Page 1

DSM (Digital Signal Processor System Memory)

For Analog Devices ADSP-2191 DSPs (3.3V Supply)

FEATURES SUMMARY

■ Glueless Connection to DSP

– Easily add memory, logic, and I/O to the Exter-

nal Port of ADSP-2191 DSP

■ Dual Flash Memories

– Two independent Flash memory arrays for stor-

ing DSP code and data. DSP may access the

two arrays concurrently (read from one while

erasing or writing the other)

– 256K x 8 Main Flash memory divided into 8 sec-

tors (32KByte each)

– Ample storage for booting DSP code/data

upon reset and subsequent code swaps

– Large capacity for data recording

– 32K x 8 Secondary Flash memory divided into 4

sectors (8 KByte each). Multiple uses:

– Small sector size ideal for small data sets,

and calibration or configuration constants

– Store custom start-up code in one or more

sectors and configure DSP to run from external memory upon reset (no boot)

– Concatenate Secondary Flash with Main

Flash for total of 288 KBytes

– Each Flash sector can be write protected.

– Built-in programmable address decoding logic

allows mapping individual Flash sectors to any

address boundary

■ Up to 16 Multifunction I/O Pins

– Increase total DSP system I/O capability

– I/O controlled by DSP software or PLD logic

■ Genera l pu rpo s e P LD

– Over 3,000 Gates of PLD with 16 macro cells

– Use for peripheral glue logic to keypads, control

panel, displays, LCDs, and other devices

– Eliminate PLDs and external logic devices

– Create state machines, chip selects, simple

shifters and counters, clock dividers, delays

TM

– Simple PSDsoft Express

■ Operating Range

: 3.3V±10%; Temperature: –40oC to +85oC

–V

CC

software...Free

DSM2190F4V

Figure 1. Packages

PQFP52 (T)

PLCC52 (K)

■ In-System Programming (ISP) with JTAG

– Program entire chip in 10-25 seconds with no in-

volvement of the DSP

– Links with ADSP-2191 JTAG debug port

– Eliminate sockets f or pre-prog ramm ed me mory

and logic devices

– ISP allows efficient manufacturing and product

testing supporting Just-In-Time inventory

– Use low-cost FlashLINK

■ Content Security

– Programmable Security Bit blocks access of de-

vice programmers and readers

■ Zero-Power Technology

– As low as 25µA standby current

■ Packaging

– 52-pin PQFP or 52-pin PLCC

■ Flash Memory Speed, Endurance, Retention

– 150 ns, 100K cycles, 15 year retention

TM

cable with PC

1/61September 2002

Page 2

DSM2190F4

TABLE OF CONTENTS

Summary Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Architectural Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

DSP Address/Data/Control Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Main Flash Memory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Secondary Flash Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Programmable Logic (PLDs). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Runtime Control Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Memory Page Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

I/O Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

JTAG ISP Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Power Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Security and NVM Sector Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Typical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Typical Memory Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Specifying the Memory Map with PSDsoft ExpressTM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Runtime control register definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 5

Detailed Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Flash Memories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Instruction Sequences. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Reading Flash Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Programming Flash Memory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Erasing Flash Memory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Flash Memory Sector Protect.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

DSM Security Bit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Reset Flash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Page Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

PLDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Decode PLD (DPLD). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2/61

Page 3

DSM2190F4

Complex PLD (CPLD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

DSP Bus Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

I/O Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Port Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Port B – Functionality and Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Port C – Functionality and Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Port D – Functionality and Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Power Management. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

PLD Power Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 8

PSD Chip Select Input (CSI, PD2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Power On Reset, Warm Reset, Power-down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Programming In-Circuit using JTAG ISP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

AC/DC Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table: Absolute Maximum Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Table: Operating Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Table: DC Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Table: CPLD Combinatorial Timing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Table: CPLD Macrocell Synchronous Clock Mode Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Table: CPLD Macrocell Asynchronous Clock Mode Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Table: Input Macrocell Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Table: Read Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table: Write Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Table: Flash Memory Program, Write and Erase Times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Table: Reset (Reset) Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 3

Table: ISC Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Package Mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 5

Table: PLCC52 - 52 lead Plastic Leaded Chip Carrier, rectangular . . . . . . . . . . . . . . . . . . . . . . . . 55

Table: Assignments – PLCC52 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Table: PQFP52 - 52 lead Plastic Quad Flatpack. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Table: Pin Assignments – PQFP52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Table: Ordering Information Scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

3/61

Page 4

DSM2190F4

SUMMARY DESCRIPTION

The DSM2190F4 is a system memory device for

use with the Analog Devices ADSP-2191 DSP.

DSM means Digital signal processor System

Memory. A DSM device brings In-System Programmable (ISP) Flash memory, param eter storage, programmable logic, and additional I/O to

DSP systems. The result is a simple and flexible

two-chip solution for DSP designs. DSM devices

provide the flexibility of Flash memo ry and smart

JTAG programming technique s for both manu facturing and the field. On-chip integrated memory

decode logic makes it easy to map dual banks of

Flash memory to the ADSP -2191 in a variety of

ways for bootloading, code execution, data recording, code swapping, and parameter storage.

JTAG ISP reduces development time, simplifies

manufacturing flow, and lowers the cost of field upgrades. The JTAG ISP interface eliminates the

need for sockets and pre-programmed memory

and logic devices. For man ufacturing, end products may be assembled with a blank DSM device

soldered to the circuit board and programmed at

the end of the manufacturing line in 10 to 25 seconds with no involvement of the DS P. This a llows

efficient means to test product and manage inventory by rapidly programming test code, then appli-

cation code as determined by inventory

requirements (Just-In Time inv entory). A ddi tionally, JTAG ISP reduces development time by turning

fast iterations of DSP code in the lab. Code updates in the field require n o disassembly o f product. The FlashLINK

TM

JTAG programming cable

costs $59 USD and plugs into any PC or notebook parallel port.

In addition to ISP Flash memory, DSM devices

add programmable logic (PLD) and up to 16 configurable I/O pins to the DSP system. The state of

each I/O pin can be driven by DSP software or

PLD logic. PLD and I/O configuration are programmable by JTAG I SP, just like the Flash m emory.

The PLD consists of more than 3000 gates and

has 16 macro cell registers. Common uses for the

PLD include chip selects for external devices,

state-machines, simple shifters and counters, keypad and control panel interfaces, clock dividers,

handshake delay, multiplexers, etc. This eliminates the need for small external PLDs and l ogic

devices. Configuration of PLD, I/O, and Flash

memory mapping are easily entered in a pointand-click environment using the software development tool, PSDsoft Express

available at no charge from

TM

. This software is

www.st.com/psm

.

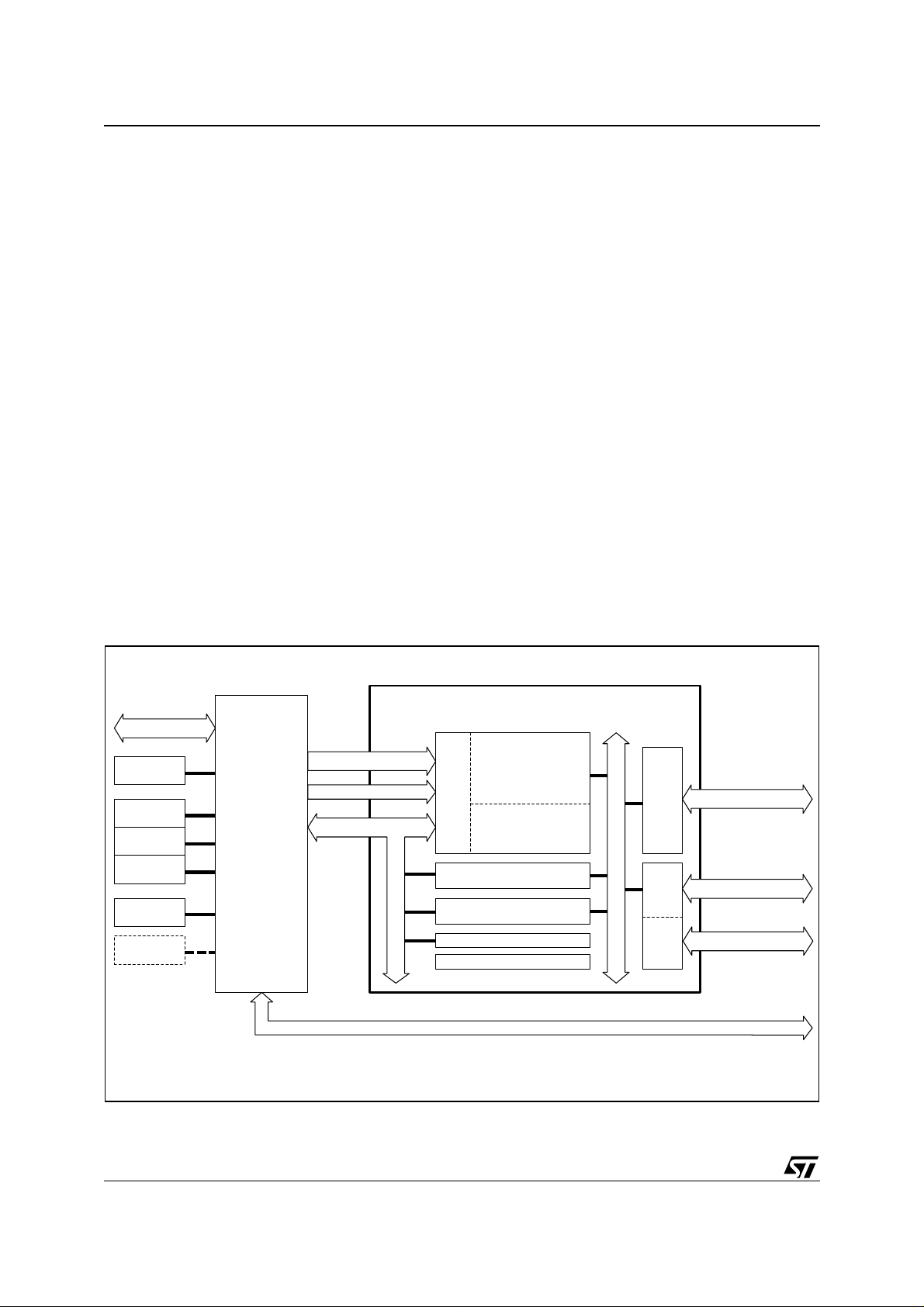

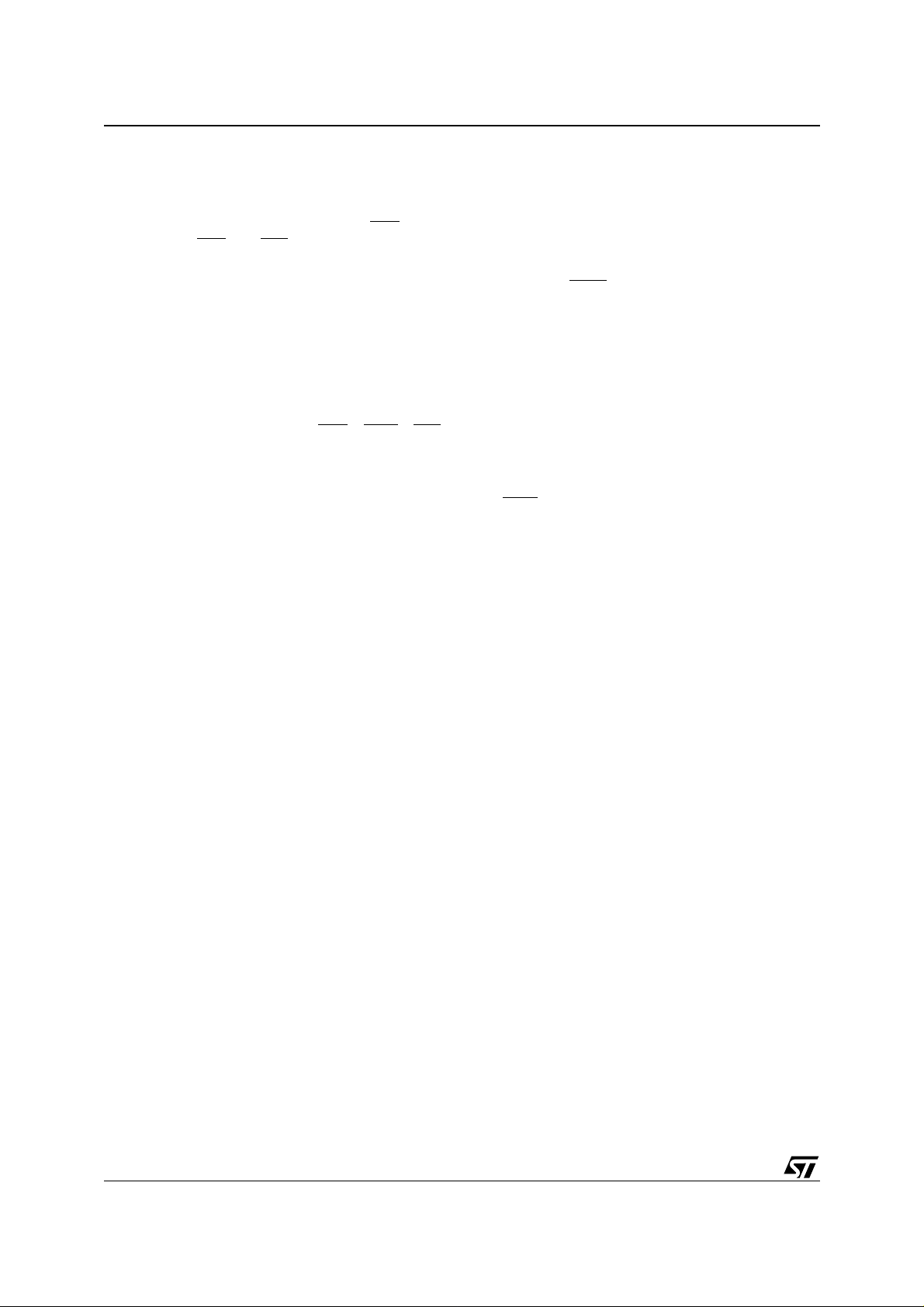

Figure 2. System Block Diagram, Two-C hip Solution

16 FLAGS

TIMER/

CAPTURE

SERIAL

DEVICE

SERIAL

DEVICE

SERIAL

DEVICE

UART

DEVICE

HOST

MCU

ANALOG

DEVICES

DSP

ADSP-2191

22 ADDRESS

WR, RD, BMS, MSx, IOMS

8 DATA

JTAG DEBUG

DSP SYSTEM MEMORY

LOGIC

ADDR & DECODE

16 MACROCELL PLD

POWER MANAGEMENT

CONTENT SECURITY

DSM2190F4

PRIMARY

FLA SH MEMORY

256K X 8

SECONDARY

FLA SH MEMORY

32K X 8

I/O CONTROL

8 I/O

I/O, PLD, CHIP SELECTS

PORTS

I/O BUS

8 I/O

PORTS

JTAG

ISP TO

ALL

AREAS

I/O, PLD, CHIP SEL

JTAG ISP

AI04959B

4/61

Page 5

DSM2190F4

The two-chip combination of a D SP and a DSM

device is ideal for systems which have limitations

on size, EMI levels, and power consumption. DSM

memory and logic are “zero-power”, meaning they

automatically go to standby between memory accesses or logic input changes , producing low active and standby current consumption, which is

ideal for battery powered products.

Table 1. DSM2190F4V DSP Memory S ystem Devi ces

Secondar y

Flash

Memory

32KBytes =

4 sectors x

8KByte

32KBytes =

4 sectors x

8KByte

PLD

16

macro

-cells

16

macro

-cells

Part Number

DSM2190F4VV15T6

DSM2190F4VV15K6

Main Flash

Memory

256KBytes =

8 sectors x

32KByte

256KBytes =

8 sectors x

32KByte

Table 2. Compatible Analog Devices DSP

DSP Part Number

A programmable security bit in the DSM protects

its contents from unauthorized viewing and copying. When set, the security bit will block access of

programming devices (JTAG or others) to the

DSM Flash memories and PLD configuration. The

only way to defeat the security bit is to erase the

entire DSM device, after which the device is blank

and may be used again. The DSP will always have

access to Flash memory contents through the 8-bit

data port even while the security bit is set.

I/O

Ports

Up to

16

Up to

16

and I/O

V

CC

3.3V ±10% 150 ns

3.3V ±10% 150 ns

Operating Voltage, V

Mem

Speed

Package

52-pin

PQFP

52-pin

PLCC

CC

Operating

Temp

o

C to

–40

o

+85

o

C to

–40

o

+85

I/O Capability

C

C

ADSP-2191M 2.5V 2.5 - 3.6V

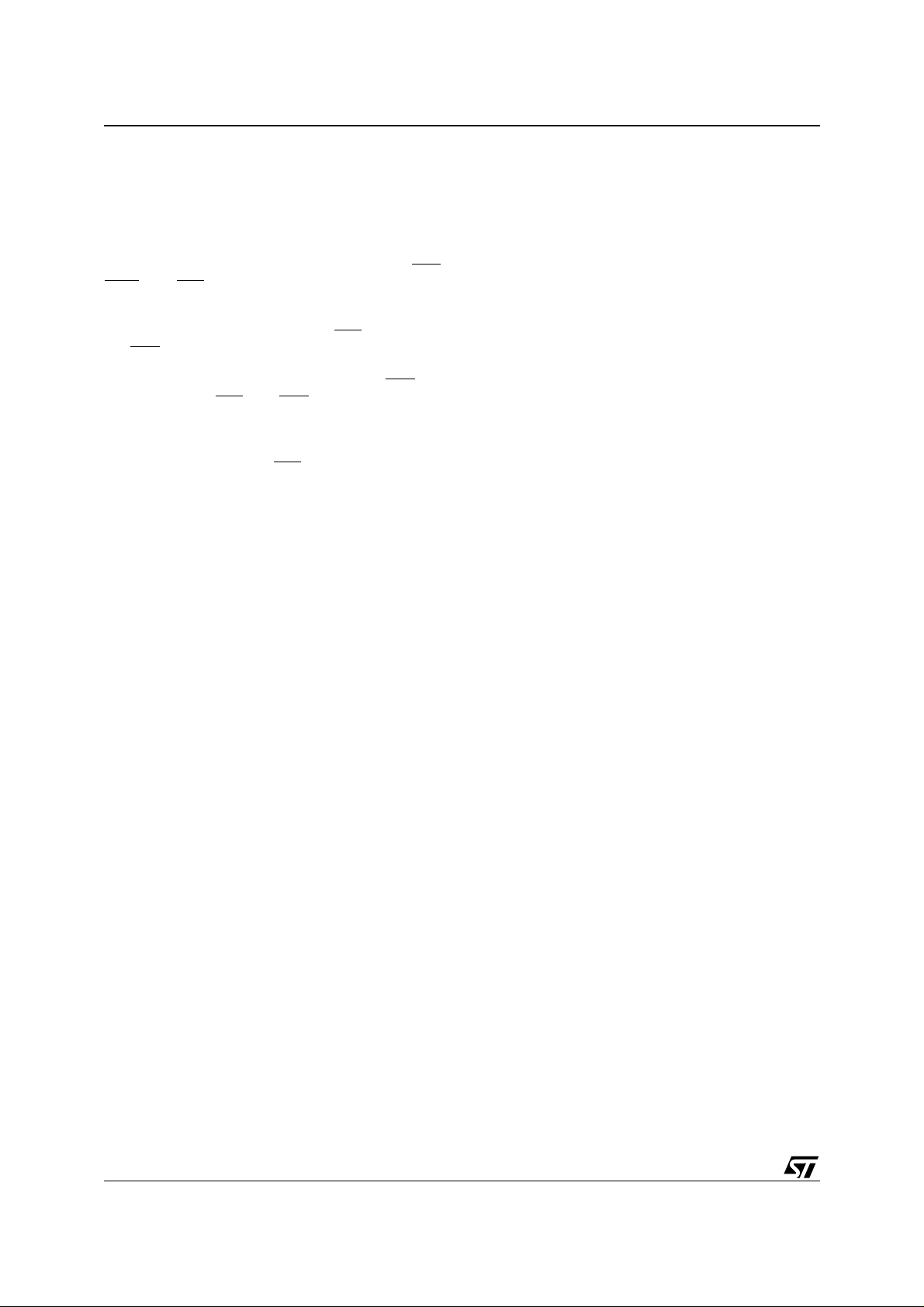

Figure 3. PLC C C onnection s Figure 4. PQFP C onnection s

RESET

PB7

CNTL2

CNTL0

CNTL1

PB0

PB1

PB2

PB3

PB4

PB5

GND

PB6

PB7

CNTL1

CNTL2

RESET

51

AD15

46

AD14

45

AD13

44

AD12

43

AD11

42

AD10

41

AD9

40

AD8

39

V

38

CC

AD7

37

AD6

36

AD5

35

AD4

34

PA0

AD2

AD1

AD3

AD0

AI02857

PD2

PD1

PD0

PC7

PC6

PC5

PC4

V

GND

PC3

PC2

PC1

PC0

CC

52515049484746454443424140

1

2

3

4

5

6

7

8

9

10

11

12

13

14151617181920212223242526

PA7

PA6

PA5

PA4

PA3

PA2

PA1

GND

47

48

49

50

CNTLO

39 AD15

38 AD14

37 AD13

36 AD12

35 AD11

34 AD10

33 AD9

32 AD8

31 V

CC

30 AD7

29 AD6

28 AD5

27 AD4

PA0

AD0

AD1

AD2

AD3

PD2

PD1

PD0

PC7

PC6

PC5

PC4

V

GND

PC3

PC2

PC1

PC0

PB0

PB1

PB2

PB3

PB4

PB5

GND

PB6

4

567

8

9

10

11

12

13

14

15

CC

16

17

18

19

20

21222324252627282930313233

PA7

PA6

PA5

PA4

52

2

3

1

PA3

PA2

PA1

GND

AI02858

5/61

Page 6

DSM2190F4

ARCHITECTURAL OVERVIEW

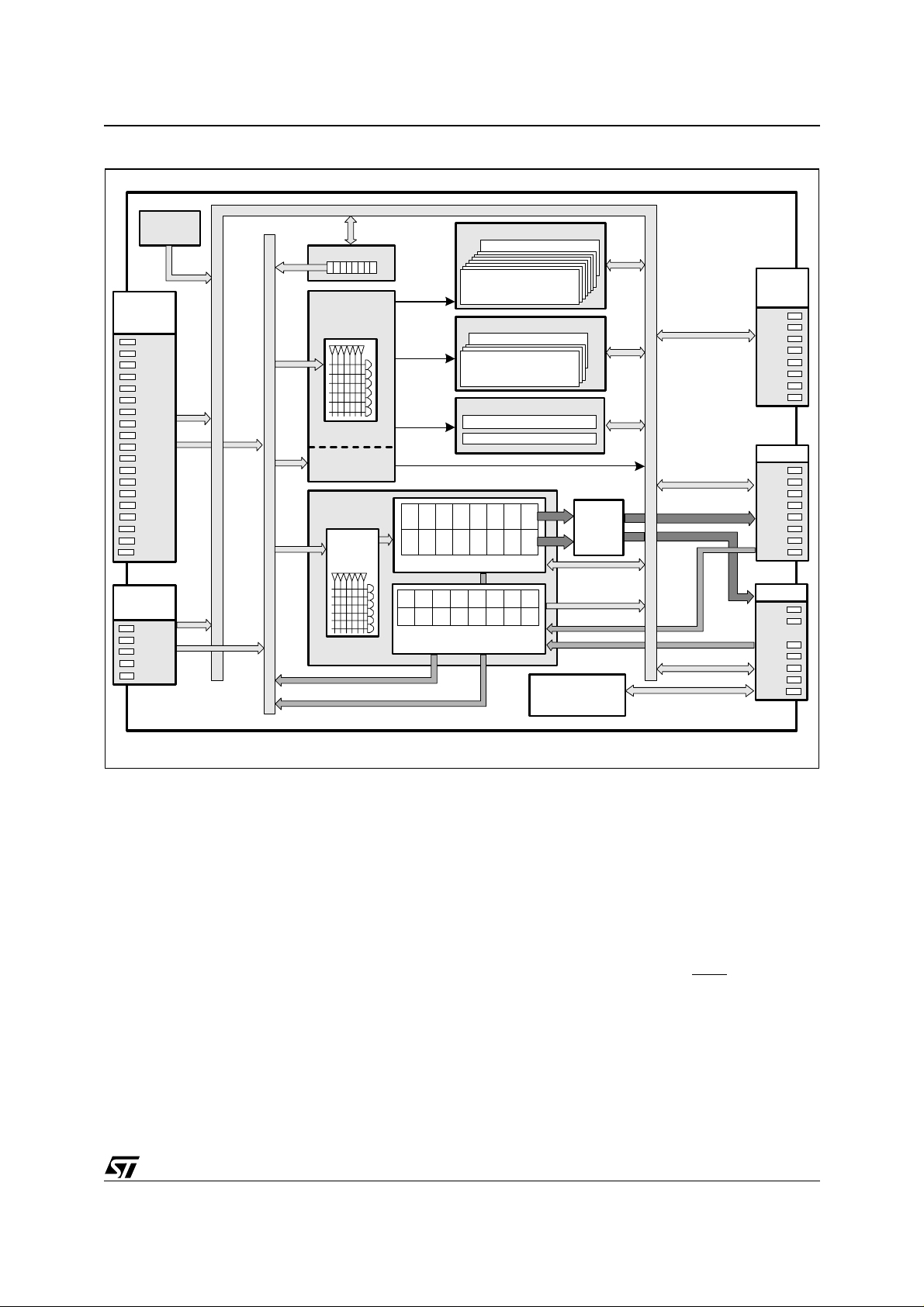

Major functional blocks are shown in Figure 5.

DSP Address/Data/Control Interface

These DSP signals attach directly to the DSM for

a glueless connection. An 8-bit data connection is

formed and all 22 DSP address lines can be decoded as well as DSP memory strobes;

IOMS, and MSx. There are many different ways the

DSM2190F4 can be configured and used depending on system requirements. One convenient way

is to combine the function of t he

the

BMS signal. Doing this allows the DS P core t o

MSx signals into

access DSM memory at runtime even after the

boot process is complete using only the

nal. Comb ining

MSx and BMS consumes less I/O

pin(s) on the DMS device. See Analog Devices

ADSP-2191 DSP Hardware Reference Manual,

Chapter 7, Code Example: BMS Runtime Access.

Alternatively, any of the

MSx signals may also be

used to decode any of the sectors of DSM Main

Flash or Secondary flash memories.

Main Flash Memory

The 2M bit (256K x 8) Flash memory is divided into

eight equally-sized 32 K byte s ect ors t hat are i ndividually selectable through the Decode PLD. Each

Flash memory sector can be located at any address as defined by the user with PSDsoft Express. DSP code and data is easily placed in flash

memory using the P SDsoft Express software development tool.

Secondary Flash Memory

The 256K bit (32K x 8) Flash memory is divided

into eight equally-sized 8K byte sectors that are individually selectable through the Decode PLD.

Each Flash memory sector can be located at any

address as defined by the user with PSDsoft Express. DSP code and data can also be placed

Secondary Flash memory using the PSDsoft Express development tool.

Secondary flash memory is good for storing dat a

because of its small sectors. Additionally, software

EEPROM em ulation techniques can be used for

small data sets that change frequently on a byteby-byte basis.

Secondary flash may also be used to store custom

start-up code for applications that do not “boot” using DMA, but instead start executing code from external memory upon reset. Storing code here can

keep the entire Main Flash free of initialization

code for clean software partitioning. If only on e or

more 8K byte sectors are needed for start-up

code, the remaining sectors of Secondary Flash

may be used for data storage.

BMS,

BMS sig-

Secondary Flash may also be used as an extension to Main Flash memory producing a total of

288K bytes

Miscellaneous: Main and Secondary Flash memories are totally independent, allowing concurrent

operation if needed. The DSP can read from one

memory while erasing or programming the other.

The DSP can erase Flash memories by individual

sectors or the entire Flash memory array may be

erased at one time. Each sector in either Flash

memory may be individually write protected, blocking any writes from the DSP (good for boot and

start-up code protection). The Flash memories automatically go to standby between DSP read or

write accesses to conserve power. Maximum access times include sector decoding time. Maximum erase cycles is 100K and data retention is 15

years minimum. Flash memory, as well as the entire DSM device may be programmed with the

JTAG ISP interface with no DSP involvement.

Programm a b le Logic (PLD s)

The DSM family contains two PLDS that m ay optionally run in Turbo or Non-Turbo mode. PLDs operate faster (less propagation delay) while in

Turbo mode but consume more power than NonTurbo mode. Non-Turbo mode allows the PLDs to

automatically go to standby when no inputs are

change to conserve power. The Turbo mode setting is controlled at runtime by DSP software.

Decode PLD (DPLD). This is programmable logic used to select one of the eigh t individual Main

Flash memory segments, one of four individual

Secondary Flash memory segments, or the group

of control registers within the DSM device. The

DPLD can also optionally drive external chip select

signals on Port D pins. DPLD input signals include:

DSP address and control signals, Page Register

outputs, DSM Port Pins, CPLD logic feedback.

Complex PLD (CPLD). This programmable logic

is used to c reate bo th combinatorial and sequential general purpose logic. The C PLD contains 16

Output Macrocells (OMCs) and 16 Input Macrocells (IMCs). PSD Macrocell registers a re unique

in that that have direct connection to the DSP data

bus allowing them to be loaded and read directly

by the DSP at runtime. This di rect access is g ood

for making small peripheral devices (shifters,

counters, state machines, etc.) that are accessed

directly by the DSP with little overhead. DPLD inputs include DSP address and control signals,

Page Register outputs, DSM Port Pins, and CPLD

feedback.

6/61

Page 7

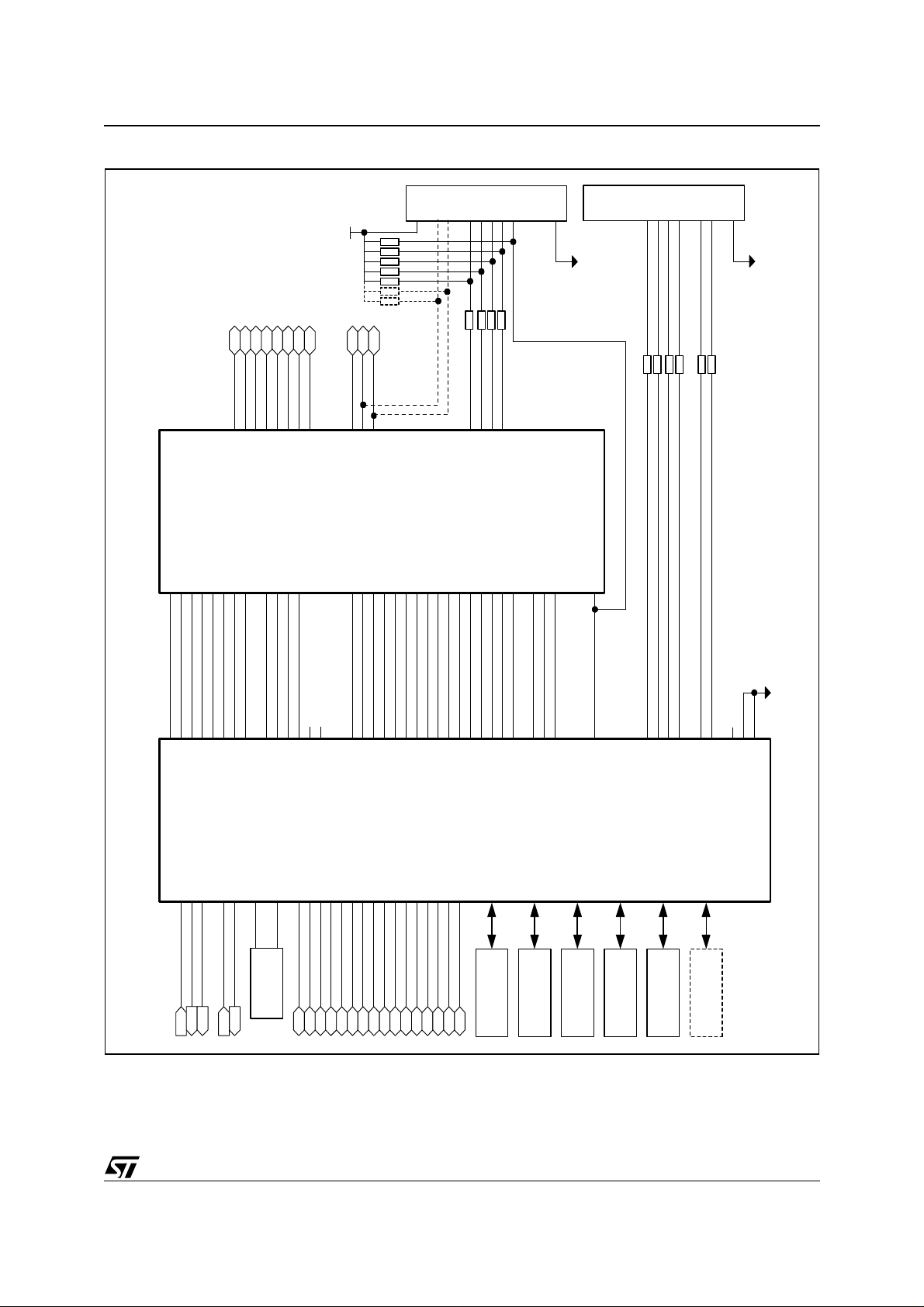

Figure 5. Block Diagram

DSM2190F4

SECURITY

LOCK

DSP

ADDR

AD0

AD1

AD2

AD3

AD4

AD5

AD6

AD7

AD8

AD9

AD10

AD11

AD12

AD13

AD14

AD15

PD0

PD1

PD2

DSP

CONTROL

CNTL0

CNTL1

CNTL2

PC2

RST\

INTERNAL ADDR, DATA, CONTROL BUS LINKED TO DSP

MAIN FLASH MEMORY

PAGE REG

DECODE PLD

(DPLD)

EXTERNAL

CHIP SELEC T S

COMPL EX PLD

PLD INPUT BUS

PIN FEEDBACK

NODE FEED BACK

(CPLD)

ARRAY

AND

FS0-7

CSBOOT0-3

CSIOP

EXTERNAL CHIP SELECTS, ESC0-2

ABA

B

BCBCBCBCBCBCBCB

16 Output Macrocells

BBB

CCCCBCBCBCBC

fs7

fs0

8 SEGMENTS, 32 KB

256 KBytes TOTAL

2nd FLASH MEMORY

csboot3

csboot0

4 SEGMEN T S, 8 KB

32 KBytes TOTAL

RUNTIME CONTROL

CSIOP REGISTER FILE

POWER MANAGEMENT

ABABABABABA

B

16 Input

Macrocell

B

C

JTAG-ISP

TO ALL AREAS

OF CHIP

ALLO-

CATOR

DSM2190F4

DSP SYS T EM

MEMORY

DSP

DATA

PA0

PA1

PA2

PA3

PA4

PA5

PA6

PA7

I/O PORT

PB0

PB1

PB2

PB3

PB4

PB5

PB6

PB7

I/O PORT

PC0

PC1

PC3

PC4

PC5

PC6

PC7

OMCs: The general structure of the CPLD is similar in nature to a 22V10 PLD device wit h t he familiar sum-of-products (AND-OR) construct. True

and compliment versions of 64 input signals are

available to a large AND array. AND array outputs

feed into a multiple product-term O R gate within

each OMC (up to 10 product-terms for each

OMC). Logic output of the OR gate can be passed

on as combinatorial logic or combined with a flipflop within in each OMC to realize sequential logic.

OMCs can be used a s a buried nodes with feedback to the AND array or OMC output can be routed to pins on Port B or PortC.

IMCs: Inputs from pins on Port B or Port C are

routed to IMCs for conditioning (clocking or latching) as they enter the chip, which is good for sampling and debouncing inputs. Alternatively, IMCs

can pass Port input signals directly to P LD inputs

without clocking or latching. The DSP may read

the IMCs at any time.

AI04960B

Runtime Control Registers

A block of 256 byt es is decoded inside the DSM

device as DSM control and status registers. 27

registers are used in the block of 256 locations to

control the output state of I/O pins, to read I/O

pins, to control p ower managem ent, to read /write

macrocells, and other functions at runtime. See

Table 4 for description. The base address of these

256 locations is referred to in this data sheet as

csiop

(Chip Select I/O Port). Individual registers

within this block are accessed with an offset from

csiop

the base address. The DSP accesses

ters using I/O memory with the

IOMS strobe.

regis-

csiop

registers are accessed as bytes.

Memory Page Register

This 8-bit register can be l oaded and read b y the

csiop

DSP at runtime as one of the

registers. Its

outputs feed directly into the PLDs. The page register can be used for special memory mapping requirements and also for general logic.

7/61

Page 8

DSM2190F4

I/O Po r t s

The DSM has 19 individually configurable I/O pins

distributed over the three ports (Ports B, C, and D).

Each I/O pin can be individually configured for different functions such as standard MCU I/O p orts

or PLD I/O on a pin by pin basis. (MCU I/O means

that for each pin, its output state can be controlled

or its input value can be read by the DSP at runt-

csiop

ime using the

registers like an MCU would

do.)

Port C hosts the JTAG ISP signals. Sinc e JTAG-

ISP does not occur frequently during the life of a

product, those Port C pins are under-utilized. In

applications that need every I/O pin, JTAG signals

can be multiplexed with general I/O signals to use

them for I/O when not performing ISP. See section

titled “Programming In-Circuit using JTAG ISP” on

page 40 for muxing JTAG pins on Port C, and Application Note

The static configuration of all Port pins is d efined

with the PSDsoft Express

AN1153

.

TM

software development tool. The dynami c ac tion of th e P orts p ins is

controlled by DSP runtime software.

JTAG ISP Port

In-System Programming (ISP) can be pe rformed

through the JTAG signals on Port C. This serial interface allows programming of the entire DSM device or subsections (that is, only Flash memory but

not the PLDs) without the participation of the DSP.

A blank DSM device soldered to a circuit board

can be completely programmed i n 10 to 25 seconds. The basic JTAG signals; TMS, TCK, TDI,

and TDO form the IEEE-1149.1 interface. The

DSM device does not implement the IEEE-1149.1

Boundary Scan functions. The DSM uses the

JTAG interface for ISP only. However, the DSM

device can reside i n a standard JTAG chain with

other JTAG devices (including the ADSP-2191)

and it will remain in BYPASS mode while other devices perform Boundary Scan.

ISP programming time can be reduced as much as

30% by using two more signals on Port C, TSTAT

and TERR

in addition to TMS, TCK, TDI and TDO.

TM

The FlashLINK

JTAG programming cable is

available from STMicroelectronics for $59USD

and PSDsoft Express software is available at no

charge from

www.st.com/psm

. That is all that is

needed to program a DSM device using the parallel port on any PC or note-book. See section titled

“Programming In-Circuit using JTAG ISP” on page

40.

Power Management

csiop

The DSM has bits in

control registers that

are configured at run -time by the DSP to reduce

power consumption of the CPLD. The Turbo bit in

the PMMR0 register can be set to logic 1 and the

CPLD will go to Non-Turbo mode, meaning it will

latch its outputs and go to sleep until the next transition on its inputs. There is a slight penalty in PLD

performance (longer propagation delay), but significant power savings are realized.

Additionally, bits in two

csio p

registers can be set

by the DSP to selectively block signals from entering the CPLD which reduces power consumption.

See section titled “Power Management” on page

37.

Security and NVM Sector Protection

A programmable security bit in the DSM protects

its contents from unauthorized viewing and copying. When set, the security bit will block access of

programming devices (JTAG or others) to the

DSM Flash memory and PLD configuration. The

only way to defeat the security bit is to erase the

entire DSM device, after which the device is blank

and may be used again.

Additionally, the content s of ea ch in dividual F lash

memory sector can be write protected (sector protection) by configuration with PSDsoft Express

TM

This is typically used to protect DSP boot code

from being corrupted by inadvertent writes to

Flash memory from the DSP.

Pin Assign m ent s

Pin assignment are shown for the 52-pin PLCC

package in F igure 3, and the 5 2-pin PQFP package in Figure 4.

.

8/61

Page 9

Table 3. Pin Description

Pin Name Type Description

ADIO0-15 In Sixteen address inputs from the DSP.

DSM2190F4

CNTL0 In Active low write strobe input (WR

CNTL1 In Active low read strobe input (RD

CNTL2 In Active low Byte Memory Select (BMS

Reset

PA0-7 I/O Eight data bus signals connected to DSP pins D8 - D15.

PB0-7 I/O

PC0-7 I/O

PD0-2 I/O

V

CC

GND Ground pins

Active low reset input from system. Resets DSM I/O Ports, Page Register contents, and other

In

DSM configuration registers. Must be logic Low at Power-up.

Eight configurable Port B signals with the following functions:

1. MCU I/O – DSP may write or read pins directly at runtime with csiop registers.

2. CPLD Output Macrocell (McellAB0-7 or McellBC0-7) outputs.

3. Inputs to the PLDs (Input Macrocells).

Note: Each of the four Port B signals PB0-PB3 may be configured at run-time as either standard

CMOS or for high slew rate. Each of the four Port B signals PB3-PB7 may be configured at

run-time as either standard CMOS or Open Drain Outputs.

Eight configurable Port C signals with the following functions:

1. MCU I/O – DSP may write or read pins directly at runtime with csiop registers.

2. CPLD Output Macrocell (McellBC0-7) output.

3. Input to the PLDs (Input Macrocells).

4. Pins PC0, PC1, PC5, and PC6 can optionally form the JTAG IEEE-1149.1 ISP serial

interface as signals TMS, TCK, TDI, and TDO respectively.

5. Pins PC3 and PC4 can optionally form the enhanced JTAG signals TSTAT and TERR

respectively. Reduces ISP programming time by up to 30% when used in addition to the

standard four JTAG signals: TDI, TDO, TMS, TCK.

6. Pin PC3 can optionally be configured as the Ready/Busy output to indicate Flash memory

programming status during parallel programming. May be polled by DSP or used as DSP

interrupt to indicate when Flash memory byte programming or erase operations are

complete.

Note 1: Port C pin PC2 input (or any PLD input pin) can be connected to the DSP IOMS

Note 2: When used as general I/O, each of the eight Port C signals may be configured at run-time

Note 3: The JTAG ISP pins may be multiplexed with other I/O functions.

Three configurable Port D signals with the following functions:

Note 1: Port D pin PD0 (or any PLD input pin) can be connected to the DSP A16 output. See

Note 2: Port D pin PD1 (or any PLD input pin) can be connected to the DSP A17 output. See

Note 3: Port D pin PD2 (or any PLD input pin) can be connected to the DSP A18 output. See

Supply Voltage

See Figure 6.

as either standard CMOS or Open Drain Outputs.

1. MCU I/O – DSP may write or read pins directly at runtime with csiop registers.

2. Input to the PLDs (no associated Input Macrocells, routes directly into PLDs).

3. CPLD output (External Chip Select). Does not consume Output Macrocells.

4. Pin PD1 can optionally be configured as CLKIN, a common clock input to PLD.

5. Pin PD2 can optionally be configured as CSI

memory. Flash memory is disabled to conserve more power when CSI

connect CSI

Figure 6

Figure 6.

Figure 6

to ADSP-218X PWDACK output signal.

) from the DSP

) from the DSP.

) signal from the DSP.

, an active low Chip Select Input to select Flash

output.

is logic high. Can

9/61

Page 10

DSM2190F4

TYPICAL CONNECTIONS

Figure 6 shows a typical connection scheme.

Many connection possibilities exist since many

DSM pins are multipurpose. This scheme illustrates the use of a com bined function

(functions as

BMS and MSx), and many I/O pins. It

also illustrates how to chain the DSM and DSP devices together on the JTAG bus. The J TAG connector definition depends on development and

production environment requi reme nts. A s pe cially

defined connector can be devised to combine the

signals of the FlashLINK and the Analog Devices

emulator. Alternatively, two separate JTAG connectors can be used, one matching the pin out of

FlashLINK and the other matching the emulator pinout.

Keep in mind that signals

BMS, IOMS, MSx,

ADDR16, ADDR17, ADDR18 can be connected to

any DSM pin t hat is a PLD input. I /O pins on Po rt

B and Port C are m ore capable (more PLD functions) than Port D pins. It is recommended to use

Port D pins primarily for decode inputs first, leaving pins on Port B and Port C available for general

BSM signal

logic. Figure 6 illustrates a com mon way to m ake

connections.

Following are connection options to consider:

Port C JTAG: Figure 6 shows four JTAG signals

(TMS, TCK, TDI, TDO) connected to the DSM. Alternatively, using six-pin JTAG (two m ore signal s,

TSTAT and

TERR) can reduce ISP time by as

much as 30% compared to four-pin JTAG. Other

JTAG options include multiplexing JTAG pins with

general I/O (see “Programming In-Circuit using

JTAG ISP” on page 40 and Application Note

AN1153

), or not using J TAG at all. If no JTAG is

used, the DSM device has to be programmed on a

conventional programmer before it is installed on

the circuit board. Using no JTAG makes more

DSM I/O available.

Pins PC2 and PD2. If not all 288K a ddress locations need to be decoded in the DSM, then

ADDR18 on pin P D2 is n ot needed. In t his case,

IOMS signal can be connected to pin PD2, free-

the

ing pin PC2 for general I/O usage.

10/61

Page 11

Figure 6. Typical Connections

DSM2190F4

DSM2190F4

PA0

PA1

PA2

PA3

PA4

I/O

PB0

PA5

I/O

PB1

PA6

I/O

PB2

PA7

I/O

I/O

PB3

PB4

CNTL0

I/O

CNTL1

I/O

PB6

PB5

CNTL2

PC2

I/O

PB7

CONNECTOR

DSM JTAG

VCC

JTAG_TDI

10k ohm

33 ohm

I/O

I/O

I/O

PC7

PC3

PC4

ADIO0

ADIO1

ADIO2

ADIO3

ADIO4

optional _TERR

optional TSTAT

TMS

TCK

TDI

TDO

PC1

PC0

PC6

PC5

ADIO5

ADIO6

ADIO7

ADIO8

ADIO9

ADIO10

ADIO11

ADIO12

ADIO13

ADIO14

ADIO15

PD1

PD2

PD0

_RESET

_RESET

DSP JTAG

JTAG_TMS

JTAG_TCK

JTAG_TDO

CONNECTOR

AI04961B

JTAG_TRST

EMULATOR STATUS

33 ohm

DATA1

DATA0

D0D1D2

_BR

BUS_REQUEST

DATA4

DATA2

DATA3

D3D4D5D6D7

ADSP-2191

_BG

_BGH

GRANT_HUNG

BUS_GRANT

DATA6

DATA5

CLKOUT

BYPASS

CLOCK OUT

PLL BYPASS

READ

WRITE

DATA7

I/O MEM SELECT

BOOT MEM SELECT

_RD

_WR

_MSx

_BMS

_IOM S

ADDR1

ADDR0

ADDR2

A0A1A2A3A4A5A6A7A8

ACK

ADDR4

ADDR6

ADDR8

ADDR10

ADDR3

ADDR5

ADDR7

ADDR13

ADDR9

ADDR11

ADDR12

ADDR14

ADDR15

ADDR16

ADDR17

ADDR18

RESET

A9

A12

A13

A14

A15

A18

A16

A10

A11

A17

_RESET

CLKIN

XTAL

PF1

PF2

PF3

PF0

I/O

I/O

I/O

I/O

I/O

XTAL

CLOCK or

PF8

PF9

PF6

PF10

PF7

PF4

PF5

I/O

I/O

I/O

PF11

PF12

PF13

PF14

PF15

SPORT0

SERIAL CHN

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

SERIAL

DEVICE

SPORT1

SERIAL CHN

DEVICE

SERIAL CHN

SERIAL

DEVICE

SPORT1

SERIAL

RxD, TxD

UART

DEVICE

JTAG TDI

TDI

JTAG TDO

TDO

TIMER/

JTAG TCK

TCK

TMR2-0

CAPTURE

JTAG _TRST

JTAG TMS

EMULATOR STATUS

TMS

_EMU

_TRST

BMODE0

BMODE1

OPMODE

Hx

HOST

PORT

11/61

Page 12

DSM2190F4

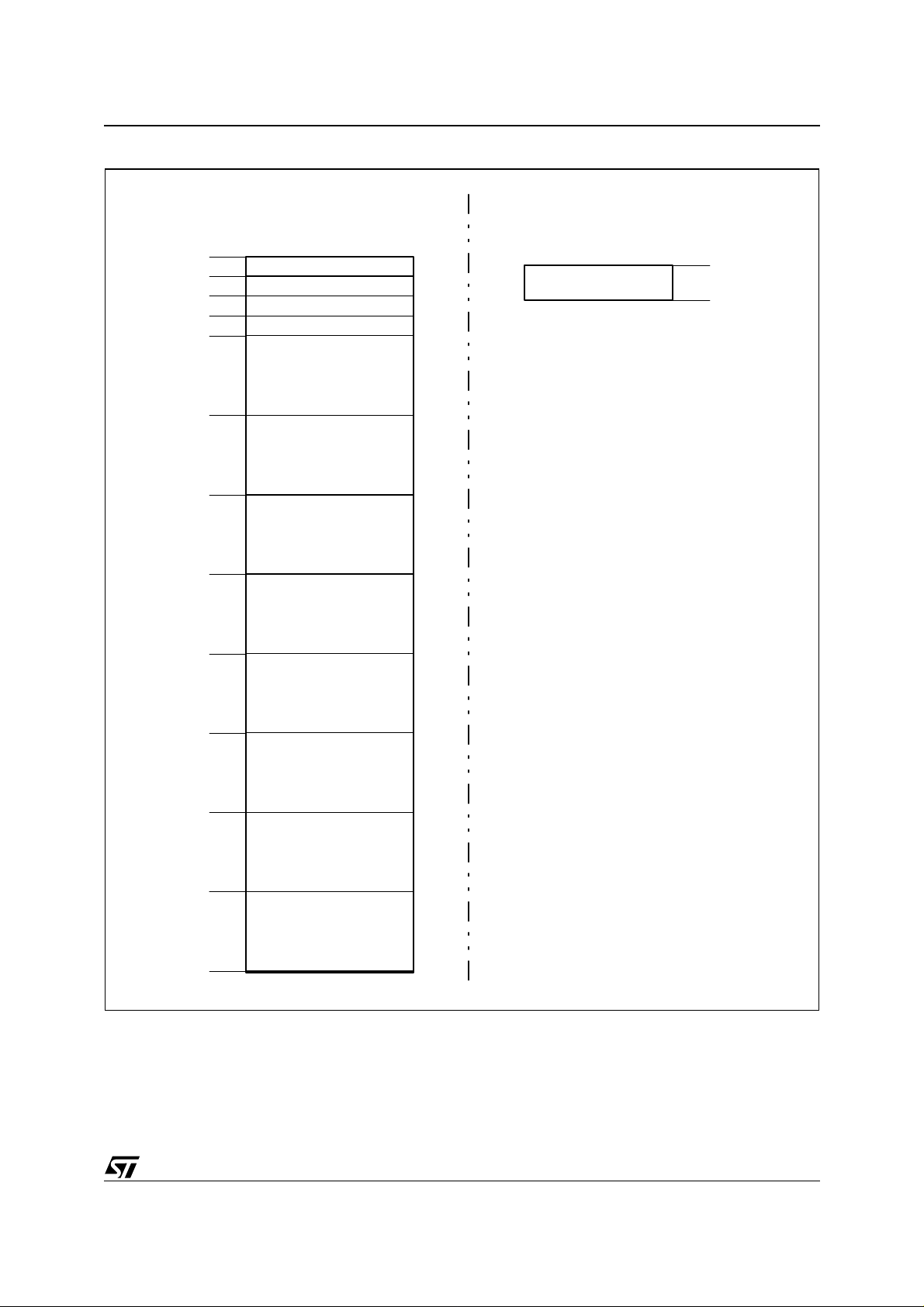

TYPICAL MEMORY MAP

There many different ways to plac e (or map) the

addresses of DSM memory and I/O depending on

system requirements. The DP LD al lows com plete

mapping flexibility. Figure 7 shows one possible

system memory map. In this case, the DSP will

bootload (via DMA) the contents of Main Flash

memory upon reset. The Secondary Flash memory can be used for parameter storage or additional

code storage. BMS and MS x are conf igured in the

DSP to be combined into the

the DSP to access both Flash memories at runtime (after DMA boot). The DSP may execute code

BMS signal, allowing

directly from the DSM and well as erase and write

new code or data to DSM Flash.

The nomenclature

fs0..f s 7

are designators f or the

individual sectors of Main Flash memory, 32K

bytes each.

csboot0..csboot3

are designators for

the individual Secondary Flash memory segments, 8K bytes each.

csiop

designates the DSM

control register block.

The designer may easily specify memory mapping

in a point-and-click software environment using

PSDsoft Express

TM

.

12/61

Page 13

Figure 7. Typ ic a l Sy st em Mem ory Map

DSM2190F4

56000-57FFF

54000-55FFF

52000-53FFF

50000-51FFF

4FFFF

48000

47FFF

40000

3FFFF

38000

37FFF

30000

2FFFF

28000

27FFF

20000

1FFFF

18000

17FFF

10000

DSP Boot Memory

Space (BMS)

csboot

, 8KB 2nd Flash

csboot

, 8KB 2nd Flash

csboot

, 8KB 2nd Flash

csboot

, 8KB 2nd Flash

fs7

32K bytes Main Flash

fs6

32K bytes Main Flash

fs5

32K bytes Main Flash

fs4

32K bytes Main Flash

fs3

32K bytes Main Flash

fs2

32K bytes Main Flash

fs1

32K bytes Main Flash

fs0

32K bytes Main Flash

DSP I/O Memor y

Space (IOMS)

csiop

256 CONTROL REGS

02000-020FF

AI04962

13/61

Page 14

DSM2190F4

SPECIFYING THE MEMORY MAP WITH PSDSOFT EXPRESS

The memory map shown in Figure 7 can be easily

implemented using PSDsoft Express

and-click environment. PSDsoft Express

TM

in a point-

TM

will

statemen ts of the ABEL language. Figure 8 shows

the resulting equations generated by PSDsoft ExpressTM.

TM

generate Hardware Definition Language (HDL)

Figure 8. HDL Statements Generated from PSDsoft Express to Implement Memory M ap

csiop = ((address >= ^h2000) & (address <= ^h20FF) & (!_ioms));

fs0 = ((address >= ^h10000) & (address <= ^h17FFF) & (!_bms));

fs1 = ((address >= ^h18000) & (address <= ^h1FFFF) & (!_bms));

fs2 = ((address >= ^h20000) & (address <= ^h27FFF) & (!_bms));

fs3 = ((address >= ^h28000) & (address <= ^h2FFFF) & (!_bms));

fs4 = ((address >= ^h30000) & (address <= ^h37FFF) & (!_bms));

fs5 = ((address >= ^h38000) & (address <= ^h3FFFF) & (!_bms));

fs6 = ((address >= ^h40000) & (address <= ^h47FFF) & (!_bms));

fs7 = ((address >= ^h48000) & (address <= ^h4FFFF) & (!_bms));

csboot0 = ((address >= ^h50000) & (address <= ^h51FFF) & (!_bms));

csboot1 = ((address >= ^h52000) & (address <= ^h53FFF) & (!_bms));

csboot2 = ((address >= ^h54000) & (address <= ^h55FFF) & (!_bms));

csboot3 = ((address >= ^h56000) & (address <= ^h57FFF) & (!_bms));

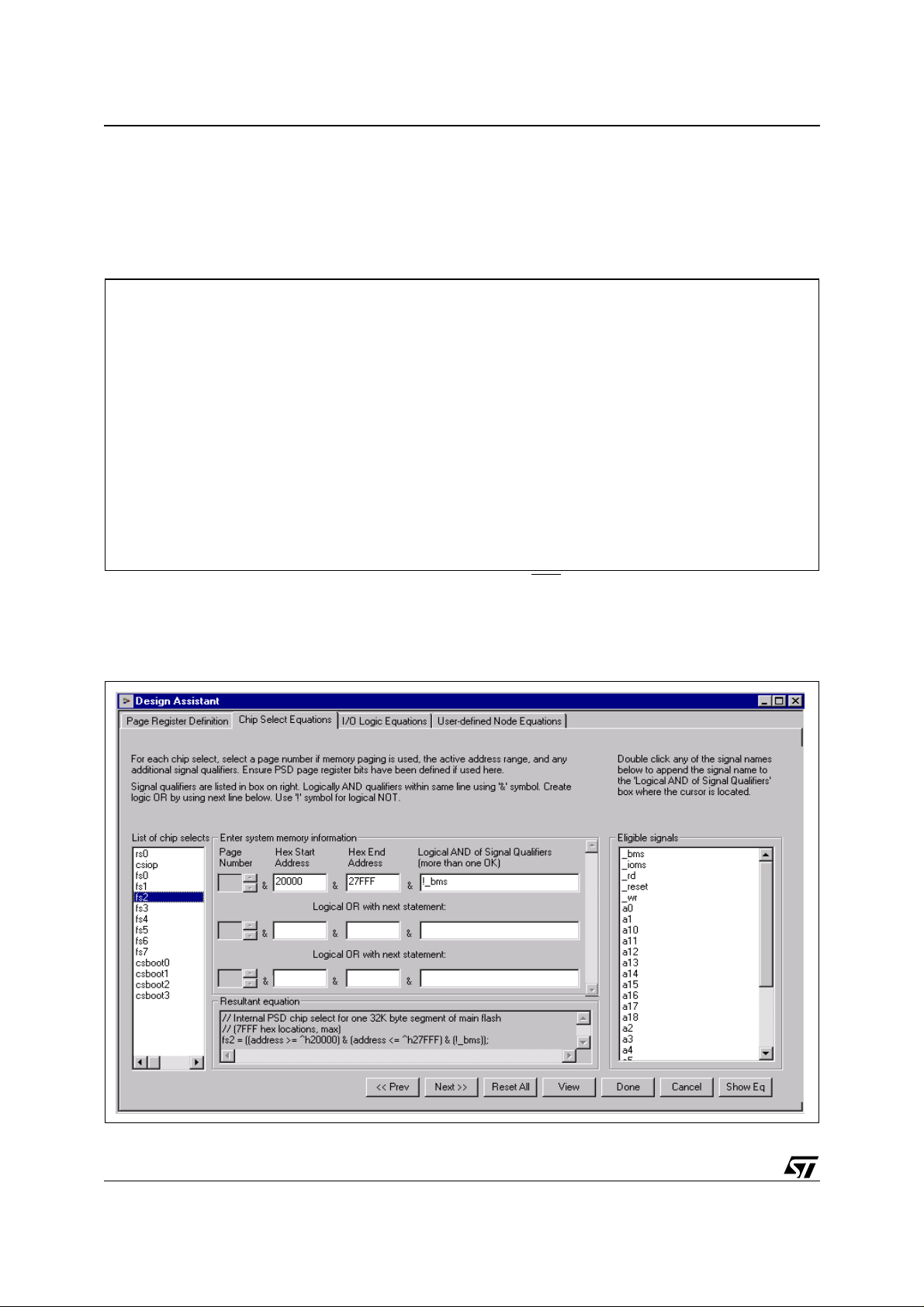

Specifying these equations using PSDsoft Ex-

TM

press

is very simple. Figure 9 shows how to

specify the equation for the 32K Byt e Fl ash mem-

fs2

ory se gment,

. Notice

fs2

is qualified with the

signals

BMS. This specif ication proces s is repeat-

ed for all other Flash memory segments, the

register block, and any external chip select signals

that may be needed (ADC, etc.).

csiop

Figure 9. PSDsoft Express

TM

Memory Mapping

14/61

Page 15

RUNTIME CONTROL REGISTER DEFINITION

There are up to 256 addresses decoded inside the

DSM device for control and status information. 27

of these locations contain registers that the DSP

can access at runtime. The base address of this

block of 256 locations is referred to in this manual

as

csiop

(Chip Select I/O Port). Table 4 lists the 27

registers and their offsets (in hexadecimal) from

csiop

the

base address needed t o acc ess in dividual DSM control and status registers. The DSP will

access these registers in I/O memory space using

DSM2190F4

its

IOMS strobe. These regis ters are accesses in

bytes, so the DSP should ignore the upper byte of

its 16-bit I/O access.

Note1: All

reset.

Note2: Do not write to unused locations within the

csiop

logic zero.

csiop

registers are cleared to logic 0 at

block of 256 registers. They should remain

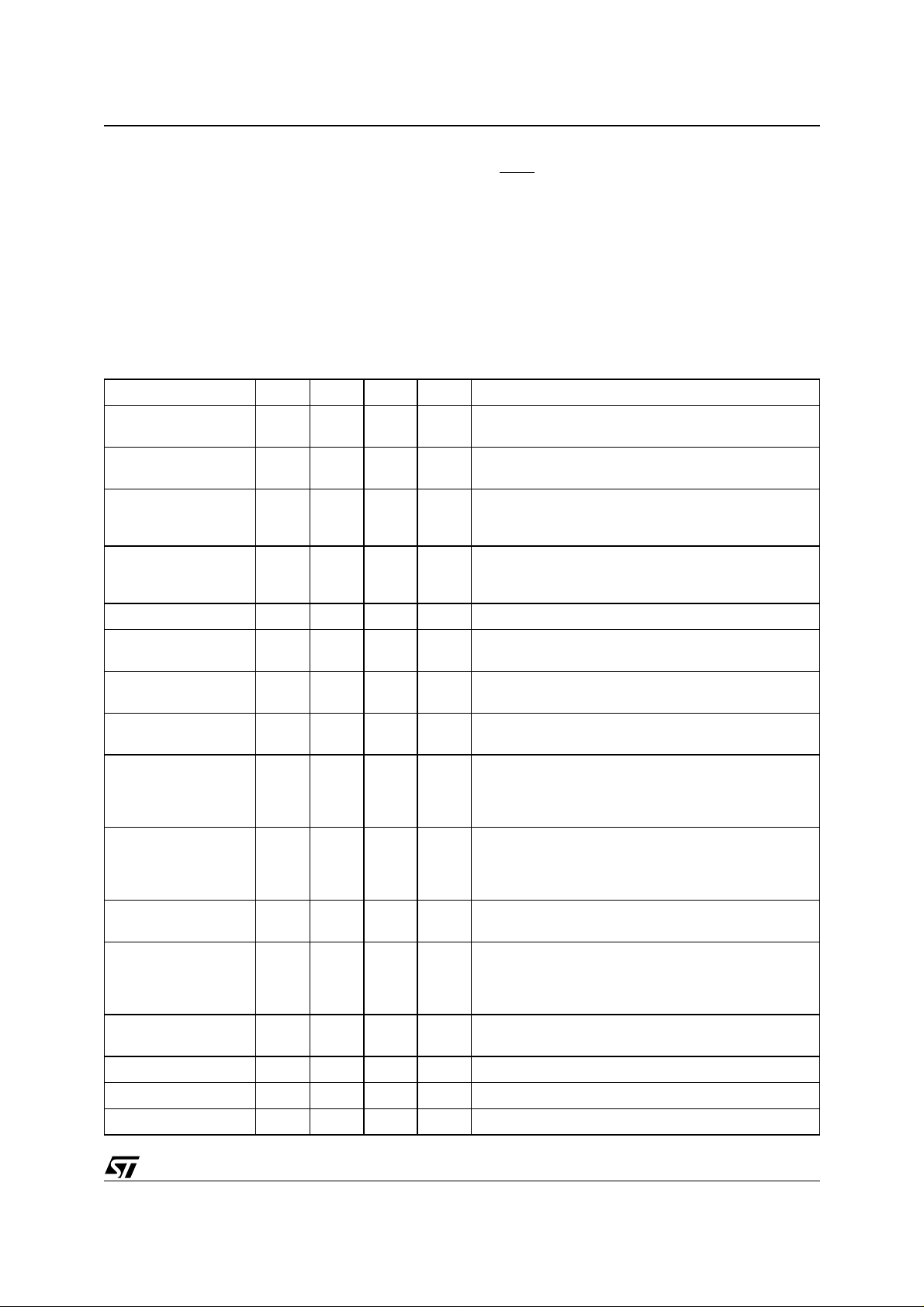

Table 4.

Data In 01 10 11

Data Out 05 12 13

Direction 07 14 15

Drive Select 09 16 17

Input Macrocells 0B 18 Read to obtain state of IMCs. No writes.

Enable Out 0D 1A 1B

Output Macrocells AB 20

Output Macrocells BC 21

Mask Macrocells AB 22

Mask Macrocells BC 23

CSIOP

Register Name Port B P ort C Port D Other Description

Registers and their Offsets (in hexadecimal)

MCUI/O input mode. Read to obtain current logic level of

Port pins. No writes.

MCU I/O output mode. Write to set logic level on Port

pins. Read to check status.

MCU I/O mode. Configures Port pin as input or output.

Write to set direction of Port pins.

Logic 1 = out, Logic 0 = in. Read to check status.

Write to configure Port pins as either standard CMOS or

Open Drain on some pins, while selecting high slew rate

on other pins. Read to check status.

Read to obtain the status of the output enable logic on

each I/O Port driver. No writes.

Read to get logic state of output of OMC bank AB.

Write to load registers of OMC bank AB.

Read to get logic state of output of OMC bank BC.

Write to load registers of OMC bank BC.

Write to set mask for loading OMCs in bank AB. A logic

1 in a bit position will block reads/writes of the

corresponding OMC. A logic 0 will pass OMC value.

Read to check status.

Write to set mask for loading OMCs in bank BC. A logic

1 in a bit position will block reads/writes of the

corresponding OMC. A logic 0 will pass OMC value.

Read to check status.

Main Flash Sector

Protection

Security Bit and

Secondary Flash

Sector Protection

JTAG Enable C7

PMMR0 B0 Power Management Register 0. Write and read.

PMMR2 B4 Power Management Register 2. Write and read.

Page E0 Memory Page Register. Write and read.

Read to determine Main Flash Sector Protection

C0

Setting. No writes.

Read to determine if DSM devices Security Bit is active.

Logic 1 = device secured.

C2

Also read to determine Secondary Flash Protection

Setting status. No Writes.

Write to enable JTAG Pins (optional feature). Read to

check status.

15/61

Page 16

DSM2190F4

DETAILED OPERATION

Figure 5 shows major functional areas of the device :

■ Flash Memories

■ PLDs (DPLD, CPLD, Page Register)

■ DSP Bus Interface (Address, Data, Control)

■ I/O Por ts

■ Runtime Control Registers

■ JTAG ISP Interface

The following describes these functions in more

detail.

Flash Memories

The Main Flash memory array is divided into eight

equal 32K byte sectors. The Secondary Flash

memory array is divided into four equ al 8K byte

sectors. Each sector is selected by the DPLD can

be separately protected from program and erase

cycles. This configuration is specified by using PSDsoft Express

Memory Sector Select Signals. The DPLD generates the Select signals for all the internal memory blocks (see Figure 14). Each of the twelve

sectors of the Flash mem ories has a sel ec t signal

FS0-FS7, or CSBOOT0-CSBOOT3

(

tains up to three product terms. Having t hree product terms for each select signal allows a given

sector to be mapped into multiple ar e as of system

memory if needed.

Ready/Busy

output the Ready/

output on Ready/

Flash memory array is being written,

ther Flash memory array is being erased. The output is a 1 (Ready) wh en no Write o r Erase cycle is

TM

.

) which con-

(PC3 ). This signal can be used to

Busy status of the device. The

Busy is a 0 (Busy) when either

or

when ei-

in progress. This signal may be polled by the DSP

or used as a DSP interrupt to indicate when an

erase or program cycle is complete.

Memory Operation. The Flash memories are accessed through the DSP Address, Data, and Control Bus Interface.

DSPs and MCUs cannot write to Flash memory as

it would an SRAM device. Flash memory must first

be “unlocked” with a special sequence of byte

write operations to invoke an internal algorithm,

then a single data byte is written to the Flash memory array, then programming status is chec ked by

a byte read operation or by checking the Ready/

Busy pin (PC3). Table 5 lists all of the special in-

struction sequences to program (write) data to the

Flash memory arrays, erase the arrays, and check

for different types of status from the arrays. These

instruction sequences are different combinations

of individual byte write and byte read operations.

IMPORTANT: The DSP may not read and execute

code from the same Flash memory array for which

it is directing an instruction sequence. Or more

simply stated, the DSP may not read code the

same Flash array that is writing or erasing. Instead, the DSP must execute code from an alternate memory (like its own internal SRAM or a

different Flash array) while sending instructions to

a given Flash array. Since the two Flash memory

arrays inside the DSM device are completely independent, the DSP may read code from one array

while sending instructions to the other.

After a Flash memo ry array is programmed (written) it will go to “Read Array” mo de, then th e DSP

can read from Flash mem ory just as if would from

any 8-bit ROM or SRAM device.

16/61

Page 17

DSM2190F4

Table 5. Instruction Sequences

Instruction

Sequence

Cycle 1 Cycle 2 Cycle 3 Cycle 4 Cycle 5 Cycle 6 Cycle 7

1,2,3,4

Read byte

Read Memory

Contents

5

from any

valid Flash

memory addr

Read Flash

Identifier (Main

Flash only)

6,7

Read Memory

Sector Protection

6,7,8

Status

Program a Flash

Byte

Flash Bulk Erase

Flash Sector

10

Erase

Write AAh to

XX555h

Write AAh to

XX555h

Write AAh to

XX555h

Write AAh to

9

XX555h

Write AAh to

XX555h

Write 55h

to XXAAAh

Write 55h

to XXAAAh

Write 55h

to XXAAAh

Write 55h

to XXAAAh

Write 55h

to XXAAAh

Write 90h

to XX555h

Write 90h

to XX555h

Write A0h

to XX555h

Write 80h

to XX555h

Write 80h

to XX555h

Read identifier

with addr lines

A6,A1,A0 =

0,0,1

Read identifier

with addr lines

A6,A1,A0 =

0,1,0

Write

(program)

data to addr

Write AAh to

XX555h

Write AAh to

XX555h

Write 55h

to XXAAAh

Write 55h

to XXAAAh

Write 10h

to XX555h

Write 30h

to another

Sector

Write 30h

to another

Sector

Write B0h to

Suspend Sector

11

Erase

address that

activates any

of FS0 - FS7

Write 30h to

Resume Sector

12

Erase

addr that

activates any

of FS0 - FS7

Write F0h to

Reset Flash

6

address that

activates any

of FS0 - FS7

Note: 1. All val ues are in hexadecimal, X = Don’t Care

2. A d esired int ernal Flash memory sec tor select signal (FS0 - F S 7 or CSBOO T 0 - CSBOOT3 ) m ust be acti ve for each write or read

cycle. Only one of these sector select signals will be active at any given time depending on the address presented by the DSP and

the memory mapping defi ned in PSDs oft Express. FS0 - FS7 and CSBOOT0- CS BOOT3 are act i ve high logic internal l y.

3. DS P addres ses A18 thr ough A12 ar e Don’t Care during t he instruc tion sequ ence de coding . Only addre ss bits A 11-A0 are used

during Fl ash memo ry instructio n sequence decoding b us cycles . The individ ual sector select sign al (FS0 - F S7 or CSB OOT0CSBOOT3) which is active during the instruction sequences determines the complete address.

4. For write operations, addresses are latched on the falling edge of Write Strobe (WR

Write Strobe (WR

5. No Unlock or In st ruction cycl es are required when the device is in the Read Arr ay mode. Operation is like reading a ROM device.

6. The Reset Flash instruction is required to return to the normal Read Array mode if the Error Flag (DQ5) bit goes High, or after reading the Flash I dentifier or after read i ng t he Sector Protection Status.

7. The DSP cannot invoke this instruction sequence while executing code from the same Flash memory as that for which the instruction sequence is intended. The DSP must fetch, for example, the code from the DSP SRAM when reading the Flash memory Identifier or Sector Protection Status.

8. The da ta is 00h for an unprote cted sector, and 01h for a pr otected sec tor. In the fo urth cycle, th e Sector Sele ct is active, and

(A1,A0)= (1,0)

9. Di recting this comma nd to any in dividua l active Flash memory seg ment (FS 0 - FS7) will invoke th e bulk era se of all eight Flash

memory sectors.

10. DS P wr ites c omma nd s eque n ce t o init ial s egme nt t o be erase d, t hen wr ite s the byte 30h to ad diti onal sect ors to b e er ased . Th e

byte 30h must be addressed to one of the other Flash memory segments (FS0 - FS7) for each additional segment (write 30h to any

address within a desir ed sector). No more than 80uS can elaps e between su bsequent additional sector erase commands .

11. The s y stem ma y perfo rm R ead an d P rogra m c ycl es in n on- erasi ng s ecto rs, read t he Flas h ID o r read t he Se ctor Protec t S tatu s,

when in the Suspend Sector Erase mode. The Suspend Sector Erase instruction sequence is valid only during a Sector Erase cycle.

12. The Resume Sector Erase instru ction sequence is valid only during the Suspend Sector Erase mode.

, CNTL0)

, CNTL0), Dat a i s latched on the risin g e dge of

17/61

Page 18

DSM2190F4

Instruction Sequences

An instruction sequence consists of a sequence of

specific write or read operations. Each byte written

to the device is received and sequentially decoded

and not executed as a standard write operation to

the memory array. The instruction sequence is executed when the correct number of bytes are properly received and the time between two

consecutive bytes is shorter than the time-out period. Some instruction sequences are structured to

include read operations after the initial write operations.

The instruction sequence must be followed exac tly. Any in valid com binatio n of ins truction bytes o r

time-out between two consecutive bytes while addressing Flash memory resets the device logic into

Read Array mode (Flash memory is read like a

ROM device). The device s upports the instruction

sequences summarized in Table 5:

Flash memory:

■ Erase memory by chip or sector

■ Suspend or resume sector erase

■ Program a Byte

■ Reset to Read Array mode

■ Read primary Flash Identifier value

■ Read Sector Protection Status

These instruction sequences are detailed in Table

5. For efficient decoding of the instruction sequences, the first two bytes of an i nstruction sequence are the coded cycles and are followed by

an instruction byte or confirmation byte. The coded

cycles consist of writing the data AAh to address

XX555h during the first cycle and data 55h to address XXAAAh during the second cycle. Address

signals A18-A12 are Don’t Care during the instruction sequence Write cycles. However, the appropriate internal Sector Select (

CSBOOT0-CSBOOT3

) must be selected internal-

FS0-FS7 or

ly (active, which is logic 1).

Reading Flash Memory

Under typical conditions, the D SP may read the

Flash memory using read operations just as it

would a ROM or RAM device. Alternately, the DSP

may use read operations to obtain status information about a Program or Erase cycle that is currently in progress. Lastly, the DSP may use

instruction sequences to read special data from

these memory blocks. The following sections describe these read instruction sequences.

Read Memory Contents. Flash memory is

placed in the Read Array mode after Power-up,

chip reset, or a Reset Flash memory instruction

sequence (see Table 5). The DSP can read the

memory contents of the Flash memory by using

read operations any time the read operation is not

part of an instruction sequence.

Read Main Flash Identifier. The Main Flash

memory identifier is read with an instruction sequence composed of 4 operations: 3 specific write

operations and a read operation (see Table 5).

During the read operation, address bits A6, A1,

and A0 must be 0,0,1, respectively, and the appropriate internal Sector Select (

FS0-FS7

) must be

active. The identifier is 0xE7. Not Applicable to

Secondary Flash.

Read Memory Sector Protection Status. The

Flash memory Sector Protection Status is read

with an instruction sequence composed of 4 operations: 3 specific write operations and a read operation (see Table 5). During the read operation,

address bits A6, A1, and A0 must be 0,1,0, respectively, while internal Sector Sele ct (FS0-FS7

or CSBOOT0-CSBOOT3) designates the Flash

memory sector whose protection has to be verified. The read operation produces 01h if the Flash

memory sector is protected, or 00h if th e sector is

not protected.

The sector protection status can also be read by

the DSP accessing the Flash memory Prot ection

csiop

registers in

space. See the section ent itled

“Flash Memory Sector Protect” for register definitions .

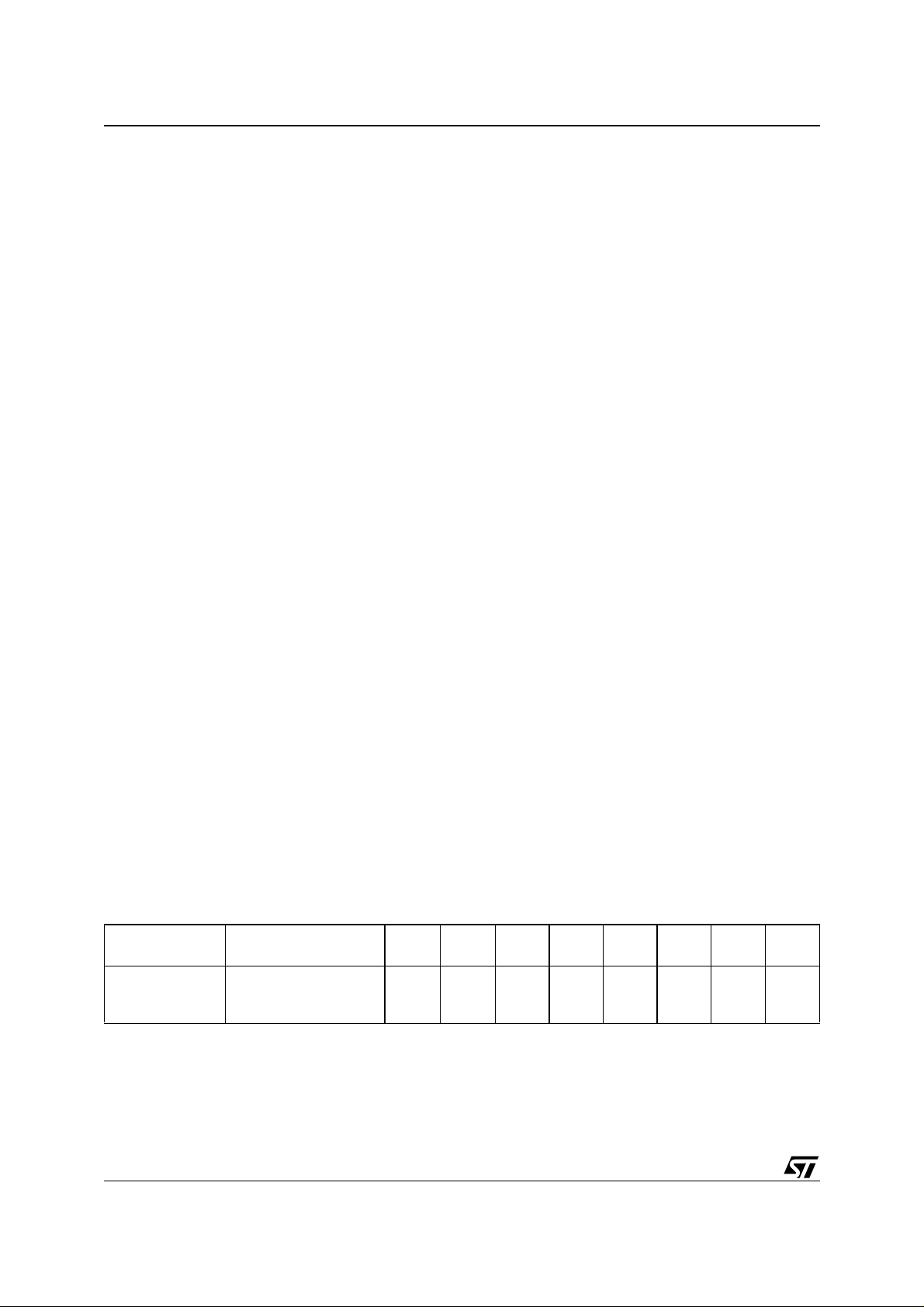

Table 6. Status Bit Definition

Functional Block

Flash Memory

Note: 1. X = Not guaranteed value, can be rea d ei t her 1 or 0.

2. DQ7-DQ0 represent the Data Bus bits, D7-D0.

FS0-FS7, or

CSBOOT0-CSBOOT3

Active (the desired

segment is selected)

DQ7 DQ6 DQ5 DQ4 DQ3 DQ2 DQ1 DQ0

Data

Polling

Reading the Erase/Program Status Bits. The

device provides several status bits to be used by

the DSP to confirm the completion of an Erase or

18/61

Toggle

Flag

Error

Flag

Erase

X

Time-

out

XXX

Program cycle of Flash memory. These st atus bits

minimize the time that the DSP spends performing

these tasks and are defined in Table 6. The status

bits can be read as many times as needed.

Page 19

DSM2190F4

For Flash memory, the DS P can perform a read

operation to obtain these status bits while an

Erase or Program instruction sequence is being

executed by the embedded algorithm. See the

section entitled “Programming Flash Memory”, on

page 19, for details.

Data Polling Flag (DQ7). When erasing or programming in Flash memory, the Data Polling Flag

(DQ7) bit outputs the co mplem ent of the bit bei ng

entered for programming/writing on the Data P olling Flag (DQ7) bit. Once the Program instruction

sequence or the write operation is c ompleted, t he

true logic value is read on the Data Polling Flag

(DQ7) bit (in a read operation).

Flash memory instruction features.

■ Data Polling is effective after the fourth Write

pulse (for a Program instruction sequence) or

after the sixth Write pulse (for an Erase

instruction sequence). It must be performed at

the address being programmed or at an address

within the Flash memory sector being erased.

■ During an Erase cycle, the Data Polling Flag

(DQ7) bit outputs a 0. After completion of the

cycle, the Data Polling Flag (DQ7) bit outputs

the last bit programmed (it is a 1 after erasing).

■ If the byte to be programmed is in a protected

Flash memory sector, the instruction sequence

is ignored.

■ If all the Flash memory sectors to be erased are

protected, the Data Polling Flag (DQ7) bit is

reset to 0 for about 100 µs, and then returns to

the previous addressed byte. No erasure is

performed.

Toggle Flag ( DQ6 ). The device offers another

way for determining when t he F lash memory Program cycle is completed. During the in ternal write

operation and when the Sector Select FS0-FS7 (or

CSBOOT0-CSBOOT3) is true, the Toggle Flag

(DQ6) bit toggles from 0 to 1 and 1 to 0 on subsequent attempts to read any byte of the memory.

When the internal cycle is complete, the toggling

stops and the data read on the Data Bus D0-7 is

the addressed mem ory byte. The device is now

accessible for a new read or write operation. The

cycle is finished when two successive reads yield

the same output data. Flash m emo ry spe cific features:

■ The Toggle Flag (DQ6) bit is effective after the

fourth write operation (for a Program instruction

sequence) or after the sixth write operation (for

an Erase instruction sequence).

■ If the byte to be programmed belongs to a

protected Flash memory sector, the instruction

sequence is ignored.

■ If all the Flash memory sectors selected for

erasure are protected, the Toggle Flag (DQ6) bit

toggles to 0 for about 100 µs and then returns to

the previous addressed byte.

Error Flag (DQ5). During a normal Program or

Erase cycle, the Error Flag (DQ5) bit is to 0. T his

bit is set to 1 when there is a failure during Flash

memory Byte Program, Sector Erase, or Bulk

Erase cycle.

In the case of Flash memory programming, the Error Flag (DQ5) bit indicates the attempt to program

a Flash memory bit from the programmed state, 0,

to the erased state, 1, whi ch is not vali d. The Error

Flag (DQ5) bit may also indicate a Time-out condition while attempting to program a byte.

In case of an error in a Flash memory Sector Erase

or Byte Progra m cycle, the Fl ash memory sector i n

which the error occurred or to which the programmed byte belongs must no longer be used.

Other Flash memory sectors may still be used.

The Error Flag (DQ5) bit is reset after a Reset

Flash instruction sequence.

Erase Time-out Flag (DQ3). The Erase Timeout Flag (DQ3) bit reflects the time-out period allowed between two consecutive Sec tor Erase instruction sequence bytes. The Erase Time-out

Flag (DQ3) bit is reset to 0 after a Sector Erase cycle for a time period of 100 µs + 20% unless an additional Sector Erase instruction sequence is

decoded. After this time period, or when the additional Sector Erase instruction sequence is decoded, the Erase Time-out Flag (DQ3) bit is set to 1.

Programming Flash Memory

When a byte of Flash memory is programmed, individual bits a re p ro grammed to logic 0. You cannot program a bit in Flash memory to a logic 1

once it has b een programmed to a logic 0. A bit

must be erased to logic 1, and programmed to logic 0. That means Flash memory must be erased

prior to being programmed. A b yte o f Flash memory is erased to all 1s (FFh). The DSP may erase

the entire Flash memory array all at once or individual sector-by-sector, but not byte-by-byte.

However, the DSP may program Flash memory

byte-by-byte.

The Flash memory requires the DSP to send an instruction sequence to program a byte or to erase

sectors (see Table 5).

Once the DSP issues a Flash memory Program or

Erase instruction sequence, it must check for the

status bits for completion. The embedded algorithms that are invoked inside the device provide

several ways give status to the DSP. Status may

19/61

Page 20

DSM2190F4

be checked using any of three methods: Data Polling, Data Toggle, or Ready/Busy

(pin PC3).

Data Polling. Polling on the Data Polling Flag

(DQ7) bit is a method of checking whether a Program or Erase cycle is in progress or has completed. Figure 10 shows the Data Polling algorithm.

When the DSP issues a Program instruction sequence, the embedded algorithm within the device

begins. The DSP then reads the location of the

byte to be programmed in Flash memory to check

status. The Data Polling Flag (DQ7) bit of this location becomes the compliment of bit 7 of the original data byte to be programmed. The DSP

continues to poll this location, comparing the Data

Polling Flag (DQ7) bit and monitoring the Error

Flag (DQ5) bit. When the Data Polling Flag (DQ7)

bit matches bit7 of the original data, and the Error

Flag (DQ5) bit remains 0, then the em bedded algorithm is complete. If the Error Flag (DQ5) bit is

1, the DSP should test the Data Polling Flag (DQ7)

bit again since the Data Polling Flag (DQ7) bit may

have changed simultaneously wi th the Error Flag

(DQ5) bit (see Figure 10).

The Error Flag (DQ5) bit is set if either an internal

time-out occurred while the embedded algorithm

attempted to program the byte or if the DS P attempted to program a 1 to a bit that was not erased

(not erased is logic 0).

It is suggested (as with all Flash memories) to read

the location again after the embedded programming algorithm has completed, to compare the

byte that was written to the Flash memory with the

byte that was intended to be written.

When using the Data Polling method during an

Erase cycle, Figure 10 still applies. However, the

Data Polling Flag (DQ7) bit is 0 until the Erase cycle is complete. A 1 on the Error Flag (DQ5) bit indicates a time-out condition on the Erase cycle, a

0 indicates no error. The DSP can read any location within the sector being erased to get the Data

Polling Flag (DQ7) bit and the Error Flag (DQ5) bit.

PSDsoft Express generates ANSI C code functions which implement these Data Polling algorithms.

Figure 10. Data Polling Flowchart

START

READ DQ5 & DQ7

at VALID ADDRESS

DQ7

DATA

NO

DQ5

READ DQ7

DQ7

DATA

FAIL PASS

= 1

YES

=

NO

YES

YES

=

NO

AI01369B

Data Toggle. Checking the Toggle Flag (DQ6) bit

is a method o f det erm ining whether a P rogram or

Erase cycle is in progress or has completed. Figure 11 shows the Data Toggle algorithm.

When the DSP issues a Program instruction sequence, the embedded algorithm within the device

begins. The DSP then reads the location of the

byte to be programmed in Flash memory to check

status. The Toggle Flag (DQ6) bit of this location

toggles each time the DSP reads this location until

the embedded algorithm is complete. The DSP

continues to read this location, check ing the Toggle Flag (DQ6) bit and monitoring the Error Flag

(DQ5) bit. When the Toggle Flag (DQ6) bit stops

toggling (two consecutive reads yield the same

value), and the Error Flag (DQ5) bit remains 0,

then the embedde d algorithm is complete. If the

Error Flag (DQ5) bit is 1, the DSP should test the

Toggle Flag (DQ6) bit again, since the Toggle Flag

(DQ6) bit may have chan ged simultaneo usly with

the Error Flag (DQ5) bit (see Figure 11).

20/61

Page 21

DSM2190F4

Figure 11. Data Toggle Flowchart

START

READ

DQ5 & DQ6

DQ6

=

TOGGLE

NO

DQ5

= 1

READ DQ6

DQ6

=

TOGGLE

FAIL PASS

NO

YES

YES

NO

YES

AI01370B

The Error Flag (DQ5) bit is set if either an internal

time-out occurred while the embedded algorithm

attempted to program the byte, or if the DSP attempted to program a 1 to a bit that was not erased

(not erased is logic 0).

It is suggested (as with all Flash memories) to read

the location again after the embedded programming algorithm has completed, to compare the

byte that was written to Flash memory with the

byte that was intended to be written.

When using the Data Toggle method after an

Erase cycle, Figure 11 still applies. the Toggle

Flag (DQ6) bit toggles until the Erase cycle is complete. A 1 on the Error Flag (DQ5) bit indicates a

time-out condition on the Erase cycle, a 0 indicates no error. The DSP can read any location

within the sector being erased t o get the Toggle

Flag (DQ6) bit and the Error Flag (DQ5) bit.

PSDsoft Express generates ANSI C code functions which implement these Data T oggling algorithms.

Erasing Flash Memory

Flash Bulk Erase. The Flash Bulk Erase instruc-

tion sequence uses six write operations followed

by a read o peration of the status regist er, as described in Table 5. If any byte of the Bulk Erase instruction sequence is wrong, the Bulk Erase

instruction sequence aborts and the device is re-

set to the Read Flash memory status. The Bulk

Erase command may be addresses to any one individual valid Flash memory segment (

CSBOOT0-CSBOOT3

) and the entire array (all

FS0-FS7 or

segments in one array) will be erased.

During a Bulk Erase, the memory status may be

checked by reading the Error Flag (DQ5) bit, the

Toggle Flag (DQ6) bi t, and the Dat a Polling Flag

(DQ7) bit, as detailed in the section entitled “Programming Flash Memory”, on page 19. The Error

Flag (DQ5) bit returns a 1 if there has been an

Erase Failure (maximum number of Erase cycles

have been executed).

It is not necessary to program the memory with

00h because the device automatically does this

before erasing to 0FFh.

During execution of the Bulk Erase instruction sequence, the Flash memory does not accept any instruction sequences.

The address provided with the Flash Bulk Er ase

command sequence (Table 5) may select any one

of the eight internal Flash memory Sector Select

signals FS0 - FS7 or one of the four signals

CSBOOT0-CSBOOT3. An erase of that entire

Flash memory array will occur even though the

command was sent to just one Flash memory sector.

Flash Sector Erase. The Sector Erase instruction sequence uses six write operations, as described in Table 5. Additional Flash Sector Erase

codes and Flash memory sector addresses can be

written subsequently to erase other Flash memory

sectors in parallel, without further coded cycles, if

the additional bytes are transmitted in a shorter

time than the time-out period of about 100 µs. The

input of a new Sector Erase code restarts the timeout period.

The status of the internal timer can be monitored

through the level of the Erase Time-out Flag (DQ3)

bit. If the Erase Time-out Flag (DQ3) bit i s 0, the

Sector Erase instruction sequence has been received and the time-out p eriod is counting. If the

Erase Time-out Flag (DQ3) bit is 1, the time-out

period has expired and the device is busy erasing

the Flash memory sector(s). Before and during

Erase time-out, any instruction sequence other

than Suspend Sector Erase an d Resume Sector

Erase instruction sequences abort the cycle that is

currently in progress, and reset the device to Read

Array mode. It is not necessary to program the

Flash memory sector with 00h as the device does

this automatically before erasing (byte=FFh).

During a Sector Erase, the memory status may be

checked by reading the Error Flag (DQ5) bit, the

Toggle Flag (DQ6) bi t, and the Dat a Polling Flag

(DQ7) bit, as detailed in the section entitled “Programming Flash Memory”, on page 19.

21/61

Page 22

DSM2190F4

During execution of the Erase cycle, the Flash

memory accepts only Reset and Suspend Sector

Erase instruction sequences. Erasure of one

Flash memory sector may be suspended, in order

to read data from anot her Flash memory sector,

and then resumed.

The address provided with the initial Flash Sector

Erase command sequence (Table 5) must select

the first desired sector (FS0 - FS7 or CSBOOT0CSBOOT3) to erase. Subsequent sector erase

commands that are appended on within the timeout period must be addressed to other desired

segments (FS0 - FS7 or CSBOOT0-CSBOOT3).

Suspend Sector Erase. When a Sector Erase

cycle is in progress, the Suspend Sector Erase instruction sequence can be used to suspend the

cycle by writing 0B0h to any address when an appropriate Sector Select (FS0-FS7 or CSBOOT0CSBOOT3) is selected (See Table 5). This allows

reading of data from another Flash memory sector

after the Erase cycle has been sus pended. Suspend Sector Erase is accepted only during an

Erase cycle and defaults to Read mode. A Suspend Sector Erase instruction sequence executed

during an Erase time-out period, in addition to suspending the Erase cycle, terminat es the time out

period.

The Toggle Flag (DQ6) bit stops toggling when the

device internal logic is suspended. The status of

this bit must be m onitored at an address within the

Flash memory sector being erased. The Toggle

Flag (DQ6) bit stops toggling between 0.1 µs and

15 µs after the Susp end Sector Erase instruction

sequence has been execut ed. The device i s then

automatically set to Read mode.

If an Suspend Sector Erase instruction sequence

was executed, the following rules apply:

– Attempting to read from a Flash memory sector

that was being erased outputs invalid data.

– Reading from a Flash memory sect or that was

not

being erased is valid.

cannot

– The Flash memory

be programmed, and

only responds to Resume Sector Erase and Reset Flash instruction sequences (Read is an operation and is allowed).

– If a Reset Flash instruction sequence is re-

ceived, data in the Flash memory sector that

was being erased is invalid.

Resume Sector Erase. If a Suspend Sector

Erase instruction sequence was previously executed, the erase cycle may be resumed with this

instruction sequence. The Resume Sector Erase

instruction sequence consists of writing 030h to

any address while an appropriate Sector Select

(FS0-FS7 or CSBOOT0-CSBOOT3) is active.

(See Table 5.)

Flash Memory Sector Protect.

Each Flash memory sector can be separately protected against Program and Erase cycles. Sector

Protection provides additional data security because it di sables all Pr ogram o r Erase cycles. This

mode can be activated through the JTAG Port or a

Device Programmer. Sector protection can be selected for each sector using PSDsoft Express.

This automatically protects selected sectors when

the device is programmed through the JTAG Port

or a Device Programmer. Flash memory sectors

can be unprotected to allow updating of their contents using the JTAG Port or a Device Programmer. The DSP can read (but cannot change) the

sector protection bits.

Any attempt to program or erase a protected Flash

memory sector is ignored by the device. The Verify

operation results in a read of the protected data.

This allows a guarantee of the retention of the Protection status.

The sector protection status ca n be read by the

DSP through the Main Flash memory protection

csiop

register (in the

block) as defined in Table 7,

and Secondary Flash memory protection register

in Table 8.

Table 7. Main Flash Memory Protection Register Definition

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Sec7_Prot Sec6_Prot Sec5_Prot Sec4_Prot Sec3_Prot Sec2_Prot Sec1_Prot Sec0_Prot

Note: Bit Definitio ns:

Sec<i>_Prot 1 = Flash memory sector <i> is write protected.

Sec<i>_Prot 0 = Flash memory sector <i> is not wri te p rot ected.

Table 8. Secondary Flash Memory Protection/Security Bit Register Definition

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Security_Bit not used not used not used Sec3_Prot Sec2_Prot Sec1_Prot Sec0_Prot

Note: Securit y_Bit = 1, device is secu re d .

Note: Sec<i>_Prot 1 = Flash memory sector <i> is write protected.

Sec<i>_Prot 0 = Flash memory sector <i> is not wri te p rot ected.

22/61

Page 23