Page 1

General Description

The DS4026 is a temperature-compensated crystal

oscillator (TCXO) that provides ±1ppm frequency stability over the -40°C to +85°C industrial temperature

range. Each device is factory calibrated over temperature to achieve the ±1ppm frequency stability. Standard

frequencies for the device include 12.8, 19.44, 20.0,

38.88, 40.0, and 51.84MHz. Contact the factory for custom frequencies.

The DS4026 provides excellent phase-noise characteristics. The output is a push-pull CMOS square wave with

symmetrical rise and fall times. In addition, the DS4026 is

designed to provide a maximum frequency deviation of

less than ±4.6ppm over 10 years. The device also provides an I2C interface to allow pushing and pulling of the

output frequency by a minimum of ±8ppm (±5ppm for

10MHz) with typical 1ppb resolution.

The DS4026 implements a temperature-to-voltage conversion with a nonlinear relationship. The output from the

temperature-to-voltage converter is used to drive the voltage-controlled crystal oscillator to compensate for frequency change.

The device implements an on-chip temperature sensor

lookup table, and a digital-to-analog converter (DAC) to

adjust the frequency. An I2C interface used to communicate with the DS4026 performs temperature readings and

frequency push-pull.

Applications

Reference Clock Generation Wireless

Telecom/Datacom/SATCOM Test and Measurement

Features

o ±1ppm Frequency Accuracy Over -40°C to +85°C

o Standard Frequencies: 12.8, 19.44, 20.0, 38.88,

40.0, 51.84MHz

o Maximum ±4.6ppm Deviation Over 10 Years

o Minimum ±8ppm (±5ppm for 10MHz) Digital

Frequency Tuning Through I2C Interface

o Surface-Mount 16-Pin SO Package

o Pb Free/RoHS Compliant

DS4026

10MHz to 51.84MHz TCXO

______________________________________________

Maxim Integrated Products

1

Pin Configuration

Rev 1; 9/07

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

+

Denotes a lead-free package.

*

The top mark will include a “+” for a lead-free/RoHS-compliant device.

Ordering Information continued at end of data sheet.

Ordering Information

TOP VIEW

GNDA

V

REF

V

V

OSC

GNDOSC

N.C.

N.C.

N.C.

1

2

3

CC

4

DS4026

5

6

7

8

SO

16

V

CCD

15

FOUT

14

GNDD

13

SCL

12

SDA

GND

11

10

N.C.

9

N.C.

PART TEMP RANGE

DS4026S+BCC

DS4026S+BCN -40°C to +85°C 12.8 16 SO DS4026-BCN

DS4026S+HCC 0°C to +70°C 19.44 16 SO DS4026-HCC

DS4026S+HCN -40°C to +85°C 19.44 16 SO DS4026-HCN

DS4026S+JCC 0°C to +70°C 20.0 16 SO DS4026-JCC

DS4026S+JCN -40°C to +85°C 20.0 16 SO DS4026-JCN

0°C to +70°C 12.8 16 SO DS4026-BCC

OUTPUT (f

(MHz, CMOS)

NOM

)

PIN-PACKAGE TOP MARK*

Page 2

DS4026

10MHz to 51.84MHz TCXO

2 _____________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

RECOMMENDED DC OPERATING CONDITIONS

(TA= -40°C to +85°C, unless otherwise noted.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

Voltage Range on V

CC

,

V

CCD

, and V

OSC

Relative to Ground..............................................-0.3V to +3.8V

Voltage Range on SDA, SCL, and FOUT

Relative to Ground...................................-0.3V to (V

CC

+ 0.3V)

Operating Temperature Range (noncondensing)....-40°C to +85°C

Storage Temperature Range .............................-55°C to +125°C

Soldering Temperature………………………….See IPC/JEDEC

J-STD-020 Specification

DC ELECTRICAL CHARACTERISTICS (Note 1)

(VCC= 3.135V to 3.465V, TA= -40°C to +85°C, unless otherwise noted.) (Notes 2, 3)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Power-Supply Voltage V

Oscillator Power Supply V

Driver Power Supply V

CC

OSC

CCD

VCC Active-Supply Current I

V

OSC

Current

V

CCD

Current

SCL Input Leakage I

SDA Leakage I

SCL, SDA High Input Voltage V

SCL, SDA Low Input Voltage V

SDA Logic 0 Output I

FOUT High Output Voltage V

FOUT Low Output Voltage V

FOUT Rise/Fall Time tR/t

FOUT Duty Cycle t

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

CC

(Note 4) 1.5 2.5 mA

FOUT CMOS output on, CL = 10pF,

Oscillator Active-Supply

I

OSC

frequency < 25MHz

FOUT CMOS output on, CL = 10pF,

frequency ≥ 25MHz

FOUT CMOS output on, CL = 10pF,

Driver Active-Supply

I

CCD

frequency < 25MHz

FOUT CMOS output on, CL = 10pF,

frequency ≥ 25MHz

LI

LO

OL

OH

OL

Output off -1 +1 µA

IH

IL

VCC = 3.0V, VOL = 0.4V 3 mA

V

= 3V, IOH = -2mA 2.4 V

CCD

V

= 3V, IOL = 2.0mA 0.4 V

CCD

(0.1 x V

F

D

0.5 x V

CCD

CCD

3.135 3.3 3.465 V

3.135 3.3 3.465 V

3.135 3.3 3.465 V

34

59

23

35

-1 +1 µA

) - (0.9 x V

0.7 x

V

CC

-0.3

)2ns

CCD

V

CC

+ 0.3

+0.3 x

V

CC

(Note 5) 45 55 %

mA

mA

V

V

Page 3

DS4026

10MHz to 51.84MHz TCXO

_____________________________________________________________________ 3

AC ELECTRICAL CHARACTERISTICS (Note 1)

(VCC= 3.135V to 3.465V, TA= -40°C to +85°C, unless otherwise noted.)

PHASE NOISE

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Frequency Stability vs.

Temperature

Frequency Stability vs. Voltage Δf1/V CL = 10pF to ground, +25°C -2 +2 ppm/V

Aging, First Year Δf1/Yr (Note 5) -1 +1 ppm

Aging, Years 2–15 Δf1/Yr (Note 5) -2 +2 ppm

Frequency Pull

Range

Frequency Pull Resolution Δf

Except 10MHz ±8 ±15

10MHz

Δf

1/TA

Δf

RES

CL = 10pF to ground

FTU N E H = 3Fh and FTU N E L = FFh;

FTU N E H = 40h and FTU N E L = 00h at + 25° C

f

NOM

– 1ppm

±5 ±10

f

NOM

f

NOM

+ 1ppm

1 ppb

ppm

ppm

PHASE NOISE (dBc/Hz) (TYPICAL, +25°C, 3.3V)

OFFSET (MHz) 10Hz 100Hz 1kHz 10kHz 100kHz 1MHz

12.80 -88.41 -130.16 -147.84 -150.84 -151.71 -151.87

19.44 -82.63 -125.12 -145.03 -146.87 -151.69 -151.52

20.00 -83.71 -120.76 -145.44 -150.96 -151.18 -151.45

CARRIER

FREQUENCY

38.88 -79.01 -120.06 -141.75 -150.59 -152.50 -153.06

40.00 -80.80 -115.44 -141.17 -151.59 -152.37 -153.00

51.84 -74.09 -120.39 -142.33 -151.14 -153.21 -153.94

10.0 -92.52 -134.83 -147.22 -150.84 -151.25 -150.84

16.384 -87.44 -128.53 -147.67 -150.78 -152.72 -151.75

16.8 -89.6 -126.20 -146.88 -151.90 -152.28 -151.93

24.0 -83.98 -119.45 -143.08 -150.33 -150.34 -150.67

Page 4

DS4026

10MHz to 51.84MHz TCXO

4 _____________________________________________________________________

TEMPERATURE SENSOR ELECTRICAL CHARACTERISTICS (Note 1)

(VCC= 3.135V to 3.465V, TA= -40°C to +85°C, unless otherwise noted.)

AC ELECTRICAL CHARACTERISTICS

(VCC= 3.135V to 3.465V, TA= -40°C to +85°C, unless otherwise noted.) (Note 2)

PARAMETER S YMBOL CONDITIONS MIN TYP MAX UNITS

Temperature Sensor Accuracy T -3 +3 °C

Temperature Sensor Convers ion

Time

Temperature Sensor Resolution N2 12 Bits

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

SCL Clock Frequency f

Bus Free Time Between STOP

and START Conditions

Hold Time (Repeated) START

Condition (Note 6)

Low Period of SCL Clock t

High Period of SCL Clock t

Data Hold Time

(Notes 7, 8)

Data Setup Time (Note 9) t

Start Setup Time t

Rise Time of Both SDA and SCL

Signals (Note 10)

Fall Time of Both SDA and SCL

Signals (Note 10)

t

11 ms

CONVT

SCL

t

BUF

t

HD:STA

LOW

HIGH

t

HD:DAT

SU:DAT

SU:STA

t

t

Standard mode 0 100

Fast mode 100 400

Standard mode 4.7

Fast mode 1.3

Standard mode 4.0

Fast mode 0.6

Standard mode 4.7

Fast mode 1.3

Standard mode 4.0

Fast mode 0.6

Standard mode 0 0.9

Fast mode 0 0.9

Standard mode 250

Fast mode 100

Standard mode 4.7

Fast mode 0.6

Standard mode 20 + 0.1C

R

Fast mode 20 + 0.1C

Standard mode 20 + 0.1C

F

Fast mode 20 + 0.1C

B

B

B

B

1000

300

300

300

kHz

µs

µs

µs

µs

µs

ns

µs

ns

ns

Page 5

DS4026

10MHz to 51.84MHz TCXO

_____________________________________________________________________ 5

Note 1: Typical values are at +25°C, nominal supply voltages, unless otherwise indicated.

Note 2: Voltages referenced to ground.

Note 3: Limits at -40°C are guaranteed by design and not production tested.

Note 4: Specified with I

2

C bus inactive.

Note 5: Guaranteed by design and not production tested.

Note 6: After this period, the first clock pulse is generated.

Note 7: A device must internally provide a hold time of at least 300ns for the SDA signal (referred to the V

IH(MIN)

of the SCL signal)

to bridge the undefined region of the falling edge of SCL.

Note 8: The maximum tHD:DAT need only be met if the device does not stretch the low period (t

LOW

) of the SCL signal.

Note 9: A fast-mode device can be used in a standard-mode system, but the requirement that t

SU:DAT

≥ 250ns must then be met.

This is automatically the case if the device does not stretch the low period of the SCL signal. If such a device does not

stretch the low period of the SCL signal, it must output the next data bit to the SDA line t

R(MAX)

+ t

SU:DAT

= 1000 + 250 =

1250ns before the SCL line is released.

Note 10: C

B

—total capacitance of one bus line in pF.

AC ELECTRICAL CHARACTERISTICS (continued)

(VCC= 3.135V to 3.465V, TA= -40°C to +85°C, unless otherwise noted.) (Note 2)

Data Transfer on I

2

C Serial Bus

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Setup Time for STOP Condition t

Pin Capacitance SDA, SCL

(Note 5)

Capacitive Load for Each Bus

Line (Note 10)

Pulse Width of Spikes That Must

Be Suppressed by the Input Filter

SU:STO

C

I/O

C

t

SP

Standard mode 4.7

Fast mode 0.6

B

Fast mode 30 ns

µs

10 pF

400 pF

SDA

SCL

t

BUF

STOP START

t

LOW

t

HD:STA

t

SP

t

SU:STO

t

R

t

HD:DAT

t

HD:STA

t

F

t

t

HIGH

t

SU:DAT

REPEATED

START

SU:STA

Page 6

DS4026

10MHz to 51.84MHz TCXO

6 _____________________________________________________________________

Typical Operating Characteristics

(VCC= +3.3V, TA = +25°C, unless otherwise noted.)

ACTIVE-SUPPLY CURRENT

vs. POWER-SUPPLY CURRENT

DS4026 toc01

VCC (V)

CURRENT (mA)

3.53.43.33.23.1

0.3

0.2

0.1

0.6

0.5

0.4

0.8

0.7

0.9

1.1

1.0

1.4

1.3

1.2

1.6

1.5

0

3.0 3.6

12.8

51.84

ACTIVE-SUPPLY CURRENT

vs. OSCILLATOR POWER SUPPLY

DS4026 toc02

V

OSC

(V)

CURRENT (mA)

3.53.43.33.23.1

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

0

3.0 3.6

51.84

12.8

ACTIVE-SUPPLY CURRENT

vs. DRIVER POWER SUPPLY

DS4026 toc03

V

CCD

(V)

CURRENT (mA)

3.53.43.33.23.1

8.0

6.0

4.0

2.0

10.0

-0.1

3.0 3.6

51.84

12.8

FREQUENCY vs. FTUNE

DS4026 toc04

VC (V)

OFFSET (ppm)

000h4000h

-25

-20

-15

-10

-5

0

5

10

15

20

-30

3FFFh

12.8

51.84

FREQUENCY vs. TEMPERATURE

DS4026 toc05

TEMPERATURE (°C)

DEVIATION (ppm)

6040

200

-20

-10

-13

-8

-3

-5

3

15

13

10

8

5

18

0

20

-15

-40

80

DCOMP = 1

DCOMP = 0

PHASE NOISE (TYP)

DS4026 toc06

OFFSET (Hz)

PHASE NOISE (dBc/Hz)

-5.0

-30.0

-55.0

-80.0

-105.0

-130.0

-155.0

-180.0

10 100 1000 10,000 100,000 1,000,000

51.84MHz

12.8MHz

19.44MHz

38.88MHz

Page 7

DS4026

10MHz to 51.84MHz TCXO

_____________________________________________________________________ 7

Pin Description

PIN NAME FUNCTION

1 GNDA Ground for DAC

2V

REF

Voltage Reference Output. This pin must be decoupled with a 100µF ceramic capacitor to ground.

3V

CC

Power Supply for Digital Control and Temperature Sensor. This pin must be decoupled with a 100nF

capacitor to ground.

4V

OSC

Power Supply for Oscillator Circuit. This pin must be decoupled with a 0.1µF capacitor to ground.

5 GNDOSC Ground for Oscillator Circuit

6–10 N.C. No Connection. Must be connected to ground.

11 GND Ground for Digital Control, Temperature Sensor, and Controller Substrate

12 SDA

Serial Data Input/Output. SDA is the data input/output for the I

2

C interface. This open-drain pin

requires an external pullup resistor.

13 SCL

Serial Clock Input. SCL is the clock input for the I

2

C Interface and is used to synchronize data

movement on the serial interface.

14 GNDD Ground for Oscillator Output Driver

15 FOUT Frequency Output, CMOS Push-Pull

16 V

CCD

Power Supply for Oscillator Output Driver. This pin must be decoupled with a 0.1µF capacitor to

ground. A 20Ω resistor must be placed in series between the power supply and V

CCD

.

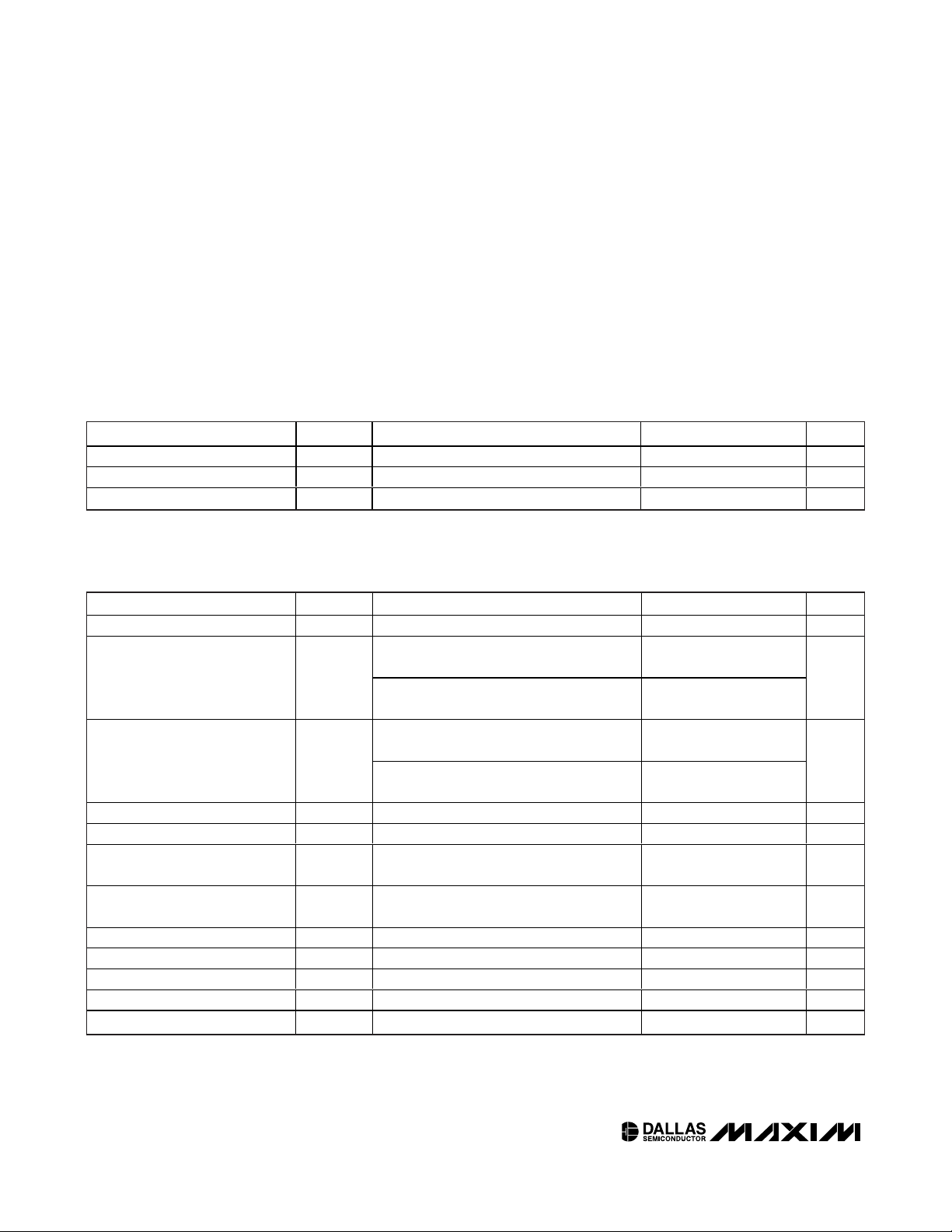

Figure 1. Typical Operating Circuit

GNDA

100μF ±5%

CERAMIC

V

REF

DS4026

V

CC

0.1μF

0.1μF

V

OSC

GNDOSC

N.C.

N.C.

N.C.

V

CCD

FOUT

GNDD

SCL

SDA

GND

N.C.

N.C.

0.1μF

20Ω

Page 8

DS4026

10MHz to 51.84MHz TCXO

8 _____________________________________________________________________

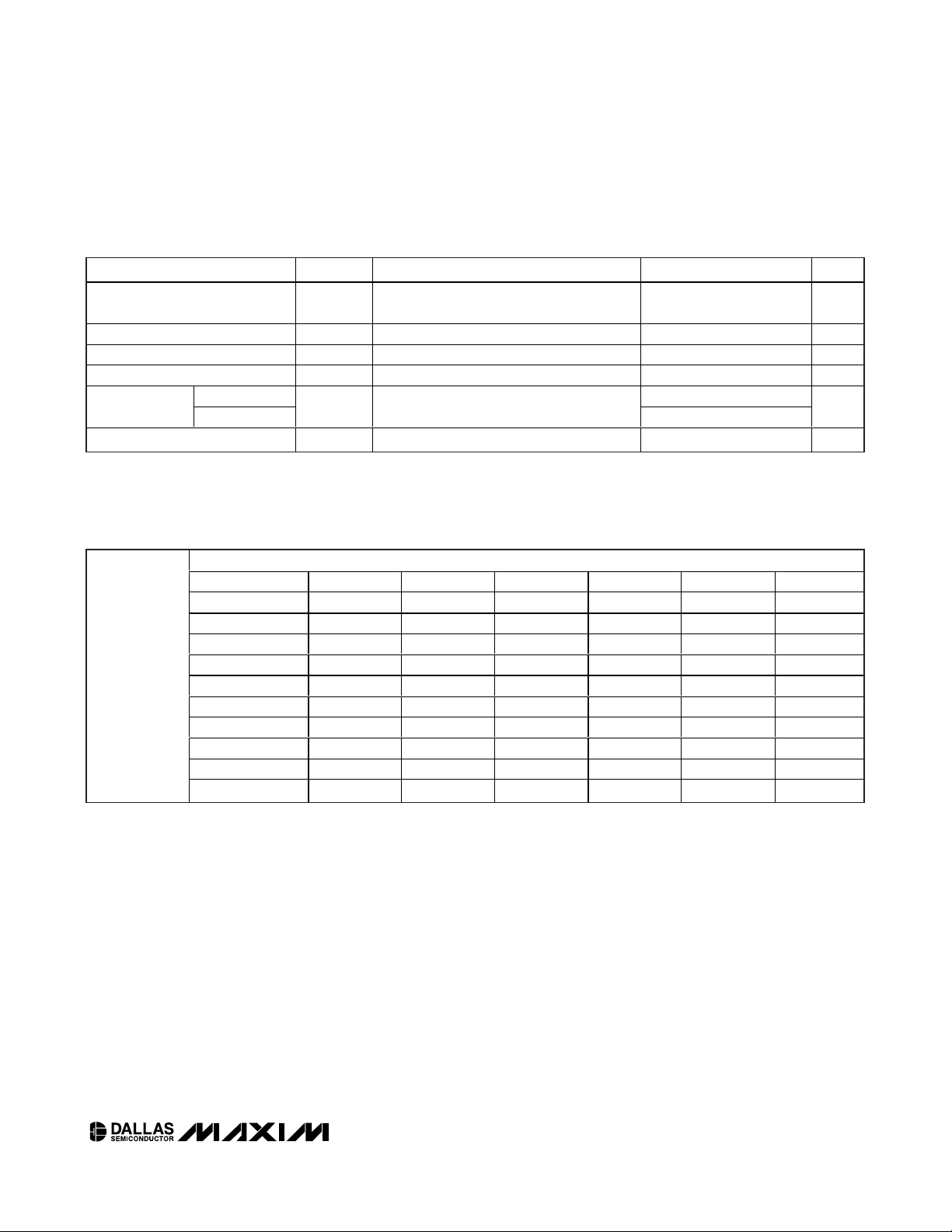

Figure 2. Functional Diagram

Detailed Description

The DS4026 is a TCXO capable of operating at 3.3V

±5%, and it allows digital tuning of the fundamental frequency. The device is calibrated in the factory to

achieve an accuracy of ±1ppm over the industrial temperature range, and its minimum pullability is ±8ppm

with a typical resolution of 1ppb (typ) per LSB.

The DS4026 contains the following blocks:

• Oscillator block with variable capacitor for compensation

• Output driver block

• Temperature sensor

• Controller to read the temperature, control lookup

table, and adjust the DAC input

• DAC output to adjust the capacitive load

•I

2

C interface to communicate with the chip

The oscillator block consists of an amplifier and variable

capacitor in a Pierce crystal oscillator with a crystal resonator of fundamental mode. The oscillator amplifier is a

single transistor amplifier and its transconductance is

temperature compensated. The variable capacitor is

adjusted by the DAC to provide temperature compensation. With the FTUNEH and FTUNEL registers, a minimum

pullability of ±8ppm (±5ppm for 10MHz) is achieved with

a typical resolution of 1ppb (typ) per LSB.

V

CC

V

CC

GND

SCL

SDA

V

OSC

V

CC

2

C

I

INTERFACE

GND

TEMP

SENSOR

V

CC

CONTROLLER

GND

A/D

GND

DAC

EEPROM

ARRAY

DS4026

CMOS

BUFFER

V

REF

GNDA

V

CCD

FOUT

GNDOSC GNDD

Page 9

DS4026

The output driver is a CMOS square-wave output with

symmetrical rise and fall time.

The temperature sensor provides a 12-bit temperature

reading with a resolution of 0.0625°C. The sensor is in

continuous conversion mode. If DCOMP is set, conversions continue but temperature updates are inhibited.

The controller coordinates the conversion of temperature into digital codes. When the temperature reading is

different from the previous one or the frequency tuning

register is changed, the controller looks up the two corresponding capacitance trim codes from the lookup

table at a 0.5°C increment. The trim codes are interpolated to 0.0625°C resolution.

The result is added with the tuning value from the frequency tuning register and loaded into the DAC registers to adjust voltage output. The monotonic DAC

provides an analog voltage based on temperature

compensation to drive the variable capacitor.

The DS4026 operates as a slave device on the serial

bus. Access is obtained by implementing a START

condition and providing a device identification code followed by data. Subsequent registers can be accessed

sequentially until a STOP condition is executed.

Address Map

Disable Compensation Update (DCOMP)

DCOMP is bit 7 of the frequency tuning register (see

the

Frequency Tuning Register (00h–01h), POR = 00h

table). When set to logic 1, this bit’s temperature-compensation function is disabled. This disabling prevents

the variable capacitor in the oscillator block from

changing. However, the temperature register still performs temperature conversions. The temperature trim

code from the last temperature conversion before

DCOMP is enabled is used for temperature compensation. The FTUNE registers are still functional when

DCOMP is disabled.

The frequency tuning registers adjust the base frequency. The frequency tuning value is represented in two’s

complement data. Bit 6 of FTUNEH is the sign, bit 5 is

the MSB, and bit 0 of FTUNEL is the LSB (see Table 1).

When the tuning register low (01h) is programmed with

a value, the next temperature update cycle sums the

programmed value with the factory compensated

value. This allows the user to digitally control the base

frequency using the I

2

C protocol.

These frequency tuning register bits allow the tuning of

the base frequency. Each bit typically represents

about 1ppb (typ). For FTUNEH = 3Fh and FTUNEL =

FFh, the device pushes the base frequency by approximately +15ppm.

10MHz to 51.84MHz TCXO

_____________________________________________________________________ 9

Frequency Tuning Register (00h–01h), POR = 00h

Temperature Register (02h–03h)

ADDRESS BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

00h DCOMP Sign Data Data Data Data Data Data

POR00000000

01h Data Data Data Data Data Data Data Data

POR00000000

ADDRESS BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

02h Sign Data Data Data Data Data Data Data

POR00000000

03h Data Data Data Data 0 0 0 0

POR00000000

Page 10

DS4026

Read Mode

In the temperature register (see the

Temperature

Register (02h–03h)

table), temperature is represented

as a 12-bit code and is accessible at location 02h and

03h. The upper 8 bits are at location 02h and the lower

4 bits are in the upper nibble of the byte at location

03h. Upon power reset, the registers are set to a +25°C

default temperature and the controller starts a temperature conversion. The temperature register stores new

temperature readings.

The current temperature is loaded into the (user) temperature registers when a valid I2C slave address and

write is received and when a word address is received.

Consequently, if the two temperature registers are read

in individual I2C transactions, it is possible for a temperature conversion to occur between reads, and the

results can be inaccurate. To prevent this from occurring, the registers should be read using a single, multibyte read operation (Figure 5). I2C reads do not affect

the internal temperature registers.

I2C Serial Data Bus

The DS4026 supports a bidirectional I2C bus and data

transmission protocol. A device that sends data onto

the bus is defined as a transmitter and a device receiving data is defined as a receiver. The device that controls the message is called a master. The devices that

are controlled by the master are slaves. The bus must

be controlled by a master device that generates the

serial clock (SCL), controls the bus access, and generates the START and STOP conditions. The DS4026

operates as a slave on the I2C bus. Connections to the

bus are made through the open-drain I/O lines SDA

and SCL. Within the bus specifications, a standard

mode (100kHz maximum clock rate) and a fast mode

(400kHz maximum clock rate) are defined. The DS4026

works in both modes.

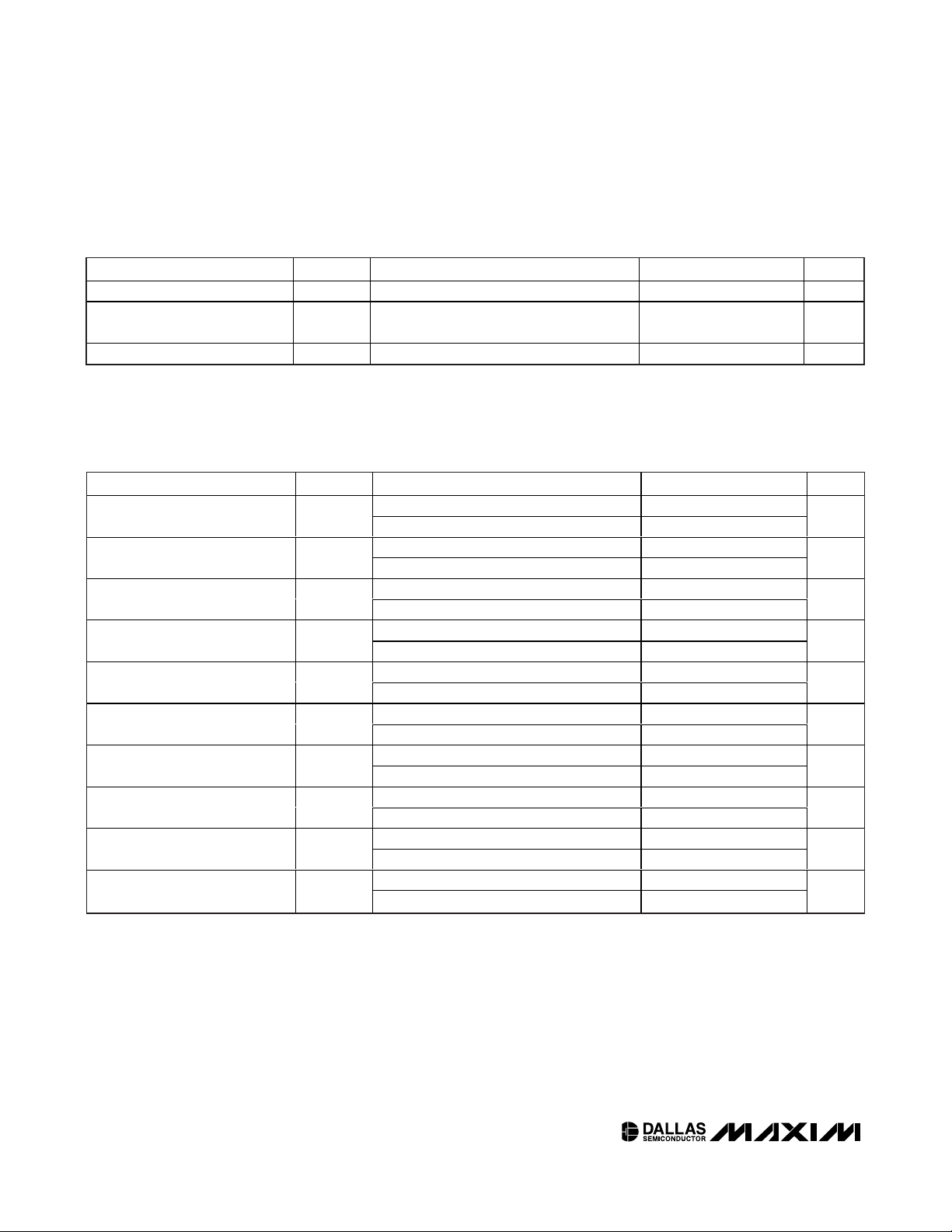

The following bus protocol has been defined (Figure 3):

• Data transfer can be initiated only when the bus is

not busy.

10MHz to 51.84MHz TCXO

10 ____________________________________________________________________

Table 1. Register Map

Figure 3. I2C Data Transfer Overview

ADDRESS BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0 FUNCTION

00 DCOMP SIGN FTUNEH Frequency Tuning High

01 FTUNEL Frequency Tuning Low

02 SIGN TREGH Temperature MSB

03 TREGL Temperature LSB

SDA

MSB

SLAVE ADDRESS

SCL

12 678 9 12 893–7

START

CONDITION

R/W

DIRECTION

BIT

ACKNOWLEDGEMENT

SIGNAL FROM RECEIVER

ACK

REPEATED IF MORE BYTES

ACKNOWLEDGEMENT

SIGNAL FROM RECEIVER

ARE TRANSFERED

ACK

STOP

CONDITION

OR REPEATED

START

CONDITION

Page 11

• During data transfer, the data line must remain stable

whenever the clock line is high. Changes in the data

line while the clock line is high are interpreted as

control signals.

Accordingly, the following bus conditions have been

defined:

Bus not busy: Both data and clock lines remain

high.

Start data transfer: A change in the state of the data

line from high to low, while the clock line is high,

defines a START condition.

Stop data transfer: A change in the state of the data

line from low to high, while the clock line is high,

defines a STOP condition.

Data valid: The state of the data line represents valid

data when, after a START condition, the data line is

stable for the duration of the high period of the clock

signal. The data on the line must be changed during

the low period of the clock signal. There is one clock

pulse per bit of data.

Each data transfer is initiated with a START condition

and terminated with a STOP condition. The number

of data bytes transferred between the START and the

STOP conditions is not limited, and is determined by

the master device. The information is transferred

byte-wise and each receiver acknowledges with a

ninth bit.

Acknowledge: Each receiving device, when

addressed, is obliged to generate an acknowledge

(ACK) after the reception of each byte. The master

device must generate an extra clock pulse that is

associated with this acknowledge bit.

A device that acknowledges must pull down the SDA

line during the acknowledge clock pulse in such a

way that the SDA line is stable low during the high

period of the acknowledge-related clock pulse. Of

course, setup and hold times must be taken into

account. A master must signal an end of data to the

slave by not generating an acknowledge bit on the

last byte that has been clocked out of the slave. In

this case, the slave must leave the data line high to

enable the master to generate the STOP condition.

Figures 4 and 5 detail how data transfer is accomplished on the I2C bus. Depending upon the state of

the R/W bit, two types of data transfer are possible:

Data transfer from a master transmitter to a slave

receiver. The first byte transmitted by the master is

the slave address. Next follows a number of data

bytes. The slave returns an acknowledge (ACK) bit

after each received byte.

Data transfer from a slave transmitter to a master

receiver. The first byte (the slave address) is trans-

mitted by the master. The slave then returns an

acknowledge bit. Next follows a number of data

bytes transmitted by the slave to the master. The

master returns an acknowledge bit after all received

bytes other than the last byte. At the end of the last

received byte, a not acknowledge (NACK) is

returned.

The master device generates all the serial clock

pulses and the START and STOP conditions. A transfer is ended with a STOP condition or with a repeated START condition. Because a repeated START

condition is also the beginning of the next serial

transfer, the bus is not released.

DS4026

10MHz to 51.84MHz TCXO

____________________________________________________________________ 11

Figure 4. Slave Receiver Mode (Write Mode)

Figure 5. Slave Transmitter Mode (Read Mode)

<SLAVE

ADDRESS>

S = START

A = ACKNOWLEDGE

P = STOP

R/W = READ/WRITE OR DIRECTION BIT ADDRESS = 82h

<WORD

ADDRESS (n)>

<RW>

AXXXXXXXXA1000001S 0 XXXXXXXX A XXXXXXXX A XXXXXXXX A P

DATA TRANSFERRED

(X + 1 BYTES + ACKNOWLEDGE)

<SLAVE

<DATA (n + X)><DATA (n + 1)><DATA (n)>

ADDRESS>

S = START

A = ACKNOWLEDGE

P = STOP

A = NOT ACKNOWLEDGE

R/W = READ/WRITE OR DIRECTION BIT ADDRESS = 83h

<RW>

<DATA (n)>

<DATA (n + X)><DATA (n + 2)><DATA (n + 1)>

AXXXXXXXXA1000001S 1 XXXXXXXX A XXXXXXXX A XXXXXXXX A P

DATA TRANSFERRED

(X + 1 BYTES + ACKNOWLEDGE)

NOTE: LAST DATA BYTE IS FOLLOWED BY

A NOT ACKNOWLEDGE (A) SIGNAL

Page 12

The DS4026 can operate in the following two modes:

Slave receiver mode (write mode): Serial data and

clock are received through SDA and SCL. After each

byte is received, an acknowledge bit is transmitted.

START and STOP conditions are recognized as the

beginning and end of a serial transfer. Address

recognition is performed by hardware after reception

of the slave address and direction bit. The slave

address byte is the first byte received after the master generates a START condition. The slave address

byte contains the 7-bit DS4026 address, which is

1000001, followed by the direction bit (R/W), which is

0 for a write. After receiving and decoding the slave

address byte, the DS4026 outputs an acknowledge

on SDA. After the DS4026 acknowledges the slave

address and write bit, the master transmits a word

address to the DS4026. This sets the register pointer

on the DS4026, with the DS4026 acknowledging the

transfer. The master can then transmit zero or more

bytes of data, with the DS4026 acknowledging each

byte received. The register pointer increments after

each data byte is transferred. The master generates

a STOP condition to terminate the data write.

Slave transmitter mode (read mode): The first byte

is received and handled as in the slave receiver

mode. However, in this mode, the direction bit indicates that the transfer direction is reversed. Serial

data is transmitted on SDA by the DS4026 while the

serial clock is input on SCL. START and STOP conditions are recognized as the beginning and end of a

serial transfer. Address recognition is performed by

hardware after reception of the slave address and

direction bit. The slave address byte is the first byte

received after the master generates a START condition. The slave address byte contains the 7-bit

DS4026 address, which is 1000001, followed by the

direction bit (R/W), which is 1 for a read. After receiving and decoding the slave address byte, the

DS4026 outputs an acknowledge on SDA. The

DS4026 then begins to transmit data starting with the

register address pointed to by the register pointer. If

the register pointer is not written to before the initiation of a read mode, the first address that is read is

the last one stored in the register pointer. The

DS4026 must receive a not acknowledge to end a

read.

Ordering Information (continued)

+

Denotes a lead-free package.

*

The top mark will include a “+” for a lead-free/RoHS-compliant device.

DS4026

10MHz to 51.84MHz TCXO

12 ____________________________________________________________________

PART TEMP RANGE

DS4026S+MCC 0°C to +70°C 38.88 16 SO DS4026-MCC

DS4026S+MCN -40°C to +85°C 38.88 16 SO DS4026-MCN

DS4026S+PCC 0°C to +70°C

DS4026S+PCN -40°C to +85°C

DS4026S+QCC 0°C to +70°C 51.84 16 SO DS4026-QCC

DS4026S+QCN -40°C to +85°C 51.84 16 SO DS4026-QCN

DS4026S+ACC 0°C to +70°C 10.0 16 SO DS4026-ACC

DS4026S+ACN -40°C to +85°C 10.0 16 SO DS4026-ACN

DS4026S+FCC 0°C to +70°C 16.384 16 SO DS4026-FCC

DS4026S+FCN -40°C to +85°C 16.384 16 SO DS4026-FCN

DS4026S+ECC 0°C to +70°C 16.8 16 SO DS4026-ECC

DS4026S+ECN -40°C to +85°C 16.8 16 SO DS4026-ECN

DS4026S+RCC 0°C to +70°C 24.0 16 SO DS4026-RCC

DS4026S+RCN -40°C to +85°C 24.0 16 SO DS4026-RCN

OUTPUT (f

(MHz, CMOS)

40.0

40.0

NOM

)

PIN-PACKAGE TOP MARK*

16 SO DS4026-PCC

16 SO DS4026-PCN

Page 13

DS4026

10MHz to 51.84MHz TCXO

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600 ____________________

13

© 2007 Maxim Integrated Products is a registered trademark of Maxim Integrated Products, Inc.

is a registered trademark of Dallas Semiconductor Corporation.

Package Information

For the latest package outline information, go to

www.maxim-ic.com/packages

.

Chip Information

TRANSISTOR COUNT: 77, 712

SUBSTRATE CONNECTED TO GROUND

PROCESS: CMOS

Revision History

Pages changed at Rev 1: 1–12

PACKAGE TYPE DOCUMENT NO.

16-pin SO (300 mils) 56-G4009-001

Loading...

Loading...