Datasheet DAC08EP, DAC08CS-REEL, DAC08CS, DAC08HP, DAC08ES-REEL Datasheet (Analog Devices)

...Page 1

8-Bit, High-Speed, Multiplying D/A Converter

a

(Universal Digital Logic Interface)

FEATURES

Fast Settling Output Current: 85 ns

Full-Scale Current Prematched to ⴞ1 LSB

Direct Interface to TTL, CMOS, ECL, HTL, PMOS

Nonlinearity to 0.1% Maximum over

Temperature Range

High Output Impedance and Compliance:

–10 V to +18 V

Complementary Current Outputs

Wide Range Multiplying Capability: 1 MHz Bandwidth

Low FS Current Drift: ⴞ10 ppm/ⴗC

Wide Power Supply Range: ⴞ4.5 V to ⴞ18 V

Low Power Consumption: 33 mW @ ⴞ5 V

Low Cost

Available in Die Form

GENERAL DESCRIPTION

The DAC08 series of 8-bit monolithic digital-to-analog converters provide very high-speed performance coupled with low cost

and outstanding applications flexibility.

Advanced circuit design achieves 85 ns settling times with very

low “glitch” energy and at low power consumption. Monotonic

multiplying performance is attained over a wide 20-to-1 reference

current range. Matching to within 1 LSB between reference and

DAC08

full-scale currents eliminates the need for full-scale trimming in

most applications. Direct interface to all popular logic families

with full noise immunity is provided by the high swing, adjustable threshold logic input.

High voltage compliance complementary current outputs are

provided, increasing versatility and enabling differential operation to effectively double the peak-to-peak output swing. In

many applications, the outputs can be directly converted to

voltage without the need for an external op amp.

All DAC08 series models guarantee full 8-bit monotonicity,

and nonlinearities as tight as ± 0.1% over the entire operating

temperature range are available. Device performance is essentially unchanged over the ±4.5 V to ±18 V power supply range,

with 33 mW power consumption attainable at ±5 V supplies.

The compact size and low power consumption make the DAC08

attractive for portable and military/aerospace applications;

devices processed to MIL-STD-883, Level B are available.

DAC08 applications include 8-bit, 1 µs A/D converters, servo

motor and pen drivers, waveform generators, audio encoders

and attenuators, analog meter drivers, programmable power

supplies, CRT display drivers, high-speed modems and other

applications where low cost, high speed and complete input/

output versatility are required.

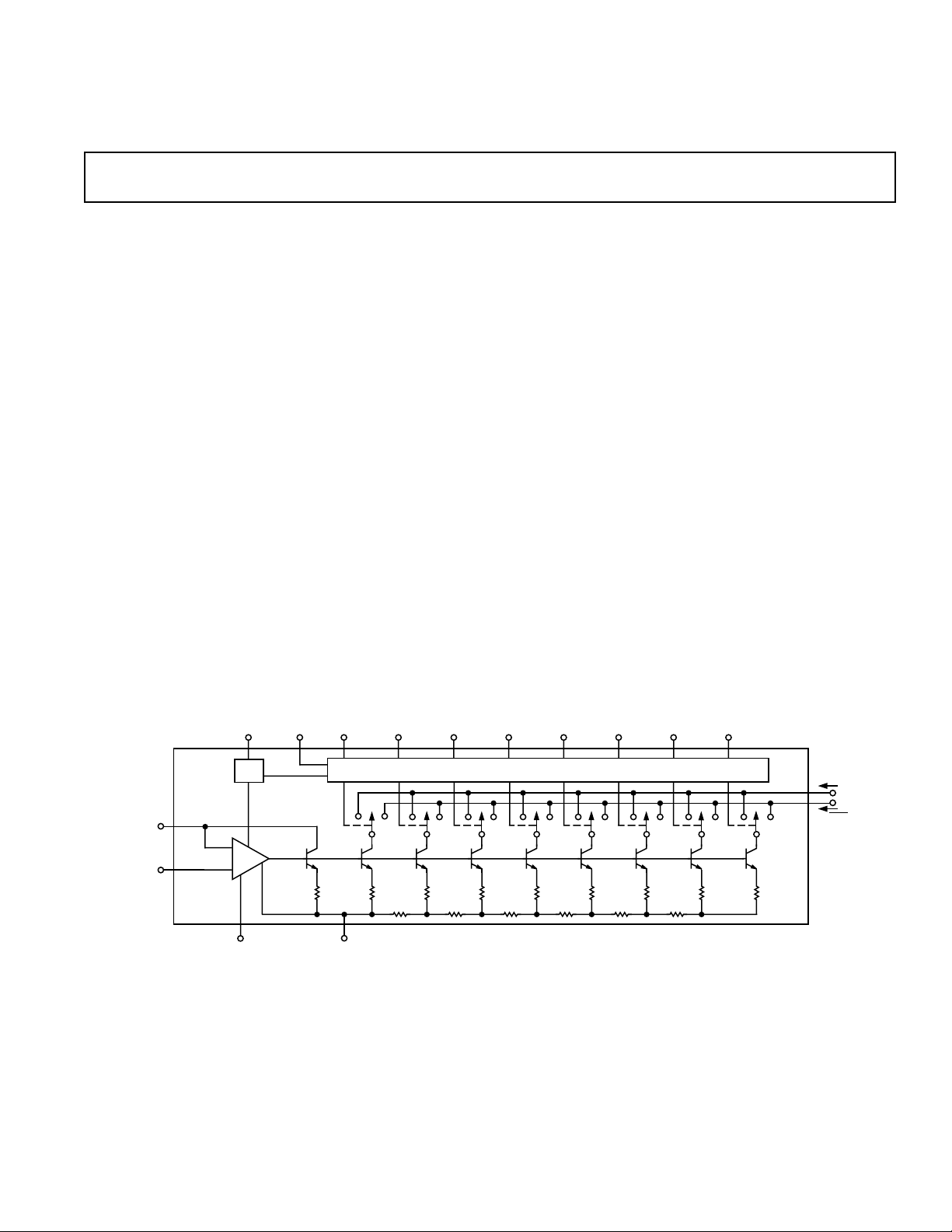

FUNCTIONAL BLOCK DIAGRAM

V+

13 1 5 6 7 8 9 10 11 12

DAC08

BIAS

NETWORK

14

V

(+)

REF

15

V

(–)

REF

REFERENCE

AMPLIFIER

16

COMP

V

LC

CURRENT

SWITCHES

MSB

B1

V–

B2 B3 B4 B5 B6 B7

3

REV. B

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices.

LSB

B8

I

OUT

4

2

I

OUT

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2002

Page 2

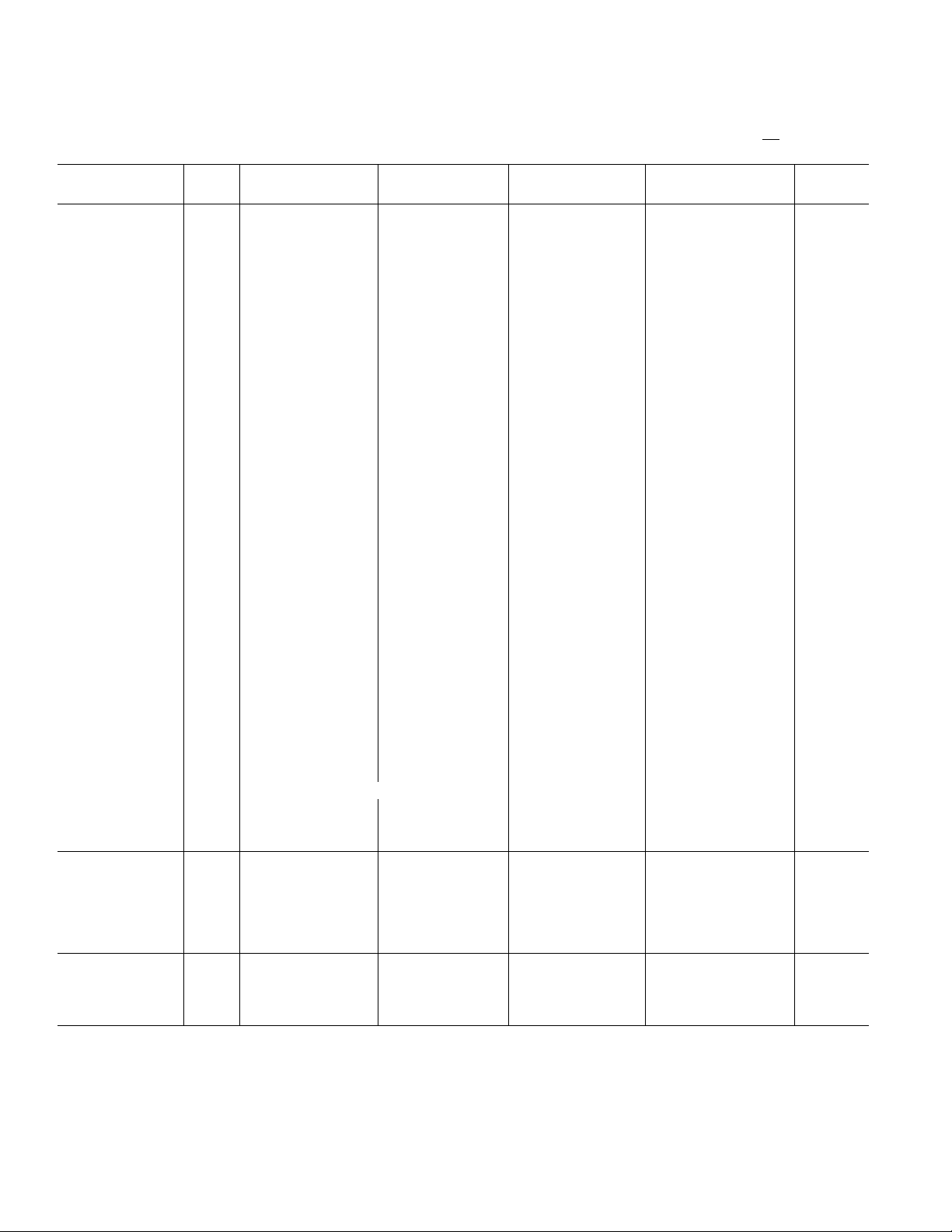

DAC08–SPECIFICATIONS

ELECTRICAL CHARACTERISTICS

for DAC08E and DAC08H, –40ⴗC to +85ⴗC for DAC08C, unless otherwise noted. Output characteristics refer to both I

(@ VS = ⴞ15 V, I

= 2.0 mA, –55ⴗC TA +125ⴗC for DAC08/08A, 0ⴗC TA +70ⴗC

REF

OUT

and

I

.)

OUT

DAC08A/H DAC08E DAC08C

Parameter Symbol Conditions Min Typ Max Min Typ Max Min Typ Max Unit

Resolution 8 8 8 Bits

Monotonicity 8 8 8 Bits

Nonlinearity NL ± 0.1 ± 0.19 ± 0.39 % FS

Settling Time t

Propagation Delay

Each Bit t

All Bits Switched t

Full-Scale Tempco

1

S

PLH

PHL

TCI

To ± 1/2 LSB, 85 135 85 150 85 150 ns

All Bits Switched ON

or OFF, T

TA = 25°C

= 25°C

A

1

1

35 60 35 60 35 60 ns

35 60 35 60 35 60 ns

FS

± 10 ± 50 ± 10 ± 80 ±10 ± 80 ppm/°C

DAC08E ± 50

Output Voltage

Compliance V

Full-Scale Current

OC

(True Compliance) Change <1/2 LSB, –10 +18 –10 +18 –10 +18 V

R

> 20 MΩ typ

Full Range Current I

FR4

OUT

V

= 10.000 V 1.984 1.992 2.000 1.94 1.99 2.04 1.94 1.99 2.04 mA

REF

R14, R15 = 5.000 kΩ

T

= 25°C

Full Range Symmetry I

Zero-Scale Current I

Output Current Range I

I

FRS

ZS

OR1

OR2

A

I

FR4

– I

FR2

± 0.5 ± 4 ± 1 ± 8 ±2 ± 16 µA

0.1 1 0.2 2 0.2 4 µA

R14, R15 = 5.000 kΩ 2.1 2.1 2.1 mA

V

= +15.0 V,

REF

V– = –10 V

V

= +25.0 V, 4.2 4.2 4.2 mA

REF

V– = –12 V

Output Current Noise I

= 2 mA 25 25 25 nA

REF

Logic Input Levels

Logic “0” V

Logic Input “1” V

Logic Input Current V

Logic “0” I

Logic Input “1” I

IL

IH

Logic Input Swing V

Logic Threshold Range V

Reference Bias Current I

15

Reference Input dI/dt R

Slew Rate R

Power Supply Sensitivity PSSI

PSSI

Power Supply Current I+ VS = ± 5 V, I

VLC = 0 V 0.8 0.8 0.8 V

IL

IL

LC

= 0 V

22 2 V

VIN = –10 V to +0.8 V –2 –10 –2 –10 –2 –10 µA

VIN = 2.0 V to 18 V 0.002 10 0.002 10 0.002 10 µA

V– = –15 V –10 +18 –10 +18 –10 +18 V

IS

THR

VS = ± 15 V

1

–10 +13.5 –10 +13.5 –10 +13.5 V

–1 –3 –1 –3 –1 –3 µA

= 200 Ω 4 8 4 8 4 8 mA/µs

EQ

= 100 Ω

L

C

= 0 pF See Fast Pulsed Ref. Info Following.

C

V+ = 4.5 V to 18 V ± 0.0003 ± 0.01 ± 0.0003 ± 0.01 ± 0.0003 ± 0.01 %∆IO/%∆V+

FS+

V– = –4.5 V to –18 V ± 0.002 ± 0.01 ± 0.002 ±0.01 ± 0.002 ± 0.01 %∆IO/%∆V–

FS–

I

= 1.0 mA

REF

= 1.0 mA 2.3 3.8 2.3 3.8 2.3 3.8 mA

REF

1

I– –4.3 –5.8 –4.3 –5.8 –4.3 –5.8 mA

Power Dissipation P

I+ V

I– I

I+ V

I– I

D

= +5 V, –15 V, 2.4 3.8 2.4 3.8 2.4 3.8 mA

S

= 2.0 mA –6.4 –7.8 –6.4 –7.8 –6.4 –7.8 mA

REF

= ±15 V, 2.5 3.8 2.5 3.8 2.5 3.8 mA

S

= 2.0 mA –6.5 –7.8 –6.5 –7.8 –6.5 –7.8 mA

REF

± 5 V, I

= 1.0 mA 33 48 33 48 33 48 mW

REF

+5 V, –15 V,

I

= 2.0 mA 108 136 103 136 108 136 mW

REF

± 15 V, I

NOTES

1

Guaranteed by design.

Specifications subject to change without notice.

= 2.0 mA 135 174 135 174 135 174 mW

REF

–2–

REV. B

Page 3

DAC08

WARNING!

ESD SENSITIVE DEVICE

TYPICAL ELECTRICAL CHARACTERISTICS

(@ VS = ⴞ15 V, and I

characteristics apply to both I

= 2.0 mA, unless otherwise noted. Output

REF

OUT

and

I

.)

OUT

All Grades

Parameter Symbol Conditions Typical Unit

Reference Input Slew Rate dI/dt 8 mA/µs

Propagation Delay t

Settling Time t

PLH

S

, t

PHL

TA = 25°C, Any Bit 35 ns

To ± 1/2 LSB, All Bits

Switched ON or OFF, 85 ns

TA = 25°C

Specifications subject to change without notice.

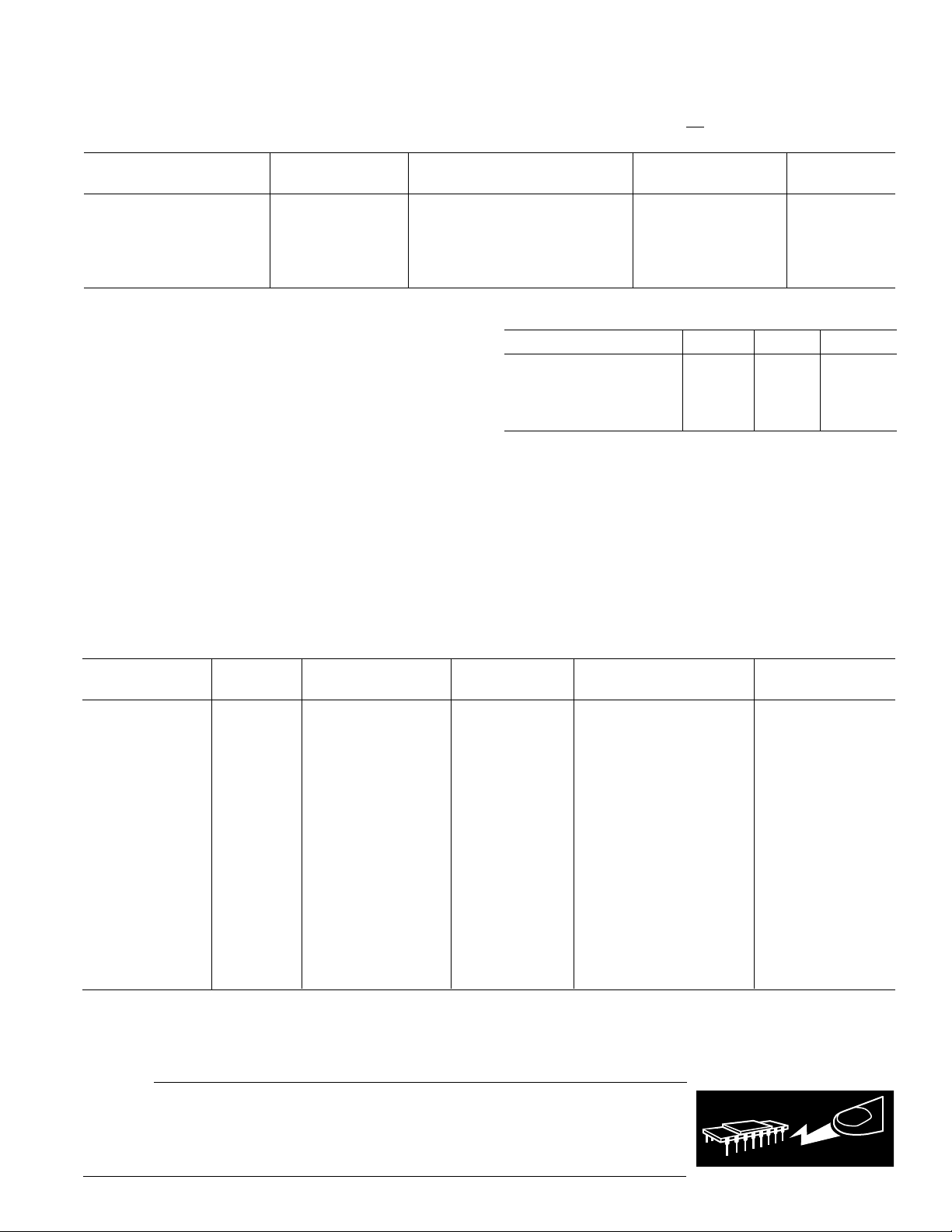

ABSOLUTE MAXIMUM RATINGS

1

Operating Temperature

DAC08AQ, Q . . . . . . . . . . . . . . . . . . . . . –55°C to +125°C

DAC08HQ, EQ, CQ, HP, EP . . . . . . . . . . . . 0°C to +70°C

DAC08CP, CS . . . . . . . . . . . . . . . . . . . . . –40°C to +85°C

Junction Temperature (T

) . . . . . . . . . . . . . –65°C to +150°C

J

Storage Temperature Q Package . . . . . . . . . –65°C to +150°C

Storage Temperature P Package . . . . . . . . . –65°C to +125°C

Lead Temperature (Soldering, 60 sec) . . . . . . . . . . . . . 300°C

V+ Supply to V– Supply . . . . . . . . . . . . . . . . . . . . . . . . . 36 V

Logic Inputs . . . . . . . . . . . . . . . . . . . . . . . V– to V– plus 36 V

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V– to V+

V

LC

Analog Current Outputs (at V

Reference Input (V

to V15) . . . . . . . . . . . . . . . . . . . V– to V+

14

– = 15 V) . . . . . . . . . . 4.25 mA

S

Package Type

16-Lead Cerdip (Q) 100 16 °C/W

16-Lead Plastic DIP (P) 82 39 °C/W

20-Terminal LCC (RC) 76 36 °C/W

16-Lead SO (S) 111 35 °C/W

NOTES

1

Absolute maximum ratings apply to both DICE and packaged parts, unless

otherwise noted.

2

θJA is specified for worst-case mounting conditions, i.e., θJA is specified for device

in socket for cerdip, Plastic DIP, and LCC packages; θJA is specified for device

soldered to printed circuit board for SO package.

2

JA

JC

Unit

Reference Input Differential Voltage

to V15) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ± 18 V

(V

14

Reference Input Current (I

) . . . . . . . . . . . . . . . . . . . 5.0 mA

14

ORDERING GUIDE

1

Temperature Package Package # Parts Per

Model NL Range Description Option Container

DAC08AQ ± 0.10% –55°C to +125°C Cerdip-16 Q-16 25

DAC08AQ

2

/883C ±0.10% –55°C to +125°C Cerdip-16 Q-16 25

DAC08HP ± 0.10% 0°C to 70°C P-DIP-16 N-16 25

DAC08HQ ± 0.10% 0°C to 70°C Cerdip-16 Q-16 25

DAC08Q ± 0.19% –55°C to +125°C Cerdip-16 Q-16 25

DAC08Q

2

/883C ± 0.19% –55°C to +125°C Cerdip-16 Q-16 25

DAC08RC/883C ± 0.19% –55°C to +125°C LCC-20 E-20 55

DAC08EP ± 0.19% 0°C to 70°C P-DIP-16 N-16 25

DAC08EQ ± 0.19% 0°C to 70°C Cerdip-16 Q-16 25

DAC08ES ±0.19% 0°C to 70°C SO-16 R-16A (Narrow Body) 47

DAC08ES-REEL ±0.19% 0°C to 70° C SO-16 R-16A (Narrow Body) 2500

DAC08CP ± 0.39% –40°C to +85°C P-DIP-16 N-16 25

DAC08CQ ± 0.39% 0°C to 70°C Cerdip-16 Q-16 25

DAC08CS ± 0.39% –40°C to +85°C SO-16 R-16A (Narrow Body) 47

DAC08CS-REEL ± 0.39% –40°C to +85°C SO-16 R-16A (Narrow Body) 2500

DAC08NBC ± 0.10% 25°C DICE

DAC08GBC ± 0.19% 25°C DICE

DAC08GRBC ± 0.39% 25°C DICE

NOTES

1

Devices processed in total compliance to MIL-STD-883. Consult factory for 883 data sheet.

2

For availability and burn-in information on SO and PLCC packages, contact your local sales office.

The DAC08 contains 84 transistors. Die size 63 mil x 87 mil = 5,481 square mils.

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection. Although

the DAC08 features proprietary ESD protection circuitry, permanent damage may occur on devices

subjected to high-energy electrostatic discharges. Therefore, proper ESD precautions are

recommended to avoid performance degradation or loss of functionality.

REV. B

–3–

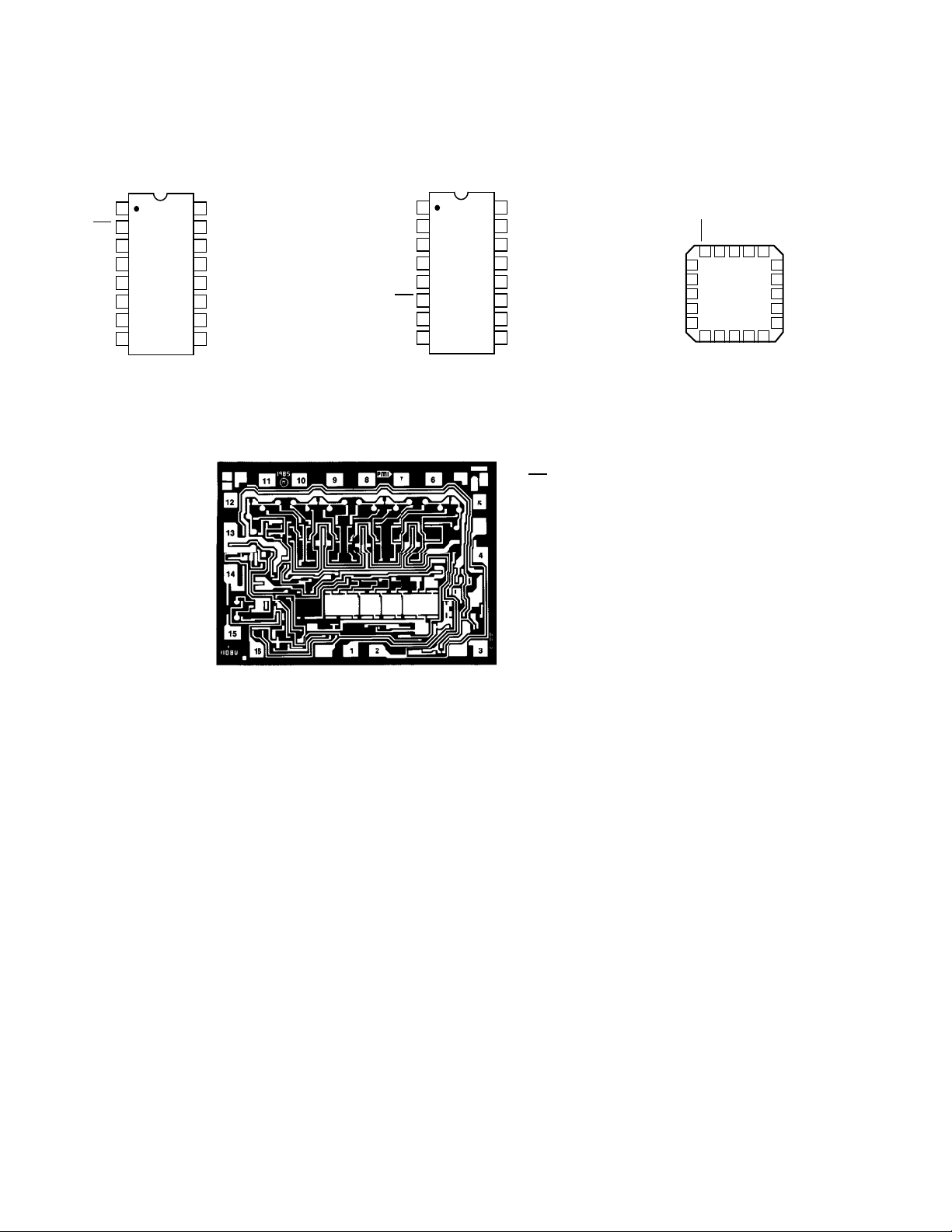

Page 4

DAC08

PIN CONNECTIONS

16-Lead Dual-In-Line Package

(Q and P Suffix)

V

I

OUT

I

OUT

MSB B1

1

LC

2

3

V–

4

5

6

B2

7

B3

8

B4

16

COMPENSATION

15

V

(–)

REF

14

V

(+)

REF

13

V+

12

B8 LSB

11

B7

10

B6

9

B5

16-Lead SO

(S Suffix)

16

15

14

13

12

11

10

9

B8 LSB

B7

B6

B5

B4

B3

B2

B1 MSB

V

REF

V

REF

(+)

(–)

COMP

V

I

OUT

I

OUT

1

V+

2

3

4

5

LC

6

7

V–

8

DICE CHARACTERISTICS

(125°C Tested Dice Available)

1. V

LC

2. I

OUT

3. V–

4. I

OUT

5. BIT 1 (MSB)

6. BIT 2

7. BIT 3

8. BIT 4

9. BIT 5

10. BIT 6

11. BIT 7

12. BIT 8 (LSB)

13. V+

(+)

14. V

REF

15. V

(–)

REF

16. COMP

DIE SIZE 0.087 ⴛ 0.063 inch, 5,270 sq. mils

(2.209 ⴛ 1.60 mm, 3.54 sq. mm)

DAC08RC/883 20-Lead LCC

(RC Suffix)

(–)

LC

NC

V

20 19123

B4NCB5

V

COMP

B6

REF

18

17

16

15

14

V

REF

V+

NC

B8 LSB

B7

(+)

I

OUT

NC

MSB B1

V–

B2

OUT

I

4

5

6

7

8

10 11 12 13

9

B3

NC = NO CONNECT

–4–

REV. B

Page 5

DAC08

WAFER TEST LIMITS

(@ VS = ⴞ15 V, I

I

and

I

OUT

OUT

= 2.0 mA; TA = 25ⴗC, unless otherwise noted. Output characteristics apply to both

REF

.)

DAC08N DAC08G DAC08GR

Parameter Symbol Conditions Limit Limit Limit Unit

Resolution 8 8 8 Bits min

Monotonicity 8 8 8 Bits min

Nonlinearity NL ± 0.1 ± 0.19 ± 0.39 % FS max

Output Voltage V

OC

Full-Scale Current +18 +18 +18 V max

Compliance Change < 1/2 LSB –10 –10 –10 V min

Full-Scale Current I

Full-Scale Symmetry I

Zero-Scale Current I

Output Current Range I

or V

FS4

I

FS2

FSS

ZS

or V– = –10 V,

FS1

REF

R14, R15 = 5.000 kΩ 1.94 1.94 1.94 mA min

V

REF

= 10.000 V 2.04 2.04 2.04 mA max

± 8 ± 8 ± 16 µA max

244µA max

= +15 V 2.1 2.1 2.1 mA min

V– = –12 V,

I

FS2

Logic Input “0” V

Logic Input “1” V

IL

IH

Logic Input Current V

Logic “0” I

Logic “1” I

Logic Input Swing V

IL

IH

IS

V

= +25 V 4.2 4.2 4.2 mA min

REF

R

, R15 = 5.000 kΩ

14

0.8 0.8 0.8 V max

222V min

= 0 V

LC

VIN = –10 V to +0.8 V ± 10 ± 10 ± 10 µA max

VIN = +2.0 V to +18 V ± 10 ± 10 ± 10 µA max

V– = –15 V +18 +18 +18 V max

–10 –10 –10 V min

Reference Bias Current I

Power Supply PSSI

Sensitivity PSSI

Power Supply Current I+ V

Power Dissipation P

NOTE

Electrical tests are performed at wafer probe to the limits shown. Due to variations in assembly methods and normal yield loss, yield after packaging is not guaranteed

for standard product dice. Consult factory to negotiate specifications based on dice lot qualification through sample lot assembly and testing.

15

FS+

FS–

D

V+ = +4.5 V to +18 V 0.01 0.01 0.01 % FS/% V max

V– = –4.5 V to –18 V

I

= 1.0 mA

REF

= ± 15 V 3.8 3.8 3.8 mA max

S

I

≤ 2.0 mA –7.8 –7.8 –7.8 µA max

REF

VS = ± 15 V 174 174 174 mW max

I

≤ 2.0 mA

REF

–3 –3 –3 µA max

REV. B

–5–

Page 6

DAC08

0V

TYPICAL VALUES:

= 5k⍀

R

IN

= 10V

+V

IN

+V

REF

OPTIONAL RESISTOR

R

REF

EQ

P

14

15 16

FOR OFFSET INPUTS

NO CAP

R

4

2

L

R

L

R

IN

R

200⍀

R

0mA

1.0mA

2.0mA

(0000|0000) I

= 2mA (1111|1111)

REF

I

OUT

I

OUT

Figure 1. Pulsed Reference Operation

C2

C1 R1

16 15 14 13 12 11 10 9

12345 678

C3

+18V

DAC08

–18V MIN

R1 = 9k⍀

C1 = 0.001F

C2, C3 = 0.01F

Figure 2. Burn-in Circuit

1V

2.5V

0.5V

–0.5mA

I

OUT

–2.5mA

100mV

R

EQ

R

L

C

C

200⍀

= 100⍀

= 0

200ns/DIVISION

200ns

Figure 4. True and Complementary Output Operation

100mV

2V

50ns

50ns/DIVISION

2.4V

0.4V

8A

5mV

0V

0

Figure 5. LSB Switching

ALL BITS SWITCHED ON

1V

2.4V

LOGIC INPUT

0.4V

OUTPUT –1/2LSB

SETTLING 0V

+1/2LSB

10mV

SETTLING TIME FIXTURE

= 2mA, RL = 1k⍀

I

FS

1/2LSB = 4A

50ns

50ns/DIVISION

Figure 3. Fast Pulsed Reference Operation

–6–

Figure 6. Full-Scale Settling Time

REV. B

Page 7

Typical Performance Characteristics–DAC08

5.0

TA = T

ALL BITS “HIGH”

4.0

3.0

2.0

, OUTPUT CURRENT – mA

FS

1.0

I

0.0

0.0

TO T

MIN

1.0 2.0 3.0 4.0 5.0

I

, REFERENCE CURRENT – mA

REF

MAX

LIMIT FOR

V– = –5V

LIMIT FOR

V– = –15V

TPC 1. Full-Scale Current vs.

Reference Current

4.0

TA = T

TO T

MIN

3.6

3.2

2.8

2.4

V– = –15V V– = –5V V+ = +15V

2.0

1.6

1.2

OUTPUT CURRENT – mA

0.8

0.4

0.0

–10 –6 –22 61014

–14

V15, REFERENCE COMMON-MODE VOLTAGE – V

MAX

NOTE: POSITIVE COMMON-MODE

RANGE IS ALWAYS (V+) –1.5V

ALL BITS ON

I

REF

I

REF

I

= 0.2mA

REF

= 2mA

= 1mA

500

400

300

1LSB = 7.8A

200

PROPAGATION DELAY – ns

100

0

0.05 0.02 0.1 0.5 2.0

0.01 0.05 0.2 1.0 5.0

IFS, OUTPUT FULL SCALE CURRENT – mA

1LSB = 61nA

TPC 2. LSB Propagation Delay vs. I

10

FS

10

R14 = R15 = 1k⍀

500⍀

R

8

L

ALL BITS “ON”

6

V

= 0V

R15

4

2

0

–2

–4

–6

CC = 15pF, V

1.

CENTERED AT +1.0V

–8

RELATIVE OUTPUT – dB

LARGE SIGNAL

–10

2.

C

= 15pF, V

C

CENTERED AT +200mV

–12

SMALL SIGNAL

–14

0.1

0.2 0.5 1.0 2.0 10

= 2.0V p–p

IN

= 50mV p–p

IN

FREQUENCY – MHz

2

1

5.0

TPC 3. Reference Input Frequency

Response

10.0

8.0

6.0

4.0

LOGIC INPUT – A

2.0

0

–8.0 –4.0 0 4.0 8.0 12.0 16.0

18

–12.0

LOGIC INPUT VOLTAGE – V

2.0

1.6

1.2

– V

LC

– V

TH

0.8

V

0.4

0

–50

0 50 100 150

TEMPERATURE – ⴗC

TPC 4. Reference Amp CommonMode Range

4.0

TA = T

TO T

MIN

3.6

3.2

2.8

2.4

V– = –15V V– = –5V

2.0

1.6

1.2

OUTPUT CURRENT – mA

0.8

0.4

0.0

–10 –6 –22 61014

–14

MAX

OUTPUT VOLTAGE – V

ALL BITS ON

I

REF

I

REF

I

= 0.2mA

REF

= 2mA

= 1mA

18

TPC 7. Output Current vs. Output

Voltage (Output Voltage Compliance)

TPC 5. Logic Input Current vs. Input

Voltage

28

24

20

16

12

SHADED AREA INDICATES

PERMISSIBLE OUTPUT VOLTAGE

8

RANGE FOR V– = –15V. I

4

FOR OTHER V– OR I

0

SEE OUTPUT CURRENT VS. OUTPUT

OUTPUT VOLTAGE – V

VOLTAGE CURVE.

4

8

12

–50 0 50 100 150

TEMPERATURE – ⴗC

REF

REF

.

2.0mA.

TPC 8. Output Voltage Compliance

vs. Temperature

TPC 6. V

1.8

1.6

1.4

1.2

1.0

0.8

0.6

OUTPUT CURRENT – mA

0.4

0.2

V– = –15V

0

–12 0 4 8 16–8 –412

NOTE: B1 THROUGH B8 HAVE IDENTICAL

TRANSFER CHARACTERISTICS. BITS ARE FULLY

SWITCHED WITH LESS THAN 1/2 LSB ERROR, AT

LESS THAN

THESE SWITCHING POINTS ARE GUARANTEED

TO LIE BETWEEN 0.8V AND 2.0V OVER THE

OPERATING TEMPERATURE RANGE

– VLC vs. Temperature

TH

I

= 2.0mA

REF

V– = –5V

LOGIC INPUT VOLTAGE – V

100mV FROM ACTUAL THRESHOLD.

B1

B2

B3B4

(V

= 0.0V).

LC

B5

TPC 9. Bit Transfer Characteristics

REV. B

–7–

Page 8

DAC08

10

ALL BITS “HIGH” OR “LOW”

8

7

6

5

4

3

2

POWER SUPPLY CURRENT – mA

1

0

020294 6 8 10 12 14 16 18

V+, POSITIVE POWER SUPPLY – V dc

I–

I+

TPC 10. Power Supply Current vs. V+

+V

REF

R

REF

I

REF

IN

I

REF

R

R15

14

15

PEAK NEGATIVE SWING OF I

REF

14

15

V

R

V

IN

REF

IN

R15

I

IN

R

+V

REF

(OPTIONAL)

HIGH INPUT

IMPEDANCE

+V

MUST BE ABOVE PEAK POSITIVE SWING OF V

REF

10

BITS MAY BE “HIGH” OR “LOW”

8

7

6

5

4

3

2

POWER SUPPLY CURRENT – mA

1

0

–0 –20–29–4 –6 –8 –10 –12 –14 –16 –18

V–, NEGATIVE POWER SUPPLY – V dc

I– WITH I

I– WITH I

I– WITH I

REF

REF

REF

= 2mA

= 1mA

= 0.2mA

I+

TPC 11. Power Supply Current vs. V–

BASIC CONNECTIONS

I

REF

+V

REF

R

REF

(R14)

R15

IN

255

+V

REF

IFR =

+ IO = I

I

IN

O

ALL LOGIC STATES

ⴛ

R

256

REF

FOR

FR

V

V

10

ALL BITS “HIGH” OR “LOW”

9

8

POWER SUPPLY CURRENT – mA

7

6

5

4

3

2

1

0

V– = –15V

I

= 2.0mA

REF

V+ = +15V

–50 0 50 100 150

TEMPERATURE – ⴗC

TPC 12. Power Supply Current vs.

Temperature

REF

REF

0.1F

MSB

B1

B2 B3B4 B5 B6B7

(+)

6789101112

5

14

(–)

15

316131

V–

0.1F

V– V+ V

C

C

COMP

LSB

B8

4

2

FOR FIXED REFERENCE,

V+

TTL OPERATION,

TYPICAL VALUES ARE:

V

REF

R

REF

R15 = R

CC = 0.01F

V

= 0V (GROUND)

LC

LC

I

O

I

O

= 10.000V

= 5.000k⍀

REF

I–

I+

Figure 7. Accommodating Bipolar References

LSB

B8

I

E

O

5.000k⍀

O

4

5.000k⍀

2

I

O

E

O

I

REF

= 2.000mA

MSB

B1

B2 B3B4 B5 B6 B7

14

Figure 9. Basic Unipolar Negative Operation

FULL RANGE

HALF-SCALE +LSB

HALF-SCALE

HALF-SCALE –LSB

ZERO-SCALE +LSB

ZERO-SCALE

–8–

Figure 8. Basic Positive Reference Operation

mA

IOmA

B1

B2

B3

B4

B5

B6

B7

B8

I

O

1

1

1

1

1

1

0

0

1

0

0

0

1

1

0

0

0

0

0

0

1

0

0

0

0

0

0

1

1

1

0

0

0

0

0

0

1.992

1

1

1.008

0

1

1.000

0

0

0.992

1

1

0.008

0

1

0.000

0

0

0.000

0.984

0.992

1.000

1.984

1.992

E

O

–9.960

–5.040

–5.000

–4.960

–0.040

0.000

E

O

–0.000

–4.920

–4.960

–5.000

–9.920

–9.860

REV. B

Page 9

I

4

2

I

O

I

O

E

O

0 TO –IFR ⴛ R

L

OP711

I

FR

= I

REF

255

256

R

L

FOR COMPLEMENTARY OUTPUT (OPERATION AS A NEGATIVE LOGIC DAC),

CONNECT NONINVERTING INPUT OF OP AMP TO IO (PIN 2); CONNECT IO (PIN 4)

TO GROUND.

(+) = 2.000mA

REF

MSB

B1

B2 B3B4 B5 B6 B7

14

10.000V

LSB

B8

I

I

O

O

10.000k⍀

4

2

POS. FULL RANGE

10.000k⍀

POS. FULL RANGE –LSB

ZERO-SCALE +LSB

E

O

E

O

ZERO-SCALE

ZERO-SCALE –LSB

NEG. FULL-SCALE +LSB

NEG. FULL-SCALE

B1

1

1

1

1

0

0

0

Figure 10. Basic Bipolar Output Operation

DAC08

B2

B3

B4

B5

B6

B7

B8

1

1

1

1

0

0

1

0

0

1

1

1

1

0

0

0

0

0

0

1

1

1

0

0

0

0

0

0

–9.920

1

1

1

–9.840

1

1

0

–0.080

0

0

1

0.000

0

0

0

+0.080

1

1

1

+9.920

0

0

1

+10.000

0

0

0

E

E

O

O

+10.000

+9.920

+0.160

+0.080

0.000

–9.840

–9.920

LOW T.C.

⍀

V

REF

10V

10k

POT

4.5k

I

(+)

REF

⍀

39k

⍀

APPROX

5k

1V

⍀

2mA

14

15

Figure 11. Recommended Full-Scale Adjustment Circuit

10k⍀

15V

2

10V

REF01*

MSB

B1

B2 B3 B4 B5 B6

5.000k⍀

6

V

O

5

5.0k⍀

V+ V– CCV

LSB

B8

B7

I

O

4

2

I

O

LC

5.0k⍀

+15V

OP711

4

*OR ADR01

+15V –15V

–15V

Figure 13. Offset Binary Operation

R

L

I

O

4

I

2

OP711

O

0 TO +IFR ⴛ R

IFR = I

FOR COMPLEMENTARY OUTPUT (OPERATION AS A NEGATIVE LOGIC DAC),

CONNECT INVERTING INPUT OF OP AMP TO IO (PIN 2); CONNECT IO (PIN 4) TO

GROUND.

255

256

REF

E

O

L

R

REF

14

I

REF

FS

R15

15

–V

R

NOTE

REF

REF

SETS IFS; R15 IS FOR

R

REF

BIAS CURRENT CANCELLATION.

–V

4

2

Figure 12. Basic Negative Reference Operation

B1

B2

B3

B4

B5

B6

B7

B8

E

POS. FULL RANGE

ZERO-SCALE

E

O

NEG. FULL-SCALE +1 LSB

NEG. FULL-SCALE

1

1

1

1

1

1

0

0

0

0

0

0

0

0

1

0

0

0

0

0

0

0

0

0

O

1

1

+4.960

0

0

0.000

0

1

–4.960

0

0

–5.000

I

O

I

O

Figure 14. Positive Low Impedance Output Operation

V

TH

15V

TTL, DTL

= 1.4V

V

TH

V

LC

1

REV. B

9.1k⍀

6.2k⍀ 0.1F

Figure 16. Interfacing with Various Logic Families

= VLC 1.4V

15V CMOS

V

= 7.6V

TH

Figure 15. Negative Low Impedance Output Operation

ECL

13k⍀

V

LC

“A”

39k⍀

2N3904

–5.2V

2N3904

3k⍀

TO PIN 1

6.2k⍀

TEMPERATURE COMPENSATING VLC CIRCUITS

CMOS, HTL, NMOS

20k⍀

“A”

20k⍀

V

LC

V+

2N3904

3k⍀

2N3904

TO PIN 1

R3

400A

V

LC

–9–

Page 10

DAC08

APPLICATION INFORMATION

REFERENCE AMPLIFIER SETUP

The DAC08 is a multiplying D/A converter in which the output

current is the product of a digital number and the input reference current. The reference current may be fixed or may vary

from nearly zero to 4.0 mA. The full-scale output current is a

linear function of the reference current and is given by:

255

II

=×

FR REF

256

, where I

REF

= I

14

In positive reference applications, an external positive reference

voltage forces current through R14 into the V

REF(+)

terminal

(Pin 14) of the reference amplifier. Alternatively, a negative

reference may be applied to V

flows from ground through R14 into V

at Pin 15; reference current

REF(–)

as in the positive

REF(+)

reference case. This negative reference connection has the advantage of a very high impedance presented at Pin 15. The voltage

at Pin 14 is equal to and tracks the voltage at Pin 15 due to the

high gain of the internal reference amplifier. R15 (nominally equal

to R14) is used to cancel bias current errors; R15 may be eliminated with only a minor increase in error.

Bipolar references may be accommodated by offsetting V

REF

or

Pin 15. The negative common-mode range of the reference

amplifier is given by: V

– = V– plus (I

CM

× 1 kΩ) plus 2.5 V.

REF

The positive common-mode range is V+ less 1.5 V.

When a dc reference is used, a reference bypass capacitor is

recommended. A 5.0 V TTL logic supply is not recommended

as a reference. If a regulated power supply is used as a reference,

R14 should be split into two resistors with the junction bypassed to

ground with a 0.1 µF capacitor.

For most applications the tight relationship between I

will eliminate the need for trimming I

. If required, full-scale

REF

REF

and I

FS

trimming may be accomplished by adjusting the value of R14, or

by using a potentiometer for R14. An improved method of

full-scale trimming which eliminates potentiometer T.C. effects

is shown in the recommended full-scale adjustment circuit.

Using lower values of reference current reduces negative power

supply current and increases reference amplifier negative common-mode range. The recommended range for operation with

a dc reference current is 0.2 mA to 4.0 mA.

REFERENCE AMPLIFIER COMPENSATION FOR MULTIPLYING APPLICATIONS

AC reference applications will require the reference amplifier to

be compensated using a capacitor from Pin 16 to V–. The value

of this capacitor depends on the impedance presented to Pin 14:

for R14 values of 1.0, 2.5 and 5.0 kΩ, minimum values of C

C

are 15, 37 and 75 pF. Larger values of R14 require proportionately increased values of C

ratio of C

(pF) to R14 (kΩ) = 15.

C

for proper phase margin, so the

C

For fastest response to a pulse, low values of R14 enabling

small C

values should be used. If Pin 14 is driven by a high

C

impedance such as a transistor current source, none of the

above values will suffice and the amplifier must be heavily

compensated which will decrease overall bandwidth and slew

rate. For R14 = 1 kΩ and C

slews at 4 mA/µs enabling a transition from I

= 15 pF, the reference amplifier

C

= 0 to I

REF

REF

=

2 mA in 500 ns.

Operation with pulse inputs to the reference amplifier may be

accommodated by an alternate compensation scheme. This

–10–

technique provides lowest full-scale transition times. An internal

clamp allows quick recovery of the reference amplifier from a

cutoff (I

= 0) condition. Full-scale transition (0 mA to 2 mA)

REF

occurs in 120 ns when the equivalent impedance at Pin 14 is

200 Ω and C

which is relatively independent of R

= 0. This yields a reference slew rate of 16 mA/µs,

C

and VIN values.

IN

LOGIC INPUTS

The DAC08 design incorporates a unique logic input circuit

that enables direct interface to all popular logic families and

provides maximum noise immunity. This feature is made possible by the large input swing capability, 2 µA logic input

current and completely adjustable logic threshold voltage.

For V– = –15 V, the logic inputs may swing between –10 V

and +18 V. This enables direct interface with 15 V CMOS

logic, even when the DAC08 is powered from a 5 V supply.

Minimum input logic swing and minimum logic threshold

voltage are given by: V– plus (I

× 1 kΩ) plus 2.5 V. The

REF

logic threshold may be adjusted over a wide range by placing

an appropriate voltage at the logic threshold control pin (Pin 1,

). The appropriate graph shows the relationship between

V

LC

and VTH over the temperature range, with VTH nominally

V

LC

1.4 above V

1. When interfacing ECL, an I

. For TTL and DTL interface, simply ground pin

LC

= 1 mA is recommended. For

REF

interfacing other logic families, see preceding page. For general

set-up of the logic control circuit, it should be noted that Pin 1

will source 100 µA typical; external circuitry should be designed

to accommodate this current.

Fastest settling times are obtained when Pin 1 sees a low impedance. If Pin 1 is connected to a 1 kΩ divider, for example, it

should be bypassed to ground by a 0.01 µF capacitor.

ANALOG OUTPUT CURRENTS

Both true and complemented output sink currents are provided

+

where I

= IFS. Current appears at the “true” (IO) output

I

O

O

when a “1” (logic high) is applied to each logic input. As the

binary count increases, the sink current at pin 4 increases proportionally, in the fashion of a “positive logic” D/A converter.

When a “0” is applied to any input bit, that current is turned

off at Pin 4 and turned on at Pin 2. A decreasing logic count

increases

as in a negative or inverted logic D/A converter.

I

O

Both outputs may be used simultaneously. If one of the outputs

is not required, it must be connected to ground or to a point

capable of sourcing I

; do not leave an unused output pin open.

FS

Both outputs have an extremely wide voltage compliance enabling

fast direct current-to-voltage conversion through a resistor tied

to ground or other voltage source. Positive compliance is 36 V

above V– and is independent of the positive supply. Negative

compliance is given by V– plus (I

× 1 kΩ) plus 2.5 V.

REF

The dual outputs enable double the usual peak-to-peak load

swing when driving loads in quasi-differential fashion. This

feature is especially useful in cable driving, CRT deflection and

in other balanced applications such as driving center-tapped

coils and transformers.

POWER SUPPLIES

The DAC08 operates over a wide range of power supply voltages

from a total supply of 9 V to 36 V. When operating at supplies

of ± 5 V or less, I

≤ 1 mA is recommended. Low reference

REF

current operation decreases power consumption and increases

negative compliance, reference amplifier negative common-mode

REV. B

Page 11

DAC08

range, negative logic input range and negative logic threshold

range; consult the various figures for guidance. For example,

operation at –4.5 V with I

= 2 mA is not recommended

REF

because negative output compliance would be reduced to near

zero. Operation from lower supplies is possible; however, at

least 8 V total must be applied to ensure turn-on of the internal

bias network.

Symmetrical supplies are not required, as the DAC08 is quite

insensitive to variations in supply voltage. Battery operation is

feasible as no ground connection is required: however, an artificial

ground may be used to ensure logic swings, etc., remain

between acceptable limits.

Power consumption may be calculated as follows:

P

= (I+) (V+) + (I–) (V–)

D

A useful feature of the DAC08 design is that supply current is

constant and independent of input logic states; this is useful in

cryptographic applications and further serves to reduce the size

of the power supply bypass capacitors.

TEMPERATURE PERFORMANCE

The nonlinearity and monotonicity specifications of the DAC08

are guaranteed to apply over the entire rated operating temperature

range. Full-scale output current drift is low, typically ±10 ppm/°C,

with zero-scale output current and drift essentially negligible

compared to 1/2 LSB.

The temperature coefficient of the reference resistor R14 should

match and track that of the output resistor for minimum overall

full-scale drift. Settling times of the DAC08 decrease approximately 10% at –55°C; at +125°C an increase of about 15%

is typical.

The reference amplifier must be compensated by using a capacitor

from pin 16 to V–. For fixed reference operation, a 0.01 µF

capacitor is recommended. For variable reference applications,

see “Reference Amplifier Compensation for Multiplying Applications” section.

MULTIPLYING OPERATION

The DAC08 provides excellent multiplying performance with an

extremely linear relationship between I

and I

FS

over a range

REF

of 4 µA to 4 mA. Monotonic operation is maintained over a

typical range of I

from 100 µA to 4.0 mA.

REF

SETTLING TIME

The DAC08 is capable of extremely fast settling times, typically

85 ns at I

= 2.0 mA. Judicious circuit design and careful

REF

board layout must be employed to obtain full performance

potential during testing and application. The logic switch design

enables propagation delays of only 35 ns for each of the 8 bits.

Settling time to within 1/2 LSB of the LSB is therefore 35 ns,

with each progressively larger bit taking successively longer. The

MSB settles in 85 ns, thus determining the overall settling time

of 85 ns. Settling to 6-bit accuracy requires about 65 ns to 70 ns.

The output capacitance of the DAC08 including the package is

approximately 15 pF, therefore the output RC time constant

dominates settling time if R

> 500 Ω.

L

Settling time and propagation delay are relatively insensitive to

logic input amplitude and rise and fall times, due to the high

gain of the logic switches. Settling time also remains essentially

constant for I

values. The principal advantage of higher I

REF

REF

values lies in the ability to attain a given output level with lower

load resistors, thus reducing the output RC time constant.

Measurement of settling time requires the ability to accurately resolve ± 4 µA, therefore a 1 kΩ load is needed to provide adequate drive for most oscilloscopes. The settling time fixture shown in schematic labelled “Settling Time Measurement” uses a cascade design to permit driving a 1 kΩ load with less than 5 pF of parasitic capacitance at the measurement node. At I

values of less than 1.0 mA, excessive RC damping of the

REF

output is difficult to prevent while maintaining adequate sensitivity. However, the major carry from 01111111 to 10000000

provides an accurate indicator of settling time. This code change

does not require the normal 6.2 time constants to settle to

within ± 0.2% of the final value, and thus settling times may be

observed at lower values of I

REF

.

DAC08 switching transients or “glitches” are very low and may

be further reduced by small capacitive loads at the output at a

minor sacrifice in settling time.

Fastest operation can be obtained by using short leads, minimizing

output capacitance and load resistor values, and by adequate

bypassing at the supply, reference, and V

terminals. Supplies

LC

do not require large electrolytic bypass capacitors as the supply

current drain is independent of input logic states; 0.1 µF capacitors

at the supply pins provide full transient protection.

REV. B

1F

+5V

Q2

–15V

15k⍀

V

OUT

PROBE

1X

+0.4V

–0.4V

0.1F

0V

0V

V

I

OUT

L

1k⍀

Q1

1F50F

1k⍀

100k⍀ 2k⍀

FOR TURN-ON, V

FOR TURN-OFF, VL = 0.7V

V

CL

0.7V

+V

REF

R

R15

REF

0.1F

14

15

0.1F

5

V

IN

6789101112

DAC08

13

316

+15V

–15V

= 2.7V

L

MINIMUM

CAPACITANCE

4

2

0.01F

0.1F

Figure 17. Settling Time Measurement

–11–

Page 12

DAC08

TOP

VIEW

0.358 (9.09)

0.342 (8.69)

SQ

1

20

4

9

8

13

19

14

3

18

BOTTOM

VIEW

0.028 (0.71)

0.022 (0.56)

45° TYP

0.015 (0.38)

MIN

0.055 (1.40)

0.045 (1.14)

0.050 (1.27)

BSC

0.075 (1.91)

REF

0.011 (0.28)

0.007 (0.18)

R TYP

0.095 (2.41)

0.075 (1.90)

0.100 (2.54) BSC

0.200 (5.08)

BSC

0.150 (3.81)

BSC

0.075

(1.91)

REF

0.358

(9.09)

MAX

SQ

0.100 (2.54)

0.064 (1.63)

0.088 (2.24)

0.054 (1.37)

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

PIN 1

0.210 (5.33)

MAX

0.160 (4.06)

0.115 (2.93)

0.1574 (4.00)

0.1497 (3.80)

PIN 1

0.0098 (0.25)

0.0040 (0.10)

16-Lead Plastic DIP (N-16)

0.840 (21.34)

0.745 (18.92)

16

18

0.022 (0.558)

0.014 (0.356)

0.100

(2.54)

BSC

9

0.280 (7.11)

0.240 (6.10)

0.060 (1.52)

0.015 (0.38)

0.070 (1.77)

0.045 (1.15)

16-Lead SO (R-16A)

0.3937 (10.00)

0.3859 (9.80)

16 9

0.050 (1.27)

BSC

0.0192 (0.49)

0.0138 (0.35)

0.2440 (6.20)

0.2284 (5.80)

81

0.0688 (1.75)

0.0532 (1.35)

SEATING

PLANE

0.130

(3.30)

MIN

SEATING

PLANE

0.0099 (0.25)

0.0075 (0.19)

0.325 (8.25)

0.300 (7.62)

0.015 (0.381)

0.008 (0.204)

0.0196 (0.50)

0.0099 (0.25)

8ⴗ

0ⴗ

0.195 (4.95)

0.115 (2.93)

0.0500 (1.27)

0.0160 (0.41)

ⴛ 45ⴗ

16-Lead Cerdip (Q-16)

0.005 (0.13) MIN

PIN 1

0.200 (5.08)

MAX

0.200 (5.08)

0.125 (3.18)

16

0.840 (21.34) MAX

0.023 (0.58)

0.014 (0.36)

0.080 (2.03) MAX

9

0.310 (7.87)

0.070 (1.78)

0.030 (0.76)

0.220 (5.59)

0.060 (1.52)

0.015 (0.38)

0.150

(3.81)

MIN

SEATING

PLANE

18

0.100

(2.54)

BSC

0.320 (8.13)

0.290 (7.37)

15°

0°

20-Terminal Leadless Chip Carrier (E-20)

0.015 (0.38)

C00268–0–2/02(B)

0.008 (0.20)

Revision History

Location Page

Data Sheet changed from REV. A to REV. B.

Edits to SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Edits to ABSOLUTE MAXIMUM RATINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Edits to ORDERING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Edits to WAFER TEST LIMITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Edit to Figure 13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Edits to Figures 14 and 15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Replacement of SO-16 with R-16A Package Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

–12–

PRINTED IN U.S.A.

REV. B

Loading...

Loading...