Page 1

E

NEW

®

INNOVATION and EX C ELL E N C

DTL Series

DTL2A Model

100 Watt, Digitally Programmable

Serial-Input, Electronic Loads

®

Features

■

12-bit, optically isolated (500Vdc),

CMOS/TTL-compatible serial input

■

0-20 Amp output in 5mA increments

■

10MΩ minimum output impedance

■

Output voltage to 50 Volts

■

Output power to 100 Watts

■

±5mA offset error; ±0.1% gain error

■

100µsec full-scale step response

■

Update rates to 20kHz

■

Operate in parallel for higher power

■

Miniature, 2" x 2" metal package

Applications

■

Static/dynamic power-supply burn-in

■

Power-supply test and characterization

■

Battery capacity testing

■

Current-source testing

■

Capacitor discharge testing

■

Real-time load simulation

DATEL’s new DTL2A is an optically isolated, digitally programmable, serial-input,

electronic load. It is essentially a digitally controlled current source that can sink

currents from 0 to 20 Amps, at loading voltages from 2.5 to 50 Volts, up to a maximum

power of 100 Watts. The DTL2A is packaged in a thermally effi cient, 2" x 2" x 0.5"

metal package that incorporates an aluminum baseplate with through-hole spacers

for easy pcb mounting and/or external heat-sink attachment.

The DTL2A accepts a serialized, 12-bit, CMOS/TTL-compatible, digital input word

easily generated by any standard digital I/O card. The DTL2A buffers and then

optically isolates (500Vdc) the digital input data before storing it in a register and

presenting it to an on-board, 12-bit, digital-to-analog (D/A) converter. The D/A output

drives a near-ideal (10MΩ minimum output impedance), voltage-controlled current

source. One LSB (least signifi cant bit) of the D/A converter corresponds to a 5mA

increment (0.025% of 20A) in load current.

The DTL2A features a max. ±5mA offset error and a max. ±0.1% gain error. It

has an impressive full-scale step response time of 100µsec and can be operated

dynamically at update rates up to 20kHz. Powered by a single +5V supply, the DTL2A

draws a mere 150mA (maximum).

While operating in the constant-current mode up to 20 Amps (100W max. power),

the output compliance voltage of the DTL2A is 2.5 to 50 Volts. Should the output/load

voltage drop below the 2.5V minimum required for proper biasing, an internal monitoring

circuit activates the DTL2A's output Fault line. See DATEL’s DTL2A-LC for compliance

voltages as low as 0.6V.

DTL2A’s and other electronic loads, controller boards, and software from DATEL

are outstanding building-block components for power-supply burn-in and test systems.

They are an extremely reliable, cost-effective solution that enables you to quickly

confi gure impressively accurate systems.

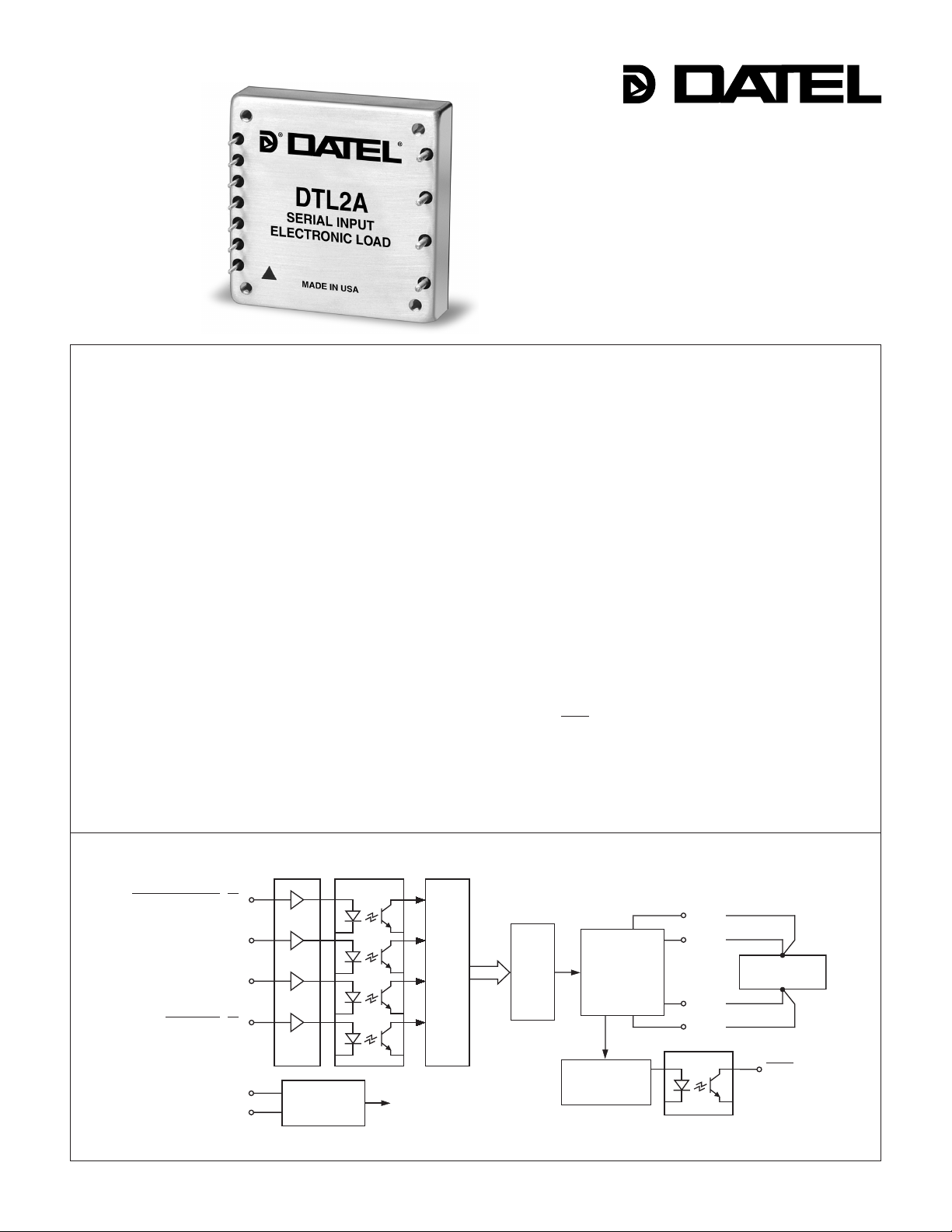

INPUT

BUFFERS

CONTROL STROBE (CS)

CLOCK (CLK)

SERIAL DATA INPUT (SDI)

LATCH DATA (LD)

+5V SUPPLY

GROUND

DATEL, Inc., Mansfi eld, MA 02048 (USA) · Tel: (508)339-3000, (800)233-2765 Fax: (508)339-6356 · Email: sales@datel.com · Internet: www.datel.com

ISOLATED

DC/DC

CONVERTER

OPTO

ISOLATORS

DATA

LATCH

Figure 1. Simplifi ed Schematic

12-BIT

D/A

AMPLIFIER

AND

CURRENT

SENSOR

UNDERVOLTAGE

DETECTION

+LOAD

+LOAD

–LOAD

–LOAD

POWER DEVICE

UNDER TEST

FAULT

Page 2

DTL Series

0

100 WATT, SERIAL-INPUT ELECTRONIC LOADS

Performance Specifi cations and Ordering Guide

➀

Input Output

Compliance

Resolution Logic Current Resolution Voltage Power Package

Model (Bits) Compatibility (Amps) (mA)

➁ (Volts) ➂ (Watts) (Case, Pinout)

DTL2A 12 CMOS/TTL ➃ 0-20 5 2.5-50 0-100 C24, P31

➀ Typical at TA = +25°C with nominal +5V supply voltage unless noted.

➁ The smallest increment/decrement in output current is defi ned by one LSB (least signifi cant bit) of the 12-bit

digital input word. One LSB is equal to full scale (FS) divided by 4096 which corresponds to 0.0244% of 20A or 4.88mA.

➂ For proper operation, the unit's output/load voltage must remain within this range. Voltages greater than the listed

maximum can damage the device. Voltages less than the minimum provide insuffi cient bias for the output stage

and will result in unpredictable or no operation. See Output Compliance Voltage and the Fault Line for details.

➃ See Performance/Functional Specifi cations for details.

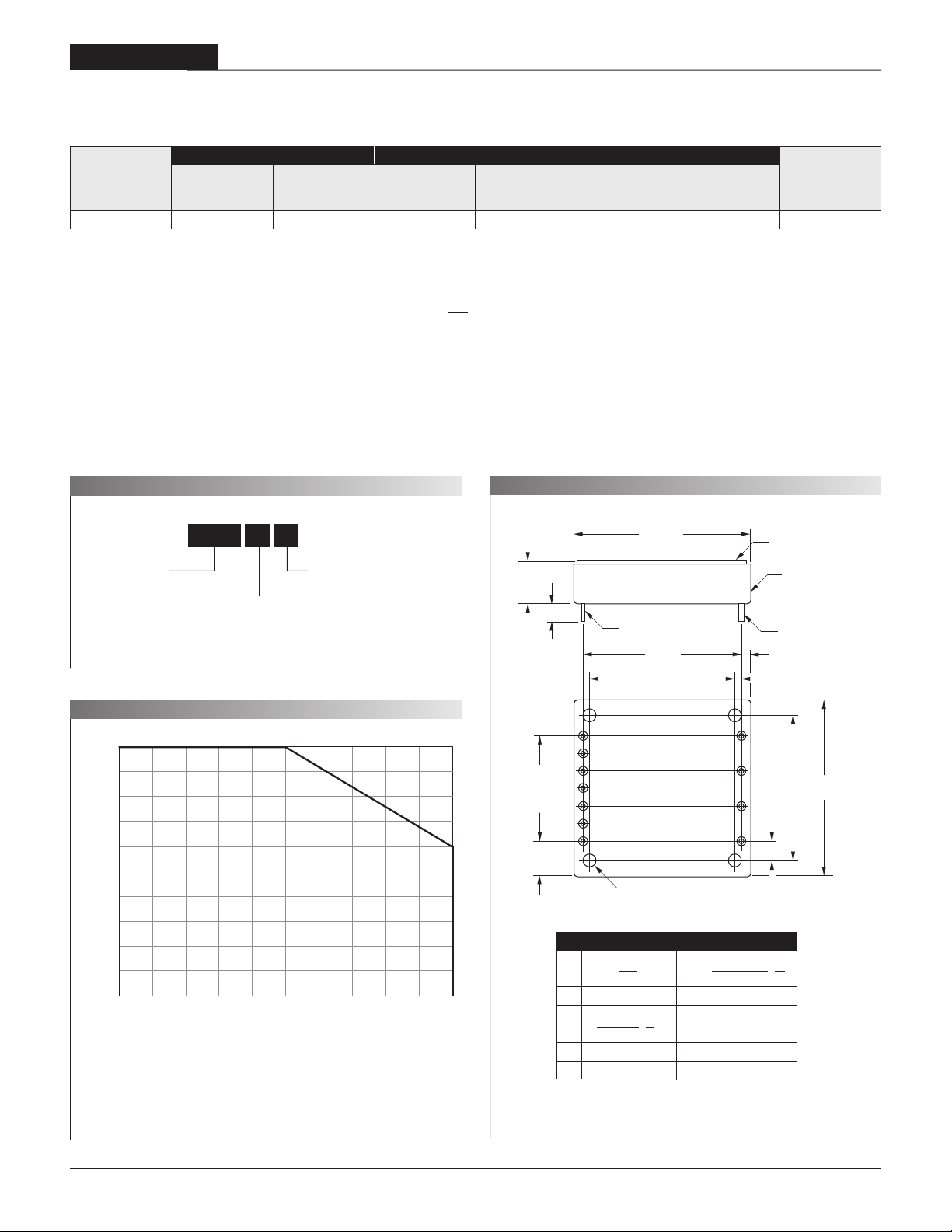

PART NUMBER STRUCTURE

DTL 2

DATEL

Electronic Load

A

A-Series

High Reliability

MECHANICAL SPECIFICATIONS

2.00

(50.80)

0.50

(12.70)

Case C24

ALUMINUM BASEPLATE

METAL CASE

Voltage Range:

2 = 2.5 to 50V

0.20 MIN

(5.08)

0.040 ±0.002 DIA.

(1.016 ±0.051)

1.800

(45.72)

1.640

(41.66)

0.060 ±0.002 DIA.

(1.524 ±0.051)

0.10

(2.54)

0.08

(2.03)

TEMPERATURE DERATING

10

11

BOTTOM VIEW

8

9

2.00

1.640

(50.80)

(41.66)

0.22

(5.59)

100

90

80

70

60

50

40

Output Power/Load (Watts)

30

20

10

010 203040506070809010

Baseplate Temperature (°C)

The horizontal axis of the above chart references the temperature of the DTL2A’s alumi-

num baseplate. The device can continually dissipate up to 100 Watts if the baseplate

7

6

1.20

(30.48)

6 EQ. SP. @

0.200 (5.08)

0.40

(10.16)

5

4

3

2

1

#4-40 CLEAR THRU

(TYP. 4 PL)

I/O Connections

Pin Function P31 Pin Function P31

1 Fault 7 Control Strobe (CS)

2 Ground 8 –Load

3 +5 Volt Supply 9 –Load

4 Latch Data (LD) 10 +Load

5 Serial Data In (SDI) 11 +Load

6 Clock (CLK)

is maintained at or below +50°C. At +25°C ambient temperature, with no heat sink or

supplemental air fl ow, the DTL2A can reliably dissipate a continuous 10 Watts.

Contact DATEL for Heat Sink information.

2

Page 3

100 WATT, SERIAL-INPUT ELECTRONIC LOADS

Performance/Functional Specifi cations

Typical @ TA = +25°C with nominal +5V supply voltage, unless noted.

Digital Inputs/Outputs

Logic Compatibility (Pins 1, 4-7) CMOS/TTL

Input Logic Levels:

Logic "1" +2 Volts, minimum

Logic "0" +0.8 Volts, maximum

Input Logic Loading:

Logic "1" (I

Logic "0" (I

Output Logic Levels:

Logic "1" (@ 150µA) +3.5 Volts, minimum

Logic "0" (@ 1.6mA) +0.4 Volts, maximum

Timing See Timing Diagram

Current:

Range 0-20 Amps

Resolution

Accuracy

Voltage Range ➁ 2.5-50 Volts

Power Range 0-100 Watts

Impedance 10MΩ, minimum

Offset Error

Gain Error ±0.1%, maximum

Isolation Voltage:

Digital Inputs/Output to ±Load 500Vdc, minimum

Any Pin to Case 500Vdc, minimum

Isolation Resistance 100MΩ, minimum

Output Slew Rate ±10A/µsec, minimum

Output Settling Time

Digital Input Update Rate to 20kHz

Power Supply Range (+VCC, Pin 3) +4.75-5.25 Volts (+5V nominal)

Power Supply Current 110mA typ., 150mA max.

Operating Temperature ➄ –40 to +100°C (Case)

Storage Temperature –40 to +125°C (Ambient)

Humidity (Non-condensing) to 95%

Altitude Above Sea Level 10,000 feet

Dimensions 2" x 2" x 0.5" (51 x 51 x 12.7mm)

Shielding 6-sided (Connected to pin 2)

Case Material Tin-plated steel shell with

aluminum baseplate

Pin Material Brass, solder coated

Mounting Holes Through-hole spacers, #4-40 clearance

Weight 1.9 ounces (54 grams)

IH @ VIH = 5 Volts) 20µA, maximum

IL @ VIL = 0 Volts) –0.6mA, maximum

Output

➀ 0.024%FS (4.88mA)

➅ ±1%, maximum

➂ ±5mA, maximum

Dynamic Performance

➃ 100µsec

Power Requirements

Environmental

Physical

DTL2A Model

➀ The smallest increment/decrement in output current is defi ned by one LSB (least signifi cant

bit) of the 12-bit digital input word. One LSB is equal to full scale (FS) divided by 4096 which

corresponds to 0.0244% of 20A or 4.88mA.

➁ For proper operation, the unit's output/load voltage must remain within this range. Voltages

greater than the listed maximum can damage the device. Voltages less than than the minimum

provide insuffi cient bias for the output stage and will result in unpredictable or no operation.

See Output Compliance Voltage and the Fault Line for details.

➂ Offset error is defi ned as the current sunk/sourced by the DTL2A’s output, under any output

voltage conditions, when the digital input word is all "0's."

➃ Full scale step (20 Amps) settling to within ±5mA of its fi nal value.

➄ See Temperature Derating.

➅ Applies over all specifi ed ranges/combinations of load voltage/current, operating temperature,

and V

CC.

Absolute Maximum Ratings

Power Supply Voltage (+VCC, Pin 3) –0.5 to +5.5 Volts

Digital Input Voltage (Pins 4-7) –0.5 to +5.5 Volts

Output Reverse-Polarity Protection No protection

Output Overvoltage Protection No protection

Output Undervoltage Protection Yes (See Fault Line)

Case Temperature +105°C

Storage Temperature (Ambient) –40 to +125°C

Lead Temperature (soldering, 10 sec.) +300°C

These are stress ratings. Exposure of devices to any of these conditions may adversely

affect long-term reliability. Proper operation under conditions other than those listed in the

Performance/Functional Specifi cations Table is not implied.

TECHNICAL NOTES

Overview

The DTL2A is a digitally programmable, CMOS/TTL-compatible, serial-input

current sink. It’s output/load current range is 0 to 20 Amps (in 4.88mA

increments), over a compliance voltage range of 2.5 to 50 Volts and an output/

load power range of 0 to 100 Watts. The device’s digital I/O coding is straight

binary (see table below). A digital input of all "0’s" forces a load current of 0

Amps. A digital input of all "1’s" forces a load current of 19.995 Amps.

In a typical power-supply test or burn-in application, the output pins of the

device under test (DUT) are connected to the DTL2A’s +Load (pins 10 and 11)

and –Load (pins 8 and 9) outputs. The DTL2A’s operation is controlled by its

four digital input lines (Serial Data In, Clock, Latch Data and Control Strobe).

Serial Input Data Word Load Current (Amps)

MSB LSB DTL2A

1111 1111 1111 19.995

1100 0000 0000 15.000

1000 0000 0000 10.000

0111 1111 1111 9.995

0100 0000 0000 5.000

0010 0000 0000 2.500

0000 0000 0001 0.005

0000 0000 0000 0.000

Mapping of the Serial-Input Data to Load Current

3

Page 4

DTL Series

100 WATT, SERIAL-INPUT ELECTRONIC LOADS

Initialization

Preparing the DTL2A to accept new digital data is accomplished by applying

logic "1's" to Control Strobe (CS, pin 7), Latch Data (LD, pin 4) and Clock

(CLK, pin 6) with all signals present and stable for a minimum of 1µsec.

During this interval, it does not matter whether or not data is present on the

Serial Data In (SDI, pin 5) line.

Serial Data

Following initialization, the 12-bit digital word representing the desired output

current is applied to the SDI pin. The serial data should appear starting with

the most signifi cant bit (MSB, bit 1, D11) and ending with the least signifi cant

bit (LSB, bit 12, D0). With each data bit present and stable on the SDI line,

the CLK must be toggled through a low-to-high transition to register that bit.

Twelve rising clock edges, at rates up to 500kHz, are required to clock all 12

digital bits into the DTL2A’s input register.

Latching Data and Presenting It to the D/A

After loading the LSB, the serial data word is latched by bringing the Control

Strobe (pin 7) high and then toggling the Latch Data pin (pin 4) through a

high-low-high sequence. Approximately 100µsec later, the output current will

settle to its fi nal desired value.

Software: C Language

The following steps describe a typical timing sequence when using the

DTL2A’s 4 digital inputs and a programming language such as C. Using 4 bits

of a typical 8-bit port, assign BIT_0 to the Control Strobe (CS, pin 7), BIT_1

to Latch Data (LD, pin 4), BIT_2 to Serial Data In (SDI, pin 5), and BIT_3

to the Clock (CLK, pin 6).

Output Compliance Voltage and the Fault Line

For proper operation, the DTL2A’s output/load voltage must always be

between 2.5 and 50 Volts. The device cannot be used to directly load low-

voltage, e.g. 1.8V or 2.5V, power components or to simulate a true short

circuit (0 Volts). Voltages greater than 50V can damage the device. Voltages

<2.5V will result in insuffi cient biasing of the output current source and

consequently unpredictable or no operation. Accordingly, we have installed

an internal output/load-voltage monitoring circuit. If the output/load voltage

drops below 2.5V and the DTL2A’s output is at risk of becoming disabled,

the Fault line activates.

The Fault line is an optically isolated, active-low function with an opencollector output (internal 10kΩ pull-up resistor to +5V). Under normal condi-

tions, its output is high (logic "1"). Under fault conditions (V

OUT < 2.5V), its

output drops to a logic "0." There is no output/load-voltage monitoring circuit

for voltages greater than 50V, and operation above 50V can damage the

device.

An "offset supply" can be inserted between the DTL2A’s –Load output (pins

8 and 9) and the power device under test (DUT) to "translate" the DTL2A’s

47.5V output/load voltage range. The offset supply must have adequate

current capabilities and be connected with the polarities indicated in Figure 2

below. Under no circumstances should the voltage across the DTL2A’s output

be allowed to experience a polarity reversal.

If a 5V/20A offset supply is inserted as shown, the range of DUT voltages

will be –2.5 to +45 Volts. Such a confi guration can be used for true short-

circuit testing. A mechanical relay can be used to short the outputs of the

DUT while the offset supply ensures the DTL2A always sees at least 5 Volts

across its outputs.

1. Initialize with Control Strobe, Latch Data, and Clock high:

BIT_0 = 1, BIT_1 = 1, BIT_2 = X (don’t care), BIT_3 = 1

2. Bring the Control Strobe low.

BIT_0 = 0

3. Apply the MSB (D11) of the serial data word to Serial Data In.

BIT_2 = 0 or 1

4. Toggle the Clock high-low-high.

BIT_3 = 1 to 0 to 1

5. Apply D10 of the serial data word to Serial Data In.

BIT_2 = 0 or 1

6. Toggle the Clock high-low-high.

BIT_3 = 1 to 0 to 1

7. Repeat the process for remaining data bits D9 through D0.

8. Drive the Control Strobe high.

BIT_0 = 1

9. Toggle the Latch Data input high-low-high.

BIT_1 = 1 to 0 to 1.

+LOAD

DTL2A

–LOAD

11

10

5V

9

8

Figure 2. An "Offset Supply" Enables

True Short-Circuit Testing

+

–

+

DUT

–

SHORT

CIRCUIT

RELAY

Thermal Considerations

The DTL2A can reliably handle 100W loads if its case temperature is

maintained at or below +50°C. With no heat sinking or auxiliary cooling, the

device can only handle loads up to 10 Watts. Please refer to the Temperature

Derating Curve for additional information. DATEL’s Electronic Load Applica-

tions Engineers can assist you in developing heat-sink solutions for your

higher-power DTL2A applications. Please contact us for details.

4

Page 5

E

100 WATT, SERIAL-INPUT ELECTRONIC LOADS

t

dh

DTL2A Model

CLK

CS

LD

SDI

D11 D10 D9 D8 D7 D6 D5 D4 D2D3 D1 D0

t

ds

t

in

t

t

css

t

ld1

cl

t

ch

Timing Min. Typ. Max. Units

CLK – – 500 kHz

tin 1 – – µsec

tcl = tch 1 – – µsec

tcss 1 – – µsec

tcsh 1 – – µsec

tld1 2 – – µsec

tld2 2 – – µsec

tldw 2 – – µsec

tds 0.5 – – µsec

tdh 0.5 – – µsec

t

csh

t

ld2

t

ldw

Figure 3. DTL2A Timing Diagram

®

INNOVATION and EX C ELL E N C

DATEL, Inc. 11 Cabot Boulevard, Mansfi eld, MA 02048-1151

Tel: (508) 339-3000 (800) 233-2765 Fax: (508) 339-6356

Internet: www.datel.com Email: sales@datel.com

DATEL makes no representation that the use of its products in the circuits described herein, or the use of other technical information contained herein, will not infringe upon existing or future patent rights. The descriptions contained herein

do not imply the granting of licenses to make, use, or sell equipment constructed in accordance therewith. Specifi cations are subject to change without notice. The DATEL logo is a registered DATEL, Inc. trademark.

®

ISO 9001 REGISTERED

DS-0450B 9/00

DATEL (UK) LTD. Tadley, England Tel: (01256)-880444

DATEL S.A.R.L. Montigny Le Bretonneux, France Tel: 01-34-60-01-01

DATEL GmbH München, Germany Tel: 89-544334-0

DATEL KK Tokyo, Japan Tel: 3-3779-1031, Osaka Tel: 6-354-2025

5

Loading...

Loading...