Page 1

查询D2547P供应商

Wavelength-Selected High-Power D2587P-Type (with

Wavelength Locker)/D2547P-Type Isolated DFB Laser Modules

Applications

■

Telecommunications:

— Dense WDM

— SONET/SDH OC-192/STM-64

— Extended and ultralong reach

— Undersea systems

■

Digital video

Data Sheet, Rev. 2

July 2001

Featuring wavelength selection and locking capabilities, the

D2587P Laser Module is ideally suited for use with external

lithium niobate modulators, and in high-power (20 mW) applications.

Features

■

High-performance, multiquantum-well (MQW),

distributed-feedback (DFB) laser

■

D2587P-Type is offered on 50 GHz ITU grid

wavelengths ranging from 1528.77 nm—

1610.06 nm

■

D2547P-Type is offered on 100 GHz ITU grid

wavelengths ranging from 1528.77 nm—

1610.06 nm

■

Polarization-maintaining fiber pigtail

■

For use with lithium niobate modulators

Description

The D2587P-Type DFB laser module is designed for

use with an external lithium niobate modulator and

also in applications where high power (20 mW) is

required.

The use of an internal wavelength locker greatly

enhances long-term reliability and reduces chirp and

mode dispersion when used in conjunction with LN

modulators at OC-192 data rates.

A companion device, the D2547P high-power DFB

laser module, is also designed for use with a lithium

niobate external modulator, but without the use of an

internal wavelength locker.

■

High optical power (20 mW, CW)

■

Hermetic, 14-pin package

Page 2

Wavelength-Selected, High-Power D2587P-Type (with Wavelength Data Sheet, Rev. 2

Locker)/D2547P-Type Isolated DFB Laser Modules July 2001

Description

(continued)

Principles of Operation (Controlled W avelength)

The single-channel, wavelength-selected DFB (ILM) package contains internal wavelength-disc riminating optics , i.e . ,

two etalons and associated photodiodes. The output consists of analog signals suitable for controlling the electrical

current of the thermoelectric cooler (TEC) and the DFB

laser.

Controlled Feedback

The module contains an internal optical isolator that suppresses optical feed back in laser-based, fiber-optic systems. Light reflected back to the laser is attenuated a

minimum of 30 dB.

Controlled Temperature

An integral TEC provides stable thermal characteristics.

The TEC allows for heat ing and cooling of the laser chip to

maintain a temperature of 25 °C for ca se temperatures fro m

–25 °C to +70 °C. The laser temperature is monitored by

the internal thermistor, which can be used with external circuitry to control the laser chip temperature.

Agere Systems’ optoelectronic components are being qualified to rigorous internal standards that are consistent with

Telcordia Technologies

manufacturing oper ations are

†

TR-NWT-000468. All design and

§

9001 certified. The

ISO

module is being fully qualified for central office applications.

*

†

§

is a registered trademark of Fujikura Ltd.

Fujikura

Telcordia Technologies

Inc.

is a registered trademark of The International Organization for

ISO

Standardization.

is a trademark of Telcordia Technologies

CORE

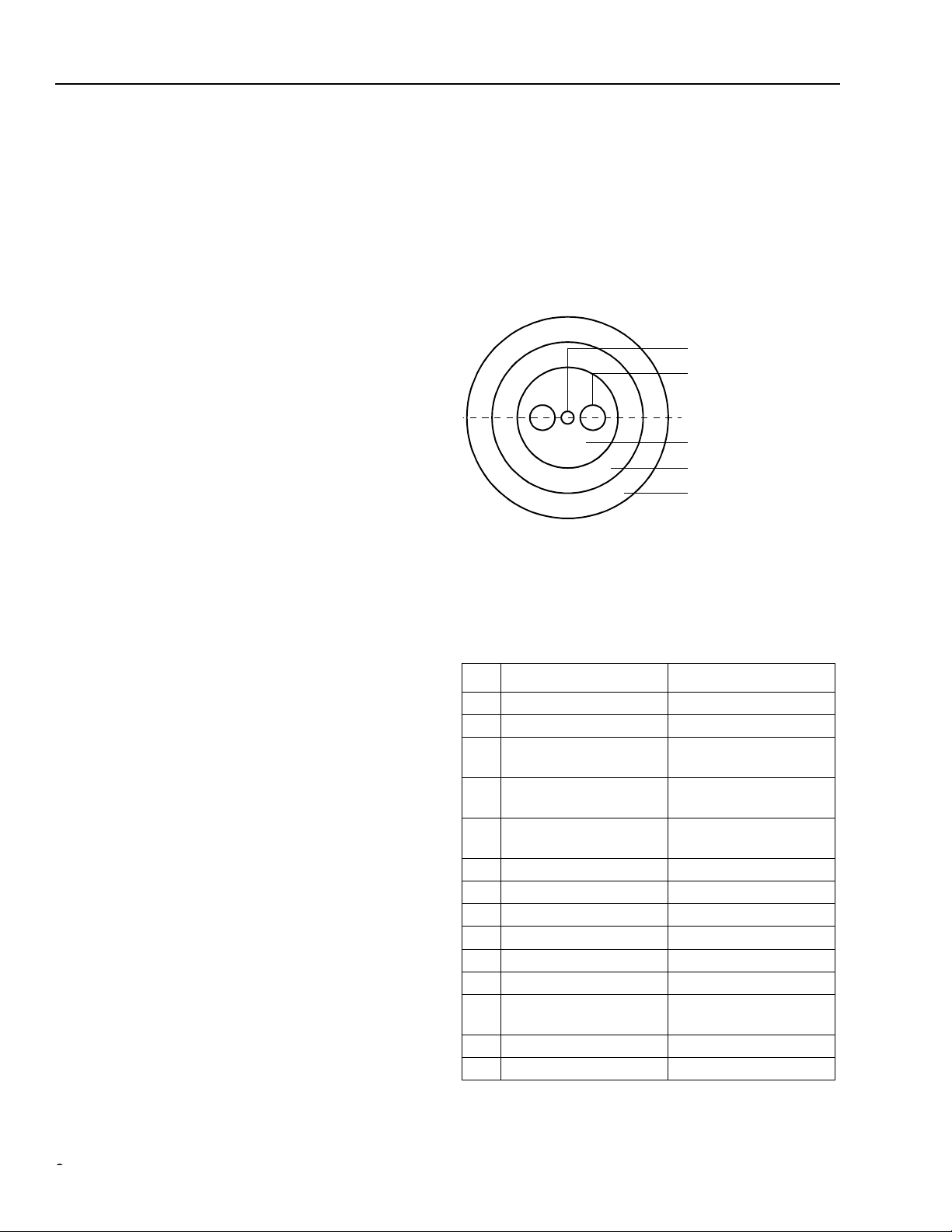

STRESS ROD

PRINCIPLE POLARIZATION

AXIS

CLADDING

INNER COATING

(SILICON & ACRYLATE)

OUTER COAT ING

1-771(C).a

Figure 1. Polarization-Maintaining Fiber

Pin Information

Table 1. Pin Descriptions

Controlled Power

An internal, InGaAs, PIN photodiode functions as the backfacet monitor. The photodiode monitors emission from the

rear facet of the laser and, when used in conjun ct io n with

control circuitry, can control optic al power launched into the

fiber. Normally, this configuration is used in a feedbac k

arrangement to maintain consistent laser output power.

Standard Package

The laser module is fabricated in a 14-pin, hermetic, metal/

ceramic butterfly package that incorporates a bias tee that

separates the dc-bias p ath from the RF input. The RF input

has a nominal 25 Ω impedance.

The laser module is equipped with

Fujikura

maintaining fiber (PMF). The fiber is PANDA type an d is the

same fiber that is used on the Agere Systems Inc. lithium

niobate modulators. It has a mode field diameter of

10.5 µm, a cladding diameter of 125µm ±3 µm, and a

loose tube jacketed fiber 900 µm in diameter. Figure 1

shows the orientation of polarization in the fiber.

* polarization-

Pin D2587P-Type D2547P-Type

1 Thermistor Thermistor

2 Thermistor Thermistor

3 Laser dc Bias

(Cathode) (–)

4 Back-facet Monitor

Anode (–)

5 Back-facet Monitor

Cathode (+)

6TEC (+)

7TEC (–)

1

1

Laser dc Bias

(Cathode) (–)

Back-facet Monitor

Anode (–)

Back-facet Monitor

Cathode (+)

TEC (+)

TEC (–)

1

1

8 Case Ground Case Ground

9

Photodiode 2 Anode

λ

10λ Photodiode 1 Anode

11 Laser Anode (+)

2

12 RF Laser Input

Cathode (–)

13 Laser Anode (+)

2

14 NC

1.A positive current through the thermoelectric heat pump cools the

laser.

2.Both leads should be grounded for optimum performance.

Case Ground

Case Ground

Laser Anode (+)

RF Laser Input

Cathode (–)

Laser Anode (+)

Case Ground

2

2

22

Agere Systems Inc.

Page 3

Data Sheet, Rev. 2 Wavelength-Selected, High-Power D2587P-Type (with Wavelength

July 2001 Locker)/D2547P-Type Isolated DFB Laser Modules

Description

(continued)

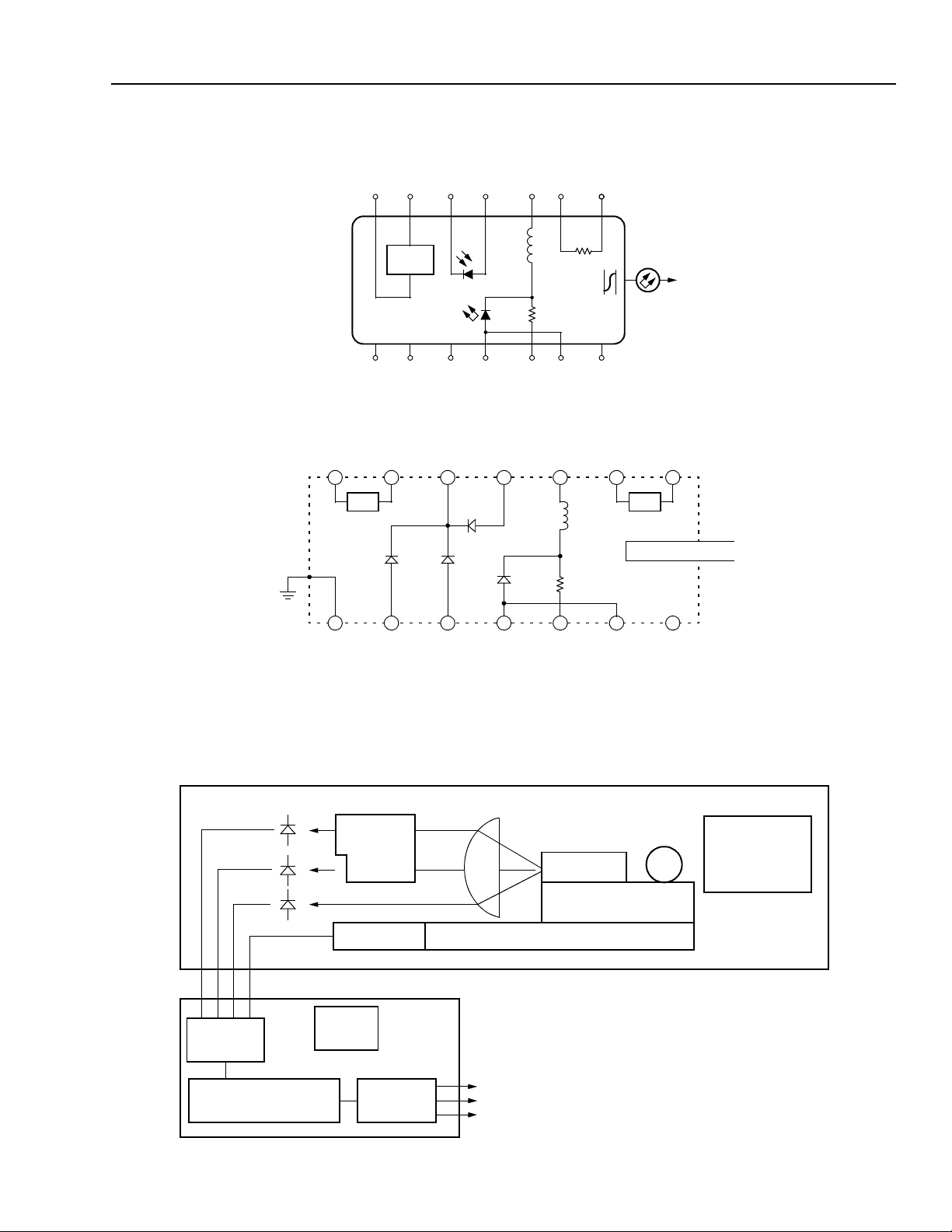

76 54 32 1

–+ +– –

L1

TEC

PACKAGE

GROUNDS

8 9 10 11 12 13

140 nH

+–+

R1

20

TH

10 k

ISOLATOR

Ω

Ω

NC

14

1-567

Top view .

Figure 2. D2547P Circuit Schematic

7654321

R

TEC

PD

WAVE

PD

WAVE

PD

POWER

LD

RFC

R

RF

TH

PM FIBER PIGTAIL

Block Diagram

A TO D

CONVERTER

MICROPROCESSOR

8 9 10 11 12 13 14

Figure 3. D2587P Circuit Schematic

DUAL

ETALON

THERMISTOR

EEPROM

D TO A

CONVERTER

THERMOELECTRIC COOLER

SUGGESTED

ELECTRONICS MODULE (CUSTOMER SUPPLIED)

VOLTAGE PROPORTIONAL TO WAVELENGTH

VOLTAGE PROPORTIONAL TO OPTICAL POWER

VOLTAGE PROPORTIONAL TO TEMPERATURE

DFB

SILICON SUBMOUNT

1-1130(F)

LASER MODULE

ISOLATOR AND

FIBER COUPLING

OPTICS

Agere Systems Inc.

1-1129(F)

3

Page 4

Wavelength-Selected, High-Power D2587P-Type (with Wavelength Data Sheet, Rev. 2

Locker)/D2547P-Type Isolated DFB Laser Modules July 2001

Absolute Maximum Ratings

Stresses in excess of the absolute maximum ratings can cause permanent damage to the device. These are absolute stress ratings only. Functional operation of the device is not implied at these or any other conditions in excess

of those given in the operations sections of the data sheet. Exposure to absolute maximum ratings for extended

periods can adversely affect device reliability.

Parameter Symbol Min Max Unit

Laser Reverse Voltage V

dc Forward Current I

Operating Case Temperature Range T

Storage Case Temperature Range* T

Photodiode Reverse Vo lta ge V

Photodiode Forward Current I

* Does not apply to shipping container.

RLMAX

FLMAX

C

stg

RPDMAX

FPDMAX

—2 V

— 225 mA

–25 70 °C

–40 70 °C

—10 V

—2 mA

Handling Precautions

Power Sequencing

To avoid the possibility of damage to the laser module

from power supply switching transients, follow this

turn-on sequence:

1. All ground connections

2. Most negative supply

3. Most positive supply

4. All remaining connections

Reverse the order for the proper turn-off sequence.

Electrostatic Discharge

CAUTION: This device is susceptible to damage as

a result of electrostatic discharge. Take

proper precautions during both handling and testing. Follow guidelines

such as JEDEC Publication No. 108-A

(Dec. 1988).

Agere Systems employs a human-body model (HBM)

for ESD-susceptibility testing and protection-design

evaluation. ESD voltage thresholds are dependent on

the critical parameters used to define the model. A

standard HBM (resistance = 1.5 kΩ, capacitance = 100

pF) is widely used and, therefore, can be used for comparison purposes. The HBM ESD threshold presented

here was obtained using these circuit parameters:

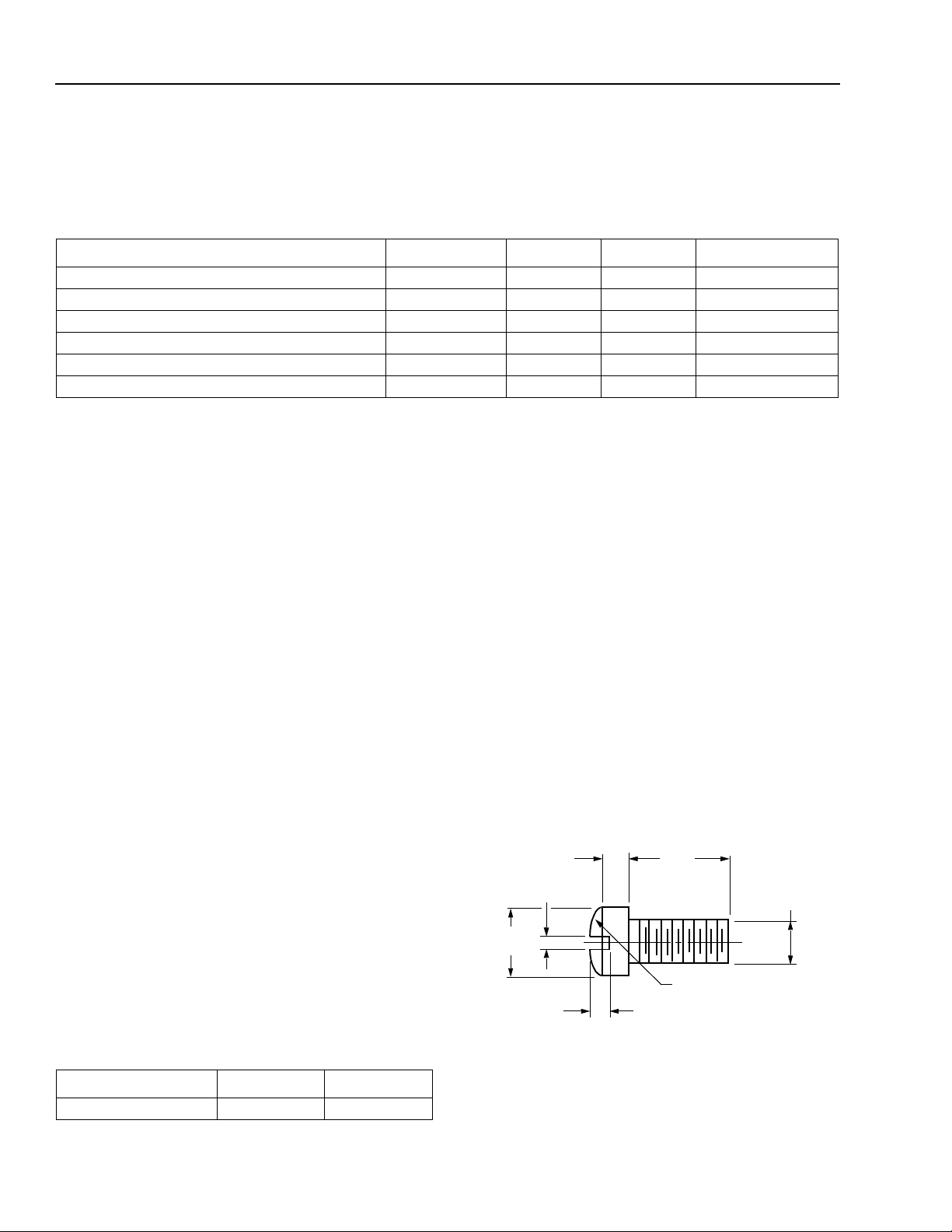

Mounting Instructions

The minimum fiber bend radius is 1.0 in. (25.4 mm)

To avoid degradation in performance, mount the mod-

ule on the board as follows:

1. Place the bottom flange of the module on a flat heat

sink at least 0.5 in. x 1.180 in. (12.7 mm x 30 mm) in

size. The surface finish of the heat sink should be

better than 32 µin. (0.8 µm), and the surface flatness

must be better than 0.001 in. (25.4 µm). Using thermal conductive grease is optional; however, thermal

performance can be improved by up to 5% if conductive grease is applied between the bottom flange and

the heat sink.

2. Mount four #2-56 screws with Fillister heads

(M2-3 mm) at the four screw hole locations (see Outline Diagram). The Fillister head diameter must not

exceed 0.140 in. (3.55 mm). Do not apply more than

1 in.-lb. of torque to the screws.

0.062 (1.58)

0.031 (0.79)

0.140

(3.56)

Note: Dimensions are in inches and (millimeters).

0.118

(3.00)

0.086

(2.18)

0.129 (3.28) R

0.041 (1.04)

1-532(C)

Parameter Value Unit

Human-body Model >400 V

4

Figure 4. Fillister Head Screw

Agere Systems Inc.

Page 5

Data Sheet, Rev. 2 Wavelength-Selected, High-Power D2587P-Type (with Wavelength

July 2001 Locker)/D2547P-Type Isolated DFB Laser Modules

Characteristics

Minimum and maximum values are testing requirements. Typical values are device characteristics and are results

of engineering evaluations; they are for information purposes only and are not part of the testing requirements.

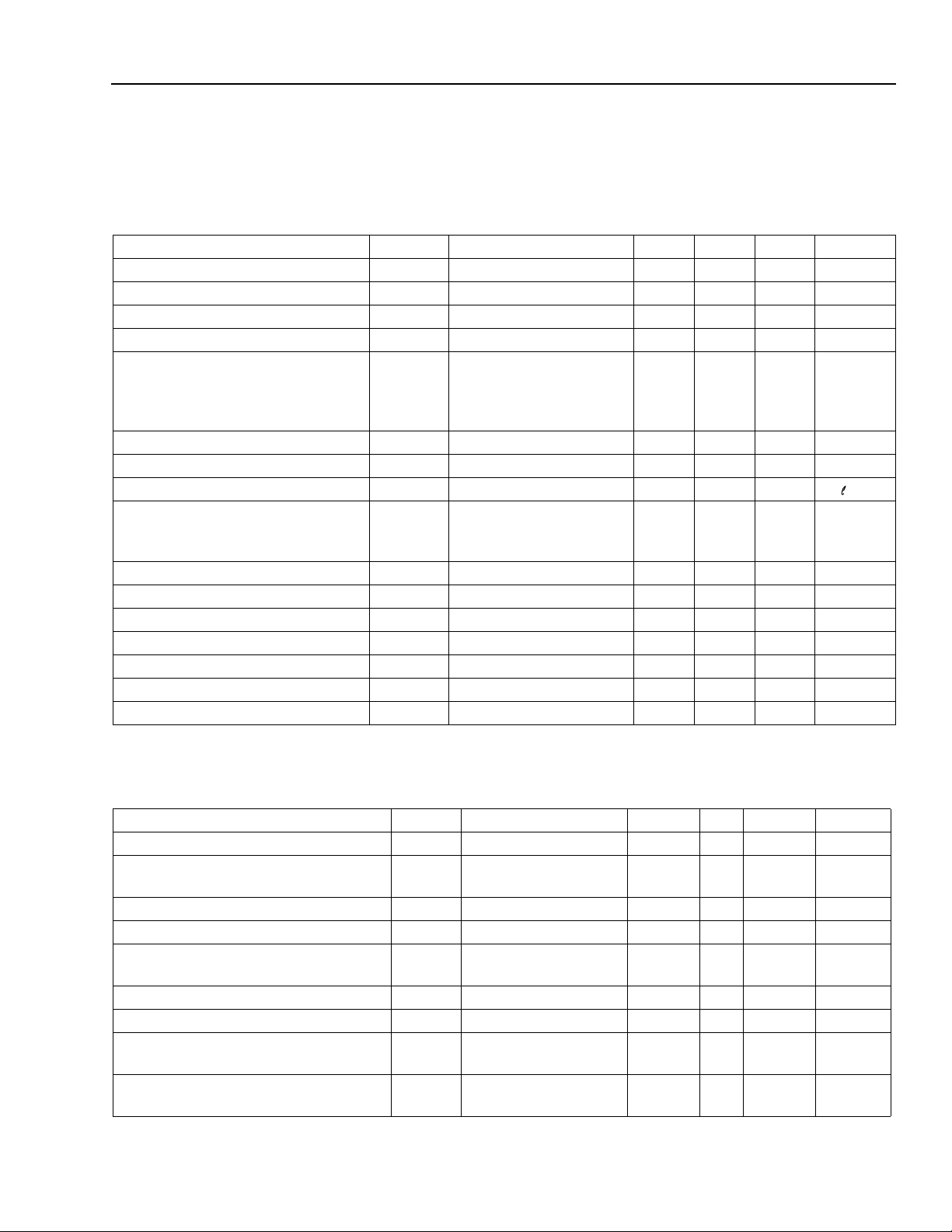

Table 2. D2587-Type Electrical Characteristics

(at 25 °C laser temperature)

Parameter Symbol Test Conditions Min Typ Max Unit

Threshold Current I

TH

Drive Current — L

RMON

RMON

I

λ

PD1

I

λ

PD2

I

LF

D

IN

LF = 20 mW (CW) — 2 2.5 V

PO = 20 mW (CW)

IF = 0, V

Laser Forward Voltage V

Monitor Reverse-bias Voltage* V

Monitor Current:

Back-facet Monitor

Photodiode 1

λ

Photodiode 2

λ

Monitor Dark Current I

Input Impedance Z

— — 15 40 mA

F

= 20 mW — — 165 mA

—3510V

0.003

0.003

0.003

RMON

= 5 V — 0.01 0.1 µA

—

—

—

0.06

0.06

0.06

——25—Ω

Filter Slope — — 0.5 — 8 /nm

Frequency Capture Range — Measured from λ

ITU

15 — — GHz

toward increasing λ and

decreasing λ

Thermistor Current I

Resistance Ratio

†

Thermistor Resistance R

Laser Submount Temperature T

TEC Current I

TEC Voltage V

TEC Capacity ∆TT

TC

— 10 — 100 µA

— — 9.1 9.6 10.1 —

TH

SET

TEC

TEC

TL = 25 °C 9.5 — 10.5 kΩ

—20—35°C

TL = 25 °C, TC = 70 °C — — 1.7 A

TL = 25 °C, TC = 70 °C — — 2.8 V

C

= 70 °C — 50 °C

mA

mA

mA

* S tandard operating condition is 5.0 V reverse bias.

† Ratio of thermistor resistance at 0 °C to thermistor resistance at 50 °C.

Table 3. D2587-Type Optical Characteristics

(at 25 °C laser temperature)

Parameter Symbol Test Conditions Min Typ Max Unit

Peak Optical Output Power P

Center Wavelength*

(See Ordering Information, page 9.)

Line Width (3 dB full width) ∆λ CW, P

P

C

λ

λ

—20.0——mW

SET

TL = T

C

ITU

= λ

± 0.1 nm

F

= 20.0 mW — 2 10 MHz

1528.77 — 1610.06 nm

Side-mode Suppression Ratio SMSR CW 35 45 — dB

Relative Intensity Noise RIN CW, P

= 20 mW

F

— — –135 dB/Hz

200 MHz < f < 10 GHz

Optical Isolation — T

Optical Polarization Extinction Ratio

†

— 0 °C to 75 °C 20 — — dB

FM Efficiency FM f

Wavelength Drift (EOL) ∆λ

C

C

= 0 °C to 75 °C 30 — — dB

MOD

= 30 kHz,

F

P

= 20 mW

Tested over

—100—MHz/mA

——±2.5GHz

25-year lifeti me

* Custom wavelengths available.

† The

®

ST

ferrule key is not aligned to slow axis of fiber. Connector is intended for testing purposes only.

Agere Systems Inc.

5

Page 6

Wavelength-Selected, High-Power D2587P-Type (with Wavelength Data Sheet, Rev. 2

Locker)/D2547P-Type Isolated DFB Laser Modules July 2001

Characteristics

(continued)

Minimum and maximum values are testing requirements. Typical values are device characteristics and are results

of engineering evaluations; they are for information purposes only and are not part of the testing requirements.

Table 4. D2547P-Type Electrical Characteristics

(at 25 °C laser temperature)

Parameter Symbol Test Conditions Min Typ Max Unit

Threshold Current I

TH

Drive Current — L

Laser Forward Voltage V

Monitor Reverse-bias Vol tage * V

Back-facet Monitor Current: I

Monitor Dark Current I

Input Impedance Z

Thermistor Current I

Resistance Ratio

†

Thermistor Resistance R

Laser Submount Temperature T

TEC Current I

TEC Vo ltage V

LF

RMON

RMON

D

IN

TC

LF = 20 mW (CW) — 2 2.5 V

PO = 20 mW (CW) 0.2 — — mA

IF = 0, V

— — 9.1 9.6 10.1 —

TH

LASER

TEC

TEC

TL = 25 °C, TC = 70 °C — — 1.7 A

TL = 25 °C, TC = 70 °C — — 2.8 V

TEC Capacity ∆TT

— — 15 40 mA

F

= 20 mW — — 165 mA

—3510V

RMON

= 5 V — 0.01 0.1 µA

——25—Ω

—10—100µA

TL = 25 °C 9.5 — 10.5 kΩ

— 20 — 35 °C

C

= 70 °C — — 50 °C

* Standard operating condition is 5.0 V reverse bias.

† Ratio of thermistor resistance at 0 °C to thermistor resistance at 50 °C.

Table 5. D2547P-Type Optical Characteristics

(at 25 °C laser temperature)

Parameter Symbol Test Conditions Min Typ Max Unit

Peak Optical Output Power P

Center Wavelength*

(See Ordering Information,

P

C

λ

λ

—20.0——mW

SET

C

TL = T

= λ

ITU

± 0.1 nm

1528.77 — 1610.06 nm

page 12.)

F

Line Width (3 dB full width) ∆λ CW, P

= 20.0 mW — 2 10 MHz

Side-mode Suppression Ratio SMSR CW 35 45 — dB

Relative Intensity Noise RIN CW, P

= 20 mW

F

— — –135 dB/Hz

200 MHz < f < 10 GHz

Optical Isolation — T

Optical Polarization Extinction

†

Ratio

— 0 °C to 75 °C 20 — — dB

FM Efficiency FM f

Wavelength Drift (EOL) ∆λ

C

C

= 0 °C to 75 °C 30 — — dB

MOD

= 30 kHz,

F

P

= 20 mW

Tested over

— 100 — MHz/mA

——±0.1 nm

25-year lifetime

* Custom wavelengths available.

ST

† The

ferrule key is not aligned to slow axis of fiber. Connector is intended for testing purposes only.

6

Agere Systems Inc.

Page 7

Data Sheet, Rev. 2 Wavelength-Selected, High-Power D2587P-Type (with Wavelength

July 2001 Locker)/D2547P-Type Isolated DFB Laser Modules

Characteristics

(continued)

Table 6. D2587P/D2547P Fiber Pigtail and Optical Connector Characteristics

Parameter Symbol Description Min Typ Max Unit

Pigtail Length L

Fujikura

PANDA or equivalent

1.5 — — m

polarization-maintaining fiber

Connector Style —

ST

plug (FC/PC optional) — — — —

Outline Diagram

Dimensions are in inches and (millimeters). Tolerances are ±0.005 in. (±0.127 mm).

0.605

(15.37)

MAX

0.500 (12.70)

MIN

0.500

(12.70)

0.350

(8.89)

1.025 (26.04)

0.020 (0.51) TYP

~

PIN 1

TRADEMARK, CODE, LASER SERIAL NUMBER,

AND DATE CODE IN APPROX. AREA SHOWN

STRAIN

RELIEF

0.10 ± 0.002

(2.54 ± 0.051)

0.036

(0.91)

0.200

(5.08)

0.365

(9.27)

MAX

0.105 (2.67) DIA

TYP (4) PLACES

0.180 (4.56)

0.056 (1.42)

0.215 (5.45)

0.100 (2.54) TYP

0.820 (20.83)

0.700 (17.78)

1.180 (29.97)

2.03 (51.6)

HEAT SINK

0.078 (1.98)

PIN 14

0.213 (5.40) TYP

0.863 (21.91)

0.575 (14.61)

0.030 (0.75)

59.06 (1500.00)

MIN

0.10

(2.5)

0.215

(5.47)

REF

0.260 (6.60)

1-520.h

Agere Systems Inc.

7

Page 8

Wavelength-Selected, High-Power D2587P-Type (with Wavelength Data Sheet, Rev. 2

Locker)/D2547P-Type Isolated DFB Laser Modules July 2001

High-Power Product

Class IIIb Laser Product

FDA/CDRH Class IIIb laser product. All versions are Class IIIb laser products per CDRH, 21 CFR 1040 Laser

Safety requirements. The device has been classified with the FDA under accession number 8720010.

This product complies with 21 CFR 1040.10 and 1040.11.

8 µm/125 µm ±3 µm single-mode fiber with 900 µm loose-tube jacketed fiber and connector

Wavelength = 1.5 µm

Maximum power = 40 mW

Because of size constraints, laser safety labeling (including an FDA Class IIIb label) is not affixed to the module but

attached to the outside of the shipping carton.

Product is not shipped with power supply.

Caution: Use of controls, adjustments, and procedures other than those specified herein may result in

hazardous laser radiation exposure.

DANGER

INVISIBLE LASER RADIATION

IS EMITTED FROM THE END

OF FIBER OR CONNECTOR

Avoid direct exposure to beam

Do not view beam directly with

optical instruments

INVISIBLE LASER RADIATION EMITTED FROM END OF FIBER OR CONNECTOR

Class IIIb Laser Product FDA/CDRH, 21 CFR 1040 Max. Output: 40 mW Wavelength: 1.5 µm

Avoid exposure to beam

8

Agere Systems Inc.

Page 9

Data Sheet, Rev. 2 Wavelength-Selected, High-Power D2587P-Type (with Wavelength

July 2001 Locker)/D2547P-Type Isolated DFB Laser Modules

Ordering Information

Table 7. D2587P 20 mW CW Laser with Locker (C- and L-Band) Ordering Information

Device

Code

ITU-T

Frequency

(THz)

D2587P61 196.1 1528.77 108835422 D2587P41 194.1 1544.53 108835620

D2587P605 196.05 1529.16 108875220 D2587P405 194.05 1544.92 108875444

D2587P60 196.0 1529.55 108835430 D2587P40 194.0 1545.32 108835638

D2587P595 195.95 1529.94 108875238 D2587P395 193.95 1545.72 108875451

D2587P59 195.9 1530.33 108835448 D2587P39 193.9 1546.12 108835646

D2587P585 195.85 1530.72 108875246 D2587P385 193.85 1546.52 108875469

D2587P58 195.8 1531.12 108835455 D2587P38 193.8 1546.92 108835653

D2587P575 195.75 1531.51 108875253 D2587P375 193.75 1547.32 108875477

D2587P57 195.7 1531.90 108835463 D2587P37 193.7 1547.72 108835661

D2587P565 195.65 1532.29 108875261 D2587P365 193.65 1548.11 108875485

D2587P56 195.6 1532.68 108835471 D2587P36 193.6 1548.51 108835679

D2587P555 195.55 1533.07 108875279 D2587P355 193.55 1548.91 108875493

D2587P55 195.5 1533.47 108835489 D2587P35 193.5 1549.32 108835687

D2587P545 195.45 1533.86 108875287 D2587P345 193.45 1549.72 108875501

D2587P54 195.4 1534.25 108835497 D2587P34 193.4 1550.12 108835695

D2587P535 195.35 1534.64 108875303 D2587P335 193.35 1550.52 108875519

D2587P53 195.3 1535.04 108835505 D2587P33 193.3 1550.92 108835703

D2587P525 195.25 1535.43 108875311 D2587P325 193.25 1551.58 108875527

D2587P52 195.2 1535.82 108835513 D2587P32 193.2 1551.72 108835711

D2587P515 195.15 1536.22 108875329 D2587P315 193.15 1552.12 108875535

D2587P51 195.1 1536.61 108835521 D2587P31 193.1 1552.52 108835729

D2587P505 195.05 1537.00 108875345 D2587P305 193.05 1552.93 108875543

D2587P50 195.0 1537.40 108835539 D2587P30 193.0 1553.33 108835737

D2587P495 194.95 1537.79 108875352 D2587P295 192.95 1553.73 108875550

D2587P49 194.9 1538.19 108835547 D2587P29 192.9 1554.13 108835745

D2587P485 194.85 1538.58 108875360 D2587P285 192.85 1554.54 108875568

D2587P48 194.8 1538.98 108835554 D2587P28 192.8 1554.94 108835752

D2587P475 194.75 1539.37 108875378 D2587P275 192.75 1555.34 108875576

D2587P47 194.7 1539.77 108835562 D2587P27 192.7 1555.75 108835760

D2587P465 194.65 1540.16 108875386 D2587P265 192.65 1556.15 108875584

D2587P46 194.6 1540.56 108835570 D2587P26 192.6 1556.55 108835778

D2587P455 194.55 1540.95 108875394 D2587P255 192.55 1556.96 108875592

D2587P45 194.5 1541.35 108835588 D2587P25 192.5 1557.36 108835786

D2587P445 194.45 1541.75 108875402 D2587P245 192.45 1557.77 108875600

D2587P44 194.4 1542.14 108835596 D2587P24 192.4 1558.17 108835794

D2587P435 194.35 1542.54 108875410 D2587P235 192.35 1558.58 108875618

D2587P43 194.3 1542.94 108835604 D2587P23 192.3 1558.98 108835802

D2587P425 194.25 1543.33 108875428 D2587P225 192.25 1559.39 108875626

D2587P42 194.2 1543.73 108835612 D2587P22 192.2 1559.79 108835810

D2587P415 194.15 1544.13 108875436 D2587P215 192.15 1560.20 108875634

Center

Wavelength

(nm)

Comcode Device

Code

ITU-T

Frequency

(THz)

(continued)

Center

Wavelength

(nm)

Comcode

Agere Systems Inc.

9

Page 10

Wavelength-Selected, High-Power D2587P-Type (with Wavelength Data Sheet, Rev. 2

Locker)/D2547P-Type Isolated DFB Laser Modules July 2001

Ordering Information

Table 7. D2587P 20 mW CW Laser with Locker (C- and L-Band) Ordering Information

Device

Code

D2587P21 192.1 1560.61 108835828 D2587P900 190.0 1577.86 108836990

D2587P205 192.05 1561.01 108875642 D2587P8995 189.95 1578.27 108876079

D2587P20 192.0 1561.42 108835836 D2587P899 189.9 1578.69 108836982

D2587P195 191.95 1561.83 108875659 D2587P8985 189.85 1579.10 108876061

D2587P19 191.9 1562.23 108835844 D2587P898 189.8 1579.52 108836974

D2587P185 191.85 1562.64 108875667 D2587P8975 189.75 1579.93 108876046

D2587P18 191.8 1563.05 108835851 D2587P897 189.7 1580.35 108836511

D2587P175 191.75 1563.45 108875675 D2587P8965 189.65 1580.77 108876038

D2587P17 191.7 1563.86 108835869 D2587P896 189.6 1581.18 108836503

D2587P9165 191.65 1564.27 109976244 D2587P8955 189.55 1581.60 108876020

D2587P916 191.6 1564.68 108838418 D2587P895 189.5 1582.02 108836495

D2587P9155 191.55 1565.09 108876236 D2587P8945 189.45 1582.44 108876012

D2587P915 191.5 1565.50 108838400 D2587P894 189.4 1582.85 108836487

D2587P9145 191.45 1565.90 108876228 D2587P8935 189.35 1583.27 108876004

D2587P914 191.4 1566.31 108837139 D2587P893 189.3 1583.69 108836479

D2587P9135 191.35 1566.72 108876210 D2587P8925 189.25 1584.11 108875980

D2587P913 191.3 1567.13 108837121 D2587P892 189.2 1584.53 108836461

D2587P9125 191.25 1567.54 108876202 D2587P8915 189.15 1584.95 108875972

D2587P912 191.2 1567.95 108837113 D2587P891 189.1 1585.36 108836453

D2587P9115 191.15 1568.36 108876194 D2587P8905 189.05 1585.78 108875964

D2587P911 191.1 1568.77 108837105 D2587P890 189.0 1586.20 108836446

D2587P9105 191.05 1569.18 108876186 D2587P8895 188.95 1586.62 108875956

D2587P910 191.0 1569.59 108837097 D2587P889 188.9 1587.04 108836438

D2587P9095 190.95 1570.01 108876178 D2587P8885 188.85 1587.46 108875949

D2587P909 190.9 1570.42 108837089 D2587P888 188.8 1587.88 108836420

D2587P9085 190.85 1570.83 108876160 D2587P8875 188.75 1588.30 108875931

D2587P908 190.8 1571.24 108837071 D2587P887 188.7 1588.72 108836412

D2587P9075 190.75 1571.65 108876152 D2587P8865 188.65 1589.15 108875923

D2587P907 190.7 1572.06 108837063 D2587P886 188.6 1589.57 108836404

D2587P9065 190.65 1572.48 108876145 D2587P8855 188.55 1589.99 108875915

D2587P906 190.6 1572.89 108837055 D2587P885 188.5 1590.41 108836396

D2587P9055 190.55 1573.30 108876137 D2587P8845 188.45 1590.83 108875907

D2587P905 190.5 1573.71 108837048 D2587P884 188.4 1591.26 108836388

D2587P9045 190.45 1574.13 108876129 D2587P8835 188.35 1591.68 108875899

D2587P904 190.4 1574.54 108837030 D2587P883 188.3 1592.10 108836370

D2587P9035 190.35 1574.95 108876111 D2587P8825 188.25 1592.52 108875881

D2587P903 190.3 1575.37 108837022 D2587P882 188.2 1592.95 108836362

D2587P9025 190.25 1575.78 108876103 D2587P8815 188.15 1593.37 108875873

D2587P902 190.2 1576.20 108837014 D2587P881 188.1 1593.79 108836354

D2587P9015 190.15 1576.61 108876095 D2587P8805 188.05 1594.22 108875865

D2587P901 190.1 1577.03 108837006 D2587P880 188.0 1594.64 108836347

D2587P9005 190.05 1577.44 108876087 D2587P8795 187.95 1595.06 108875857

10

ITU-T

Frequency

(THz)

(continued)

Center

Wavelength

(nm)

Comcode Device

Code

ITU-T

Frequency

(THz)

(continued)

Center

Wavelength

(nm)

Comcode

Agere Systems Inc.

Page 11

Data Sheet, Rev. 2 Wavelength-Selected, High-Power D2587P-Type (with Wavelength

July 2001 Locker)/D2547P-Type Isolated DFB Laser Modules

Ordering Information

Table 7. D2587P 20 mW CW Laser with Locker (C- and L-Band) Ordering Information

Device

Code

D2587P879 187.9 1595.49 108836339 D2587P870 187.0 1603.17 108835950

D2587P8785 187.85 1595.91 108875840 D2587P8695 186.95 1603.60 108875758

D2587P878 187.8 1596.34 108836321 D2587P869 186.9 1604.03 108835943

D2587P8775 187.75 1596.76 108875832 D2587P8685 186.85 1604.46 108875741

D2587P877 187.7 1597.19 108836313 D2587P868 186.8 1604.88 108835935

D2587P8765 187.65 1597.62 108875824 D2587P8675 186.75 1605.31 108875733

D2587P876 187.6 1598.04 108836016 D2587P867 186.7 1605.74 108835927

D2587P8755 187.55 1598.47 108875816 D2587P8665 186.65 1606.17 108875725

D2587P875 187.5 1598.89 108836008 D2587P866 186.6 1606.60 108835919

D2587P8745 187.45 1599.32 108875808 D2587P8655 186.55 1607.04 108875717

D2587P874 187.4 1599.75 108835992 D2587P865 186.5 1607.47 108835901

D2587P8735 187.35 1600.17 108875790 D2587P8645 186.45 1607.90 108875709

D2587P873 187.3 1600.60 108835984 D2587P864 186.4 1608.33 108835893

D2587P8725 187.25 1601.03 108875782 D2587P8635 186.35 1608.76 108875691

D2587P872 187.2 1601.46 108835976 D2587P863 186.3 1609.19 108835885

D2587P8715 187.15 1601.88 108875774 D2587P8625 186.25 1609.62 108875683

D2587P871 187.1 1602.31 108835968 D2587P862 186.2 1610.06 108835877

D2587P8705 187.05 1602.74 108875766

ITU-T

Frequency

(THz)

(continued)

Center

Wavelength

(nm)

Comcode Device

Code

ITU-T

Frequency

(THz)

(continued)

Center

Wavelength

(nm)

Comcode

Agere Systems Inc.

11

Page 12

Wavelength-Selected, High-Power D2587P-Type (with Wavelength Data Sheet, Rev. 2

Locker)/D2547P-Type Isolated DFB Laser Modules July 2001

Ordering Information

Table 8. D2547P 20 mW CW Laser without Locker (C-Band)

Device

Code

D2547P61 196.1 1528.77 108838301 D2547P38 193.8 1546.92 108838079

D2547P60 196.0 1529.55 108838293 D2547P37 193.7 1547.72 108838061

D2547P59 195.9 1530.33 108838285 D2547P36 193.6 1548.51 108838053

D2547P58 195.8 1531.12 108838277 D2547P35 193.5 1549.32 108838046

D2547P57 195.7 1531.90 108838269 D2547P34 193.4 1550.12 108838038

D2547P56 195.6 1532.68 108838251 D2547P33 193.3 1550.92 108838020

D2547P55 195.5 1533.47 108838244 D2547P32 193.2 1551.72 108838012

D2547P54 195.4 1534.25 108838236 D2547P31 193.1 1552.52 108838004

D2547P53 195.3 1535.04 108838228 D2547P30 193.0 1553.33 108837998

D2547P52 195.2 1535.82 108838210 D2547P29 192.9 1554.13 108837980

D2547P51 195.1 1536.61 108838202 D2547P28 192.8 1554.94 108837972

D2547P50 195.0 1537.40 108838194 D2547P27 192.7 1555.75 108837964

D2547P49 194.9 1538.19 108838186 D2547P26 192.6 1556.55 108837956

D2547P48 194.8 1538.98 108838178 D2547P25 192.5 1557.36 108837949

D2547P47 194.7 1539.77 108838160 D2547P24 192.4 1558.17 108837931

D2547P46 194.6 1540.56 108838152 D2547P23 192.3 1558.98 108837923

D2547P45 194.5 1541.35 108838145 D2547P22 192.2 1559.79 108837915

D2547P44 194.4 1542.14 108838137 D2547P21 192.1 1560.61 108837907

D2547P43 194.3 1542.94 108838129 D2547P20 192.0 1561.42 108837899

D2547P42 194.2 1543.73 108838111 D2547P19 191.9 1562.23 108837881

D2547P41 194.1 1544.53 108838103 D2547P18 191.8 1563.05 108837873

D2547P40 194.0 1545.32 108838095 D2547P17 191.7 1563.86 108837865

D2547P39 193.9 1546.12 108838087

ITU-T

Frequency

(THz)

(continued)

Center

Wa velength

(nm)

Comcode

Device

Code

ITU-T

Frequency

(THz)

Center

Wavelength

(nm)

Comcode

12

Agere Systems Inc.

Page 13

Data Sheet, Rev. 2 Wavelength-Selected, High-Power D2587P-Type (with Wavelength

July 2001 Locker)/D2547P-Type Isolated DFB Laser Modules

Ordering Information

Table 9. D2547P 20 mW CW Laser without Locker (L-Band) Ordering Information

Device

Code

D2547P916 191.6 1564.68 108837840 D2547P888 188.8 1587.88 108837568

D2547P915 191.5 1565.50 108837832 D2547P887 188.7 1588.73 108837394

D2547P914 191.4 1566.31 108837824 D2547P886 188.6 1589.57 108837386

D2547P913 191.3 1567.13 108837816 D2547P885 188.5 1590.41 108837378

D2547P912 191.2 1567.95 108837808 D2547P884 188.4 1591.26 108837360

D2547P911 191.1 1568.77 108837790 D2547P883 188.3 1592.10 108837352

D2547P910 191.0 1569.59 108837782 D2547P882 188.2 1592.95 108837345

D2547P909 190.9 1570.42 108837774 D2547P881 188.1 1593.79 108837337

D2547P908 190.8 1571.24 108837766 D2547P880 188.0 1594.64 108837329

D2547P907 190.7 1572.06 108837758 D2547P879 187.9 1595.49 108837311

D2547P906 190.6 1572.89 108837741 D2547P878 187.8 1596.34 108837303

D2547P905 190.5 1573.71 108837733 D2547P877 187.7 1597.19 108837295

D2547P904 190.4 1574.54 108837725 D2547P876 187.6 1598.04 108837287

D2547P903 190.3 1575.37 108837717 D2547P875 187.5 1598.89 108837279

D2547P902 190.2 1576.20 108837709 D2547P874 187.4 1599.75 108837261

D2547P901 190.1 1577.03 108837691 D2547P873 187.3 1600.60 108837253

D2547P900 190.0 1577.86 108837683 D2547P872 187.2 1601.46 108837246

D2547P899 189.9 1578.69 108837675 D2547P871 187.1 1602.31 108837238

D2547P898 189.8 1579.52 108837667 D2547P870 187.0 1603.17 108837220

D2547P897 189.7 1580.35 108837659 D2547P869 186.9 1604.03 108837212

D2547P896 189.6 1581.18 108837642 D2547P868 186.8 1604.88 108837204

D2547P895 189.5 1582.02 108837634 D2547P867 186.7 1605.74 108837196

D2547P894 189.4 1582.85 108837626 D2547P866 186.6 1606.60 108837188

D2547P893 189.3 1583.69 108837618 D2547P865 186.5 1607.47 108837170

D2547P892 189.2 1584.53 108837600 D2547P864 186.4 1608.33 108837162

D2547P891 189.1 1585.36 108837592 D2547P863 186.3 1609.19 108837154

D2547P890 189.0 1586.20 108837584 D2547P862 186.2 1610.06 108837147

D2547P889 188.9 1587.04 108837576

ITU

Frequency

(THz)

(continued)

Center

Wavelength

(nm)

Comcode

Device

Code

ITU

Frequency

(THz)

Center

Wavelength

(nm)

Comcode

Agere Systems Inc.

13

Page 14

Wavelength-Selected, High-Power D2587P-Type (with Wavelength Data Sheet, Rev. 2

Locker)/D2547P-Type Isolated DFB Laser Modules July 2001

For additional information, contact your Agere Systems Account Ma na ger or the following:

INTERNET:

E-MAIL:

N. AMERICA: Agere Systems Inc., 555 Union Boulevard, Room 30L-15P-BA, Allentown, PA 18109-3286

ASIA PACIFIC: Agere Systems Singapore Pte. Ltd., 77 Science Park Drive, #03-18 Cintech III, Singapore 118256

CHINA: Agere Systems (Shanghai) Co., Ltd., 33/F Jin Mao Tower, 88 Century Boulevard Pudong, Shanghai 200121 PRC

JAPAN: Agere Systems Japan Ltd., 7-18, Higashi-Gotanda 2-chome, Shinagawa-ku, Tokyo 141, Japan

EUROPE: Data Requests: DATALINE:

Agere Systems Inc. reserves the right to make changes to the product(s) or information contained herein without notice. No liability is assumed as a result of their use or application. ST is a

registered trademark of Agere Systems Inc.

Copyright © 2001 Agere Systems Inc.

All Rights Reserved

July 2001

DS00-263OPTO-2 (Replaces DS00-263OPTO-1)

http://www.agere.com

docmaster@micro.lucent.com

1-800-372-2447

Tel. (65) 778 8833

Tel. (86) 21 50471212

Tel. (81) 3 5421 1600

Technical Inquiries: OPTOELECTRONICS MARKETING:

, FAX 610-712-4106 (In CANADA:

, FAX (65) 777 7495

, FAX (86) 21 50472266

, FAX (81) 3 5421 1700

Tel. (44) 7000 582 368

1-800-553-2448

, FAX (44) 1189 328 148

, FAX 610-712-4106)

(44) 1344 865 900

(Ascot UK)

Loading...

Loading...