Page 1

Flat Proximity Sensor

E2K-F

Saves Installation Space with a

Thickness of Only 10 mm

■ Flat, Built-in Amplifier Models offer excellent space

efficiency and provide a 10-mm sensing distance.

■ Detects both metallic and nonmetallic objects (water, oil,

glass, plastic, etc.).

■ Direct mounting onto a metallic surface is possible.

Be sure to read Safety Precautions on

page 3.

Ordering Information

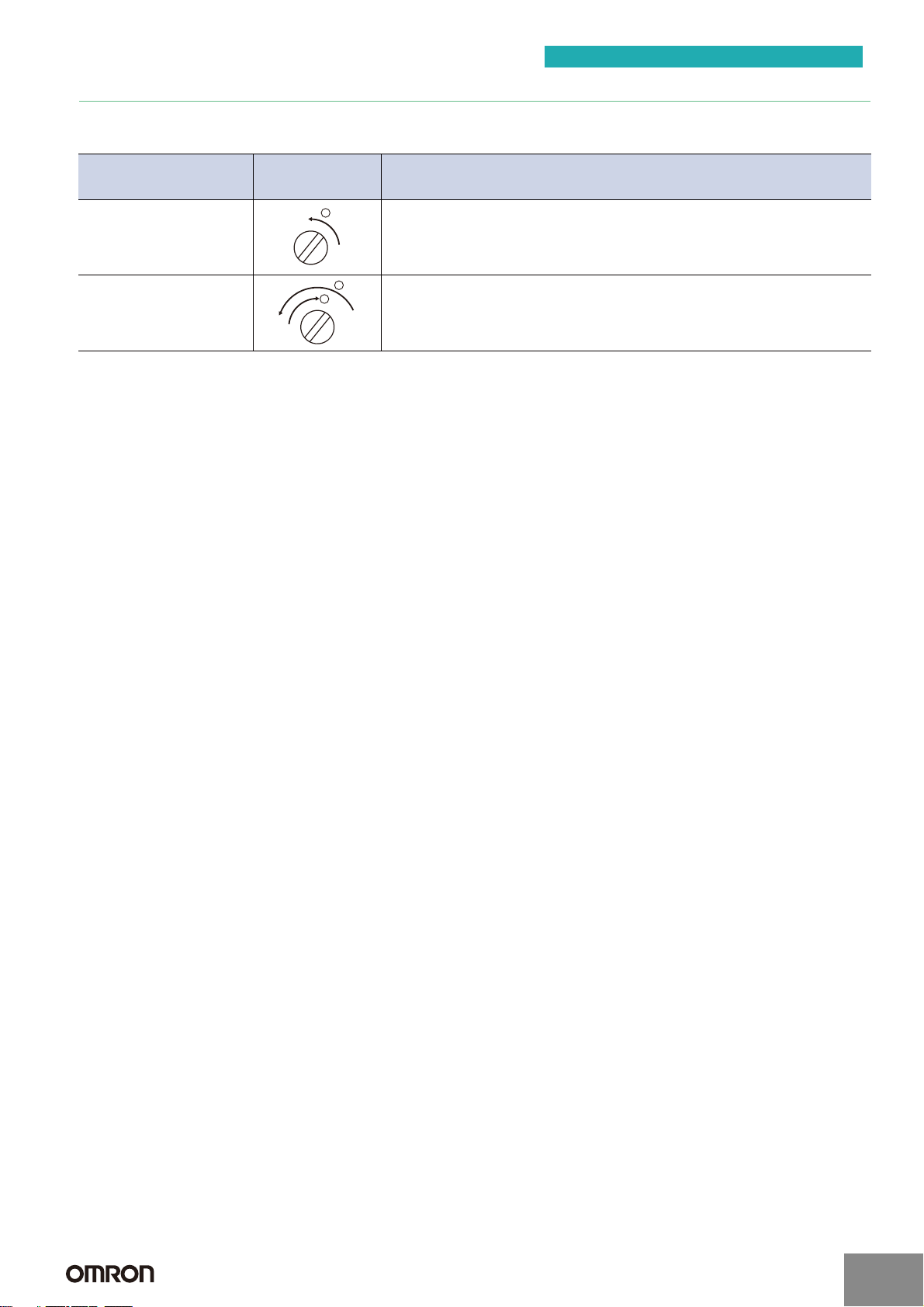

Appearance Sensing distance Output configuration

Flat

Unshielded

10 mm

4 to 10 mm

DC 3-wire

NPN

Model/Operation mode

NO NC

E2K-F10MC1 E2K-F10MC2

E2K-F10MC1-A E2K-F10MC2-A

http://www.ia.omron.com/

(c)Copyright OMRON Corporation 2007 All Rights Reserved.

1

Page 2

Ratings and Specifications

)

)

Item Model E2K-F10MC@-A E2K-F10MC@

Sensing distance 4 to 10 mm (adjustable with 12-turn adjuster) 10 mm r10%

Set distance 0 to 7.5 mm *

Differential travel 15% max. of sensing distance

Detectable object Conductors and dielectrics

Standard sensing object Grounded metal plate: 50 u 50 u 1 mm

Response frequency 100 Hz

Power supply voltage (operating

voltage range)

Current consumption 10 mA max. at 24 VDC

Control

output

Load current NPN open collector, 100 mA max. (at 30 VDC)

Residual voltage 1.5 V max. (Load current: 100 mA, Cable length: 2 m)

Indicators Detection indicator (red)

Operation mode (with sensing

object approaching)

Protection circuits Reverse polarity protection, Surge suppressor

Ambient temperature range Operating/Storage: 10 to 55qC (with no icing or condensation)

Ambient humidity range Operating/Storage: 35% to 95% Operating/Storage: 35% to 95%

Temperature influence r15% max. of sensing distance at 23qC in the temperature range of 10 to 55qC

Voltage influence r2.5% max. of sensing distance at rated voltage at rated voltage r10%

Insulation resistance 50 M: min. (at 500 VDC) between current-carrying parts and case

Dielectric strength 500 VAC, 50/60 Hz for 1 min between current-carrying parts and case

Vibration resistance Destruction: 10 to 55 Hz, 1.5-mm double amplitude for 2 hours each in X, Y, and Z directions

Shock resistance Destruction: 500 m/s2 3 times each in X, Y, and Z directions

Degree of protection IP64 (IEC) IP66 (IEC)

Connection method Pre-wired Models (Standard cable length: 2 m)

Weight (packed state) Approx. 35 g

Materials

Case

Sensing surface

Accessories Instruction manual

* The value for the E2K-F10MC@-A is when it is adjusted to 10 mm.

12 to 24 VDC (10 to 30 VDC), ripple (p-p): 10% max.

NO (Refer to the timing charts under I/O Circuit Diagrams on page 3 for details.)

Heat-resistant ABS

E2K-F

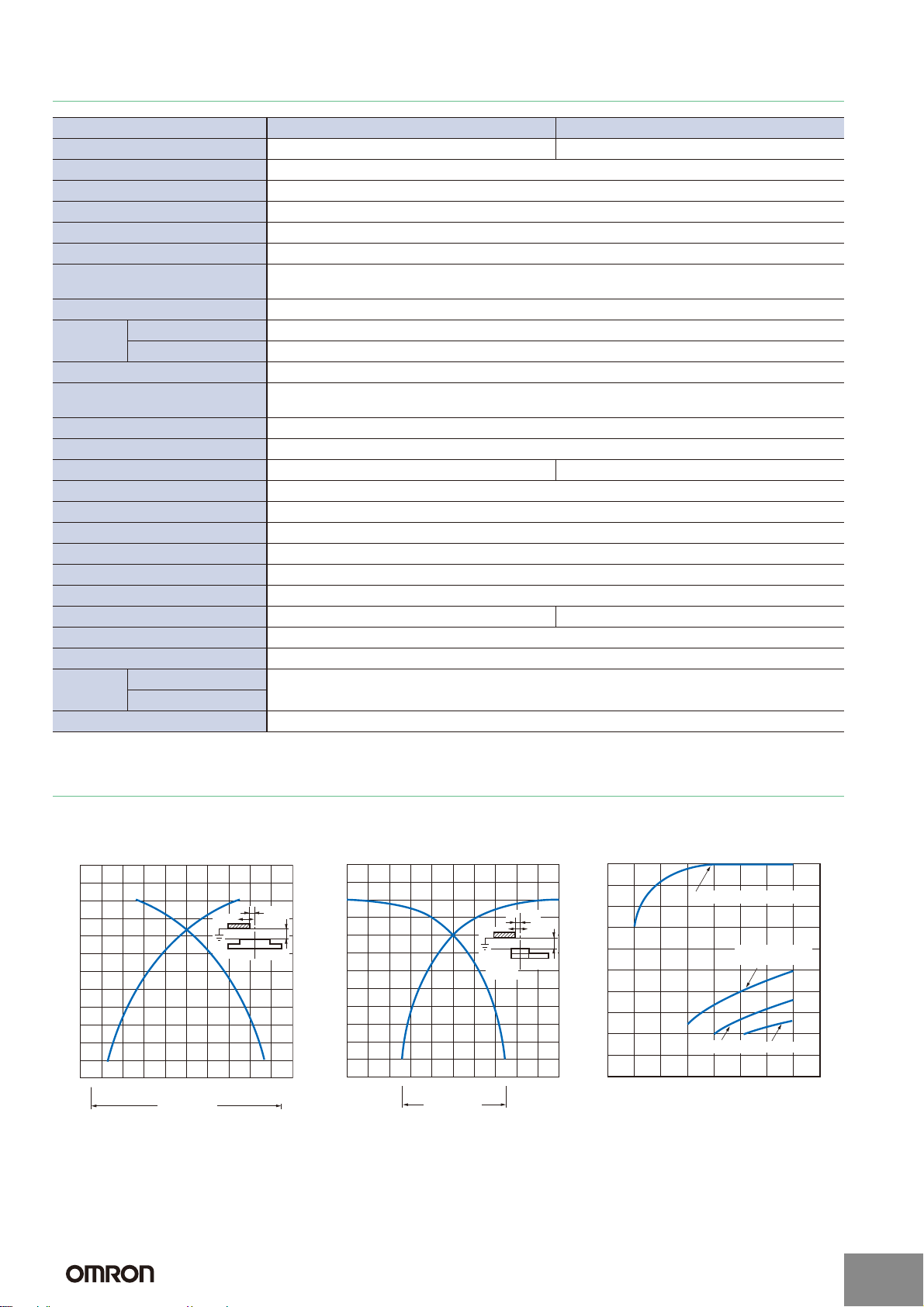

Engineering Data (Typical)

Sensing Area (Grounded Metal Plate) Influence of Sensing Object Size and

Material

201612840−4−8

10

9

8

Distance (mm)

7

6

5

4

3

2

1

100

Grounded metal plate (t = 1)

Non-grounded

metal plate (t = 10)

Glass (t = 10)

Side length of sensing object (mm

Phenol (t = 10)

80706050403020

12

11

10

9

Distance X (mm)

8

7

6

5

4

3

2

1

−12−16−20

Sensing Head

Left and

right

Distance Y (mm

12

11

Y

X

201612840−4−8

10

9

Distance X (mm)

8

7

6

5

4

3

2

1

−12−16−20

Sensing Head

Up and

down

Y

X

Distance Y

(mm)

http://www.ia.omron.com/

(c)Copyright OMRON Corporation 2007 All Rights Reserved.

2

Page 3

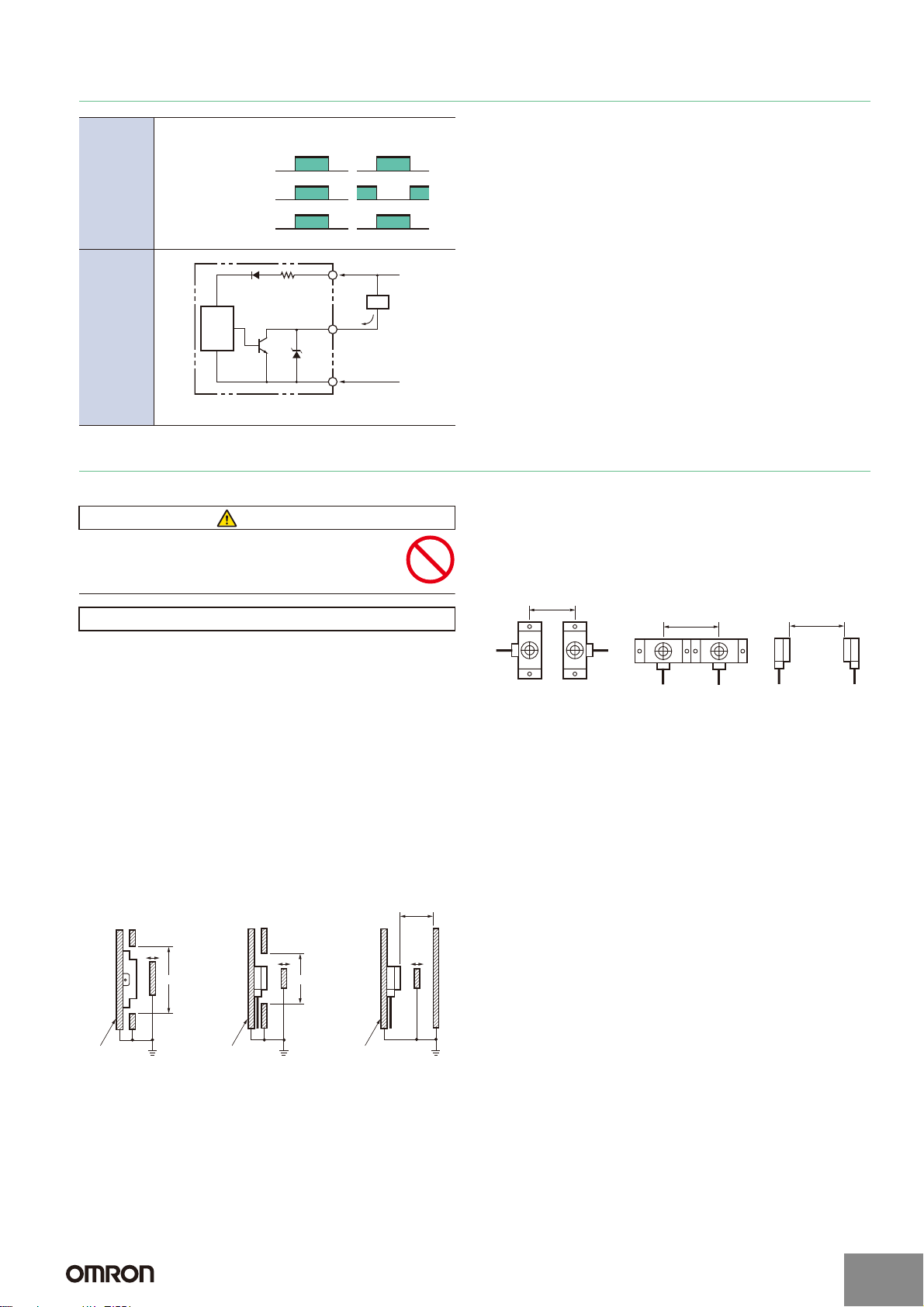

I/O Circuit Diagrams

V

Present

Not present

Timing

chart

Sensing

object

Output transistor

(load)

Detection

indicator (red)

E2K-F

NO Models NC Models

ON

OFF

ON

OFF

Output

circuit

100 Ω

Proximity

Sensor

main

circuit

* Load current: 100 mA max.

Brown

Black

Output

Blue

+V

Load

*

0

Safety Precautions

Refer to Warranty and Limitations of Liability.

WARNING

This product is not designed or rated for ensuring

safety of persons either directly or indirectly.

Do not use it for such purposes.

Precautions for Correct Use

Do not use this product under ambient conditions that exceed the

ratings.

● Design

Sensing Object Material

The E2K-F can detect almost any type of object. The sensing distance

of the E2K-F, however, will vary with the electrical characteristics of

the object, such as the conductance and inductance of the object, and

the water content and capacity of the object. The maximum sensing

distance of the E2K-F will be obtained if the object is made of

grounded metal. There are objects that cannot be detected indirectly.

Therefore, be sure to test the E2K-F in a trial operation with the

objects before using the E2K-F in actual applications.

Influence of Surrounding Metal

Separate the E2K-F from surrounding metal as shown below.

Mutual Interference

When mounting more than one E2K-F face-to-face or side-by-side,

separate them as shown below.

40 mm

50 mm

Close mounting possible Face-to-face mounting

50 mm

Effects of a High-frequency Electromagnetic Field

The E2K-F may malfunction if there is an ultrasonic washer, highfrequency generator, transceiver, portable telephone, or inverter

nearby.

For major measures, refer to Noise of Warranty and Limitations of

Liability for Photoelectric Sensors.

● Wiring

The characteristics of the E2K-F will not change if the cable is

extended. Extending the cable, however, will result in a voltage drop,

so do not extend the length past 200 m.

Metal

object

45 mm60 mm

Metal

object

http://www.ia.omron.com/

Metal

object

30 mm

(c)Copyright OMRON Corporation 2007 All Rights Reserved.

3

Page 4

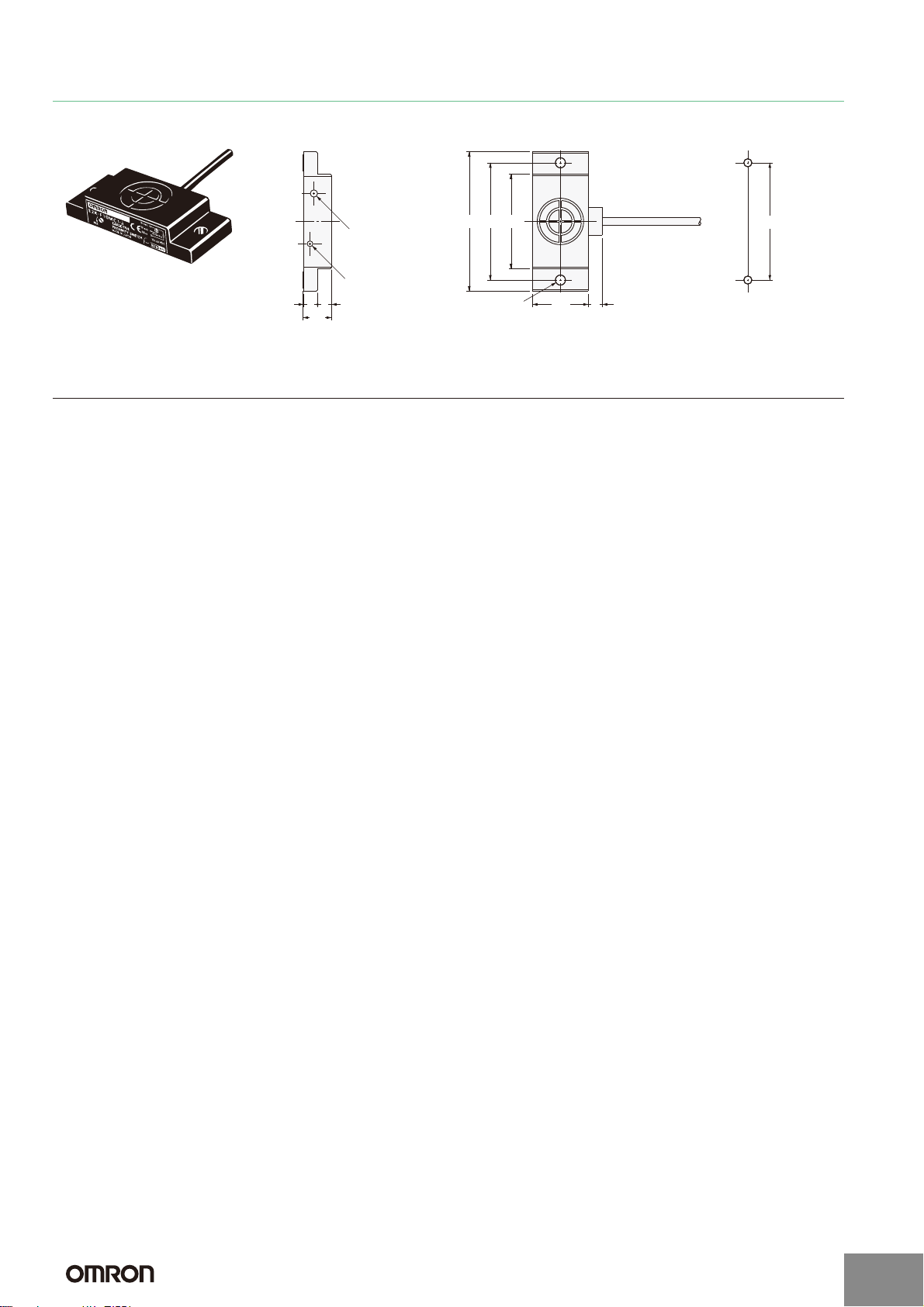

E2K-F

Dimensions (Unit: mm)

E2K-F

Two, 3.5 dia.

2

,

344250

Sensitivity adjuster *1

Detection indicator (red)

55

10.1

*1. Only the E2K-F10MC@-A has a sensitivity adjuster.

*2. 2.9-dia. vinyl-insulated round cable

(Conductor cross section: 0.14 mm

Insulator diameter: 0.9 mm), Standard length: 2 m.

20 5

Mounting Hole Dimensions

Two, M3 or 3.5 dia.

*2

42±0.2

http://www.ia.omron.com/

(c)Copyright OMRON Corporation 2007 All Rights Reserved.

4

Page 5

Operating Procedures: Proximity Sensors

E2K-F

Sensitivity Adjustment

After the Sensor is mounted, adjust the detecting sensitivity using the (12-turn) sensitivity adjuster in the way shown below.

Status of the indicator when

the liquid level is aligned

with the setting position

Not lit

Lit

Note: While adjusting the sensitivity, do not put your hand on the Sensor and make sure that the cable is properly secured. Failure to observe these points may affect

the detection level.

Sensitivity adjuster Adjustment procedure

1

Turn the sensitivity adjuster counter-clockwise using a screwdriver until the indicator

lights.

2

1

Turn the sensitivity adjuster clockwise using a screwdriver until the indicator turns OFF.

Then, turn the sensitivity adjuster counter-clockwise until the indicator lights again.

http://www.ia.omron.com/

(c)Copyright OMRON Corporation 2007 All Rights Reserved.

5

Page 6

Proximity Sensors Technical Guide

−

General Precautions

For precautions on individual products, refer to the Safety Precautions in individual product information.

WARNING

These products cannot be used in safety devices for

presses or other safety devices used to protect human

life.

These products are designed for use in applications for

sensing workpieces and workers that do not affect safety.

Precautions for Safe Use

To ensure safety, always observe the following precautions.

●Wiring Considerations

Item Typical examples

Power Supply Voltage

Do not use a voltage that exceeds the operating voltage range. Applying a voltage that is

higher than the operating voltage range, or using an AC power supply (100 VAC or higher)

for a Sensor that requires a DC power supply

may cause explosion or burning.

Load short-circuiting

• Do not short-circuit the load. Explosion or

burning may result.

• The load short-circuit protection function operates when the power supply is connected

with the correct polarity and the power is

within the rated voltage range.

DC 3-Wire NPN Output Sensors DC 2-Wire Sensors

Brown

Sensor

Blue

DC 3-Wire NPN Output Sensors • DC 2-Wire Sensors

Brown

Sensor

Blue

Black

Black

Load

Load

(Load short

circuit)

Load

Brown

Sensor

Blue

• Even with the load short-circuit protection

function, protection will not be provided when

a load short circuit occurs if the power supply

polarity is not correct.

Load

(Load short circuit)

+

−

Brown

Sensor

−

+

Blue

Incorrect Wiring

Be sure that the power supply polarity and other wiring is correct. Incorrect wiring may cause

explosion or burning.

Connection without a Load

If the power supply is connected directly without a load, the internal elements may explode

or burn. Be sure to insert a load when connecting the power supply.

DC 3-Wire NPN Output Sensors

Load

Brown

Sensor

Black

Blue

−

+

• DC 2-Wire Sensors

• Even with the load short-circuit protection

function, protection will not be provided if

both the power supply polarity is incorrect

and no load is connected.

Brown

Sensor

Blue

−

+

●Operating Environment

Do not use the Sensor in an environment where there are explosive or combustible gases.

Brown

Sensor

Black

AC 2-Wire Sensors

Brown

Sensor

Blue

Load

+

Blue

http://www.ia.omron.com/

(c)Copyright OMRON Corporation 2007 All Rights Reserved.

C-1

Page 7

Proximity Sensors Technical Guide

S

r

r

Precautions for Correct Use

The following conditions must be considered to understand the conditions of the application and location as well as the relation to control

equipment.

●Model Selection

Item Points of consideration

Check the relation between the sensing object

and the Proximity Sensor.

pecific condi-

tions of object

Direction of object movement

Peripheral metalSensing distance

Sensing

object and

operating

condition of

Proximity

Sensor

Electrical

conditions

Environmental

conditions

Sensing object

Sensing

distance

Surrounding

metals

Proximity Sensor

Verify the electrical conditions of the control system

to be used and the electrical performance of the

Proximity Sensor.

Output

Sensor

Proximity

Switching element

The environmental tolerance of the Proximity Sensor

is better than that of other types of Sensors. However,

investigate carefully before using a Proximity Sensor

under harsh temperatures or in special atmospheres.

Temperature

and humidity

Atmosphere Water, oil, iron

Vibration and

shock

Load

Highest or lowest

values, existence

of direct sunlight,

etc.

powder, or other

special chemicals

Size, duration Need for strength,

When deciding the mounting method, take into consideration not

only restrictions due to mechanical devices, but also ease of maintenance and inspection, and interference between Sensors.

Material, size,

shape, existence

of plating, etc.

Sensing (set) distance, shape of Sensor (rectangular, cylindrical, throughbeam, grooved), influence of peripheral metal (Shielded Sensors, Nonshielded Sensors), response speed (response frequency), influence of

temperature, influence of voltage, etc.

DC (voltage fluctuation, current capacity value)

AC (voltage fluctuation, frequency, etc.)

Need for S3D2 Controller

Resistive load - Non-contact control system

Inductive load - Relay, solenoid, etc.

Lamp load

Open/close frequency

Temperature influence,

high-temperature use,

low temperature use,

need for shade, etc.

N

e

r

o

d

e

f

a

t

r

o

e

c

n

e

n

r

o

d

e

f

r

p

r

t

s

f

o

o

mounting method

Power

supply

Power

supply

Load

Transit interval,

speed, existence

of vibration, etc.

•

Steady-state current, inrush current

• Operating, reset voltage (current)

•

Steady-state current, inrush current

• Water Resistance

Do not use the Sensor in water, rain, or outdoors.

• Ambient Conditions

To maintain reliability of operation, do not use the

Sensor outside the specified temperature range or

outdoors. Even though the Proximity Sensor has a

water-resistant structure, it must be covered to prevent direct contact with water or water-soluble cutting

oil. Do not use the Sensor in atmospheres with chem-

s

e

r

e

r

w

t

a

is

-

ical vapors, in particular, strong alkalis or acids (nitric

a

t

s

i

s

e

il

o

r

lo

p

x

e

e

r

u

t

c

u

,

e

c

n

acid, chromic acid, or hot concentrated sulfuric acid).

n

o

i

s

-

• Explosive Atmospheres

Do not use the Sensor in atmospheres where

there is a danger of explosion. Use an Explosionproof Sensor.

Material, distance

to Sensor, orientation, etc.

Fluctuation in transit point, allowable

error, etc.

Selecting the power

supply type

DC

DC + S3D2 Controlle

{

AC

Selecting the power

supply type

DC

DC + S3D2 Controlle

{

AC

Control output

Maximum current

(voltage)

Leakage current

Residual load voltage

Mounting

conditions

Influence of

external

electromagnetic fields

Other considerations

* mT (millitesla) is a unit for expressing magnetic flux density. One tesla is the equivalent of 10,000 gauss.

• The influence within a DC magnetic field is 20 mT* max. Do not use the Sensor at a level higher than 20 mT.

• Sudden changes in the DC magnetic field may cause malfunction. Do not use the Sensor for applications that involve turning a

DC electromagnet ON and OFF.

• Do not place a transceiver near the Sensor or its wiring. Doing so may cause malfunction.

Cost feasibility: Price/delivery time Life: Power-ON time/frequency of use

http://www.ia.omron.com/

Wiring method,

existence of inductance surges

Connection

Wires

Wire type, length, oil-resistant

cable, shielded cable, robot

cable, etc.

Conduits, ducts, pre-wired,

terminal wiring, ease of maintenance and inspection

(c)Copyright OMRON Corporation 2007 All Rights Reserved.

Mounting procedure

Installation location

Existence of mounting

brackets, direct mounting,

secured with bolts or screws

Ease of maintenance and

inspection, mounting space

C-2

Page 8

●Design

Sensing Object Material

The sensing distance varies greatly depending on the material of the

sensing object. Study the engineering data for the influence of

sensing object material and size and select a distance with sufficient

leeway.

• In general, if the

sensing object is a nonmagnetic metal (for

example, aluminum),

the sensing distance

decreases.

Example: E2-X10D@

14

12

10

8

6

Sensing distance X (mm)

4

2

05

Side length (one side) of sensing object: d (mm)

t=1mm

X

d

Aluminum

10 15 20 25 30 35 40 45 50 55

Steel

(SPCC)

Stainless steel

Brass

Copper

Size of Sensing Object

In general, if the object is smaller

than the standard sensing

object, the sensing distance

decreases.

• Design the setup for an object

size that is the same or greater

than the standard sensing

object size from the graphs

showing the sensing object

size and sensing distance.

• When the size of the standard

sensing object is the same or

less than the size of the

standard sensing object,

select a sensing distance with

sufficient leeway.

Sensing distance X (mm)

Sensing

distance

becomes

short

Side length (one side)

of sensing object: d (mm)

Standard

Stability

sensing

object

Proximity Sensors Technical Guide

Thickness of Sensing Object

• The thickness of ferrous metals

(iron, nickel, etc.) must be 1 mm

or greater.

• When the coating thickness is

0.01 mm or less, a sensing

distance equivalent to a

magnetic body can be obtained.

When the coating is extremely

thin and is not conductive, such

as a vacuum deposited film,

detection is not possible.

• Influence of Plating

If the

sensing object is plated, the

sensing distance will change

(see the table below).

Effect of Plating (Typical)

(Reference values: Percent of non-plated sensing distance)

Thickness and base material of

plating

No plating 100 100

Zn 5 to 15 μm 90 to 120 95 to 105

Cd 5 to 15 μm 100 to 110 95 to 105

Ag 5 to 15 μm 60 to 90 85 to 100

Cu 10 to 20 μm 70 to 95 95 to 105

Cu 5 to 15 μm - 95 to 105

Cu (5 to 10 μm) + Ni (10 to 20 μm) 70 to 95 -

Cu (5 to 10 μm) + Ni (10 μm)

+ Cr (0.3 μm)

Mutual Interference

• Mutual interference refers to a state where a Sensor is affected by

magnetism (or static capacitance) from an adjacent Sensor and the

output is unstable.

• One means of avoiding interference when mounting Proximity

Sensors close together is to alternate Sensors with different

frequencies. The model tables indicate whether different

frequencies are available. Please refer to the tables.

• When Proximity Sensors with the same frequency are mounted

together in a line or face-to-face, they must be separated by a

minimum distance. For details, refer to Mutual Interference in the

Safety Precautions for individual Sensors.

Sensing object shape: Square

10

8

6

4

Sensing distance X (mm)

2

0 0.01 0.1 1 10

Thickness of sensing object: t (mm)

Aluminum

Steel Brass

75 to 95 -

d=30mm

Reset

Operate

Steel

http://www.ia.omron.com/

Power Reset Time

A Sensor is ready for detection within 100 ms after turning ON the

power. If the load and Sensor are connected to separate power

supplies, design the system so that the Sensor power turns ON first.

(c)Copyright OMRON Corporation 2007 All Rights Reserved.

C-3

Page 9

Proximity Sensors Technical Guide

Turning OFF the Power

An output pulse may be generated when the power is turned OFF, so

design the system so that the load or load line power turns OFF first.

Influence of Surrounding Metal

The existence of a metal object other than the sensing object near the

sensing surface of the Proximity Sensor will affect detection performance, increase the apparent operating distance, degrade temperature characteristics, and cause reset failures. For details, refer to the

influence of surrounding metal table in Safety Precautions for individ-

ual Sensors.

The values in the table are for the nuts provided with the Sensors.

Changing the nut material will change the influence of the surrounding

metal.

Power Transformers

Be sure to use an insulated transformer for a DC power supply. Do

not use an auto-transformer (single-coil transformer).

Precautions for AC 2-Wire/DC 2-Wire Sensors

Surge Protection

Although the Proximity Sensor has a surge absorption circuit, if there

is a device (motor, welder, etc.) that causes large surges near the

Proximity Sensor, insert a surge absorber near the source of the

surges.

Influence of Leakage Current

Even when the Proximity Sensor is OFF, a small amount of current

runs through the circuit as leakage current.

For this reason, a small current may remain in the load (residual

voltage in the load) and cause load reset failures. Verify that this

voltage is lower than the load reset voltage (the leakage current is

less than the load reset current) before using the Sensor.

Using an Electronic Device as the Load for an AC 2-Wire

Sensor

When using an electronic device, such as a Timer, some types of

devices use AC half-wave rectification. When a Proximity Sensor is

connected to a device using AC half-wave rectification, only AC halfwave power will be supplied to the Sensor. This will cause the Sensor

operation to be unstable. Also, do not use a Proximity Sensor to turn

the power supply ON and OFF for electronic devices that use DC halfwave rectification. In such a case, use a relay to turn the power supply

ON and OFF, and check the system for operating stability after

connecting it.

Examples of Timers that Use AC Half-wave Rectification

Timers: H3Y, H3YN, H3RN, H3CA-8, RD2P, and H3CR (-A, -A8, -AP,

-F, -G)

Countermeasures for Leakage Current (Examples)

AC 2-Wire Sensors

Connect a bleeder resistor to bypass the leakage current flowing in

the load so that the current flowing through the load is less than the

load reset current.

When using an AC 2-Wire Sensor, connect a bleeder

resistor so that the Proximity Sensor current is at least 10

mA, and the residual load voltage when the Proximity

Sensor is OFF is less than the load reset voltage.

Load

AC power supply

Bleeder resistor R

Calculate the bleeder resistance and allowable power using the

following equation.

Vs

R ≤

P : Watts of bleeder resistance (the actual number of watts

I : Load current (mA)

It is recommend that leeway be included in the actual values used.

For 100 VAC, use 10 kΩ or less and 3 W (5 W) or higher, and for 200

VAC, use 20 kΩ or less and 10 W (20 W) or higher. If the effects of

heat generation are a problem, use the number of watts in

parentheses ( ) or higher.

(kΩ)P >

10 - I R

used should be several times this number)

Vs

2

voltage Vs

(mW)

DC 2-Wire Sensors

Connect a bleeder resistor to bypass the leakage current flowing in

the load, and design the load current so that (leakage current) × (load

input impedance) < reset voltage.

Load

Bleeder resistor R

Calculate the bleeder resistance and allowable power using the

following equation.

R ≤

It is recommend that leeway be included in the actual values used.

For 12 VDC, use 15 kΩ or less and 450 mW or higher, and for 24

VDC, use 30 kΩ or less and 0.1 W or higher.

Vs

i

R - iOFFR R

P : Watts of bleeder resistance (the actual number of watts

R : Leakage current of Proximity Sensor (mA)

i

OFF : Load reset current (mA)

i

(kΩ) P >

used should be several times this number)

Vs

2

(mW)

Vs

http://www.ia.omron.com/

(c)Copyright OMRON Corporation 2007 All Rights Reserved.

C-4

Page 10

Proximity Sensors Technical Guide

Loads with Large Inrush Current

Loads, such as lamps or motors, that cause a large inrush current* will

weaken or damage the switching element. In this situation, use a

relay.

*E2K, TL-N@Y: 1 A or higher

●Mounting

Mounting the Sensor

When mounting a Sensor, do not tap it with a hammer or otherwise

subject it to excessive shock. This will weaken water resistance and

may damage the Sensor. If the Sensor is being secured with bolts,

observe the allowable tightening torque. Some models require the

use of toothed washers.

For details, refer to the mounting precautions in Precautions for

Correct Use in individual product information.

Mounting/Removing Using DIN Track

(Example for E2CY)

<Mounting>

(1)Insert the front of the Sensor into the special Mounting Bracket

(included) or DIN Track.

(2)Press the rear of the Sensor into the special Mounting Bracket or

DIN Track.

Rear

Front

<Removing>

• While pressing the Amplifier Unit in the direction of (3), lift the fiber

plug in the direction of (4) for easy removal without a screwdriver.

(4)

DIN Track

(3)

Set Distance

The sensing distance may vary due to fluctuations in temperature and

voltage. When mounting the Sensor, it is recommend that installation

be based on the set distance.

(2)

(1)

DIN Track (or Mounting Bracket)

• When mounting the side of the Sensor using the special Mounting

Bracket, first secure the Amplifier Unit to the special Mounting

Bracket, and then mount the special Mounting Bracket with M3

screws and flat washers with a diameter of 6 mm maximum.

Flat washers (6 dia. max.)

Mounting track (yellow)

http://www.ia.omron.com/

(c)Copyright OMRON Corporation 2007 All Rights Reserved.

C-5

Page 11

●Wiring Considerations

AND/OR Connections for Proximity Sensors

Model

DC 2-Wire

Type of

connection

AND (series

connection)

OR (parallel

connection)

Connection Description

+

-

+

-

+

-

+

Load

Load

Load

Proximity Sensors Technical Guide

Keep the number of connected Sensors (N) within the range of the following

equation.

V

S - N × VR ≥ Operating load voltage

N : Number of Sensors that can be connected

R: Residual output voltage of Proximity Sensor

Vs

Vs

V

S

V

S: Power voltage

V

It is possible, however, that the indicators may not light correctly and error

pulses (of approximately 1 ms) may be generated because the rated power

supply voltage and current are not supplied to individual Proximity Sensors.

Verify that this is not a problem before operation.

Keep the number of connected Sensors (N) within the range of the following

equation.

N × i ≤ Load reset current

N: Number of Sensors that can be connected

i: Leakage current of Proximity Sensor

Example: When an MY (24-VDC) Relay is used as the load, the maximum number

of Sensors that can be connected is 4.

<TL-NY, TL-MY, E2K-@MY@, TL-T@Y>

The above Proximity Sensors cannot be used in a sereis connection. If needed, connect through relays.

Load

X

Load

V

2

X

1

X

2

L

VS≥ 100V

AND (series

connection)

X

1

AC 2-wire

(A)

(B)

Load

OR (parallel

connection)

(A)

Note: When AND/OR connections are used with Proximity Sensors, the effects of erroneous pulses or leakage current may prevent use. Verify that there are no

problems before use.

(B)

1

X

Load

X2

X1

X2

<E2E-X@Y>

For the above Proximity Sensors, the voltage VL that can be applied to the

load when ON is V

V

S

both 100 VAC and 200 VAC.

The load will not operate unless V

This must be verified before use.

When using two or more Sensors in series with an AND circuit, the limit is three

Sensors. (Be careful of the VS value in the diagram at left.)

V

S

In general it is not possible to use two or more Proximity Sensors in parallel

with an OR circuit.

A parallel connection can be used if A and B will not be operated simultaneously and there is no need to hold the load. The leakage current, however,

will be n times the value for each Sensor and reset failures will frequently occur.

("n" is the number of Proximity Sensors.)

If A and B will be operated simultaneously and the load is held, a parallel connection is not possible.

If A and B operate simultaneously and the load is held, the voltages of both A

and B will fall to about 10 V when A turns ON, and the load current will flow

through A causing random operation. When the sensing object approaches B,

the voltage of both terminals of B is too low at 10 V and the switching element

of B will not operate. When A turns OFF again, the voltages of both A and B

AC power supply

voltage Vs

rise to the power supply voltage and B is finally able to turn ON.

During this period, there are times when A and B both turn OFF (approximately

10 ms) and the loads are momentarily restored. In cases where the load is to

be held in this way, use a relay as shown in the diagram at left.

L = VS - (Output residual voltage × Number of Sensors), for

L is higher than the load operating voltage.

http://www.ia.omron.com/

(c)Copyright OMRON Corporation 2007 All Rights Reserved.

C-6

Page 12

Proximity Sensors Technical Guide

Model

DC 3-wire

Note: When AND/OR connections are used with Proximity Sensors, the effects of erroneous pulses or leakage current may prevent use. Verify that there are no

problems before use.

Extending Cable Length

The cable of a Built-in Amplifier Sensor can be extended to a

maximum length of 200 m with each of the standard cables

(excluding some models).

For Separate Amplifier Sensors (E2C-EDA, E2C, E2J, E2CY), refer

to the specific precautions for individual products.

Bending the Cable

If you need to bend the cable, we recommend a bend radius that is at

least 3 times the outer diameter of the cable (with the exception of

Type of

connection

AND (series

connection)

OR (parallel

connection)

(A)

(B)

Connection Description

Keep the number of connected Sensors (N) within the range of the following

equation.

iL + (N - 1) × i ≤ Upper limit of Proximity Sensor control output

S - N × VR ≥ Operating load voltage

V

N : Number of Sensors that can be con-

nected

R: Residual output voltage of Sensor

V

V

S: Power supply voltage

i : Current consumption of Sensor

iL: Load current

Note: When an AND circuit is connected, the operation of Proximity Sensor B

causes power to be supplied to Proximity Sensor A, and thus erroneous

pulses (approximately 1 ms) may be generated in A when the power is

turned ON. For this reason, take care when the load has a high

response speed because malfunction may result.

For Sensors with a current output, a minimum of three OR connections is possible. Whether or not four or more connections is possible depends on the

model.

+

+

+

+

-

-

-

OUT

OUT

OUT

OUT

i

iL

Load

i

Load

Vs

Vs

Example of Connection with S3D2 Sensor Controller

DC 2-Wire Sensors

Using the S3D2 Sensor Controller

Operation can be reversed with the signal input

switch on the S3D2.

Example: A maximum of two

Sensors can be used when an

MY (24-VDC) Relay is used for

the load.

Blue 0 V

Brown OUT

coaxial and shielded cables).

9

11810712

Cable Tensile Strength

In general, do not subject the cable to a tension greater than that

indicated in the following table.

Cable diameter Tensile strength

Less than 4 mm 30 N max.

4 mm min. 50 N max.

Note: Do not subject a shielded cable or coaxial cable to tension.

Separating High-voltage Lines

Using Metal Conduits

If a power line is to be located near the Proximity Sensor cable, use a

separate metal conduit to prevent malfunction or damage. (Same for

DC models.)

52416

S3D2

Connecting to a Relay Load

Brown

X

Blue

Note: DC 2-Wire Sensors have a residual voltage of 3 V. Check the operating

voltage of the relay before use.

The residual voltage of the E2E-XD-M1J-T is 5 V.

24 VDC

DC 3-Wire Sensors

Operation can be reversed with the signal input

switch on the S3D2.

Blue 0 V

Black OUT

Brown +12 V

S3D2

11810712

52416

3

9

3

http://www.ia.omron.com/

(c)Copyright OMRON Corporation 2007 All Rights Reserved.

C-7

Page 13

●Operating Environment

Water Resistance

Do not use the Sensor in water, rain, or outdoors.

Ambient Conditions

Do not use the Sensor in the following environments.

Doing so may cause malfunction or failure of the Sensor.

1. To maintain operational reliability and service life, use the Sensor

only within the specified temperature range and do not use it

outdoors.

2. The Sensor has a water resistant structure, however, attaching a

cover to prevent direct contact with water will help improve

reliability and prolong product life.

3. Avoid using the Sensor where there are chemical vapors,

especially strong alkalis or acids (nitric acid, chromic acid, or hot

concentrated sulfuric acid).

●Maintenance and inspection

Periodic Inspection

To ensure long-term stable operation of the Proximity Sensor, inspect

for the following on a regular basis. Conduct these inspections also

for control devices.

1. Shifting, loosening, or deformation of the sensing object and

Proximity Sensor mounting

2. Loosening, bad contact, or wire breakage in the wiring and

connections

3. Adherence or accumulation of metal powder

4. Abnormal operating temperature or ambient conditions

5. Abnormal indicator flashing (on setting indicator types)

Proximity Sensors Technical Guide

Disassembly and Repair

Do not under any circumstances attempt to disassemble or repair the

product.

Quick Failure Check

You can conveniently check for failures by connecting the E39-VA

Handy Checker to check the operation of the Sensor.

http://www.ia.omron.com/

(c)Copyright OMRON Corporation 2007 All Rights Reserved.

C-8

Page 14

Read and Understand This Catalog

Please read and understand this catalog before purchasing the products. Please consult your OMRON representative if you have any questions or

comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a period of one year (or other period if

specifi ed) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NON-INFRINGEMENT, MERCHANTABILITY, OR

FITNESS FOR PARTICULAR PURPOSE OF THE PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE

HAS DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE. OMRON DISCLAIMS ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS, OR COMMERCIAL

LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR

STRICT LIABILITY.

In no event shall responsibility of OMRON for any act exceed the individual price of the product on which liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS REGARDING THE PRODUCTS UNLESS

OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT

SUBJECT TO CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the combination of products in the customer's

application or use of the product.

At the customer's request, OMRON will provide applicable third party certifi cation documents identifying ratings and limitations of use that apply to the

products. This information by itself is not suffi cient for a complete determination of the suitability of the products in combination with the end product,

machine, system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not intended to be an exhaustive list of all possible

uses of the products, nor is it intended to imply that the uses listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or uses not described in this catalog.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical equipment, amusement machines, vehicles, safety

equipment, and installations subject to separate industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR PROPERTY WITHOUT ENSURING THAT THE

SYSTEM AS A WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT IS PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifi cations and accessories may be changed at any time based on improvements and other reasons.

It is our practice to change model numbers when published ratings or features are changed, or when signifi cant construction changes are made.

However, some specifi cations of the product may be changed without any notice. When in doubt, special model numbers may be assigned to fi x

or establish key specifi cations for your application on your request. Please consult with your OMRON representative at any time to confi rm actual

specifi cations of purchased product.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when tolerances are shown.

ERRORS AND OMISSIONS

The information in this catalog has been carefully checked and is believed to be accurate; however, no responsibility is assumed for clerical,

typographical, or proofreading errors, or omissions.

PERFORMANCE DATA

Performance data given in this catalog is provided as a guide for the user in determining suitability and does not constitute a warranty. It may represent

the result of OMRON’s test conditions, and the users must correlate it to actual application requirements. Actual performance is subject to the OMRON

Warranty and Limitations of Liability.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any consequence thereof.

COPYRIGHT AND COPY PERMISSION

This catalog shall not be copied for sales or promotions without permission.

This catalog is protected by copyright and is intended solely for use in conjunction with the product. Please notify us before copying or reproducing this

catalog in any manner, for any other purpose. If copying or transmitting this catalog to another, please copy or transmit it in its entirety.

OMRON Corporation

Industrial Automation Company

http://www.ia.omron.com/

In the interest of product improvement, specifications are subject to change without notice.

(c)Copyright OMRON Corporation 2007 All Rights Reserved.

2007.12

Loading...

Loading...