Page 1

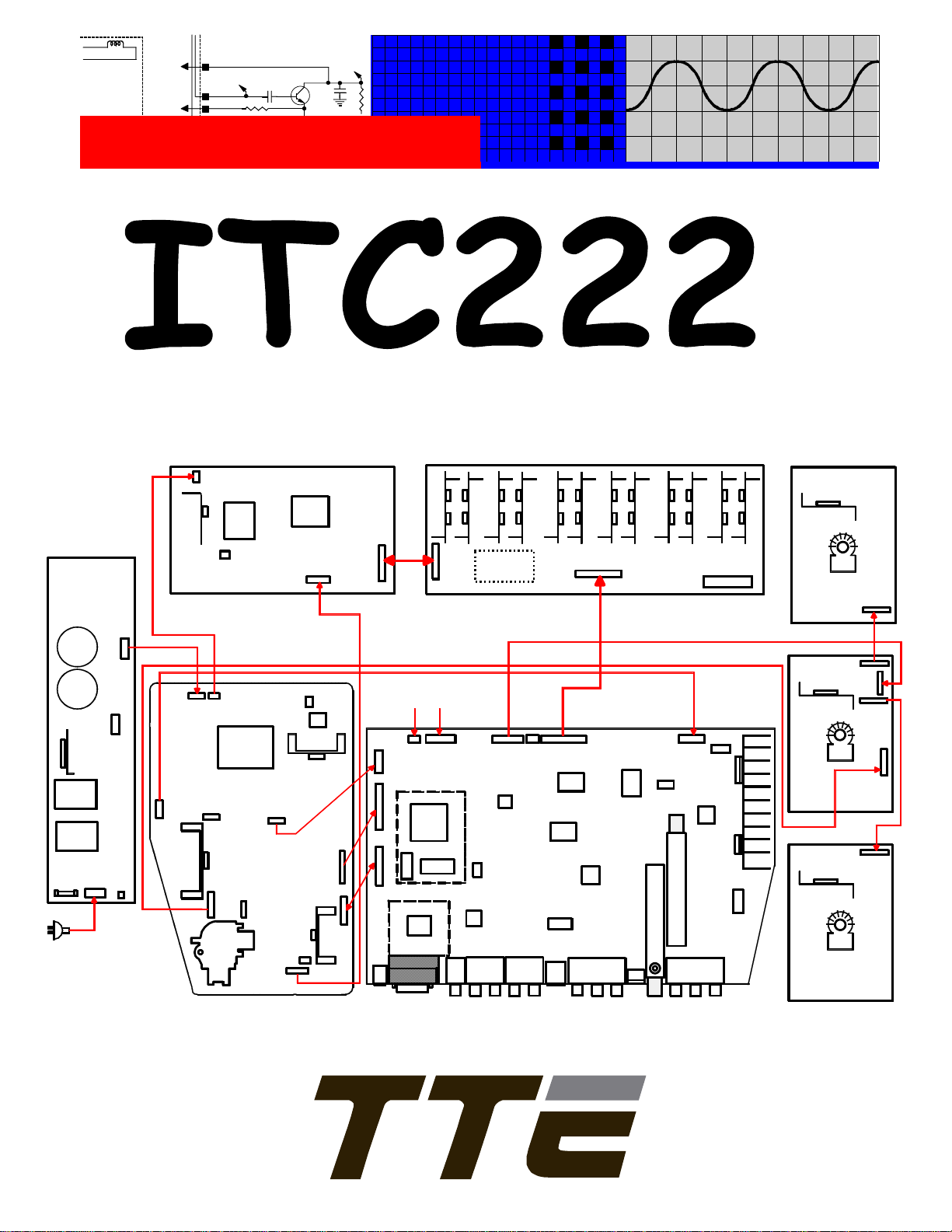

VERTICAL

TO

E8

RED BIAS

<21-B>

TO

E7

GRN BIAS

E5003

E5007

TP50

RED OUTPUT

TP24

194V

TECHNICAL TRAINING

Field Service Guide

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

1

0

0

1

0

1

0

1

1

0

0

1

1

0

0

1

0

1

0

1

0

1

1

0

1

1

0

0

0

1

1

0

1

1

0

0

1

0

1

0

0

1

0

1

1

1

0

1

0

1

0

1

1

0

FP400

MID

CP410

CP411

DP400

LP401

LP400

BP400

BP401

BP414

TP630

BP610

IP650

LP650

LP605

BL600

BH

BL660

BW004

BV

Watchdog

Circuit Area

CPS

2

0

4

P

B

BP010

BP130

BP120

TL010

BL200

BP011

LP050

LL008

PSD

BP150

BL035

BF001

TP020

BL500

IP080

LP020

BP005

BL111

BP501

BP500

BV001

G

Link

BK202

IR & Key Board

BR001

IR001

Gem Cam

IT600

DVI

DVI

Aud

IX400

Comp

1

BV500

IV400

IR006

Comp

GH GV RH RV

BW005

CAM

IV100

CVBS

SSB

IC040

s

s

u

B

I

C

E

1&2

T

BK270

IK201

IV300

IX300

S

2

Vid

BA002

r

e

n

u

T

n

i

a

M

BA010

r

e

n

u

T

d

n

o

c

e

S

Monitor

BW001 BW002

BA001

IA001

Out

IA900

IB101

R-CRT

IB201

Grn

IB301

Blue

Red

BB104

BB204

BB201

BB203

BB202

G-CRT

BB303

B-CRT

Page 2

Page 3

Sections

MODEL-TO-MAJOR ASSEMBLY CROSS REFERENCE........................... I

DISASSEMBLY........................................................................................... II

INTERCONNECT....................................................................................... III

VOL TAGE CHARTS................................................................................... Iv

WAVEFORMS............................................................................................. V

ALIGNMENT PROCEDURES....................................................................VI

ERROR CODES .......................................................................................VII

TROUBLESHOOTING FLOW CHARTS AND PROCEDURES .............. VIII

COMMON PARTS ORDERED...................................................................IX

IN-HOME SERVICE INFORMATION (Contact Phone Numbers)............IX

TECH-LINE INFORMATION .......................................................................X

MISC. INFORMATION ...............................................................................XI

CROSS REFERENCE CHARTS ...............................................................XI

BULLETINS (TTP, TV)...............................................................................XI

Page 4

Page 5

I

MODEL

-TO-

MAJOR

ASSEMBLY CROSS

REFERENCE

Page 6

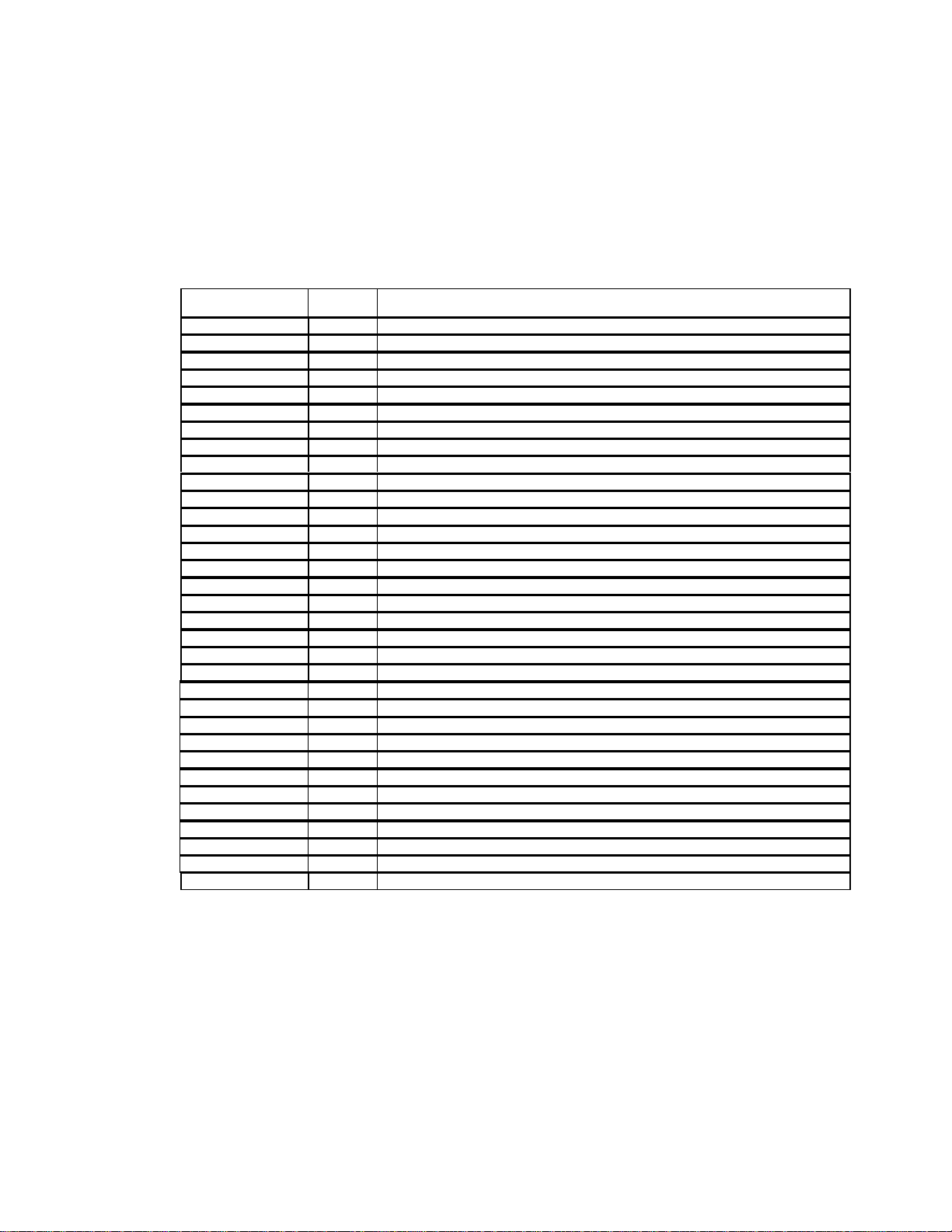

MODEL-TO-MAJOR ASSEMBLY CROSS REFERENCE

KEY TO MAJOR ASSEMBLIES

IR1 - IR Receiver Board (10849310)

ADM1 - ATSC Tuner Board (10913610)

ADM2 - ATSC Tuner Board (10916570)

ADM3 - A TSC T uner Board (16655100)

CAB1 - Convergence Amplifier Board (10859730)

CAB2 - Convergence Amplifier Board (5609624Q)

CAB3 - Convergence Amplifier Board (5614795Q)

CONVP1 - Convergence Power Board (10803530)

CONVP2 - Convergence Power Board (5609624R)

CONVP3 - Convergence Power Board (5614795R)

CRT1 - CRT Driver Board 10840410)

CRT2 - CRT Driver Board (Red) (10859120)

CRT3 - CRT Driver Board (Green) (10859130)

CRT4 - CRT Driver Board (Blue) (10859140)

IR2 - IR Receiver Board (5609626T)

IR3 - IR Receiver Board (5609626Z)

LSC1 - Loud Speaker Connections (10849520)

MID1 - Mains Input Doubler (10849430)

PSD1 - Power Supply/Deflection PCB (10849230)

PSD2 - Power Supply/Deflection PCB (10849190)

PSD3 - Power Supply/Dynamic Focus (10859740)

PSD4 - Power Supply/Deflection PCB (10802090)

PSD5 - Power Supply/Deflection PCB (10920590)

PSD6 - Power Supply/Deflection PCB (1091 1450)

PSD7 - Power Supply/Deflection PCB (56096260)

PSD8 - Power Supply/Deflection PCB (5609626A)

CRTCl1 - CRT Driver Boards (56096250/A)

CRTCl2 - CRT Driver Boards (56147970/A)

DFB1 - Dynamic Focus Board (10773320)

DVD1 - DVD Assembly (21297430)

DVDIN- DVD Interface Board (10926930)

DVDIN2- DVD Interface Board (166551 10)

DVDPOWER1 - DVD Power Supply (10856500)

DVDPOWER2 - DVD Power Supply (5614795S)

DVDPOWER3 - DVD Power Supply (56190900)

ES1 - EchoStar SIP Module (10856130)

FCB1 - Front Connections Board (10849270)

FCB2 - Front Connections Board (10817610)

FCB3 - Front Connections Board (5609626R)

FCB4 - Front Connections Board (5609626W)

FPA1 - Front Panel Assembly (10849250)

FPA2 - Front Panel Assembly (10849220)

FPA3 - DVD Front Panel Assembly (10856510)

FPA4 - Front Panel Assembly (5609626S)

FPA5 - Front Panel Assembly (5609626Y)

SSB1 - Small Signal Board (10857000)

SSB2 - Small Signal Board (10862350)

SSB3 - Small Signal Board (10822270)

SSB4 - Small Signal Board (10918240)

SSB5 - Small Signal Board (10914030)

SSB6 - Small Signal Board (10914040)

SSB7 - Small Signal Board (10941320)

SSB8 - Small Signal Board (16654960)

SSB9 - Small Signal Board (16655010)

SSB10 - Small Signal Board (16555050)

SSB11 - Small Signal Board (16655060)

SSB12 - Small Signal Board (16655070)

SSB13 - Small Signal Board (16655080)

SSB14 - Small Signal Board (16655090)

SSB15 - Small Signal Board (10882720)

SSB16 - Small Signal Board (10889940)

I-1

Page 7

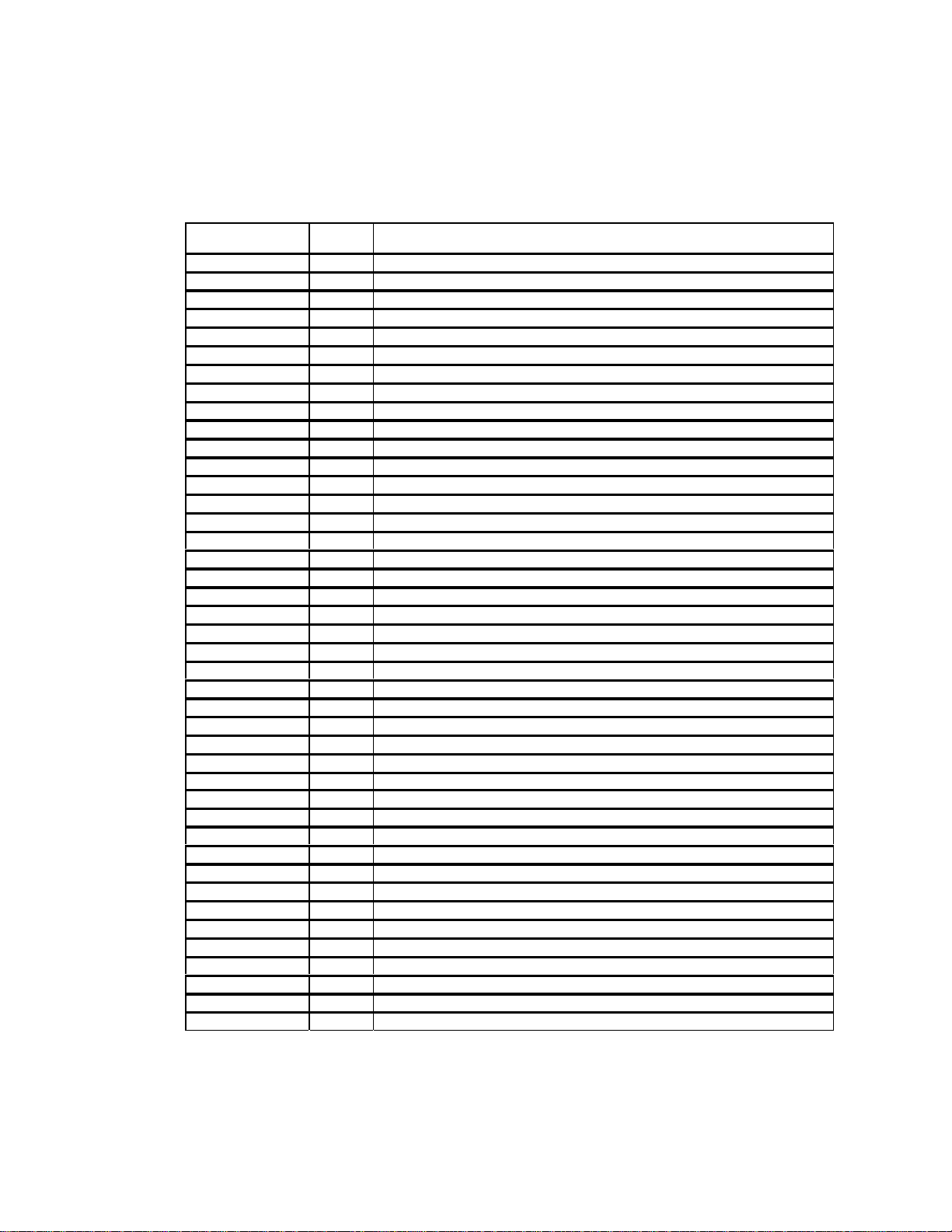

MODEL-TO-MAJOR ASSEMBLY CROSS REFERENCE

MODEL/

SERVICE NO.

D27F750TYX1 DV CRT1, FCB1, FPA2, MID1, PSD2, SSB2,

D32F750TYX1 DV CRT1, FCB1, FPA2, MID1, PSD2, SSB2,

D34W20BYX1 DV CRT1, DFB1, FCB1, FPA2, LSC1, MID1, PSD2, SSB2,

D34EW16YX1 DV CRT1, DFB1 ES1, FCB1, FPA2, LSC1, MID1, PSD2, SSB1,

D40EW11YX1 PTV CAB1, CRT2, CRT3, CRT4, ES1, FCB1, FPA1, IR1, LSC1, MID1, PSD1, PSD3, SSB1, CONVP1

D40EW16YX2 PTV CAB1, CRT2, CRT3, CRT4, ES1, FCB1, FPA1, IR1, LSC1, MID1, PSD1, PSD3, SSB1, CONVP1

D40EW16YX10 PTV CAB1, CRT2, CRT3, CRT4, ES1, FCB1, FPA1, IR1, LSC1, MID1, PSD1, PSD3, SSB1, CONVP1

D40EW21YX1 PTV CAB1, CRT2, CRT3, CRT4, ES1, FCB1, FPA1, IR1, LSC1, MID1, PSD1, PSD3, SSB1, CONVP1

D40W136DCYX1 PTV CAB1, CRT2, CRT3, CRT4, DVD1, DVD2, FCB1, FPA1, FPA3, IR1, LSC1,

MID1, PSD1, PSD3, SSB2, CONVP1

D40W15BYX1 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, LSC1, MID1, PSD1, PSD3, SSB2, CONVP1

D40W15BYX2 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, LSC1, MID1, PSD1, PSD3, SSB2, CONVP1

D40W15BYX10 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, LSC1, MID1, PSD1, PSD3, SSB2, CONVP1

D40W17BYX1 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, LSC1, MID1, PSD1, PSD3, SSB2, CONVP1

D40W17BYX2 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, LSC1, MID1, PSD1, PSD3, SSB2, CONVP1

D40W17BYX10 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, LSC1, MID1, PSD1, PSD3, SSB2, CONVP1

D40W20BYX1 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, LSC1, MID1, PSD1, PSD3, SSB2, CONVP1

D40W20BYX2 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, LSC1, MID1, PSD1, PSD3, SSB2, CONVP1

D40W20BYX10 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, LSC1, MID1, PSD1, PSD3, SSB2, CONVP1

D52GW12BYX1 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, LSC1, MID1, PSD1, PSD3, SSB2, CONVP1

D52GW12BYX10 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, LSC1, MID1, PSD1, PSD3, SSB2, CONVP1

D52W131BYX1 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, LSC1, MID1, PSD1, PSD3, SSB2, CONVP1

D52W136DBYX1 PTV CAB1, CRT2, CRT3, CRT4, DVD1, DVD2, FCB1, FPA1, FPA3, IR1, LSC1,

MID1, PSD1, PSD3, SSB2, CONVP1

D52W136DBYX2 PTV CAB1, CRT2, CRT3, CRT4, DVD1, DVD2, FCB1, FPA1, FPA3, IR1, LSC1,

MID1, PSD1, PSD3, SSB2, CONVP1

D52W136DBYX10 PTV CAB1, CRT2, CRT3, CRT4, DVD1, DVD2, FCB1, FPA1, FPA3, IR1, LSC1,

MID1, PSD1, PSD3, SSB2, CONVP1

D52W138DYX1 PTV CAB1 , CRT2, CRT3, CRT4, DVD1 , DV D2, FCB1, FPA1, FP A3, IR1, LSC1,

MID1, PSD1, PSD3, SSB2, CONVP1

D52W138DYX10 PTV CAB1, CRT2, CRT3, CRT4, DVD1, DVD2, FCB1, FPA1, FPA3, IR1, LSC1,

MID1, PSD1, PSD3, SSB2, CONVP1

D52GW12YX2 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, LSC1, MID1, PSD1, PSD3, SSB2, CONVP1

CHASSIS MAJOR ASSEMBLIES

I-2

Page 8

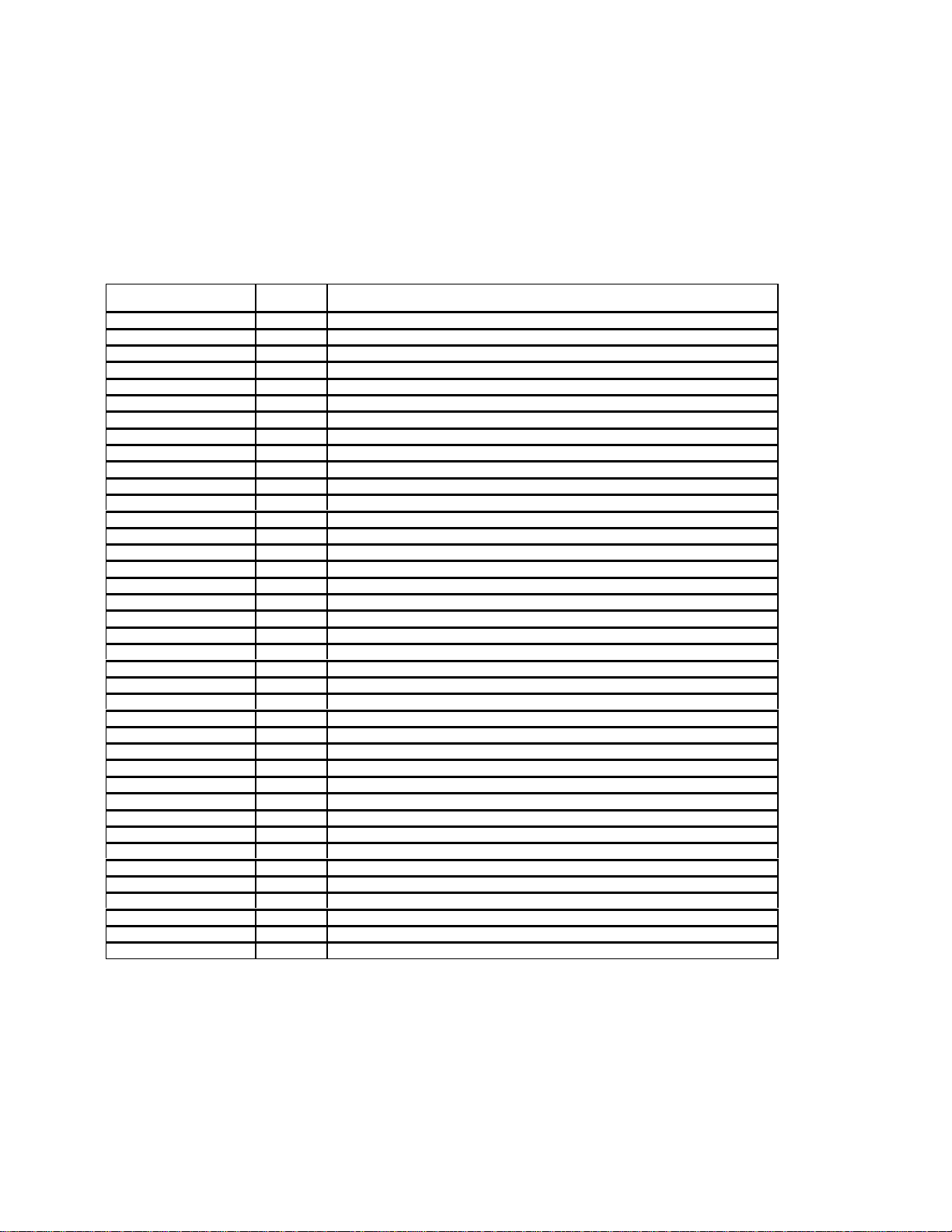

MODEL-TO-MAJOR ASSEMBLY CROSS REFERENCE

MODEL/

SERVICE NO. CHASSIS MAJOR ASSEMBLIES

D52W14BYX1 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, LSC1, MID1, PSD1, PSD3, SSB2, CONVP1

D52W14BYX10 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, LSC1, MID1, PSD1, PSD3, SSB2, CONVP1

D52W14BYX2 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, LSC1, MID1, PSD1, PSD3, SSB2, CONVP1

D52W14BYX38 PTV CAB2, CRTCL1, CONVP2, FCB4, FPA5, IR3, LSC1, MID1, PSD8, SSB10

D52W14BYX39 PTV CAB2, CRTCL2, CONVP2, FCB4, FPA5, IR3, LSC1, MID1, PSD8, SSB10

D52W15BYX1 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, LSC1, MID1, PSD1, PSD3, SSB2, CONVP1

D52W15BYX2 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, LSC1, MID1, PSD1, PSD3, SSB2, CONVP1

D52W15BYX10 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, LSC1, MID1, PSD1, PSD3, SSB2, CONVP1

D52W17BYX1 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, LSC1, MID1, PSD1, PSD3, SSB2, CONVP1

D52W17BYX2 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, LSC1, MID1, PSD1, PSD3, SSB2, CONVP1

D52W17BYX10 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, LSC1, MID1, PSD1, PSD3, SSB2, CONVP1

D52W17BYX20 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, LSC1, MID1, PSD1, PSD3, SSB2, CONVP1

D52W19BYX1 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, LSC1, MID1, PSD1, PSD3, SSB2, CONVP1

D52W19BYX2 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, LSC1, MID1, PSD1, PSD3, SSB2, CONVP1

D52W19BYX5 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, LSC1, MID1, PSD1, PSD3, SSB2, CONVP1

D52W19BYX10 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, LSC1, MID1, PSD1, PSD3, SSB2, CONVP1

D52W19BYX20 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, LSC1, MID1, PSD1, PSD3, SSB2, CONVP1

D52W19BYX22 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, LSC1, MID1, PSD1, PSD3, SSB2, CONVP1

D52W19BYX30 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, LSC1, MID1, PSD3, PSD4, SSB3, CONVP1

D52W19BYX31 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, LSC1, MID1, PSD3, PSD4, SSB3, CONVP1

D52W19BYX32 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, LSC1, MID1, PSD3, PSD6, SSB3, CONVP1

D52W19BYX38 PTV CAB2, CRTCL1, CONVP2, FCB4, FPA5, IR3, LSC1, MID1, PSD8, SSB8

D52W19BYX39 PTV CAB2, CRTCL2, CONVP2, FCB4, FPA5, IR3, LSC1, MID1, PSD8, SSB8

D52W19YX1 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, LSC1, MID1, PSD1, PSD3, SSB2, CONVP1

D52W19YX10 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, LSC1, MID1, PSD1, PSD3, SSB2, CONVP1

D52W19BYX20 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, LSC1, MID1, PSD1, PSD3, SSB2, CONVP1

D52W19BYX30 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, LSC1, MID1, PSD3, PSD4, SSB3, CONVP1

D52W19BYX31 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, LSC1, MID1, PSD3, PSD4, SSB3, CONVP1

D52W19BYX32 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, LSC1, MID1, PSD3, PSD5, SSB3, CONVP1

D52W20BYX5 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, LSC1, MID1, PSD3, PSD4, SSB3, CONVP1

D52W23YX22 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD6, SSB4, CONVP1

D52W23YX30 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD4, SSB4, CONVP1

D52W23YX31 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD4, SSB4, CONVP1

D52W23YX32 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD6, SSB4, CONVP1

D52W23YX33 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD6, SSB4, CONVP1

D52W23YX38 PTV CAB2, CRTCL1, CONVP2, FCB4, FPA5, IR3, LSC1, MID1, PSD8, SSB13

D52W23YX39 PTV CAB2, CRTCL2, CONVP2, FCB4, FPA5, IR3, LSC1, MID1, PSD8, SSB13

D52W23YX50 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD4, SSB4, CONVP1

D52W23YX51 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD4, SSB4, CONVP1

I-3

Page 9

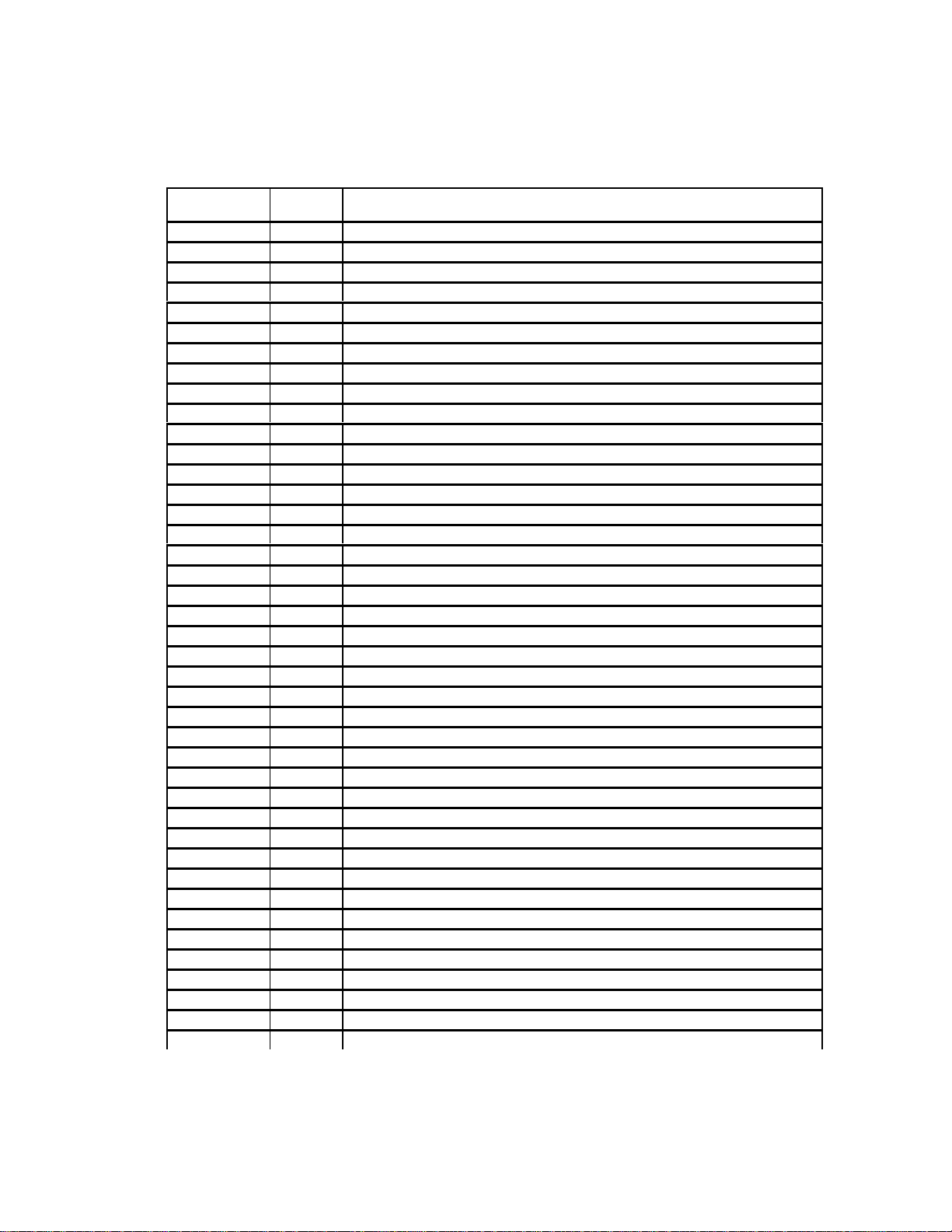

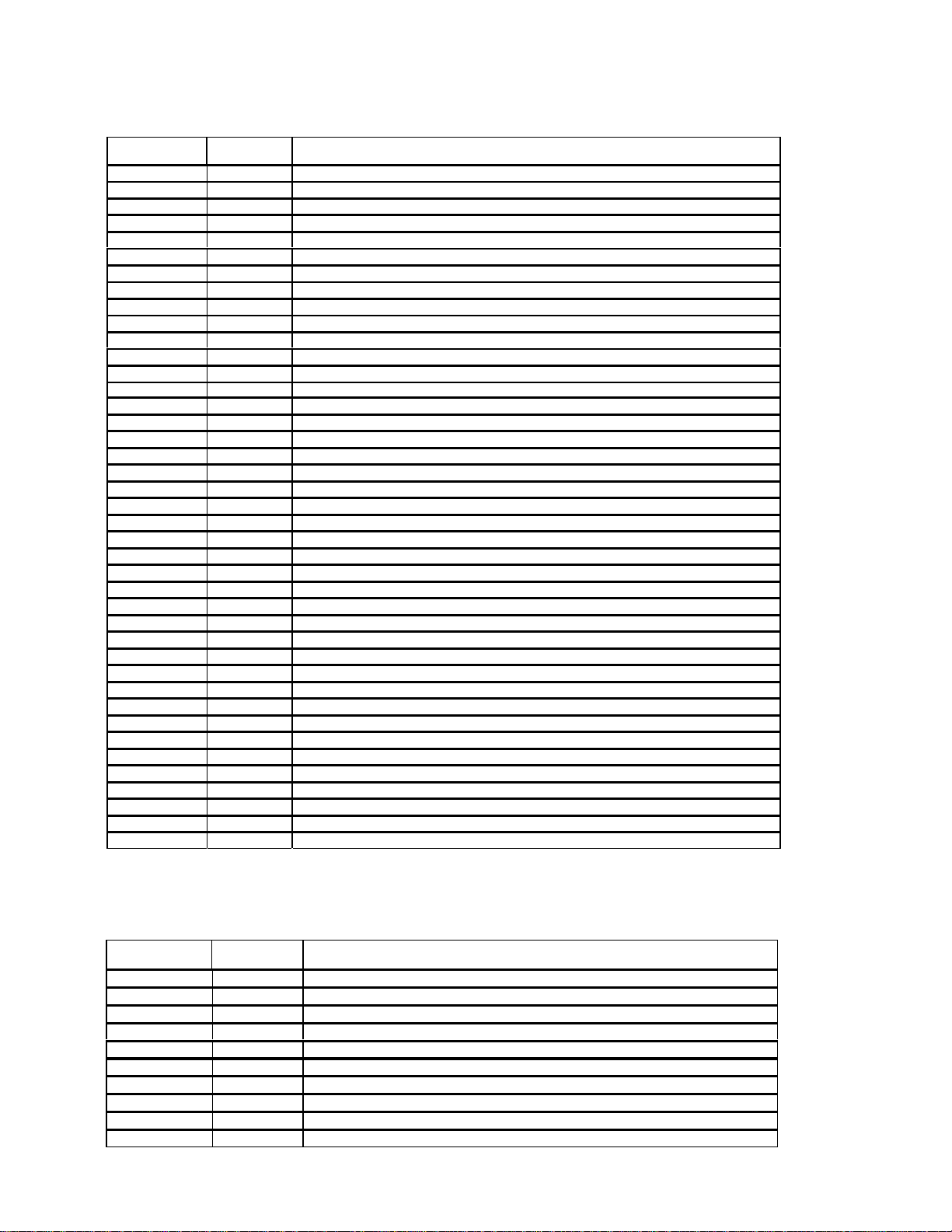

MODEL-TO-MAJOR ASSEMBLY CROSS REFERENCE

MODEL/

SERVICE NO. CHASSIS MAJOR ASSEMBLIES

D52W25YX1 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD1, PSD3, SSB2, CONVP1

D52W25YX10 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD1, PSD3, SSB2, CONVP1

D52W25YX38 PTV CAB2, CRTCL1, CONVP2, FCB4, FPA5, IR3, LSC1, MID1, PSD8, SSB10

D52W25YX39 PTV CAB2, CRTCL2, CONVP2, FCB4, FPA5, IR3, LSC1, MID1, PSD8, SSB10

D52W26BYX1 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD1, PSD3, SSB2, CONVP1

D52W26BYX10 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD1, PSD3, SSB2, CONVP1

D52W26YX2 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD1, PSD3, SSB2, CONVP1

D52W26YX30 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD4, SSB5, CONVP1

D52W26YX31 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD4, SSB5, CONVP1

D52W26YX32 PTV CAB2, CRTCL1, CONVP2, FCB3, FP A4, IR2, MID1, PSD7, SSB16

D52W26YX33 PTV CAB2, CRTCL2, CONVP2, FCB3, FP A4, IR2, MID1, PSD7, SSB16

D52W26YX35 PTV CAB2, CRTCL1, CONVP2, FCB3, FP A4, IR2, MID1, PSD7, SSB16

D52W26YX36 PTV CAB2, CRTCL2, CONVP2, FCB3, FP A4, IR2, MID1, PSD7, SSB16

D52W26YX38 PTV CAB2, CRTCL1, CONVP2, FCB4, FP A5, IR3, MID1, PSD8, SSB10

D52W26YX39 PTV CAB2, CRTCL2, CONVP2, FCB4, FP A5, IR3, MID1, PSD8, SSB10

D52W27DYX1 PTV CAB1, CRT2, CRT3, CRT4, DVD1, DVD2, FCB1, FPA1, FPA3, IR1

MID1, PSD1, PSD3, SSB2, CONVP1

D52W27DYX2 PTV CAB1, CRT2, CRT3, CRT4, DVD1, DVD2, FCB1, FPA1, FPA3, IR1,

MID1, PSD1, PSD3, SSB2, CONVP1

D52W27DYX10 PTV CAB1, CRT2, CRT3, CRT4, DVD1, DVD2, FCB1, FPA1, FPA3, IR1,

MID1, PSD1, PSD3, SSB2, CONVP1

D52W27DYX22 PTV CAB1, CRT2, CRT3, CRT4, DVD1, DVD2, FCB1, FPA1, FPA3, IR1,

MID1, PSD3, PSD5, SSB2, CONVP1

D52W27DYX23 PTV CAB1, CRT2, CRT3, CRT4, DVD1, DVD2, FCB1, FPA1, FPA3, IR1,

MID1, PSD3, PSD6, SSB15, CONVP1

D52W27DYX32 PTV CAB3, CRTCL1, CONVP3, DVDPOWER2, FCB3, FPA4, FPA3, IR2,

MID1, PSD7, SSB15

D52W27DYX33 PTV CAB3, CRTCL2, CONVP3, DVDPOWER2, FCB3, FPA4, FPA3, IR2,

MID1, PSD7, SSB15

D52W27DYX35 PTV CAB3, CRTCL1, CONVP3, DVDPOWER2, FCB3, FPA4, FPA3, IR2,

MID1, PSD7, SSB15

D52W27DYX38 PTV CAB3, CRTCL1, CONVP3, DVDPOWER3, FCB4, FPA5, FPA3, IR3,

MID1, PSD8, SSB9

D52W27DYX39 PTV CAB3, CRTCL2, CONVP3, DVDPOWER3, FCB4, FPA5, FPA3, IR3,

MID1, PSD8, SSB9

D56W136DBYX1 PTV CAB1, CRT2, CRT3, CRT4, DVD1, DVD2, FCB1, FPA1, FPA3, IR1, LSC1,

MID1, PSD1, PSD3, SSB2, CONVP1

D56W136DBYX2 PTV CAB1, CRT2, CRT3, CRT4, DVD1, DVD2, FCB1, FPA1, FPA3, IR1, LSC1,

MID1, PSD1, PSD3, SSB2, CONVP1

D56W136DBYX1

MID1, PSD1, PSD3, SSB2, CONVP1

PTV CAB1, CRT2, CRT3, CRT4, DVD1, DVD2, FCB1, FP A1, FPA3, IR1, LSC1,

I-4

Page 10

MODEL-TO-MAJOR ASSEMBLY CROSS REFERENCE

MODEL/ SERVICE NO.

D56W20BYX1 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, LSC1, MID1, PSD1, PSD3, SSB2, CONVP1

D56W20BYX2 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, LSC1, MID1, PSD1, PSD3, SSB2, CONVP1

D56W20BYX10 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, LSC1, MID1, PSD1, PSD3, SSB2, CONVP1

D61W136DBYX1 PTV CAB1, CRT2, CRT3, CRT4, DVD1, DVD2, FCB1, FPA1, FPA3, IR1, LSC1,

MID1, PSD1, PSD3, SSB2, CONVP1

D61W136DBYX2 PTV CAB1, CRT2, CRT3, CRT4, DVD1, DVD2, FCB1, FPA1, FPA3, IR1, LSC1,

MID1, PSD1, PSD3, SSB2, CONVP1

D61W136DBYX10 PTV CAB1, CRT2, CRT3, CRT4, DVD1, DVD2, FCB1, FPA1, FPA3, IR1, LSC1,

MID1, PSD1, PSD3, SSB2, CONVP1

D61W20BYX1 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, LSC1, MID1, PSD1, PSD3, SSB2, CONVP1

D61W20BYX2 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, LSC1, MID1, PSD1, PSD3, SSB2, CONVP1

HD52W59YX2 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD1, PSD3, SSB5, ADM1, CONVP1

HD52W59YX8 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD5, PSD3, SSB5, ADM2, CONVP1

HD52W59YX10 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD1, PSD3, SSB5, ADM1, CONVP1

HD52W59YX20 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD1, PSD3, SSB5, ADM2, CONVP1

HD52W59YX22 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD5, SSB5, ADM2, CONVP1

HD52W59YX23 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD5, SSB5, ADM2, CONVP1

HD52W59YX30 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD4, SSB5, ADM2, CONVP1

HD52W59YX31 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD4, SSB5, ADM2, CONVP1

HD52W59YX32 PTV CAB1, CRTCL1, FCB1, FPA1, IR1, MID1, PSD3, PSD6, SSB5, ADM2, CONVP1

HD52W59YX33 PTV CAB2, CRTCL2, CONVP2, FCB3, FPA4, IR2, MID1, PSD3, PSD7, SSB5, ADM2

HD52W59YX35 PTV CAB2, CRTCL1 CONVP2, FCB3, FPA4, IR2, MID1, PSD3, PSD7, SSB5, ADM2

HD52W59YX36 PTV CAB2, CRTCL2 CONVP2, FCB3, FPA4, IR2, MID1, PSD3, PSD7, SSB5, ADM2

HD52W59YX38 PTV CAB3, CRTCL1 CONVP3, FCB4, FPA5, IR3, MID1, PSD3, PSD8, SSB11, ADM3

HD52W59YX39 PTV CAB3, CRTCL2 CONVP3, FCB4, FPA5, IR3, MID1, PSD3, PSD8, SSB11, ADM3

HD52W59YX50 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD1, PSD3, SSB5, ADM2, CONVP1

HD52W59YX51 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD1, PSD3, SSB5, ADM2, CONVP1

HD52W64YX2 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD1, PSD3, SSB5, ADM1, CONVP1

HD52W64YX10 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD1, PSD3, SSB5, ADM1, CONVP1

HD52W64YX20 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD1, PSD3, SSB5, ADM2, CONVP1

HD52W64YX38 PTV CAB3, CRTCL1 CONVP3, FCB4, FPA5, IR3, MID1, PSD3, PSD8, SSB11, ADM3

HD52W64YX39 PTV CAB3, CRTCL2 CONVP3, FCB4, FPA5, IR3, MID1, PSD3, PSD8, SSB11, ADM3

HD52W65YX2 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD1, PSD3, SSB5, ADM1, CONVP1

HD52W65YX10 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD1, PSD3, SSB5, ADM1, CONVP1

HD52W65YX20 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD1, PSD3, SSB5, ADM2, CONVP1

HD52W65YX38 PTV CAB3, CRTCL1 CONVP3, FCB4, FPA5, IR3, MID1, PSD3, PSD8, SSB11, ADM3

HD52W65YX39 PTV CAB3, CRTCL2 CONVP3, FCB4, FPA5, IR3, MID1, PSD3, PSD8, SSB11, ADM3

HD52W66YX2 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD1, PSD3, SSB5, ADM1, CONVP1

HD52W66YX10 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD1, PSD3, SSB5, ADM1, CONVP1

HD52W66YX20 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD1, PSD3, SSB5 ADM2, CONVP1

HD52W66YX30 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD4, SSB6 ADM2, CONVP1

HD52W66YX31 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD4, SSB6 ADM2, CONVP1

CHASSIS

MAJOR ASSEMBLIES

I-5

Page 11

MODEL-TO-MAJOR ASSEMBLY CROSS REFERENCE

SERVICE NO.

HD52W66YX32 PTV CAB1, CRTCL1, FCB3, FPA4, IR2, MID1, PSD3, PSD7, SSB6 ADM2, CONVP1

HD52W66YX33 PTV CAB2, CRTCL2, CONVP 2, F CB3, FP A4, IR2, MID1, PSD7, SSB6 ADM2

HD52W66YX35 PTV CAB2, CRTCL1, CONVP 2, F CB3, FP A4, IR2, MID1, PSD7, SSB6 ADM2

HD52W66YX36 PTV CAB2, CRTCL2, CONVP 2, F CB3, FP A4, IR2, MID1, PSD7, SSB6 ADM2

HD52W66YX38 PTV CAB3, CRTCL1, CONVP 3, F CB4, FPA5, IR3, MID1, PSD8, SSB12 ADM3

HD52W66YX39 PTV CAB3, CRTCL2, CONVP 3, F CB4, FPA5, IR3, MID1, PSD8, SSB12 ADM3

HD52W66YX50 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD5, SSB6 ADM2, CONVP1

HD52W67YX20 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD6, SSB5, ADM2, CONVP1

HD52W67YX22 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD6, SSB5, ADM2, CONVP1

HD52W67YX23 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD6, SSB5, ADM2, CONVP1

HD52W67YX30 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD6, SSB5, ADM2, CONVP1

HD52W67YX31 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD6, SSB5, ADM2, CONVP1

HD52W67YX32 PTV CAB1, CRTCL1, FCB3, FPA4, IR2, MID1, PSD3, PSD7, SSB5, ADM2, CONVP1

HD52W67YX33 PTV CAB2, CRTCL2, CONVP 2, F CB3, FP A4, IR2, MID1, PSD7, SSB5 ADM2

HD52W67YX35 PTV CAB2, CRTCL1, CONVP 2, F CB3, FP A4, IR2, MID1, PSD7, SSB5 ADM2

HD52W67YX36 PTV CAB2, CRTCL2, CONVP 2, F CB3, FP A4, IR2, MID1, PSD7, SSB5 ADM2

HD52W67YX38 PTV CAB3, CRTCL1, CONVP 3, F CB4, FPA5, IR3, MID1, PSD8, SSB11 ADM3

HD52W67YX39 PTV CAB3, CRTCL2, CONVP 3, F CB4, FPA5, IR3, MID1, PSD8, SSB11 ADM3

HD52W67YX50 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD6, SSB5, ADM2, CONVP1

HD52W67YX51 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD6, SSB5, ADM2, CONVP1

HD52W68YX20 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD4, SSB6, ADM2, CONVP1

HD52W68YX22 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD4, SSB3, ADM2, CONVP1

HD52W68YX30 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD4, SSB6, ADM2, CONVP1

HD52W68YX31 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD4, SSB6, ADM2, CONVP1

HD52W68YX32 PTV CAB1, CRT2, CRT3, CRT4, FCB3, FPA4, IR2, MID1, PSD3, PSD7, SSB6, ADM2, CONVP1

HD52W68YX38 PTV CAB3, CRTCL1, CONVP3, FCB4, FPA5, IR3, MID1, PSD8, SSB12 ADM3

HD52W68YX39 PTV CAB3, CRTCL2, CONVP 3, F CB4, FPA5, IR3, MID1, PSD8, SSB12 ADM3

HD52W68YX50 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD5, SSB6, ADM2, CONVP1

HD52W69DYX21 PTV

IR1, MID1, PSD3, PSD4, SSB3, A D M2, CON V P1

HD52W69DYX22 PTV

IR1, MID1, PSD3, PSD6, SSB7, A D M2, CON V P1

HD52W69DYX23 PTV

IR1, MID1, PSD3, PSD6, SSB7, A D M2, CON V P1

HD52W69DYX30 PTV

IR1, MID1, PSD3, PSD4, SSB5, A D M2, CON V P1

HD52W69DYX31 PTV

IR1, MID1, PSD3, PSD4, SSB5, A D M2, CON V P1

HD52W69DYX32 PTV

IR2, MID1, PSD7, SSB7, ADM2

HD52W69DYX33 PTV

IR2, MID1, PSD7, SSB7, ADM2

CHASSIS MAJOR ASSEMBLIES

CAB1, CRT2, CRT3, CRT4, DVD1, DVDIN, DVD2, FCB1, FPA1, FPA3,

CAB1, CRT2, CRT3, CRT4, DVD1, DVDIN, DVD2, FCB1, FPA1, FPA3,

CAB1, CRT2, CRT3, CRT4, DVD1, DVDIN, DVD2, FCB1, FPA1, FPA3,

CAB1, CRT2, CRT3, CRT4, DVD1, DVDIN, DVD2, FCB1, FPA1, FPA3,

CAB1, CRT2, CRT3, CRT4, DVD1, DVDIN, DVD2, FCB1, FPA1, FPA3,

CAB2, CRTCL1, CONVP2, DVD1, DVDIN, DVDPOWER2, FCB3, FPA4, FPA3,

CAB2, CRTCL2, CONVP2, DVD1, DVDIN, DVDPOWER2, FCB3, FPA4, FPA3,

I-6

Page 12

MODEL-TO-MAJOR ASSEMBLY CROSS REFERENCE

MODEL/

SERVICE NO. CHASSIS

HD52W69DYX38 PTV

IR3, MID1, PSD8, SSB14 , ADM3

HD52W69DYX39 PTV

IR3, MID1, PSD8, SSB14, ADM3

HD56W65YX20 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD4, SSB5, ADM2, CONVP1

HD56W65YX21 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD4, SSB5, ADM2, CONVP1

HD56W65YX38 PTV CAB3, CRTCL1, CONVP3, FCB4, FPA5, IR3, MID1, PSD8, SSB11, ADM3

HD56W65YX39 PTV CAB3, CRTCL2, CONVP3, FCB4, FPA5, IR3, MID1, PSD8, SSB11, ADM3

HD56W66YX20 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD4, SSB6, ADM2, CONVP1

HD56W66YX21 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD4, SSB6, ADM2, CONVP1

HD56W66YX22 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD6, SSB6, ADM2, CONVP1

HD56W66YX23 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD6, SSB6, ADM2, CONVP1

HD56W66YX30 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD4, SSB6, ADM2, CONVP1

HD56W66YX31 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD4, SSB6, ADM2, CONVP1

HD56W66YX32 PTV CAB1, CRTCL1, FCB3, FPA4, IR2, MID1, PSD3, PSD7, SSB6, ADM2, CONVP1

HD56W66YX33 PTV CAB2, CRTCL2, CONVP2, FCB3, FPA4, IR2, MID1, PSD7, SSB6, ADM2

HD56W66YX38 PTV CAB3, CRTCL1, CONVP3, FCB4, FPA5, IR3, MID1, PSD8, SSB12, ADM3

HD56W66YX39 PTV CAB3, CRTCL2, CONVP3, FCB4, FPA5, IR3, MID1, PSD8, SSB12, ADM3

HD56W66YX50 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD5, SSB6, ADM2, CONVP1

HD56W66YX51 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD5, SSB6, ADM2, CONVP1

HD56W68YX2 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD1, PSD3, SSB3, ADM1, CONVP1

HD56W68YX20 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD4, SSB6, ADM2, CONVP1

HD56W68YX30 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD4, SSB6, ADM2, CONVP1

HD56W68YX31 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD4, SSB6, ADM2, CONVP1

HD56W68YX38 PTV CAB3, CRTCL1, CONVP3, FCB4, FPA5, IR3, MID1, PSD8, SSB12, ADM3

HD56W68YX39 PTV CAB3, CRTCL2, CONVP3, FCB4, FPA5, IR3, MID1, PSD8, SSB12, ADM3

HD61W66YX20 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD4, SSB6, ADM2, CONVP1

HD61W66YX21 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD4, SSB6, ADM2, CONVP1

HD61W66YX22 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD6, SSB6, ADM2, CONVP1

HD61W66YX30 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD4, SSB6, ADM2, CONVP1

HD61W66YX31 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD4, SSB6, ADM2, CONVP1

HD61W66YX32 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD7, SSB6, ADM2, CONVP1

HD61W66YX50 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD5, SSB6, ADM2, CONVP1

HD61W66YX51 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD5, SSB6, ADM2, CONVP1

HD61W68YX20 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD6, SSB6, ADM2, CONVP1

HD61W68YX22 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD6, SSB6, ADM2, CONVP1

HD61W68YX23 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD6, SSB6, ADM2, CONVP1

HD61W68YX30 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD4, SSB6, ADM2, CONVP1

HD61W66YX31 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD4, SSB6, ADM2, CONVP1

HD61W66YX32 PTV CAB1, CRTCL1, FCB3 , FPA4, IR2, MID1, PSD3, PSD7, SSB6, ADM2, CONVP1

HD61W66YX33 PTV CAB1, CRTCL2, FCB3 , FPA4, IR2, MID1, PSD3, PSD7, SSB6, ADM2, CONVP1

MAJOR ASSEMBLIES

CAB3, CRTCL1, CONVP3, DVD1, DVDIN2, DVDPOWER3, FCB4, FPA5, FPA3,

CAB3, CRTCL2, CONVP3, DVD1, DVDIN2, DVDPOWER3, FCB4, FPA5, FPA3,

MODEL/

SERVICE NO. CHASSIS

HD61W66YX38 PTV CAB3, CRTCL1, CONVP3, FCB4, FPA5, IR3, MID1, PSD8, SSB12, ADM3

HD61W66YX39 PTV CAB3, CRTCL2, CONVP3, FCB4, FPA5, IR3, MID1, PSD8, SSB12, ADM3

HD61W66YX50 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD5, SSB6, ADM2, CONVP1

HD61W66YX51 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD5, SSB6, ADM2, CONVP1

HD61W68YX22 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD6, SSB6, ADM2, CONVP1

HD61W68YX30 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD6, SSB6, ADM2, CONVP1

HD61W68YX31 PTV CAB1, CRT2, CRT3, CRT4, FCB1, FPA1, IR1, MID1, PSD3, PSD6, SSB6, ADM2, CONVP1

HD61W68YX32 PTV CAB2, CRTCL1, CONVP2, FCB3, FPA4, IR2, MID1, PSD7, SSB6, ADM2,

HD61W68YX38 PTV CAB3, CRTCL1, CONVP3, FCB4, FPA5, IR3, MID1, PSD8, SSB12, ADM3

HD61W68YX39 PTV CAB3, CRTCL2, CONVP3, FCB4, FPA5, IR3, MID1, PSD8, SSB12, ADM3

MAJOR ASSEMBLIES

I-7

Page 13

CIRCUIT PROTECTION

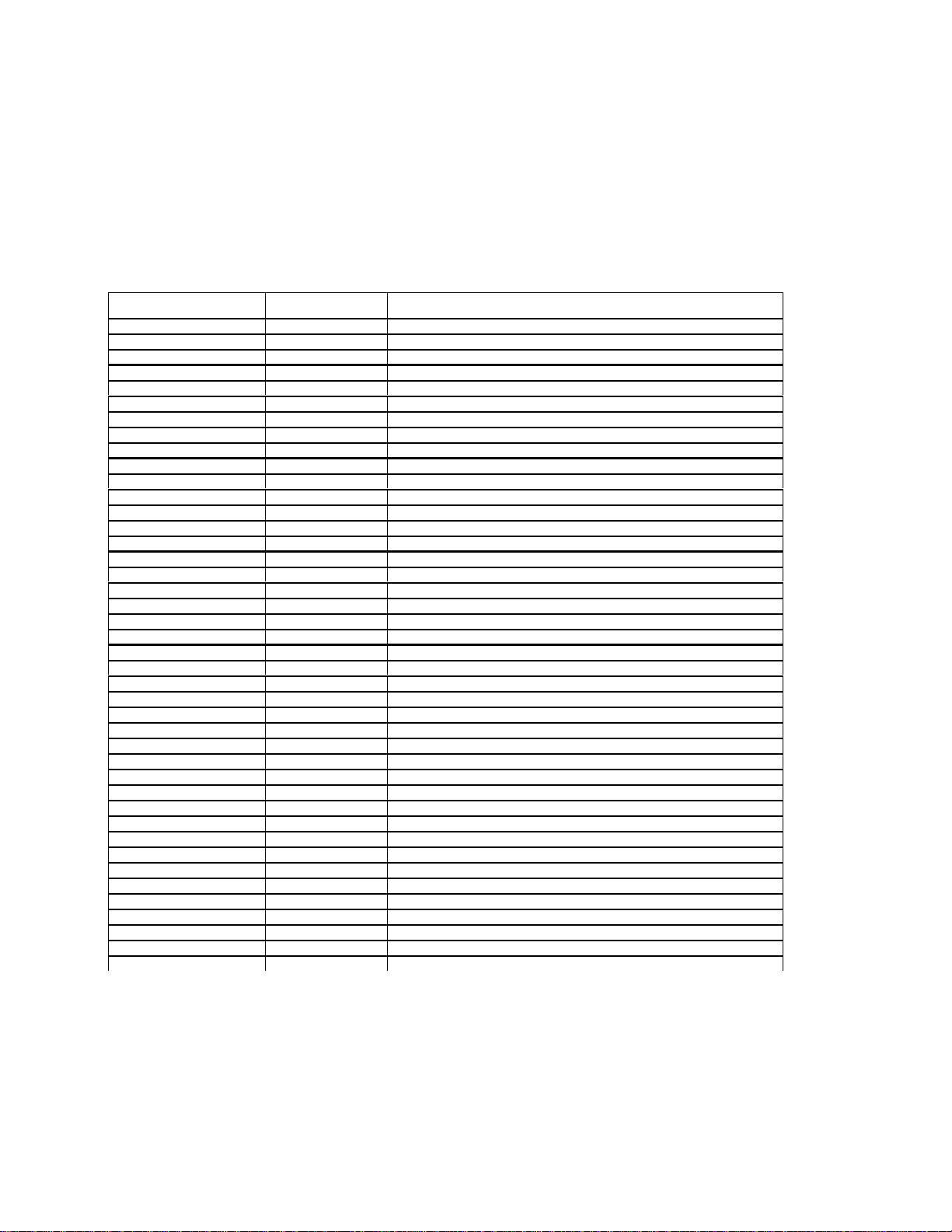

Fusible Device Circuit Protected Physical Location

FL221 (1.25, 125V) -13V Supply Power Supply/Deflection PCB

FL231 (400ma, 125V) +40V Supply Power Supply/Deflection PCB

FL251 (1.25A, 125V) +13V Supply Power Supply/Deflection PCB

FP400 (6A, 125V) AC Input Mains Input Doubler PCB

FP602 (1A, 250V) DVD Power Supply Mains Input Doubler PCB

COMPONENT NUMBERING SYSTEM

Serviceability of this chassis is enhanced by road mapping on the top and bottom of the circuit boards. In

addition components are marked as to the Component Type and generally marked as to their circuit. The

operation and features of the “ITC” chassis is similar to the “CTC” series chassis. However the component

numbering system is different than that in the past in the “CTC” series chassis but is similar to the component

markings of the “TX” series chassis. The component numbering for the chassis reflects the component’s

type and use as to the general circuit areas it is used. The component labeling system is described below:

COMPONENT DESIGNATION: X X XXX

COMPONENT TYPE CIRCUIT COMPONENT NUMBER

B-Connector A - Audio 01 - 499 PS/D PCB (top)

C-Capacitor C - Chroma 500 - 599 PS/D PCB (bottom)

D-Diode D - DC-DC Convertor

F-Fuse F - Vertical 01 - 099 DFB PCB (top)

I-Integrated Circuit G - Gemstar

J-Jumper H - Tuner 001 - 099 FCB PCB (top)

L-Transformer/Inductor I - IF 501 - 599 FCB PCB (top)

P-V ariable Resistor J - Sync Separator

Q-Filter/Crystal K - Customer Control 001 - 099 FPA PCB (top)

R-Resistor L - Horizont al 501 - 599 FP A PCB (top)

S-Switch P - Power Supplies

T-T ransistor R - System Control 01 - 99 Kine PCB (top)

V-Delay Line U - Kine Drivers 500 - 599 Kine PCB (bottom)

V - Video

Z - XRP

EXAMPLES:

TP20 - Transistor, Power, 20 (number, top side of PS/D PCB)

RA543 - Resistor, Audio, 543 (number, bottom side of SSB PCB)

CF04 - Capacitor, Vertical, 07 (number , top side of PS/D PCB)

IR02 - Integrated Circuit, System Control, 02 (number, top side of SSB PCB)

I-8

Page 14

Page 15

II

DISASSEMBLY

Page 16

DISASSEMBLY

Direct View Models

Lower Back Cover Removal

The back cabinet is held in place with several T-20

Torx head screws. The number and placement of

the screws may vary with cabinet designs.

Chassis Tray/Front Control Panel/Front AV

Jack/ Removal/Service Position

1. Remove the Back Cabinet Assembly

2. Lift sides of chassis tray assembly

3. Slide chassis tray assembly away from CRT

approximately 2 - 3".

4. Chassis will release from bottom cabinet

assembly.

5. Remove 1 T -20 Torx head screw from Front

A/V Jack Housing.

6. With a small screwdriver release tab

securing Front A/V Housing to Cabinet

Assembly . Slide Housing away from cabinet

to remove.

7. Remove 2 T-20 T orx head screws mounting

Front Control Panel to Front Cabinet

Assembly.

8. Chassis may now be placed in the Service

Position. See diagram below.

9. T o place chassis tray back into the cabinet,

align the bottom of the chassis tray with the

locking mechanism of the bottom cabinet

assembly.

10. Slide chassis towards the CRT . Chassis will

drop into the locking mechanism. Continue

to slide forward to lock chassis into place.

Note: Lead dress is critical to the performance of

the instrument. Care should be taken to

dress all leads in their original positions. See

section on Critical Lead Dress.

CRT Removal

1. Remove Back Cabinet Assembly (See Back

Cabinet Removal).

2. Disconnect cables to Speaker Assemblies,

Front Panel Assembly, Degauss Coil,

Deflection Yoke, Field Correction Coil and

SVM Coil.

3. Remove Front A/V Assembly . (See Front AV

Jack Removal, step 6).

4. Remove Anode Lead from CRT. Care

should be taken to prevent shock before

removal. Discharge CRT Anode to CRT

Ground.

5. Remove Kine Drive PCB from CRT.

6. Disconnect CRT Ground Lead.

7. Remove Chassis Tray Assembly . (See steps

2 and 3 of Chassis Tray Removal).

8. Remove Degauss Coil and Degauss Coil

clips from CRT.

9. Remove Field Correction Coil.

10. Lay instrument face down on a soft surface

to prevent damage to the Front Cabinet

Assembly and CRT face.

11. Remove 4, 10mm bolts securing CRT to

Cabinet Assembly .

12. Carefully remove CRT from Cabinet

Assembly . Remove Ground Strap and place

on new CRT.

13. Reinstall in reverse order.

Power Supply/Scan PCB Removal

1. Remove Chassis Tray from bottom Cabinet

Assembly (See Chassis Tray Removal).

2. Remove Dynamic Focus PCB.

3. Disconnect cables

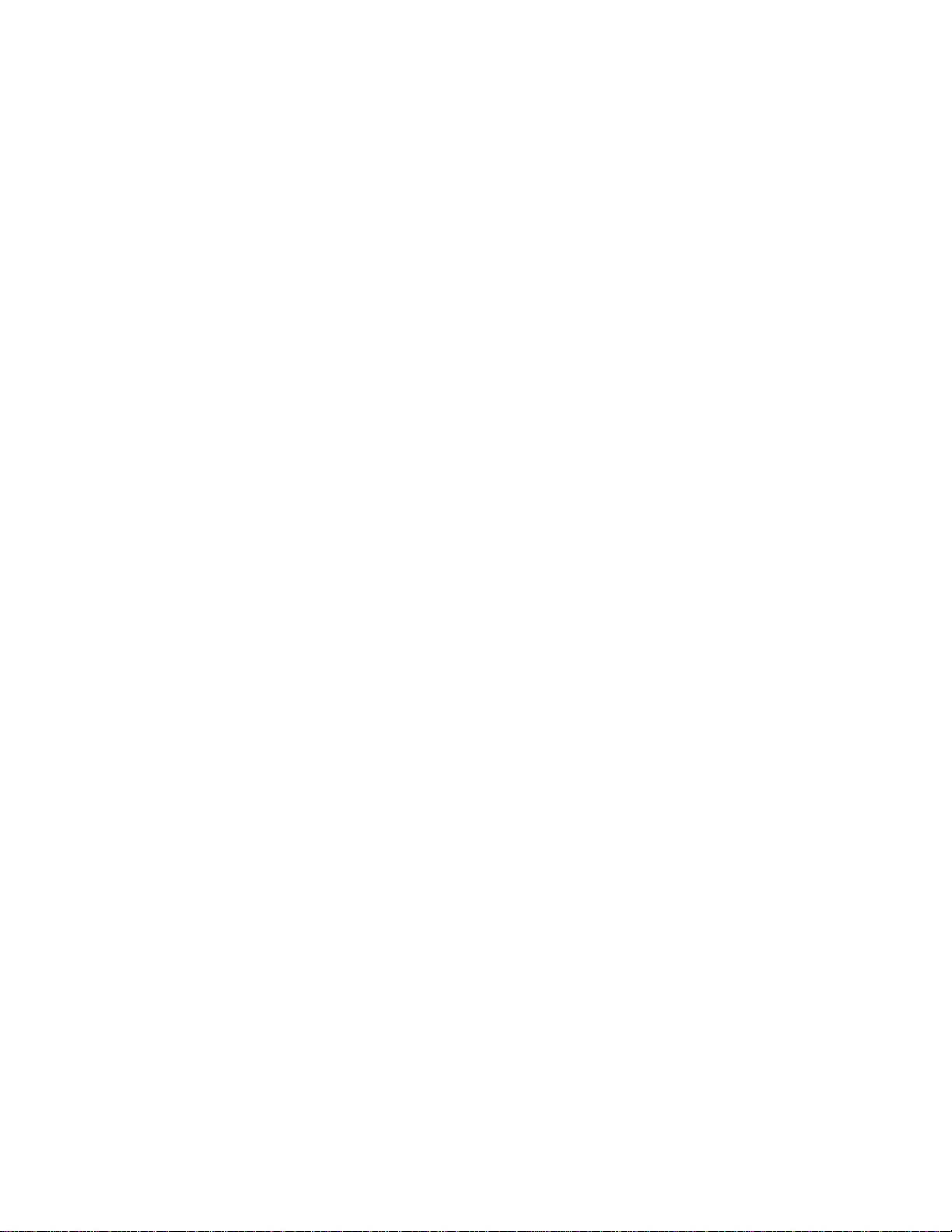

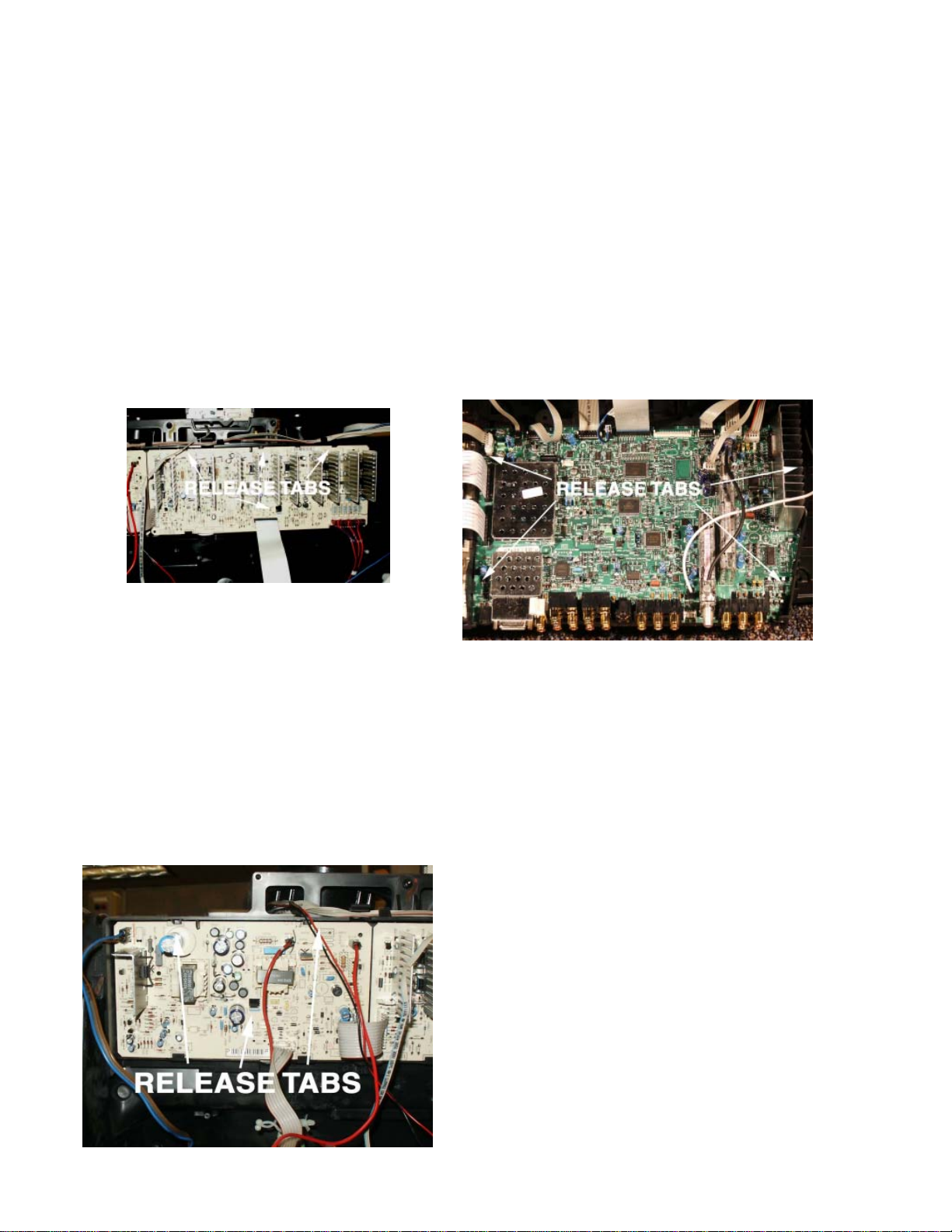

4. Press tabs to release Power Supply/Scan

PCB from the Chassis Tray.

5. Lift PCB from the rear to remove from

chassis tray .

Reinstall in reverse order .

II-1

Page 17

Mains Input Doubler (MID) PCB Removal

1. Remove chassis tray from cabinet assembly

(See Chassis Tray Removal).

2. With a small screwdriver release 2 tabs

holding MID bracket to chassis tray .

3. Disconnect cables.

4. Release tabs on chassis tray.

5. Lift MID PCB from the chassis tray.

Small Signal (SSB) PCB Removal

1. Remove DRI PCB (See above).

2. Remove DRI PCB Bracket. Release 2 tabs

at front of bracket. Lift front of bracket to

remove from chassis tray.

3. Remove 3 T-10H Torx head screws from

Jack Panel portion of the Chassis Tray

Assembly.

4. Disconnect cables.

5. Release tabs on Chassis T ray Assembly.

6. Slide Small Signal PCB towards the front of

the instrument and lift out to remove.

7. Reinstall in reverse order .

II-2

Page 18

DISASSEMBLY

Projection Models

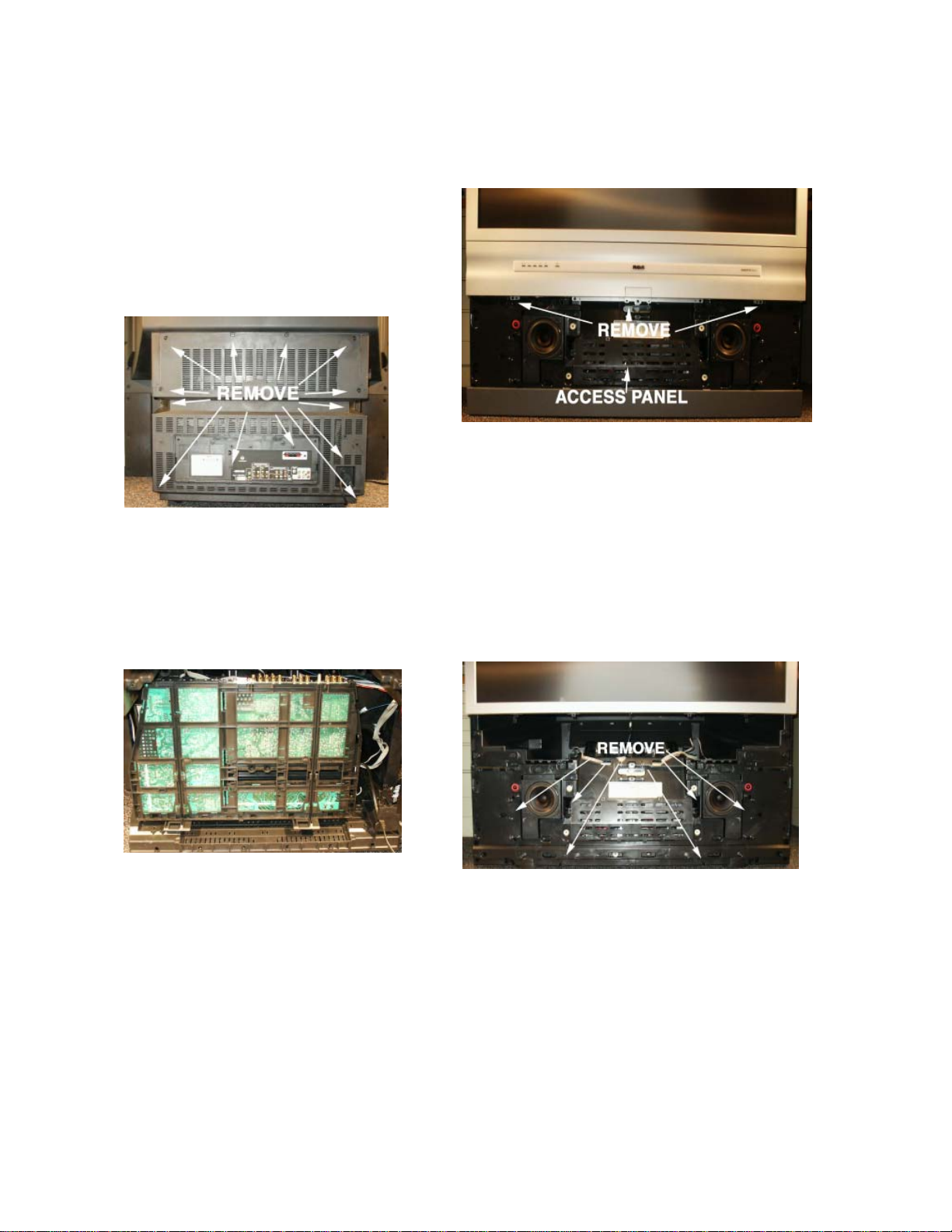

Back Cabinet Removal

The back cabinet is held in place with several T -20

Torx head screws. The number and placement of

the screws may vary with cabinet designs. If model

has a subwoofer, disconnect cable at bottom of

cabinet assembly .

Chassis Tray Removal/Service Position

1. Remove the Back Cabinet Assembly

2. Lift sides of chassis tray assembly

3. Slide chassis tray assembly away from

CRT’s approximately 2 - 3".

4. Chassis will release from bottom cabinet

assembly.

5. Chassis may now be placed in the Service

Position. See diagram below.

3. Remove T-20 Torx head screws holding

front cabinet assembly. Unplug cables for

Front Panel Assembly and Front Audio/

Video Jack Assembly. FPA and Front A/V

Assemblies may now be serviced.

4. Access Panel may now be removed to allow

service of Kine Drive circuits.

5. Remove T-20 Torx head screws securing

front frame to cabinet assembly .

6. Speaker Assemblies may now be serviced.

Remove 5 T-20 Torx head screws to gain

access to crossover circuit located internal

to each speaker enclosure.

7. Reassembly in reverse order. If instrument

is a DVD Model, ensure DVD door is aligned

properly

6. T o place chassis tray back into the cabinet,

align the bottom of the chassis tray with the

locking mechanism of the bottom cabinet

assembly.

Cabinet Front Disassembly , FPA/Front A/V

PCB/Speaker Removal

1. Grasp Speaker Grille on the sides. Pull

away from instrument to remove.

2. Remove T-20 Torx head screws holding

front bottom.

Screen/Mirror Removal, IR PCB/Convergence

Auto Sensor Replacement.

1. Remove Front Cabinet Assembly. (See

steps 1 and 3 in Cabinet Front Disassembly)

2. Remove T-20 Torx head screws securing

Screen Assembly to cabinet frame.

3. With Screen Assembly removed, IR PCB

may now be serviced.

4. Convergence Auto Sensors may now be

replaced. Remove T-20 Torx head screws

securing each sensor to the cabinet frame.

5. Remove 4 T -20 Torx head screws securing

the mirror to the cabinet frame.

II-3

Page 19

CRT Assembly Removal, Focus/Screen

Assembly/HV Splitter Assembly Replacement

1. Remove Cabinet Front Assembly. (See

Cabinet Front Disassembly).

2. Remove Screen Assembly. (See Screen/

Mirror Removal).

3. Remove Kine Drive PCB’s from CRT.

4. Remove IR PCB from holder located on top

of CRT Assembly.

5. Disconnect Convergence Y oke Cables from

Convergence Amp PCB and Deflection

Yoke Cables from Convergence Adapter

PCB. Disconnect SVM cables and CRT

ground cables from each Kine Drive PCB.

6. Remove Anode Lead from HV S plitter (Lead

from IHVT to HV Splitter). Anode Lead can

be removed by pushing in slightly , then twist

and pull. If HV Splitter Assembly needs to

be replaced, remove Anode Leads to each

CRT . Use same procedure to remove leads.

Disconnect Ground lead. Remove ¼ inch

screw securing assembly to bracket

7. Remove ¼ inch screw securing Focus/

Screen Assembly to CRT Frame.

8. Remove 4 T -20 Torx head screws securing

CRT assembly to Cabinet Frame. Slide CRT

Assembly out to remove from cabinet. (It

may be necessary to remove the Speaker

Assemblies).

9. Reinstall in reverse order .

7. Lift Upper Cabinet straight up to remove.

8. Reassemble in reverse order.

Power Supply/Scan PCB Removal

1. Remove Chassis Tray from bottom Cabinet

Assembly (See Chassis Tray Removal).

2. Disconnect cables

3. Press tabs to release Power Supply/Scan

PCB from the Chassis Tray.

4. Lift PCB from the rear to remove from

chassis tray .

5. Reinstall in reverse order .

Note: Lead Dress is critical to the operation of the

instrument. Care should be taken to dress

all leads in their original positions. See

section on Critical Lead Dress.

Upper Cabinet Assembly Removal

For ease of service the upper and lower cabinet

assemblies may be separated.

1. Remove back cabinet assembly . (See Back

Cabinet Removal).

2. Remove Cabinet Front Assembly. (See

Cabinet Front Disassembly .

3. Remove Front Panel Assembly and Front

A/V from holder. (Front A/V may be left in

the Cabinet Front Assembly by

disconnection the cables).

4. Disconnect cable to Auto Convergence

Sensors.

5. Disconnect cables from DVD assembly if

instrument is a DVD model.

6. Remove 4 T -20 Torx head screws securing

Upper and Lower Cabinet Assemblies.

Mains Input Doubler (MID) PCB Removal

1. Remove chassis tray from cabinet assembly

(See Chassis Tray Removal).

2. Remove bracket behind SSB board.

3. With a small screwdriver release 2 tabs

holding MID bracket to chassis tray .

II-4

Page 20

DISASSEMBLY

4. Disconnect cables.

5. Release tabs on chassis tray.

6. Lift MID PCB from the chassis tray.

Convergence Adapter PCB/ Convergence

Amplifier PCB Removal

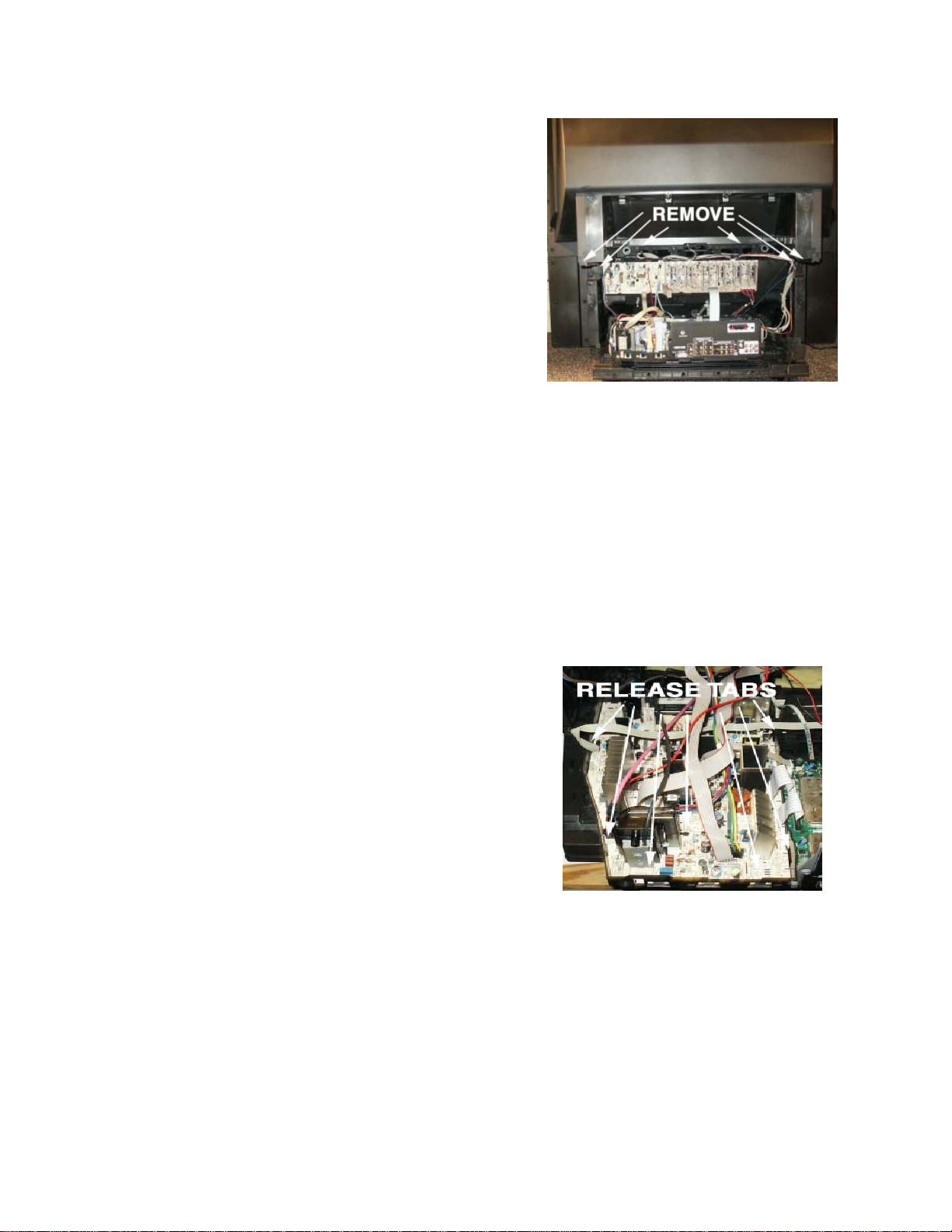

1. Remove T -20 Torx head screw from middle

of PCB.

2. Release tabs at top of PCB to remove from

bracket.

3. Disconnect cables

4. Reinstall in reverse order .

Small Signal (SSB) PCB Removal

1. Remove DRI PCB (See above).

2. Remove DRI PCB Bracket. Release 2 tabs

at front of bracket. Lift front of bracket to

remove from chassis tray.

3. Remove 3 T-10H Torx head screws from

Jack Panel portion of the Chassis Tray

Assembly.

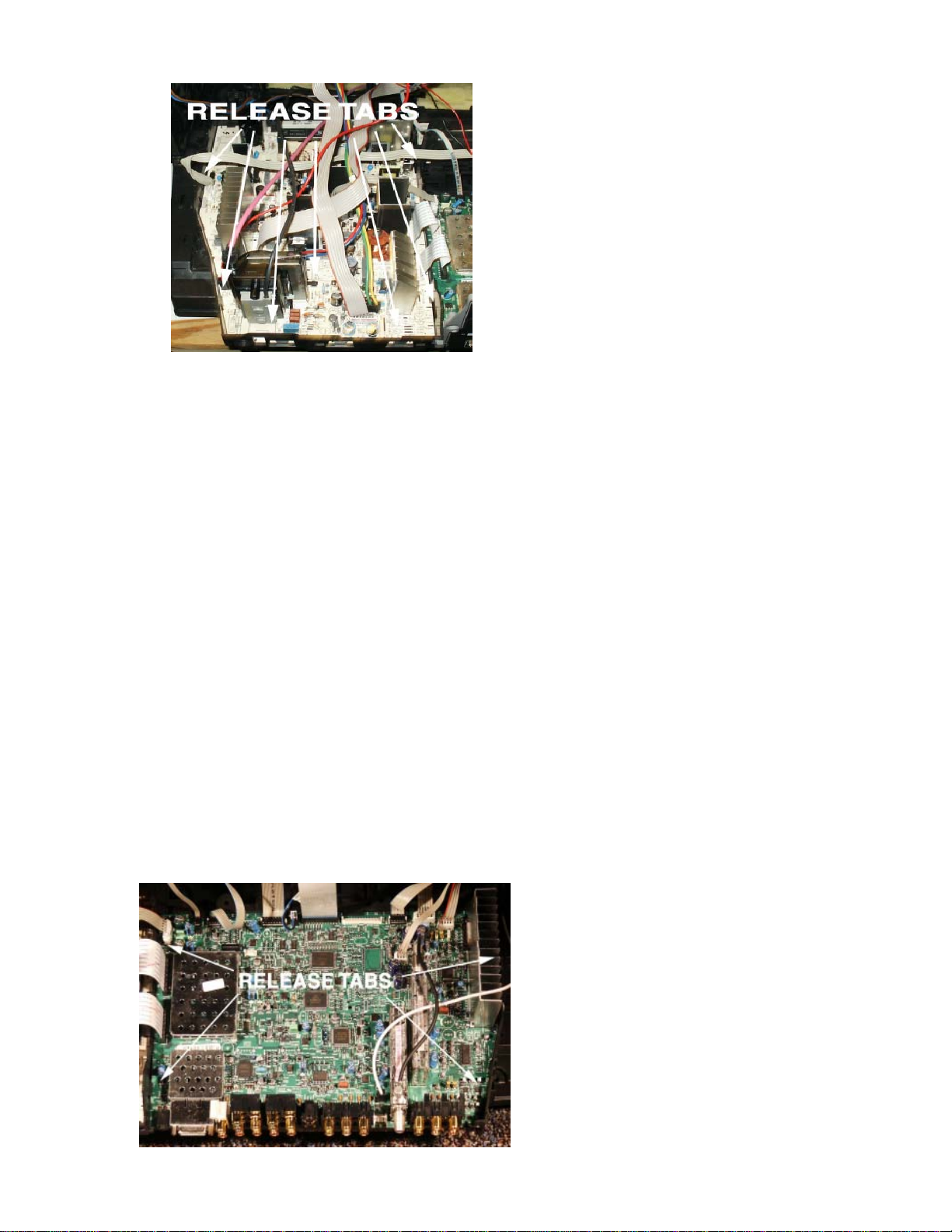

4. Disconnect cables.

5. Release tabs on Chassis T ray Assembly.

6. Slide Small Signal PCB towards the front of

the instrument and lift out to remove.

7. Reinstall in reverse order .

Convergence Signal PCB Removal

1. Using a screwdriver pry up on tab under

bracket. (See diagram below).

2. Pull back on bracket to remove convergence

signal bracket from chassis.

3. Release tabs on top of bracket to remove

Convergence Signal PCB.

4. Disconnect cables.

5. Reinstall in reverse order .

DVD Unit Removal (PTV Models)

1. Remove Back Cabinet Assembly.

2. Remove Front Cabinet Assembly (See Front

Cabinet Disassembly).

3. Disconnect cables from DVD Unit.

4. Remove T-20 Torx head screws securing

DVSD Unit to Cabinet Frame.

5. Lift to remove DVD Unit from Cabinet.

6. Reinstall in reverse order .

II-5

Page 21

III

Interconnect

Page 22

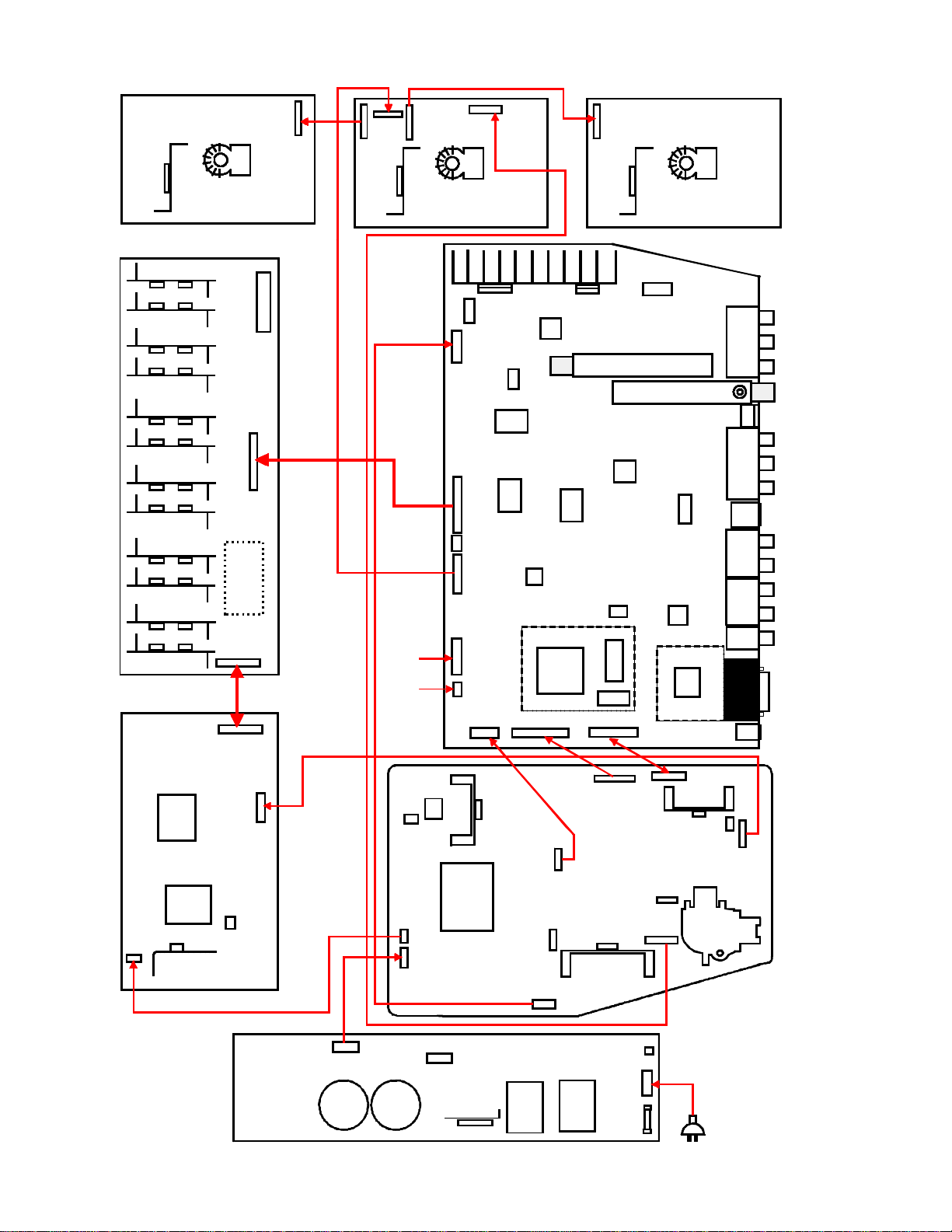

Interconnect

BB104

Red

IB101

BB204

BB203

BB201

IB201

BB202

Grn

G-CRT

R-CRT

BW001 BW002

BA001

IA001

BA010

BA002

CAM

IC040

SSB

BW005

GH GV RH RV

BV

Watchdog

Circuit Area

BH

BW004

IR & Key Board

IK201

BK270BV500

IV400

BR001

IR001

BB303

Blue

IB301

B-CRT

IA900

Out

n

o

c

e

S

r

e

n

u

T

d

r

e

n

u

T

IV100

IV300

IR006

Gem Cam

IX300

IX400

IT600

Monitor

n

i

a

M

E

T

s

C

B

s

I

u

1&2

CVBS

S

Vid

2

Comp

1

Comp

DVI

Aud

DVI

BK202

LP050

DP400

BP501

TP020

LP401

BL660

LP020

LP605

BL600

CPS

LP650

IP650

BP610

TP630

B

2

0

4

P

MID

CP410

IP080

PSD

BP010 BP011

BP401

CP411

BP500

BP005

BP150

BP120

BP130

LP400

TL010

BV001

BL111

BL035

BL200

BP414

BP400

FP400

G

Link

BL500

BF001

LL008

III-1

Page 23

III-2

Page 24

Page 25

IVII-4

VOLTAGE

CHARTS

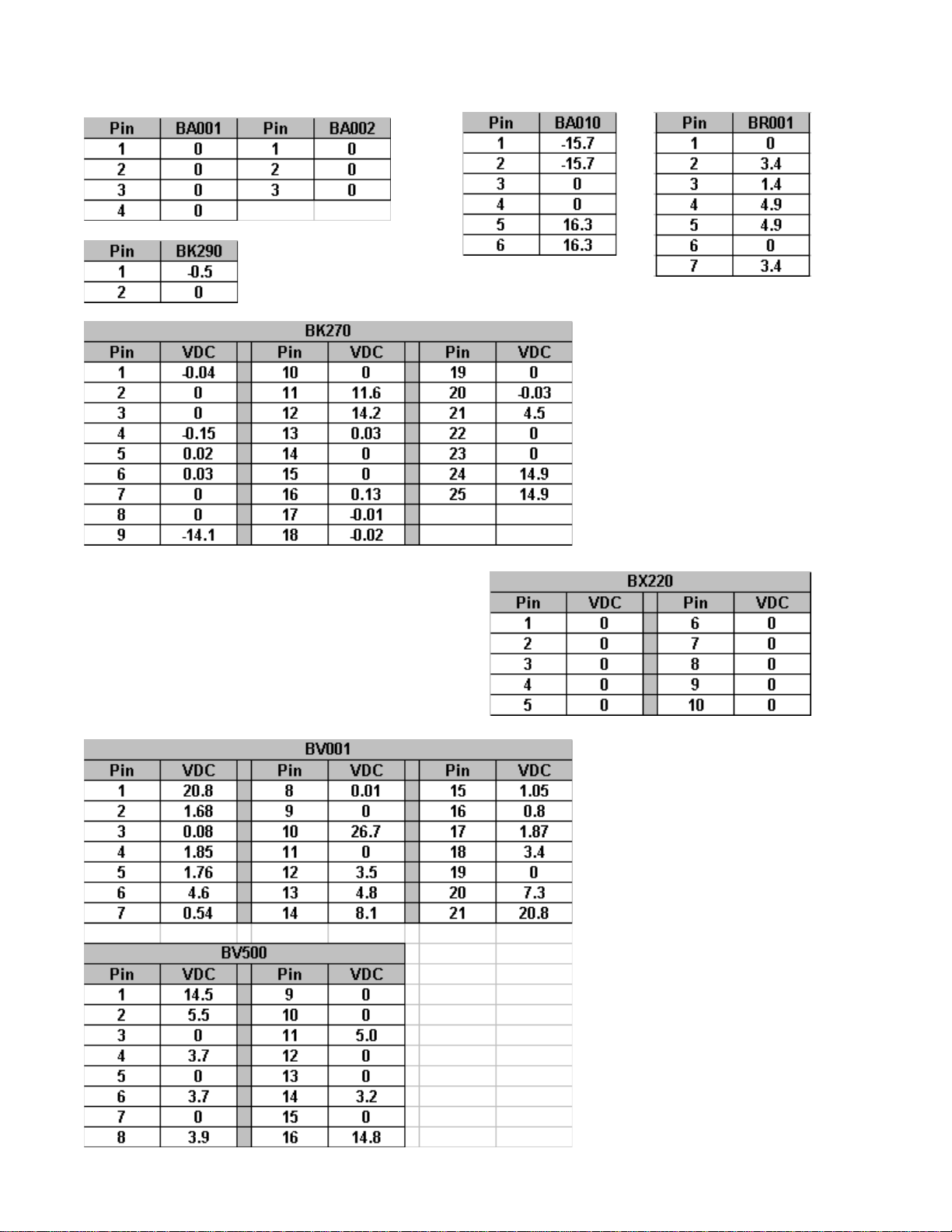

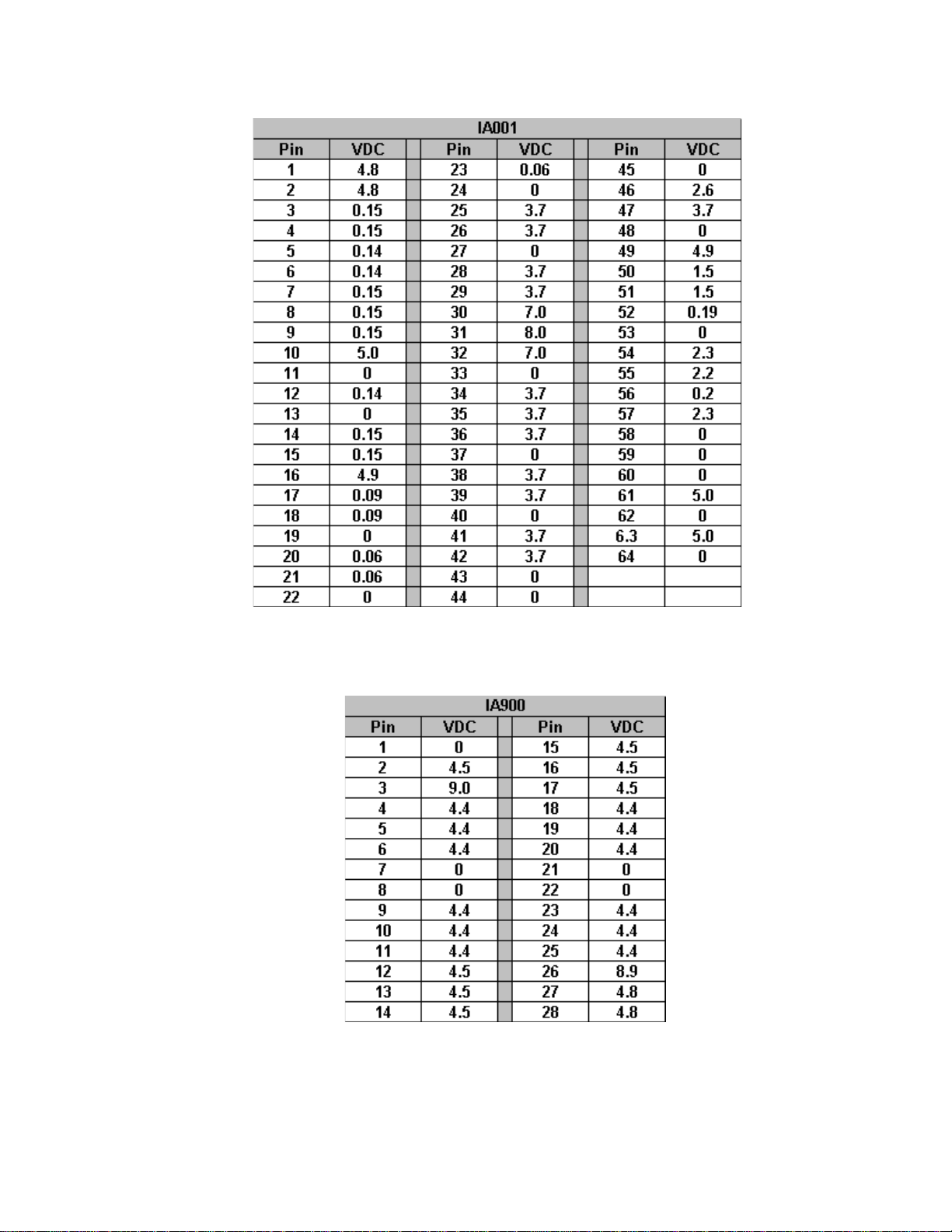

Page 26

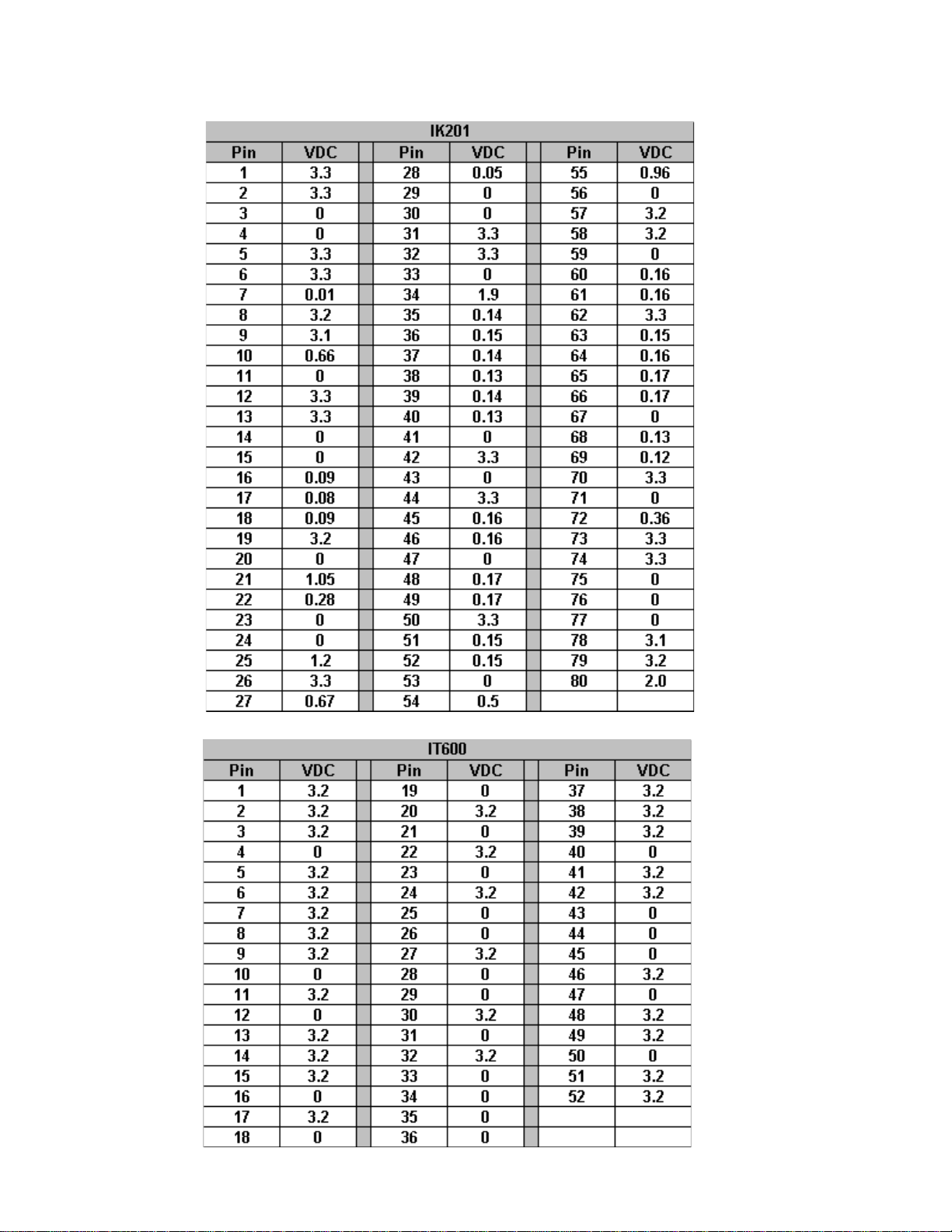

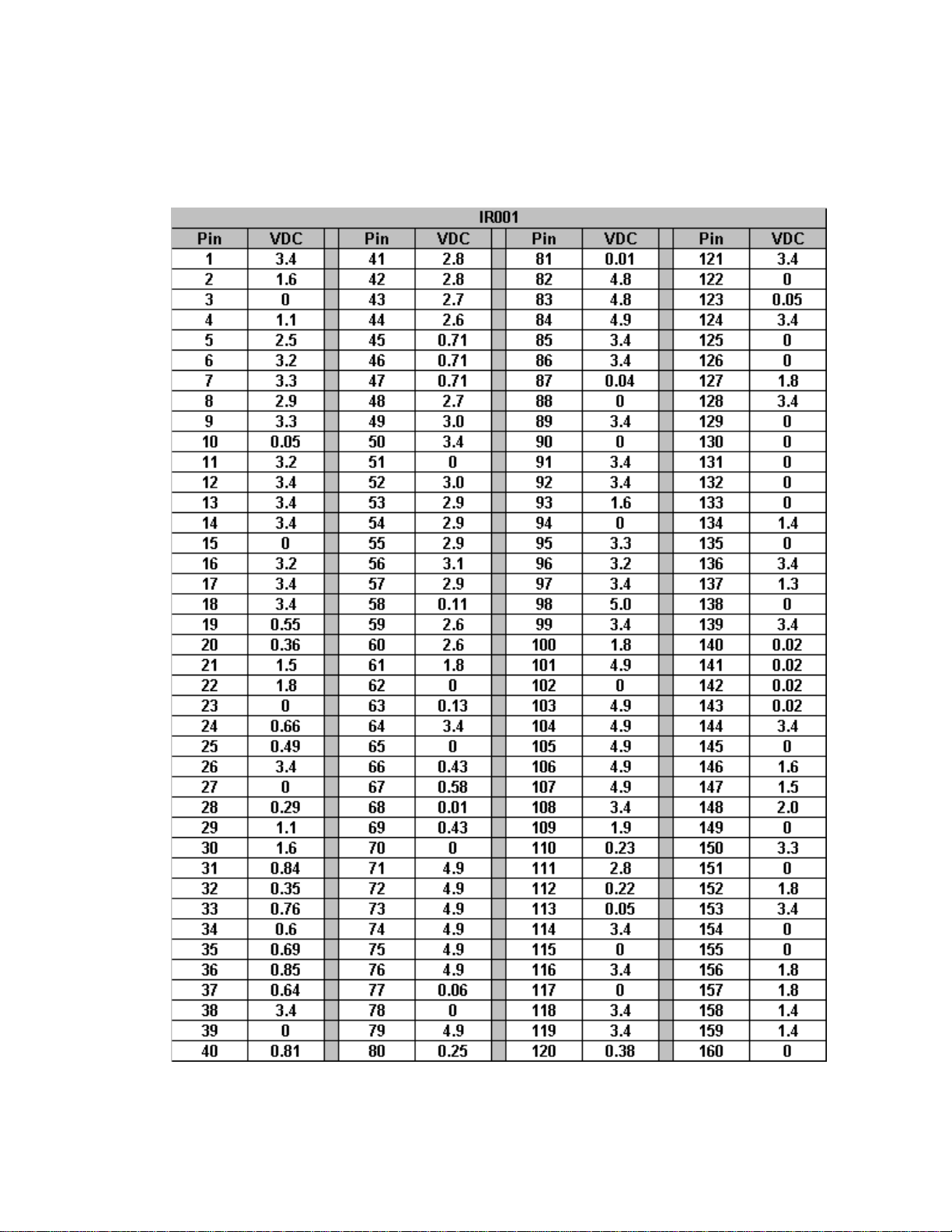

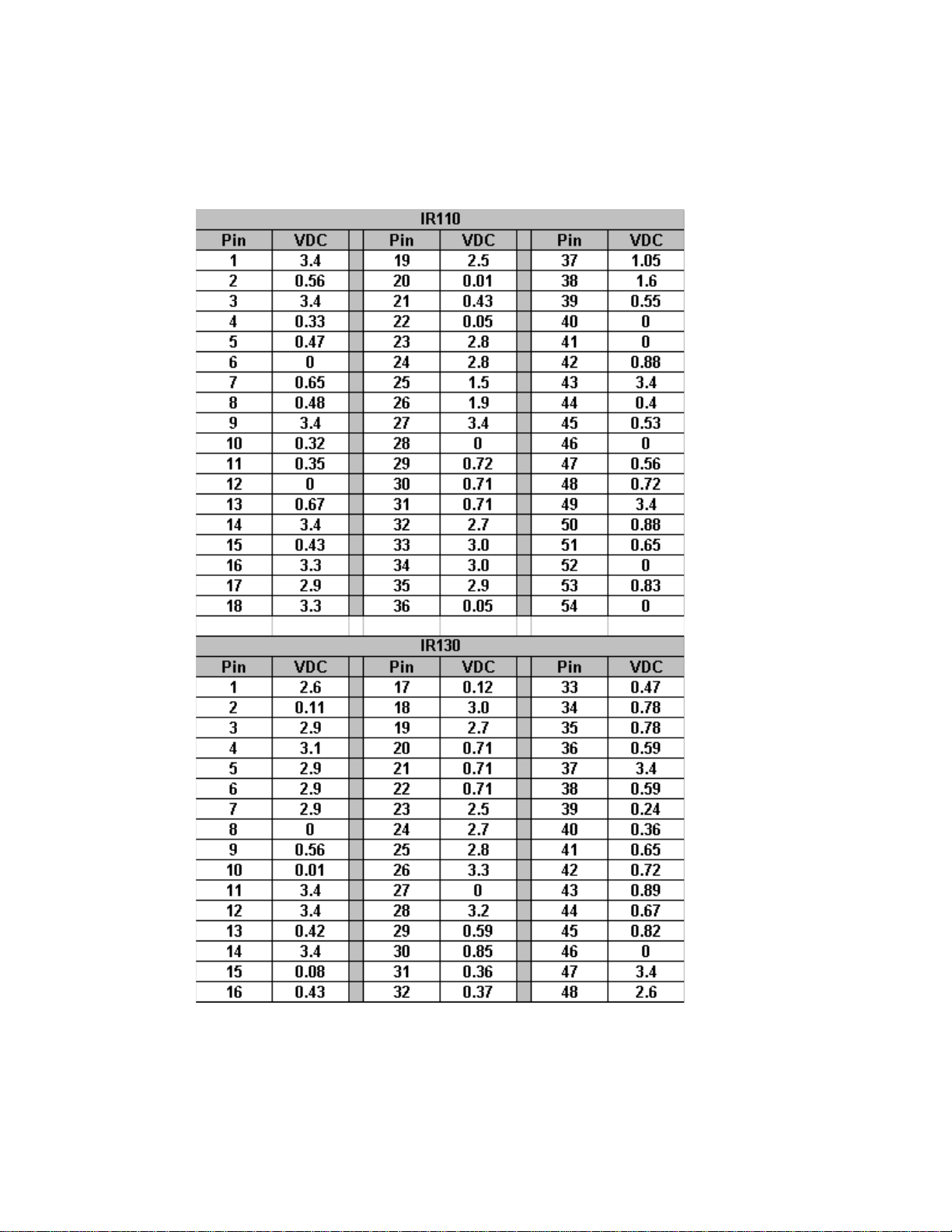

VOL T AGE CHARTS

IV-1

Page 27

VOL T AGE CHARTS

IV-2

Page 28

VOL T AGE CHARTS

IV-3

Page 29

VOL T AGE CHARTS

IV-4

Page 30

VOL T AGE CHARTS

IV-5

Page 31

VOL T AGE CHARTS

IV-6

Page 32

VOL T AGE CHARTS

IV-7

Page 33

V

WAVEFORMS

Page 34

WAVEFORMS

WFC10 WFC11

WFC12 WFC13

WFC14 WFC15

V-1

Page 35

W AVEFORMS

WFC16

WFC18 WFC19

WFC17

WFC20 WFC21

V-2

Page 36

WAVEFORMS

WFC22 WFC23

WFC24 WFC25

WFC26 WFC27

V-3

Page 37

W AVEFORMS

WFC28 WFC29

WFC30 WFC31

WFC32 WFC33

V-4

Page 38

WAVEFORMS

WFC34 WFC35

WFC36 WFC37

WFC38 WFC39

V-5

Page 39

W AVEFORMS

WFC40 WFC41

WFC42 WFC43

WFC44 WFC45

V-6

Page 40

WAVEFORMS

WFD01

WFD03

WFD02

WFD04

WFD05 WFD06

V-7

Page 41

W AVEFORMS

WFD07 WFD08

WFD09 WFD10

WFD11 WFD12

V-8

Page 42

WAVEFORMS

WFD13 WFD14

WFD15 WFD16

WFD17 WFD18

V-9

Page 43

W AVEFORMS

WFD19 WFD20

WFD21 WFD22

WFD23 WFD24

V-10

Page 44

WAVEFORMS

WFD25 WFD26

WFD27 WFD28

WFD29 WFD30

V-11

Page 45

W AVEFORMS

WFD31 WFD32

WFD33 WFD34

WFK01 WFK02

V-12

Page 46

WAVEFORMS

WFK04WFK03

V-13

WFK06WFK05

WFK08WFK07

Page 47

W AVEFORMS

WFP01WFK09

V-14

WFP02WFP01A

WFP03WFP02A

Page 48

WAVEFORMS

WFP03A WFP04

WFP04A WFP05

WFP05A WFP06

V-15

Page 49

W AVEFORMS

WFP07 WFP08

WFP09 WFP10

WFP11 WFP12

V-16

Page 50

WAVEFORMS

WFP13 WFP14

WFP15 WFP16

WFP17 WFP18

V-17

Page 51

W AVEFORMS

WFP19 WFP120

WFP21

WFP23 WFP25

WFP22

V-18

Page 52

WFP25

V-19

Page 53

VI

ALIGNMENT

PROCEDURES

Page 54

ALIGNMENT PROCEDURES

Operating Conditions

Unless otherwise noted, the following conditions

must be observed when aligning the ITC222 chassis:

Chassis must be operated from a 120V AC isolation

transformer, with line volt age set to 120V AC (±2.0V).

Picture controls (black level, contrast, etc.) must be

set to factory presets via the Picture Quality menu.

Procedures must be performed in the sequence

given. A 10X probe must be used for oscilloscope

and frequency measurements.

The audio output leads must not be shorted together

or to ground with the chassis on. All video signals

must have -40 IRE sync tips unless specified

otherwise. Chassis AC power must be removed for

10 seconds before disconnecting any cable.

A 3-minute warm-up is required for chassis or

module related alignments. A 15-minute warm-up

is required for Kine or Convergence related

alignments.

Required T est Equipment

- Dual-Trace Oscilloscope

- Digital Voltmeter

- Frequency Counter

- Audio Signal Generator

- NTSC Signal Generator (B&K 1249, or

equivalent)

- MTS Signal Generator (B&K 2009, or

equivalent)

- Sweep/Marker Generator (or Standard Signal

Generator)

- YPrPb Signal Generator (DVD player w/YPrPb)

- DC Power Supply (5.0V/0.25A) for TAG001

- Chipper Check® software

- Chipper Check® interface box and computer

- Personal Computer (IBM Compatible w/ CD

ROM and Sound Card)

NOTE: For optimum performance it is critical that

this instrument be properly aligned. For Auto

Convergence to work correctly it is HIGHLY

RCOMMENDED that the geometry alignments are first verified

Small Signal Board (SSB) Replacement

All alignment data is stored in EEPROMs located

on the Small Signal Board (SSB). If the SSB needs

to be replaced, it is HIGHLY RECOMMENDED the

EEPROM data be downloaded by using Chipper

Check. Once the SSB has been replaced, upload

the alignment data back into the instrument. Then

verify that the instrument is properly aligned.

1. Open Chipper Check. Select “Dead Set”

“ITC222”. Follow the On Screen Instructions to

establish a connection. Fill in the Customer Information on the “Customer Info” tab and

change to the EEPROM tab.

The following menu should appear.

2. Press the “Replace SSB Board” The following

screen appears

VI-1

Page 55

The instrument should display the following menu:

Soft-Ver. ITC222_V100-0 000046 :37

DVD Soft -Ver. 3.12

Config. W - - V - - -P - Serial-No. AMN456789

QUIT

TUBE

CHASSIS SETUP

FEATURE SETUP

GEOMETRY

VIDEO

EVENT HISTORY

SOUND

MISCELLANEOUS

CONVERGENCE

DVD

3. Follow the instructions on this screen to copy

the alignment data from the defective SSB to

the new SSB.

NOTE: It may be necessary to perform the geom-

etry alignment to get the auto convergence

to work correctly . Please refer to the section

on Geometry Alignments

CRT Replacement (PTV Models)

If only 1 or 2 CRT’s are replaced use a convergence

pattern to align the new CRT. Align the new CR T to

the pattern generated by the existing CRT. Then run

Auto Convergence.

If all 3 CRT’s are replaced, it will be necessary to

first center the Green CRT using a pattern with a

center dot. Then align Red and Blue following the

Geometry Alignment procedures in the service data.

Service Mode

Most of the alignments for this chassis are softwaredriven. Most of the alignments must be accessed

and modified through the front panel service mode.

Entering the TV Service Mode Using the Front

Panel Controls

1. Press and release the POWER button to turn

the instrument off.

2. Wait 10 seconds before trying to enter the Field

Service Mode.

3. Press and hold the VOLUME DOWN and

CHANNEL DOWN buttons for at least 8

seconds.

4. The instrument will switch on and come up with

the field service main menu on the screen. LED

will illuminate before the picture comes up.

UP DOWN

SELECT

Main Menu

The CH /\ and CH \/ buttons on the front panel

are used to navigate up or down in the menu.

The VOL + and VOL - buttons on the FPA are

used to select a menu item or decrease or

increase a value in a selection list.

NOTE: Before the Field Service Mode is exited; you

must check STORE or all changes to

alignments will be lost.

The remote control can also be used to navigate

the field service mode.

• Clear button: When this button is pressed

the Field Service Mode disappears and the

every-day TV functions are available.

• Menu button: To re-enter the Field Service

Mode, make a long press on the Menu

button. The service technician re-enters in

the same menu point where he left the Field

Service Mode.

∧∧

•

∧: This button is used to navigate up in the

∧∧

menu.

∨∨

•

∨: This button is used to navigate down in

∨∨

the menu.

VI-2

Page 56

• <: This button is used to select a menu item,

to decrease a value or to select the previous

value in a selection list.

• >: This button is used to select a menu item,

to increase a value or to select the next value

in a selection list.

• OK: This button is used to select or deselect

a menu item.

Main Menu

Soft-Ver: Displays the current software version.

Runtime Counter: Displays the total runtime in

hours and mintues.

TUBE

Return

Tube Type RP 16x9

Store

Restore

UP DOWN SELECT

DVD Soft-Ver: For DVD models only , displays

the current software version.

Config: Displays the configuration code of the

instrument. Each character represents a

paraticular hardware feature or option.

Serial-No.: Displays the serial number of the

instrument.

Common features found in the submenus

Return: The submenu is closed and the main

Field Service Mode menu appears.

Defaults: The default values for the current

menu are copied from ROM to RAM.

Note: If Default is checked a complete realignment of

that particular menu is required.

Store: All current values from a menu group are

stored into memory .

Restore: The last stored settings for the menu

displayed are copied from NVM to RAM.

Tube Submenu

Chassis Setup

Subwoofer: Allows the instrument to be

configured for a subwoofer

Pict. Rotation: Specifies whether the picture

rotation option is available or not. (DV Models

Only)

Autoconvergence: Specifies whether the

autoconvergence option is available or not. (PTV

Models Only)

DVI: Specifies whether the DVI option is

available or not.

Toplight: Specifies whether the toplight option

is available or not.

CHASSIS SETUP

Re tur n

Tube Type Menu

1. Select the correct tube type from a pulled down

list on the right hand side of the menu. (This

will activate new tube type values along with

default video and geometry parameters)

2. Check STORE to save new parameters in

memory.

Subwoofer

Pict. Rota t ion

Autoconvergence

DVI

Toplight

Defaults

UP DOWN SELECT

Chassis Setup Submenu

VI-3

Page 57

Feature Setup

Curtains Effect: Determines if the curtains

feature is available to the user.

Opt. Still Pict. : Determines if the Optimised

Still Picture feature is available to the user.

Auto Film Mode: Determines if the Automatic

Film Mode Detection feature is available to the

user.

Burn-In Prot. : Determines if the Burn-In

Protection feature is available to the user.

FEATURE SETUP

Return

Curt ai n s Effe ct

Opt. Still Pict.

Auto Film Mode

Demo Mode

Burn-In Prot.

Welcome/Contact

Program Info

Defaults

UP DOWN SELECT

Feature Setup Submenu

Geometry Alignment

Entering the Geometry menu the display mode

must be set to Standard Scanning Mode (480i/

480p and 1080i). All 480i/480p alignment s should

be completed using the RF input. Use either

component input or DVI-input for 1080i

adjustments.

Geometry Submenu

Alignment Procedure (Direct View Models

Only)

NOTE: Unless otherwise noted all Geometry

adjustments must performed in both 480i/p

and 1080i modes.

1. Place the instrument in the Field Service Mode.

2. Enter the Tube submenu. V erify the correct tube

type is selected.

3. Enter the Geometry submenu.

4. Adjust H-Amplitude (Horizontal Amplitude) for

slight underscan.

5. Enter the Video submenu. Selct the G2 alignment. Adjust the Screen control on the flyback

until the just becomes visible.

VI-4

Geometry Submenu

Page 58

6. Adjust PL557 on the Dynamic Focus Board to

center the raster between the tube border.

7. Realign G2 for 150V on the highest cathode.

8. Tune the instrument to receive a crosshatch

pattern.

9. Return to the Geometry submenu.

10. Adjust V-Slope (Vertical Slope) until the middle

line of the test pattern is just visible.

1 1. Using a Monoscope pattern, adjust V -Amplitude

(Vertical Amplitude) until the first and last horizontal line of the test pattern is just hidden by

the tube.

NOTE: Instruments with 16/9 CR T’s must have this

alignment performed with the format set to

16/9.

12. Adjust V-Position (V ertical Position) until the picture is centered vertically. It may be necessary

to recheck the V-Amplitude (S tep 1 1) adjustment.

13. Adjust V-Linearity (Vertical Linearity) for equal

height of the squares in the crosshatch pattern.

NOTE: Instruments with 16/9 CR T’s must have this

alignment performed with the format set to

16/9.

14. Adjust H-Position (Horizontal Position) until the

test pattern is horizontally centered.

15. Using a Monoscope pattern adjust H-Amplitude

(Horizontal Amplitude) until the first and last horizontal line of the test pattern is just hidden by

the tube. It may be necessary to recheck the HPosition (Step 14) adjustment.

16. Using a Crosshatch pattern adjust EW-Amplitude (East West Amplitude) until the vertical lines

in the middle of the CRT are straight.

17. Adjust EW-Upper Corner (East West Corner)

until the vertical lines are straight at the top of

the screen.

18. Adjust EW-Lower Corner (East West Corner)

until are straight at the bottom of the screen.

19. Adjust EW-Symmetry (East West Symmetry or

H-Bow) until the left and right border of the screen

are the same.

NOTE: It may be necessary to repeat S teps 14- 19

after this adjustment for optimum

performance.

zontal amplitude will change with different beam

current at the same ratio as vertical amplitude.

23. H-Max and H-M set the range limitations of the

H-Amplitude adjustment. This adjustment should

only be used in cases where CRT is replaced

and it does not appear in the CRT list. To access

this adjustment, the Development Support must

be checked in the Miscellanous Setup menu.

24. Check the box to set the shutdown threshold for

the XRP circuitry . During this automatic process

the screen will blank, then reappear once it is

finished.

25. Before exiting the Geometry menu, check Store

to save changes to memory .

26. After the Geometry Alignments, check the EarthField Compensation (EFC) adjustment (DV Models Only). Enter the Advanced Picture Setting

Menu. Using a crosshatch pattern, adjust the

EFC for minimum picture rotation at the top and

bottom.

Alignment Procedure (Projection Models Only)

NOTE: Unless otherwise noted all Geometry

adjustments must performed in both 480i/p

and 1080i modes.

1. Place the instrument in the Field Service Mode.

NOTE: It is recommended the Geometry alignments

be performed using the Green CRT only.

2. Enter the Tube submenu. V erify the correct tube

type is selected.

3. Tune the instrument to receive a crosshatch

pattern.

4. Return to the Geometry submenu.

5. Adjust V-Slope (Vertical Slope) until the middle

line of the test pattern is just visible.

6. Exit the Geometry submenu and turn the instrument OFF. Disconnect the Convergence Yoke

connectors BW001 and BW002 (Located in

lower right corner of the Convergence Amplifier

PCB). Turn the instrument ON and tune to receive a center line pattern. Adjust horizontal and

vertical center lines according to the chart below with the static convergence magnets. When

completed turn the instrument OFF and reconnect the convergence yoke connectors.

20. Adjust H-Parallel (Horizontal Parallelogram) the

offset between the top and bottom of the picture.

21. Adjust EW-Trapezium (East West Trapezium)

for best compromise between Left and right vertical lines.

22. Adjust Breathing (EHT Compensation) until hori-

VI-5

Page 59

eziSneercS

"04)ni49.0(mc4.2)ni49.0(mc4.2

eniLretneCdeR

retneCfotfeLteS

Yoke Centering Ring Adjustment

eniLretneCeulB

If Chipper Check is not available it is possible to re-

retneCfothgiRteS

place a single CRT and realign geometry by using

the centering rings on the CRT.

"25)ni22.1(mc1.3)ni22.1(mc1.3

"65)ni92.1(mc3.3)ni

"16)ni73.1(mc5.3)ni73.1(mc5.3

92.1(mc3.3

7. Turn the instrument ON and place in the Field

Service Mode. Tune to recieve a crosshatch

pattern. Enter the Geometry submenu. Using a

Monoscope pattern, adjust V -Amplitude (Vertical Amplitude) until the first and last horizontal

line of the test pattern is just hidden by the tube.

8. Adjust V-Position (V ertical Position) until the picture is centered vertically .

9. Adjust V-Linearity (Vertical Linearity) for equal

height of the squares in the crosshatch pattern.

10. Adjust H-Position (Horizontal Position) until the

test pattern is horizontally centered.

1 1. Using a Monoscope pattern adjust H-Amplitude

(Horizontal Amplitude) until the first and last horizontal line of the test pattern is just hidden by

the tube.

12. Using a Crosshatch pattern adjust EW-Amplitude (East West Amplitude) until the vertical

lines in the middle of the CRT are straight.

13. Adjust EW-Trapezium (East West Trapezium)

for best compromise between Left and right

vertical lines.

14. Adjust EW-Symmetry (East West Symmetry or

H-Bow) until the left and right border of the

screen are the same.

NOTE: It may be necessary to repeat Steps 10-

14 after this adjustment for optimum

performance.

15. Adjust Breathing (EHT Compensation) until horizontal amplitude will change with different beam

current at the same ratio as vertical amplitude.

16. H-Max and H-M set the range limitations of the

H-Amplitude adjustment. This adjustment

should only be used in cases where CRT is replaced and it does not appear in the CRT list.

To access this adjustment, the Development

Support must be checked in the Miscellanous

Setup

Using the convergence pattern available when in service menu the pattern from the replacement CRT

may be adjusted to align with either of the two remaining CRT's using the centering rings shown in

Figure 1.

Phosphor

Screen

Centering

SVM Y oke

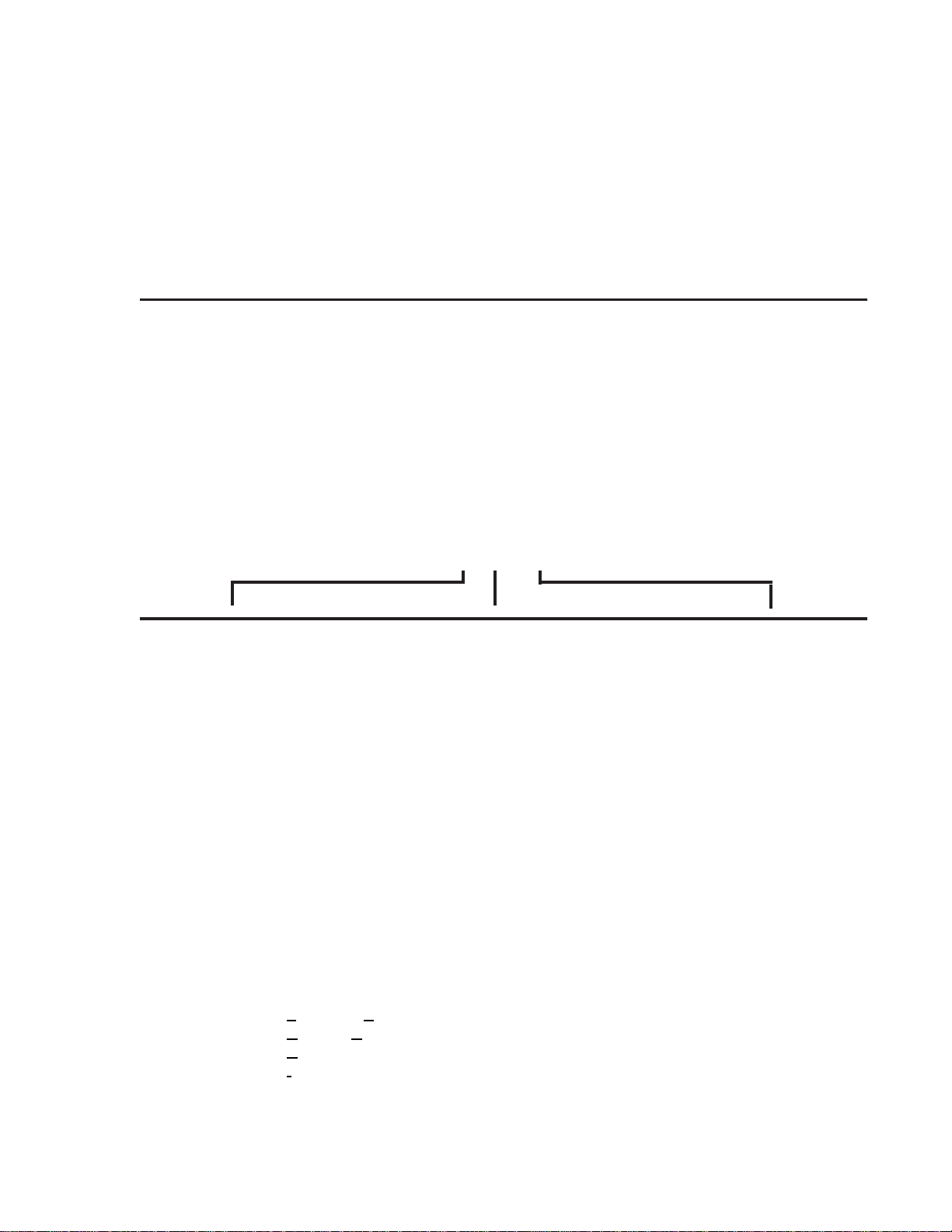

Kine

Socket

Figure 1 - Centering Rings

First make certain the replacement CRT and yoke

are assembled and placed back in the mounting as

close as possible to the original CRT and yoke. At

this point having the convergence pattern on screen

will assist in the mechanical mounting.

Using the centering rings and observing the convergence pattern, rotate and move the pattern until the

replacement color overlays as close as possible to

the two colors not replaced. Moving the ring tabs

together around the neck of the CRT draws the raster in small circles. Spreading the tabs ap art moves

the raster in more linear angles. The closer the tabs

are together, the less affect on the CRT beam they

have.

When the raster is as close as possible fix the magnets with paint or nail polish to prevent further movement.

VI-6

Page 60

After fixing the magnets, if gross geometry errors

are apparent, geometry alignment is indicated. If

the raster is close, use the "Auto-convergence" feature provided in the consumer menu to re-align convergence. This should correct most minor geometry problems. Follow auto-convergence with the

consumer red and blue centering adjustments, then

evaluate the raster again.

In most cases convergence will now be acceptable.

If only slight convergence errors are noted the technician should enter the manual digital convergence

menu and begin "touch-up" of the screen.

If gross geometry errors are still apparent re-evaluate whether the errors are noticable on the replacement CRT or whether they are global, affecting all

three CRT's. If the errors affect all three CRT's a full

geometry alignment is indicated. If the errors only

affect one CRT, particulary the replacement, return

to the mechanical placement and centering ring adjustments and begin those procedures again.

Rotate Tabs Together

Focus Adjustments

Before attempting the Focus Adjustments, allow

the

instrument to warm up for a minimum of 15

minutes.

Dynamic Focus CRT (DV Models Only)

1. Tune the instrument to receive a crosshatch

pattern.

2. Turn the F1 (Static) control on the focus block

fully clockwise

3. Adjust the F1 control while observing the vertical lines along the left side of the screen for best

possible focus.

4. Turn the F2 (Dynamic) control on the focus block

fully clockwise.

5. Adjust the F2 control while observing the

horzontal lines. Adjust for best possible focus.

6. Repeat step 3 and 5 for best possible overall

focus.

Single Focus CRT (DV Models Only)

1. Tune the instrument to receive a crosshatch

pattern.

2. Turn PL501 (Located on the Dynamic Focus

PCB) to the full counter clockwise position.

3. Adjust F2 on the focus block for best possible

focus of the horizontal lines.

4. Adjust PL501 for best possible focus of the vertical lines.

5. Repeat steps 3 and 4 for best possible overall

focus.

Spread Tabs Apart

Figure 2 - Centering Ring Tab Movement

Focus Adjustment (PTV Models)

1. Tune instrument to receive a crosshatch pattern.

2. Preset Contrast to maximun.

3. Adjust each CRT separately. Cover the two

CRT’s not being adjusted and adjust for best

overall focus.

5. Adjust the Green Electrical Focus control, located

behind the speaker grill for best overall focus.

6. Repeat procedure for the Red and Blue CRT’s.

VI-7

Page 61

Video Alignments

VIDEO PAL RF - BG

Return

Peak White

Whitepoint R

Whitepoint G

Whitepoint B

G2 Alignm ent

Scaling Colour

Scaling Brightness

Cuto ff R

Cuto ff G

UP DOWN SELECT/CHAN GE

VIDEO PAL RF - BG

Scaling Contrast

Scaling Tint

Contrast max

Drive Loop Dis able

Text Contrast

Full W hite 4/3

Driv e L evel

Defaults

Store

Restore

UP DOWN SELECT/CHANGE

Video Alignment Submenu

D4

80

F0

40

- 22

78

+90

D4

80

-18

- 22

78

12. Select a 75% color bar test pattern.

13. Connect a scope to the Blue Cathode of the

CRT board.

14. Adjust the Scaling Color to the levels shown

below.

Note: This alignment must be performed in each

of the following modes, Tuner, Comp 1H,

Comp 2H, DVI and AUX_RGB (if DVD

option is installed).

16. The Drive Level Alignment is preset

according to the CRT type selected and

does not need to be adjusted.

17. Before exiting the Video Alignment

Submenu, check Store to save all

alignments.

Before attempting the Video Alignment s, allow the

instrument to warm up for a minimum of 15 minutes.

1. Tune the instrument to receive a

crosshatch pattern.

5. Place the instrument in the Field Service

Mode.

6. Enter the Video submenu.

7. Select G2 adjustment.

8. Adjust Screen control until retrace lines

become visible, then adjust to make retrace

lines invisible.

9. Press any key to exit the G2 alignment

mode.

10. Select a pluge test pattern. Pattern should

have a 0% background with a -2% and

+2% bar.

11. Adjust Scaling Black Level to make the 2% bar invisible, keeping the +2% bar

visible.

Color T emperature

Color Temperature for the ITC222 is similar to past

chassis. Some form of staircase pattern similar to

the following figure is required. Proper identification

of the “0” (if available) and “7.5” or “setup” bars on

screen and the waveform produced on the cathodes

of the CRT will be needed. Consult the specifications

manual for the pattern generator used to confirm

the location of these bars.

The oscilloscope waveform shows the relationship

between the bars and the video signal at the

cathodes of the CRT. This waveform is present on

all three cathodes. With the oscilloscope adjusted

to provide a full peak to peak readout of the

waveform at the horizontal rate, the 7.5 IRE setup

bar will the critical area. Be certain this bar can be

identified using the equipment available. If a 7.5 IRE

bar is not available, 10 IRE may be used.

VI-8

Page 62

It should be noted that bar patterns differ . Some vary

from 10 to 100 IRE in various steps and in different

directions, but most should have an identifiable 7.5

to 10 IRE bar.

The purpose of the color temperature setup is to

assure uniform gray level from black to the brightest

scenes. If a uniform gray screen is displayed, no

matter the brightness level, no tinting in either red,

green or blue direction should be apparent. This is

known as “color tracking”. Once the proper color

temperature is set, AKB will maintain the cutoff of

the CRT to assure proper low light performance.

Black Cutoff R/G, Whitepoint R/G/B Setup

(Recommended Method)

1. Apply a gray test pattern giving a 12 IRE

flat window. Connect Colorimeter near the

center of the screen.

2. Adjust Black Offset R and Black Offset G to

obtain the following color coordinates:

Direct View Projection TV

X 0.282 0.283

Y 0.298 0.296

3. Apply a gray test pattern giving a 50 IRE flat

window.

4. Adjust Whitepoint R, G, and B for the

following color coordinates:

Direct View Projection TV

X 0.282 0.278

Y 0.298 0.291

Note: This alignment must be done in the following

modes, RF (NTSC), Comp 1H, Comp 2H,

DVI and AUX_RGB (If unit has DVD option

installed).

Black Cutoff R/G, Whitepoint R/G/B Setup

(Alternative Method)

1. Apply a vertical gray bar staircase pattern

(at least 8 bars from “7.5” to “>75” IRE).

Identify the 7.5 IRE bar location. It is the

“black” or “cutoff” bar . For these adjustments

this bar and the next brighter bar will be

used. On most patterns the remainder of

the bars will progressively become brighter.

2. Adjust Black Cutoff R or Black Cutoff G until

any tinting disappears from the black bar.

When properly adjusted the adjacent bar

should be a very low level gray with no color

tinting.

3. Now observe the brighter portions of the

bars. Adjust Whitpoint R, G, or B to remove

any signs of tint in the higher brightness

bars. Observe the bars for signs of CRT

overdrive. Some compromise may be

required, but the higher IRE bars should be

as free from color tinting as possible.

Note: There are separate color temperature

alignments for RF (NTSC), Comp 1H, Comp

2H, DVI and AUX_RGB (If unit has DVD

option installed).

Peak White Alignment

1. Apply a white centered pattern of 100 IRE

2% of the picture surface on a dark

background.

2. Adjust for peak white at center of the screen.

3. Check Scaling Black Level, Whitepoint,

Black Offset and Peak White adjustments.

It may be necessary to adjust these

alignments several times for optimum

performance.

VI-9

Page 63

Note: This alignment must be done in the following

modes, RF (NTSC), Comp 1H, Comp 2H,

DVI and AUX_RGB (If unit has DVD option

installed).

Full White 3/4 Alignment

1. Insert a full white pattern of 100 IRE through

RF. (Instrument will automatically set to ¾

mode).

2. Adjust for full white across the screen.

T ext Contrast, Contrast Max, Scaling Contrast

Alignments

1. Insert a white centered pattern of 100 IRE,

2% of the picture surface with a black

background.

2. Adjust for peak white.

3. Contrast Max and Scaling Contrast are

preset according to the CRT type selected

and do not need to be adjusted.

Event

If a run-time event occurs, its error code will be stored

in the NVM. The stored event codes can be read in

one of two methods. The first is with the event menu.

The last five event codes will be displayed, along

with a time stamp from the run time counter. The

time stamp will display the last occurrence of a particular event. The time stamp is displayed as “Run

Hours”. An event counter counts how many times

that event has occurred. The counter will not count

beyond 255. The most recent event code is displayed

on top. To clear the event codes from memory, select the Clear Event Codes box. A long press will

clear all stored codes.

Only the last error code stored in the NVM can be

read with this method. The LED will blink two

separate digits.

Example, if the error code of 23 is the last error code

stored

in the NVM, the LED will have 2 short flashes,

followed by a short pause. Then will flash 3 times,

followed by a long pause. This will be repeated 4

times.

First allow the instrument to sit unplugged for 60

seconds. At plug in the LED will first blink twice to

indicate microprocessor has reset. When an attempt

is made to power up, the instrument will attempt 3

times to start. The LED will display a series of flashes

followed by the error codes. The LED will flash the

error code 4 times.

Sound Setup

Effect Strength (MED): Modifies the bass effect

strength for the user setting MEDIUM.

Effect Stength (HIGH) : Modifies the bass effect

strength for the user setting HIGH.

Low Pass Frequency: Modifies the low pass

cut-off frequency.

High Pass Frequency : Modifies the high pass

cut-off frequency.

Sub-woofer Corner Frequency : Modifies the

sub-woofer corner cut-off frequency.

SOUND

Return

Effect Strengt h (MED) 80

Effect Strengt h (HIGH) 9A

Low Pass Frequency 80

High Pass Frequency 56

Sub-wo ofer Corner F r eq u ency 80

Defaults

Store

Rest ore

UP DOWN SELECT/CHANGE

EVENT HISTORY

Return

Clear Event Codes

Code Co unt T ime Stamp

11 00 1 00 0135:30

24 01 2 00 0090:10

78 00 3 00 0043:54

51 00 1 00 0001:20

00 00 0 00 0000:00

Test: Brightness Sensor: 2 Colour: R

Direction: Right Value: 125 Scan mode: 2H

UP DO WN SELECT/CHANGE

Event Submenu

Sound Setup Submenu

VI-10

Page 64

Miscellaneous

A

Clear Programs: Select with a 2 second press

to clear all programs stored in memory and set

Picture Preference, User Picture and Audio

settings to factory values. Returns the

instrument to “Out of Factory Mode”.

Default Presets : Sets the default value for all

factory sound and picture presets.

Bus Quiet: In this mode the NVM can be read,

modified or reprogrammed. Enter this function

with with a 2 second press. This mode is

cancelled with a press of Clear, Lef t, Right, Up,

Down or On-Off keys.

Level 3: Provides 195 adjustment points

CONVERGE NC E AL I G NM E N T

Ret u r n

1 (3 x 3 )

2 (5 x 5 )

3 ( 1 5 x

1 3 )

Le vel

Le vel

L e v e l

S e n s or c a l i br a t i o n

u t o c o n v er ge nc e

Def a ul t s

St or e

R e s t or e

10 80

Development Support : Enables or Disables

access to development support functions in

the field service menus.

Restore Factory Settings : Restores the

correct “Out of Box” condition.

Switch 2nd T uner to Main : Causes the current

signal on the 2nd tuenr to be switched to the

main screen and the monitor output jacks. Any

channel change will override this feature and

return tuning to normal.

MISCELLANOUS

Return

Clear Progs

Default Presets

Bus Quiet

Development S uppo rt

Restore Factory Settings

FFI Bit

Switch 2nd tuner to main

UP DOWN SELECT

Miscellaneous Setup Menu

Convergence (PTV Models Only)

U P

D O W N

S E L E C T / C H

A N G E

Convergence Submenu

It is recommended to adjust Levels 1 and 2 only if

repairs have been made to the Convergence Signal

circuitry or after CRT replacement. Before

performing the Convergence Alignment procedure

it is HIGHLY RECOMMENDED the Geometry

Alignment of the instrument is checked.

Note: Alignments must be performed in order. If

Level 3 is adjusted, prior to Levels 1 or 2,

all Level 3 alignments will be lost.

In Level 1 and 2, Press OK to select the color to be

aligned. The position of the adjustment point can

adjusted using the navigation keys (up, down, left

and right) on the remote. Press the 2 key of the

remote to move to the next adjustment point. Press

the EXIT/CLEAR key to exit when completed.

Level 3 alignment works simular to Levels 1 and 2.

The only difference, to move to the next adjustment

point press 2 (up), 8 (down), 6 (right) and 4 (left) on

the remote unit. When completed with convergence,

press STORE to save all changes.

The ITC222 employs a ditigal convergence circuit

that makes it possible to electronically align up to

208 separate points on the screen. 3 levels of

convergence adjustment is provided.

Sensor Calibration is used to calculate a reference

border for the autoconvergence photo sensors.

Check the box to begin the process.

Autoconvergence starts the autoconvergence

process.

Level 1: Provides 9 adjustment points

Level 2: Provides 25 adjustment points

Defaults enters a default submenu. Checking the

box loads a set of default values from the

VI-11

Page 65

convergence backup NVM to the Convergence IC

RAM. The box will remain checked until the value is

changed or store or restore is pressed in the

convergence submenu.

Note: Before the Convergence Alignement menu

is exited, you must check Store or all

settings will be lost.

Manual Convergence Procedure

1. Turn instrument “On”. Allow to warm up for

20 munitues. Turn instrument “Off”. Enter

the Service Menu holding the “Channel

Down” and “Volume Down” on the FPA

for 8 seconds. Enter the “Convergence