Page 1

DS2223/DS2224

DS2223/DS2224

EconoRAM

FEATURES

• Low–cost, general–purpose, 256–bit memory

– DS2223 has 256–bit SRAM

– DS2224 has 32–bit ROM, 224–bit SRAM

• Reduces control, address and data interface to a

single pin

• Each DS2224 32–bit ROM is factory–lasered with a

unique serial number

• DS2224 portion of ROM with custom code and unique

serial number available

• Minimal operating power: 45 nanocoulombs per

transaction @1.5V typical

• Less than 15 nA standby current at 25°C

• Nonvolatile data retention easily achieved via low–

cost alkaline batteries or capacitors

• Directly connects to a port pin of popular microcontrol-

lers

• Operation from 1.2 to 5.5 volts

• Popular TO–92 or SOT–223 surface mount package

• Operates over industrial temperature range –40°C to

+85°C

PACKAGE OUTLINE

TO–92

123

123

See Mech. Drawings

Section

See Mech. Drawings

PIN CONNECTIONS

Pin 1 GND – Ground

Pin 2 DQ – Data In/Out

Pin 3 V

Pin 4 GND – Ground

CC

– Supply

SOT–223

1

234

TOP VIEWBOTTOM VIEW

Section

DESCRIPTION

The DS2223 and DS2224 EconoRAMs are fully static,

micro–powered, read/write memories in low–cost

TO–92 or SOT–223 packages. The DS2223 is organized as a serial 256 x 1 bit static read/write memory.

The DS2224’s first 32 bits are lasered with a unique ID

code at the time of manufacture; the remaining 224 bits

are static read/write memory. Signaling necessary for

reading or writing is reduced to just one interface lead.

Both the DS2223 and DS2224 are not recommended

for new designs. However, the parts will remain available until the year 2003, at least.

ORDERING INFORMATION

DS2223 256–bit SRAM – TO–92 Package

DS2223Z 256–bit SRAM – SOT–223 Package

DS2223T 1000 piece tape–and–reel of DS2223

DS2223Y 2500 piece tape–and–reel of DS2223Z

DS2224 32–bit serial number (ROM), 224–bit

SRAM – TO–92 Package

DS2224Z 32–bit serial number (ROM), 224–bit

SRAM – SOT–223 Package

DS2224T 1000 piece tape–and–reel of DS2224

DS2224Y 2500 piece tape–and–reel of DS2224Z

080598 1/10

Page 2

DS2223/DS2224

OPERATION

All communications to and from the EconoRAM are

accomplished via a single interface lead. EconoRAM

data is read and written through the use of time slots. All

data is preceded by a command byte to specify the type

of transaction. Once a specific transaction has been

initiated, either a read or a write, it must be completed for all memory locations before another

transaction can be started.

1–WIRE SIGNALLING

The EconoRAM requires strict protocols to insure data

integrity . The protocol consists of three types of signalling on one line: Write 0 time slot, Write 1 time slot and

Read Data time slot. All these signals are initiated by the

host.

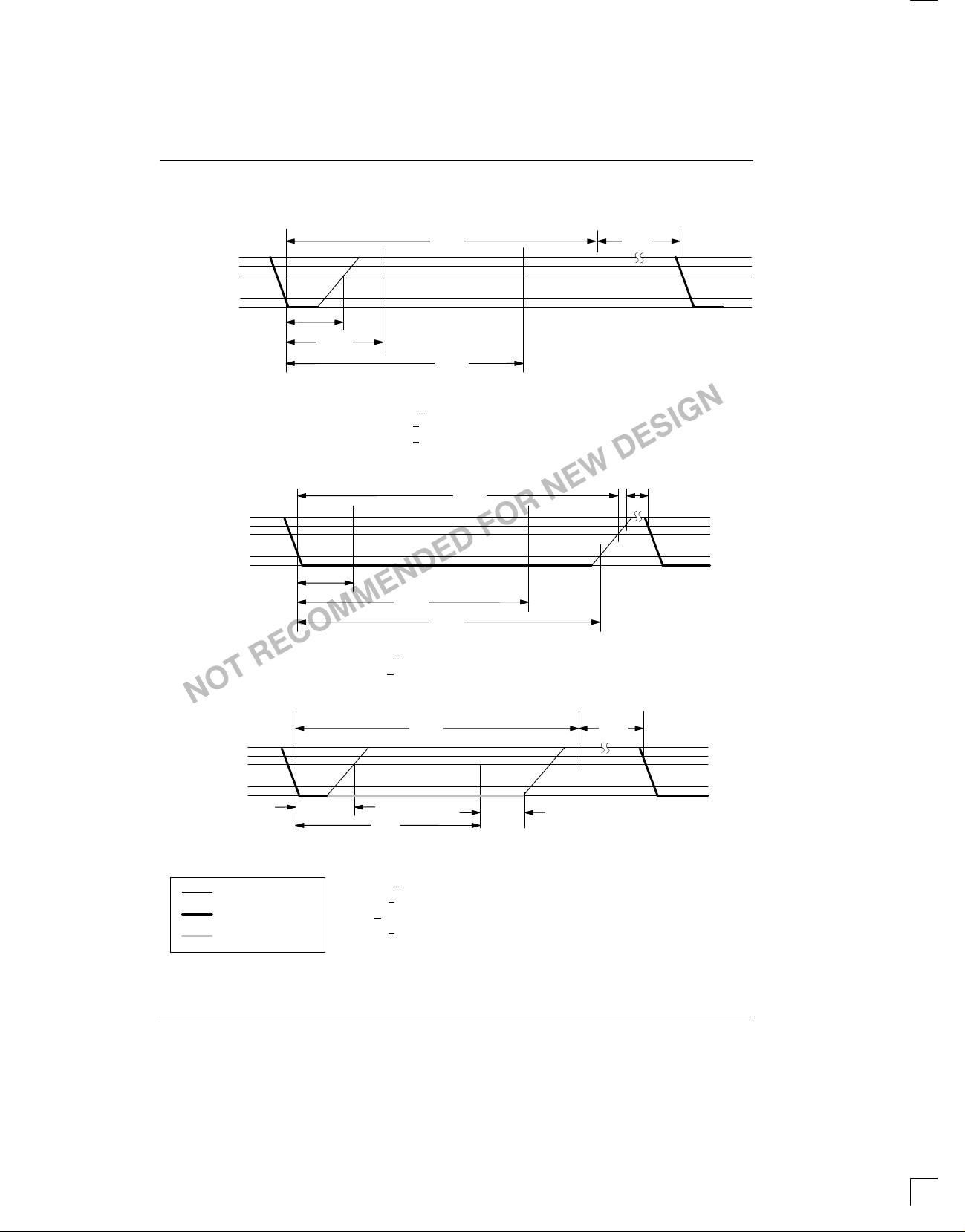

READ/WRITE TIME SLOTS

The definitions of write and read time slots are illustrated

in Figures 1 through 3. All time slots are initiated by the

host driving the data line low. The falling edge of the data

line synchronizes the EconoRAM to the host by triggering a delay circuit in the EconoRAM. During write time

slots, the delay circuit determines when the EconoRAM

will sample the data line. For a read data time slot, if a “0”

is to be transmitted, the delay circuit determines how

long the EconoRAM will hold the data line low overriding

the 1 generated by the host. If the data bit is a “1”, the

EconoRAM will leave the read data time slot

unchanged.

COMMAND BYTE

The command byte to specify the type of transaction is

transmitted LSB first from the host to the EconoRAM

using write time slots. The first bit of the command byte

(see Figure 4) is a logic 1. This indicates to the EconoRAM that a command byte is being written. The next two

bits are the select bits which denote the physical

address of the EconoRAM that is to be accessed (set to

00 currently). The remaining five bits determine whether

a read or a write operation is to follow. If a write operation

is to be performed, all five bits are set to a logic 1 level. If

a read operation is to be performed, any or all of these

bits are set to a logic 0 level. All eight bits of the command byte are transmitted to the EconoRAM with a separate time slot for each bit.

READ OR WRITE TRANSACTION

Read or write transactions are performed by initializing

the EconoRAM to a known state, issuing a command

byte, and then generating the time slots to either read

EconoRAM contents or write new data. Each transaction consists of 264 time slots. Eight time slots transmit

the command byte, the remaining 256 time slots transfer the data bits. (See Figure 5.) Once a transaction is

started, it must be completed before a new transaction

can begin.

To initially set the EconoRAM into a known state, 264

Write Zero time slots must be sent by the host. These

Write Zero time slots will not corrupt the data in the EconoRAM since a command byte has not been written.

This operation will increment the address pointer internal to the EconoRAM to its maximum count value. Upon

reaching this maximum value, the EconoRAM will

ignore all additional Write Zero time slots issued to it and

the internal address pointer will remain locked at the top

count value. This condition is removed by the reception

of a Write One time slot, typically the first bit of a command byte.

Once the EconoRAM has been set into a known state,

the command byte is transmitted to the EconoRAM with

eight write time slots. This resets the address pointer

internal to the EconoRAM and prepares it for the

appropriate operation, either a read or a write.

After the command byte has been received by the EconoRAM, the host controls the transfer of data. In the

case of a read transaction, the host issues 256 read time

slots. In the case of a write transaction, the host issues

256 write time slots according to the data to be written.

All data is read and written least significant bit first.

Although the DS2224 has the first 32 bits replaced by

lasered ROM rather than SRAM, it requires 256 write

time slots for a complete write transaction. The data

being sent during the first 32 write time slots has no

effect on the DS2224 other than advancing the internal

address pointer. As stated previously, it is not possible

to change from read to write or vice versa before a transaction is completed.

080598 2/10

Page 3

READ/WRITE TIMING DIAGRAM

Write–One Time Slot Figure 1

DS2223/DS2224

V

PULLUP

V

PULLUP MIN

V

IH MIN

V

IL MAX

0V

t

LOW1

15 µs

Write–Zero Time Slot Figure 2

V

PULLUP

V

PULLUP MIN

V

IH MIN

V

IL MAX

0V

15 µs

60 µs <

1 µs <

1 µs <

SAMPLING WINDOW

60 µs

60 µs < t

t

1 µs <

REC

t

SLOT

DS2223/DS2224

SAMPLING WINDOW

60 µs

t

<

SLOT

t

< 15 µs

LOW1

t

<

REC

t

SLOT

DS2223/DS2224

t

LOW0

< t

SLOT

<

LOW0

<

t

REC

t

REC

Read–Data Time Slot Figure 3

V

PULLUP

V

PULLUP MIN

V

IH MIN

V

IL MAX

0V

RESISTOR

MASTER

DS2223/DS2224

t

LOWR

HOST SAMPLING

WINDOW

t

RDV

60 µs < t

SLOT

1 µs <

t

LOWR

0 <

t

RELEASE

t

1 µs <

REC

t

= 15 µs

RDV

t

SLOT

< 15 µs

<

<

< 45 µs

t

RELEASE

t

REC

080598 3/10

Page 4

DS2223/DS2224

COMMAND WORD Figure 4

MSB LSB

W/R

W/R W/R W/R W/R 001

ALL 1s – WRITE

ANY 0 – READ

READ/WRITE TRANSACTION Figure 5

LSB

COMMAND WORD

DS2224

264–BIT

TRANSACTION

COMMAND WORD ROM 224–BIT SRAM

INCREMENT ADDRESS POINTER

256–BIT SRAMDS2223

READ/WRITE FLOW

RECEIVE COMMAND WORD

(RESET ADDRESS POINTER)

READ/WRITE DATA BIT AND

SELECT BITS

8 BITS

080598 4/10

IS ADDRESS

POINTER = 256?

Y

HOLD ADDRESS POINTER

VALUE, WAIT FOR NEW

COMMAND WORD TO RESET

ADDRESS COUNTER

N

Page 5

TYPICAL CURRENT CONSUMPTION VS. BIT RATE Figure 6

4V @ +25°C

10 µA

1 µA

100 nA

CURRENT CONSUMPTION

10 nA

5 nA

10 bps 100 bps 1 kbps 10 kbps 100 kbps

BIT RATE

TYPICAL LEAKAGE CURRENT VS. TEMPERATURE Figure 7

15.0

VCC = 4.0V

DS2223/DS2224

129 pC/BIT

12.0

9.0

NANOAMPS

LEAKAGE CURRENT

6.0

3.0

0.0

–10 0 +10 +20 +30 +40 +50 +60 +70

TEMPERATURE (DEG. C)

080598 5/10

Page 6

DS2223/DS2224

1–WIRE INTERFACE

The 1–Wire interface has only a single line by definition;

it is important that host and EconoRAM be able to drive it

at the appropriate time. The EconoRAM is an open drain

part with an internal circuit equivalent to that shown in

Figure 8. The host can be the same equivalent circuit. If

a bidirectional pin is not available, separate output and

input pins can be tied together.

The 1–Wire interface requires a pull–up resistor with a

value of approximately 5 kΩ to system V

on the data

CC

signal line. The EconoRAM has an internal open–drain

driver with a 500 kΩ pull–down resistor to ground. The

open–drain driver allows the EconoRAM to be powered

by a small standby energy source, such as a single 1.5

volt alkaline battery, and still have the ability to produce

CMOS/TTL output levels. The pull–down resistor holds

the DQ pin at ground when the EconoRAM is not connected to the host.

APPLICATION EXAMPLES

EconoRAMs are extremely conservative with power.

Data can be retained in these small memories for as

long as a month using the energy stored in a capacitor.

Data is retained as long as the voltage on the V

CC

pin of

HOST TO ECONORAM INTERFACE Figure 8

V

CC

the EconoRAM (V

) is at least 1.2 volts. A typical cir-

CAP

cuit is shown in Figure 9.

When V

EconoRAM receives power directly from V

is applied, capacitor C1 is charged and the

CC

CC

. After

power is removed, the diode CR1 prevents current from

leaking back into the system, keeping the capacitor

charged.

In the standby mode, the EconoRAM typically consumes only 12 nA at 25°C. However, the power–down

process of the system can cause a slightly higher current drain. This is due to the fact that as system power

ramps down, the signal attached to the DQ pin of the

EconoRAM transitions slowly through the linear region,

while the V

voltage remains at its initial value. While

CAP

in this region, the part draws more current as a function

of the DQ pin voltage (see Figure 10).

The data retention time can be estimated with the aid of

Figure 1 1. In this figure, the vertical axis represents the

value of the capacitor C1; the horizontal axis is the data

retention time in hours. The two curves represent initial

V

voltages of 3 and 5 volts. These curves are based

CAP

on the assumption that the time the DQ pin is in the linear region is less than 100 ms.

TX

RX

080598 6/10

OPEN

DRAIN

5 kΩ

HOST ECONORAM

500 kΩ

V

CC

100 OHM MOSFET

RX

TX

Page 7

SUGGESTED CIRCUIT Figure 9

DS2223/DS2224

V

V

CAP

CC

V

CC

DQ

GND

Econo

Memory

ICC VS. DQ VOLTAGE Figure 10

SUPPLY CURRENT

(µA)

400

200

0

0 12345

+

C1

DQ PIN VOLTAGE

CR1

VCC = +5V

Room Temperature

SUPPLY CURRENT

<2 nA

080598 7/10

Page 8

DS2223/DS2224

DATA RETENTION TIME VS. CAPACITANCE Figure 11

CAPACITANCE

(µF)

10K

1K

100

10

0

0.1 1 10 100 1K 10K

TIME (hours)

Using Battery Backup

14 mA–Hr => 144 million transactions

3

DATA

PIN

2

DS2223

DS2224

1

Initial VCC Voltage

VCC = 3.0

V

CC

+

1.5V

EVEREADY

NO. 321

= 5.0

080598 8/10

Page 9

DS2223/DS2224

ABSOLUTE MAXIMUM RATINGS*

Voltage on Any Pin Relative to Ground –0.5V to +6.5V

Operating Temperature –40°C to +85°C

Storage Temperature –55°C to +125°C

Soldering Temperature 260°C for 10 seconds

* This is a stress rating only and functional operation of the device at these or any other conditions above

those indicated in the operation sections of this specification is not implied. Exposure to absolute maximum rating conditions for extended periods of time may affect reliability.

RECOMMENDED DC OPERATING CONDITIONS (–40°C to +85°C)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Data Pin DQ –0.5 6.0 V 1

Supply Voltage V

CC

1.2 5.5 V 1

DC ELECTRICAL CHARACTERISTICS (–40°C to +85°C; VCC=2.0V to 5.5V)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Input Logic Low V

Input Logic High V

Sink Current I

Output Logic Low V

Output Logic High V

Input Resistance I

Operating Current I

Standby Current I

IL

IH

L

OL

OH

R

OP

STBY

–0.5 0.4 0.8 V 1

VCC–0.5 6.0 V 1

1 2 mA 4

0.4 V 1

V

PUP

5.5 V 1, 2

500 kΩ 3

36 nC 5

2 25 nA 6

DC ELECTRICAL CHARACTERISTICS (–40°C to +85°C; VCC=1.4V ± 10%)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Input Logic Low V

Input Logic High V

Sink Current I

Output Logic Low V

Output Logic High V

Input Resistance I

Operating Current I

Standby Current I

IL

IH

L

OL

OH

R

OP

STBY

–0.5 0.2 V 1

1.0 6.0 V 1

1 2 mA 7

0.4 V 4

V

PUP

5.5 V 1, 2

500 kΩ 3

36 nC 5

2 15 nA 6

080598 9/10

Page 10

DS2223/DS2224

AC ELECTRICAL CHARACTERISTICS (–40°C to +85°C; VCC=1.4V ± 10%)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Time Slot t

Read Data Valid t

Release Time t

RELEASE

Write 1 Low Time t

Write 0 Low Time t

Data Setup Time t

Recovery Time t

SLOT

RDV

LOW1

LOW0

SU

REC

70 µs

exactly 15 µs

0 15 45 µs

1 15 µs

60 µs

1 µs 8

1 µs

AC ELECTRICAL CHARACTERISTICS (–40°C to +85°C; VCC=2.0V to 5.5V)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Time Slot t

Read Data Valid t

Release Time t

RELEASE

Write 1 Low Time t

Write 0 Low Time t

Data Setup Time t

Recovery Time t

SLOT

RDV

LOW1

LOW0

SU

REC

60 µs

exactly 15 µs

0 15 45 µs

1 15 µs

60 µs

1 µs 8

1 µs

NOTES:

1. All voltages are referenced to ground.

2. V

3. Input pull–down resistance to ground.

4. @ V

5. 36 nanocoulombs per 264 time slots @ 1.5V (see Figure 6).

6. See Figure 7 for typical values over temperature.

7. @ V

8. Read data setup time refers to the time the host must pull the 1–Wire line low to read a bit. Data is guaran-

= external pull–up voltage to system sypply.

PUP

=0.4V

OL

=0.2V

OL

teed to be valid within 1 µs of this falling edge and will remain valid for 14 µs minimum (15 µs total from falling

edge on the 1–Wire line).

080598 10/10

Loading...

Loading...