Page 1

Industrial Automation Headquarters

Delta Electronics, Inc.

Taoyuan Technology Center

No.18, Xinglong Rd., Taoyuan City,

Taoyuan County 33068, Taiwan

TEL: 886-3-362-6301 / FAX: 886-3-371-6301

Asia

Delta Electronics (Jiangsu) Ltd.

Wujiang Plant 3

1688 Jiangxing East Road,

Wujiang Economic Development Zone

Wujiang City, Jiang Su Province, P.R.C. 215200

TEL: 86-512-6340-3008 / FAX: 86-769-6340-7290

Delta Greentech (China) Co., Ltd.

238 Min-Xia Road, Pudong District,

ShangHai, P.R.C. 201209

TEL: 86-21-58635678 / FAX: 86-21-58630003

Delta Electronics (Japan), Inc.

Tokyo Ofce

2-1-14 Minato-ku Shibadaimon,

Tokyo 105-0012, Japan

TEL: 81-3-5733-1111 / FAX: 81-3-5733-1211

DVP15MC

Operation Manual

Delta Electronics (Korea), Inc.

1511, Byucksan Digital Valley 6-cha, Gasan-dong,

Geumcheon-gu, Seoul, Korea, 153-704

TEL: 82-2-515-5303 / FAX: 82-2-515-5302

Delta Electronics Int’l (S) Pte Ltd.

4 Kaki Bukit Ave 1, #05-05, Singapore 417939

TEL: 65-6747-5155 / FAX: 65-6744-9228

Delta Electronics (India) Pvt. Ltd.

Plot No 43 Sector 35, HSIIDC

Gurgaon, PIN 122001, Haryana, India

TEL : 91-124-4874900 / FAX : 91-124-4874945

Americas

Delta Products Corporation (USA)

Raleigh Ofce

P.O. Box 12173,5101 Davis Drive,

Research Triangle Park, NC 27709, U.S.A.

TEL: 1-919-767-3800 / FAX: 1-919-767-8080

Delta Greentech (Brasil) S.A.

Sao Paulo Ofce

Rua Itapeva, 26 - 3° andar Edicio Itapeva One-Bela Vista

01332-000-São Paulo-SP-Brazil

TEL: 55 11 3568-3855 / FAX: 55 11 3568-3865

Europe

Delta Electronics (Netherlands) B.V.

Eindhoven Ofce

De Witbogt 20, 5652 AG Eindhoven, The Netherlands

TEL : +31 (0)40-8003800 / FAX : +31 (0)40-8003898

DVP15MC

Operation Manual

DVP-0191920-00

*We reserve the right to change the information in this manual without prior notice.

2016-06-30

www.deltaww.com

Page 2

DVP15MC11T Operation Manual

Table of Contents

Chapter 1 Preface ................................................................................................ 1-1

1.1 Explanation of Symbols in This Manual ...................................................... 1-2

1.2 Revision History ......................................................................................... 1-2

Chapter 2 Overview of DVP15MC11 T ................................................................... 2-1

2.1 Product Description .................................................................................... 2-2

2.2 Functions ................................................................................................... 2-2

2.3 Profile and Components ............................................................................. 2-3

Chapter 3 Specifications ...................................................................................... 3-1

3.1 Function Specifications .............................................................................. 3-2

3.1.1 Specifications ........................................................................................ 3-2

3.1.2 Devices and Data Types ......................................................................... 3-3

3.1.2.1 Devices ............................................................................................. 3-3

3.1.2.2 Valid Ranges of Devices ...................................................................... 3-4

3.1.2.3 Latched Devices ................................................................................. 3-5

3.1.2.4 Data Types and Valid Ranges Supported ................................................ 3-6

3.2 Electrical Specifications ............................................................................. 3-7

Chapter 4 System Architecture ............................................................................ 4-1

4.1 System Constitution ................................................................................... 4-2

4.2 Power Supply ............................................................................................. 4-2

4.3 Left-side Extension .................................................................................... 4-2

4.3.1 Connectable Left-side Extension Module .................................................... 4-2

4.3.2 Allocation of Left-side Network Module Addresses ....................................... 4-3

4.3.3 Method of Reading/Writing of Left-side Modules ......................................... 4-3

4.4 Right-side Extension .................................................................................. 4-3

4.4.1 Connectable Right-side Extension Modules ................................................ 4-3

4.4.2 Allocation of Right-side Extension Module Addresses ................................... 4-4

4.5 Connectable Servo Drives........................................................................... 4-4

4.6 SD Memory Card ......................................................................................... 4-6

4.6.1 Model and Specification .......................................................................... 4-6

4.6.2 Function ............................................................................................... 4-8

Chapter 5 Installation .......................................................................................... 5-1

i

Page 3

5.1 Dimensions ................................................................................................ 5-2

5.1.1 Profile and Dimensions of DVP15MC11T .................................................... 5-2

5.1.2 Dimensions of Left-side and Right-side Extension Modules ........................... 5-2

5.1.3 Connecting to the Left-side Extension Module ............................................ 5-3

5.1.4 Connecting to the Right-side Extension Module .......................................... 5-4

5.1.5 SD Card Installing and Removing ............................................................. 5-5

5.2 Installing the Module in the Control Cabinet .............................................. 5-7

5.2.1 Installing the Module to DIN rail .............................................................. 5-7

5.2.2 Illustration of Installation Inside the Control Cabinet .................................. 5-7

5.2.3 Environmental Temperature in the Control Cabinet ..................................... 5-7

5.2.4 Actions for Anti-interference ................................................................... 5-8

5.2.5 Dimension Requirement in the Control Cabinet .......................................... 5-8

Chapter 6 Wiring, Communication Setting and Network Construction ................. 6-1

6.1 Wiring ........................................................................................................ 6-3

6.1.1 Power Supply ........................................................................................ 6-3

6.1.2 Safety Circuit Wiring .............................................................................. 6-3

6.2 Input Point and Output Point Wiring .......................................................... 6-4

6.2.1 Function that Input Points Suppo r t ........................................................... 6-4

6.2.2 Input Point Wiring ................................................................................. 6-5

6.2.3 Output Point Wiring ............................................................................... 6-6

6.3 RS-485 Communication Port ...................................................................... 6-8

6.3.1 Function that RS-485 Port Supports ......................................................... 6-8

6.3.2 Definitions of RS-485 Port Pins ................................................................ 6-8

6.3.3 RS-485 Hardware Connection .................................................................. 6-8

6.3.4 Supported Function Codes and Exception Codes ...................................... 6-10

6.4 RS-232 Communication Port .................................................................... 6-11

6.4.1 Function that RS-232 Port Supports ....................................................... 6-11

6.4.2 Definitions of RS-232 Port Pins .............................................................. 6-11

6.4.3 RS-232 Hardware Connection ................................................................ 6-11

6.4.4 Supported Function Codes and Exception Codes ...................................... 6-12

6.5 SSI Absolute Encoder Port ....................................................................... 6-13

6.5.1 Function of SSI Absolute Encoder .......................................................... 6-13

6.5.2 Definitions of SSI Port Pins ................................................................... 6-13

6.5.3 SSI Absolute Encoder Hardware Connection ............................................ 6-13

6.6 Incremental Encoders .............................................................................. 6-15

6.6.1 Function of Incremental Encoder ........................................................... 6-15

6.6.2 Definition of Incremental Encoder Port Pins ............................................. 6-15

6.6.3 Incremental Encoder Hardware Connection ............................................. 6-16

6.7 Ethernet Communication Port .................................................................. 6-17

6.7.1 Function that Ethernet Communication Port Supports ............................... 6-17

6.7.2 Pins of Ethernet Communication Port ...................................................... 6-17

6.7.3 Network Connection of Ether ne t Communication Port ............................... 6-17

6.7.4 Function Codes that Ethernet Communication Port Supports ...................... 6-18

6.8 Motion Communication Port ..................................................................... 6-18

6.8.1 Function that Motion Communication Port Supports .................................. 6-18

ii

Page 4

6.8.2 Pins of Motion Communication Port ........................................................ 6-18

6.8.3 Motion Network Connection ................................................................... 6-19

6.8.4 Communication Speed and Co m m unication Distance ................................. 6-19

6.9 CANopen Communication Port.................................................................. 6-20

6.9.1 Functions that CANopen Comm unication Port Supports ............................. 6-20

6.9.2 Pins of CANopen Communication Port ..................................................... 6-21

6.9.3 PDO Mapping at CANopen Communication Port ........................................ 6-21

6.9.4 Network Connection at CANopen Communication Port ............................... 6-21

6.9.5 CANopen Communication Rate and Communication Distance ..................... 6-22

Chapter 7 Execution Principle of DVP15MC11T Controller ................................... 7-1

7.1 Tasks .......................................................................................................... 7-2

7.1.1 Task Types ........................................................................................... 7-2

7.1.2 Priority levels of Tasks ............................................................................ 7-4

7.1.3 Watchdog for a Task .............................................................................. 7-6

7.1.4 Motion Instructions for Each Task Type ..................................................... 7-7

7.2 The Impact of PLC RUN or STOP on Variables and Devices ......................... 7-8

7.3 Relationship between Motion Program and Motion Bus .............................. 7-8

7.4 Synchronization Cycle Period Setting ......................................................... 7-9

Chapter 8 Logic Instructions ............................................................................... 8-1

8.1 Table of Logic Instructions ......................................................................... 8-4

8.2 Explanation of Logic Instructions ............................................................... 8-7

8.2.1 EN and ENO .......................................................................................... 8-7

8.3 Sequence Input /Output Instructions ........................................................ 8-7

8.3.1 R_TRIG ................................................................................................ 8-7

8.3.2 F_TRIG ................................................................................................ 8-9

8.3.3 RS ..................................................................................................... 8-11

8.3.4 SR ..................................................................................................... 8-13

8.3.5 SEMA ................................................................................................. 8-15

8.4 Data Movement Instructions .................................................................... 8-17

8.4.1 MOVE ................................................................................................ 8-17

8.4.2 MoveBit .............................................................................................. 8-18

8.4.3 TransBit ............................................................................................. 8-20

8.4.4 MoveDigit ........................................................................................... 8-22

8.4.5 Exchange ........................................................................................... 8-24

8.4.6 Swap ................................................................................................. 8-26

8.5 Comparison Instructions .......................................................................... 8-28

8.5.1 LT ..................................................................................................... 8-28

8.5.2 LE ..................................................................................................... 8-30

8.5.3 GT ..................................................................................................... 8-32

8.5.4 GE ..................................................................................................... 8-34

8.5.5 EQ ..................................................................................................... 8-36

8.5.6 NE ..................................................................................................... 8-38

8.6 Timer Instructions ................................................................................... 8-40

iii

Page 5

8.6.1 TON .................................................................................................. 8-40

8.6.2 TOF ................................................................................................... 8-42

8.6.3 TP ..................................................................................................... 8-44

8.7 Counter Instructions ................................................................................ 8-46

8.7.1 CTU ................................................................................................... 8-46

8.7.2 CTD ................................................................................................... 8-48

8.7.3 CTUD ................................................................................................. 8-50

8.8 Math Instructions ..................................................................................... 8-53

8.8.1 ADD .................................................................................................. 8-53

8.8.2 SUB .................................................................................................. 8-56

8.8.3 MUL .................................................................................................. 8-59

8.8.4 DIV ................................................................................................... 8-62

8.8.5 MOD .................................................................................................. 8-65

8.8.6 MODREAL ........................................................................................... 8-67

8.8.7 MODTURNS ........................................................................................ 8-69

8.8.8 MODABS ............................................................................................ 8-71

8.8.9 ABS ................................................................................................... 8-73

8.8.10 DegToRad .......................................................................................... 8-75

8.8.11 RadToDeg .......................................................................................... 8-77

8.8.12 SIN ................................................................................................... 8-79

8.8.13 COS .................................................................................................. 8-81

8.8.14 TAN ................................................................................................... 8-83

8.8.15 ASIN ................................................................................................. 8-85

8.8.16 ACOS ................................................................................................ 8-88

8.8.17 ATAN ................................................................................................. 8-90

8.8.18 LN ..................................................................................................... 8-92

8.8.19 LOG .................................................................................................. 8-94

8.8.20 SQRT ................................................................................................. 8-96

8.8.21 EXP ................................................................................................... 8-98

8.8.22 EXPT ................................................................................................ 8-100

8.8.23 RAND ............................................................................................... 8-102

8.8.24 TRUNC .............................................................................................. 8-104

8.8.25 FLOOR .............................................................................................. 8-106

8.8.26 FRACTION ......................................................................................... 8-108

8.9 Bit String Instructions ........................................................................... 8-110

8.9.1 AND ................................................................................................. 8-110

8.9.2 OR ................................................................................................... 8-113

8.9.3 NOT ................................................................................................. 8-116

8.9.4 XOR ................................................................................................. 8-118

8.9.5 XORN ............................................................................................... 8-121

8.10 Shift Instructions ................................................................................... 8-124

8.10.1 SHL .................................................................................................. 8-124

8.10.2 SHR ................................................................................................. 8-126

8.10.3 ROL .................................................................................................. 8-128

8.10.4 ROR ................................................................................................. 8-130

8.11 Selection Instructions ............................................................................ 8-132

8.11.1 MAX ................................................................................................. 8-132

8.11.2 MIN .................................................................................................. 8-134

iv

Page 6

8.11.3 SEL ................................................................................................. 8-136

8.11.4 MUX ................................................................................................ 8-138

8.11.5 LIMIT ............................................................................................... 8-140

8.11.6 BAND ............................................................................................... 8-143

8.11.7 ZONE ............................................................................................... 8-146

8.12 Data Type Conversion Instructions ........................................................ 8-149

8.12.1 BOOL_TO_*** .................................................................................. 8-149

8.12.2 Bit strings_TO_*** ............................................................................ 8-152

8.12.3 Integers_TO_*** .............................................................................. 8-159

8.12.4 Real numbers_TO_*** ....................................................................... 8-168

8.12.5 Times,dates_TO_*** ......................................................................... 8-171

8.12.6 Strings_TO_*** ................................................................................ 8-173

8.13 CANopen Communic atio n Instructions ................................................... 8-176

8.13.1 DMC_ReadParameter_CANopen ........................................................... 8-176

8.13.2 DMC_WriteParameter_CANopen ........................................................... 8-182

8.14 String Processing Instructions ............................................................... 8-187

8.14.1 CONCAT ........................................................................................... 8-187

8.14.2 DELETE ............................................................................................ 8-189

8.14.3 INSERT ............................................................................................ 8-191

8.14.4 LEFT / RIGHT .................................................................................... 8-193

8.14.5 MID ................................................................................................. 8-195

8.14.6 REPLACE .......................................................................................... 8-197

8.14.7 LEN ................................................................................................. 8-199

8.14.8 FIND ................................................................................................ 8-200

8.15 Immediate Refresh Instructi o ns ............................................................ 8-202

8.15.1 FROM ............................................................................................... 8-202

8.15.2 TO ................................................................................................... 8-206

8.15.3 ImmediateInput ................................................................................ 8-210

8.15.4 ImmediateOutput .............................................................................. 8-212

Chapter 9 Introductions of Axis Parameters ........................................................ 9-1

9.1 Description of Axis Parameters .................................................................. 9-2

Chapter 10 Motion Control Function .................................................................... 10-1

10.1 EN and ENO .............................................................................................. 10-2

10.2 Relation among Velocity, Acceleration and Jerk ....................................... 10-3

10.3 Introduction of BufferMode ...................................................................... 10-6

10.4 The State Machine .................................................................................. 10-32

Chapter 11 Motion Control Instructions ............................................................... 11-1

11.1 Table of Motion Control Instructions ........................................................ 11-3

11.2 About Motion Control Instructions ........................................................... 11-4

11.2.1 Composition of A Motion Control Instruction ............................................ 11-4

11.2.2 Program Languages that Motion Control Instructions Support .................... 11-4

11.2.3 Configuration of Motion Control Instructions ............................................ 11-4

v

Page 7

11.3 Single-axis Instructions ........................................................................... 11-5

11.3.1 MC_Power .......................................................................................... 11-5

11.3.2 MC_Home ......................................................................................... 11-14

11.3.3 MC_MoveVelocity ............................................................................... 11-19

11.3.4 MC_Halt ............................................................................................ 11-26

11.3.5 MC_Stop ........................................................................................... 11-31

11.3.6 MC_MoveRelative ............................................................................... 11-36

11.3.7 MC_MoveAdditive ............................................................................... 11-44

11.3.8 MC_MoveAbsolute .............................................................................. 11-52

11.3.9 MC_MoveSuperimposed ...................................................................... 11-61

11.3.10 MC_HaltSuperimposed ........................................................................ 11-68

11.3.11 MC_SetPosition .................................................................................. 11-73

11.3.12 MC_SetOverride ................................................................................. 11-83

11.3.13 MC_Reset .......................................................................................... 11-87

11.3.14 DMC_SetTorque ................................................................................. 11-90

11.3.15 MC_ReadAxisError .............................................................................. 11-94

11.3.16 MC_ReadActualPosition ....................................................................... 11-96

11.3.17 MC_ReadStatus ................................................................................ 11-101

11.3.18 MC_ReadMotionState ........................................................................ 11-106

11.3.19 DMC_ReadParameter_Motion ............................................................. 11-111

11.3.20 DMC_WriteParameter_Motion ............................................................. 11-115

11.3.21 DMC_TouchProbe ............................................................................. 11-119

11.4 Multi-axis Instructi ons ......................................................................... 11-128

11.4.1 MC_GearIn ...................................................................................... 11-128

11.4.2 MC_GearOut .................................................................................... 11-134

11.4.3 MC_CombineAxes ............................................................................. 11-139

11.4.4 Introduction of Electronic Cam ........................................................... 11-147

11.4.5 MC_CamIn ...................................................................................... 11-148

11.4.6 MC_CamOut .................................................................................... 11-169

11.5 Application Instructions ....................................................................... 11-175

11.5.1 Rotary Cut Technology ...................................................................... 11-175

11.5.2 Rotary Cut Parameters ...................................................................... 11-176

11.5.3 Control Feature of Rotary Cut Function ................................................ 11-177

11.5.4 Introduction to Cam Curve with Rotary Cut Function ............................. 11-178

11.5.5 Rotary-cut Instructions ..................................................................... 11-182

11.5.5.1 APF_RotaryCut_Init ....................................................................... 11-182

11.5.5.2 APF_RotaryCut_In ......................................................................... 11-185

11.5.5.3 APF_RotaryCut_Out ....................................................................... 11-187

11.5.6 Application Example of Rotary Cut Instructions ..................................... 11-189

Chapter 12 Troubleshooting ................................................................................ 12-1

12.1 Explanation of LED Indicators .................................................................. 12-2

12.2 Table of Error IDs in Motion Instructions ................................................. 12-8

12.3 System Trouble Diagnosis through System Error Codes ......................... 12-12

Appendix A Modbus Communication ...................................................................... A-1

A.1 Message Format in ASCII Mode .................................................................. A-2

vi

Page 8

A.2 Message Format in RTU Mode ..................................................................... A-5

A.3 Modbus Function Codes Supported ............................................................. A-7

A.4 Modbus Exception Response Code Supported ............................................ A-7

A.5 Introduction to Modbus Function Codes ..................................................... A-8

A.6 Table of Registers and Corresponding Modbus addresses ........................ A-15

Appendix B Modbus TCP Communication ................................................................ B-1

B.1 Modbus TCP Message Structure .................................................................. B-2

B.2 Modbus Function Codes Supported in Modbus TCP ..................................... B-2

B.3 Exception Response Code in Modbus TCP ................................................... B-3

B.4 Modbus Function Codes in Modbus TCP ...................................................... B-3

B.5 Registers in DVP15MC11T and Corresponding Modbus Addresses ............ B-12

Appendix C CANopen Protocol ................................................................................ C-1

C.1 Node States ................................................................................................ C-4

C.2 Network Management (NMT) ..................................................................... C-7

C.3 PDO (Process Data Object) ........................................................................ C-7

C.4 SDO (Service Data Object) ......................................................................... C-9

Appendix D Explanation of Homing Modes ............................................................ D-1

D.1 Explanation of Homing Modes ................................................................... D-2

Appendix E List of Accessories ............................................................................... E-1

E.1 Accessories for CANopen Communication .................................................. E-2

E.2 Accessories for PROFIBUS DP Communication ........................................... E-4

E.3 Accessories for DeviceNet Communication ................................................. E-4

vii

Page 9

Memo

viii

Page 10

1

Chapter 1 Preface

Table of Contents

1.1 Explanation of Symbols in This Manual ...................................................... 1-2

1.2 Revision History ......................................................................................... 1-2

1-1

Page 11

DVP15MC11T Operation Manual

_1

! Danger

!

Warning

!

Caution

Thank you for purchasing DVP15MC11T motion controller which is created on the basis of motion control and

we are providing you with a high-end motion control system.

This manual describes the product specifications, functions, system architecture, installation, wiring,

execution principle, logic instructions and motion control instructions, trouble-shooting, communication

protocols, homing modes and other relevant information.

Make sure that you have well known about the motion control system configuration and product operation

before using DVP15MC11T.

1.1 Explanation of Symbols in This Manual

Precautions before operation

Before operation, please read relevant safety instructions carefully so as to prevent an injury t o personnel and

damage to products.

It indicates the highly potential hazards. It is possible to cause a severe injury or even

fatal harm to personnel if you do not follow the instructions.

It indicates the potential hazards. It is possible to cause a minor injury or even fatal

harm to personnel if you do not follow the instructions.

It indicates much attention should be paid. An unex pected result may occur if you do

not follow the instructions.

1.2 Revision History

Version Revision Release Date

1st The first version was published. May 30, 2018

1-2

Page 12

2

Chapter 2 Overview of DVP15MC11T

Table of Contents

2.1 Product Description .................................................................................... 2-2

2.2 Functions ................................................................................................... 2-2

2.3 Profile and Components ............................................................................. 2-3

2-1

Page 13

DVP15MC11T Operation Manual

_2

2.1 Product Description

DVP15MC11T is a type of multi-axis motion controller researched and produced by Delta autonomously on

the basis of CANopen field bus. It complies with CANopen DS301 basic communication protocol and

DSP402 motion control protocol. In addition, i t also supports standard instruction libraries defined by

international organizations for motion control . It brings great convenience to user to learn and develop

projects quickly. Maximum 24 axes can be controlled by means of Motion port. The single-axis motion

instructions including velocity, position, torque and homing instruct ions as well as multi-axis in structio ns such

as electronic gear, electronic cam, rotary cut and G code are supported.

Multiple communication ports are built in DVP 15MC11T. And thus various communication function s c an be

realized without adding modules. DVP15MC11T has left-side and right-side extension ports for adding

DVP-S series modules to its left and right sides. (The left-side port is a high-speed parallel extension port.)

The communication system adopts highly reliable CAN bus as the main line and hence users just need

simple cables for wiring.

Thanks to the high-speed reliable motio n control system , DVP15M C11T can be widely a pplied to a variety of

automation control industries such as packagi ng, printing, encapsulating, wire cutting, drug manufact uring

and so on.

2.2 Functions

Able to control up to 24 real axes (with axis No. ranging from 1 to 32).

The virtual axis and encoder axis can be built inside DVP15MC11T (with the axis No. ranging from 1

to 32, which can not be the same as that of real axes).

Equipped with 1GHz high-speed floating-point operation processor; supporting 64-bit floating point

(Lreal) and capable to meet various complicated motion control.

With two built-in incremental encoder ports and one SSI absolute encoder port.

With one RS232 port, one RS485 port and two Ethernet ports.

With one built-in CAN port serving as CANopen master or slave.

Supports powerful field network (as Ethernet master or slave, CANopen master or slave and

Profibus-DP slave) for construction of a function-complicated control system.

With a variety of I/O extensions (Left-side high-speed AIAO; right-side low-speed A IAO and DIDO

and temperature modules).

Using the easy-to-use software interface with the features of complete function and conv enient

application.

Providing standard bus cables, terminal resistors, distributor boxes and other acce ssorie s as well as

easy and convenient plug-and-play wiring.

2-2

Page 14

_

2.3 Profile and Components

CAN

ERR

1

RUN

ERR

2

RUN

00

10

00

01

11

01

02

12

02

03

13

03

04

14

04

05

15

05

06

16

06

07

17

07

EXTENSION

PORT

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

Chapter 2 Specifications

2

1E

○

A

2E

○

A

3E

○

A

4E

○

A

5E

○

A

6E

○

A

7E

○

A

8E

○

A

9E

○

Model name

State indicators

IO indicators

COM/SSI communication port

Incremental encoder port

Ethernet communication port

CANopen communication port

CANmotion communication port

Input and output pins and symbols

A

10E

○

A

11E

○

A

12E

○

A

13E

○

A

14E

○

A

15E

○

A

16E

○

A

17E

○

SD card slot

Right-side extension module port

24V power port

Screw fixing clip

Extension module fixing clip

Left-side extension module port

Nameplate

DIN rail fixing clip

2-3

Page 15

DVP15MC11T Operation Manual

_2

MEMO

2-4

Page 16

3

Chapter 3 Specifications

Table of Contents

3.1 Function Specifications .............................................................................. 3-2

3.1.1 Specifications ........................................................................................ 3-2

3.1.2 Devices and Data Types ......................................................................... 3-3

3.1.2.1 Devices ............................................................................................. 3-3

3.1.2.2 Valid Ranges of Devices ...................................................................... 3-4

3.1.2.3 Latched Devices ................................................................................. 3-5

3.1.2.4 Data Types and Valid Ranges Supported ................................................ 3-6

3.2 Electrical Specifications ............................................................................. 3-7

3-1

Page 17

DVP15MC11T Operation Manual

_3

Size

20M

Number of

Memory

variables

Retained

Size

128K

One single G code

program

G code programs

Quantity

64

Real axis: 1~24, Virtual axis: 1~32.

Max. number of axes for linear

interpolation

Max. number of axes for circular

interpolation

Number of

cams

Cam key

points

Key points of one

single cam

One CAN port supports the

Ethernet

2

Two independent Ethernet ports

RS-232

1

Used as a master or slave

RS485

1

Used as a master or slave

Incremental

encoder

Builds an encoder axis. Z signal can

trigger an interrupt program.

SSI absolute

16 points (External interrupt trigger

is supported.)

Output points

Quantity

8 points

Left-side extension

port

Slim-series left-side extension

module

Right-side

extension port

Left-side

Left-side extension

8 pieces of Slim series left-side

8 pieces of Slim series special

modules

Number of

points

240 input points and 240 output

points

3.1 Function Specifications

3.1.1 Specifications

Item Specification

Program

capacity

Quantity

POU

definitions

1024

Programming

Motion

control

capacity for

G code

Number of

controlled

axes

Non-retained Size 20M

Size 256K

Max. number of axes for

single-axis control

Size Quantity 64

Quantity 2048

CAN 2

The virtual axis number is different

from the real axis number.

8

3

standard CANopen protocol and the

other CAN port is used in Motion.

Built-in ports of DVP15MC11T

Left-side and

right-side

extension

3-2

extension

Right-side

extension

2

encoder

Input points Quantity

modules

Special modules Quantity

Digital modules

1 Builds an encoder axis

1

1 Slim series special module

Quantity

extension modules

Page 18

3_

3.1.2 Devices and Data Types

% I X 0 0.

Digital point number

Prefix 2 symbol

Prefix 1 symbol

A fixed character

No.

Item

Content

1

Prefix 1 symbol

I Q M

Input

device

Output

device

Intermediate

device

3

Prefix 2 symbol

X B W D L

4

Data type of prefix 2

BIT

BYTE

WORD

DWORD

QWORD

5

%IX0.0

%IB0

%IW0

%ID0

%IL0

6

%QX0.0

%QB0

%QW0

%QD0

%QL0

7

%MX0.0

%MB0

%MW0

%MD0

%ML0

Device

Corresponding relationships

The 1st WORD

The 2nd WORD

The 3rd WORD

The 4th WORD

0

7

8

15

0

8

15

0

7

8

15

0

8

15

%MB

%MB0

%MB1

%MB2

%MB3

%MB4

%MB5

%MB6

%MB7

%MW

%MW0

%MW1

%MW2

%MW3

%MD

%MD0

%MD1

%ML

%ML0

Device

Corresponding relationships

%MX

3.1.2.1 Devices

Device Name Explanation

Relevant Devices of DVP15MC11T Used in the Software

Chapter 3 Specifications

2 Prefix 1 name

Device example

The Corresponding Relationships of Devices

%ML0 includes %MB0~%MB7, %MD0 includes %MB0~%MB3 and %MW0 includes %MB0~%MB1 as shown

in the following table.

name

%MX

Bit

%MX0.0~0.7 %MX1.0~1.7 %MX2.0~2.7 %MX3.0~3.7 %MX4.0~4.7 %MX5.0~5.7 %MX6.0~6.7 %MX7.0~7.7

...

Bit

Bit

…

Bit

Bit

...

Bit 7 Bit

…

Bit

Bit

...

Bit

Bit

…

Bit

Bit

...

Bit 7 Bit

…

Bit

%ML1 includes %MB8~%MB15, %MD2 includes %MB8~%MB11, %MW4 includes %MB8~%MB9

and %MB8 includes %MX8.0~8.7 as shown in the following table.

name

%MX

%MB

%MW

%MD

The 5th WORD The 6th WORD The 7th WORD The 8th WORD

Bit

0

%MX8.0~8.7 %MX9.0~9.7

Bit 7 Bit

...

%MB8 %MB9 %MB10 %MB11 %MB12 %MB13 %MB14 %MB15

8

%MW4 %MW5 %MW6 %MW7

Bit

…

Bit

15

0

%MX10.0~10.7 %MX11.0~11.7 %MX12.0~12.7 %MX13.0~13.7 %MX14.0~14.

%MD2 %MD3

...

Bit 7 Bit

8

…

Bit

15

Bit

0

...

Bit 7 Bit

8

…

Bit

15

Bit

0

...

7

Bit 7 Bit

8

Bit

…

15

15.0~15.

7

3-3

Page 19

DVP15MC11T Operation Manual

_3

Device

Device name

Expression

Range

The 5th WORD The 6th WORD The 7th WORD The 8th WORD

name

Bit

0

...

Bit 7 Bit

8

…

Bit

15

Bit

0

Corresponding relationships

...

Bit 7 Bit

8

…

Bit

15

Bit

0

...

Bit 7 Bit

8

…

Bit

15

Bit

0

...

Bit 7 Bit

8

…

Bit

15

%ML

%ML1

3.1.2.2 Valid Ranges of Devices

The table of valid ranges of the devices in DVP15MC11T

%IX %IX0.0~%IX0.7 %IX0.0~%IX127.7

%QX %QX0.0~%QX0.7 %QX0.0~%QX127.7

%MX %MX0.0 %MX0.0~%MX131071.7

%IB %IB0 %IB0~%IB127

%QB %QB0 %QB0~%QB127

%MB %MB0 %MB0~%MB131071

%IW %IW0 %IW0~%IW63

%QW %QW0 %QW0~%QW63

%MW

%ID %ID0 %ID0~%ID31

%QD %QD0 %QD0~%QD31

%MD %MD0 %MD0~%MD32767

%MW0

%MW0~%MW65535

%IL %IL0 %IL0~%IL15

%QL %QL0 %QL0~%QL15

%ML %ML0 %ML0~%ML16383

3-4

Page 20

3_

The table of Modbus device addresses

Device

type

Modbus address

type

%IX0.0~%IX0.7

0x6000~0x6007

%IX1.0~%IX1.7

0x6008~0x600F

……

……

%IX127.0~%IX127.7

0x63F8~0x63FF

Word

%IW0~%IW63

0x8000~0x803F

%QX0.0~%QX0.7

0xA000~0xA007

%QX1.0~%QX1.7

0xA008~0xA00F

……

……

%QX127.0~%QX127.7

0xA3F8~0xA3FF

Word

%QW0~%QW63

0xA000~0xA03F

%MX0.0~%MX0.7

0x10000000~0x10000007

addresses

%MX1.0~%MX1.7

0x10000008~0x1000000F

……

……

%MX131071.0~%MX131071.7

0x100FFFF8~0x100FFFFF

Standard Modbus

address

Delta-extended

Modbus addresses

Chapter 3 Specifications

Device area

I

(Input)

Q

(Output)

M

(Register)

Bit

Bit

Bit

Word

Word

%MW0~%MW32767 0x0000~0x7FFF

%MW32768~%MW65535 0x20008000~0x2000FFFF

3.1.2.3 Latched Devices

Range Modbus address

Standard Modbus

address

Delta-extended

Modbus

The %MW0~%MW999 devices are latched devices in which data are retained when power off. Besides, the

variables defined in the software can select Retain as its property. The capacity of latched devices is 128K

bytes.

3-5

Page 21

DVP15MC11T Operation Manual

_3

No.

Data type

Valid range

Initial value

1

BOOL

TRUE or FALSE

FALSE

2

BYTE

16#00 ~ FF

16#00

3

WORD

16#0000 ~ FFFF

16#0000

4

DWORD

16#00000000 ~ FFFFFFFF

16#00000000

5

LWORD

16#0000000000000000 ~ FFFFFFFFFFFFFFFF

16#0000000000000000

6

USINT

0 ~ +255

0

7

UINT

0 ~ +65535

0

8

UDINT

0 ~ +4294967295

0

9

ULINT

0 ~ +18446744073709551615

0

10

SINT

−128 ~ +127

0

11

INT

−32768 ~ +32767

0

12

DINT

−2147483648 ~ +2147483647

0

13

LINT

−9223372036854775808 ~ +9223372036854775807

0

−3.402823e+38 ~ −1.175495e-38,

+1.175495e-38 ~ +3.402823e+38

−1.79769313486231e+308 ~

Range:T#0ns~213503d23h34m33s709.551ms

D#Y-M-D. Range: D#1970-01-01~D#2106-02-07. Unit:

TOD#H:M:S:MS, Range:TOD#00:00:00~23:59:59.999.

is displayed. If 1 is

DT#Y-M-D-H-M-S. Range:

DT#1970-01-01-0:0:0~2106-02-07-6:28:15. Unit: s.

20

STRING

0~32000 characters

‘’

3.1.2.4 Data Types and Valid Ranges Supported

The data types and valid ranges of the variables in the software that DVP15MC11T uses are shown in the

following table.

14 REAL

15 LREAL

16 TIME

17 DATE

18 TOD

19 DT

0,

−2.22507385850721e-308,

0,

+2.22507385850721e−308 ~

+1.79769313486231e+308,

T#XXXXXXdXXhXXmXXsXXXms,Unit: ns.

s.

Unit: ms. If 0 is written, TOD#00:00:00

written, TOD#00:00:00.001 is displayed. If 86399999 is

written, TOD#23:59:59.999 is displayed. If 86400000 is

written, TOD#00:00:00 is displayed. If 4294967295 is

written, TOD#17:2:47.295 is displayed.

0.0

0.0

T#0ms

D#1970-01-01

TOD#00:00:00

DT#1970-01-01-0:0:0

3-6

Page 22

3_

3.2 Electrical Specifications

Item

Content

Fuse capacity

3 A/30 VDC, Polyswitch

Consumption

power

Static electricity: 8KV Air Discharge, 4KV Contact Discharge

Work: 0°C ~ 55°C (Temperature), 5 ~ 95% (Humidity), pol lution level 2

Weight

About 425g

Item

Content

Number of input

channels

Channel type

High-speed digital input type for the 16 channels

Common terminal

24 VDC, 5mA

The unshielded cable: 300m

Item

Content

Number of output

channels

Common terminal

for output points

Power voltage for

output points

Electrical specification

Chapter 3 Specifications

Power voltage

Isolation voltage

Vibration/shock

immunity

Interference

immunity

Environment

Electrical specificati on for input points

24 VDC(-15% ~ +20%)

500 VDC(Secondary-PE)

8W Max

Standard: IEC61131-2,IEC 68-2-6 (TEST Fc)/IEC61131-2 & IEC 68-2-27 (TEST

Ea)

EFT: Power Line: ±2KV, Digital Input: ±1KV,

Communication I/O: ±1KV

RS: 80MHz ~ 1000MHz, 10V/m.

Conducted Susceptibility Test: 150kHz ~ 80MHz, 3V/m

Surge Test: Power line 0.5KV DM/CM

Storage: -25°C ~ 70°C (Temperature), 5 ~ 95% (Humidity).

16 channels

Input terminals

for input points

Input type Sink or Source mode

Input delay

Input current

Max. cable length

Electrical specificati on for output points

Channel type High-speed digital output type for 8 channels

Output terminals Terminal Q0~Q7

Output delay

Terminal I0~I7,I10~I17

Terminal S0/S1

2.5µS (OFF ->ON), 5 µS (ON -> OFF)

The shielded cable: 500m;

8 transistors for output (N-MOS)

Terminal UP/ZP (Used for connection of anode or cathode of supply power)

24 VDC(-15% ~ +20%)#1

2µS ( OFF -> ON), 3µS ( ON -> OFF)

3-7

Page 23

DVP15MC11T Operation Manual

_3

Item

Content

Max. switch

frequency

The shielded cable: 500m

The unshielded cable: 300m

1KHZ

Resistance: 0.5A/1point (2A/ZP)

Max. loading

Max. cable length

#1: UP and ZP must connect the auxiliary power 24VDC (-15%~20%).

Inductance: 13W(24VDC)

Bulb: 2.5W(24VDC)

3-8

Page 24

4

Chapter 4 System Architecture

Table of Contents

4.1 System Constitution ................................................................................... 4-2

4.2 Power Supply ............................................................................................. 4-2

4.3 Left-side Extension .................................................................................... 4-2

4.3.1 Connectable Left-side Extension Module .................................................... 4-2

4.3.2 Allocation of Left-side Network Module Addresses ....................................... 4-3

4.3.3 Method of Reading/Writing of Left-side Modules ......................................... 4-3

4.4 Right-side Extension .................................................................................. 4-3

4.4.1 Connectable Right-side Extension Modules ................................................ 4-3

4.4.2 Allocation of Right-side Extension Module Addresses ................................... 4-4

4.5 Connectable Servo Drives........................................................................... 4-4

4.6 SD Memory Card ......................................................................................... 4-6

4.6.1 Model and Specification .......................................................................... 4-6

4.6.2 Function ............................................................................................... 4-8

4-1

Page 25

DVP15MC11T Operation Manual

_4

Module

name

Input

voltage

Output

voltage

Output

current

International

Standard

1

DVP04AD-SL

Analog module

Analog input

2

DVP04DA-SL

Analog module

Analog output

4.1 System Constitution

A multi-layer industrial network can be built by means of DVP15MC11T. By using DVP15MC11T, the

network can consist of top-layer Ethernet, middle-layer CANopen and Profibus bus as well as bottom-layer

RS-485 bus which supports Modbus as follows.

The figure above illustrates the peripheral device s which are connected to various ports of DVP15MC11T in

the entire system. Refer to chapter 6 for details on the functions of communication ports.

4.2 Power Supply

Delta power modules are recommended as the power supply for DVP15MC11T. The information of Delta

power modules is shown in the following table.

No.

1 DVPPS02

2 DVPPS05 120W 5A

Phase

Single

phase

Power

48W 2A

85~264VAC 24VDC

4.3 Left-side Extension

4.3.1 Connectable Left-side Extension Module

Max. 8 high-speed extension modules can be connected to the left side of DVP15MC11T and the

connectable modules are listed in the following table.

No. Module name Module type Description

3

4-2

DVPPF02-SL

Network module Profibus communication

Page 26

Chapter 4 System Architecture

4_

Mapping

Position

Input data

length

Output data

length

7

DVP16SP11R/T

8 bits

8 bits

4.3.2 Allocation of Left-side Network Module Addresses

About Input and Output Mapping Areas of Left-side Network Modules

The input and output mapping areas of different po sitions of the left side of PLC CPU are listed as follows

when the network modules connected to the left side of DVP15MC11T serve as a slave. The position 1 is for

the first module connected to the left side of P LC CPU; the position 2 is for the second one connected to the

left side of PLC CPU and so on.

area

1

2

3

4

5

6

7

8

Refer to the operation manuals of modules for details on al location of left-side extension module mapping

areas. Pay attention to how the mapping address expression format is changed in the operation manual.

For example, the output mapping area for DVPPF02-SL is D6250~D6349. But the area address is expressed

as %MW6250~%MW6349 when the module is connected to the left of DVP15MC11T.

Output mapping area Input mapping area

%MW6250~%MW6377 %MW6000~%MW6127

%MW6750~%MW6877 %MW6500~%MW6627

%MW7250~%MW7377 %MW7000~%MW7127

%MW7750~%MW7877 %MW7500~%MW7627

%MW8250~%MW8377 %MW8000~%MW8127

%MW8750~%MW8877 %MW8500~%MW8627

%MW9250~%MW9377 %MW9000~%MW9127

%MW9750~%MW9877 %MW9500~%MW9627

4.3.3 Method of Reading/Writing of Left-side Modules

The controller can read and write the data in CR regi st ers of the left-side extension modules via FROM/TO

instruction. For instance, the modules such as DVP04AD-SL and DVP04DA-SL may use FROM/TO to read

and write data in CR.

4.4 Right-side Extension

4.4.1 Connectable Right-side Extension Modules

Slim-series extension modules including digital modules, analog modules and temperature modules can be

connected to the right side of DVP15MC11T. Digital m odules can conne ct maximum 240 inp ut points and 24 0

output points. Maximum 8 analog modules can be connected. The connectable right-side extension module s

are listed in the following table.

No. Module name

1 DVP08SM11N 8 bits 2 DVP16SM11N 16 bits 3 DVP06SN11R - 6 bits

4 DVP08SN11R/T - 8 bits

5 DVP16SN11T - 16 bits

6

DVP08SP11R/T

8

DVP16SP11TS(PNP)

9 DVP32SM11N 32 bits - Pin-connector input

4 bits

8 bits 8 bits

4 bits

Input point extension

Output point extension

Input extension and output

extension

Extension type

4-3

Page 27

DVP15MC11T Operation Manual

_4

Input data

length

Output data

length

16

DVP06XA-S

4 words

2 words

Analog input and analog output

-

-

Sensor

(Model: J, K, R, S, T thermocouples)

No. Module name

10 DVP32SN11TN - 32 bits Pin-connector output

11 DVP08ST11N 8 bits - Digital switch

12 DVP04AD-S 4 words 13 DVP06AD-S 6 words 14 DVP04DA-S - 4 words

15 DVP02DA-S

17 DVP04PT-S

18 DVP06PT-S

19 DVP04TC-S 4 words -

-

4 words

6 words

2 words

Analog input

Analog output

Sensor

(Model: PT100)

Extension type

4.4.2 Allocation of Right-side Extension Module Addresses

DVP15MC11T can connect Slim-series extension modules to its right side and max. 240 di gital input points

and 240 digital output points are connectable. Max. 8 special modules are connectable such as analog

modules, temperature modules and pulse modules. Up to 14 digi tal modul es and special m odules at mo st are

connectable to the right side of DVP15MC11T.

Input point number and output point number of right-side digital extension modules

The input point number and output point number of t he digi tal extension modules connected to the right of

DVP15MC11T start from 2.0. For example, the input point for the first digital module starts from %IX2.0 and

the output point starts from %QX2.0. It is counted as 8 points if the n um ber is less than 8.

Digital input points and output points are numbe red as below: (Octal)

%IX2.0 ~%IX2.7,......, %IX16.0 ~%IX16.7,......, %IX31.0 ~ %IX31.7

%QX2.0 ~ %QX2.7,......, %QX16.0 ~ %QX16.7,......, %QX31.0 ~ %QX31.7

About the right-side special module and serial number

The right-side extension modules such as analog modules, temperature modules and pulse

modules are regarded as special modules.

The serial number of the first special module to the right side of DVP15MC11T is 0; the serial

number of the second one is 1, and so on. Maximum 8 special modules can be connect ed. The start

address for input of the right-side special module is %MW10000 an d t he start address for output of

the right-side special module is %MW10500.

DVP15MC11T can directly read and write the right-side module parameters through the hardware

configuration interface of the software. Also, it can grant a value to an address or grant a value to a

variable with which an address is combined in a prog ram to read and write right-side module

parameters.

4.5 Connectable Servo Drives

There are many models for ASDA-A2-series servo drives. ASDA-A2-XXXX-M model supports CANopen

communication. Only ASDA-A2-XXXX-M servo drives can be used to build CANopen motion control network

through connecting the motion port of DVP15MC11T. The connection between DVP15MC11T and the servo

drive can be made with UC-CMC003-01A or UC-CMC005-01A cable through CN6 po rt.

4-4

Page 28

4_

Illustration of the servo drive model

address of the servo in the CANopen

corresponds to must be consistent with that of

0203: CANopen baud rate is 500Kbps

Chapter 4 System Architecture

Relevant servo parameter settings are shown in the following table when DVP15MC11T and the

servo drive are connected.

Parameter Explanation Setting value Explanation

P1-01

P3-00

P3-01

*1:The output directions of the torque are illustrated as below w hen the value of X is 0 and 1 respectively.

Setting the control

mode of the servo

Setting a node ID

Baud rate

X0B*1 Set as CANopen mode

Setting range:

1~24

0403

The setting of this parameter corresponds to

the node

network

The baud rate that the parameter value

DVP15MC11T.

0403: CANopen baud rate is 1Mbps

4-5

Page 29

DVP15MC11T Operation Manual

_4

0

1

P CCW( )

N CW( )

N CW( )

P CCW( )

Positive

direction

Negative

direction

The wiring figure of DVP15MC11T and ASDA-A2-XXXX-M-series servo drives

Notes:

1. Please refer to the servo user manual for the wiring of ASDA-A2-XXXX-M-series servo drives, servo

motors and encoders.

2. Choose UC-CMC003-01A or UC-CMC005-01A or UC-CMC010-01A communication cable according

to the field status.

3. There is one 120Ω terminal resistor embedded at Motion port. In the CANopen network consisting of

Motion port and servos, the other end of the network must be connected with a terminal resistor

TAP-TR01 which could be found in the packing box of DVP15MC11T.

4.6 SD Memory Card

4.6.1 Model and Specification

Model and Appearance

SD memory cards can be classified into SD, Mini S D and Mic ro SD acc ording to it s size. DVP15MC11T only

supports the standard-dimension SD.

4-6

Page 30

Chapter 4 System Architecture

4_

Class

SD

SDHC

SDXC

Capacity

32MB~2GB

4GB~32GB

32GB~2TB

Size

SD

SDHC

Mini SDHC

Micro SDHC

SDXC

Micro SDXC

SD

Mini SD

Micro SD

Specification

There are various SD card specifications on current m ark et. Except that SD cards are different in size, they

can be classified into SD, SDHC and SDXC according to its capacity . However, DVP15MC11T only supports

basic SD specification currently. The following table includes the information of SD card family members.

DVP15MC11T only supports SD and SDHC. Please make sure to purcha se t he SD card of the right

specification that DVP15MC11T supports.

SD card classification

File system

SD speed

level

* Please notice that there is a kind of MMC card which is v ery similar to SD card in appearance and thus

please differentiate them carefully during pur chase.

Before use of SD card

Write-protection function of the memory card

There is a write-protection switch for general SD cards. The data can not be written into SD card if the

switch is moved to the Lock position. Hence, please ensure that the write-protection switch of SD card

has been released correctly before SD card is used and then the write-into function can be executed in

DVP15MC11T.

FAT16/FAT32 FAT32

CLASS 2 (Min. 2MB/Sec.)

N/A

CLASS 4 (Min. 4MB/Sec.)

CLASS 6 (Min. 6MB/Sec.) CLASS 10

(Min. 10MB/Sec.)

exFAT(FAT64)

CLASS 2 (Min. 2MB/Sec.)

CLASS 4 (Min. 4MB/Sec.)

CLASS 6 (Min. 6MB/Sec.)

CLASS 10 (Min. 10MB/Sec.)

4-7

Page 31

DVP15MC11T Operation Manual

_4

Write-

protected

Released

4.6.2 Function

The main purpose of SD card is to upgrade the firmware of DVP15MC11T.

4-8

Page 32

5

Chapter 5 Installation

Table of Contents

5.1 Dimensions ................................................................................................ 5-2

5.1.1 Profile and Dimensions of DVP15MC11T .................................................... 5-2

5.1.2 Dimensions of Left-side and Right-side Extension Modules ........................... 5-2

5.1.3 Connecting to the Left-side Extension Module ............................................ 5-3

5.1.4 Connecting to the Right-side Extension Module .......................................... 5-4

5.1.5 SD Card Installing and Removing ............................................................. 5-5

5.2 Installing the Module in the Control Cabinet .............................................. 5-7

5.2.1 Installing the Module to DIN rail .............................................................. 5-7

5.2.2 Illustration of Installation Inside the Control Cabinet ................................... 5-7

5.2.3 Environmental Temperature in the Control Cabinet ..................................... 5-7

5.2.4 Actions for Anti-interference .................................................................... 5-8

5.2.5 Dimension Requirement in the Control Cabinet .......................................... 5-8

5-1

Page 33

DVP15MC11T Operation Manual

_5

CAN

ERR

1

RUN

ERR

2

RUN

00

10

00

01

11

01

02

12

02

03

13

03

04

14

04

05

15

05

06

16

06

07

17

07

128

EXTENSION

PORT

110

68.4

116.2

96

90

33.1 60

5.1 Dimensions

5.1.1 Profile and Dimensions of DVP15MC11T

Unit: mm

5.1.2 Dimensions of Left-side and Right-side Extension Modules

See the following dimension figure of a left-side extension module by taking DVPCOPM-SL for example.

The length, width and height of all left-side modules are the same as that of DVPCOPM-SL.

Unit: mm

See the following dimension figure of a right-side extension module, which takes DVP04AD-S for

example. The length, width and height of all left-side modules are the same as that of DVP04AD-S.

5-2

Page 34

5_

96

90

25.2

60

Unit: mm

CAN

ERR

1

RUN

ERR

2

RUN

00

10

00

01

11

01

02

12

02

03

13

03

04

14

04

05

1 5

05

06

1 6

06

07

1 7

07

1

2

2

Chapter 5 Installation

5.1.3 Connecting to the Left-side Extension Module

Connection of DVP15MC11T and DVPDNET-SL

Pull open the extension module clips on the top left and bottom left of DVP15MC11T and

install DVPDNET-SL along four mounting holes in the four angles of DVP15MC11T as step 1

in figure 5.1.3.1.

Press the clips respectively on the top left and bottom left of DVP15MC11T to fix the module tightly

and ensure that their contact is normal as step 2 in figure 5.1.3.1.

Figure 5.1.3.1

Installing DVP15MC11T and DVPDNET-SL into DIN rail

Use standard 35mm DIN rail.

Pull open DIN rail clips of DVP15MC11T and DVPDNET-SL and then insert the two modules into

DIN rail.

5-3

Page 35

DVP15MC11T Operation Manual

_5

35mm

Din Rail

CA N

ER R

1

RU N

ER R

2

RU N

0 0

1 0

0 0

0 1

11

0 1

0 2

12

0 2

03

13

03

04

14

04

05

15

05

06

16

06

07

17

07

CA N

E RR

1

RU N

E RR

2

RU N

0 0

1 0

0 0

0 1

1 1

0 1

0 2

1 2

0 2

0 3

1 3

0 3

0 4

1 4

0 4

0 5

15

0 5

0 6

16

0 6

0 7

17

0 7

1

2

2

Press the DIN rail clips into DVP15MC11T and DVPDNET-SL to fix the two modules in DIN rail as

figure 5.1.3.2.

Figure 5.1.3.2

5.1.4 Connecting to the Right-side Extension Module

Connection of DVP15MC11T and DVP16SP11T

Pull open the extension module clips on the top right and bottom rig ht of DVP15MC11T and

install DVP16SP11T along four mounting holes in the four angles of DVP15M C11T as step 1

in figure 5.1.4.1.

Press the clips on the upper right and bottom right of DVP15MC11T to fix the module tightly

and ensure that their contact is normal as step 2 in figure 5.1.4.1

Installing DVP15MC11T and DVP16SP11T in DIN Rail

Use standard 35mm DIN rail.

Pull open DIN rail clips of DVP15MC11T and DVP16SP11T and then insert the two modules into

DIN rail.

Figure 5.1.4.1

Press the DIN rail clips into DVP15MC11T and DVP16SP11T to fix the two modules in DIN rail as

figure 5.1.4.2.

5-4

Page 36

Chapter 5 Installation

5_

35mm

Din Rail

CAN

ERR

1

RUN

ERR

2

RUN

00

10

00

01

11

01

02

12

02

03

1 3

03

04

1 4

04

0 5

1 5

0 5

0 6

1 6

0 6

0 7

1 7

0 7

CA N

ER R

1

RU N

ER R

2

RU N

0 0

1 0

0 0

0 1

1 1

0 1

0 2

1 2

0 2

0 3

1 3

0 3

0 4

1 4

0 4

0 5

15

0 5

0 6

16

0 6

0 7

17

0 7

Me mor y

card slo t

CAN

ERR

1

RUN

ERR

2

RUN

00

10

00

01

11

01

02

1 2

02

03

13

03

04

14

04

05

15

05

06

16

06

07

17

07

CAN

ERR

1

RUN

ERR

2

RUN

00

10

00

01

11

01

0 2

12

0 2

03

13

03

04

14

04

05

15

05

06

16

06

07

17

07

CAN

ERR

1

RUN

ERR

2

RUN

00

10

00

01

11

01

02

12

02

03

13

03

04

14

04

0 5

15

0 5

06

16

06

07

17

07

Figure 5.1.4.2

5.1.5 SD Card Installing and Removing

The memory card slot of DVP15MC11T

The memory card slot is seated in the right side of the front of DVP15MC11T as illustrated below.

Installing SD card

Insert an SD card to the memory card slot directly and push it to the end of the slot until hearing a click. After

the installation is finished, the SD card should be f i xed tightly. If the SD card inserted to the slot is loose, the

installation is unsuccessful. In addition, the SD card has a fool-proofing design. If the direction in which SD

card is inserted is wrong, the card will fail to reach the end of the slot. In this case, do not force to push the

SD card toward the end of the slot in order to avoid the damage to the module and SD card.

Follow the instructions in the figures below to insert the SD card in the right direction.

5-5

Page 37

DVP15MC11T Operation Manual

_5

CAN

ERR

1

RUN

ERR

2

RUN

0 0

10

0 0

01

11

01

02

12

02

03

13

03

04

14

04

05

15

05

06

1 6

06

0 7

17

0 7

CAN

ERR

1

RUN

ERR

2

RUN

00

10

00

01

11

01

02

12

02

03

1 3

03

04

14

04

05

15

05

06

16

06

07

17

07

CAN

ERR

1

RUN

ERR

2

RUN

00

10

00

01

11

01

0 2

12

0 2

03

13

03

04

14

04

05

15

05

06

16

06

07

17

07

Removing SD card

Just push the SD card to t he end of the slot so that the SD card will l oosen and rebound f rom inside the slot.

And then remove the SD card out of the slot easily.

5-6

Page 38

Chapter 5 Installation

5_

Ethernet

LAN1 LAN 2 CAN1 CAN2

CANopen M otion

OUT

IN

DVP15MC11T

000 102 030 4 0506 07

1011 12 131 4 1516 17

000 102 030 4 0506 07

00

01

02

03

04

05

06

07

S0

10

11

12

13

14

15

16

17

S1

00

01

02

03

04

05

06

07

UPZP

0V 24V

15

10

5 1

6

11 15

10

5 1

6

11

ENCODER COM /SSI

CAN

ERR

1

RUN

ERR

2RUN

PWR

RUN

ERR

SD

RS232

RS485

LAN1

LAN2

5.2 Installing the Module in the Control Cabinet

5.2.1 Installing the Module to DIN rail

Pull down the clips at the bottom of DVP15MC11T. T hen st i ck the h oriz ontal slots at the rear of t he modul e on

the DIN rail. Finally, push up the clips to fix the module inside the control cabinet.

5.2.2 Illustration of Installation Inside the Control Cabinet

5.2.3 Environmental Temperature in the Control Cabinet

Requirements

1. The environment inside the control cabinet for DVP15MC11T is 0°C ~ 55°C in temperature and 5 ~

95% in humidity.

2. Please do not make the installation near the equipment of high temperature.

5-7

Page 39

DVP15MC11T Operation Manual

_5

. In order to ensure that the

3. Keep enough space for ai r ventilation.

4. The fan or air conditio ner must be installed if the environment temperature is higher than 55°C.

Notes:

1. The control cabinet of the height 1.0m~2.0m is easy for installation and operation.

2. Make the installation away from the high-voltage equipment and po wer equipment.

3. The power supply in the control cabinet must be cut before installation.

5.2.4 Actions for Anti-interference

Do not install the controller in the control cabinet where there is high-voltage equipment.

Please keep at least 200mm far away from the power wire for the installation.

There should be a grounding wire for the control cabinet.

5.2.5 Dimension Requirement in the Control Cabinet

Installation Figure

DVP15MC11T has to be installed in an

enclosure

controller radiates heat normally, the space

between the controller and the enclosure has

to be larger than 50 millimeters. D > 50mm

5-8

Page 40

6

Chapter 6 Wiring, Communication

Setting and Network

Construction

Table of Contents

6.1 Wiring ........................................................................................................ 6-3

6.1.1 Power Supply ........................................................................................ 6-3

6.1.2 Safety Circuit Wiring .............................................................................. 6-3

6.2 Input Point and Output Point Wiring .......................................................... 6-4

6.2.1 Function that Input Points Suppo r t ........................................................... 6-4

6.2.2 Input Point Wiring ................................................................................. 6-5

6.2.3 Output Point Wiring ............................................................................... 6-6

6.3 RS-485 Communication Port ...................................................................... 6-8

6.3.1 Function that RS-485 Port Supports ......................................................... 6-8

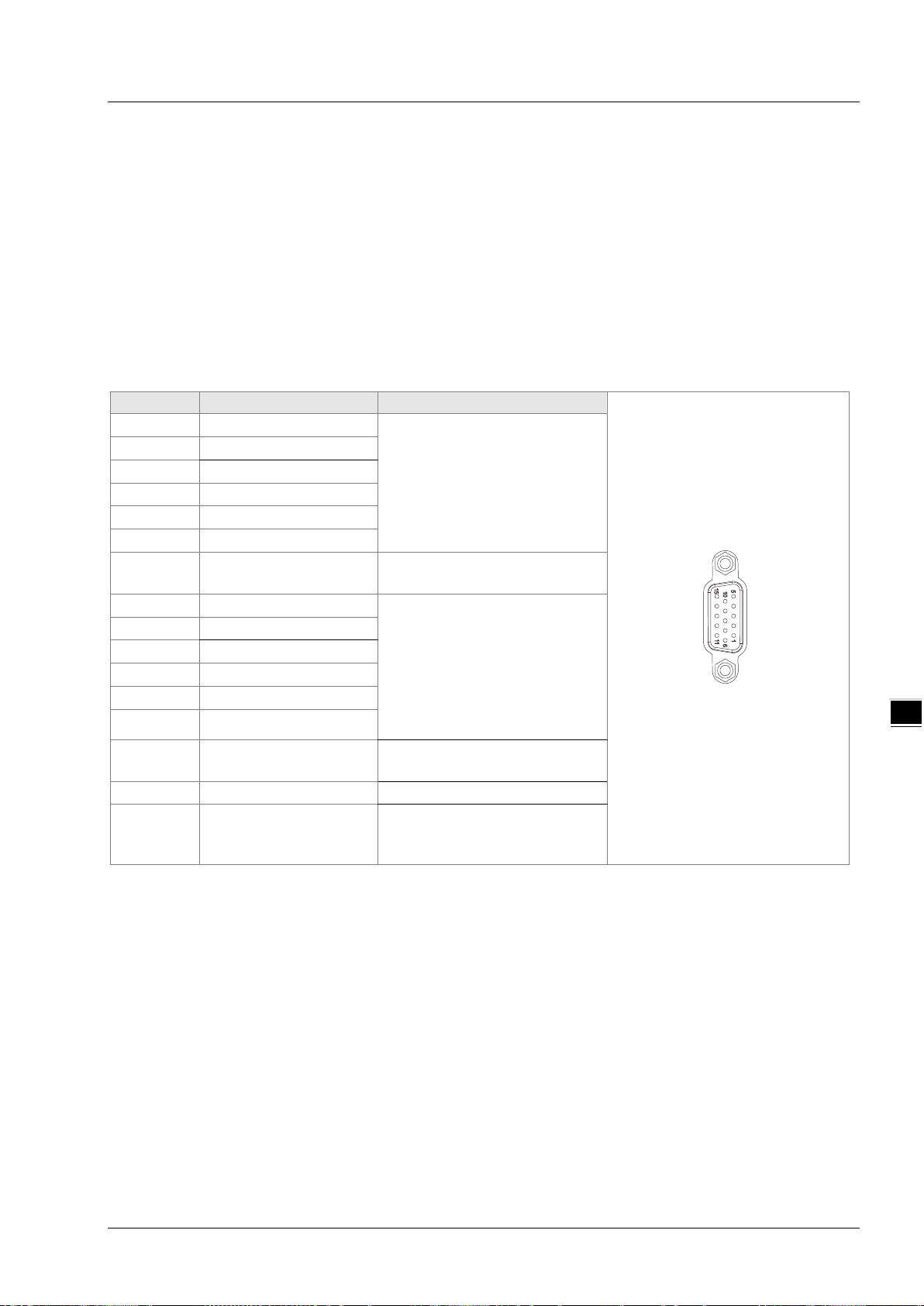

6.3.2 Definitions of RS-485 Port Pins ................................................................ 6-8