Page 1

查询DS1207供应商

DS1207

DS1207

TimeKey

FEATURES

• Cannot be deciphered by reverse engineering

• Time allotment from one day to 512 days for trial

periods, rentals, and leasing

• Partitioned memory thwarts pirating

• User-insertable packaging allows personal

possession

• Exclusive blank keys on request

• Appropriate identification can be made with a 64-bit

reprogrammable memory

• Unreadable 64-bit match code virtually prevents

discovery by exhaustive search with over 10

possibilities

• Random data generation on incorrect match codes

obscures real accesses

• 384 bits of secure read/write memory create

additional barriers by permitting data changes as

often as needed

• Rapid erasure of identification, security match code

and secure read/write memory can occur if tampering

is detected

• Durable and rugged

• Applications include software authorization, gray

market software protection, proprietary data, financial

transactions, secure personnel areas, and system

access control

PIN ASSIGNMENT

DALLAS

DS1207

TimeKey

SIDE

19

15

BOTTOM: PIN VIEW

See Mech. Drawings Section

PIN DESCRIPTION

Pin 1 NC No connection

Pin 2 RST Reset

Pin 3 DQ Data input/output

Pin 4 CLK Clock

Pin 5 GND Ground

1.0 IN

DESCRIPTION

The DS1207 TimeKey is a miniature security system

that stores 64 bits of user-definable identification code

and a 64-bit security match code that protects 384 bits of

read/write nonvolatile memory . The 64-bit identification

code and the security match code are programmed into

the TimeKey via a special program mode operation. After programming, the TimeKey follows a procedure with

a serial format to retrieve or update data. The TimeKey

is set to expire from one day to 512 days or infinity, as

specified by the customer. The T imeKey starts its countdown from the first access by the end user.

Interface cost to a microprocessor is minimized by

on-chip circuitry that permits data transfer with only

three signals: Clock (CLK), Reset

Output (DQ). Low pin count and a guided entry for a

mating receptacle overcome mechanical problems normally encountered with conventional integrated circuit

packaging, making the device transportable and

user-insertable.

(RST) and Data Input/

021798 1/17

Page 2

DS1207

OPERATION – NORMAL MODE

The TimeKey has two modes of operation: normal and

program. The normal mode of operation provides the

functions of reading and writing the 384-bit secure

memory. The block diagram (Figure 1) illustrates the

main elements of the TimeKey when used in the normal

mode. T o initiate data transfer with the T imeKey , RST

taken high and 24 bits are loaded into the command register on each low-to-high transition of the CLK input. The

command register must match the exact bit pattern

which defines normal operations with a function code of

read or write. If one of these patterns is not matched,

communications are ignored. If the command register is

loaded properly , communications are allowed to continue. Data is clocked out of the TimeKey on the

high-to-low transition of the clock. If the pattern matched

in the command register calls for a normal read or write,

the next 64 cycles following the command word are read

and data is clocked out of the identification memory. The

next 64 write cycles are written to the compare register

(Figure 2). These 64 bits must match the exact pattern

stored in the security match memory. If a match is not

found, access to additional information is denied. Instead, if a normal read mode is selected, random

garbled data is output for the next 384 cycles. If a normal

write cycle is selected and a match is not achieved, the

TimeKey will ignore any additional information. However, when a security match is achieved, access is permitted to write the 384-bit secure memory .

OPERATION - PROGRAM MODE

The program mode of operation provides the functions

of programming the identification and security match

memory, and setting and reading the amount of time the

TimeKey can be used. The block diagram in Figure 3 illustrates the main elements of the TimeKey when used

in the program mode. T o initiate the program mode, RST

is driven high and 24 bits are loaded into the command

register on each low-to-high transition of the CLK input.

The command register must match the exact bit pattern

that defines the program mode for the identification and

security match bits or the program mode for setting and

reading the amount of time for which the TimeKey can

be used. If an exact match for one of the seven function

codes of the program mode is not found, the remainder

of the program mode is ignored. When the command

register is properly loaded for programming the identification and security match bits, the next 128 bits are written to the identification and security match memory

(Figure 4). When this mode of operation is invoked, all

memory contents are erased.

SETTING AND READING TIME REMAINING

There are six functions of the program mode which are

used to set or read the amount of time for which the

TimeKey will allow full operation. T o initiate any of the six

functions of the program mode used for setting and

reading time remaining, RST

is

are loaded into the command register on each

low-to-high transition of the CLK input. If the command

register is properly loaded with the function code for

reading the 20-bit day clock counter, the next 20 bits will

be output (LSB first) as a binary count of the amount of

time elapsed in the current day (see Figure 5). The time

can be calculated by dividing this count reading by 2

(20 bits is equal to 1,048,576 counts). One minus this result is the fraction of a day remaining. The 20-bit day

clock counter is driven by an internal oscillator that has a

period of 82.4 ms. If the command register is properly

loaded with the function code for reading the 9-bit number of days counter, the next 9 bits will be output (LSB

first) as a binary count of the days remaining (see

Figure 6). This count is decremented each time the day

clock counter rolls over to zero. When the number of

days remaining counter rolls through zero, normal and

program mode write cycles are inhibited. If the program

mode read cycle to the number of days counter is attempted, the nine bits will be returned as all ones.

If the command register is properly loaded with the function code for writing the 9-bit number of days counter,

the next nine bits will be input (LSB first) as a binary

count of the desired number of days in which the TimeKey will be fully functional (see Figure 7). The number of

days counter can be changed by writing over an entered

value as often as required until the lock command is entered. The lock command is given when the command

register is properly loaded with the function code for

locking up the number of days counter. The lock command consists of the 24-bit command word only (see

Figure 8). Once the lock command is given, all future

write cycles to the number of days register are ignored.

After the correct value has been written and locked into

the number of days counter, the DS1207 will start counting the time from the entered value to zero after the first

access to the TimeKey is executed, provided the arm

oscillator bit is set. The arm oscillator bit is set when the

command register has been properly loaded with the

function code for arming the oscillator. The arm oscillator command consists of the 24-bit command word only

(see Figure 9). One other command is also available for

use in setting and reading time remaining. A stop oscillator command is given when the command register is

is driven high and 24 bits

20

021798 2/17

Page 3

DS1207

properly loaded with the function code for stopping the

oscillator. The stop oscillator command consists of the

24-bit command word only (see Figure 10). This command will only execute prior to issuing a lock command.

After the lock command is issued, stop oscillator commands are ignored.

A sequence for properly setting the expiration time of

the DS1207 is as follows (see Figure 1 1). First, program

the identification and security match bits to the desired

value. Use normal mode operation to write the appropriate secure data. Second, write the number days remaining register to the desired value. This number can be immediately verified by reading the number of days

remaining. Next, arm the oscillator by writing the appropriate command. Then do a normal mode read. This action will start the internal oscillator. Now read the 20-bit

day clock counter several times to verify that the oscillator is running. After oscillator activity has been verified,

issue the stop oscillator command. The lock command

should be issued, followed by the arm oscillator command. The TimeKey will start the countdown to expiration on the next access. T o guarantee security , a locked

TimeKey cannot be unlocked. The key cannot be reprogrammed after expiration. The oscillator verification

portion of this sequence is not required and can be deleted when speed in setting time remaining is important.

COMMAND WORD

Each data transfer for normal and program mode begins

with a 3-byte command word as shown in Figure 12. As

defined, the first byte of the command word specifies the

function code. Eight function codes are acceptable

(Figure 13). If any one of the bits of the first byte of the

command word fails to meet one of the exact patterns

for function codes, the data transfer will be aborted.

count, lock number of days count, arm oscillator, and

stop oscillator.

The remaining six bits of byte 2 and the first four bits of

byte 3 must be written to match one of the five patterns

as indicated in Figure 12 or data transfer will abort. Under special contract with Dallas Semiconductor, these

bits can be defined by the user as any bit pattern other

than those specified as unavailable. The bit pattern as

defined by the user must be written exactly or data

transfer will abort. The last four bits of byte 3 of the command word must be written 1011 or data transfer will

abort. Table 1 provides a summary of the command

words in hexadecimal as they apply to all function codes

for both program mode and normal mode.

RESET AND CLOCK CONTROL

All data transfers are initiated by driving the RST input

high. The reset input serves three functions. First, it

turns on control logic which allows access to the command register for the command sequence. Second, the

RST signal provides a power source for the cycle to follow. To meet this requirement, a drive source for RST

2 mA at 3.5 volts is required. Third, the RST

signal pro-

vides a method of terminating data transfer.

A clock cycle is a sequence of a falling edge followed by

a rising edge. For data inputs, the data must be valid

during the rising edge of the clock cycle. Command bits

and data bits are input on the rising edge of the clock.

Data bits are output on the falling edge of the clock. The

rising edge of the clock returns the DQ pin to a high impedance state. All data transfer terminates if the RST

pin is low and the DQ pin goes to a high impedance

state. Data transfer is illustrated in Figure 14 for normal

mode and Figure 15 for program mode.

of

The first two bits of the second byte of the command

word specify whether the data transfer to follow is program or normal mode. The bit pattern for program mode

is 0 in bit 0 and 1 in bit 1. The bit pattern for normal mode

is a 1 in bit 0 and a 0 in bit 1. The other two possible combinations for the first two bits of byte 2 will cause the

transfer to abort. The program mode can be invoked

with one of seven function codes: program identification

and security match, read the 20-bit day clock counter,

read the number of days count, write the number of days

TIMEKEY CONNECTIONS

The TimeKey is designed to be plugged into a standard

5-pin 0.1 inch center SIP receptacle. A guide is provided

to prevent the TimeKey from being plugged in backwards and aid in alignment of the receptacle. For portable applications, contact to the TimeKey pins can be determined to ensure connection integrity before data

transfer begins. CLK, RST

pulldown resistors to ground that can be sensed by a

reading device.

, and DQ all have 20K ohm

021798 3/17

Page 4

DS1207

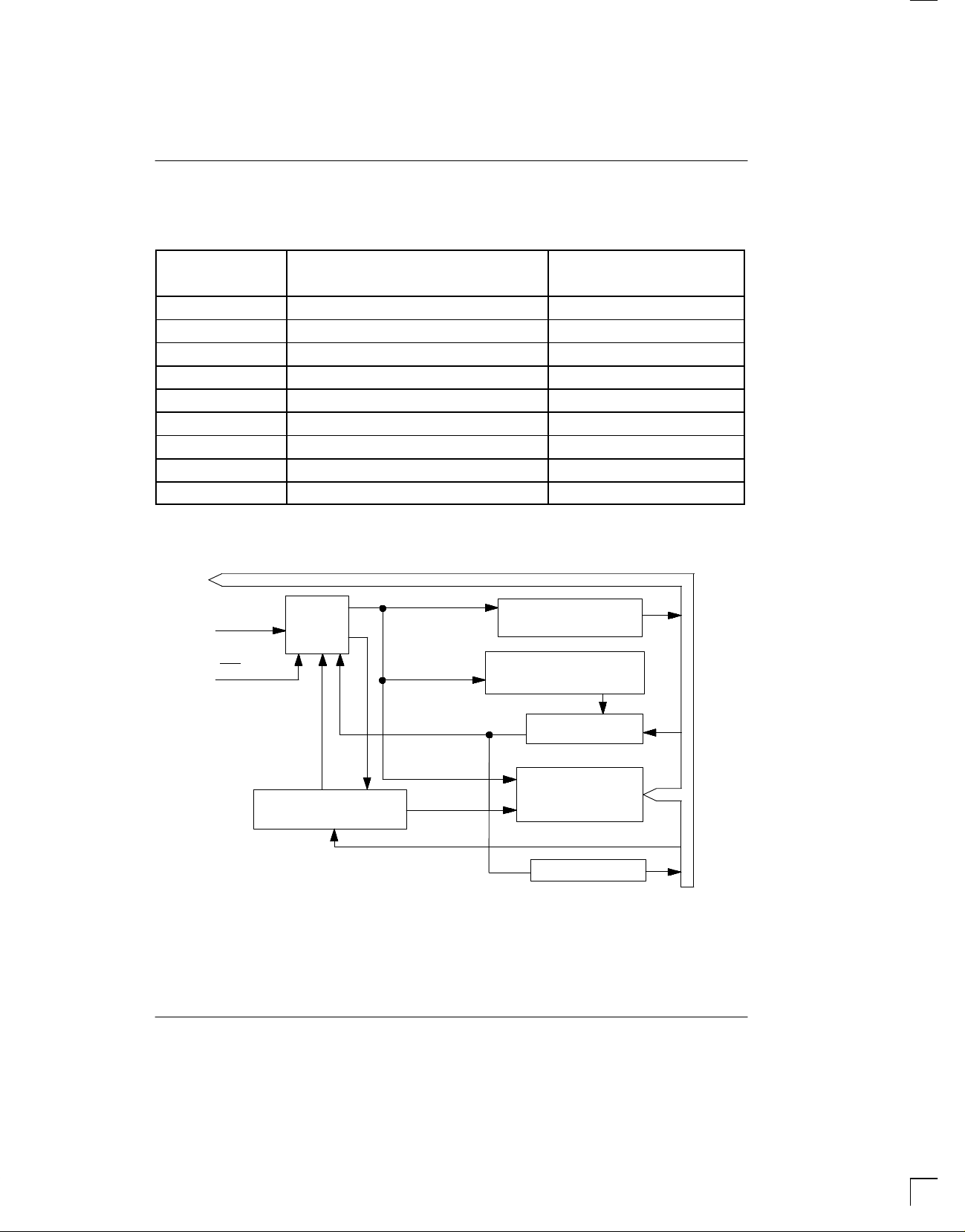

COMMAND WORDS Table 1

Summary of the command words in hexadecimal as they apply to all function codes for both program mode and normal mode for the DS1207-G01 only.(See Figure 12 and Figure 13 for detailed command words.)

MODE

FUNCTION COMMAND WORDS

MSB LSB

NORMAL READ B0 01 62

NORMAL WRITE B0 01 9D

PROGRAM WRITE B0 02 9D

PROGRAM READ DAY CLOCK COUNTER B0 02 F1

PROGRAM READ DAYS REMAINING B0 02 F3

PROGRAM WRITE DAYS REMAINING B0 02 F2

PROGRAM ARM OSCILLAT OR B0 02 F5

PROGRAM LOCK NUMBER OF DAYS COUNT B0 02 F6

PROGRAM STOP OSCILLATOR B0 02 F4

BLOCK DIAGRAM: NORMAL MODE Figure 1

D/Q

CLK

RST

Control

Logic

64-Bit

Identification

64-Bit

Security Match

021798 4/17

Command Register

Compare Register

384-Bit

Secure Memory

Garbled Data

Page 5

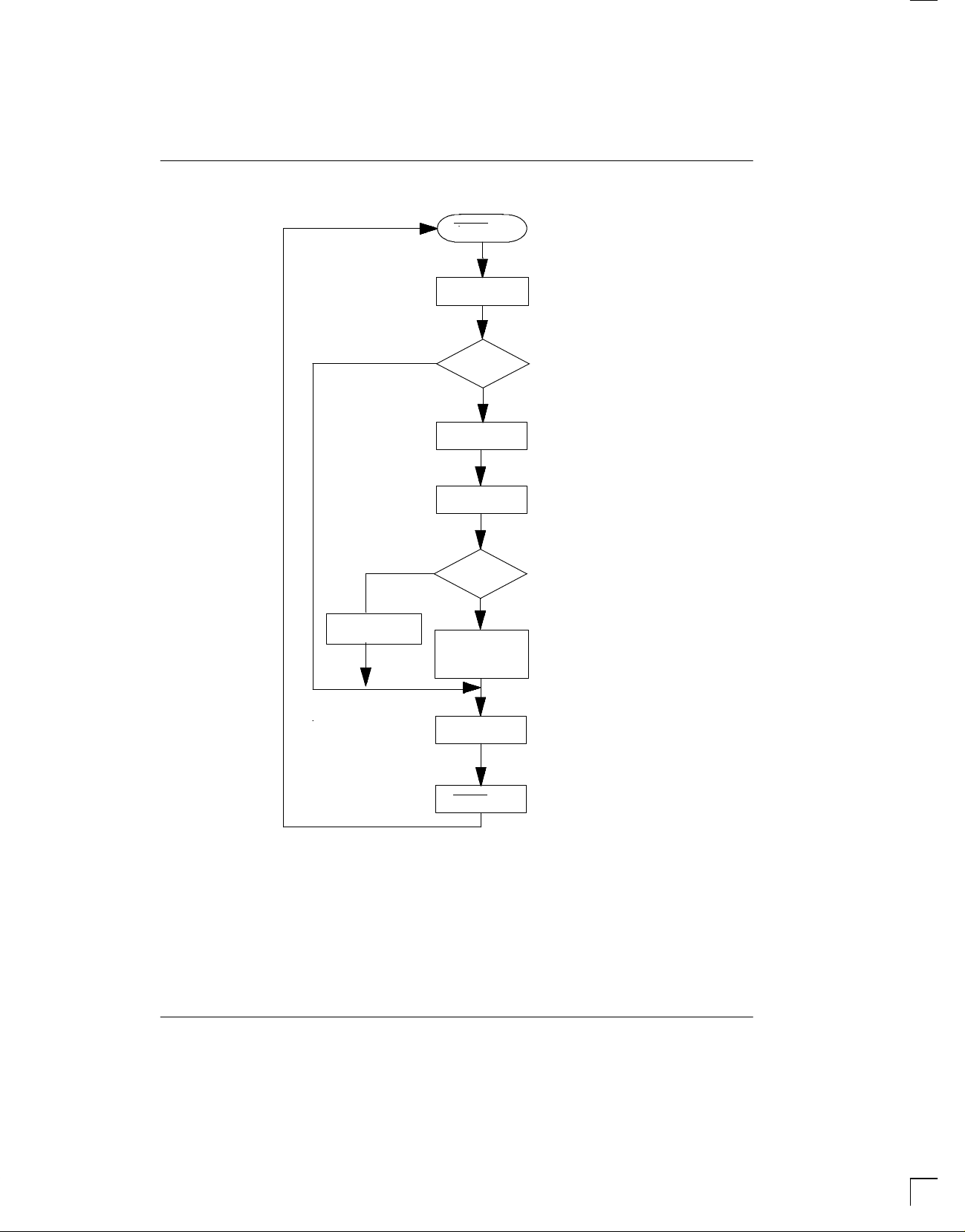

NORMAL MODE: READ OR WRITE SECURE READ/WRITE MEMORY Figure 2A

RESET High

DS1207

NO

NO

Output Garbled

Data

Write Command

Match

for Read or

Write

Read 64 Bits

Write 64 Bits

Match

Read or write

384 bits based on

function code

24 Bits Including

Function Code

Identification

Security Match

Secure Read/Write

Memory

Stop

RESET

Low

Output in High Z

021798 5/17

Page 6

DS1207

SEQUENCE: NORMAL MODE, READ OR WRITE SECURE MEMORY Figure 2B

Function Code

Command Word 64 Read Cycles

Identification Security Match

64 Write Cycles

Match

Secure Memory

384 Reads or Writes

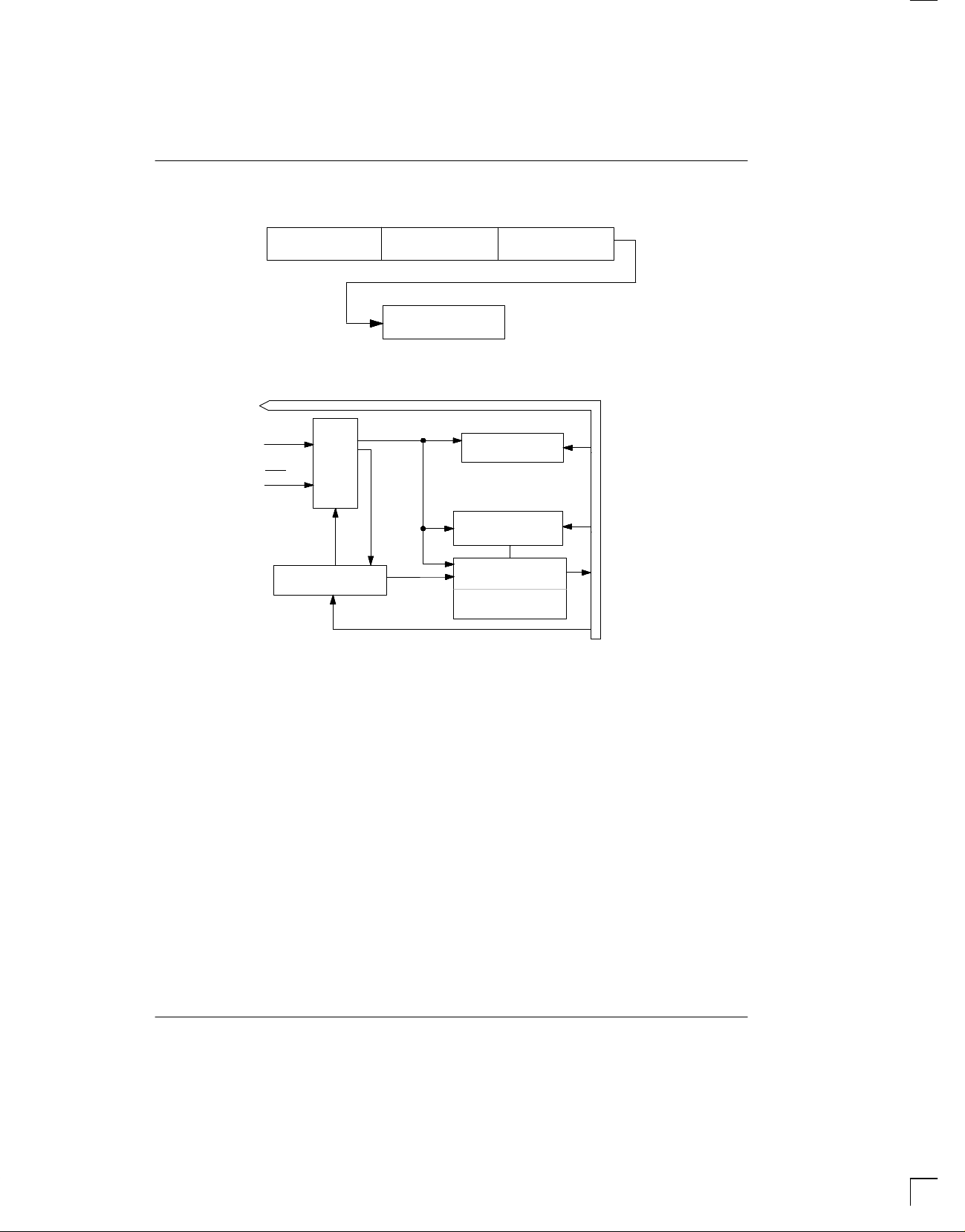

BLOCK DIAGRAM: PROGRAM MODE Figure 3

D/Q

CLK

Control

RST

Logic

Command Register

64–Bit

Identification

64–Bit

Security Match

20-Bit Clock

Counter

9-Bit No. of Days

Remaining Counter

021798 6/17

Page 7

PROGRAM MODE: PROGRAM

IDENTIFICATION AND SECURITY MATCH MEMORY Figure 4A

RESET High

DS1207

24 Bits Including

Function Code

Identification

Output in High Z

NO

Write Command

Match

Program Mode

Write 64 Bits

Write 64 Bits Security Match

Stop

Low

RESET

SEQUENCE: PROGRAM MODE, PROGRAM IDENTIFICATION AND SECURITY

MATCH BITS Figure 4B

Function Code Security Match

Command Word

Identification

64 Write Cycles

64 Write Cycles

021798 7/17

Page 8

DS1207

FLOW CHART: PROGRAM MODE, READING THE 20-BIT DAY CLOCK CALENDAR Figure 5A

High

RESET

24 Bits Including

Function Code

Day Clock

Counter

Output In High Z

NO

Write Command

Match

Program Mode

Read Day Clock

Counter

Read 20 Bits

Stop

Low

RESET

SEQUENCE: PROGRAM MODE, READING THE 20-BIT DAY CLOCK COUNTER Figure 5B

Function Code

Command Word

Day Clock Counter

20 Read Cycles

021798 8/17

Page 9

FLOW CHART: PROGRAM, READING THE 9-BIT NUMBER OF DAYS COUNTER Figure 6A

RESET High

DS1207

24 Bits Including

Function Code

Number of

Days Counter

Output In High Z

NO

Write Command

Match

Program Mode

for Reading # of Days

Counter

Read 9 Bits

Stop

RESET Low

SEQUENCE: PROGRAM MODE, READING THE 9-BIT NUMBER OF DAYS COUNTER Figure 6B

Function Code

Day Clock Counter

Command Word

9 Read Cycles

021798 9/17

Page 10

DS1207

FLOW CHART: PROGRAM MODE, WRITING TO NUMBER OF DAYS COUNTER Figure 7A

High

RESET

24 Bits Including

Function Code

Number of

Days Counter

Output in High Z

NO

Write Command

Match

Program Mode

for Reading # of Days

Counter

Write 9 Bits

Stop

RESET Low

SEQUENCE: PROGRAM MODE, WRITING THE NUMBER OF DAYS COUNTER Figure 7B

Function Code

Day Clock Counter

021798 10/17

Command Word

9 Write Cycles

Page 11

FLOW CHART: PROGRAM MODE, LOCK NUMBER OF DAYS REGISTER Figure 8

RESET

High

DS1207

24 Bits Including

Function Code

Number of Days

Counter

Output in High Z

NO

Write Command

Match

Program Mode

Lock # of Days

Number of Days

Locked

Stop

Low

RESET

FLOW CHART: PROGRAM MODE, ARM OSCILLATOR Figure 9

High

RESET

Write Command

24 Bits Including

Function Code

NO

Match

Program Mode

to Arm Oscillator

Oscillator Armed

Stop

Low

RESET

Output in High Z

021798 11/17

Page 12

DS1207

FLOW CHART: PROGRAM MODE, STOP OSCILLATOR Figure 10

RESET

High

24 Bits Including

Function Code

Output in High Z

NO

Write Command

Match

Program Mode

to Stop Oscillator

Oscillator Stopped

Stop

RESET

Low

SETTING THE TIME UNTIL EXPIRATION OF THE DS1207 Figure 11

Step 1 Program identification memory

Step 2 Program write the number of days remaining

Step 3* Issue arm oscillator command

Step 4* Do a read of any kind

Step 5* Program read the day clock counter several times (verify that the oscillator is running)

Step 6* Issue the stop oscillator command

Step 7 Issue the lock command

Step 8 Issue the arm oscillator command

Program security match bits

Write normal mode secure data

Program read the number of days remaining for verification

(time of expiration will start on first access)

* This is a stress rating only and functional operation of the device at these or any other conditions above

those indicated in the operation sections of this specification is not implied. Exposure to absolute maximum rating conditions for extended periods of time may affect reliability.

021798 12/17

Page 13

COMMAND WORD Figure 12

CCC CCCCC

DS1207

0

Byte 1

DS1207-G01

DS1207-G02

DS1207-G03

DS1207-G04

DS1207-G05

XXXXXXP

23

XXXXXX1

00000

0 000

11

0000

0 000

11

0000

0000

11

000

0000

11

000 00

0000

11

1

1

1

0

1

1

1

0

0

1

0

1

11

P

X

P

P

P

P

P

Byte 2

Byte 3

P

Byte 2

0

Byte 3

P

Byte 2

0

Byte 3

P

Byte 2

0

Byte 3

P

Byte 2

0

Byte 3

P

Byte 2

Byte 3

0

021798 13/17

Page 14

DS1207

FUNCTION CODES: FIRST BYTE OF COMMAND WORD Figure 13

MSB LSB

0 1100010

1 0011101

1 1110001

1 1110010

1 1110011

1 1110100

1 1110101

1 1110110

READ

WRITE

READ DAY CLOCK COUNTER

WRITE NUMBER OF DAYS REMAINING

READ NUMBER OF DAYS REMAINING

STOP OSCILLA TOR

ARM OSCILLATOR

LOCK NUMBER OF DAYS COUNT

DATA TRANSFER: NORMAL MODE, READ OR WRITE SECURE READ/WRITE MEMORY

Figure 14

CLK

01 23

1 D0CC

D64 DQ1

DQ0 DQ126 DG384

Q63

CLOCK

RESET

COMMAND

WORD

READ

64 BITS

WRITE

64 BITS

READ/WRITE

128 BITS

DATA TRANSFER: PROGRAM MODE, PROGRAM IDENTIFICATION AND SECURITY MATCH

MEMORY Figure 15A

CLK

021798 14/17

012 23

COMMAND

WORD

1 QO CC

WRITE

64 BITS

Q0 Q1 Q62 Q63Q1 Q62 Q63

WRITE

64 BITS

CLOCK

RESET

Page 15

DS1207

DATA TRANSFER: PROGRAM MODE, DAY CLOCK, DAYS REMAINING AND OSCILLATOR

CONTROL Figure 15B

CLK

01 23

C 1 Q0 QC Q1 Q

COMMAND

WORD

WRITE OR READ

X BITS

NOTE: The number of bits which follow the command word will be either 0, 9, or 20 bits based on the function code.

021798 15/17

Page 16

DS1207

ABSOLUTE MAXIMUM RATINGS*

Voltage on any Pin Relative to Ground -1.0V to +7.0V

Operating Temperature 0°C to 70°C

Storage Temperature -40°C to +70°C

* This is a stress rating only and functional operation of the device at these or any other conditions above

those indicated in the operation sections of this specification is not implied. Exposure to absolute maximum rating conditions for extended periods of time may affect reliability.

RECOMMENDED DC OPERATING CONDITIONS (0°C to 70°C)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Logic 1 V

Logic 0 V

Reset Logic 1 V

IH

IL

IHE

2.0 V 1

-0.3 +0.8 V 1

3.5 V 1

DC ELECTRICAL CHARACTERISTICS (0°C to 70°C; RST = 3.5V)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Input Leakage I

Output Leakage I

Output Current @2.4V I

Output Current @0.4V I

RST Input Resistance Z

D/Q Input Resistance Z

CLK Input Resistance Z

RST Current @3.5V I

IL

LO

OH

OL

RST

DQ

CLK

RST

-1 mA

10 60 K ohms

10 60 K ohms

10 60 K ohms

+500 µA 4

+500 µA

+2 mA

2 mA 6, 9

CAPACITANCE (t

= 25°C)

A

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Input Capacitance C

Output Capacitance C

IN

OUT

5 pF

7 pF

AC ELECTRICAL CHARACTERISTICS (0°C to 70°C)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Data To CLK Setup t

CLK to Data Hold t

CLK to Data t

DC

CDH

CDD

CLK Low Time Delay t

CLK High Time t

CLK Frequency f

CH

CLK

CLK Rise & Fall tR, t

RST to CLK Setup t

CLK to RST Hold t

RST Inactive Time t

RST To I/O High Z t

021798 16/17

CC

CCH

CWH

CDZ

CL

F

50 ns 2, 7

70 ns 2, 7

200 ns 2, 3, 5, 7

250 ns 2, 7

250 ns 2, 7

DC 2.0 MHz 2, 7

500 ns 2, 7

1 µs 2, 7

60 ns 2, 7

10 ms 2, 7,

70 ns 2, 7

Page 17

TIMING DIAGRAM: WRITE DATA

RESET

t

CLOCK

DATA

INPUT/OUTPUT

CC

t

DC

R/W

t

t

CDH

TIMING DIAGRAM: READ DATA

RESET

t

CC

DS1207

t

CWH

t

CL

R/W

R

t

CH

R/W

t

F

t

CCH

t

CWH

CLOCK

t

DC

R/W

t

CDD

t

CDZ

NOTES:

1. All voltages are referenced to GND.

2. Measured at V

3. Measured at V

= 2.0 or V

IH

= 2.4 volts and VOL = 0.4 volts.

OH

4. For CLK, D/Q, and RST

5. Load capacitance = 50 pF.

6. Measured with outputs open.

7. Measured at V

of RST greater than or equal to 3.5 volts.

IH

8. Each DS1207 is marked with a 4-digit code AABB. AA designates the year of manufacture. BB designates the

week of manufacture. The expected t

9. Average AC RST

I

TOTAL

I

TOTAL

current can be determined using the following formula:

= 2 + I

and I

LOAD

Applying the above formula, a load capacitance of 50 pF

running at a frequency of 2.0 MHz gives an I

= .8V and 10 ns maximum rise and fall time.

IL

.

is defined as starting at the date of manufacture.

DR

DC + (4 x 10-3)(CL + 280)f

LOAD

are in mA; CL is in pF; f is in MHz.

TOTAL

of 1.6 mA.

021798 17/17

Loading...

Loading...