Page 1

Product

Folder

Order

Now

Technical

Documents

Tools &

Software

Support &

Community

DLPS013G –APRIL 2010–REVISED JANUARY 2019

DLP5500 DLP®0.55 XGA Series 450 DMD

DLP5500

1 Features

1

• 0.55-Inch Micromirror Array Diagonal

– 1024 × 768 Array of Aluminum, Micrometer-

Sized Mirrors (XGA Resolution)

– 10.8-µm Micromirror Pitch

– ±12° Micromirror Tilt Angle

(Relative to Flat State)

– Designed for Corner Illumination

• Designed for Use With Broadband Visible Light

(420 nm – 700 nm):

– Window Transmission 97% (Single Pass,

Through Two Window Surfaces)

– Micromirror Reflectivity 88%

– Array Diffraction Efficiency 86%

– Array Fill Factor 92%

• 16-Bit, Low Voltage Differential Signaling (LVDS)

Double Data Rate (DDR) Input Data Bus

• 200 MHz Input Data Clock Rate

• Dedicated DLPC200 Controller for High-Speed

Pattern Rates:

– 5,000 Hz (1-Bit Binary Patterns)

– 500 Hz (8-Bit Grayscale Patterns)

• Series 450 Package Characteristics:

– Thermal Area 18 mm × 12 mm Enabling High

on Screen Lumens (>2000 lm)

– 149 Micro Pin Grid Array Robust Electrical

Connection

– Package Mates to Amphenol InterCon

Systems 450-2.700-L-13.25-149 Socket

2 Applications

• Industrial

– 3D Scanners for Machine Vision and Quality

Control

– 3D Printing

– Direct Imaging Lithography

– Laser Marking and Repair

– Industrial and Medical Imaging

– Medical Instrumentation

– Digital Exposure Systems

• Medical

– Opthamology

– 3D Scanners for Limb and Skin Measurement

– Hyperspectral Imaging

• Displays

– 3D Imaging Microscopes

– Intelligent and Adaptive Lighting

3 Description

Featuring over 750000 micromirrors, the high

resolution DLP5500 (0.55" XGA) digital micromirror

device (DMD) is a spatial light modulator (SLM) that

modulates the amplitude, direction, and/or phase of

incoming light. This advanced light control technology

has numerous applications in the industrial, medical,

and consumer markets. The DLP5500 enables fine

resolution for 3D printing applications.

Device Information

PART NUMBER PACKAGE BODY SIZE (NOM)

DLP5500 CPGA (149) 22.30 mm × 32.20 mm

(1) For all available packages, see the orderable addendum at

the end of the data sheet.

(1)

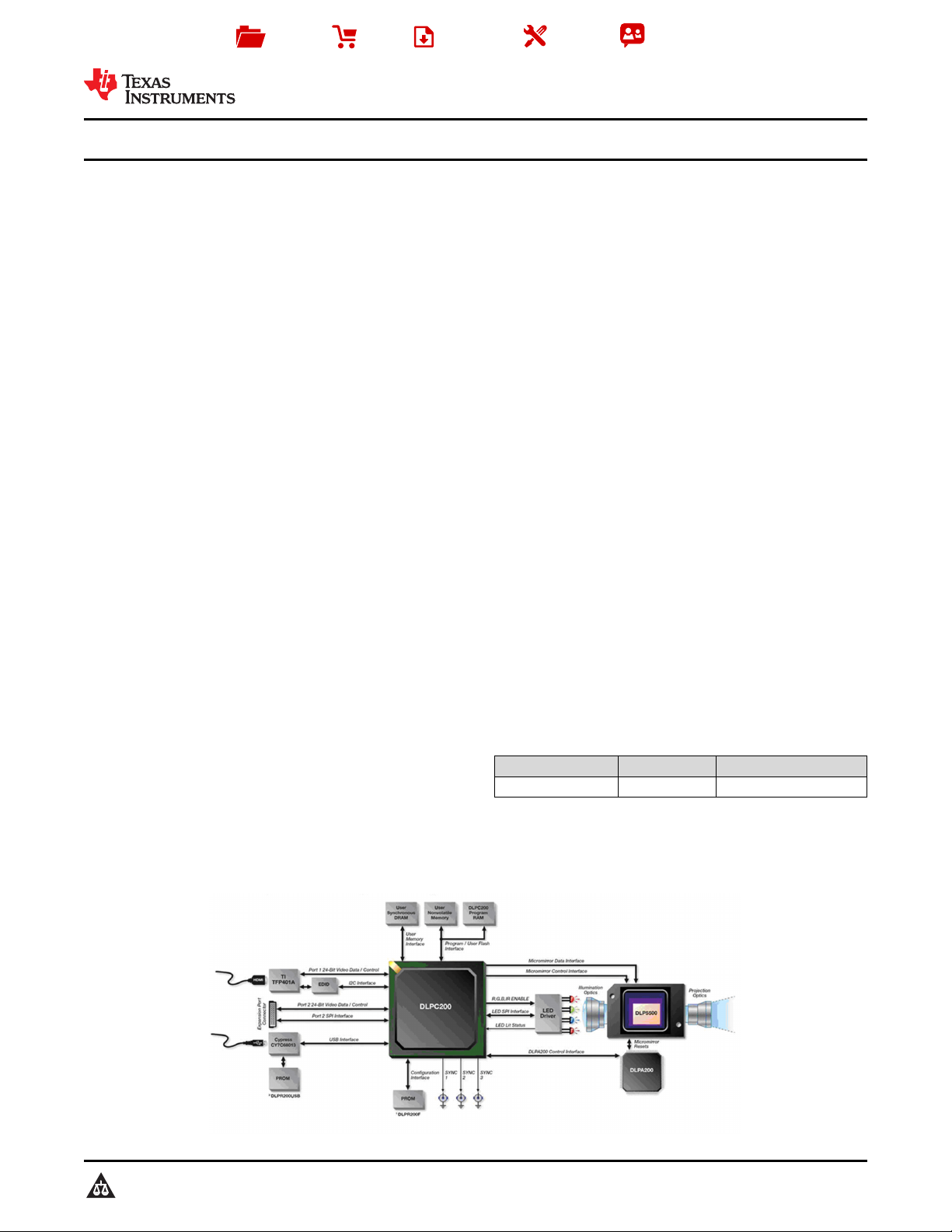

4 Typical Application Schematic

1

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

Page 2

DLP5500

DLPS013G –APRIL 2010–REVISED JANUARY 2019

www.ti.com

Table of Contents

1 Features.................................................................. 1

2 Applications ........................................................... 1

3 Description ............................................................. 1

4 Typical Application Schematic............................. 1

5 Revision History..................................................... 2

6 Description (continued)......................................... 4

7 Pin Configuration and Functions......................... 4

8 Specifications......................................................... 7

8.1 Absolute Maximum Ratings...................................... 7

8.2 Storage Conditions.................................................... 7

8.3 ESD Ratings.............................................................. 7

8.4 Recommended Operating Conditions....................... 8

8.5 Thermal Information................................................ 10

8.6 Electrical Characteristics......................................... 10

8.7 Timing Requirements.............................................. 11

8.8 System Mounting Interface Loads .......................... 15

8.9 Micromirror Array Physical Characteristics............. 16

8.10 Micromirror Array Optical Characteristics............. 17

8.11 Window Characteristics......................................... 18

8.12 Chipset Component Usage Specification ............. 18

9 Detailed Description............................................ 19

9.1 Overview................................................................. 19

9.2 Functional Block Diagram....................................... 20

9.3 Feature Description................................................. 21

9.4 Device Functional Modes........................................ 24

9.5 Window Characteristics and Optics ....................... 24

9.6 Micromirror Array Temperature Calculation............ 25

9.7 Micromirror Landed-on/Landed-Off Duty Cycle...... 27

10 Application and Implementation........................ 29

10.1 Application Information.......................................... 29

10.2 Typical Application................................................ 30

11 Power Supply Recommendations ..................... 32

11.1 DMD Power-Up and Power-Down Procedures..... 32

12 Layout................................................................... 32

12.1 Layout Guidelines ................................................. 32

12.2 Layout Example .................................................... 33

13 Device and Documentation Support................. 34

13.1 Device Support .................................................... 34

13.2 Documentation Support ........................................ 34

13.3 Related Documentation......................................... 34

13.4 Community Resources.......................................... 34

13.5 Trademarks........................................................... 35

13.6 Electrostatic Discharge Caution............................ 35

13.7 Glossary................................................................ 35

14 Mechanical, Packaging, and Orderable

Information........................................................... 35

5 Revision History

Changes from Revision F (May 2015) to Revision G Page

• Changed DMD Marking Image Object for Figure 19 ........................................................................................................... 34

Changes from Revision E (September 2013) to Revision F Page

• Added ESD Ratings, Feature Description section, Device Functional Modes, Application and Implementation

section, Power Supply Recommendations section, Layout section, Device and Documentation Support section, and

Mechanical, Packaging, and Orderable Information section ................................................................................................. 1

• Changed Incorrect V

• Changed LVDS ƒ

• Added Max Recommended DMD Temperature – Derating Curve......................................................................................... 9

• Added LVCMOS Output Measurement Condition Figure..................................................................................................... 10

• Changed Incorrect tCvalue from 4 ns to 5 ns (200 MHz clock) ........................................................................................... 11

• Changed Incorrect tWvalue from 1.25 ns to 2.5 ns (200 MHz clock)................................................................................... 11

• Changed SCP Bus Diagrams............................................................................................................................................... 11

• Added LVDS Voltage Definition Figure ................................................................................................................................ 12

• Changed LVDS Waveform Requirements Figure................................................................................................................. 13

• Added LVDS Equivalent Input Circuit Figure ....................................................................................................................... 13

• Added LVDS & SCP Rise and Fall Time Figures................................................................................................................. 14

• Moved the Mechanical section from Recommended Operating Conditions table to the System Mounting Interface

Loads section ...................................................................................................................................................................... 15

• Added Micromirror Array Physical Characteristics section .................................................................................................. 16

• Changed Micromirror Array Physical Characteristics Figure to generic image (M x N)....................................................... 16

value from 9V to 8V......................................................................................................................... 7

CC2

to200 MHz - previously incorrectly listed as 150 MHz......................................................................... 9

clock

2

Submit Documentation Feedback Copyright © 2010–2019, Texas Instruments Incorporated

Product Folder Links: DLP5500

Page 3

DLP5500

www.ti.com

• Added Micromirror Array Optical Characteristics section .................................................................................................... 17

• Changed specular reflectivity wavelength range to 420 - 700 nm (from 400 - 700 nm) to match Recommended

Operating Conditions............................................................................................................................................................ 17

• Changed Micromirror Landed Orientation and Tilt Figure to generic image (M x N) ........................................................... 18

• Added Window Characteristics section ............................................................................................................................... 18

• Added Chipset Component Usage Specification section .................................................................................................... 18

• Changed Micromirror Array, Pitch, Hinge Axis Orientation Figure to generic image (M x N).............................................. 22

• Changed Micromirror States: On, Off, Flat Figure to generic DMD image .......................................................................... 23

• Changed Test Point locations from TC1 & TC2 to TP1 - TP5 ............................................................................................. 25

• Changed Test Point location Diagram to show TP1 - TP5................................................................................................... 26

• Added Micromirror Landed-on/Landed-Off Duty Cycle section............................................................................................ 27

• Changed Typical Application diagram.................................................................................................................................. 30

• Replaced "DAD" with "DLPA200"......................................................................................................................................... 31

Changes from Revision D (October 2012) to Revision E Page

• Deleted the Device Part Number Nomenclature section...................................................................................................... 34

Changes from Revision C (June 2012) to Revision D Page

DLPS013G –APRIL 2010–REVISED JANUARY 2019

• Changed the Device Part Number Nomenclature From: DLP5500FYA To: DLP5500AFYA............................................... 34

• Updated Mechanical ICD to V2 with a minor change in the window height......................................................................... 34

Changes from Revision B (Spetember 2011) to Revision C Page

• Added the Package Footprint and Socket information in the Features list ........................................................................... 1

• Deleted redundant information from the Description.............................................................................................................. 1

• Changed the Illumination power density Max value of <420 mm From: 20 To: 2 mW/cm2................................................... 7

• Changed Storage temperature range and humidity values in Absolute Maximum Ratings .................................................. 7

• Added Operating Case Temperature, Operating Humidity, Operating Device Temperature Gradient and Operating

Landed Duty-Cycle to RECOMMENDED OPERATING CONDITIONS................................................................................. 8

• Added Mirror metal specular reflectivity and Illumination overfill values to "Micromirror Array Optical Characteristics"

table...................................................................................................................................................................................... 17

• Corrected the C

, Qarray and T

L2W

values in Micromirror Array Temperature Calculation for Uniform Illumination. ...... 26

array

• Corrected the document reference in Related Documents section...................................................................................... 34

Changes from Revision A (June 2010) to Revision B Page

• Changed the window refractive index NOM spec From: 1.5090 To: 1.5119 ....................................................................... 17

• Added table note "At a wavelength of 632.8 nm"................................................................................................................. 17

Changes from Original (April 2010) to Revision A Page

• Changed V

REF

to V

............................................................................................................................................................. 7

CC1

• Added |VID| to the absolute max table.................................................................................................................................... 7

• Added V

to the absolute max table................................................................................................................................ 7

MBRST

• Clarified Note6 measurement point ....................................................................................................................................... 7

• Changed the Illumination power density Max value of <420 mm From: 2 To: 20 mW/cm2................................................... 7

• Added Additional Related Documents.................................................................................................................................. 34

Submit Documentation FeedbackCopyright © 2010–2019, Texas Instruments Incorporated

Product Folder Links: DLP5500

3

Page 4

DLP5500

DLPS013G –APRIL 2010–REVISED JANUARY 2019

www.ti.com

6 Description (continued)

The XGA resolution has the direct benefit of scanning large objects for 3D machine vision applications. Reliable

function and operation of the DLP5500 requires that it be used in conjunction with the DLPC200 digital controller

and the DLPA200 analog driver. This dedicated chipset provides a robust, high resolution XGA, and high speed

system solution.

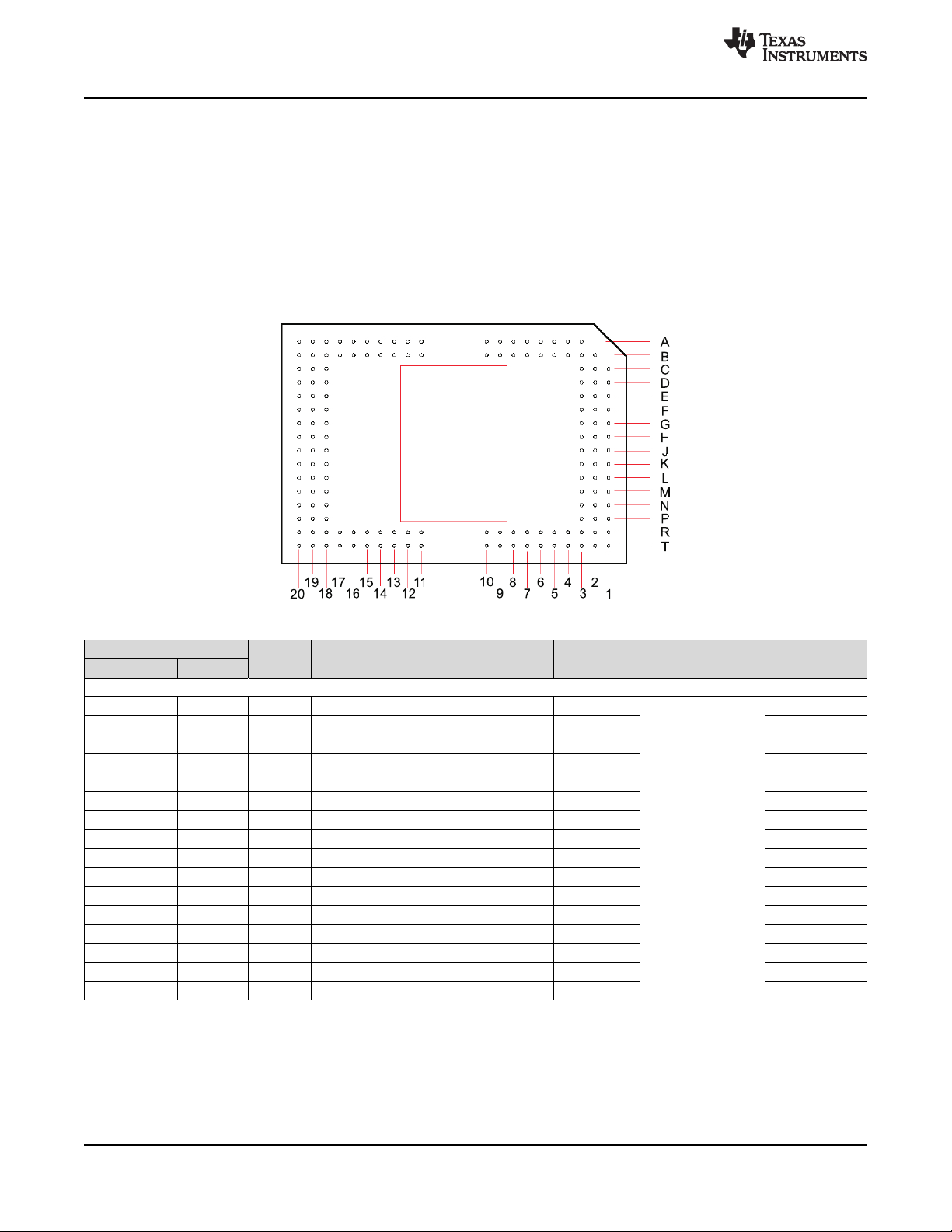

7 Pin Configuration and Functions

FYA Package

149-Pin CPGA Series 450

Bottom View

(1)

Pin Functions

PIN

NAME NO.

DATA INPUTS

D_AN1 G20 Input LVCMOS DDR Differential DCLK_A

D_AP1 H20 Input LVCMOS DDR Differential DCLK_A 744

D_AN3 H19 Input LVCMOS DDR Differential DCLK_A 688

D_AP3 G19 Input LVCMOS DDR Differential DCLK_A 703

D_AN5 F18 Input LVCMOS DDR Differential DCLK_A 686

D_AP5 G18 Input LVCMOS DDR Differential DCLK_A 714

D_AN7 E18 Input LVCMOS DDR Differential DCLK_A 689

D_AP7 D18 Input LVCMOS DDR Differential DCLK_A 705

D_AN9 C20 Input LVCMOS DDR Differential DCLK_A 687

D_AP9 D20 Input LVCMOS DDR Differential DCLK_A 715

D_AN11 B18 Input LVCMOS DDR Differential DCLK_A 715

D_AP11 A18 Input LVCMOS DDR Differential DCLK_A 732

D_AN13 A20 Input LVCMOS DDR Differential DCLK_A 686

D_AP13 B20 Input LVCMOS DDR Differential DCLK_A 715

D_AN15 B19 Input LVCMOS DDR Differential DCLK_A 700

D_AP15 A19 Input LVCMOS DDR Differential DCLK_A 719

(1) The following power supplies are required to operate the DMD: VCC, VCCI, VCC2. VSS must also be connected.

(2) DDR = Double Data Rate. SDR = Single Data Rate. Refer to the Timing Requirements for specifications and relationships.

(3) Refer to Electrical Characteristics for differential termination specification.

(4) Internal Trace Length (mils) refers to the Package electrical trace length. See the DLP®0.55 XGA Chip-Set Data Manual (DLPZ004) for

details regarding signal integrity considerations for end-equipment designs.

4

Submit Documentation Feedback Copyright © 2010–2019, Texas Instruments Incorporated

TYPE

(I/O/P )

SIGNAL

DATA

RATE

INTERNAL

(2)

TERM

(3)

Product Folder Links: DLP5500

CLOCK DESCRIPTION

Input data bus A

(LVDS)

TRACE

(mils)

715

(4)

Page 5

www.ti.com

DLPS013G –APRIL 2010–REVISED JANUARY 2019

Pin Functions (continued)

(1)

PIN

NAME NO.

D_BN1 K20 Input LVCMOS DDR Differential DCLK_B

D_BP1 J20 Input LVCMOS DDR Differential DCLK_B 745

D_BN3 J19 Input LVCMOS DDR Differential DCLK_B 686

D_BP3 K19 Input LVCMOS DDR Differential DCLK_B 703

D_BN5 L18 Input LVCMOS DDR Differential DCLK_B 686

D_BP5 K18 Input LVCMOS DDR Differential DCLK_B 714

D_BN7 M18 Input LVCMOS DDR Differential DCLK_B 693

D_BP7 N18 Input LVCMOS DDR Differential DCLK_B 709

D_BN9 P20 Input LVCMOS DDR Differential DCLK_B 687

D_BP9 N20 Input LVCMOS DDR Differential DCLK_B 715

D_BN11 R18 Input LVCMOS DDR Differential DCLK_B 702

D_BP11 T18 Input LVCMOS DDR Differential DCLK_B 719

D_BN13 T20 Input LVCMOS DDR Differential DCLK_B 686

D_BP13 R20 Input LVCMOS DDR Differential DCLK_B 715

D_BN15 R19 Input LVCMOS DDR Differential DCLK_B 680

D_BP15 T19 Input LVCMOS DDR Differential DCLK_B 700

DCLK_AN D19 Input LVCMOS - Differential –

DCLK_AP E19 Input LVCMOS - Differential – 728

DCLK_BN N19 Input LVCMOS - Differential –

DCLK_BP M19 Input LVCMOS - Differential – 728

DATA CONTROL INPUTS

SCTRL_AN F20 Input LVCMOS DDR Differential DCLK_A

SCTRL_AP E20 Input LVCMOS DDR Differential DCLK_A 731

SCTRL_BN L20 Input LVCMOS DDR Differential DCLK_B 707

SCTRL_BP M20 Input LVCMOS DDR Differential DCLK_B 722

SERIAL COMMUNICATION (SCP) AND CONFIGURATION

SCP_CLK A8 Input LVCMOS – Pull-Down – –

SCP_DO A9 Output LVCMOS – – SCP_CLK –

SCP_DI A5 Input LVCMOS – Pull-Down SCP_CLK –

SCP_EN B7 Input LVCMOS – Pull-Down SCP_CLK –

PWRDN B9 Input LVCMOS – Pull-Down – –

MICROMIRROR BIAS CLOCKING PULSE

MODE_A A4 Input LVCMOS – Pull-Down – –

MBRST0 C3 Input Analog – – –

MBRST1 D2 Input Analog – – – –

MBRST2 D3 Input Analog – – – –

MBRST3 E2 Input Analog – – – –

MBRST4 G3 Input Analog – – – –

MBRST5 E1 Input Analog – – – –

MBRST6 G2 Input Analog – – – –

MBRST7 G1 Input Analog – – – –

MBRST8 N3 Input Analog – – – –

MBRST9 M2 Input Analog – – – –

MBRST10 M3 Input Analog – – – –

MBRST11 L2 Input Analog – – – –

MBRST12 J3 Input Analog – – – –

MBRST13 L1 Input Analog – – – –

MBRST14 J2 Input Analog – – – –

MBRST15 J1 Input Analog – – – –

TYPE

(I/O/P )

SIGNAL

DATA

RATE

INTERNAL

(2)

TERM

(3)

CLOCK DESCRIPTION

Input data bus B

(LVDS)

Input data bus A Clock

(LVDS)

Input data bus B Clock

(LVDS)

Data Control (LVDS)

Micromirror Bias

Clocking Pulse

"MBRST" signals

"clock" micromirrors

into state of LVCMOS

memory cell associated

with each mirror.

DLP5500

TRACE

(4)

(mils)

716

700

700

716

–

Product Folder Links: DLP5500

Submit Documentation FeedbackCopyright © 2010–2019, Texas Instruments Incorporated

5

Page 6

DLP5500

DLPS013G –APRIL 2010–REVISED JANUARY 2019

Pin Functions (continued)

(1)

PIN

NAME NO.

POWER

B11,B12,B1

V

CC

3,B16,R12,

R13,R16,R1

7

A12,A14,A1

V

CCI

V

CC2

6,T12,T14,T16Power Analog – – –

C1,D1,M1,N

1

A6,A11,A13,

A15,A17,B4,

B5,B8,B14,

B15,B17,C2

,C18,C19,F

1,F2,F19,H1

V

SS

,H2,H3,H18,

J18,K1,K2,L

19,N2,P18,

P19,R4,R9,

R14,R15,T7

,T13,T15,T1

7

RESERVED SIGNALS (Not for use in system)

RESERVED_R7 R7 Input LVCMOS – Pull-Down –

RESERVED_R8 R8 Input LVCMOS – Pull-Down – –

RESERVED_T8 T8 Input LVCMOS – Pull-Down – –

RESERVED_B6 B6 Input LVCMOS – Pull-Down – –

A3, A7,

A10, B2,

B3, B10,

E3, F3, K3,

L3, P1, P2,

NO_CONNECT

P3, R1, R2,

R3, R5, R6,

R10, R11,

T1, T2, T3,

T4, T5, T6,

T9, T10,

T11

TYPE

(I/O/P )

SIGNAL

Power Analog – – –

DATA

RATE

INTERNAL

(2)

TERM

(3)

CLOCK DESCRIPTION

Power for LVCMOS

Logic

Power supply for LVDS

Interface

Power Analog – – –

Power Analog – – –

Power for High Voltage

CMOS Logic

Common return for all

power inputs

Pins should be

connected to V

SS

– – – – – DO NOT CONNECT –

www.ti.com

TRACE

(4)

(mils)

–

–

–

–

–

6

Submit Documentation Feedback Copyright © 2010–2019, Texas Instruments Incorporated

Product Folder Links: DLP5500

Page 7

DLP5500

www.ti.com

DLPS013G –APRIL 2010–REVISED JANUARY 2019

8 Specifications

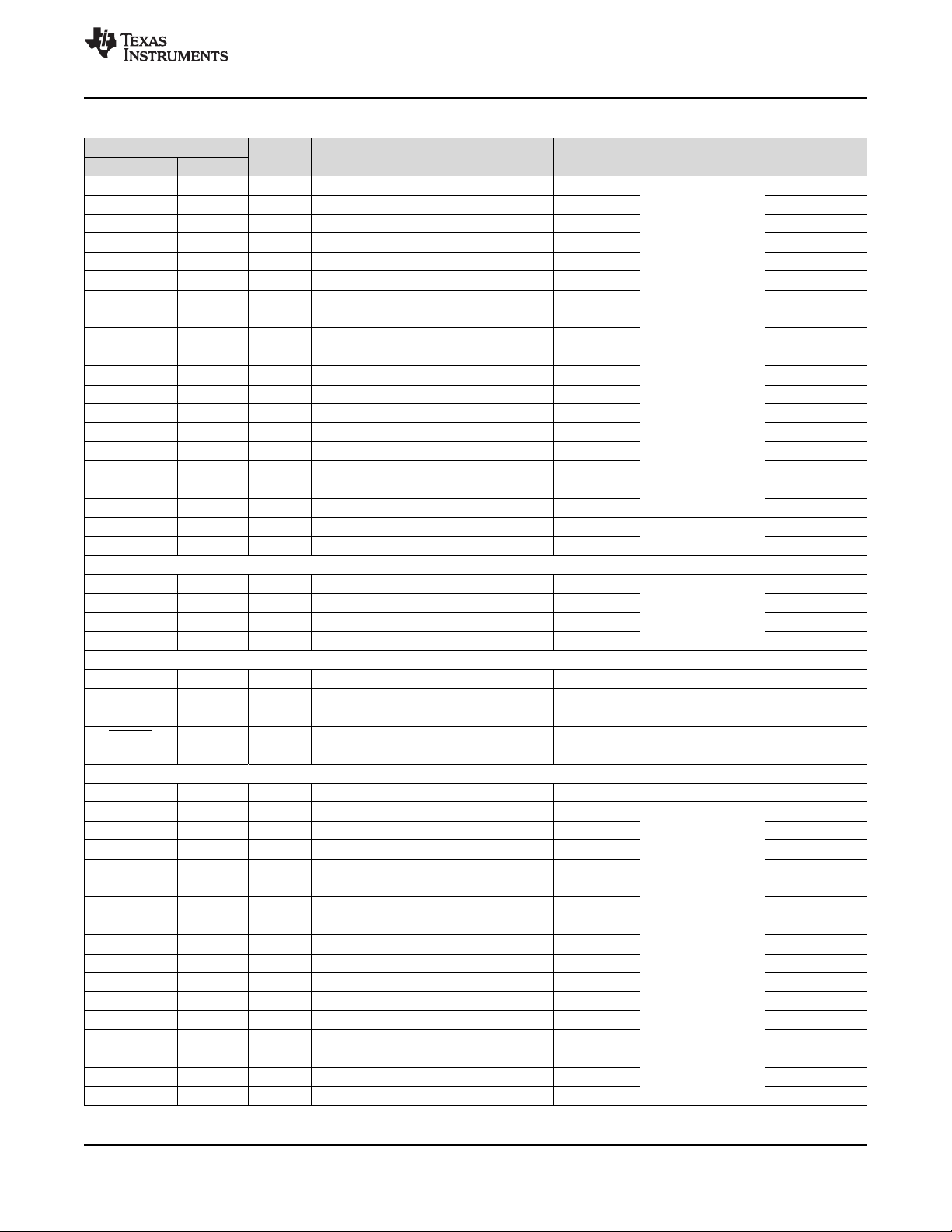

8.1 Absolute Maximum Ratings

over operating free-air temperature range (unless otherwise noted)

ELECTRICAL

V

CC

V

CCI

Voltage applied to V

Voltage applied to V

Delta supply voltage |VCC– V

|VID|

V

CC2

V

MBRST

Maximum differential voltage, Damage can occur to internal resistor if exceeded,

See Figure 6

Voltage applied to V

Voltage applied to MBRST[0:15] Input Pins –28 28 V

Voltage applied to all other pins

I

OH

I

OL

Current required from a high-level

output

Current required from a low-level

output

ENVIRONMENTAL

T

CASE

Case temperature: operational

Case temperature: non–operational

Dew Point (Operating and non-Operating) 81 ºC

(1) Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings

only, which do not imply functional operation of the device at these or any other conditions beyond those indicated under Recommended

Operating Conditions. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

(2) All voltages referenced to VSS(ground).

(3) Voltages VCC, V

(4) Exceeding the recommended allowable absolute voltage difference between VCCand V

CCI

, and V

difference between VCCand V

(5) Exposure of the DMD simultaneously to any combination of the maximum operating conditions for case temperature, differential

temperature, or illumination power density (see Recommended Operating Conditions).

(6) DMD Temperature is the worst-case of any test point shown in Figure 16, or the active array as calculated by the Micromirror Array

Temperature Calculation.

(2)(3)

CC

(2)(3)

CCI

OFFSET

CCI

(2)(3)(4)

(4)

|

(2)

VOH= 2.4 V –20 mA

VOL= 0.4 V 15 mA

(5) (6)

(6)

are required for proper DMD operation.

CC2

, | VCC- V

CCI

|, should be less than .3V.

CCI

(1)

MIN MAX UNIT

–0.5 4 V

–0.5 4 V

0.3 V

700 mV

–0.5 8 V

–0.5 VCC+ 0.3 V

–20 90 ºC

–40 90 ºC

may result in excess current draw. The

CCI

8.2 Storage Conditions

applicable before the DMD is installed in the final product

MIN MAX UNIT

T

stg

T

DP

(1) Long-term is defined as the usable life of the device.

(2) Dew points beyond the specified long-term dew point are for short-term conditions only, where short-term is defined as less than 60

DMD storage temperature –40 80 °C

Storage dew point

Storage Dew Point - long-term

Storage Dew Point - short-term

(1)

(2)

cumulative days over the usable life of the device (operating, non-operating, or storage).

24

28

°C

8.3 ESD Ratings

VALUE UNIT

Electrostatic discharge immunity for LVCMOS [I/O] pins

V

(ESD)

Electrostatic discharge

Human body model (HBM), per ANSI/ESDA/JEDEC JS-001, all other

pins [power, control pins] except MBRST

(2)

Electrostatic discharge immunity for MBRST[0:15] pins

(1) Tested in accordance with JESD22-A114-B Electrostatic Discharge (ESD) sensitivity testing Human Body Model (HBM).

(2) JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process.

Product Folder Links: DLP5500

(1)

±2000

±2000

(1)

<250

Submit Documentation FeedbackCopyright © 2010–2019, Texas Instruments Incorporated

V

7

Page 8

DLP5500

DLPS013G –APRIL 2010–REVISED JANUARY 2019

www.ti.com

8.4 Recommended Operating Conditions

over operating free-air temperature range (unless otherwise noted)

SUPPLY VOLTAGES

V

CC

V

CCI

V

CC2

|V

V

| Supply voltage delta (absolute value)

CCI–VCC

MBRST

(1) (2)

Supply voltage for LVCMOS core logic 3.15 3.3 3.45 V

Supply voltage for LVDS receivers 3.15 3.3 3.45 V

Mirror electrode and HVCMOS supply voltage 8.25 8.5 8.75 V

(3)

Micromirror clocking pulse voltages -27 26.5 V

LVCMOS PINS

V

IH

V

IL

I

OH

I

OL

T

PWRDNZ

High level Input voltage

Low level Input voltage

High level output current at VOH= 2.4 V –20 mA

Low level output current at VOL= 0.4 V 15 mA

PWRDNZ pulse width

(4)

(4)

(5)

SCP INTERFACE

ƒ

clock

t

SCP_SKEW

t

SCP_DELAY

t

SCP_BYTE_INTERVAL

t

SCP_NEG_ENZ

t

SCP_PW_ENZ

t

SCP_OUT_EN

ƒ

clock

SCP clock frequency

Time between valid SCPDI and rising edge of SCPCLK

Time between valid SCPDO and rising edge of SCPCLK

Time between consecutive bytes 1 µs

Time between falling edge of SCPENZ and the first rising edge of SCPCLK 30 ns

SCPENZ inactive pulse width (high level) 1 µs

Time required for SCP output buffer to recover after SCPENZ (from tri-state) 1.5 ns

SCP circuit clock oscillator frequency

(6)

(7)

(7)

(8)

(1) Supply voltages VCC, VCCI, VOFFSET, VBIAS, and VRESET are all required for proper DMD operation. VSS must also be connected.

(2) VOFFSET supply transients must fall within specified max voltages.

(3) To prevent excess current, the supply voltage delta |VCCI – VCC| must be less than specified limit.

(4) Tester Conditions for VIHand VIL:

Frequency = 60MHz. Maximum Rise Time = 2.5 ns at (20% to 80%)

Frequency = 60MHz. Maximum Fall Time = 2.5 ns at (80% to 20%)

(5) PWRDNZ input pin resets the SCP and disables the LVDS receivers. PWRDNZ input pin overrides SCPENZ input pin and tri-states the

SCPDO output pin.

(6) The SCP clock is a gated clock. Duty cycle shall be 50% ± 10%. SCP parameter is related to the frequency of DCLK.

(7) Refer to Figure 3.

(8) SCP internal oscillator is specified to operate all SCP registers. For all SCP operations, DCLK is required.

MIN NOM MAX UNIT

0.3 V

1.7 2.5 VCC + 0.15 V

– 0.3 0.7 V

10 ns

500 kHz

–800 800 ns

700 ns

9.6 11.1 MHz

8

Submit Documentation Feedback Copyright © 2010–2019, Texas Instruments Incorporated

Product Folder Links: DLP5500

Page 9

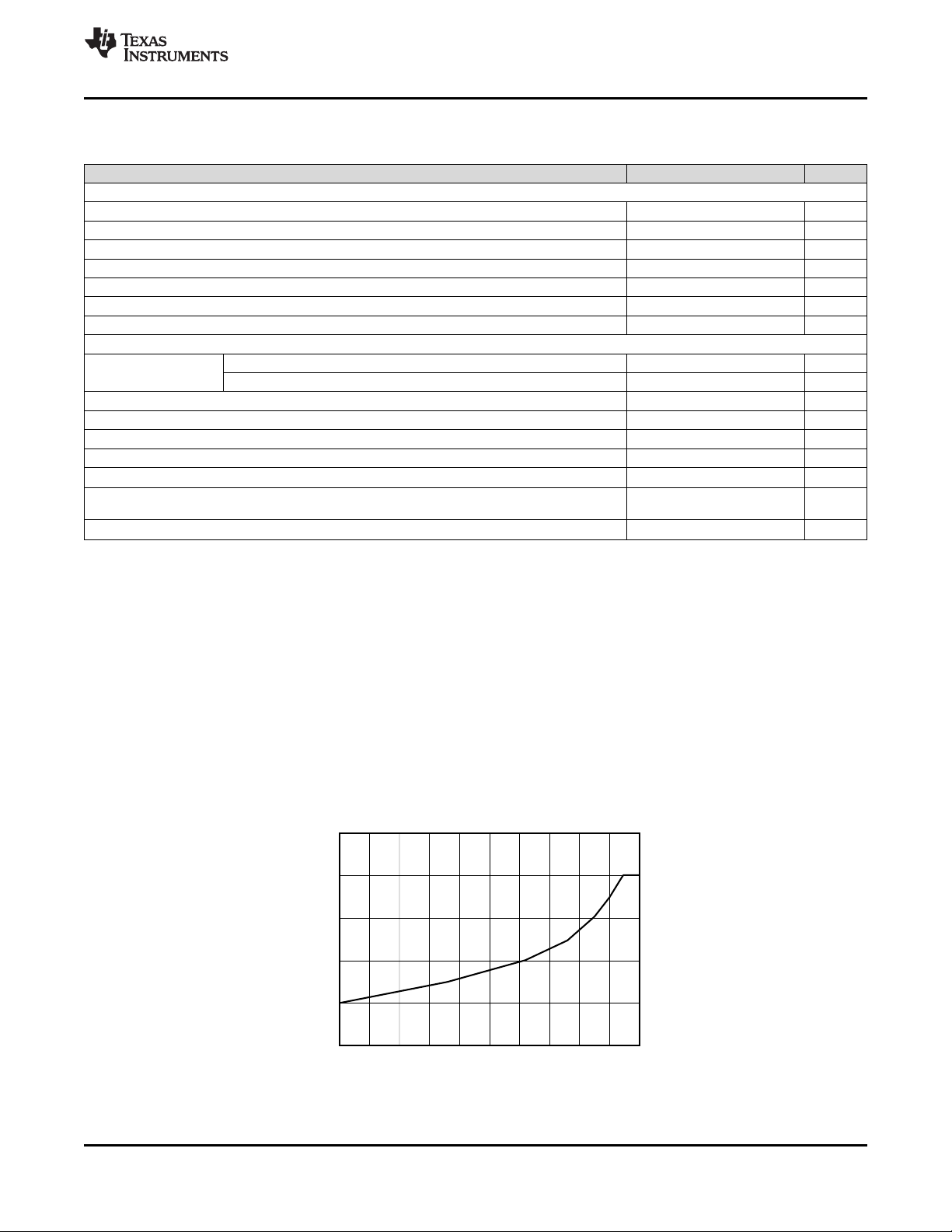

Micromirror Landed Duty Cycle

Operational (°C)

0/100 5/95 10/90 15/85 20/80 25/75 30/70 35/65 40/60 45/55

30

40

50

60

70

80

D001

50/50

100/0 95/5 90/10 85/15 80/20 75/25 70/30 65/35 60/40 55/45

Max Recommended Array Temperature –

DLP5500

www.ti.com

DLPS013G –APRIL 2010–REVISED JANUARY 2019

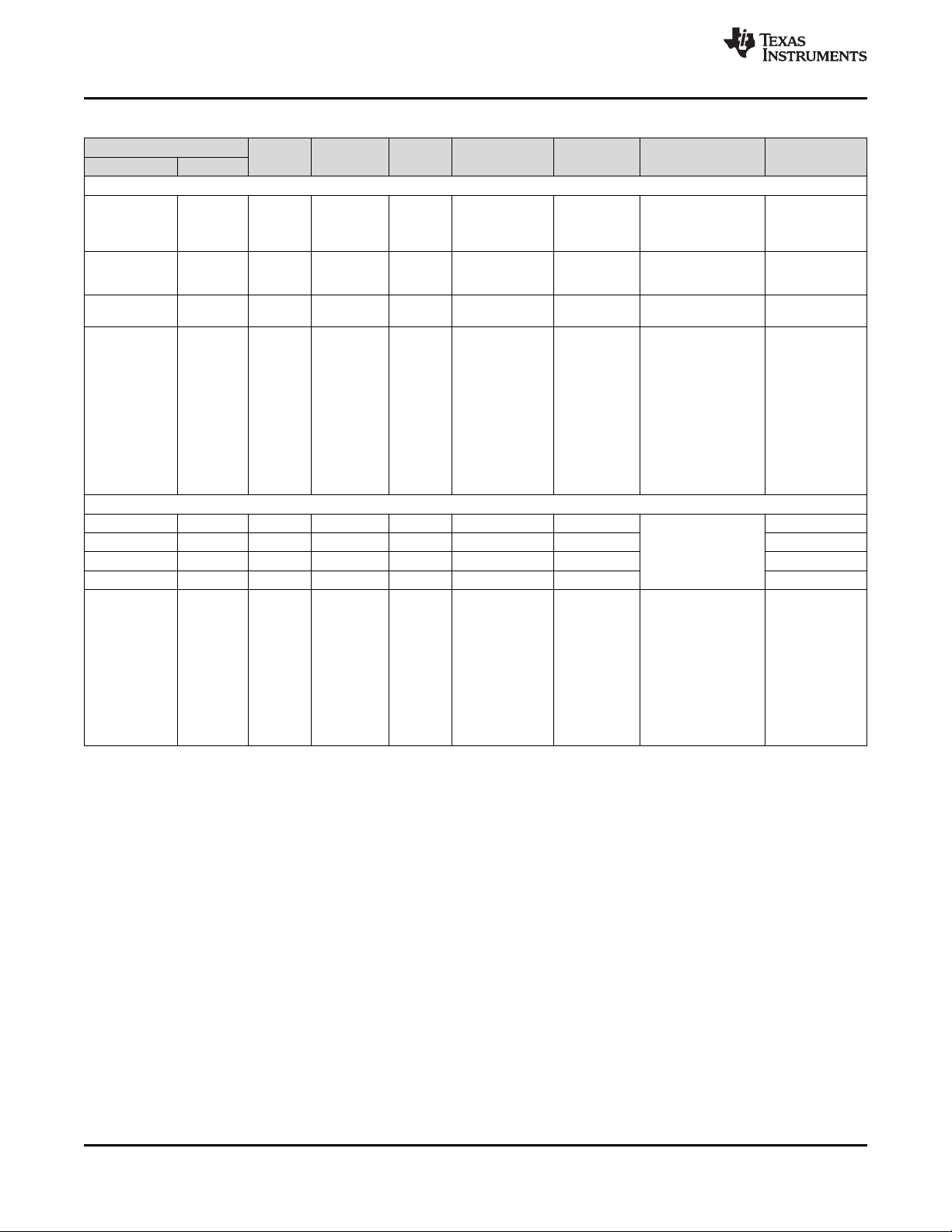

Recommended Operating Conditions (continued)

over operating free-air temperature range (unless otherwise noted)

MIN NOM MAX UNIT

LVDS INTERFACE

ƒ

clock

|VID| Input differential voltage (absolute value)

V

CM

V

LVDS

t

LVDS_RSTZ

Z

IN

Z

LINE

ENVIRONMENTAL

T

DMD

T

WINDOW

T

CERAMIC-WINDOW-DELTA

ILL

UV

ILL

VIS

ILL

IR

(9) Refer to Figure 5, Figure 6, and Figure 7.

(10) Optimal, long-term performance and optical efficiency of the Digital Micromirror Device (DMD) can be affected by various application

parameters, including illumination spectrum, illumination power density, micromirror landed duty-cycle, ambient temperature (storage

and operating), DMD temperature, ambient humidity (storage and operating), and power on or off duty cycle. TI recommends that

application-specific effects be considered as early as possible in the design cycle.

(11) DMD Temperature is the worst-case of any thermal test point in Figure 16, or the active array as calculated by the Micromirror Array

Temperature Calculation for Uniform Illumination.

(12) Per Figure 1, the maximum operational case temperature should be derated based on the micromirror landed duty cycle that the DMD

experiences in the end application. Refer to Micromirror Landed-on/Landed-Off Duty Cycle for a definition of micromirror landed duty

cycle.

(13) Long-term is defined as the average over the usable life of the device.

(14) Short-term is defined as less than 60 cumulative days over the over the usable life of the device.

(15) Window temperature as measured at thermal test points TP2, TP3, TP4 and TP5 in Figure 16.The locations of thermal test points TP2,

TP3, TP4 and TP5 in Figure 16 are intended to measure the highest window edge temperature. If a particular application causes

another point on the window edge to be at a higher temperature, a test point should be added to that location.

(16) Ceramic package temperature as measured at test point 1 (TP 1) in Figure 16.

(17) Dew points beyond the specified long-term dew point (operating, non-operating, or storage) are for short-term conditions only, where

short-term is defined as< 60 cumulative days over the usable life of the device.

(18) Refer to Thermal Information and Micromirror Array Temperature Calculation.

Clock frequency for LVDS interface, DCLK (all channels) 200 MHz

Common mode

LVDS voltage

(9)

(9)

(9)

100 400 600 mV

1200 mV

0 2000 mV

Time required for LVDS receivers to recover from PWRDNZ 10 ns

Internal differential termination resistance 95 105 Ω

Line differential impedance (PWB/trace) 90 100 110 Ω

(10)

(15)

(11) (12) (13)

(11) (14)

10 40 to 70

–20 75 °C

(15) (16)

Long-term DMD temperature (operational)

Short-term DMD temperature (operational)

Window temperature – operational

Delta ceramic-to-window temperature -operational

Long-term dew point (operational & non-operational) 24 °C

Short-term dew point

(13) (17)

(operational & non-operational) 28 °C

Illumination, wavelength < 420 nm 0.68

Illumination, wavelengths between 420 and 700 nm

Thermally

Limited

Illumination, wavelength > 700 nm 10

(12)

90 °C

30 °C

mW/cm

mW/cm

(18)

mW/cm

°C

2

2

2

Figure 1. Max Recommended DMD Temperature – Derating Curve

Product Folder Links: DLP5500

Submit Documentation FeedbackCopyright © 2010–2019, Texas Instruments Incorporated

9

Page 10

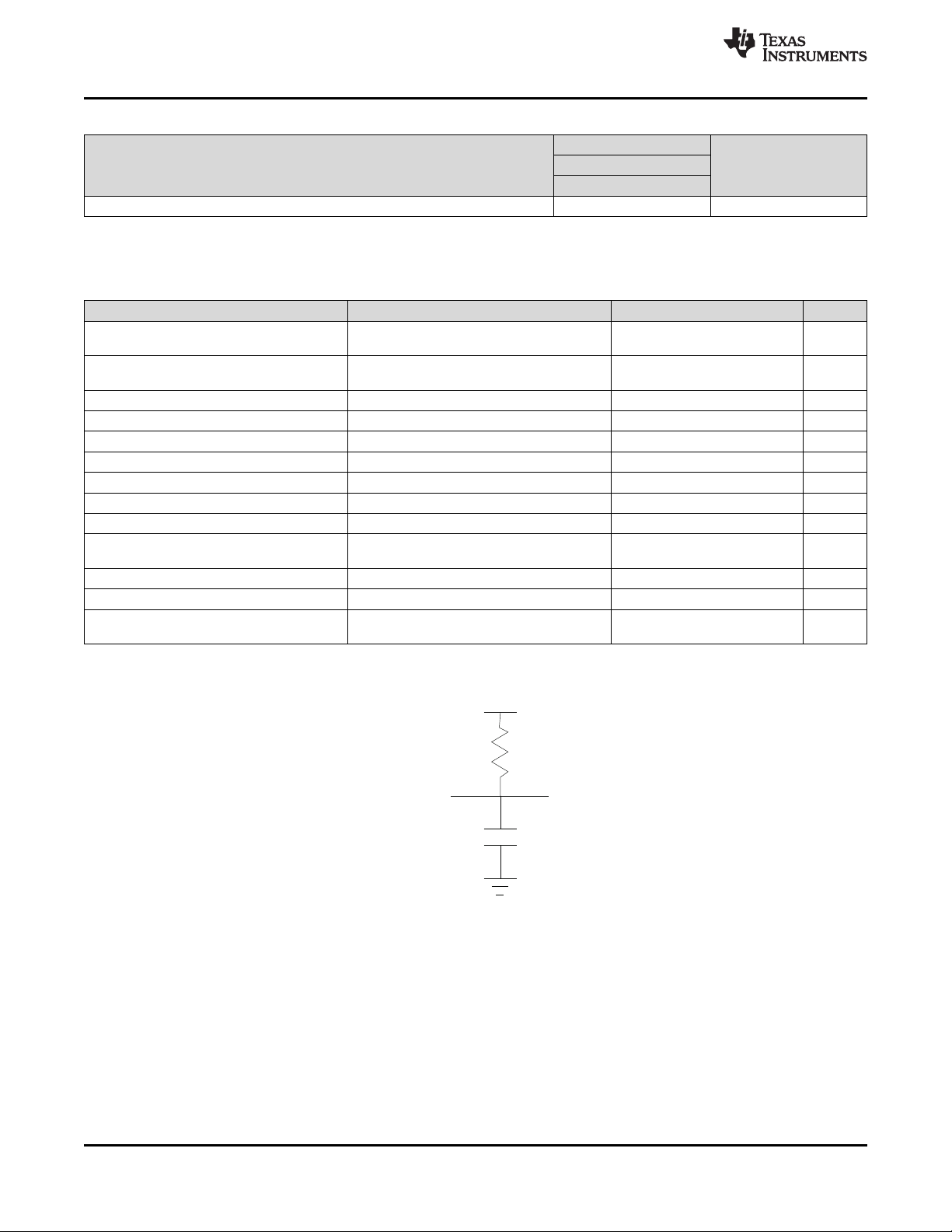

From Output

Under Test

Tester

Channel

LOAD CIRCUIT

C = 50 pF

C = 5 pF for Disable Time

L

L

R

L

DLP5500

DLPS013G –APRIL 2010–REVISED JANUARY 2019

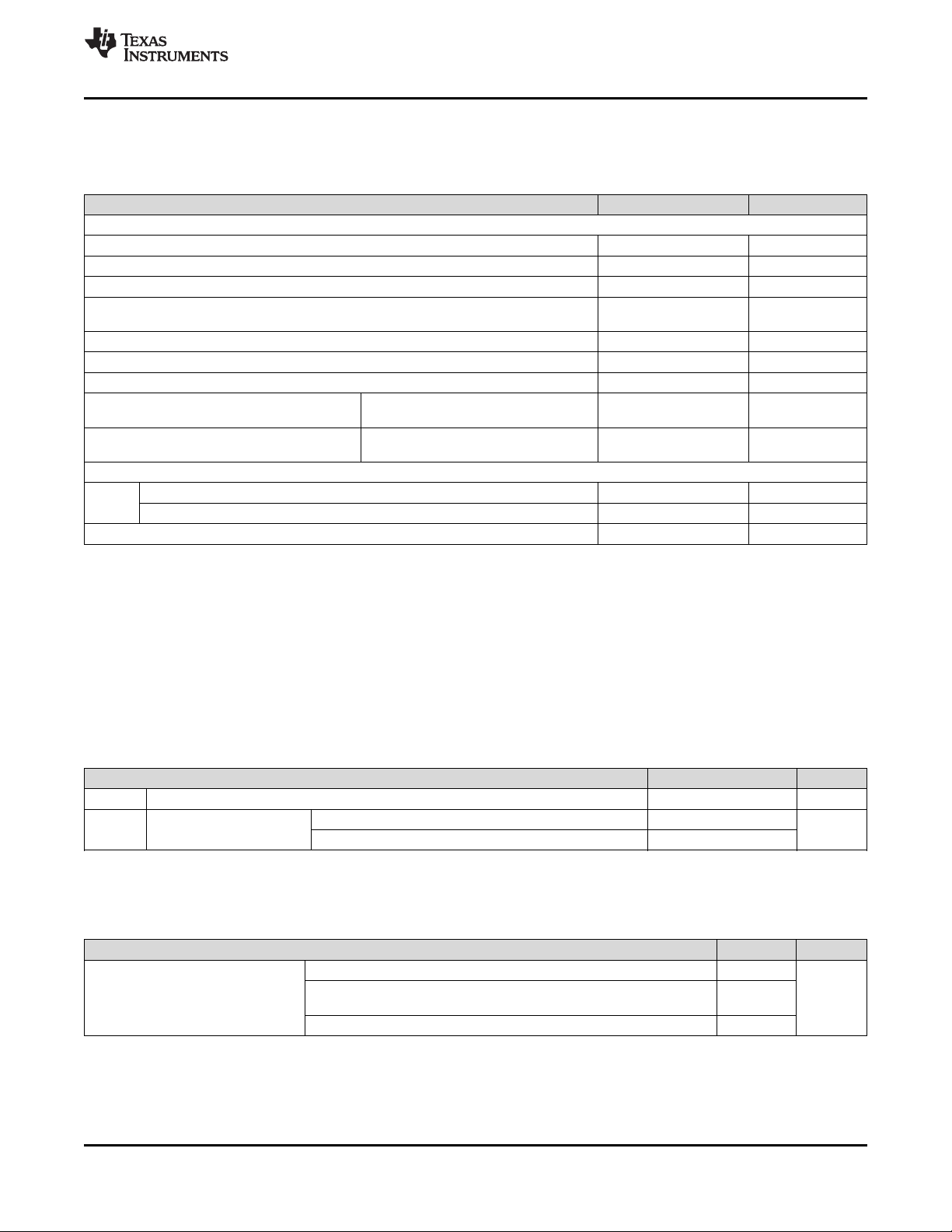

8.5 Thermal Information

THERMAL METRIC

Thermal resistance from active array to specified point on case (TP1)

(1)

(1) For more information, see Micromirror Array Temperature Calculation.

8.6 Electrical Characteristics

over operating free-air temperature range (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

V

I

I

I

I

I

I

Z

Z

C

C

C

OH

OL

OZ

IL

IH

CC

CCI

CC2

IN

LINE

I

O

IM

High-level output voltage

Figure 2

Low-level output voltage

Figure 2

High impedance output current

Low-level input current

High-level input current

Current into VCCpin VCC= 3.6 V, 750 mA

Current into V

Current into V

OFFSET

CC2

Internal Differential Impedance 95 105 Ω

Line Differential Impedance (PWB

or Trace)

Input capacitance

Output capacitance

Input capacitance for

MBRST[0:15] pins

(1) Applies to LVCMOS pins only

(2) Exceeding the maximum allowable absolute voltage difference between VCCand V

Absolute Maximum Ratings for details)

(1)

, See

(1)

, See

(1)

(1)

(1)

(2)

pin

pin V

(1)

(1)

VCC= 3.0 V, IOH= –20 mA 2.4 V

VCC= 3.6 V, IOL= 15 mA 0.4 V

VCC= 3.6 V 10 µA

VCC= 3.6 V, VI= 0 V –60 µA

VCC= 3.6 V, VI= V

V

= 3.6 V 450 mA

CCI

= 8.75V 25 mA

CC2

CC

f = 1 MHz 10 pF

f = 1 MHz 10 pF

f = 1 MHz 160 210 pF

DLP5500

UNITFYA (CPGA)

149 PINS

0.6 °C/W

200 µA

90 100 110 Ω

may result in excess current draw. (Refer to

CCI

www.ti.com

10

Figure 2. Measurement Condition for LVCMOS Output

Submit Documentation Feedback Copyright © 2010–2019, Texas Instruments Incorporated

Product Folder Links: DLP5500

Page 11

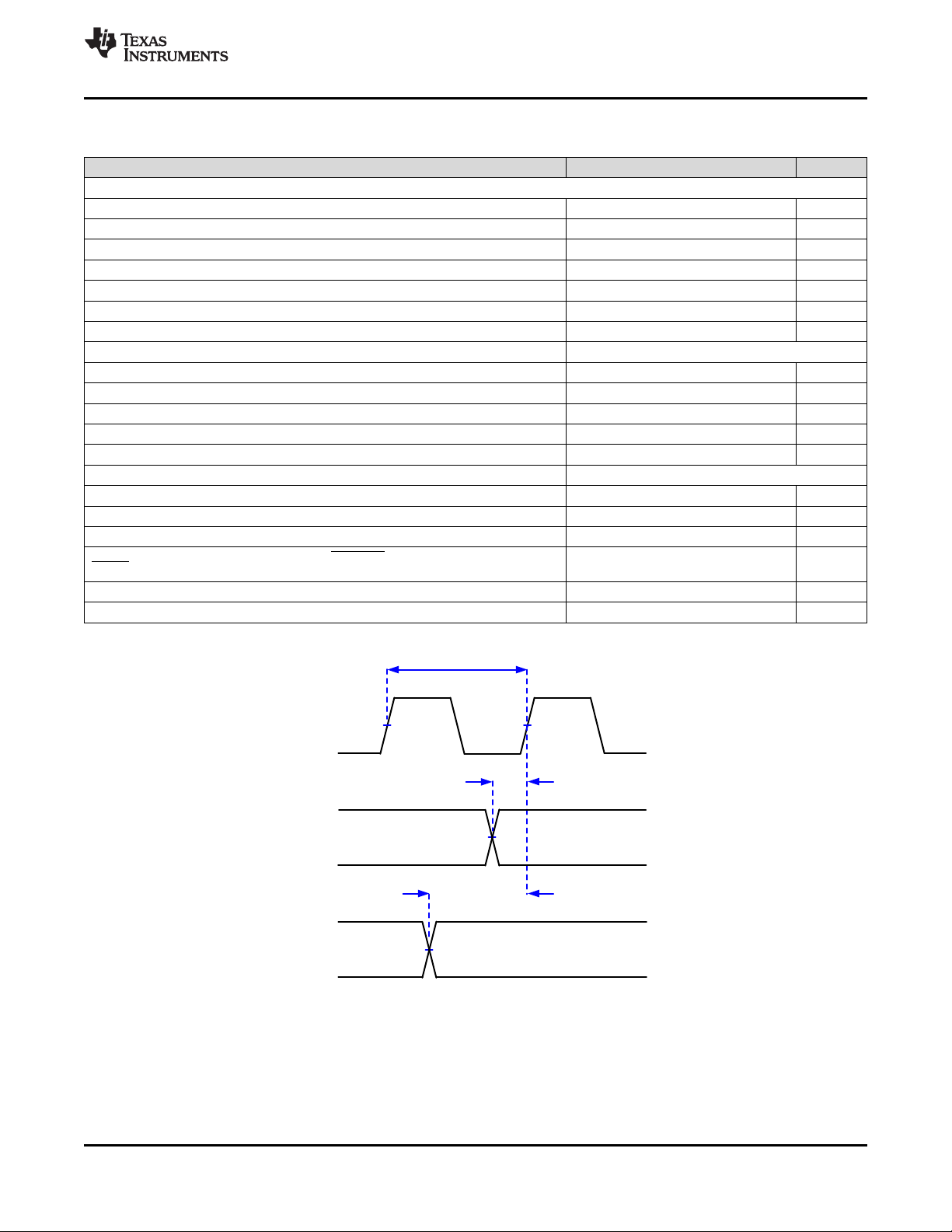

50% 50%

t

c

f

clock

= 1 / t

c

SCPCLK

SCPDI

50%

t

SCP_SKEW

SCPD0

50%

t

SCP_DELAY

DLP5500

www.ti.com

DLPS013G –APRIL 2010–REVISED JANUARY 2019

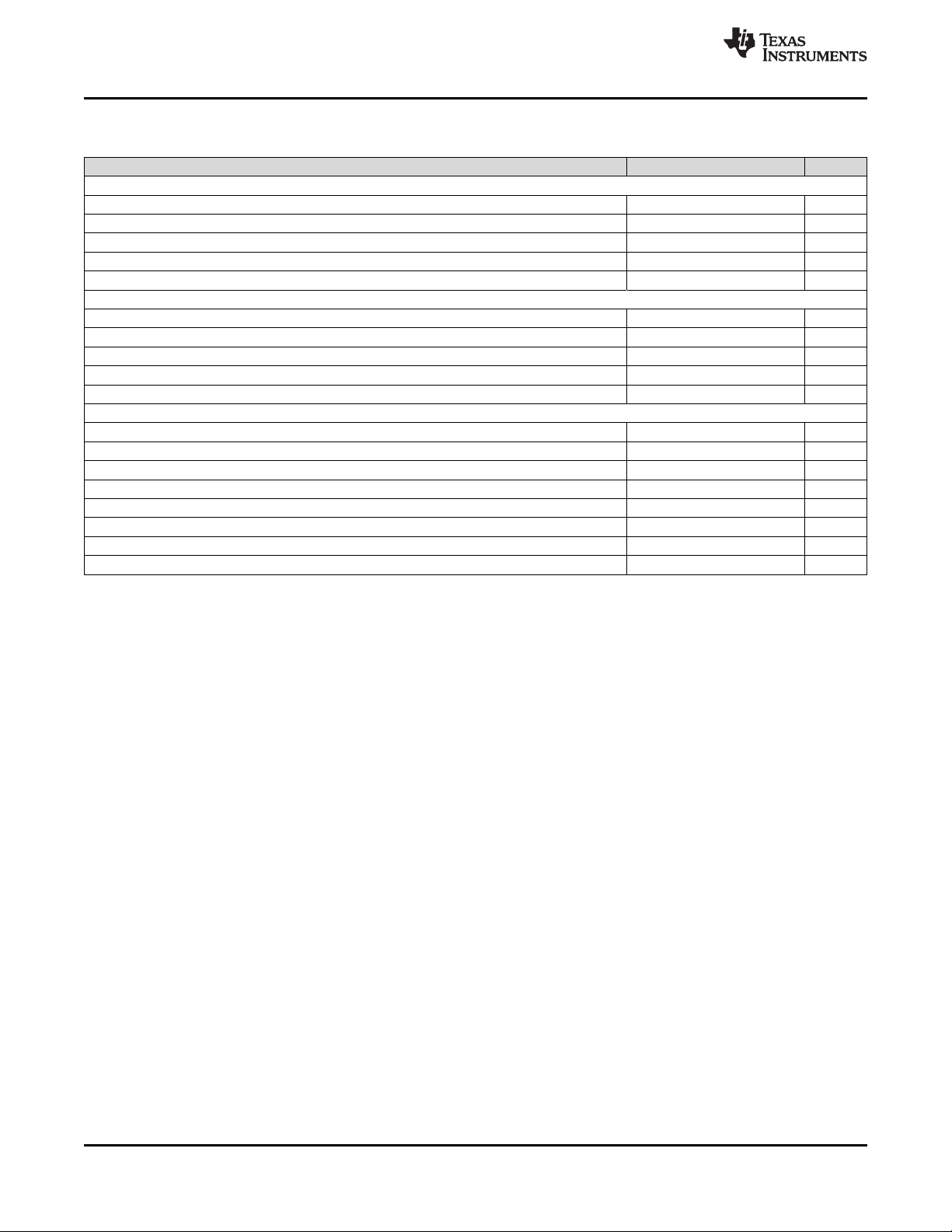

8.7 Timing Requirements

over operating free-air temperature range (unless otherwise noted)

MIN NOM MAX UNIT

LVDS TIMING PARAMETERS (See Figure 9)

t

c

t

w

t

s

t

s

t

h

t

h

t

skew

LVDS WAVEFORM REQUIREMENTS (See Figure 6)

|VID| Input Differential Voltage (absolute difference) 100 400 600 mV

V

CM

V

LVDS

t

r

t

r

SERIAL CONTROL BUS TIMING PARAMETERS (See Figure 3 and Figure 4)

f

SCP_CLK

t

SCP_SKEW

t

SCP_DELAY

t

SCP_EN

t

r_SCP

t

fP

Clock Cycle DLCK_A or DCLKC_B 5 ns

Pulse Width DCLK_A or DCLK_B 2.5 ns

Setup Time, D_A[0:15] before DCLK_A .35 ns

Setup Time, D_B[0:15] before DCLK_B .35 ns

Hold Time, D_A[0:15] after DCLK_A .35 ns

Hold Time, D_B[0:15] after DCLK_B .35 ns

Channel B relative to Channel A –1.25 1.25 ns

Common Mode Voltage 1200 mV

LVDS Voltage 0 2000 mV

Rise Time (20% to 80%) 100 400 ps

Fall Time (80% to 20%) 100 400 ps

SCP Clock Frequency 50 500 kHz

Time between valid SCP_DI and rising edge of SCP_CLK –300 300 ns

Time between valid SCP_DO and rising edge of SCP_CLK 2600 ns

Time between falling edge of SCP_EN and the first rising edge of

SCP_CLK

30 ns

Rise time for SCP signals 200 ns

Fall time for SCP signals 200 ns

Figure 3. Serial Communications Bus Timing Parameters

Product Folder Links: DLP5500

Submit Documentation FeedbackCopyright © 2010–2019, Texas Instruments Incorporated

11

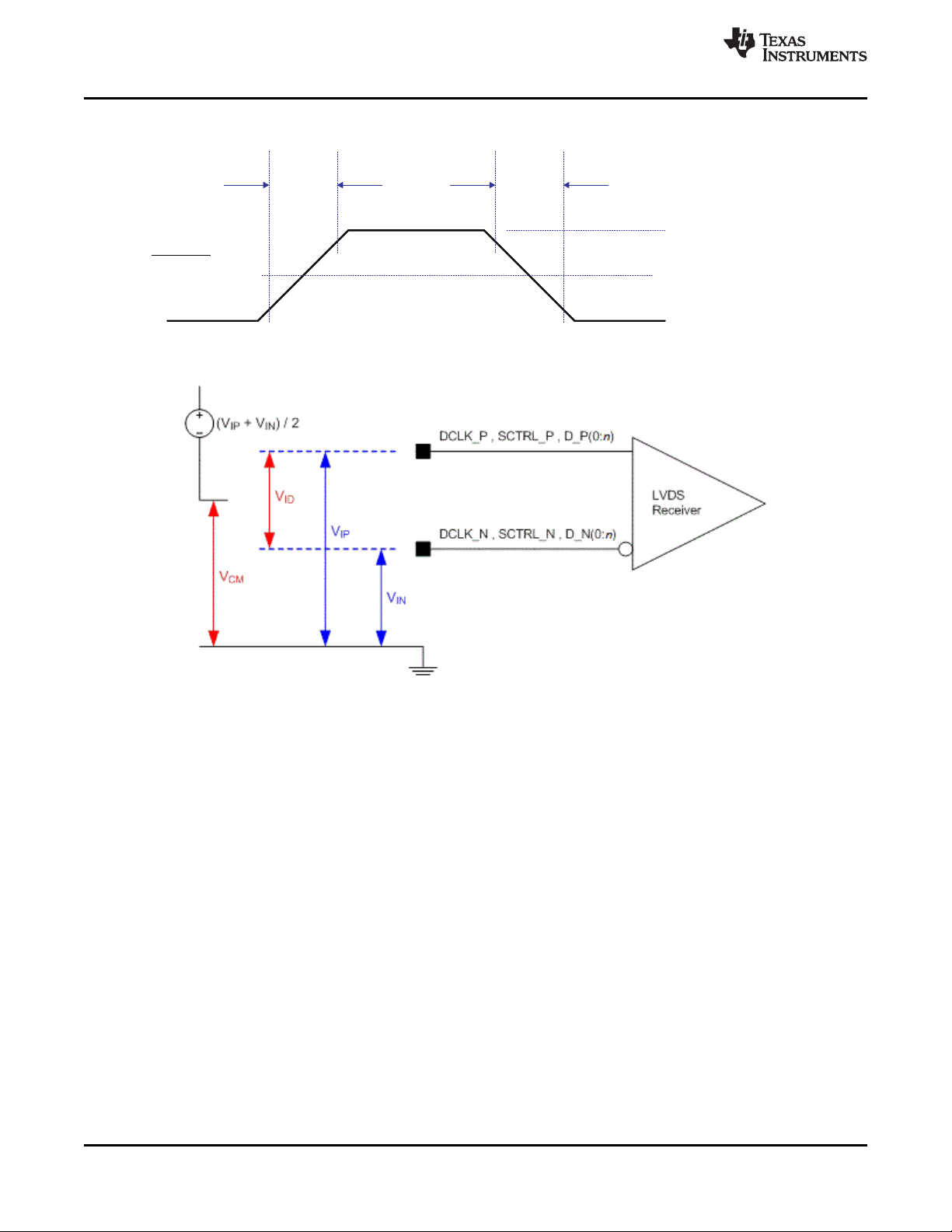

Page 12

V /2

CC

0 v

SCP_CLK,

SCP_DI,

SCP_EN

Input Controller V

CC

t

r_SCP

t

f_SCP

DLP5500

DLPS013G –APRIL 2010–REVISED JANUARY 2019

Figure 4. Serial Communications Bus Waveform Requirements

www.ti.com

12

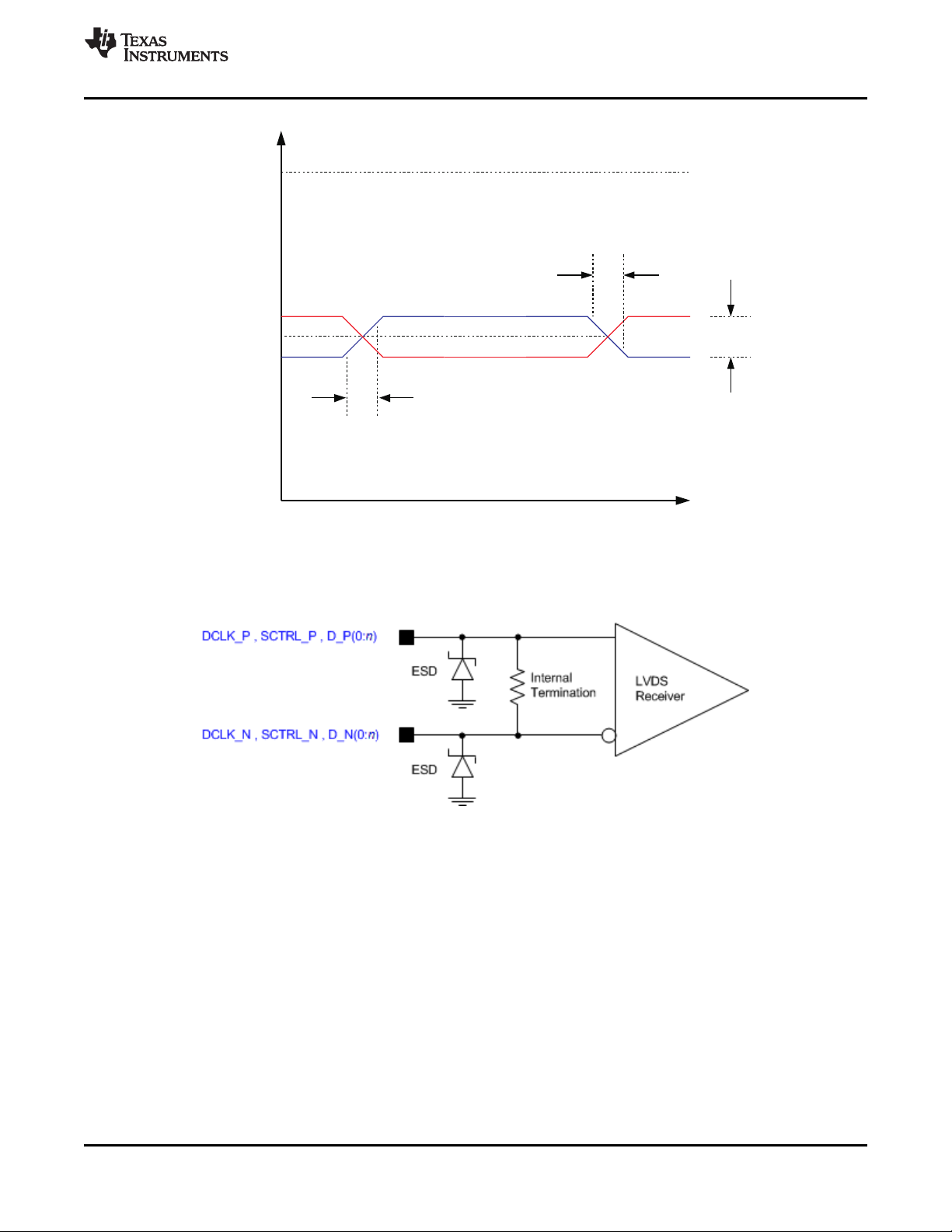

Refer to LVDS Interface section of the Recommended Operating Conditions.

Refer to Pin Configuration and Functions for list of LVDS pins.

Figure 5. LVDS Voltage Definitions (References)

Submit Documentation Feedback Copyright © 2010–2019, Texas Instruments Incorporated

Product Folder Links: DLP5500

Page 13

V

CM

V

LVDS

(v)

V

ID

Tr(20% - 80%)

Tf(20% - 80%)

Time

V

LVDSmax

V

LVDS min

V = V + |½V |

IDLVDSmax CM

V

LVDS

= VCM+/- | 1/2 VID|

V

LVDS min

= 0

www.ti.com

DLP5500

DLPS013G –APRIL 2010–REVISED JANUARY 2019

Not to scale.

Refer to LVDS Interface section of the Recommended Operating Conditions.

Figure 6. LVDS Waveform Requirements

Refer to LVDS Interface section of the Recommended Operating Conditions.

Refer to Pin Configuration and Functions for list of LVDS pins.

Figure 7. LVDS Equivalent Input Circuit

13

Submit Documentation FeedbackCopyright © 2010–2019, Texas Instruments Incorporated

Product Folder Links: DLP5500

Page 14

SCTRL_AN

SCTRL_AP

D_AN(15:0)

D_AP(15:0)

D_BN(15:0)

D_BP(15:0)

DCLK_BN

DCLK_BP

SCTRL_BN

SCTRL_BP

DCLK_AN

DCLK_AP

Tw

Tc

Tw

Th

Th

Ts

Ts

Tskew

Tw

Tc

Tw

Th

Th

Ts

Ts

0.0 * VCC

1.0 * VCC

t

f

t

r

1.0 * V

ID

0.0 * V

ID

V

CM

t

f

t

r

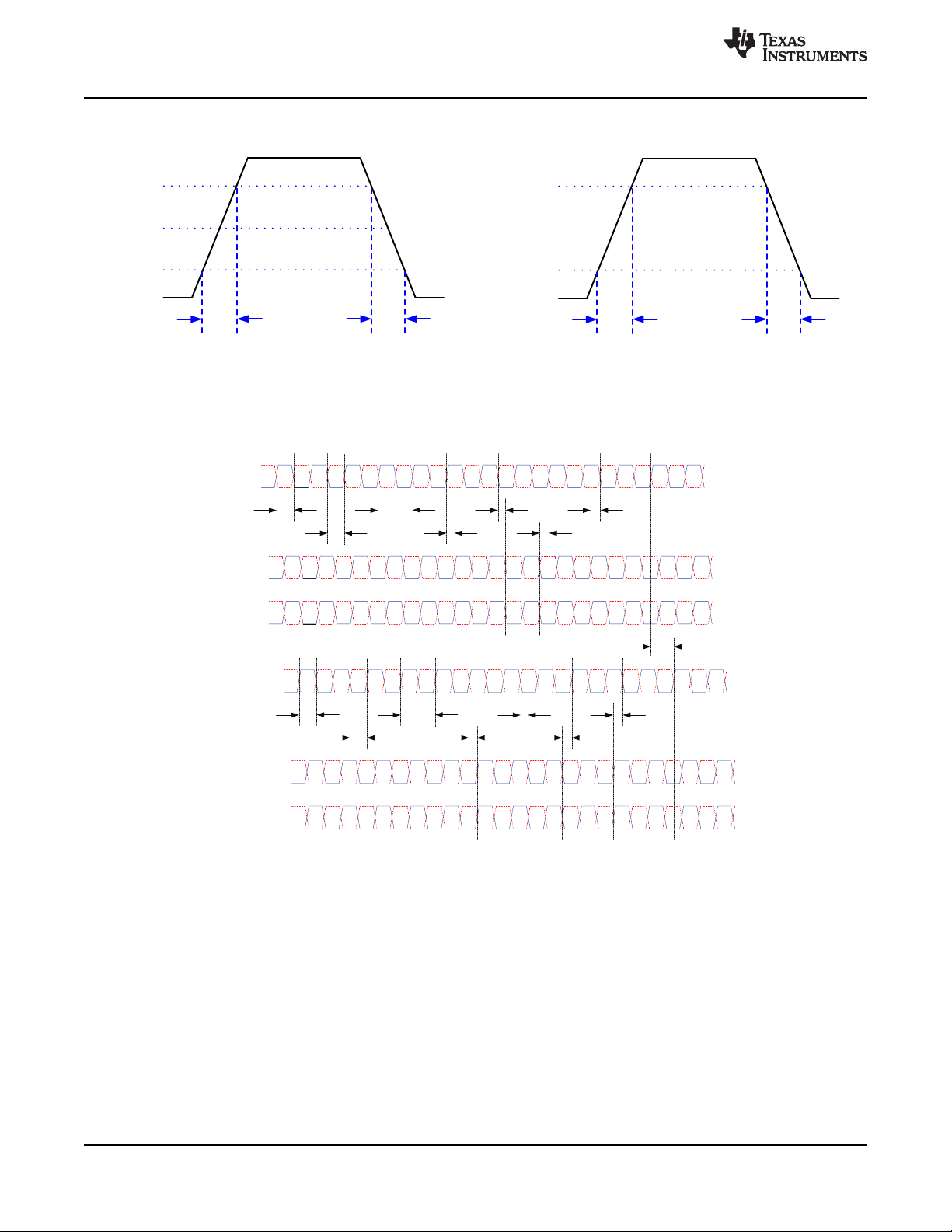

LVDS Interface SCP Interface

DLP5500

DLPS013G –APRIL 2010–REVISED JANUARY 2019

Not to scale.

Refer to the Timing Requirements.

Refer to Pin Configuration and Functions for list of LVDS pins and SCP pins.

www.ti.com

Figure 8. Rise Time and Fall Time

Figure 9. LVDS Timing Waveforms

14

Submit Documentation Feedback Copyright © 2010–2019, Texas Instruments Incorporated

Product Folder Links: DLP5500

Page 15

DLP5500

www.ti.com

DLPS013G –APRIL 2010–REVISED JANUARY 2019

8.8 System Mounting Interface Loads

PARAMETER MIN NOM MAX UNIT

Maximum system mounting interface

load to be applied to the:

Thermal Interface area Static load applied to the

thermal interface area,

See Figure 10

Electrical Interface area Static load applied to

each electrical interface

area no. 1 and no. 2,

See Figure 10

111 N

55 N

Figure 10. System Interface Loads

Product Folder Links: DLP5500

Submit Documentation FeedbackCopyright © 2010–2019, Texas Instruments Incorporated

15

Page 16

N ± 1

012

0

1

2

M ± 1

DMD Active Array

3

N ± 4

3

M ± 2

M ± 3

M ± 4

N ± 2

N ± 3

M x P

N x P

M x N Micromirrors

P

P

P

Border micromirrors omitted for clarity.

Not to scale.

P

Details omitted for clarity.

DLP5500

DLPS013G –APRIL 2010–REVISED JANUARY 2019

www.ti.com

8.9 Micromirror Array Physical Characteristics

Additional details are provided in the Mechanical, Packaging, and Orderable Information section at the end of this

document.

PARAMETER VALUE UNIT

M Number of active micromirror columns

N Number of active micromirror rows 768

P Micromirror pitch 10.8 µm

Micromirror active array width M × P 11.059 mm

Micromirror active array height N × P 8.294 mm

Micromirror active array border

(1) The structure and qualities of the border around the active array includes a band of partially functional micromirrors called the POM.

These micromirrors are structurally and/or electrically prevented from tilting toward the bright or ON state, but still require an electrical

bias to tilt toward OFF.

Pond of

Micromirror

(1)

(POM)

See Micromirror

Array Physical

Characteristics

1024

10 micromirrors /side

micromirrors

16

Submit Documentation Feedback Copyright © 2010–2019, Texas Instruments Incorporated

Refer to the Micromirror Array Physical Characteristics table for M, N, and P specifications.

Figure 11. Micromirror Array Physical Characteristics

Product Folder Links: DLP5500

Page 17

DLP5500

www.ti.com

DLPS013G –APRIL 2010–REVISED JANUARY 2019

8.10 Micromirror Array Optical Characteristics

TI assumes no responsibility for end-equipment optical performance. Achieving the desired end-equipment

optical performance involves making trade-off’s between numerous component and system design parameters.

See the Application Notes for additional details, considerations, and guidelines: DLP System Optics Application

Report (DLPA022).

PARAMETER CONDITIONS MIN NOM MAX UNIT

Micromirror tilt angle, a

Micromirror tilt angle variation, b

Micromirror Cross Over Time

Micromirror Switching Time

Non Operating micromirrors

Orientation of the micromirror axis-of-rotation

Micromirror array optical efficiency

Mirror metal specular reflectivity 420 - 700 89.4% nm

(1)(4) (6)(7)(8)

(9)

(10)

(11)

(12)

(13)(14)

DMD parked state

DMD landed state

See Figure 15 –1 1 degrees

Non-adjacent micromirrors 10

Adjacent micromirrors 0

See 44 45 46 degrees

420 - 700, with all micromirrors in the ON state 68% nm

(1)(2) (3)

, see Figure 15 0

(1)(4) (5)

, see Figure 15 12

degrees

16 22 µs

140 µs

micromirrors

(1) Measured relative to the plane formed by the overall micromirror array

(2) Parking the micromirror array returns all of the micromirrors to an essentially flat (0˚) state (as measured relative to the plane formed by

the overall micromirror array).

(3) When the micromirror array is parked, the tilt angle of each individual micromirror is uncontrolled.

(4) Additional variation exists between the micromirror array and the package datums, as shown in the section at the end of the document.

(5) When the micromirror array is landed, the tilt angle of each individual micromirror is dictated by the binary contents of the CMOS

memory cell associated with each individual micromirror. A binary value of 1 will result in a micromirror landing in an nominal angular

position of +12 degrees. A binary value of 0 will result in a micromirror landing in an nominal angular position of -12 degrees.

(6) Represents the landed tilt angle variation relative to the Nominal landed tilt angle.

(7) Represents the variation that can occur between any two individual micromirrors, located on the same device or located on different

devices.

(8) For some applications, it is critical to account for the micromirror tilt angle variation in the overall System Optical Design. With some

System Optical Designs, the micromirror tilt angle variations within a device may result in perceivable non-uniformities in the light field

reflected from the micromirror array. With some System Optical Designs, the micromirror tilt angle variation between devices may result

in colorimetry variations and/or system contrast variations.

(9) Micromirror Cross Over time is primarily a function of the natural response time of the micromirrors.

(10) Micromirror switching is controlled and coordinated by the DLPC200 (See DLPS014) and DLPA200 (See DLPS015). Nominal Switching

time depends on the system implementation and represents the time for the entire micromirror array to be refreshed.

(11) Non-operating micromirror is defined as a micromirror that is unable to transition nominally from the -12 degree position to +12 degree

or vice versa.

(12) Measured relative to the package datums B and C, shown in the Mechanical, Packaging, and Orderable Information section at the end

of this document.

(13) The minimum or maximum DMD optical efficiency observed in a specific application depends on numerous application-specific design

variables, such as but not limited to:

(a) Illumination wavelength, bandwidth or line-width, degree of coherence

(b) Illumination angle, plus angle tolerance

(c) Illumination and projection aperture size, and location in the system optical path

(d) IIlumination overfill of the DMD micromirror array

(e) Aberrations present in the illumination source and/or path

(f) Aberrations present in the projection path

The specified nominal DMD optical efficiency is based on the following use conditions:

(a) Visible illumination (420 nm – 700 nm)

(b) Input illumination optical axis oriented at 24° relative to the window normal

(c) Projection optical axis oriented at 0° relative to the window normal

(d) f/3.0 illumination aperture

(e) f/2.4 projection aperture

Based on these use conditions, the nominal DMD optical efficiency results from the following four components:

(a) Micromirror array fill factor: nominally 92%

(b) Micromirror array diffraction efficiency: nominally 86%

(c) Micromirror surface reflectivity: nominally 88%

(d) Window transmission: nominally 97% (single pass, through two surface transitions)

(14) Does not account for the effect of micromirror switching duty cycle, which is application dependant. Micromirror switching duty cycle

represents the percentage of time that the micromirror is actually reflecting light from the optical illumination path to the optical projection

path. This duty cycle depends on the illumination aperture size, the projection aperture size, and the micromirror array update rate.

Product Folder Links: DLP5500

Submit Documentation FeedbackCopyright © 2010–2019, Texas Instruments Incorporated

17

Page 18

N ± 1

012

0

1

2

M ± 1

3

N ± 4

3

M ± 2

M ± 3

M ± 4

N ± 2

N ± 3

45°

On-State

Tilt Direction

Off-State

Tilt Direction

Not To Scale

illumination

DLP5500

DLPS013G –APRIL 2010–REVISED JANUARY 2019

Refer to section Micromirror Array Physical Characteristics table for M, N, and P specifications.

Figure 12. Micromirror Landed Orientation and Tilt

www.ti.com

8.11 Window Characteristics

PARAMETER

Window material designation Corning Eagle XG

Window refractive index at wavelength 546.1 nm 1.5119

Window aperture See

Illumination overfill Refer to Illumination Overfill section

Window transmittance, single–pass

through both surfaces and glass

(1) See Window Characteristics and Optics for more information.

(2) For details regarding the size and location of the window aperture, see the package mechanical characteristics listed in the Mechanical

ICD in the Mechanical, Packaging, and Orderable Information section.

(3) See the TI application report Wavelength Transmittance Considerations for DLP®DMD Window DLPA031.

(1)

(2)

CONDITIONS MIN TYP MAX UNIT

At wavelength 405 nm. Applies to 0° and 24° AOI only. 95%

Minimum within the wavelength range 420 nm to 680 nm.

(3)

Applies to all angles 0° to 30° AOI.

Average over the wavelength range 420 nm to 680 nm.

Applies to all angles 30° to 45° AOI.

97%

97%

8.12 Chipset Component Usage Specification

The DLP5500 is a component of one or more DLP chipsets. Reliable function and operation of the DLP5500

requires that it be used in conjunction with the other components of the applicable DLP chipset, including those

components that contain or implement TI DMD control technology. TI DMD control technology is the TI

technology and devices for operating or controlling a DLP DMD.

18

Submit Documentation Feedback Copyright © 2010–2019, Texas Instruments Incorporated

Product Folder Links: DLP5500

Page 19

DLP5500

www.ti.com

DLPS013G –APRIL 2010–REVISED JANUARY 2019

9 Detailed Description

9.1 Overview

DLP5500 is a 0.55 inch diagonal spatial light modulator which consists of an array of highly reflective aluminum

micromirrors. Pixel array size and square grid pixel arrangement are shown in Figure 11.

The DMD is an electrical input, optical output micro-electrical-mechanical system (MEMS). The electrical

interface is Low Voltage Differential Signaling (LVDS), Double Data Rate (DDR).

DLP5500 DMD consists of a two-dimensional array of 1-bit CMOS memory cells. The array is organized in a grid

of M memory cell columns by N memory cell rows. Refer to the Functional Block Diagram.

The positive or negative deflection angle of the micromirrors can be individually controlled by changing the

address voltage of underlying CMOS addressing circuitry and micromirror reset signals (MBRST).

Each cell of the M × N memory array drives its true and complement (‘Q’ and ‘QB’) data to two electrodes

underlying one micromirror, one electrode on each side of the diagonal axis of rotation. Refer to Figure 15. The

micromirrors are electrically tied to the micromirror reset signals (MBRST) and the micromirror array is divided

into reset groups.

Electrostatic potentials between a micromirror and its memory data electrodes cause the micromirror to tilt

toward the illumination source in a DLP projection system or away from it, thus reflecting its incident light into or

out of an optical collection aperture. The positive (+) tilt angle state corresponds to an 'on' pixel, and the negative

(–) tilt angle state corresponds to an 'off' pixel.

Refer to Micromirror Array Optical Characteristics for the ± tilt angle specifications. Refer to the Pin Configuration

and Functions for more information on micromirror clocking pulse (reset) control.

Product Folder Links: DLP5500

Submit Documentation FeedbackCopyright © 2010–2019, Texas Instruments Incorporated

19

Page 20

DLP5500

DLPS013G –APRIL 2010–REVISED JANUARY 2019

9.2 Functional Block Diagram

www.ti.com

20

Figure 13. Functional Block Diagram

Submit Documentation Feedback Copyright © 2010–2019, Texas Instruments Incorporated

Product Folder Links: DLP5500

Page 21

DLP5500

www.ti.com

DLPS013G –APRIL 2010–REVISED JANUARY 2019

9.3 Feature Description

The DLP5500 device consists of 786,432 highly reflective, digitally switchable, micrometer-sized mirrors

(micromirrors) organized in a two-dimensional orthogonal pixel array. Refer to Figure 11 and Figure 14.

Each aluminum micromirror is switchable between two discrete angular positions, –a and +a. The angular

positions are measured relative to the micromirror array plane, which is parallel to the silicon substrate. Refer to

Micromirror Array Optical Characteristics and Figure 15.

The parked position of the micromirror is not a latched position and is therefore not necessarily perfectly parallel

to the array plane. Individual micromirror flat state angular positions may vary. Tilt direction of the micromirror is

perpendicular to the hinge-axis. The on-state landed position is directed toward the left-top edge of the package,

as shown in Figure 14.

Each individual micromirror is positioned over a corresponding CMOS memory cell. The angular position of a

specific micromirror is determined by the binary state (logic 0 or 1) of the corresponding CMOS memory cell

contents, after the mirror clocking pulse is applied. The angular position (–a and +a) of the individual

micromirrors changes synchronously with a micromirror clocking pulse, rather than being coincident with the

CMOS memory cell data update.

Writing logic 1 into a memory cell followed by a mirror clocking pulse results in the corresponding micromirror

switching to the +a position. Writing logic 0 into a memory cell followed by a mirror clocking pulse results in the

corresponding micromirror switching to the – a position.

Updating the angular position of the micromirror array consists of two steps. First, update the contents of the

CMOS memory. Second, apply a micromirror clocking pulse (reset) to all or a portion of the micromirror array

(depending upon the configuration of the system). Micromirror reset pulses are generated externally by the

DLPC200 controller in conjunction with the DLPA200 analog driver, with application of the pulses being

coordinated by the DLPC200 controller.

For more information, see the TI application report DLPA008, DMD101: Introduction to Digital Micromirror Device

(DMD) Technology.

Product Folder Links: DLP5500

Submit Documentation FeedbackCopyright © 2010–2019, Texas Instruments Incorporated

21

Page 22

DMD

Micromirror

Array

0

N±1

0

M±1

Active Micromirror Array

(Border micromirrors eliminated for clarity)

P (um)

Micromirror Pitch

Micromirror Hinge-Axis Orientation

³2Q-6WDWH´

Tilt Direction

³2II-6WDWH´

Tilt Direction

45°

P (um)

P (um)

P (um)

Incident

Illumination

Package Pin

A1 Corner

Details Omitted For Clarity.

Not To Scale.

DLP5500

DLPS013G –APRIL 2010–REVISED JANUARY 2019

Feature Description (continued)

www.ti.com

22

Refer to Figure 11 and Figure 12.

Figure 14. Micromirror Array, Pitch, Hinge Axis Orientation

Submit Documentation Feedback Copyright © 2010–2019, Texas Instruments Incorporated

Product Folder Links: DLP5500

Page 23

DMD

For Reference

Flat-State

( ³SDUNHG´)

Micromirror Position

³2II-6WDWH´

Micromirror

³2Q-6WDWH´

Micromirror

Silicon SubstrateSilicon Substrate

a ± b

-a ± b

Two

³2Q-6WDWH´

Micromirrors

Two

³2II-6WDWH´

Micromirrors

Incident

Illumination-Light Path

Incident

Illumination

-

Light Path

Projected-Light

Path

Off

-

State

-

Light

Path

Package Pin

A1 Corner

Details Omitted For Clarity.

Not To Scale.

Incident

Illumination

Incident

Illumination-Light Path

www.ti.com

Feature Description (continued)

DLP5500

DLPS013G –APRIL 2010–REVISED JANUARY 2019

Micromirror States: On, Off, Flat

Figure 15. Micromirror States: On, Off, Flat

Product Folder Links: DLP5500

Submit Documentation FeedbackCopyright © 2010–2019, Texas Instruments Incorporated

23

Page 24

DLP5500

DLPS013G –APRIL 2010–REVISED JANUARY 2019

www.ti.com

9.4 Device Functional Modes

DMD functional modes are controlled by the DLPC200 digital display controller. See the DLPC200 data sheet

listed in Related Documentation. Contact a TI applications engineer for more information.

The DLPC200 provides two basic functional mode types to control the DLP5500 DMD: video and structured light.

9.4.1 Video Modes

The controller accepts RGB-8-8-8 input to port 1 or port 2 through a selectable MUX. XGA video information is

displayed on the DMD at 6 to 60 fps.

An internal pattern generator can generate RGB-8-8-8 video patterns into an internal selectable MUX for

verification and debug purposes.

9.4.2 Structured Light Modes

The DLPC200 provides two structured light modes: static image buffer and real-time structured light.

9.4.2.1 Static Image Buffer Mode

Image data can be loaded into parallel flash memory to load to DDR2 memory at startup to be displayed, or can

be loaded over USB or the SPI port directly to DDR2 memory to be displayed. Binary (1-bit) or grayscale (8-bit)

patterns can be displayed. The memory will hold 960 binary patterns or 120 grayscale patterns.

Binary (1-bit) patterns can be displayed at up to 5000 binary patterns per second. These patterns assume a

constant illumination and do not depend on illumination modulation

Grayscale (8-bit) patterns assume illumination modulation in order to achieve higher pattern rates. When the

pattern rate requires that the lower significant bit(s) be shorter than the rate that the DMD can be switched, these

bits will require the source to be modulated to achieve the shorter time required. The trade-off is dark time during

these bits. At the maximum 500 Hz grayscale pattern rate, the dark time approaches 75%.

9.4.2.2 Real Time Structured Light Mode

RGB-8-8-8 60 fps data can be input into port 1 or port 2 and reinterpreted as up to 24 binary (1-bit) patterns or

three grayscale (8-bit) patterns. The specified number of patterns is displayed equally during the exposure time

specified. Any unused RGB-8-8-8 data in the video frame must be filled with data, usually 0s.

For example, during one video frame (16.67 ms), 12 binary patterns of the 24 RGB bits are requested to be

displayed during half of the video frame time (exposure time = 8.33 ms). Each of the eight red bits and the four

most significant green bits are displayed as a binary pattern for 694 µs each. The remaining bits are ignored and

the remaining 8.33 ms of the frame will be dark.

9.5 Window Characteristics and Optics

NOTE

TI assumes no responsibility for image quality artifacts or DMD failures caused by optical

system operating conditions exceeding limits described previously.

9.5.1 Optical Interface and System Image Quality

TI assumes no responsibility for end-equipment optical performance. Achieving the desired end-equipment

optical performance involves making trade-offs between numerous component and system design parameters.

Optimizing system optical performance and image quality strongly relate to optical system design parameter

trades. Although it is not possible to anticipate every conceivable application, projector image quality and optical

performance is contingent on compliance to the optical system operating conditions described in the following

sections.

24

Submit Documentation Feedback Copyright © 2010–2019, Texas Instruments Incorporated

Product Folder Links: DLP5500

Page 25

DLP5500

www.ti.com

DLPS013G –APRIL 2010–REVISED JANUARY 2019

Window Characteristics and Optics (continued)

9.5.2 Numerical Aperture and Stray Light Control

The angle defined by the numerical aperture of the illumination and projection optics at the DMD optical area

should be the same. This angle should not exceed the nominal device mirror tilt angle unless appropriate

apertures are added in the illumination and/or projection pupils to block out flat-state and stray light from the

projection lens. The mirror tilt angle defines DMD capability to separate the "ON" optical path from any other light

path, including undesirable flat-state specular reflections from the DMD window, DMD border structures, or other

system surfaces near the DMD such as prism or lens surfaces. If the numerical aperture exceeds the mirror tilt

angle, or if the projection numerical aperture angle is more than two degrees larger than the illumination

numerical aperture angle, objectionable artifacts in the display’s border and/or active area could occur.

9.5.3 Pupil Match

TI’s optical and image quality specifications assume that the exit pupil of the illumination optics is nominally

centered within 2° (two degrees) of the entrance pupil of the projection optics. Misalignment of pupils can create

objectionable artifacts in the display’s border and/or active area, which may require additional system apertures

to control, especially if the numerical aperture of the system exceeds the pixel tilt angle.

9.5.4 Illumination Overfill

The active area of the device is surrounded by an aperture on the inside DMD window surface that masks

structures of the DMD device assembly from normal view. The aperture is sized to anticipate several optical

operating conditions. Overfill light illuminating the window aperture can create artifacts from the edge of the

window aperture opening and other surface anomalies that may be visible on the screen. The illumination optical

system should be designed to limit light flux incident anywhere on the window aperture from exceeding

approximately 10% of the average flux level in the active area. Depending on the particular system’s optical

architecture, overfill light may have to be further reduced below the suggested 10% level in order to be

acceptable.

9.6 Micromirror Array Temperature Calculation

Achieving optimal DMD performance requires proper management of the maximum DMD case temperature, the

maximum temperature of any individual micromirror in the active array, the maximum temperature of the window

aperture, and the temperature gradient between case temperature and the predicted micromirror array

temperature. (see Figure 16).

Refer to the Recommended Operating Conditions for applicable temperature limits.

9.6.1 Package Thermal Resistance

The DMD is designed to conduct absorbed and dissipated heat to the back of the Series 450 package where it

can be removed by an appropriate heat sink. The heat sink and cooling system must be capable of maintaining

the package within the specified operational temperatures, refer to Figure 16. The total heat load on the DMD is

typically driven by the incident light absorbed by the active area; although other contributions include light energy

absorbed by the window aperture and electrical power dissipation of the array.

9.6.2 Case Temperature

The temperature of the DMD case can be measured directly. For consistency, Thermal Test Point locations TP1

- TP5 are defined, as shown in Figure 16.

Product Folder Links: DLP5500

Submit Documentation FeedbackCopyright © 2010–2019, Texas Instruments Incorporated

25

Page 26

DLP5500

DLPS013G –APRIL 2010–REVISED JANUARY 2019

Micromirror Array Temperature Calculation (continued)

www.ti.com

Figure 16. Thermal Test Point Location

9.6.3 Micromirror Array Temperature Calculation for Uniform Illumination

Micromirror array temperature cannot be measured directly; therefore it must be computed analytically from

measurement points (Figure 16), the package thermal resistance, the electrical power, and the illumination heat

load. The relationship between micromirror array temperature and the case temperature are provided by

Equation 1 and Equation 2:

T

Q

Array

Array

= T

= Q

Ceramic

ELE

+ Q

+ (Q

ILL

Array

x R

Array-To-Ceramic

) (1)

Where the following elements are defined as:

• T

• T

• Q

• R

• Q

• Q

= computed micromirror array temperature (°C)

Array

= Ceramic temperature (°C) (TC2 Location Figure 16)

Ceramic

= Total DMD array power (electrical + absorbed) (measured in Watts)

Array

Array-To-Ceramic

= thermal resistance of DMD package from array to TC2 (°C/Watt) (see Package Thermal

Resistance)

= Nominal electrical power (Watts)

ELE

= Absorbed illumination energy (Watts) (2)

ILL

An example calculation is provided below based on a traditional DLP Video projection system. The electrical

power dissipation of the DMD is variable and depends on the voltages, data rates, and operating frequencies.

The nominal electrical power dissipation to be used in the calculation is 2.0 Watts. Thus, Q

= 2.0 Watts. The

ELE

absorbed power from the illumination source is variable and depends on the operating state of the mirrors and

the intensity of the light source. It's based on modeling and measured data from DLP projection system.

Q

= C

L2W

x SL

ILL

Where:

• C

• SL = Screen Lumens nominally measured to be 2000 lumens

• Qarray = 2.0 + (0.00274 x 2000) = 7.48 watts, Estimated total power on micromirror Array

• T

• T

is a Lumens to Watts constant, and can be estimated at 0.00274 Watt/Lumen

L2W

= 55°C, assumed system measurement

Ceramic

(micromirror active array temperature) = 55°C + (7.48 watts x 0.6 °C/watt) = 59.5°C (3)

Array

26

Submit Documentation Feedback Copyright © 2010–2019, Texas Instruments Incorporated

Product Folder Links: DLP5500

Page 27

DLP5500

www.ti.com

DLPS013G –APRIL 2010–REVISED JANUARY 2019

Micromirror Array Temperature Calculation (continued)

For additional explanation of DMD Mechanical and Thermal calculations and considerations please refer to DLP

Series-450 DMD and System Mounting Concepts (DLPA015).

9.7 Micromirror Landed-on/Landed-Off Duty Cycle

9.7.1 Definition of Micromirror Landed-On/Landed-Off Duty Cycle

The micromirror landed-on/landed-off duty cycle (landed duty cycle) denotes the amount of time (as a

percentage) that an individual micromirror is landed in the On–state versus the amount of time the same

micromirror is landed in the Off–state.

As an example, a landed duty cycle of 100/0 indicates that the referenced pixel is in the On-state 100% of the

time (and in the Off-state 0% of the time); whereas 0/100 would indicate that the pixel is in the Off-state 100% of

the time. Likewise, 50/50 indicates that the pixel is On 50% of the time and Off 50% of the time.

Note that when assessing landed duty cycle, the time spent switching from one state (ON or OFF) to the other

state (OFF or ON) is considered negligible and is thus ignored.

Since a micromirror can only be landed in one state or the other (On or Off), the two numbers (percentages)

always add to 100.

9.7.2 Landed Duty Cycle and Useful Life of the DMD

Knowing the long-term average landed duty cycle (of the end product or application) is important because

subjecting all (or a portion) of the DMD’s micromirror array (also called the active array) to an asymmetric landed

duty cycle for a prolonged period of time can reduce the DMD’s usable life.

Note that it is the symmetry/asymmetry of the landed duty cycle that is of relevance. The symmetry of the landed

duty cycle is determined by how close the two numbers (percentages) are to being equal. For example, a landed

duty cycle of 50/50 is perfectly symmetrical whereas a landed duty cycle of 100/0 or 0/100 is perfectly

asymmetrical.

9.7.3 Landed Duty Cycle and Operational DMD Temperature

Operational DMD Temperature and Landed Duty Cycle interact to affect the DMD’s usable life, and this

interaction can be exploited to reduce the impact that an asymmetrical Landed Duty Cycle has on the DMD’s

usable life. This is quantified in the de-rating curve shown in Figure 1. The importance of this curve is that:

• All points along this curve represent the same usable life.

• All points above this curve represent lower usable life (and the further away from the curve, the lower the

usable life).

• All points below this curve represent higher usable life (and the further away from the curve, the higher the

usable life).

In practice, this curve specifies the Maximum Operating DMD Temperature that the DMD should be operated at

for a give long-term average Landed Duty Cycle.

9.7.4 Estimating the Long-Term Average Landed Duty Cycle of a Product or Application

During a given period of time, the Landed Duty Cycle of a given pixel follows from the image content being

displayed by that pixel.

For example, in the simplest case, when displaying pure-white on a given pixel for a given time period, that pixel

will experience a 100/0 Landed Duty Cycle during that time period. Likewise, when displaying pure-black, the

pixel will experience a 0/100 Landed Duty Cycle.

Between the two extremes (ignoring for the moment color and any image processing that may be applied to an

incoming image), the Landed Duty Cycle tracks one-to-one with the gray scale value, as shown in Table 1.

Product Folder Links: DLP5500

Submit Documentation FeedbackCopyright © 2010–2019, Texas Instruments Incorporated

27

Page 28

DLP5500

DLPS013G –APRIL 2010–REVISED JANUARY 2019

www.ti.com

Table 1. Grayscale Value and Landed Duty Cycle

GRAYSCALE VALUE LANDED DUTY CYCLE

0% 0/100

10% 10/90

20% 20/80

30% 30/70

40% 40/60

50% 50/50

60% 60/40

70% 70/30

80% 80/20

90% 90/10

100% 100/0

Accounting for color rendition (but still ignoring image processing) requires knowing both the color intensity (from

0% to 100%) for each constituent primary color (red, green, and/or blue) for the given pixel as well as the color

cycle time for each primary color, where “color cycle time” is the total percentage of the frame time that a given

primary must be displayed in order to achieve the desired white point.

During a given period of time, the landed duty cycle of a given pixel can be calculated as follows:

Landed Duty Cycle = (Red_Cycle_% × Red_Scale_Value) + (Green_Cycle_% × Green_Scale_Value) + (Blue_Cycle_%

× Blue_Scale_Value)

where

• Red_Cycle_%, Green_Cycle_%, and Blue_Cycle_%, represent the percentage of the frame time that Red,

Green, and Blue are displayed (respectively) to achieve the desired white point. (4)

For example, assume that the red, green and blue color cycle times are 50%, 20%, and 30% respectively (in

order to achieve the desired white point), then the Landed Duty Cycle for various combinations of red, green,

blue color intensities would be as shown in Table 2.

Table 2. Example Landed Duty Cycle for Full-Color

Red Cycle Percentage

50%

Red Scale Value Green Scale Value Blue Scale Value

0% 0% 0% 0/100

100% 0% 0% 50/50

0% 100% 0% 20/80

0% 0% 100% 30/70

12% 0% 0% 6/94

0% 35% 0% 7/93

0% 0% 60% 18/82

100% 100% 0% 70/30

0% 100% 100% 50/50

100% 0% 100% 80/20

12% 35% 0% 13/87

0% 35% 60% 25/75

12% 0% 60% 24/76

100% 100% 100% 100/0

Green Cycle Percentage

20%

Blue Cycle Percentage

30%

Landed Duty Cycle

28

Submit Documentation Feedback Copyright © 2010–2019, Texas Instruments Incorporated

Product Folder Links: DLP5500

Page 29

DLP5500

www.ti.com

DLPS013G –APRIL 2010–REVISED JANUARY 2019

10 Application and Implementation

NOTE

Information in the following applications sections is not part of the TI component

specification, and TI does not warrant its accuracy or completeness. TI’s customers are

responsible for determining suitability of components for their purposes. Customers should

validate and test their design implementation to confirm system functionality.

10.1 Application Information

The DLP5500 (0.55-inch XGA DMD) is controlled by the DLPC200 contoller in conjunction with the DLPA200

driver. This combination can be used for a number of applications from 3D printers to microscopes.

The most common application is for 3D structured light measurement applications. In this application, patterns

(binary, grayscale, or even full color) are projected onto the target and the distortion of the patterns are recorded

by an imaging device to extract 3D (x, y, z) surface information.

Product Folder Links: DLP5500

Submit Documentation FeedbackCopyright © 2010–2019, Texas Instruments Incorporated

29

Page 30

Expansion Port

Connector

DLPA200 Control Interface

Micromirror

Resets

Micromirror Data Interface

Micromirror Control Interface

RED ENABLE

GREEN ENABLE

BLUE ENABLE

INFRARED ENABLE

LED Lit Status

LED SPI Interface

Port 2 DATA( 23:0 )

Port 2 VSYNC

Port 2 HSYNC

Port 2 Data Valid

Port 2 Clock

Port 1 DATA( 23:0 )

Port 1 VSYNC

Port 1 HSYNC

Port 1 Data Valid

Port 1 Clock

I2C Interface

Port 1 Interface

Port 2 Interface

DMD Interface

Illumination Interface

DLPA200 Interface

SYNC OUT 1

SYNC OUT 2

SYNC OUT 3

User SYNC Interface

Illumination

Optics

Projection

Optics

Configuration Interface

RESET

SRAM_CE

FLASH_SRAM_OE

FLASH_SRAM_WE

FLASH_SRAM_RST

FLASH_CE

SRAM_LB, SRAM_UB

USB Interface

SDRAM Interface

User Flash / SRAM Interface

Port 2 SPI Interface

HDMI

DLPR200USB PROM

DLPR200USB

DLPR200F PROM

DLPR200F

DLP5500

DLPS013G –APRIL 2010–REVISED JANUARY 2019

www.ti.com

10.2 Typical Application

A schematic is shown in Figure 17 for projecting RGB and IR structured light patterns onto a measurement

target. Typically, an imaging device is triggered through one of the three syncs to record the data as each pattern

is displayed.

30

Figure 17. Typical RGB + IR Structured Light Application

Submit Documentation Feedback Copyright © 2010–2019, Texas Instruments Incorporated

Product Folder Links: DLP5500

Page 31

DLP5500

www.ti.com

DLPS013G –APRIL 2010–REVISED JANUARY 2019

Typical Application (continued)

10.2.1 Design Requirements

All applications using the DLP 0.55-inch XGA chipset require the DLPC200 controller, the DLPA200 driver, and

the DLP5500 DMD for correct operation. The system also requires user supplied SRAM and a configuration

PROM programmed with the DLPR200F program file and a 50-MHz oscillator is for operation. For further details,

refer to the DLPC200 controller data sheet (DLPS014) and the DLPA200 analog driver data sheet (DLPS015).

10.2.2 Detailed Design Procedure

10.2.2.1 DLP5500 System Interface

Images are displayed on the DLP5500 via the DLPC200 controller and the DLPA200 driver. The DLP5500

interface consists of a 200-MHz (nominal) half-bus DDR input-only interface with LVDS signaling. The serial

communications port (SCP), 125-kHz nominal, is used by the DLPC200 to read or write control data to both the

DLP5500 and the DLPA200. The following listed signals support data transfer to the DLP5500 and DLPA200.

• DMD, 200 MHz

– DMD_CLK_AP, DMD_CLK_AN – DMD clock for A

– DMD_CLK_BP, DMD_CLK_BN – DMD clock for B

– DMD_DAT_AP, DMD_DAT_AN(1, 3, 5, 7, 9, 11, 13, 15) – Data bus A (odd-numbered pins are used for

half-bus)

– DMD_DAT_BP, DMD_DAT_BN(1, 3, 5, 7, 9, 11, 13, 15) – Data bus B (odd-numbered pins are used for

half-bus)

– DMD_SCRTL_AP, DMD_SCRTL_AN – S-control for A

– DMD_SCRTL_BP, DMD_SCRTL_BN – S-control for B

• DLPA200, 125 kHz

– SCP_DMD_RST_CLK – SCP clock

– SCP_DMD_EN – Enable DMD communication

– SCP_RST_EN – Enable DLPA200 communication

– SCP_DMD_RST_DI – Input data