Page 1

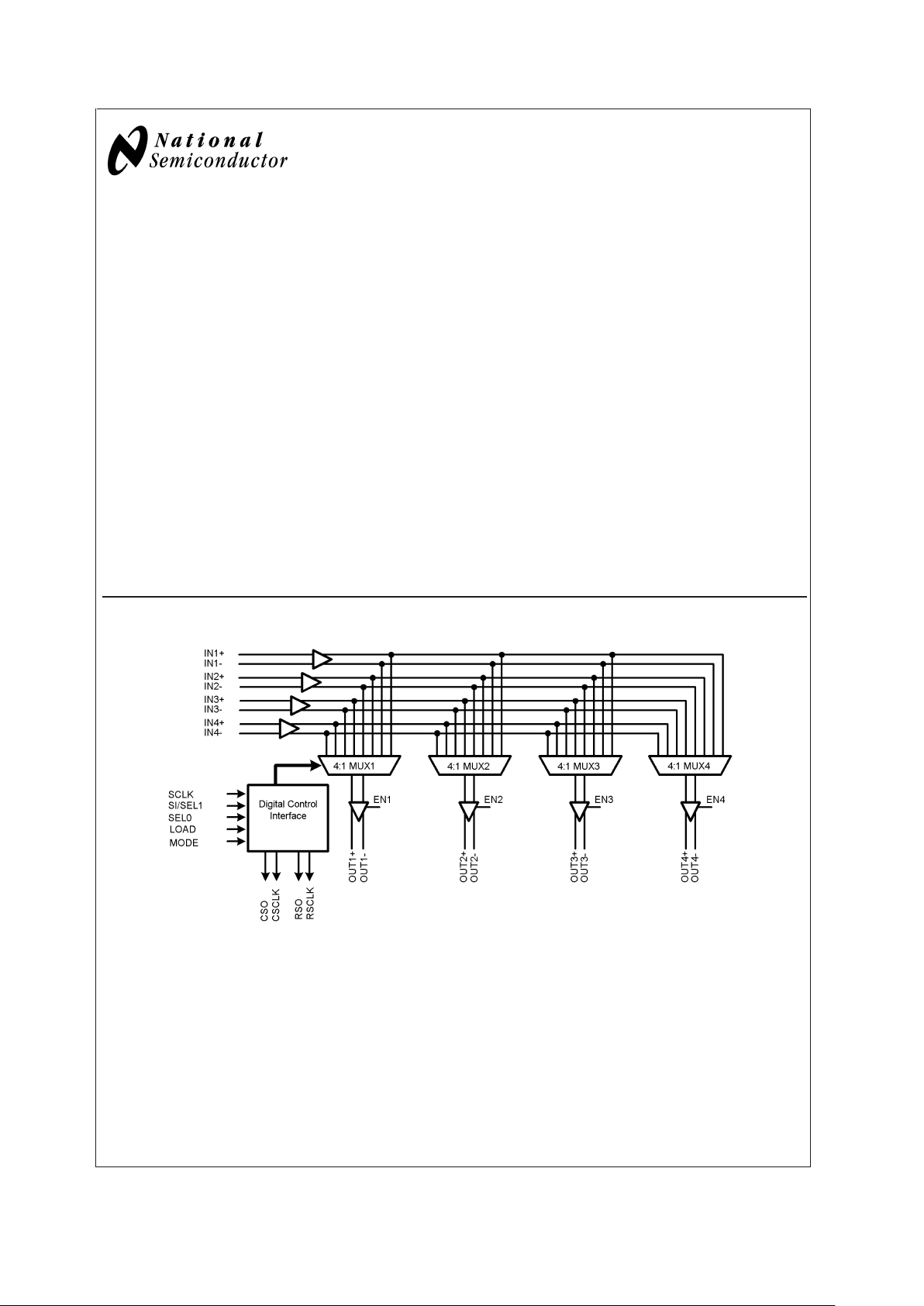

DS90CP04

4x4 Low Power 2.5 Gb/s LVDS Digital Cross-Point

Switch

General Description

DS90CP04 is a 4x4 digital cross-point switch with broadside

input and output pins for efficient board layout. It utilizes Low

Voltage Differential Swing (LVDS) technology for low power,

high-speed operation. Data paths are fully differential from

input to output for low noise. The non-blocking architecture

allows connections of any input to any output or outputs. The

switch matrix consists of four differential 4:1 multiplexes.

Each output channel connects to one of the four inputs

common to all multiplexers. Each DS90CP04 output pair is

capable of independent operation up to 2.5Gb/s.

A simple serial control interface or a configuration select port

is activated by the state of the MODE pin. When utilizing the

serial control interface a single load command will update

the new switch configuration for all outputs simultaneously.

When the direct configuration port is used, output configurations are updated immediately based on the decoded

SEL0/1 logic state.

Features

n 2.5 Gbps fully differential data paths

n Non-blocking architecture

n Broadcast from any input

n Broadside pin-out

n Possible expansion to larger switch array

n Accepts LVDS/BLVDS/LVPECL/2.5V-CML inputs

n TRI-STATE LVDS outputs

n Serial control interface with read-back capability

n Double register loading

n Single +2.5V supply

n Low power, 575 mW Typ at 2.5 Gb/s

n Lead-less LLP-32 package 6x6 mm body size)

n Fabricated with advanced CMOS process technology

Functional Block Diagrams

20028701

April 2003

DS90CP04 4x4 Low Power 2.5 Gb/s LVDS Digital Cross-Point Switch

© 2003 National Semiconductor Corporation DS200287 www.national.com

Page 2

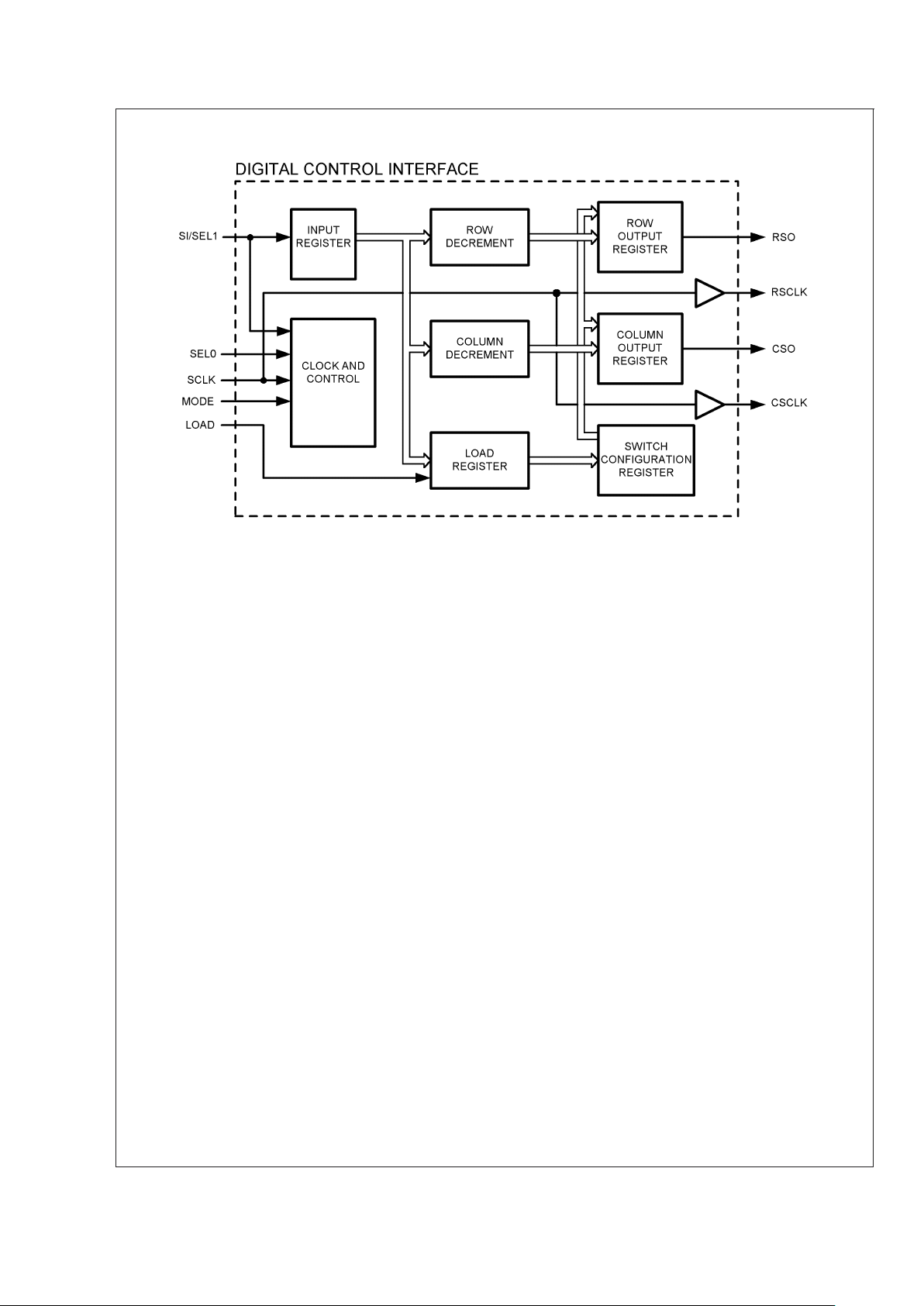

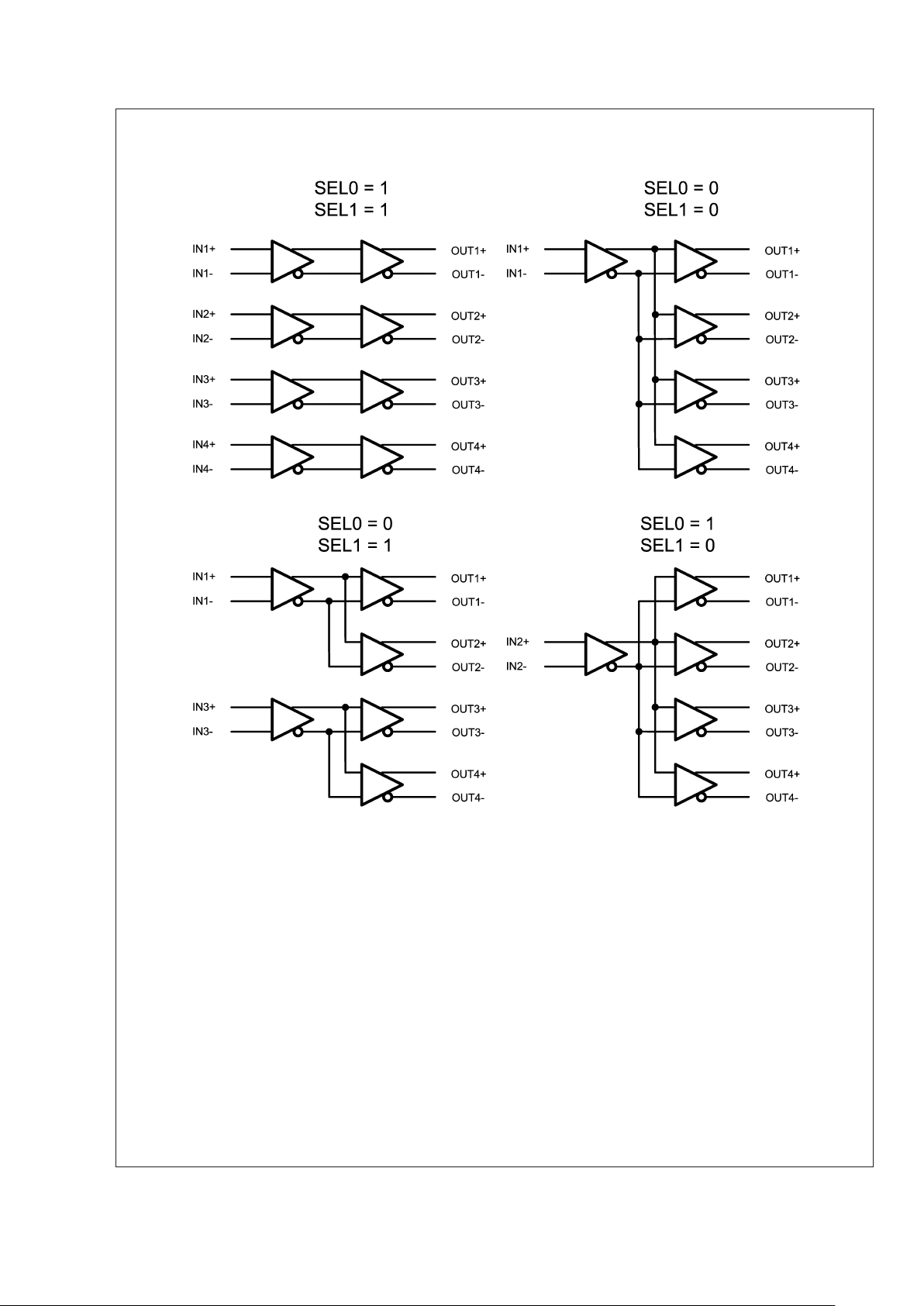

Functional Block Diagrams (Continued)

20028702

DS90CP04

www.national.com 2

Page 3

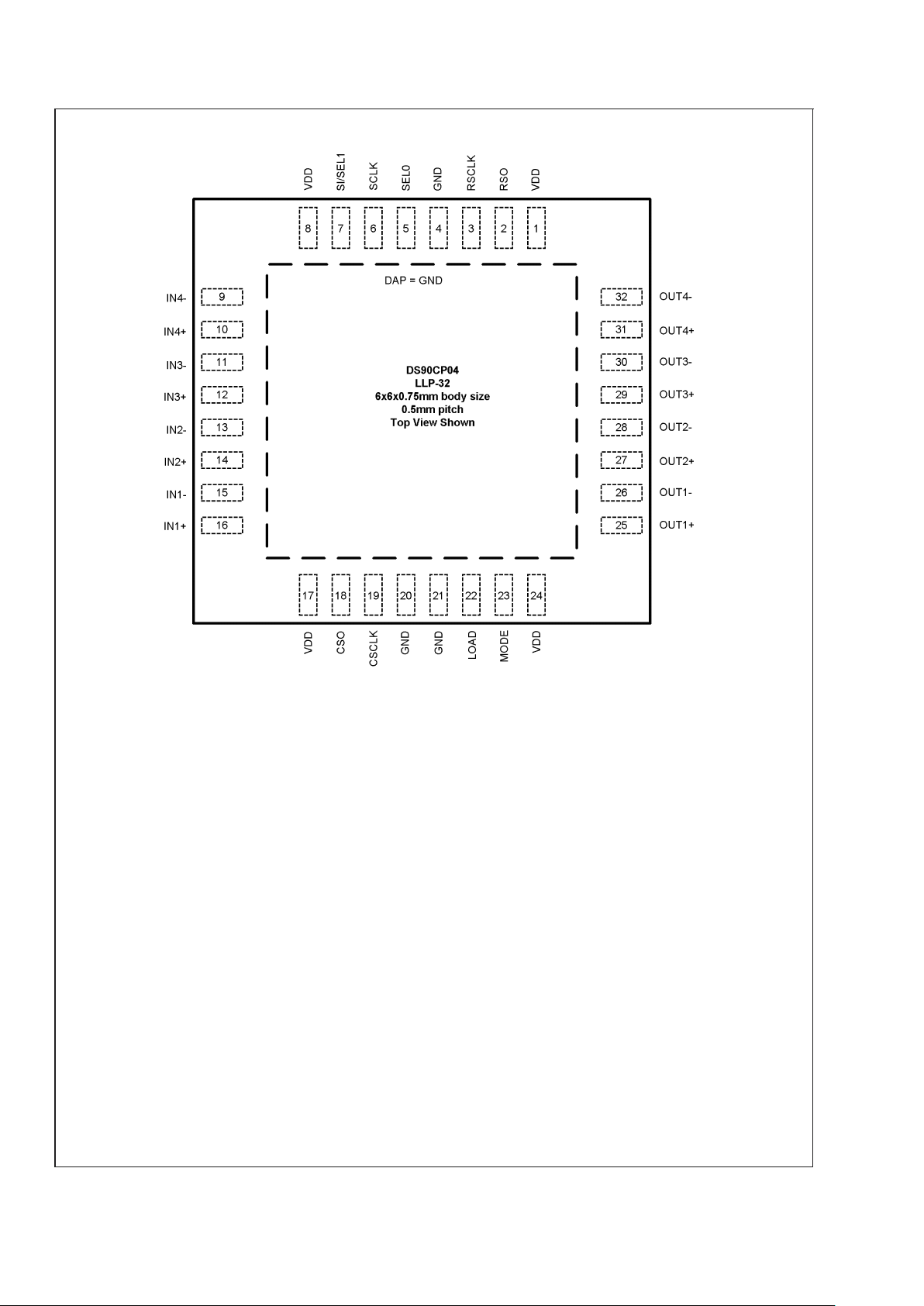

Connection Diagram

20028703

Order Number DS90CP04TLQ, DS90CP04TLQX (Tape and Reel)

See NS Package Number LQA32A

DS90CP04

www.national.com3

Page 4

Pin Descriptions

Pin

Name

Pin

Number

I/O, Type Description

DIFFERENTIAL INPUTS COMMON TO ALL MUXES

IN1+

IN1−

16

15

I, LVDS Inverting and non-inverting differential inputs.

IN2+

IN2−

14

13

I, LVDS Inverting and non-inverting differential inputs.

IN3+

IN3−

12

11

I, LVDS Inverting and non-inverting differential inputs.

IN4+

IN4−

10

9

I, LVDS Inverting and non-inverting differential inputs.

SWITCHED DIFFERENTIAL OUTPUTS

OUT1+

OUT1−

25

26

O, LVDS Inverting and non-inverting differential outputs. OUT1

±

can be connected to any

one pair IN1

±

, IN2±, IN3±,orIN4

±

OUT2+

OUT2−

27

28

O, LVDS Inverting and non-inverting differential outputs. OUT2±can be connected to any

one pair IN1

±

, IN2±, IN3±,orIN4

±

OUT3+

OUT3−

29

30

O, LVDS Inverting and non-inverting differential outputs. OUT3±can be connected to any

one pair IN1

±

, IN2±, IN3±,orIN4

OUT4+

OUT4−

31

32

O, LVDS Inverting and non-inverting differential outputs. OUT4

±

can be connected to any

one pair IN1

±

, IN2±, IN3±,orIN4

±

DIGITAL CONTROL INTERFACE

SCLK 6 I, LVCMOS Control clock to latch in programming data at SI. SCLK can be 0 MHz to

100 MHz. SCLK should be burst of clock pulses active only while accessing the

device. After completion of programming, SCLK should be kept at logic low to

minimize potential noise injection into the high-speed differential data paths.

SI / SEL1 7 I, LVCMOS Programming data to select the switch configuration. Data is latched into the input

buffer register at the rising edge of SCLK.

SEL0 5 I, LVCMOS Programming data to select the switch configuration.

CSO

RSO

18

2

O, LVCMOS With MODE low, control data is shifted out at CSO (RSO) for cascading to the

next device in the serial chain. The control data at CSO (RSO) is identical to that

shifted in at SI with the exception of the device column (row) address being

decremented by one internally before propagating to the next device in the chain.

CSO (RSO) is clocked out at the rising edge of SCLK.

CSCLK

RSCLK

19

3

O, LVCMOS With MODE low, these pins function as a buffered control clock from SCLK.

CSCLK (RSCLK) is used for cascading the serial control bus to the next device in

the serial chain.

LOAD 22 I, LVCMOS When LOAD is high and SCLK makes a LH transition, the device transfers the

programming data in the load register into the configuration registers. The new

switch configuration for all outputs takes effect. LOAD needs to remain high for

only one SCLK cycle to complete the process, holding LOAD high longer repeats

the transfer to the configuration register.

MODE 23 I, LVCMOS When MODE is low, the SCLK is active and a buffered SCLK signal is present at

the CLKOUT output. When MODE is high, the SCLK signal is uncoupled from

register and state machine internals. Internal registers will see an active low signal

until MODE is brought Low again.

POWER

V

DD

1, 8, 17,

24

I, Power VDD= 2.5V±5%. At least 4 low ESR 0.01 µF bypass capacitors should be

connected from V

DD

to GND plane.

GND 4, 20, 21,

DAP

I, Power Ground reference to LVDS and CMOS circuitry.

DAP is the exposed metal contact at the bottom of the LPP-32 package. The DAP

is used as the primary GND connection to the device. It should be connected to

the ground plane with at least 4 vias for optimal AC and thermal performance.

DS90CP04

www.national.com 4

Page 5

Serial Interface Truth Table

LOAD MODE SCLK Resulting Action

0 0 LH The current state on SI is clocked into the input shift register.

0 1 LH Uncouples SCLK input from register and state machine internals. Internal registers

will see and the RSCLK and CSCLK outputs will drive an active Low signal until

MODE is brought Low again. See Configuration Select Truth Table below.

LH 0 X Loads OUT1– OUT4 configuration information from last valid frame. Places contents

of load register into the configuration register. The switch configuration is updated

asynchronously from the SCLK input.

1 1 LH Uncouples SCLK input from register and state machine internals. Internal registers

will see and the RSCLK and CSCLK outputs will drive an active Low signal until

MODE is brought Low again. See Configuration Select Truth Table below.

Configuration Select Truth Table

MODE SEL1 SEL0 Resulting Action

0 X X The SEL0/1 pins only function in configuration select mode. See below.

1 0 0 Distribution: IN1 - OUT1 OUT2 OUT3 OUT4

1 0 1 Distribution: IN2 - OUT1 OUT2 OUT3 OUT4

1 1 0 Redundancy: IN1 - OUT1 OUT2 and IN3 - OUT3 OUT4

1 1 1 Broadside: IN1 - OUT1, IN2 - OUT2, IN3 - OUT3, IN4 - OUT4

LH: Low to High (positive edge) transition.

X: Don’t Care or Not Applicable.

DS90CP04

www.national.com5

Page 6

Configuration Select Truth Table (Continued)

20028704

FIGURE 1. DS90CP04 Configuration Select Decode

DS90CP04

www.national.com 6

Page 7

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Supply Voltage (V

DD

) −0.3V to +3V

CMOS/TTL Input Voltage −0.3V to (V

DD

+0.3V)

LVDS Receiver Input Voltage −0.3V to +3.3V

LVDS Driver Output Voltage −0.3V to +3V

LVDS Output Short Circuit Current 40mA

Junction Temperature +150˚C

Storage Temperature −65˚C to +150˚C

Lead Temperature

(Soldering, 4 sec.) +260˚C

Maximum Package Power Dissipation at 25˚C

LLP-32 3200 mW

Derating above 25˚C 38 mW/˚C

Thermal Resistance, θ

JA

26.4˚C/W

ESD Rating

HBM, 1.5 kΩ, 100 pF

LVDS Outputs

>

1.0 kV

LVDS Inputs

>

1.5 kV

All Other Pins

>

4.0 kV

EIAJ, 0Ω, 200 pF

>

100V

Recommended Operating

Conditions

Min Typ Max Unit

Supply Voltage (V

DD

– GND) 2.375 2.5 2.625 V

Receiver Input Voltage 0.05 3.3 V

Operating Free Air

Temperature −40 25 85 ˚C

Junction Temperature 110 ˚C

Electrical Characteristics

Over recommended operating supply and temperature ranges unless other specified.

Symbol Parameter Conditions Min

Typ (Note

2)

Max Units

LVCMOS/LVTTL DC SPECIFICATIONS (SCLK, SI/SEL1, SEL0, LOAD, MODE , CSCLK, RSCLK, CSO, RSO)

V

IH

High Level Input Voltage 1.7 V

DD

V

V

IL

Low Level Input Voltage GND 0.7 V

I

IH

High Level Input Current VIN=VDD=V

DDMAX

−10 +10 µA

I

IL

Low Level Input Current VIN=VSS,VDD=V

DDMAX

−10 +10 µA

C

IN1

Input Capacitance Any Digital Input Pin to V

SS

3.5 pF

C

OUT1

Output Capacitance Any Digital Output Pin to V

SS

5.5 pF

V

CL

Input Clamp Voltage ICL= −18 mA −1.5 −0.8 V

V

OH

High Level Output Voltage IOH= −4.0 mA, VDD=V

DDMIN

1.9 V

I

OH

= −100 µA, VDD= 2.5V 2.4 V

V

OL

Low Level Output Voltage IOL= 4.0 mA, VDD=V

DDMIN

0.4 V

I

OL

= 100 µA, VDD= 2.5V 0.1 V

LVDS INPUT DC SPECIFICATIONS (IN1

±

, IN2±, IN3±, IN4±)

V

TH

Differential Input High Threshold

(Note 3)

VCM= 0.05V or 1.2V or 2.45V,

V

DD

= 2.5V

050mV

V

TL

Differential Input Low Threshold VCM= 0.05V or 1.2V or 2.45V,

V

DD

= 2.5V

−50 0 mV

V

ID

Differential Input Voltage VDD= 2.5V, VCM= 0.05V to 2.45V 100 V

DD

mV

V

CMR

Common Mode Voltage Range VID= 100 mV, VDD= 2.5V 0.05 3.25 V

C

IN2

Input Capacitance IN+ or IN− to V

SS

3.5 pF

I

IN

Input Current VIN= 2.5V, VDD=V

DDMAX

or 0V −10 +10 µA

V

IN

= 0V, VDD=V

DDMAX

or 0V −10 +10 µA

LVDS OUTPUT DC SPECIFICATIONS (OUT1

±

, OUT2±, OUT3±, OUT4±)

V

OD

Differential Output Voltage (Note3)RL= 100Ω between OUT+ and

OUT−Figure 2

250 400 475 mV

∆V

OD

Change in VODbetween

Complementary States

−35 35 mV

V

OS

Offset Voltage (Note 4) 1.125 1.25 1.375 V

∆V

OS

Change in VOSbetween

Complementary States

−35 35 mV

DS90CP04

www.national.com7

Page 8

Electrical Characteristics (Continued)

Over recommended operating supply and temperature ranges unless other specified.

Symbol Parameter Conditions Min

Typ (Note

2)

Max Units

I

OZ

Output TRI-STATE Current TRI-STATE Output

V

OUT=VDD

or V

SS

−10 +10 µA

I

OFF

Power Off Leakage Current VDD= 0V, V

OUT

= 2.5V or GND −10 +10 µA

I

OS

Output Short Circuit Current,

One Complementary Output

OUT+ or OUT− Short to GND −15 -40 mA

OUT+ or OUT− Short to V

DD

15 40 mA

I

OSB

Output Short Circuit Current,

both Complementary Outputs

OUT+ and OUT− Short to GND −15 -30 mA

OUT+ and OUT− Short to V

CM

15 30 mA

C

OUT2

Output Capacitance OUT+ or OUT− to GND when

TRI-STATE

5.5 pF

SUPPLY CURRENT

I

CCD

Total Supply Current All inputs and outputs enabled,

terminated with differential load of

100Ω between OUT+ and OUT-.

220 300 mA

I

CCZ

TRI-STATE Supply Current TRI-STATE All Outputs 10 20 mA

SWITCHING CHARACTERISTICS — LVDS OUTPUTS (Figures 3, 5, 6)

t

LHT

Differential Low to High

Transition Time

Use an alternating 1 and 0 pattern

at 200 Mb/s, measure between

20% and 80% of V

OD

.

100 135 160 ps

t

HLT

Differential High to Low

Transition Time

100 135 160 ps

t

PLHD

Differential Low to High

Propagation Delay

Use an alternating 1 and 0 pattern

at 200 Mb/s, measure at 50% V

OD

between input to output.

500 750 1200 ps

t

PHLD

Differential High to Low

Propagation Delay

500 750 1200 ps

t

SKD1

Pulse Skew |t

PLHD–tPHLD

| 0 30 ps

t

SKCC

Output Channel to Channel

Skew

Difference in propagation delay

(t

PLHD

or t

PHLD

) among all output

channels in Broadcast mode (any

one input to all outputs).

0 50 100 ps

t

JIT

Jitter (Note 5)

Alternating 1 and 0 Pattern

750 MHz 1.6 2.5 psrms

1.25 GHz 1.6 2.5 psrms

K28.5 Pattern

1.5 Gb/s 10 40 psp-p

2.5 Gb/s 27 60 psp-p

PRBS 2

23

-1 Pattern

1.5 Gb/s 25 40 psp-p

2.5 Gb/s 40 70 psp-p

t

ON

LVDS Output Enable Time Time from LOAD = LH or SELx to

OUT

±

change from TRI-STATE to

active.

50 150 300 ns

t

OFF

LVDS Output Disable Time Time from LOAD = LH or SELx to

OUT

±

change from active to

TRI-STATE.

35ns

t

SW

LVDS Switching Time Time from LOAD = LH to new

switch configuration effective for

OUT

±

.

50 150 ns

DS90CP04

www.national.com 8

Page 9

Electrical Characteristics (Continued)

Over recommended operating supply and temperature ranges unless other specified.

Symbol Parameter Conditions Min

Typ (Note

2)

Max Units

t

SEL

SELx to OUT

±

Configuration select to new data at

OUT

±

.

50 150 ns

SWITCHING CHARACTERISTICS — Serial control Interface (Figures 4, 8, 9)

F

SCLK

SCLK Clock Frequency 0 100 MHz

T

DCCLK

CSCLK Duty Cycle

RSCLK Duty Cycle

Input SCLK Duty Cycle set at 50%

45 55 %

t

S

SI–SCLK or MODE–SCLK

Setup Time

From SI or MODE Input Data to

SCLK Rising Edge

1.5 ns

t

H

SCLK–SI or SCLK–MODE Hold

Time

From SCLK Rising Edge to SI or

MODE Input Data

1ns

t

DSO

SCLK to RSO or CSO Delay From SCLK to RSO or CSO 1.5 4 ns

t

DSCLK

SCLK to RSCLK or CSCLK

Delay

From SCLK to RSCLK or CSCLK

4.0 8.5 ns

t

DSDIF

|SCLK to RSCLK or

CSCLK–SCLK to RSO or CSO|

Propagation Delay Difference

between t

DSO

and t

DSCLK

1.5 4.5 ns

T

RISE

Logic Low to High Transition

Time

20% to 80% at RSO, CSO,

RSCLK, or CSCLK

1.5 ns

T

FALL

Logic High to Low Transition

Time

80% to 20% at RSO, CSO,

RSCLK, or CSCLK

1.5 ns

Note 1: “Absolute Maximum Ratings” are the ratings beyond which the safety of the device cannot be guaranteed. They are not meant to imply that the device

should be operated at these limits.

Note 2: Typical parameters are measured at V

DD

= 2.5V, TA= 25˚C. They are for reference purposes, and are not production-tested.

Note 3: Differential output voltage V

OD

is defined as |OUT+–OUT−|. Differential input voltage VIDis defined as |IN+–IN−|.

Note 4: Output offset voltage V

OS

is defined as the average of the LVDS single-ended output voltages at logic high and logic low states.

Note 5: Characterized from any input to any one differential LVDS output running at the specified data rate and data pattern, with all other 3 channels running K28.5

pattern at 1.25 Gb/s asynchronously to the channel under test. Jitter is not production-tested, but guaranteed through characterization on sample basis. Random

Jitter is measured peak to peak with a histogram including 1000 histogram window hits. K28.5 pattern is repeating bit streams of (0011111010 1100000101). This

deterministic jitter or DJ pattern is measured to a histogram mean with a sample size of 350 hits. Like RJ the Total Jitter or TJ is measured peak to peak with a

histogram including 3500 window hits.

20028712

FIGURE 2. Differential Driver DC Test Circuit

DS90CP04

www.national.com9

Page 10

Electrical Characteristics (Continued)

20028713

FIGURE 3. Differential Driver AC Test Circuit

20028714

FIGURE 4. LVCMOS Driver AC Test Circuit (Note 6)

DS90CP04

www.national.com 10

Page 11

Electrical Characteristics (Continued)

Note 6: The LVCMOS input and output AC specifications may also be verified and tested using an input attenuation network instead of a power splitter as shown

in Figure 4.

20028715

FIGURE 5. LVDS Signals

20028716

FIGURE 6. LVDS Output Transition Time

20028717

FIGURE 7. LVDS Output Propagation Delay

DS90CP04

www.national.com11

Page 12

20028718

FIGURE 8. Serial Interface Propagation Delay and Input Timing Waveforms

20028719

FIGURE 9. Serial Interface — MODE Timing and Functionality

DS90CP04

www.national.com 12

Page 13

Functional Descriptions

PROGRAMMING WITH THE SERIAL INTERFACE

The configuration of the internal multiplexer is programmed

through a simple serial interface consisting of serial clock

SCLK and serial input data line SI. The serial interface is

designed for easy expansion to larger switch array. A replicated output serial interface (RSCLK, RSO) is provided for

propagating the control data to the downstream device in the

row of an array of DS90CP04 devices in a matrix. A similar

replicated serial interface (CSCLK, CSO) is provided for

propagating the control data to the downstream devices in

the first column of the device matrix. Through this scheme,

user can program all the devices in the matrix through one

serial control bus (SCLK and SI) with the use of the feedthrough replicated control bus at RSCLK and RSO, CSCLK

and CSO.

To program the configuration of the switch, a 30-bit control

word is sent to the device. The first 6 bits shift the start frame

into SI. The only two valid start frames are 1F’h for a configuration load and 1E’h for a configuration read. The start

frame is followed by the row and column addresses of the

device to be accessed, as well as the switch configuration of

the four channels of the device. Table 1 and Table 2 are the

bit definitions of the control word. D29 is the first bit that

shifts into SI.

TABLE 1. 30-Bit Control Word

Bit Bit Length Descriptions

D29–D24 6 The start frame for control word synchronization (01 1111’b = LOAD).

D23–D18 6 Specify the row address of the device to be access. The serial interface can access up to 64

devices in the row.

D17–D12 6 Specify the column address of the device to be access. The serial interface can access up to 64

devices in the column.

D11–D9 3 Specify the switch configuration for Output 1. See Table 2.

D8–D6 3 Specify the switch configuration for Output 2. See Table 2.

D5–D3 3 Specify the switch configuration for Output 3. See Table 2.

D2–D0 3 Specify the switch configuration for Output 4. See Table 2.

TABLE 2. Switch Configuration Data

MSB LSB OUT1±Connects to OUT2±Connects to OUT3±Connects to OUT4±Connects to

0 0 0 Output 1 Tri-Stated Output 2 Tri-Stated Output 3 Tri-Stated Output 4 Tri-Stated

001IN1

±

IN1

±

IN1

±

IN1

±

010IN2

±

IN2

±

IN2

±

IN2

±

011IN3

±

IN3

±

IN3

±

IN3

±

100IN4

±

IN4

±

IN4

±

IN4

±

1 0 1 Invalid.

20028720

FIGURE 10. Configuration and Output Enable/Disable Timing

DS90CP04

www.national.com13

Page 14

Functional Descriptions (Continued)

TABLE 2. Switch Configuration Data (Continued)

MSB LSB OUT1±Connects to OUT2±Connects to OUT3±Connects to OUT4±Connects to

1 1 0 Use of these invalid combinations may cause loss of synchronization.

111

ROW AND COLUMN ADDRESSING

The upper left device in an array of NxN devices is assigned

row address 0, and column address 0. The devices to its

right have column addresses of 1 to N, whereas devices

below it have row addresses of 1 to N. The Serial Control

Interface (SCLK and SI) is connected to the first device with

the row and column addresses of 0. The Serial Control

Interface shifts in a control word containing the row and

column address of the device it wants to access. When the

control data propagates through each device, the control

word’s address is internally decremented by one before it is

sent to the next row or column device. When the control data

is sent out the column interface (CSO and CSCLK) the row

address is decremented by one. Similarly, when the column

address data is shifted out the row interface (RSO and

RSCLK) the column address is decremented by one. By the

time the control word reaches the device it has been intended to program, both the row and column addresses

have been decremented to 0.

Each device constantly checks for the receipt of a frame start

(D29-24=01 1111’b or 01 1110’b). When it detects the proper

start frame string, and the row and column addresses it

receives are both 0, the device responds by storing the

switch configuration data of the 30-bit control word into its

load register.

Each device in the array is sequentially programmed through

the serial interface. When programming is completed for the

entire array, LOAD is pulsed high and the load register’s

content is transferred to the configuration register of each

device. The LOAD pulse must wait until the final bit of the

control word has been placed into the "load" register. This

timing is guaranteed to take place two clock cycles after

programming has been completed.

Due to internal shift registers additional SCLK cycles will be

necessary to complete array programming. It takes 7 clock

(SCLK) positive edge transitions for the control data to appear at RSO and CSO for its near neighbor. Users must

provide the correct number of clock transitions for the control

data word to reach its destination in the array. Table 3 shows

an example of the control data words for a 4 device serial

chain with connections (OUT1=IN1, OUT2=IN2,

OUT16=IN16). To program the array, it requires four 30-bit

control words to ripple through the serial chain and reach

their destinations. In order to completely program the array

in the 120 clock cycles associated with the 30-bit control

words it is important to program the last device in the chain

first. The following programming data pushes the initial data

through the chain into the correct devices.

READ-BACK SWITCH CONFIGURATION

The DS90CP04 is put into read-back mode by sending a

special “Read” start frame (01 1110’b). Upon receipt of the

special read start frame the configuration register information is transferred into the shift register and output at both

RSO and CSO in the OUT1 to OUT4 bit segments of the

read control word. Each time the read-back data from a

device passes through its downstream device, its default

address (11 1111’b) is internally decremented by one. The

“relative” column address emerges at RSO of the last device

in the row and is used to determine (11 1111’b - N) the

column of the sending device. Similarly, the row address

emerges at CSO of the sending device. After inserting the

channel configuration information in the “read” control word,

the device will automatically revert to write mode, ready to

accept a new control word at SI.

Table 4 shows an example of reading back the configuration

registers of 4 devices in the first row of a 4x4 device array.

Again, due to internal shift registers additional SCLK cycles

will be necessary to complete the array read. It takes 4x30

SCLK clock cycles to shift out 4 30-bit configuration registers

plus 7 SCLK cycles per device to account for device latency

making for a total SCLK count of 148. The serialized read

data is sampled at RSO and synchronized with RSCLK of

the last device in the row. The user is recommended to

backfill with all 0’s at SI after the four reads have been

shifted in.

TABLE 3. Example to Program a 4 Device Array

Frame

D29:D24

Row

Address

D23:D18

Column

Address

D17:D12

OUT1

D11:D9

OUT2

D8:D6

OUT3

D5:D3

OUT4

D2:D0

Number of

SCLK

Cycles

Control Word

Destination

Device in

Array

Row, Column

01 1111 00 0000 00 0011 001 010 011 100 30 0, 3

01 1111 00 0000 00 0010 001 010 011 100 30 0, 2

01 1111 00 0000 00 0001 001 010 011 100 30 0, 1

01 1111 00 0000 00 0000 001 010 011 100 30 0, 0

Shift in configuration information from device furthest from system SI input first to minimize array

latency during the programming process.

The 2 clock cycle delay ensures all channel information has reached the “load” register and all

switches are ready to be configured.

2

DS90CP04

www.national.com 14

Page 15

Functional Descriptions (Continued)

TABLE 4. A Read-Back Example from a 4 Device Array

Frame

D29:D24

Row

Address

D23:D18

Column

Address

D17:D12

OUT1

D11:D9

OUT2

D8:D6

OUT3

D5:D3

OUT4

D2:D0

Number of

SCLK

Cycles

Descriptions

01 1110 00 0000 11 1111 0 00 00 0 000 00 0 30

Read-Back

(R,C)=0, 3

01 1110 00 0000 11 1110 000 000 000 000 30

Read-Back

(R,C)=0, 2

01 1110 00 0000 11 1101 000 000 000 000 30

Read-Back

(R,C)=0, 1

01 1110 00 0000 11 1100 001 010 011 100 30

Read-Back

(R,C)=0, 0

Note 7: LOAD and READ programming example is based on the 16x16 array configuration shown in Figure 11. Alternative expansion array configurations will

require a slightly different programming sequence.

SWITCH EXPANSION FOR MINIMUM PROGRAMMING

LATENCY

Programming data ripples through the array through RSO

and RSCLK in the row and CSO and CSCLK in the first

column. LOAD pins of all devices are electrically tied to-

gether and driven by the same “load” signal. To prevent

excessive stub length in the array from affecting the signal

quality of LOAD, it is recommended that the load signal is

distributed to each row or column in large crosspoint array

applications.

20028707

FIGURE 11.

DS90CP04

www.national.com15

Page 16

Programming Example

CONFIGURATION WRITE

30 Bit Control Word: [WRITE FRAME] [ROW ADDRESS][COLUMN ADDRESS] [OUT1][OUT2][OUT3][OUT4]

ARRAY WRITE:

[0 1 1111 ] [0][1] [1][1][1][1] //

*

Array position 1, Broadcast IN1*//

[0 1 1111 ] [0][0] [2][2][4][4] //

*

Array position 0, Connect IN2 to OUT1 and 2, IN4 to OUT3 and OUT4*//

LOAD = H and SCLK = LH

20028710

DEVICE 0 WRITE PROGRAMMING SEQUENCE

SCLK

Number

Event Description

6 Device 0 (R=0, C=0) detects “WRITE” frame of first Control Word.

18 Device 0 (R=0, C=0) sees Row = 1, Column = 0 of first Control Word. The Row address of the first Control

Word is decremented by 1 (Row Address = 0) and sent out RSO.

36 Device 0 (R=0, C=0) detects “WRITE” frame of second Control Word.

48 Device 0 (R=0, C=0) sees Row = 0, Column = 0 of second Control Word. This is a valid configuration write

address, Device 1 prepares to receive configuration information.

60 Device 0 (R=0, C=0) has received configuration information and is waiting for a LOAD.

DEVICE 1 WRITE PROGRAMMING SEQUENCE

SCLK

Number

Event Description

13 Device 1 (R=1, C=0) detects “WRITE” frame of first Control Word.

25 Device 1 (R=1,C=0) sees Row = 0, Column=0offirst Control Word. This is a valid configuration write

address, Device 1 prepares to receive configuration information.

37 Device 1 (R=1,C=0) has received configuration information and is waiting for a LOAD.

43 Device 1 (R=1, C=0) detects “WRITE” frame of second Control Word.

55 Device 1 (R=1,C=0) sees Row = 3F, Column=0ofsecond Control Word. The Row address of the second

Control Word is decremented by 1 (Row Address = 3E) and sent out RSO.

CONFIGURATION READ

30 Bit Control Word: [READ FRAME] [ROW ADDRESS][COLUMN ADDRESS] [OUT1][OUT2][OUT3][OUT4]

ARRAY WRITE:

[01 1110] [1][0] [0][0][0][0] //

*

Array position 1, Return Configuration Information*//

[01 1110] [0][0] [0][0][0][0] //

*

Array position 0, Return Configuration Information*//

DS90CP04

www.national.com 16

Page 17

Programming Example (Continued)

20028711

DEVICE 0 READ PROGRAMMING SEQUENCE

SCLK

Number

Event Description

6 Device 0 (R=0, C=0) detects “READ” frame of first Control Word.

18 Device 0 (R=0,C=0) sees Row = 1, Column=0offirst Control Word. The Row address of the first Control

Word is decremented by 1 (Row Address = 0) and sent out RSO.

36 Device 0 (R=0,C=0) detects "READ" frame of second Control Word.

48 Device 0 (R=0,C=0) sees Row = 0, Column=0ofsecond Control Word. This is a valid configuration read

address, Device 0 prepares to transmit configuration information. The Row address of the last Control Word is

decremented by 1 (Row Address = 3F) and sent out RSO.

60 Device 0 (R=0,C=0) has transmitted configuration information.

74 Finished transmitting configuration information at Array Output (RSO of Device 1).

DEVICE 1 READ PROGRAMMING SEQUENCE

SCLK

Number

Event Description

13 Device 1 (R=1, C=0) detects “READ” frame of first Control Word.

25 Device 1 (R=1,C=0) sees Row = 0, Column=0offirst Control Word. This is a valid configuration read

address, Device 1 prepares to transmit configuration information. The Row address of the last Control Word is

decremented by 1 (Row Address = 3F) and sent out RSO.

37 Device 1 (R=1,C=0) has transmitted configuration information at Array Output (RSO of Device 1).

DS90CP04

www.national.com17

Page 18

Physical Dimensions inches (millimeters) unless otherwise noted

LLP, Plastic, QUAD,

Order Number DS90CP04TLQ, DS90CP04TLQX (Tape and Reel)

NS Package Number LQA032A

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

labeling, can be reasonably expected to result in a

significant injury to the user.

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

National Semiconductor

Americas Customer

Support Center

Email: new.feedback@nsc.com

Tel: 1-800-272-9959

National Semiconductor

Europe Customer Support Center

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Support Center

Email: ap.support@nsc.com

National Semiconductor

Japan Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

www.national.com

DS90CP04 4x4 Low Power 2.5 Gb/s LVDS Digital Cross-Point Switch

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

Loading...

Loading...