Page 1

TRIPLE INDEPENDENT LOGIC INTERFACED HALF BRIDGES

MICROTECHNOLOGY

HTTP://WWW.APEXMICROTECH.COM (800) 546-APEX (800) 546-2739

FEATURES

• COMPATIBLE WITH PWM FREQUENCIES UP TO 30KHZ

• 50V TO 500 V MOTOR SUPPLY

• 20A CONTINUOUS OUTPUT CURRENT

• HCMOS COMPATIBLE SCHMITT TRIGGER LOGIC INPUTS

• SEPARATE EMITTER OUTPUTS FOR NEGATIVE RAIL

CURRENT SENSE

• SLEEP MODE

• WIDE RANGE FOR GATE DRIVE AND LOGIC SUPPLIES

APPLICATIONS

HIGH POWER CIRCUITS FOR DIGITAL CONTROL OF:

• THREE AXIS MOTION USING BRUSH TYPE MOTORS

• THREE PHASE BRUSHLESS DC MOTOR DRIVE

• THREE PHASE AC MOTOR DRIVE

• THREE PHASE STEP MOTOR DRIVE

DESCRIPTION

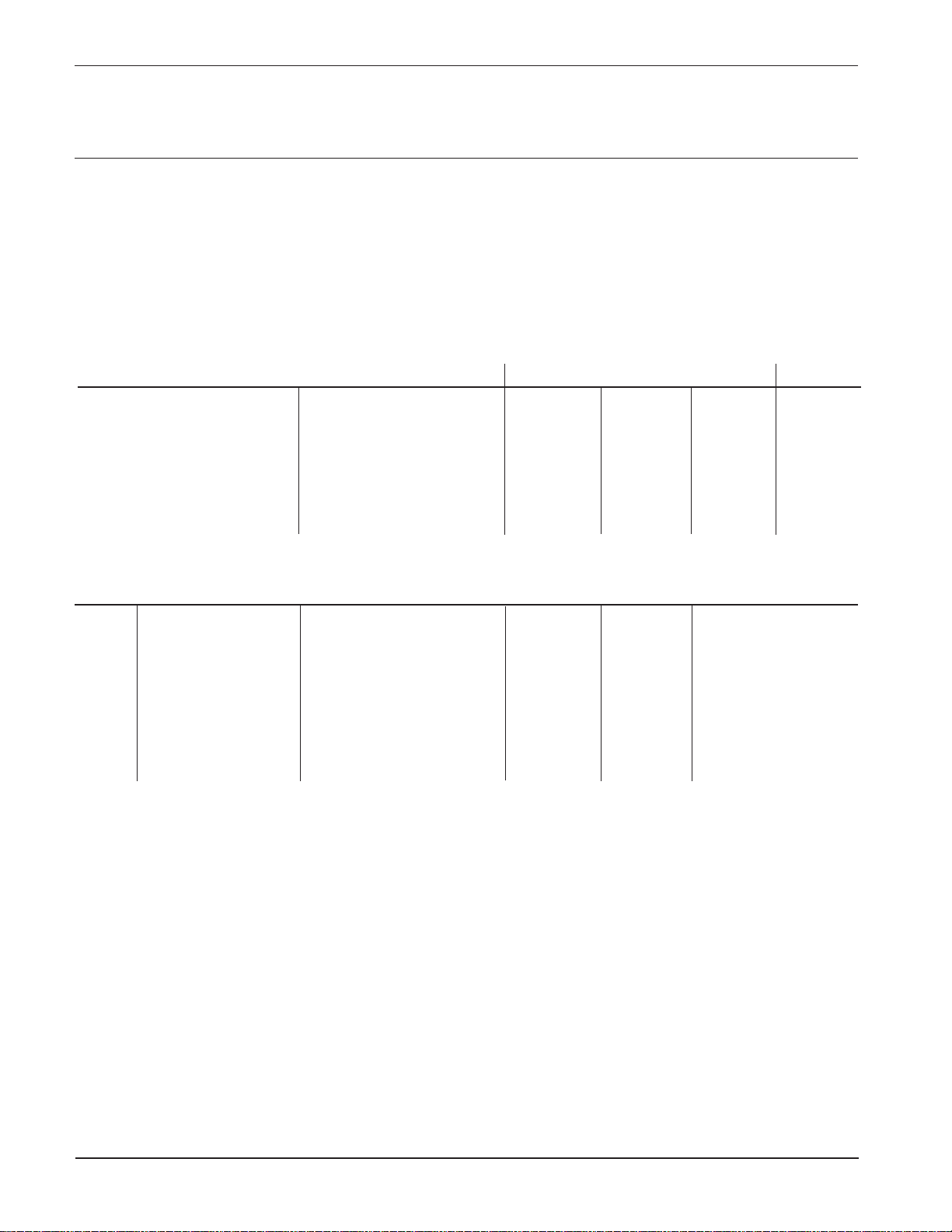

The EB01 consists of three independent IGBT half bridges

with drivers. The drivers may be interfaced with CMOS or

HCMOS level logic.

EBO1

12

Hin 1

SD

11

Lin 1

10

Half

Bridge

Driver

IGBT

Half

Bridge

Output

13

14

15

HV1

OUT1

E1

V

,Logic Ground

ss

V

,Logic Supply

dd

V 1

cc

Hin 2

Lin2

V 2

cc

Hin3

Lin 3

V 3

cc

9

8

Half

7

6

5

4

3

2

1

Bridge

Driver

Half

Bridge

Driver

IGBT

Half

Bridge

Output

IGBT

Half

Bridge

Output

16

17

18

19

20

21

22

23

24

HVRTN1

HV2

OUT2

E2

HVRTN2

HV3

OUT3

E3

HVRTN3

FIGURE 1. BLOCK DIAGRAM

APEX MICROTECHNOLOGY CORPORATION • TELEPHONE (520) 690-8600 • FAX (520) 888-3329 • ORDERS (520) 690-8601 • EMAIL prodlit@apexmicrotech.com

Page 2

EB01

ABSOLUTE MAXIMUM RATINGS

SPECIFICATIONS

ABSOLUTE MAXIMUM RATINGS

HIGH VOLTAGE SUPPLY, HV5 500V

OUTPUT CURRENT, peak1 28A

OUTPUT CURRENT, continuous 20A

DRIVER SUPPLY VOLTAGE, Vcc 20V

LOGIC SUPPLY VOLTAGE, Vdd 20V

LOGIC INPUT VOLTAGE -0.3V to Vdd + 0.3V

POWER DISSIPATION, internal2 179 Watts

THERMAL RESISTANCE TO CASE3 2.1°C/Watt

TEMPERATURE, pin solder, 10s 300°C

TEMPERATURE, junction4 150°C

TEMPERATURE RANGE, storage –65 to +150°C

OPERATING TEMPERATURE, case –25 to +85°C

SPECIFICATIONS

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

POSITIVE OUTPUT VOLTAGE I

HV=500V, Fpwm=30kHz, L=100 µH

NEGATIVE OUTPUT VOLTAGE " -2.7 2.7 Volts

POSITIVE EDGE DELAY " 1000 n-second

RISETIME " 500 n-second

NEGATIVE EDGE DELAY " 1000 n-second

FALLTIME " 500 n-second

PWM FREQUENCY Set by external circuitry 30 kHz

INPUT IMPEDANCE Set by internal resistors 50 k-ohm

INPUT AND OUTPUT SIGNALS

PIN SYMBOL FUNCTION PIN SYMBOL FUNCTION

1 V

2 Lin3 Low drive logic in 3 14 OUT1 Section 1 output

3 Hin3 High drive logic in 3 15 E1 Section 1 emitter

4 V

5 V

6 Lin2 Low drive logic in 2 18 OUT 2 Section 2 output

7 V

8 Hin2 High drive logic in 2 20 HVRTN2 Section 2 return

9 V

10 Lin1 Low drive logic in 1 22 OUT 3 Section 3 output

11 SD Shut down logic in 23 E3 Section 3 emitter

12 Hin1 High drive logic in 1 24 HVRTN 3 Section 3 return

NOTES: 1. Guaranteed but not tested.

2. Total package power dissipation at 25°C case tempterature with three outputs active.

3. Each IGBT.

4. Long term operation at the maximum junction temperature will result in reduced product life. Lower internal temperature by

reducing internal dissipation or using better heatsinking to achieve high MTTF.

5. Derate the High Voltage Supply V

3 Gate supply 3 13 HV1 High Voltage supply 1

cc

Logic supply 16 HVRTN1 Section 1 return

dd

2 Gate supply 2 17 HV2 High voltage supply 2

cc

Logic ground 19 E2 Section 2 emitter

ss

1 Gate supply 1 21 HV3 High voltage supply 3

cc

INPUT

A logic level input independently controls each IGBT in

the half bridge. A logic level high turns on the IGBT; a logic

level low turns it off. A common shutdown input turns off

all IGBTs when high.

All inputs are Schmitt triggers with the upper threshold at

and the lower threshold at 1/3 Vdd. This comfortably

2/3V

dd

interfaces with CMOS or HCMOS provided that the V

logic family and the EB01 are the same.

TTL families may be used if a pull-up to the logic supply

is added to the TTL gates driving the EBO1, and V

the EB01 is the same supply as the logic supply for the

TTL family.

An open signal connector pulls the shut down input high and

all other inputs low, insuring that all outputs are off.

=20A; Vcc=10.8V , Vdd=5V; 497.3 502.7 Volts

OUT

by -0.133% per °C below 25°C.

s

However, input impedance is 50k on all inputs; therefore, if

one input is open circuited a high radiated noise level could

supuriousy turn on an IGBT.

OUTPUT

Each output section consists of a switching mode IGBT

for the

dd

dd

for

half bridge. Separate HV supply, emitter, and HV return lines

are provided for each section.

The IGBTs are conservatively rated to carry 20A. At 20A

the saturation voltage is 2.7V maximum.

Each IGBT has a high-speed diode connected in antiparallel. When switching an inductive load this diode will

conduct, and the drop at 20A will be 2.7V maximum.

APEX MICROTECHNOLOGY CORPORATION • 5980 NORTH SHANNON ROAD • TUCSON, ARIZONA 85741 • USA • APPLICATIONS HOTLINE: 1 (800) 546-2739

Page 3

TYPICAL PERFORMANCE

GRAPHS

EB01

75

POWER DERATING

65

58W

55

45

35

EACH ACTIVE

OUTPUT TRANSISTOR

25

INTERNAL POWER DISSIPATION, (W)

0 75 100

25 50 125

CASE TEMPERATURE, (°C)

31W

85

CONTINUOUS AMPS

20

18

16

14

12

CONTINUOUS AMPS, (A)

10

25 50 75 100 125

CASE TEMPERATURE, (°C)

V RATING vs TEMPERATURE

s

1.1

1.0

s

V (NORMALIZED)

0.9

-50 0 50 100 150

T (°C)

PACKAGE SPECIFICATIONS

DIP9 PACKAGE

WEIGHT: 69 g or 2.4 oz

DIMENSIONS ARE IN INCHES

ALTERNATE UNITS ARE [MM]

APEX MICROTECHNOLOGY CORPORATION • TELEPHONE (520) 690-8600 • FAX (520) 888-3329 • ORDERS (520) 690-8601 • EMAIL prodlit@apexmicrotech.com

Page 4

EB01

OPERATING

CONSIDERATIONS

POWER SUPPLY REQUIREMENTS

SUPPLY VOLTAGE MAX CURRENT

HV1 50V to 500V 20A, continuous, 28A peak

HV2 50V to 500V 20A, continuous, 28A peak

HV3 50V to 500V 20A, continuous, 28A peak

Vcc1 10V to 20V 10mA

Vcc2 10V to 20V 10mA

Vcc3 10V to 20V 10mA

Vdd 4.5 to 20V 10mA

HV1, HV2, and HV3 may be used independently, or may

be one supply. Also V

independently or tied together. The V

compatible with the input logic. If a high v oltage logic such as

CMOS is used it may be tied with the V

requires a 5V±10% supply

1, Vcc2, and Vcc3 may be used

cc

supply must be

dd

supplies. HCMOS

cc

SPECIAL CONSIDERATIONS

GENERAL

The EB01 is designed to give the user maximum fl exibility

in a digital or DSP based motion control system. Ther mal,

overvoltage, overcurrent, and crossfi re protection circuits are

part of the user’s design.

Users should read Application Note 1, "General Operating

Considerations;” and Application Note 30, “PWM Basics”

for much useful information in applying this part. These

Application Notes are in the “Power Integrated Circuits Data

Book” and on line at www.apexmicrotech.com.

GROUNDING AND BYPASSING

As in any high power PWM system, grounding and

bypassing are one of the keys to success. The EB01 is

capable of generating 20 kW pulses with 100 n-second rise

and fall times. If improper ly grounded or bypassed this can

cause horrible conducted and radiated EMI.

In order to reduce conducted EMI, the EB01 provides a

separate power ground, named HVRTN, f or each high voltage

supply. These grounds are electrically isolated from the logic

ground (V

current ground loops. Ho w ever, more than 5V offset between

the grounds will destroy the EB01. Apex recommends

back to back high current diodes between logic and power

grounds; this will maintain isolation but keep offset at a

safe level. All grounds should tie together at one common

point in the system.

In order to reduce radiated EMI, Apex recommends a

400 µF or larger capacitor between HV and HVRTN. This

capacitor should be a a switching power grade electrolytic

capacitor with ESR rated at 20 kHz. This capacitor should be

placed physically as close to the EB01 as possible.

However, such a capacitor will typically have a few

hundred milli-ohms or so ESR. Therefore, each section

must also be bypassed with a low ESR 1µF or larger

ceramic capacitor.

In order to minimize radiated noise it is necessary to

minimize the area of the loop containing high frequency

) and each other. This isolation eliminates high

ss

current. (The siz e of the antenna.) Theref ore the 1µF ceramic

capacitors should bypass each HV to its return right at

the pins the EB01.

SHOOT THROUGH PROTECTION

IGBTs have a relatively short turn on delay, and a long

turn off delay. Unlike most semiconductor devices the turn off

delay cannot be improved very much by drive circuit design.

Therefore, if the turn on input to an IGBT in a half bridge

circuit is applied simultaneously with the turn off input to

the other IGBT in that half bridge, there will be a time when

both IGBTs are simultaneously on. This will shor t the power

rails through the IGBTs, causing excessiv e pow er dissipation

and very high EMI.

To avoid the shoot through condition the turn on of one

IGBT must be delayed long enough for the other in the same

half bridge to have completely turned off.

A delay of at least 1.5 µ-seconds is required for the EB01.

This delay must be provided after turning off Lin before Hin

of the same half bridge may be turned on; likewise it must

be provided after turning off Hin before Lin of the same half

bridge may be turned on.

PROTECTION CIRCUITS

The EB01 does not include protection circuits.

However, there is a shut down input which will turn off all

IGBTs when at logic “1”. This input may be used with user

designed temperature sensing and current sensing circuits

to shut down the IGBTs in the event of a detected unsafe

condition. This is recommended since the IGBTs may be

turned off this way even if the normal input logic or DSP

programming is faulty.

START-UP REQUIREMENTS

In order for an IGBT to be turned on, the corresponding

logic input signal must make its positive transition after SD

has been low for at least 1 µ-second.

The lower rail IGBT in the half bridge must be turned on

for at least 2 µ-seconds to charge the bootstrap capacitor

before the top rail IGBT can be turned on. This must be done

no more than 330 µ-seconds prior to turning on the top rail

IGBT. However, if the load pulls the output to ground, the

positive rail IGBT can be turned on without fi rst briefl y turning

on the negative rail IGBT.

An internal fl oating supply is used to enhance the operation

of the bootstrap bias circuit. This allows the top rail IGBTs to

be held on indefi nitely once turned on.

HEATSINK

The EB01 should be provided with suffi cient heatsink to

dissipate 179 watts while holding a case temperature of

25°C when operating at 500V, 20A, 30kHz and 3 sections

simultaneously providing maximum current.

The dissipation is composed of conduction losses (I

up to 54 watts per half bridge and switching losses of about 4

watts per half bridge. The conduction losses are proportional

; s witching losses are proportional to HV supply voltage

to I

out

and to switching frequency.

outxVsat

)

This data sheet has been carefully checked and is believed to be reliable, however, no responsibility is assumed for possible inaccuracies or omissions. All specifi ciations are subject to change without notice.

APEX MICROTECHNOLOGY CORPORATION • 5980 NORTH SHANNON ROAD • TUCSON, ARIZONA 85741 • USA • APPLICATIONS HOTLINE: 1 (800) 546-2739

EBO1U REV. B JANUARY 2001 © 2001 Apex Microtechnology Corporation

Loading...

Loading...