Datasheet DK1a1b-L2-9V, DK1a1b-L2-5V, DK1a1b-L2-3V, DK1a1b-L2-24V, DK1a1b-L2-12V Datasheet (NAIS)

...Page 1

VDE

MINIATURE POWER RELAY

20

.787

12.5

.492

10

.394

20

.787

1a 1a1b

15

.591

10

.394

mm inch

SPECIFICATIONS

Contact

Arrangement 1 Form A

Initial contact resistance, max.

(By voltage drop 6 V DC 1A)

Contact material Gold flash over silver alloy

Rating

(resistive)

Expected

life (min.

operations)

Nominal

switching capacity

Max. switching

power

Max. switching

voltage

Max. switching

current

Mechanical 5 × 10

Electrical

(resistive)

10 A 250 V AC

10 A 30 V DC

300 W, 2,500 VA 240 W, 2,000 VA

250 V AC,

30 V DC

10 A 8 A

5

10

(10 A 250 V AC,

10 A 30 V DC)

Coil

Nominal operating power 200 mW

Remarks

* Specifications will vary with foreign standards certification ratings.

1

*

Measurement at same location as "Initial breakdown voltage" section

2

Detection current: 10 mA

*

3

*

Wave is standard shock voltage of ± 1.2 × 50 µ s according to JEC-212-1981

4

Excluding contact bounce time

*

5

*

Half-wave pulse of sine wave: 11ms; detection time: 10 µ s

6

Half-wave pulse of sine wave: 6ms

*

7

*

Detection time: 10 µ s

8

*

Refer to 5. Conditions for operation, transport and storage mentioned in

AMBIENT ENVIRONMENT (Page 61).

2 Form A,

1 Form A

1 Form B

30 m Ω

8 A 250 V AC

8 A 30 V DC

250 V AC,

30 V DC

7

10

(8 A 250 V AC,

8 A 30 V DC)

DK-RELAYS

FEATURES

• Large capacity in small size: 10 A 250 V AC (1a)

• High sensitivity: 200 mW nominal operating power

• High breakdown voltage 4,000 Vrms between contacts and

coil 1,000 Vrms between open contacts Meeting FCC P art 68

• Sealed construction

• Latching types available

Characteristics

Max. operating speed 20 cpm (at rated load)

Initial insulation resistance*

Initial

breakdown

voltage*

Surge voltage between coil and

contact*

Operate time*

Between open

contacts

Between contacts

2

and coil

3

4

1

(at nominal voltage)

Release time (without diode)*

(at nominal voltage)

Temperature rise

(at nominal voltage)

5

Shock

resistance

Vibration

resistance

Functional*

Destructive*

Functional*

Destructive

Conditions for operation, transport and

storange*

8

(Not freezing and

condensing at low

5

6

7

Ambient

temp.

Humidity 5 to 85% R.H.

temperature)

Unit

weight

1 Form A Approx. 5.6 g .20 oz

1 Form A 1 Form B,

2 Form A

Min. 1,000 m Ω (at 500 V DC)

1,000 Vrms

4,000 Vrms

Min. 10,000 V

Max. 10 ms (Approx. 5 ms)

4

Max. 8 ms (Approx. 3 ms)

Max. 40 ° C with nominal coil voltage

and at 10 A switching current

Min. 98 m/s

Min. 980 m/s

88.2 m/s

2

{10 G}

2

{100 G}

2

{9 G}, 10 to 55 Hz

at double amplitude of 1.5 mm

176.4 m/s

2

{18 G}, 10 to 55 Hz

at double amplitude of 3.0 mm

–40 ° C to +65 ° C

–40 ° F to +149 ° F

Approx. 6 g .21 oz

TYPICAL

APPLICATIONS

• Switching power supply

• Power switching for various

OA equipment

• Control or driving relays for industrial

machines (robotics, numerical control

machines, etc.)

• Output relays for programmable logic

controllers, temperature controllers,

timers and so on.

• Home appliances

ORDERING INFORMATION

Ex. DK

Contact arrangement

1a: 1 Form A

2a: 2 Form A

1a1b: 1 Form A 1 Form B

Note: Standard packing Carton: 50 pcs.; Case: 500 pcs.

UL/CSA, TÜV approved type is standard.

1a L2 12V

Operating function Coil voltage

Nil: Single side stable

L2: 2 coil latching

3, 5, 6, 9, 12, 24V

239

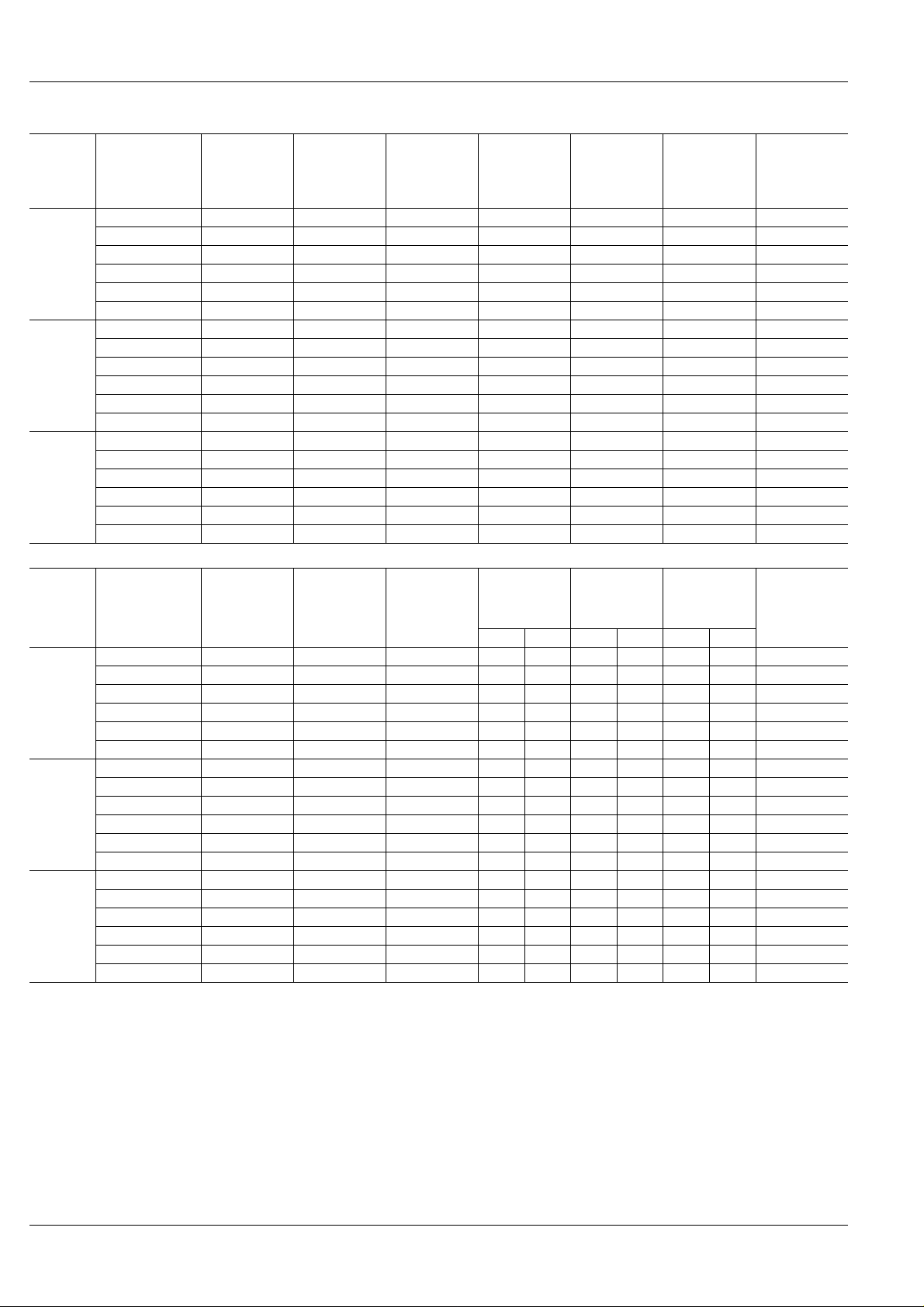

Page 2

Ω ( ±

Ω ( ±

DK

TYPES AND COIL DATA (at 20 ° C 68 ° F)

Single side stable

DK1a-3V 3 2.1 0.3 66.6 45 200 3.9

DK1a-5V 5 3.5 0.5 40 125 200 6.5

1 Form A

1 Form A

1 Form B

2 Form A

DK1a-6V 6 4.2 0.6 33.3 180 200 7.8

DK1a-9V 9 6.3 0.9 22.2 405 200 11.7

DK1a-12V 12 8.4 1.2 16.6 720 200 15.6

DK1a-24V 24 16.8 2.4 8.3 2,880 200 31.2

DK1a1b-3V 3 2.1 0.3 66.6 45 200 3.9

DK1a1b-5V 5 3.5 0.5 40 125 200 6.5

DK1a1b-6V 6 4.2 0.6 33.3 180 200 7.8

DK1a1b-9V 9 6.3 0.9 22.2 405 200 11.7

DK1a1b-12V 12 8.4 1.2 16.6 720 200 15.6

DK1a1b-24V 24 16.8 2.4 8.3 2,880 200 31.2

DK2a-3V 3 2.1 0.3 66.6 45 200 3.9

DK2a-5V 5 3.5 0.5 40 125 200 6.5

DK2a-6V 6 4.2 0.6 33.3 180 200 7.8

DK2a-9V 9 6.3 0.9 22.2 405 200 11.7

DK2a-12V 12 8.4 1.2 16.6 720 200 15.6

DK2a-24V 24 16.8 2.4 8.3 2,880 200 31.2

2 coil latching

DK1a-L2-3V 3 2.1 2.1 66.6 66.6 45 45 200 200 3.9

DK1a-L2-5V 5 3.5 3.5 40 40 125 125 200 200 6.5

1 Form A

1 Form A

1 Form B

2 Form A

DK1a-L2-6V 6 4.2 4.2 33.3 33.3 180 180 200 200 7.8

DK1a-L2-9V 9 6.3 6.3 22.2 22.2 405 405 200 200 11.7

DK1a-L2-12V 12 8.4 8.4 16.6 16.6 720 720 200 200 15.6

DK1a-L2-24V 24 16.8 16.8 8.3 8.3 2,880 2,880 200 200 31.2

DK1a1b-L2-3V 3 2.1 2.1 66.6 66.6 45 45 200 200 3.9

DK1a1b-L2-5V 5 3.5 3.5 40 40 125 125 200 200 6.5

DK1a1b-L2-6V 6 4.2 4.2 33.3 33.3 180 180 200 200 7.8

DK1a1b-L2-9V 9 6.3 6.3 22.2 22.2 405 405 200 200 11.7

DK1a1b-L2-12V 12 8.4 8.4 16.6 16.6 720 720 200 200 15.6

DK1a1b-L2-24V 24 16.8 16.8 8.3 8.3 2,880 2,880 200 200 31.2

DK2a-L2-3V 3 2.1 2.1 66.6 66.6 45 45 200 200 3.9

DK2a-L2-5V 5 3.5 3.5 40 40 125 125 200 200 6.5

DK2a-L2-6V 6 4.2 4.2 33.3 33.3 180 180 200 200 7.8

DK2a-L2-9V 9 6.3 6.3 22.2 22.2 405 405 200 200 11.7

DK2a-L2-12V 12 8.4 8.4 16.6 16.6 720 720 200 200 15.6

DK2a-L2-24V 24 16.8 16.8 8.3 8.3 2,880 2,880 200 200 31.2

Part No.

Part No.

Nominal

voltage,

V DC

Nominal

voltage,

V DC

Pick-up

voltage,

V DC (max.)

Set voltage,

V DC (max.)

V DC (min.)

Reset voltage,

V DC (max.)

Drop-out

voltage,

Nominal

operating

current,

mA ( ± 10%)

Nominal

operating

current,

mA ( ± 10%)

Set Reset Set Reset Set Reset

Coil

resistance,

10%)

Coil

resistance,

10%)

Nominal

operating

power,

mW

Nominal

operating

power,

mW

Maximum

allowable

voltage,

V DC (at 65 ° C

149°F)

Maximum

allowable

voltage,

V DC (at 65 ° C

149°F)

240

Page 3

80 90 10 110 120 130 140

0

1

2

3

4

5

6

7

8

9

Coil applied voltage,%V

Operate/release time, ms

Release time

(with diode)

Operate time

Release time

x

x

Max.

Min.

Max.

Max.

Min.

Min.

x

0

10

20

30

Operate/release time, ms

Distribution frequency

123456

Operate time

Release time

REFERENCE DATA

1. 1 Form A type

1. Maximum operating power 2. Life curve 3. Operate/Release time

100

1,000

Sample: DK1a-24V, 5 pcs.

DK

AC inductive load

10

1

Contact current, A

0.1

(cosϕ= 0.4)

DC inductive load

(L/R = 7 ms)

10 100 1,000

AC resistive load

DC resistive

load

Contact voltage, V

4. Coil temperature rise (at 30 ° C 68 ° F)

Sample: DK1a-12V, 5 pcs.

50

40

30

20

Coil temperature rise, °C

10

0

80 90 100 110 120 130

Coil applied voltage,%V

10 A

7 A

5 A

0 A

100

4

Life, ×10

10

250 V AC inductive load (cosϕ= 0.4)

30 V DC inductive load (L/R = 7 ms)

1

012345678910

250 V AC resistive load

30 V DC resistive load

Contact voltage, V

5. Ambient temperature characteristics

Sample: DK1a-24V, 6 pcs

Ambient temperature: -40 ° C to +80 ° C –40 ° F to

+176 ° F

130

Drop-out

voltage

120

110

Variation ratio, %

100

20

90

80

70

Pick-up

voltage

40 60 800–20–40

Ambient

temperature,°C

6. Operate/Release time (at 20 ° C 68 ° F)

Sample: DK1a-24V (50 pcs.)

7. Contact resistance (at 20 ° C 68 ° F)

Sample: DK1a-24V (50 pcs.)

26

24

22

20

18

16

14

12

Distribution frequency

10

8

6

4

2

0

1.5

2. 1 Form A 1 Form B type, 2 Form A type

1. Maximum operating power 2. Life curve 3. Operate/Release time (at 20 ° C 68 ° F)

AC inductive load

10

5

DC inductive load

Contact current, A

1

0.1

2.5

3.5

2.0

Contact resistance, mΩ

(cosϕ= 0.4)

(L/R = 7 ms)

10 100 1,000

4.5

3.0

4.0

5.0

AC resistive load

DC resistive

load

Contact voltage, V

Sample: DK1a1b-12V, 5 pcs.

1,000

100

4

250 V AC resistive load

Life, ×10

10

250 V AC inductive load (cosϕ= 0.4)

30 V DC inductive load (L/R = 7 ms)

1

012345678910

30 V DC resistive load

Contact current, A

9

8

7

6

5

Operate time

4

3

Operate/release time, ms

2

1

0

80 90 10 110 120 130 140

Release time

(with diode)

Release time

Coil applied voltage,%V

Max.

x

Min.

Max.

x

Min.

Max.

x

Min.

241

Page 4

DK

134

865

-

+

134

865

-

+

4. Coil temperature rise

Sample: DK1a1b-12V, 5 pcs.

Ambient temperature: 20 ° C 68 ° F

50

40

30

20

Coil temperature rise, °C

10

0

80 90 100 110 120 130

Coil applied voltage,%V

8 A

5 A

0 A

5. Ambient temperature characteristics

Pick-up

voltage

130

120

110

Variation ratio, %

100

40 60 800–20–40

Drop-out

voltage

Ambient

temperature,°C

20

90

80

70

DIMENSIONS

1. 1 Form A type

9.7

.382

0.3

.012

0.4

.016

9.7

.382

0.3

.012

0.4

.016

2.54

.100

2. 1 Form A 1 Form B type, 2 Form A type

.787

9.7

.382

0.3

.012

0.4

.016

10.16

.400

0.8

.031

Single side stable type

20

.787

0.8

.031

7.62

10.16

.300

.400

2 coil latching type

20

.787

0.8

0.4

.031

.016

7.62

7.62

.300

.300

General tolerance: ± 0.3 ± .012

Single side stable type

20

0.8

.031

1.11

7.62

.044

.300

3.5

.138

2.42

.095

0.8

.031

1.11

.044

0.8

.031

1.11

.044

3.5

.138

3.5

.138

1.2

.047

1.2

.047

15

.591

10.16

.400

PC board pattern (Copper-side view)

12.5

.492

10.16

.400

12.5

.492

10.16

.400

2.54

.100

10.16

0.4

.016

0.4

.016

.400

10.16

.400

2.54

.100

The above shows 2 coil latching type.

No.5 terminal is eliminated on single side

7.62

.300

7.62

.300

stable type.

Tolerance: ± 0.1 ± .004

PC board pattern (Copper-side view)

7.62

.300

.043 dia.

0.4

.016

10.16

.400

10.16

.400

7.62

.300

7.62

.300

1.1 dia.

(Deenergized condition)

Schematic

1.1 dia.

.043 dia.

(Bottom view)

Single side stable

(Deenergized condition)

134

-

+

6

1.1 dia.

.043 dia.

2 coil latching

(Reset condition)

134

-

++

65

Since this is a polarized relay ,

the connection to the coil

should be done according to

the above schematic.

Schematic (Bottom view)

<1 Form A 1 Form B type>

Single side stable

mm inch

2 coil latching

(Reset condition)

134

-

+7+

865

242

2 coil latching type

.012

0.3

9.7

.382

0.4

.016

2.54

.100

0.6

.024

7.62

.300

20

.787

0.8

.031

7.62

.300

0.8

.031

1.11

.044

3.5

.138

2.42

.095

15

.591

10.16

.400

Note:

Relay out-line and PC board pattern are common for both

1 Form A 1 Form B type and 2 Form A type.

General tolerance: ± 0.3 ± .012

0.4

.016

2.54

.100

10.16

.400

7.62

.300

Tolerance: ± 0.1 ± .004

7.62

.300

1.1 dia.

.043 dia.

Single side stable

(Deenergized condition)

Since this is a polarized relay, the connection

to the coil should be done according to the

above schematic.

2 coil latching

(Reset condition)

134

-

+7+

865

<2 Form A>

Page 5

DK relay socket TYPES AND RELAY COMPATIBILITY

Socket 1 Form A 1 Form A 1 Form B, 2 Form A

Relay

1 Form A

1 Form A 1 Form B

2 Form A

Single side

stable type

Single side stable type DK1a-PS DK1a-PSL2 — —

2 coil latching type — DK1a-PSL2 — —

Single side stable type — — DK2a-PS DK2a-PSL2

2 coil latching type — — — DK2a-PSL2

2 coil

latching type

Single side

stable type

SPECIFICATIONS

Breakdown voltage*

Insulation resistance Min. 1,000 mΩ (at 500 V DC)

Heat resistance 150°C (for 1 hour)

Max. continuous current 10 A (DK1a-PS, DK1a-PSL2), 8 A (DK2a-PS, DK2a-PSL2)

Remarks

*1Detection current: 10 mA

1

4,000 Vrms (Except the portion between coil terminals)

DIMENSIONS

1 Form A type

1 Form A 1 Form B type, 2 Form A type

PC board pattern (Copper-side view)

1 Form A

DK

2 coil

latching type

mm inch

15±0.6

.591±.024

13.7±0.6

.539±.024

0.3±0.1

.012±.004

2.54±0.1

.100±.004

23±0.6

.906±.024

7.62±0.3

.300±.012

0.8

.031

7.62±0.3

.300±.012

17±0.6

.669±.024

6±0.3

.236±.012

3.4±0.3

.134±.012

0.25

.010

10.16±0.3

.400±.012

15±0.6

.591±.024

17±0.6

.669±.024

6±0.3

.236±.012

3.4±0.3

.134±.012

FIXING AND REMOVAL METHOD

1. Match the direction of relay

and socket.

2. Both ends of the rela y are to

be secured firmly so that the

socket hooks on the top surface of the relay.

23±0.6

.906±.024

13.7±0.6

.539±.024

0.3±0.1

7.62±0.3

.300±.012

10.16±0.3

.400±.012

.012±.004

General tolerance: ±0.3 ±.012

3. Remo ve the relay , applying

force in the direction shown

below.

10.16±0.3

.400±.012

12

65

2.54

.100

43

1.2 dia.

.047 dia.

2.54

.100

1 Form A 1 Form B

1.2 dia.

12

87

The above shows 2 coil latching type. No.2 and 5

terminal are eliminated on single side stable type.

43

.047 dia.

65

2.54

.100

2.54

.100

Tolerance: ±0.1 ±.004

4. In case there is not enough

space to grasp relay with fingers, use screwdrivers in the

way shown below.

GOOD NO GOOD

NOTES

1. Phase synchronization of AC-load

switching

In case of switching the contact synchronized with phase of load voltage, the lif e of

contact might be shorter or contact failure

might be caused. Please confirm this

matter in the actual system in this case. If

necessary, the phase control would be

recommended.

Vin

Load

voltage

Vin

Ry

Load

Load

voltage

2. Soldering should be done under the f ollowing conditions:

250°C 482°F within 10s

300°C 572°F within 5s

350°C 662°F within 3s

For Cautions for Use, see Relay Technical Information (Page 48 to 76).

9/1/2000 All Rights Reserved, © Copyright Matsushita Electric Works, Ltd.

Go To Online Catalog

243

Loading...

Loading...