Page 1

DS0026

Dual High-Speed MOS Driver

DS0026 Dual High-Speed MOS Driver

February 2000

General Description

DS0026 is a low cost monolithic high speed two phase MOS

clock driver and interface circuit. Unique circuit design provides both very high speed operation and the ability to drive

large capacitiveloads.The deviceaccepts standard TTLoutputs and converts themto MOS logic levels. The device may

be driven from standard 54/74 series and 54S/74S series

gates and flip-flops or from drivers such as the DS8830 or

DM7440. The DS0026 is intended for applications in which

the output pulse width is logically controlled; i.e., the output

pulse width is equal to the input pulse width.

The DS0026 is designed to fulfill a wide variety of MOS interface requirements. Information on the correct usage of the

DS0026 in these as well as other systems is included in the

application note AN-76.

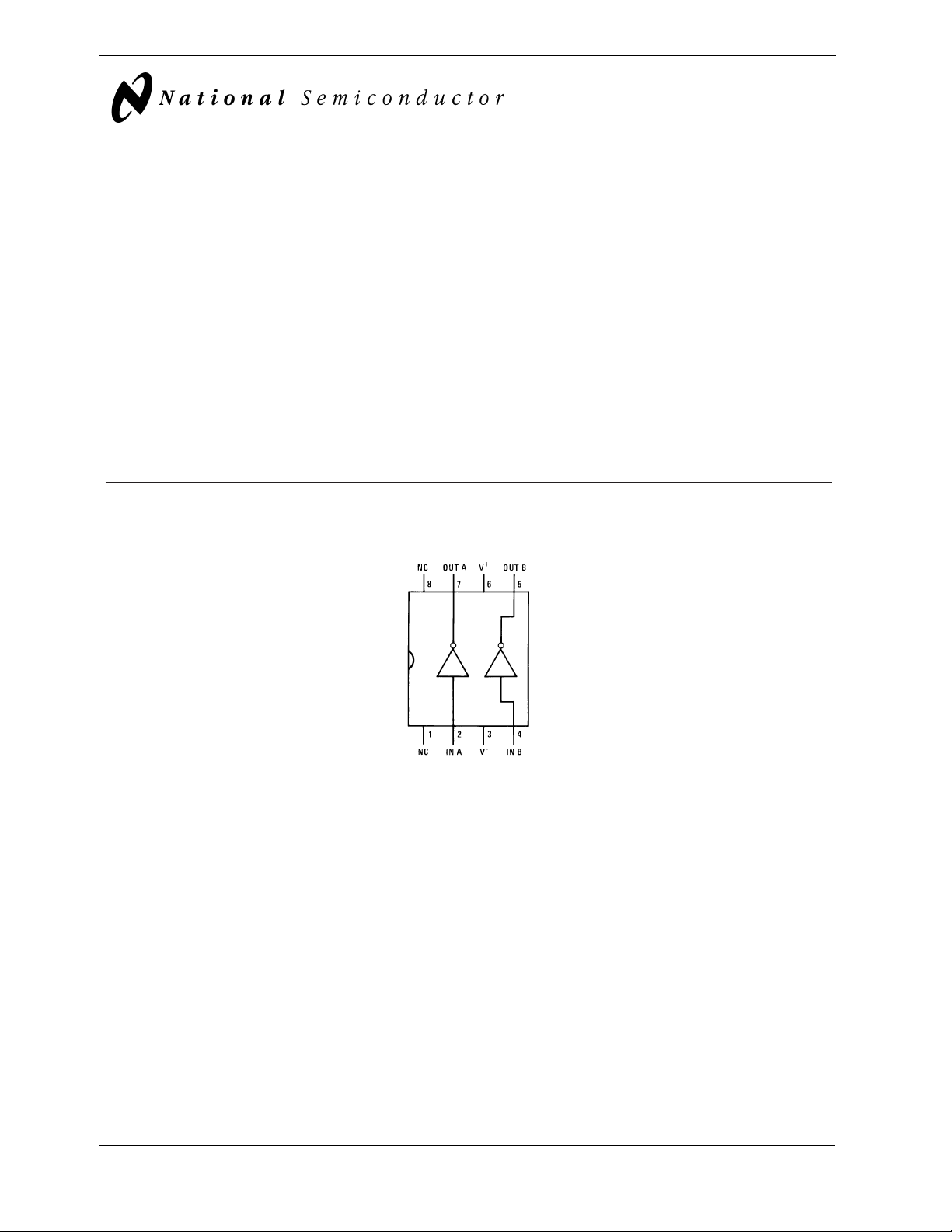

Connection Diagrams (Top Views)

Dual-In-Line Package

Features

n Fast rise and fall times— 20 ns 1000 pF load

n High output swing —20V

n High output current drive—

n TTL compatible inputs

n High rep rate —5 to 10 MHz depending on power

dissipation

n Low power consumption in MOS “0” state— 2 mW

n Drives to 0.4V of GND for RAM address drive

±

1.5 amps

DS005853-2

Order Number DS0026CN

See NS Package Number N08E

© 2000 National Semiconductor Corporation DS005853 www.national.com

Page 2

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

DS0026

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

+−V−

V

Differential Voltage 22V

Input Current 100 mA

Input Voltage (V

−V−) 5.5V

IN

Peak Output Current 1.5A

Electrical Characteristics (Notes 2, 3, 4)

=

*

Maximum Power Dissipation

25˚C 420mW

at T

A

Operating Temperature Range 0˚C to +70˚C

Storage Temperature Range −65˚C to +150˚C

Lead Temperature

(Soldering, 10 sec.) 300˚C

Note:*Derate N08E package 9.3 mW/˚C for TAabove 25˚C.θJ

A

=

107˚C/W

Symbol Parameter Conditions Min Typ Max Units

−

V

IH

I

IH

V

IL

I

IL

V

OL

V

OH

I

CC(ON)

I

CC(OFF)

Logic “1” Input Voltage V

Logic “1” Input Current VIN−V

Logic “0” Input Voltage V

Logic “0” Input Current VIN−V

Logic “1” Output Voltage VIN−V

Logic “0” Output Voltage VIN−V

“ON” Supply Current

(one side on)

“OFF” Supply Current V+−V

=

0V 2 1.5 V

−

=

−

=

I

OH

V+−V

V

IN

2.4V 10 15 mA

0V 0.6 0.4 V

−

=

0V −3 −10 µA

−

−

=

−1mA

−

−

−

−V

=

=

=

20V, V

=

20V,

=

2.4V, I

0.4V, V

0V

=

1mA V

OL

≥ V++ 1.0V

SS

−

=

−V

IN

2.4V

V

+

− 1.0 V+−0.8 V

−

+0.7 V−+1.0 V

30 40 mA

10 100 µA

Switching Characteristics

=

(T

25˚C) (Notes 5, 6)

A

Symbol Parameter Conditions Min Typ Max Units

t

ON

t

OFF

t

r

t

f

Note 1: “Absolute Maximum Ratings”are those values beyond which the safety of the device cannot beguaranteed. Except for “Operating Temperature Range” they

are not meant to imply that the devices should be operated at these limits. The table of “Electrical Characteristics provides conditions for actual device operation.

Note 2: These specifications apply for V

Note 3: All currents into device pins shown as positive, out of device pins as negative, all voltages referenced to ground unless otherwise noted. All values shown

as max or min on absolute value basis.

Note 4: All typical values for T

Note 5: Rise and fall time are given for MOS logic levels; i.e., rise time is transition from logic “0” to logic “1” which is voltage fall.

Note 6: The high current transient (as high as 1.5A) through the resistance of the internal interconnecting V

the low state can appear as negative feedback to the input. If the external interconnecting lead from the driving circuit to V

resistance, it can subtract from the switching response.

Turn-On Delay

Turn-Off Delay

Rise Time

Fall Time

=

A

25˚C.

+−V−

(Figure 1)

(Figure 2)

(Figure 1)

(Figure 2)

(Figure 1),

(Note 5)

(Figure 2),

(Note 5)

(Figure 1),

(Note 5)

(Figure 2),

(Note 5)

=

10V to 20V, C

5 7.5 12 ns

11 ns

12 15 ns

13 ns

=

C

500 pF 15 18 ns

L

=

C

1000 pF 20 35 ns

L

=

C

500 pF 30 40 ns

L

=

C

1000 pF 36 50 ns

L

=

C

500 pF 12 16 ns

L

=

C

1000 pF 17 25 ns

L

=

C

500 pF 28 35 ns

L

=

C

1000 pF 31 40 ns

L

=

1000 pF, over the temperature range of 0˚C to +70˚C for the DS0026CN.

L

−

lead during the output transition from the high state to

−

is electrically long, or has significant dc

www.national.com 2

Page 3

Typical VBBConnection

Typical Performance Characteristics

DS0026

DS005853-8

Input Current vs Input Voltage

DS005853-22

Rise Time vs Load

Capacitance

Supply Current vs Temperature

DS005853-23

Fall Time vs Load

Capacitance

Turn-On and Turn-Off Delay

vs Temperature

DS005853-24

DS005853-25

DS005853-26

www.national.com3

Page 4

Typical Performance Characteristics (Continued)

DS0026

Recommended Input Coding

Capacitance

DS005853-27

Schematic Diagram

1/2 DS0026

DC Power (PDC)vs

Duty Cycle

DS005853-28

www.national.com 4

DS005853-10

Page 5

AC Test Circuits and Switching Time Waveforms

DS005853-12

FIGURE 1.

DS0026

DS005853-13

DS005853-15

DS005853-14

FIGURE 2.

Typical Applications Application Hints

AC Coupled MOS Clock Driver

DS005853-16

DC Coupled RAM Memory Address or Precharge

Driver (Positive Supply Only)

DS005853-17

DRIVING THE MM5262 WITH THE

DS0026 CLOCK DRIVER

The clock signals for the MM5262 have three requirements

which have the potential of generating problems for the user.

These requirements, high speed, large voltage swing and

large capacitive loads, combine to provide ampleopportunity

for inductive ringing on clock lines, coupling clock signals to

other clocks and/or inputs and outputs and generating noise

on the power supplies.All of these problems have the potential of causing the memory system to malfunction. Recognizing the source and potential of these problems early in the

design of a memory system is the most critical step. The object here is to point out the source of these problems and

give a quantitative feel for their magnitude.

Line ringing comes from the fact that at a high enough frequency any line must be considered as a transmission line

with distributed inductance and capacitance. To see how

much ringing can be tolerated we must examine the clock

voltage specification.

Figure 3

in diagram form, with idealized ringing sketched in. The ringing of the clock about the V

the V

−1VOHis not maintained, at

SS

tion stored in the memory could be altered. Referring to

ure 1

, if the threshold voltage of a transistor were −1.3V, the

clock going to V

− 1 would mean that all the devices,

SS

whose gates are tied to that clock, would be only 300 mV

from turning on. The internal circuitry needs this noise margin and from the functional description of the RAM it is easy

to see that turning a clock on at the wrong time can have disastrous results.

shows the clock specification,

level is particularly critical. If

SS

all

times, the informa-

Fig-

www.national.com5

Page 6

Application Hints (Continued)

DS0026

FIGURE 3. Clock Waveform

Controlling theclock ringing is particularly difficult because of

the relative magnitude of the allowable ringing, compared to

magnitude of the transition. In this case it is 1V out of 20V or

only 5%. Ringing can be controlled by damping the clock

driver and minimizing the line inductance.

Damping the clock driver by placing a resistance in series

with its output is effective, but there is a limit since it also

slows downthe rise and fall time of theclock signal. Because

the typical clock driver can be much faster than the worst

case driver, the damping resistor serves the useful function

of limiting the minimum rise and fall time. This is very important because the faster the rise and fall times, the worse the

ringing problem becomes. The size of the damping resistor

varies because it is dependent on the details of the actual

application. It must be determined empirically. In practice a

resistance of 10Ω to 20Ω is usually optimum.

Limiting the inductance of the clock lines can be accomplished by minimizing their length and by laying out the lines

such that the return current is closely coupled to the clock

lines. When minimizing the length of clock lines it is important to minimize the distance from the clock driver output to

the furthest point being driven. Because of this, memory

boards are usually designed with clock drivers in the center

of the memory array, rather than on one side, reducing the

maximum distance by a factor of 2.

Using multilayer printed circuit boards with clock lines sandwiched between the V

the inductance of the clock lines. It also serves the function

of preventing the clocks from coupling noise into input and

output lines. Unfortunately multilayer printed circuit boards

are more expensive than two sided boards. The user must

make the decision as to the necessity of multilayer boards.

Suffice itto say here, thatreliable memory boards can bedesigned using two sided printed circuit boards.

and VSSpower plains minimizes

DD

DS005853-18

DS005853-19

FIGURE 4. Clock Waveforms (Voltage and Current)

Because of the amount of current that the clock driver must

supply to its capacitive load, the distribution of power to the

clock driver must be considered.

Figure 4

gives the idealized

voltage and current waveforms for a clock driver driving a

1000 pF capacitor with 20 ns rise and fall time.

As can be seen the current is significant. This current flows

in the V

and VSSpower lines.Any significant inductance in

DD

the lines will produce large voltage transients on the power

supplies. A bypass capacitor, as close as possible to the

clock driver, is helpful in minimizing this problem. This bypass is most effectivewhen connected between the V

V

supplies. The size of the bypass capacitor depends on

DD

and

SS

the amount of capacitance being driven. Using a low inductance capacitor, such as a ceramic or silver mica, is most effective. Another helpful technique is to run the V

DD

and V

SS

lines, tothe clock driver,adjacent to eachother. This tends to

reduce the lines inductance and therefore the magnitude of

the voltage transients.

While discussing the clock driver, it should be pointed out

that the DS0026 is a relatively low input impedance device.

It is possible to couple current noise into the input without

seeing a significant voltage. Since the noise is difficult to detect with an oscilloscope it is often overlooked.

Lastly, the clock lines must be considered as noise generators.

Figure 5

pling capacitor, C

shows a clockcoupled through a parasitic cou-

, to eight data input lines being driven by

C

a 7404. Aparasitic lumped line inductance, L, is also shown.

Let us assume, for the sake of argument, that C

is1pFand

C

that the rise time of the clock is high enough to completely

isolate the clock transient from the 7404 because of the inductance, L.

www.national.com 6

Page 7

Application Hints (Continued)

DS0026

tance could cause system malfunction, because a 7404

without apull up resistor has typically only 0.3Vof noise margin in the “1” state at 25˚C. Of course it is stretching things to

assume that the inductance, L, completely isolates the clock

transient from the 7404. However, it does point out the need

to minimize inductance in input/output as well as clock lines.

The output is current, so it is more meaningful to examine

the current that is coupled througha1pFparasitic capacitance. The current would be:

DS005853-20

FIGURE 5. Clock Coupling

With a clock transition of 20V the magnitude of the voltage

generated across C

is:

L

This has been a hypothetical example to emphasize that

with 20V low rise/fall time transitions, parasitic elements can

not be neglected. In this example, 1 pF of parasitic capaci-

This exceeds the total output current swing so it is obviously

significant.

Clock coupling to inputs and outputs can be minimized by

using multilayer printed circuit boards, as mentioned previously, physically isolating clock lines and/or running clock

lines at right angles to input/output lines. All of these techniques tend to minimize parasitic coupling capacitance from

the clocks to the signals in question.

In considering clock coupling it is also important to have a

detailed knowledge of the functional characteristics of the

device being used. As an example, for the MM5262, coupling noisefrom the φ2 clockto the address lines is of noparticular consequence. On the other hand the address inputs

will be sensitive to noise coupled from φ1 clock.

www.national.com7

Page 8

Packaging Information

Physical Dimensions

DS0026 Dual High-Speed MOS Driver

inches (millimeters) unless otherwise noted

Molded Dual-In-Line Package (N)

Order Number DS0026CN

NS Package Number N08E

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

labeling, can be reasonably expected to result in a

significant injury to the user.

National Semiconductor

Corporation

Americas

Tel: 1-800-272-9959

Fax: 1-800-737-7018

Email: support@nsc.com

www.national.com

National Semiconductor

Europe

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Response Group

Tel: 65-2544466

Fax: 65-2504466

Email: ap.support@nsc.com

National Semiconductor

Japan Ltd.

Tel: 81-3-5639-7560

Fax: 81-3-5639-7507

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

Loading...

Loading...