to be programmed

from 1.0 to 3.8V. In general:

drive for both the high-side and low-side switches is

derived through a charge pump consisting of the CP pin

and external components D1-D3 and C5-C6. The CP

output is a low resistance inverter driven at one-half the

oscillator frequency. This is used in conjunction with

D2-D3 to generate a 7.5V (typical) voltage on the C2V

pin which provides gate drive to the low-side NMOS

switch and associated level shifter. In order to use an

NMOS switch for the high-side drive it is necessary to

drive the gate voltage above the source voltage (LX).

This is accomplished by boot-strapping the VHI pin

above the C2V voltage with capacitor C6 and diode D1.

When the low-side switch is turned on the LX voltage is

close to GND potential and capacitor C6 is charged

through diodes D1-D3 to approximately 6.9V. At the

beginning of the next cycle the high side switch turns on

and the LX pin begins to rise from GND to VDD potential. As the LX pin rises the positive plate of capacitor

C6 follows and eventually reaches a value of approximately 11.2V, for VDD=5V. This voltage is then level

shifted and used to drive the gate of the high-side FET,

via the VHI pin.

Reference

A 1% temperature compensated band gap reference is

integrated in the EL7556BC. The external CREF capacitor acts as the dominant pole of the amplifier and can be

increased in size to maximize transient noise rejection.

A value of 0.1uF is recommended.

R

3

1V 1

× Volt×=

------

+

R

4

V

OUT

However, due to the relatively low open loop gain of the

system, gain errors will occur as the output voltage and

loop-gain are changed. This is shown in the performance

curves. (The output voltage is factory trimmed to minimize error at a 2.50V output). A 2uA pull-up current

from FB1 to VIN forces VOUT to GND in the event that

FB1 is not used and the VCC2DET is inadvertently toggled between the internal and external feedback mode of

operation.

NMOS Power FETS and Drive Circuitry

The EL7556BC integrates low resistance (25mΩ)

NMOS FETS to achieve high efficiency at 6A. Gate

Oscillator

The system clock is generated by an internal relaxation

oscillator with a maximum duty-cycle of approximately

96%. Operating frequency can be adjusted through the

COSC pin or can be driven by an external clock source.

If the oscillator is driven by an external source, care

must be taken in the selection of CSLOPE. Since the

COSC and CSLOPE values determine the open loop

gain of the system, changes to COSC require corresponding changes to CSLOPE in order to maintain a

constant gain ratio. The recommended ratio of COSC to

CSLOPE is 1.5:1

Temperature Sensor

An internal temperature sensor continuously monitors

die temperature. In the event that die temperature

11

Page 12

EL7556BC

Integrated Adjustable 6 Amp Synchronous Switcher

EL7556BC

exceeds the thermal trip-point, the OT pin will output a

logic 0. The upper and lower trip points are set to 135 ºC

and 100ºC respectively. To enable thermal shutdown

this pin should be tied directly to OUTEN. Use of this

feature is recommended during normal operation

Power Good and Power On Reset

During power up the output regulator will be disabled

until VIN reaches a value of approximately 4.0V.

Approximately 500mV of hysteresis is present to eliminate noise induced oscillations.

Under-voltage and over-voltage conditions on the regulator output are detected through an internal window

comparator. A logic 1 on the PWRGD output indicates

that regulated output voltage is within ±10% of the nominally programmed output voltage. Although small, the

typical values of the PWRGD threshold will vary with

changes to external feedback (and resultant loop gain) of

the system. This dependence is shown in the typical performance curves.

If the thermal shutdown pin is connected to OUTEN the

IC will enter thermal shutdown when the maximum

junction temperature is reached. For a thermal shutdown

of 135ºC and power dissipation of 2.2W the ambient

temperature is limited to a maximum value of 67ºC (typical). The ambient temperature range can be extended

with the application of air flow. For example, the addition of 100LFM reduces the thermal resistance by

approximately 15% and can extend the operating ambient to 77ºC (typical). Since the thermal performance of

the IC is heavily dependent on the board layout, the system designer should exercise care during the design

phase to ensure that the IC will operate under the worstcase environmental conditions.

Thermal Management

The EL7556BC utilizes “fused lead” packaging technology in conjunction with the system board layout to

achieve a lower thermal resistance than typically found

in standard 28-pin SO packages. By fusing (or connecting) multiple external leads to the die substrate within

the package, a very conductive heat path to the outside

of the package is created. This conductive heat path

MUST then be connected to a heat sinking area on the

PCB in order to dissipate heat out and away from the

device. The conductive paths for the EL7556BC package are the fused leads: # 7, 9, 10, 11, 12, 18, and 19. If

a sufficient amount of PCB metal area is connected to

the fused package leads, a junction-to-ambient thermal

resistance of approximately 31°C/W can be achieved

(compared to 78°C/W for a standard SO28 package).

The general relationship between PCB heat-sinking

metal area and the thermal resistance for this package is

shown in the Performance Curves section of this data

sheet. It can be readily seen that the thermal resistance

for this package approaches an asymptotic value of

approximately 31°C/W without any airflow. Additional

information can be found in Application Note #8 (Measuring the Thermal Resistance of Power Surface-Mount

Packages).

12

Page 13

EL7556BC

Integrated Adjustable 6 Amp Synchronous Switcher

EL7556BC

General Disclaimer

Specifications contained in this data sheet are in effect as of the publication date shown. Elantec, Inc. reserves the right to make changes in the circuitry or specifications contained herein at any time without notice. Elantec, Inc. assumes no responsibility for the use of any circuits described

herein and makes no representations that they are free from patent infringement.

WARNING - Life Support Policy

Elantec, Inc. products are not authorized for and should not be used

within Life Support Systems without the specific written consent of

Elantec, Inc. Life Support systems are equipment intended to sup-

Elantec Semiconductor, Inc.

675 Trade Zone Blvd.

Milpitas, CA 95035

Telephone: (408) 945-1323

(888) ELANTEC

Fax: (408) 945-9305

European Office: +44-118-977-6020

Japan Technical Center: +81-45-682-5820

port or sustain life and whose failure to perform when properly used

in accordance with instructions provided can be reasonably

expected to result in significant personal injury or death. Users contemplating application of Elantec, Inc. Products in Life Support

Systems are requested to contact Elantec, Inc. factory headquarters

to establish suitable terms & conditions for these applications. Elantec, Inc.’s warranty is limited to replacement of defective

components and does not cover injury to persons or property or

other consequential damages.

October 5, 2001

13

Printed in U.S.A.

Loading...

Loading...