Page 1

g

n

g

n

C

6

查询DS1010供应商

www.dalsemi.com

DS1010

10-Tap Silicon Delay Line

FEATURES

All-silicon time delay

10 taps equally spaced

Delays are stable and precise

Leading and trailing edge accuracy

Delay tolerance ±5% or ±2 ns, whichever is

greater

Economical

Auto-insertable, low profile

Standard 14-pin DIP or 16-pin SOIC

Low-power CMOS

TTL/CMOS-compatible

Vapor phase, IR and wave solderable

Custom delays available

Fast turn prototypes

PIN ASSIGNMENT

IN1

1

NC

2

TAP 2

TAP 4

TAP 6

TAP 8

GND

3

4

5

6

7

DS1010 14-Pin DIP (300-mil)

See Mech. Drawin

14

13

12

11

10

9

8

V

CC

TAP 1

TAP 3

TAP 5

TAP 7

TAP 9

TAP 10

s Sectio

IN1

NC

NC

TAP 2

TAP 4

TAP 6

TAP 8

GND

DS1010S 16-Pin SOIC

See Mech. Drawin

PIN DESCRIPTION

TAP 1 - TAP 10 - TAP Output Number

V

CC

GND - Ground

NC - No Connection

IN - Input

- 5 Volts

1

16

2

15

14

3

4

13

5

12

11

7

10

8

(300-mil)

9

s Sectio

V

CC

N

TAP 1

TAP 3

TAP 5

TAP 7

TAP 9

TAP 10

DESCRIPTION

The DS1010 series delay line has ten equally spaced taps providing delays from 5 ns to 500 ns. The

devices are offered in a standard 14-pin DIP which is pin-compatible with hybrid delay lines.

Alternatively, a 16-pin SOIC is available for surface mount technology which reduces PC board area.

Since the DS1010 is an all-silicon solution, better economy is achieved when compared to older methods

using hybrid techniques. The DS1010 series delay lines provide a nominal accuracy of ±5% or ±2 ns,

whichever is greater. The DS1010 reproduces the input logic state at the TAP 10 output after a fixed

delay as specified by the dash number extension of the part number. The DS1010 is designed to produce

both leading and trailing edge with equal precision. Each tap is capable of driving up to 10 74LS type

loads. Dallas Semiconductor can customize standard products to meet special needs. For special requests

and rapid delivery, call (972) 371-4348.

1 of 6 111799

Page 2

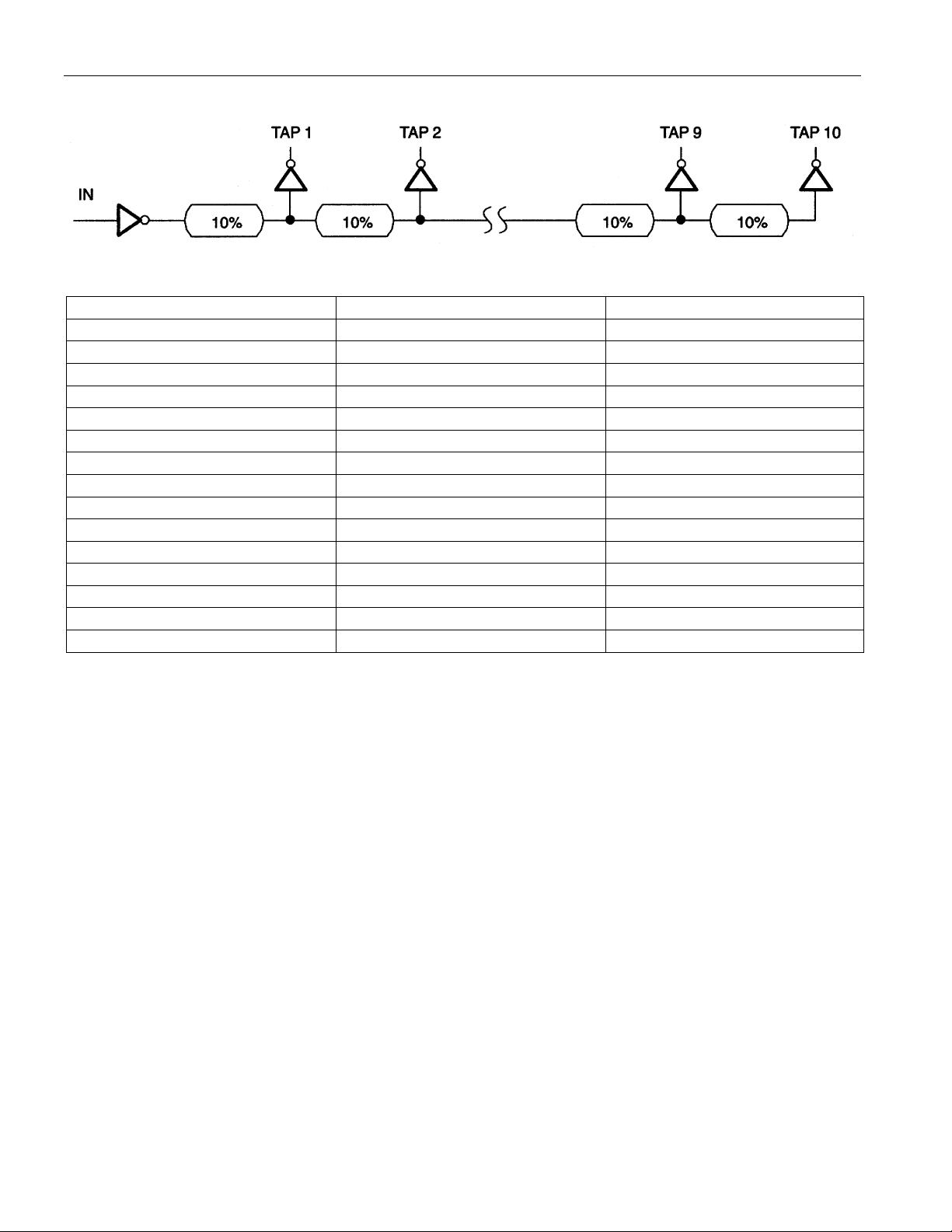

LOGIC DIAGRAM Figure 1

DS1010

PART NUMBER DELAY TABLE (t

CATALOG P/N TOTAL DELAY DELAY/TAP (ns)

DS1010-50 50 5

DS1010-60 60 6

DS1010-75 75 7.5

DS1010-80 80 8

DS1010-100 100 10

DS1010-125 125 12.5

DS1010-150 150 15

DS1010-175 175 17.5

DS1010-200 200 20

DS1010-250 250 25

DS1010-300 300 30

DS1010-350 350 35

DS1010-400 400 40

DS1010-450 450 45

DS1010-500 500 50

Custom delays available.

PHL

, t

) Table 1

PLH

2 of 6

Page 3

DS1010

ABSOLUTE MAXIMUM RATINGS*

Voltage on Any Pin Relative to Ground -1.0V to +7.0V

Operating Temperature 0°C to 70°C

Storage Temperature -55°C to +125°C

Soldering Temperature 260°C for 10 seconds

Short Circuit Output Current 50 mA for 1 second

* This is a stress rating only and functional operation of the device at these or any other conditions above

those indicated in the operation sections of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods of time may affect reliability.

DC ELECTRICAL CHARACTERISTICS (0°C to 70°C; VCC = 5.0V ± 5%)

PARAMETER SYM TEST

CONDITION

Supply Voltage V

High Level Input

V

CC

IH

Voltage

Low Level Input

V

IL

Voltage

Input Leakage

I

I

0.0V ≤ VI ≤ V

Current

Active Current I

CC

VCC=Max;

Period=Min.

High Level Output

Current

Low Level Output

Current

I

OH

VCC=Min.

VOH=4

I

OL

VCC=Min.

VOL=0.5

CC

MIN TYP MAX UNITS NOTES

4.75 5.00 5.25 V 1

2.2 VCC + 0.5 V 1

-0.5 0.8 V 1

-1.0 1.0 µA

40 150 mA 2

-1.0 mA

12 mA

AC ELEC TRICAL CHARACTE RISTICS (TA = 25°C; VCC = 5V ± 5%)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Input Pulse Width t

Input to Tap Delay

(leading edge)

Input to Tap Delay

(trailing edge)

Power-up Time t

t

PLH

t

PHL

WI

PU

40% of TAP 10 t

PLH

ns 8

Table 1 ns 3, 4, 5, 6,

Table 1 ns 3, 4, 5, 6,

100 ms

7, 9

7, 9

Period 4 (tWI)ns8

CAPACITANCE (TA = 25°C)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Input Capacitance C

IN

510pF

3 of 6

Page 4

NOTES:

1. All voltages are referenced to ground.

2. Measured with outputs open.

DS1010

3. V

= 5V @ 25°C. Input-to-tap delays accurate on both rising and falling edges within ±2 ns or ±5%

CC

whichever is greater.

4. See “Test Conditions” section.

5. For DS1010 delay lines with a TAP 10 delay of 100 ns or greater, temperature variations from 25°C

to 0°C or 70°C may produce an additional input-to-tap delay shift of ±2ns or ±3%, whichever is

greater.

6. For DS1010 delay lines with a TAP 10 delay less than 100 ns, temperature variations from 25°C to

0°C or 70°C may produce an additional input-to-tap delay shift of ±1 ns or ±9%, whichever is greater.

7. All tap delays tend to vary unidirectionally with temperature or voltage changes. For example, if TAP

1 slows down, all other taps will also slow down; TAP 3 can never be faster than TAP 2.

8. Pulse width and period specifications may be exceeded; however, accuracy will be applicationsensitive (decoupling, layout, etc.).

9. Certain high-frequency applications not recommended for -50 in 16-pin package. Consult factory.

TIMING DIAGRAM: SILICON DELAY LINE Figure 2

4 of 6

Page 5

TEST CIRCUIT Figure 3

DS1010

TERMINOLOGY

Period: The time elapsed between the leading edge of the first pulse and the leading edge of the

following pulse.

tWI (Pulse Width): The elapsed time on the pulse between the 1.5V point on the leading edge and the

1.5V point on the trailing edge, or the 1.5V point on the trailing edge and the 1.5 V point on the leading

edge.

(Input Rise Time): The elapsed time between the 20% and the 80% point on the leading edge of the

t

RISE

input pulse.

t

(Input Fall Time): The elapsed time between the 80% and the 20% point on the trailing edge of the

FALL

input pulse.

(Time Delay Rising): The elapsed time between the 1.5V point on the leading edge of the input

t

PLH

pulse and the 1.5V point on the leading edge of any tap output pulse.

t

(Time Delay, Falling): The elapsed time between the 1.5V point on the trailing edge of the input

PHL

pulse and the 1.5V point on the trailing edge of any tap output pulse.

5 of 6

Page 6

DS1010

TEST SETUP DESCRIPTION

Figure 3 illustrates the hardware configuration used for measuring the timing parameters on the DS1010.

The input waveform is produced by a precision pulse generator under software control. Time delays are

measured by a time interval counter (20 ps resolution) connected between the input and each tap. Each

tap is selected and connected to the counter by a VHF switch control unit. All measurements are fully

automated, with each instrument controlled by a central computer over an IEEE 488 bus.

TEST CONDITIONS

INPUT:

Ambient Temperature: 25°C ± 3°C

Supply Voltage (VCC): 5.0V ± 0.1V

Input Pulse: High = 3.0V ± 0.1V

Low = 0.0V ± 0.1V

Source Impedance: 50 ohm max.

Rise and Fall Time: 3.0 ns max.

Pulse Width: 500 ns (1 µs for -500)

Period: 1 µs ( 2 µs for -500)

OUTPUT:

Each output is loaded with the equivalent of one 74FO4 input gate. Dela y is measured at the 1.5V leve l

on the rising and falling edge.

NOTE:

Above conditions are for test only and do not restrict the operation of the device under other data sheet

conditions.

6 of 6

Loading...

Loading...