Page 1

CY7C6501

3

3

CY7C6511

USB Hub with Microcontroller

Cypress Semiconductor Corporation • 3901 North First Street • San Jose, CA 95134 • 408-943-2600

Document #: 38-08002 Rev. *B Revised March 12, 2003

Page 2

CY7C6501

3

3

TABLE OF CONTENTS

1.0 FEATURES ............................................ .. .. .. .. .................................................................................6

2.0 FUNCTIONAL OVERVIEW .................... ........................ .................................................................7

3.0 PIN CONFIGURATIONS .............................. .. .. ................................. ..............................................9

4.0 PRODUCT SUMMARY TABLES .................................................. .. .. ...................................... .. .. ....9

4.1 Pin Assignm e n ts ...................... .. ............. .. ........................... .. ............. ... ............. .. .. ..................9

4.2 I/O Registe r S u m ma ry ......... .............. .. ............. .. ............. ... ............. .. ............. ... .. ....................10

4.3 Instruction S e t S u mm a r y ........... .. .. ............. ... ............. .. .. ............. ... ............. .. ............. ... .. . ........11

5.0 PROGRAMM I N G M OD E L .................. .. .............. .. .. ............. .. .............. .. ............. .. ... ............. .. .......12

5.1 14-bit Program Counter ............................... ..................... ...................................... .................12

5.1.1 Program Memory Organization ......................................................................................................13

5.2 8-bit Accumulator (A) ...............................................................................................................14

5.3 8-bit Tempo r a ry R e gister (X) ............... .. ............. .. .............. .. .. ............. ... ............. .. ..................14

5.4 8-bit Program Stack Pointer (PSP) ..........................................................................................14

5.4.1 Data Memory Organization ............................................................................................................14

5.5 8-bit Data Stack Pointer (DSP) ................................. .................... .................... .......................15

5.6 Address Modes .......... .. ......................... .. ..................................................... ............................15

5.6.1 Data (Immediate) ...........................................................................................................................15

5.6.2 Direct ..............................................................................................................................................15

5.6.3 Indexed ..........................................................................................................................................15

6.0 CLOCKING ....................................................................................................................................16

CY7C6511

7.0 RESET ...................................... .. .. ............................. .. ............................. .. ...................................16

7.1 Power-on Reset .......................................................................................................................16

7.2 Watchdog Reset ......................................................................................................................17

8.0 SUSPEND MODE .................................. ........................................ .. .. ............................................17

9.0 GENERAL-PURPOSE I/O PORTS .................................... .. .. .................................... .. .. .. .............18

9.1 GPIO Configuration Port ..........................................................................................................19

9.2 GPIO Interrupt Enable Ports ............................ ........................ ................................................20

10.0 12-BIT FREE-RUNNING TIMER ....................... .. .. ......................................................... .............21

11.0 I

12.0 I2C-COMP ATIBLE CONT R OL L E R ... ... ............. .. ............. .. ........................... .. ............. ... ...........22

13.0 PROCESSOR STATUS AND CONTROL REGISTER ...............................................................24

14.0 INTERRUPTS ....................................................................... ............................... ........................25

2

C CONFIGURATION REGISTER ............................................................................................22

14.1 Interrupt Vectors ....................................................................................................................27

14.2 Interrupt Latency ....................................................................................................................28

14.3 USB Bus Reset Interrupt ........................................................................................................28

14.4 Timer Interrupt .......................................................................................................................28

14.5 USB Endpoint Interrupts ........................................................................................................28

14.6 USB Hub Interrupt ..................................................................................................................28

14.7 GPIO Interrupt ........................................................................................................................29

14.8 I

2

C Interrupt ............................................................................................................................29

15.0 USB OVERVIEW .........................................................................................................................30

15.1 USB Serial Interface Engine (SIE) .........................................................................................30

15.2 USB Enumeration ..................................................................................................................30

Document #: 38-08002 Rev. *B Page 2 of 51

Page 3

CY7C6501

3

3

TABLE OF CONTENTS (continued)

16.0 USB HUB ....................................................................................................................................31

16.1 Connecting/Disconnecting a USB Device .............................................................................. 31

16.2 Enabling/Disabling a USB Device ..........................................................................................32

16.3 Hub Downs tr e a m P or ts S ta t us a nd C o n tr o l ................... ... ............. .. ............. ... .. ............. .. .....32

16.4 Downstream Port Suspend and Resume .................. .. ............................................... ............34

16.5 USB Upstream Port Status and Control ............................................ .....................................35

17.0 USB SERIAL INTERFACE ENGINE OPERATION ....................................................................36

17.1 USB Device Addresses ..........................................................................................................36

17.2 USB Device Endpoints ...........................................................................................................37

17.3 USB Control Endpoint Mode Registers ..................................................................................37

17.4 USB Non-control Endpoint Mode Registers ........................................ ....................... .. ..........38

17.5 USB Endpoint Counter Registers .......................................................... ................................39

17.6 Endpoint Mode/Count Registers Update and Locking Mechanism ........................................39

18.0 USB MODE TABLES ..................................................................................................................41

19.0 REGISTER SUMMARY .............. .................................. .. .. .... .................................. .. .. .. .. .............45

20.0 SAMPLE SCHEMATIC ...............................................................................................................47

CY7C6511

21.0 ABSOLUTE MAXIMUM RATINGS .............................................................................................47

22.0 ELECTRICAL CHARACTERISTICS ....................... .. ................................................................ ..48

23.0 SWITCHING CHARACTERISTICS

24.0 ORDERING INFORMATION .......................................................................................................49

25.0 PACKAGE DIAGRAMS ........................... .. ................................................................ .................49

(f

= 6.0 MHz) ..................................................................................... 48

OSC

Document #: 38-08002 Rev. *B Page 3 of 51

Page 4

CY7C6501

3

3

LIST OF FIGURES

Figure 5-1. Pro g ra m M e mory Space wit h In te rrupt Vector T ab le .............. ............. .. ............. .............. 13

Figure 6-1. Clo ck Os cillator On-Ch i p Cir cuit .. .. .. ............. .. .............. .. .......................... ... ............. .. .......16

Figure 7-1. Watchdog Reset (Address 0x26) ......................................................................................17

Figure 9-1. Blo ck Di a g ra m of a GPIO Pin ................. ............. .. .. ............. ... ............. .. .. .............. .. .........18

Figure 9-2. Por t 0 Dat a ..... .. ............. .. .............. .. .. ............. ... ............. .. .. .............. .. ............. ..................18

Figure 9-3. Por t1 Da ta ...... ............. .. .............. .. .. ............. .. .............. .. .. ............. ... ............. .. ..................18

Figure 9-4. Por t 2 Dat a ..... .. ............. .. .............. .. .. ............. ... ............. .. .. .............. .. ............. ..................18

Figure 9-6. GPIO C o n fig u r a tio n R e g is te r .... ... ............. .. .......................... ... ............. .. ............. ... .. .........19

Figure 9-5. Por t 3 Dat a ..... .. ............. .. .............. .. .. ............. ... ............. .. .. .............. .. ............. ..................19

Figure 9-7. Por t 0 Int e rr u p t E na b l e .... .............. .. ............. .. .............. .. .. ............. ... ............. .. ..................20

Figure 9-8. Por t 1 Int e rr u p t E na b l e .... .............. .. ............. .. .............. .. .. ............. ... ............. .. ..................20

Figure 10-1. Ti m e r L SB Re g is t e r .............. .. .............. .. .. ............. .. .............. .. .. ............. ... ......................21

Figure 10-2. Ti m e r MS B R egister .................... .. .. ............. ... ............. .. .. .............. .. ............. .. ................21

Figure 9-9. Por t 2 Int e rr u p t E na b l e .... .............. .. ............. .. .............. .. .. ............. ... ............. .. ..................21

Figure 9-10. Port 3 Interrupt Enable ....................................................................................................21

Figure 10-3. Ti m e r Bl o c k D ia g r a m .............. .............. .. .. ............. .. .............. .. .......................... ... ...........22

Figure 11-1. I

Figure 12-1. I

Figure 12-2. I

Figure 13-1. Processor Status and Control Register ...........................................................................24

Figure 14-1. Global Interrupt Enable Register .....................................................................................25

Figure 14-2. USB Endpoint Interrupt Enable Register .........................................................................26

Figure 14-3. Interrupt Controller Function Diagram .............................................................................27

Figure 14-4. GP IO In t er ru p t Structure ................. ............. ... ............. .. .. .............. .. ............. .. .. .............. 29

Figure 16-1. Hub Ports Connect Status ...............................................................................................31

Figure 16-2. Hub Ports Speed .............................................................................................................31

Figure 16-3. Hub Ports Enable Register ..............................................................................................32

Figure 16-4. Hub Downstrea m P o rts Control Re gi s te r .... . ... ............. .. ............. ... ............. .. ............. .. ... 33

Figure 16-5. Hub P o rt s F o rce Low Registe r .... .. ............. .. .............. .. .. ............. ... ............. .. .. ................33

Figure 16-6. Hub P o rt s F o rce Low Registe r .... .. ............. .. .............. .. .. ............. ... ............. .. .. ................33

Figure 16-7. Hub P o rts SE0 Status Re g i ster .................... ... ............. .. ............. ... ............. .. .. ................33

Figure 16-8. Hub P o rt s D a ta R e g is te r .......................... .. .. .............. .. ............. .. .............. .. .. ..................34

Figure 16-9. Hub Ports Suspend Register ...........................................................................................34

Figure 16-10 . Hub P o rts R e su me Status Reg ister ...................... .............. .. ............. .. .............. .. .........35

Figure 16-11. USB Status and Control Register ..................................................................................35

Figure 17-1. USB Device Address Registers .......................................................................................36

Figure 17-2. USB Device Endpoint Zero Mode Registers ...................................................................37

Figure 17-3. USB Non-control Device Endpoint Mode Registers ........................................................38

Figure 17-4. USB Endpoint Counter Registers ....................................................................................39

Figure 17-5. Token/Data Packet Flow Diagram ...................................................................................40

2

C Configuration Registe r ................. ... .. ............. .. ............. ... ............. .. ............. ... ...........22

2

C Data Regist e r .............. .. ............. .. .............. .. .. ............. .. .............. .. ............. .. .............. 23

2

C Status and Co n trol Register ................................. .. ............. .. ... ............. .. ............. .. ... 23

CY7C6511

Document #: 38-08002 Rev. *B Page 4 of 51

Page 5

CY7C6501

3

3

LIST OF TABLES

Table 4-1. Pin Assignments ..................................................................... ..............................................9

Table 4-2. I/O Register Summary .............. ................................................. .......................... ...............10

Table 4-3. Instruction Set Summary ....................................................................................................11

Table 9-1. GPIO Port Output Control Truth Table and Interrupt Polarit y .............................................20

Table 11-1. I

Table 12-1. I

Table 14-1. Interrupt Vector Assignments ................. ...................... ...................... ..............................27

Table 16-1. Control Bit Definition for Downstream Ports ....................... ..............................................33

Table 16-2. Control Bit Definition for Upstream Port .................................. ...................... ...................36

Table 17-1. Memory Allocation for Endpoints ..................................... ...................... ..........................37

Table 18-1. USB Register Mode Encoding ......................... .................................................................41

Table 18-2. Decode table for Table 18-3: “Details of Modes for Differing Traffic Conditions” .............42

Table 18-3. Details of Modes for Differing Traffic Co nditions (see Table 18-2 for the decode legend) 43

2

C Port Configuration .......................................................................................................22

2

C Status and Control Register Bit Definitions ......................................... .................... ....23

CY7C6511

Document #: 38-08002 Rev. *B Page 5 of 51

Page 6

CY7C6501

3

3

1.0 Features

• USB hub with an integrated microcontroller

• 8-bit USB optimized microcontroller

—Harvard arc hitecture

—6-MHz external clock source

—12-MHz internal CPU clock

—48-MHz internal hub clock

• Internal memory

—256 bytes of RAM

—8 KB of PROM

• Integrated Master/Slave I

•I/O ports

—Three GPIO ports (Port 0 to 2) capable of sinking 7 mA per pin (typical)

—An additional GPIO port (Port 3) capable of sinking 12 mA per pin (typical) for high current requirements: LEDs

—Higher current drive achievable by connecting multiple GPIO pins together to drive a common output

—Each GPIO port can be configured as input s with internal pull-ups or open drain output s or traditional CMOS outputs

—Maskable interrupts on all I/O pins

• 12-bit free-running timer with one microsecond clock ticks

• Watchdog timer (WDT)

• Internal Power-on Reset (POR)

• USB Specification compliance

—Conforms to USB Specification, Version 1.1

—Conforms to USB HID Specification, Version 1.1

—Supports one or two device addresses with up to 5 user-configured endpoints

Up to two 8-byte control endpoints

Up to four 8-byte data endpoints

Up to two 32-byte data endpoints

—Integrated USB transceivers

—Supports seven (CY7C65013) or four (CY7C65113) downstream USB ports

—GPIO pins can provide individual power control outputs for each downstream USB port

—GPIO pins can provide individual port over current inputs for each downstream USB port

• Improved output drivers to reduce electromagnetic interference (EMI)

• Operating voltage from 4.0V to 5.5V DC

• Operating temperature from 0° to 70° C

• CY7C65013 available in 48-pin PDIP (-PC) or 48-pin SSOP (-PVC) packages

• CY7C65113 available in 28-pin SOIC (-SC) or 28-pin PDIP (-PC) packages

• Industry-standard programmer support.

2

C-compatible Controller (100 kHz) enabled through General-purpose I/O (GPIO) pins

CY7C6511

Document #: 38-08002 Rev. *B Page 6 of 51

Page 7

CY7C6501

3

3

2.0 Functional Overview

The CY7C65x13 device s are one-time pro grammable 8- bit microc ontrollers with a built- in 12-M bp s USB hu b t hat su pport s up to

seven downstream ports. The microcontroller instruction set has been optimized specifically for USB operations, although the

microcontrollers can be used for a variety of non-USB embedded applications.

GPIO

CY7C65013

The CY7C65013 featur es 22 GPIO pin s to support USB and other applicatio ns. The I/O p ins are grouped int o four port s (P0[7:0],

P1[7:4,2:0], P2[7:3], P3[1:0 ]) where eac h port can be co nfigured as inputs with internal pul l-ups, op en drain outpu ts, or tradi tional

CMOS outputs. Ports 0 to 2 are rated at 7 mA per pin (typical) sink current. Port 3 pins are rated at 12 mA per pin (typical) sink

current, which allows these pins to drive LEDs. Multiple GPIO pins can be connected together to drive a single output for more

drive current capa city. Additionally, ea ch I/O pin c an be u sed to genera te a GPI O inte rrupt to t he micr ocon troller. All of the GPIO

interrupts all share the same “GPIO” interrupt vector.

CY7C65113

The CY7C65113 has 11 GPIO pins (P0[7:0], P1[2:0]), both rated at 7 mA per pin (typical) sink current. Multiple GPIO pins can

be connected together to drive a single output for more drive current capacity.

Clock

The microcontroller us es an ex tern al 6 -MH z cry st a l an d an i nter nal oscillator to provide a referenc e to an inte rnal phase-locked

loop (PLL)-based clock generator. This technology allows the customer application to use an inexpensive 6-MHz fundamental

crystal that red uces the clock-related no ise emissions (EMI). A PLL cl ock generator provides the 6 -, 12-, and 48-MHz clock s ignals

for distribution within the microcontroller.

Memory

The CY7C65013 and the CY7C65113 are offered with 8 KB of PROM.

Power-on Reset, Watchdog, and Free-running Timer

These parts in clude power-o n reset logic , a Wa tchdog timer, and a 12-bit free-running timer. The PO R logic detect s when power

is applied to the device, resets the logic to a known state, and begins executing instructions at PROM address 0x0000. The

Watchdog timer is u sed to ensure the mi crocontrol ler rec overs afte r a perio d of ina ctivi ty. The firmware may become inactive for

a variety of reasons, including errors in the code or a hardware failure such as waiting for an interrupt that never occurs.

2

C

I

2

The microcontroller can communicate with external electronics through the GPIO pins. An I

dates a 100-kHz serial link with an external device.

Timer

The free-running 12-bit timer clocked at 1 MHz provides two interrupt sources, 128-µs and 1.024-ms. The timer can be used to

measure the duration of an event under firmware control by reading the timer at the start of the event and after the event is

complete. The difference between the two readings indicates the duration of the event in microseconds. The upper four bits of

the timer are lat ched into an internal regi ster when the firmware reads the lower e ight bits. A read from th e upper four bits actually

reads data from the inte rnal register , in stead of the ti mer . This featur e eliminates the ne ed for firmware to t ry to compensate if the

upper four bits increment immediately after the lower eight bits are read.

Interrupts

The microcontroller su ppo rts ten maskable interrupt s in the vectored interrupt contro lle r. Interrupt sources include the USB Bus

Reset interrupt, the 128-µs (bit 6 ) and 1.024-ms (bi t 9) outpu ts from the free -running ti mer, five USB end points, the USB h ub, the

GPIO ports, and the I

from LOW ‘0’ to HIGH ‘1’. Th e USB endpoi nts i nterrupt afte r the USB h ost has w ritten dat a to the endpoint FIFO or after the USB

controller sends a p ac ke t to th e U SB hos t. T he GPIO ports also hav e a le vel of masking to select w hic h GPI O inp uts can cause

a GPIO interrupt. Input transition polarity can be programmed for each GPIO port as part of the port configuration. The interrupt

polarity can be rising edge (‘0’ to ‘1’) or falling edge (‘1’ to ‘0’).

USB

The CY7C65013 and CY7C65113 include an integrated USB Serial Interface Engine (SIE) that supports the integrated peripherals and the hub controller function. The hardware supports up to two USB device addresses with one device address for the

hub (two endpoint s) and a device address for a compoun d device (three end points). The SIE a llows the USB host to c ommunicate

with the hub and fu nctions integrated into the microcon troller . The CY7C651 13 p art includes a 1:4 hub repeater with one upstream

port and four downstream ports, while the CY 7C65013 part inclu des a 1:7 hub repeater . The USB Hub allows power management

control of the downstream ports by using GPIO pins assigned by the user firmware. The user has the option of ganging the

downstream ports together with a single pair of power management pins, or providing power management for each port with four

(CY7C65113) or seven (CY7C65013) pairs of power management pins.

2

C-compatible master mode interface. The timer bits cause an interrupt (if enabled) when the bit toggles

C-compatible interface ac commo-

CY7C6511

Document #: 38-08002 Rev. *B Page 7 of 51

Page 8

CY7C6501

3

3

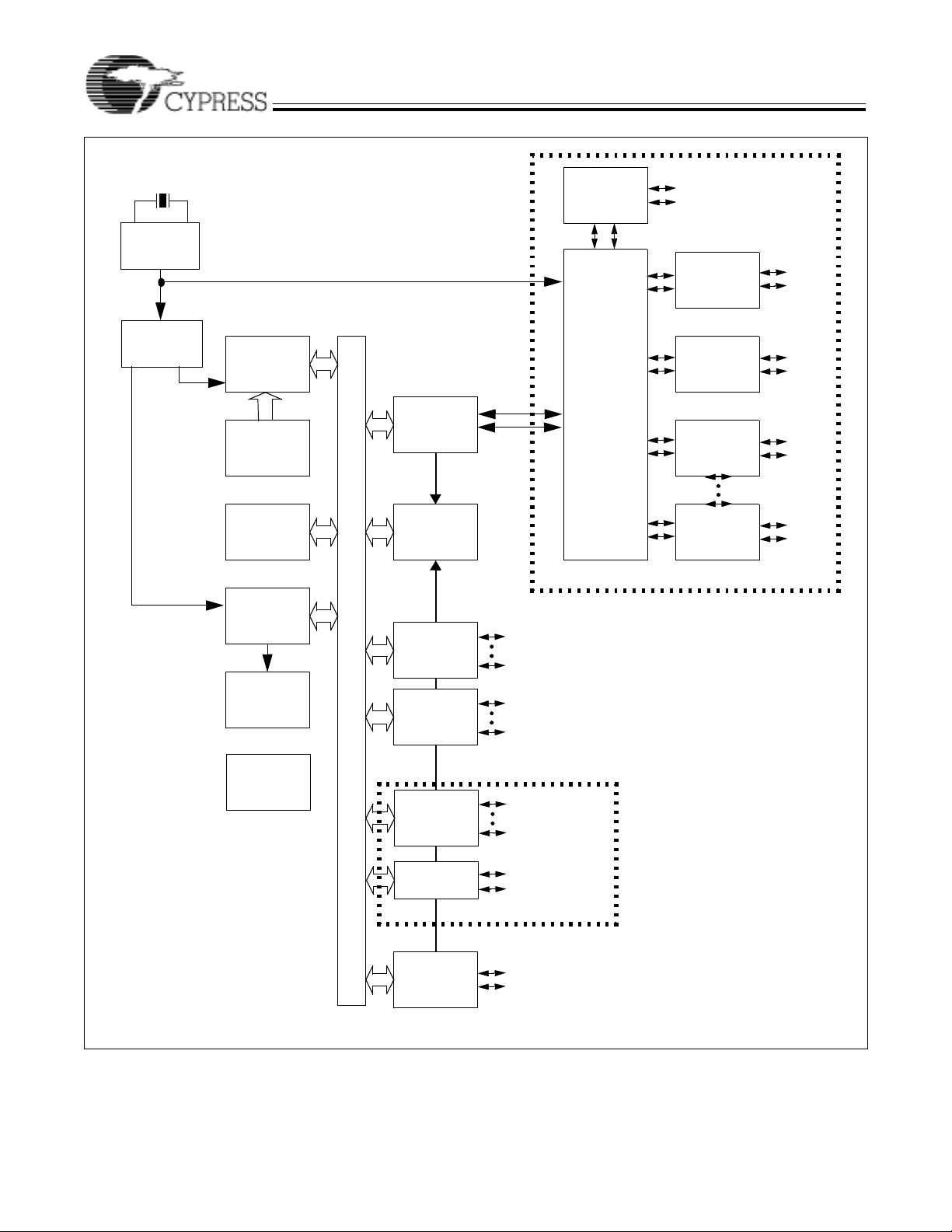

Logic Block Diagram

CY7C6511

6-MHz crystal

PLL

48 MHz

Clock

Divider

6 MHz

12 MHz

12-MHz

8-bit

CPU

PROM

8 KB

RAM

256 byte

12-bit

Timer

8-bit Bus

USB

SIE

Interrupt

Controller

GPIO

PORT 0

P0[0]

P0[7]

USB

Transceiver

Repeater

D+[0]

Upstream

USB Port

D–[0]

Downstream USB Ports

USB

Transceiver

USB

Transceiver

USB

Transceiver

USB

Transceiver

CY7C65013 only

Power management under firmware

control using GPIO pins

D+[1]

D–[1]

D+[4]

D–[4]

D+[5]

D–[5]

D+[7]

D–[7]

Watchdog

Timer

Power-on

Reset

GPIO

PORT 1

GPIO

PORT 2

GPIO

PORT 3

I2C comp.

Interface

2

*I

C-compatible interface enabled by firmware through

P2[1:0] or P1[1:0]

P1[0]

P1[2]

P2[7]

P2[3]

High Current

P3[1]

Outputs

P3[0]

CY7C65013 only

SCLK

SDATA

Document #: 38-08002 Rev. *B Page 8 of 51

Page 9

3

3

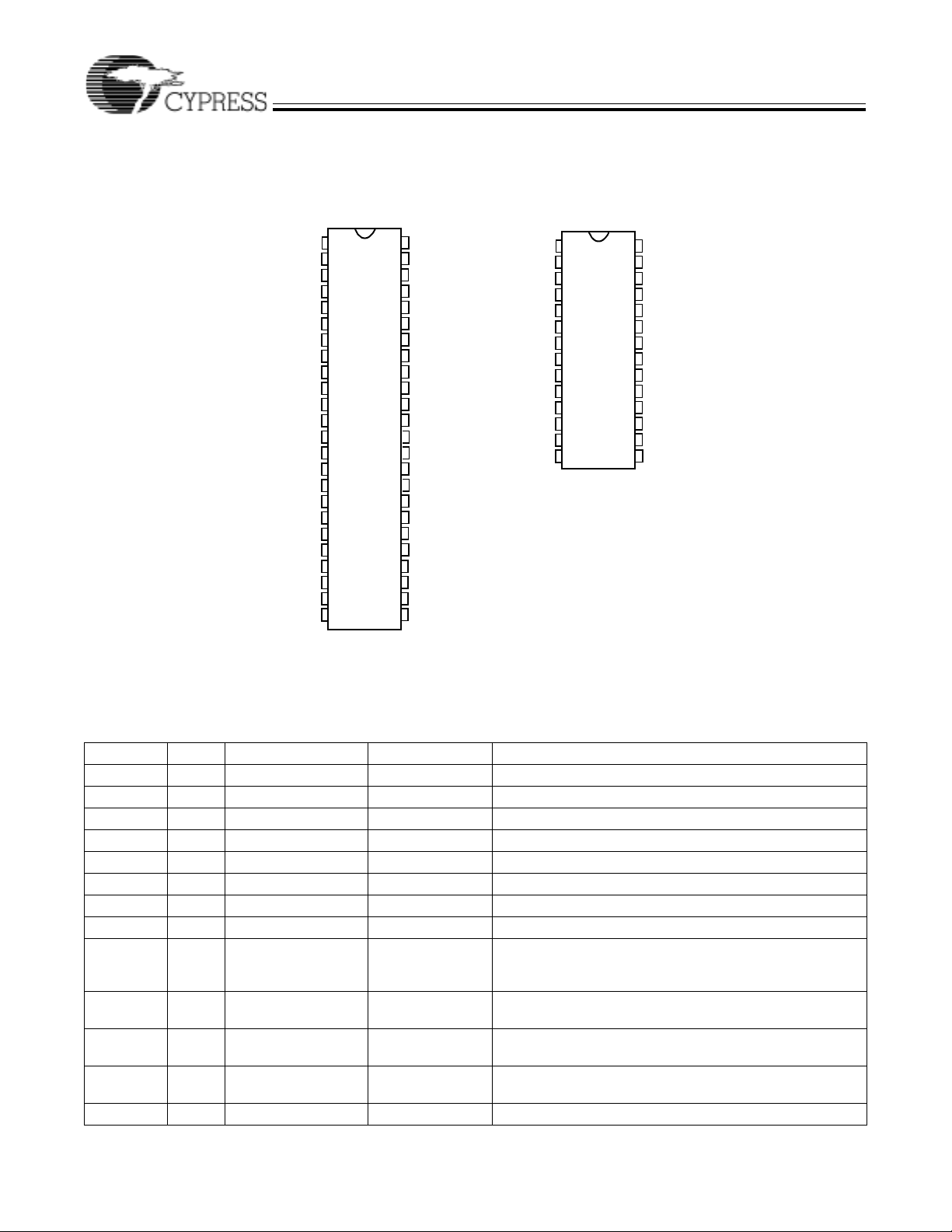

3.0 Pin Configurations

XTALOUT

XTALIN

48-pin SSOP

P1[1]

P1[5]

P1[7]

P3[1]

D+[0]

D–[0]

GND

D+[1]

D–[1]

V

REF

D+[2]

D–[2]

P2[3]

GND

P2[5]

D+[7]

D–[7]

P2[7]

P0[7]

P0[5]

P0[3]

P0[1]

CY7C65013

48

1

2

47

46

3

4

45

5

44

43

6

42

7

41

8

9

40

39

10

11

38

37

12

13

36

35

14

34

15

16

33

17

32

31

18

19

30

29

20

21

28

22

27

23

26

25

24

CY7C6501

Top View

CY7C65113

28-pin SOIC

V

CC

P1[0]

P1[2]

P1[4]

P1[6]

P3[0]

D–[3]

D+[3]

GND

D–[4]

D+[4]

V

REF

D–[5]

D+[5]

GND

P2[4]

D–[6]

D+[6]

P2[6]

V

PP

P0[0]

P0[2]

P0[4]

P0[6]

XTALOUT

XTALIN

V

GND

D+[0]

D–[0]

D+[1]

D–[1]

D+[2]

D–[2]

P0[7]

P0[5]

P0[3]

P0[1]

REF

1

28

V

2

3

4

5

6

7

8

9

10

11

12

13

14

CC

27

P1[1]

26

P1[0]

P1[2]

25

D–[3]

24

D+[3]

23

D–[4]

22

D+[4]

21

GND

20

19

V

PP

18

P0[0]

17

P0[2]

P0[4]

16

15

P0[6]

CY7C6511

4.0 Product Summary Tables

4.1 Pin Assignments

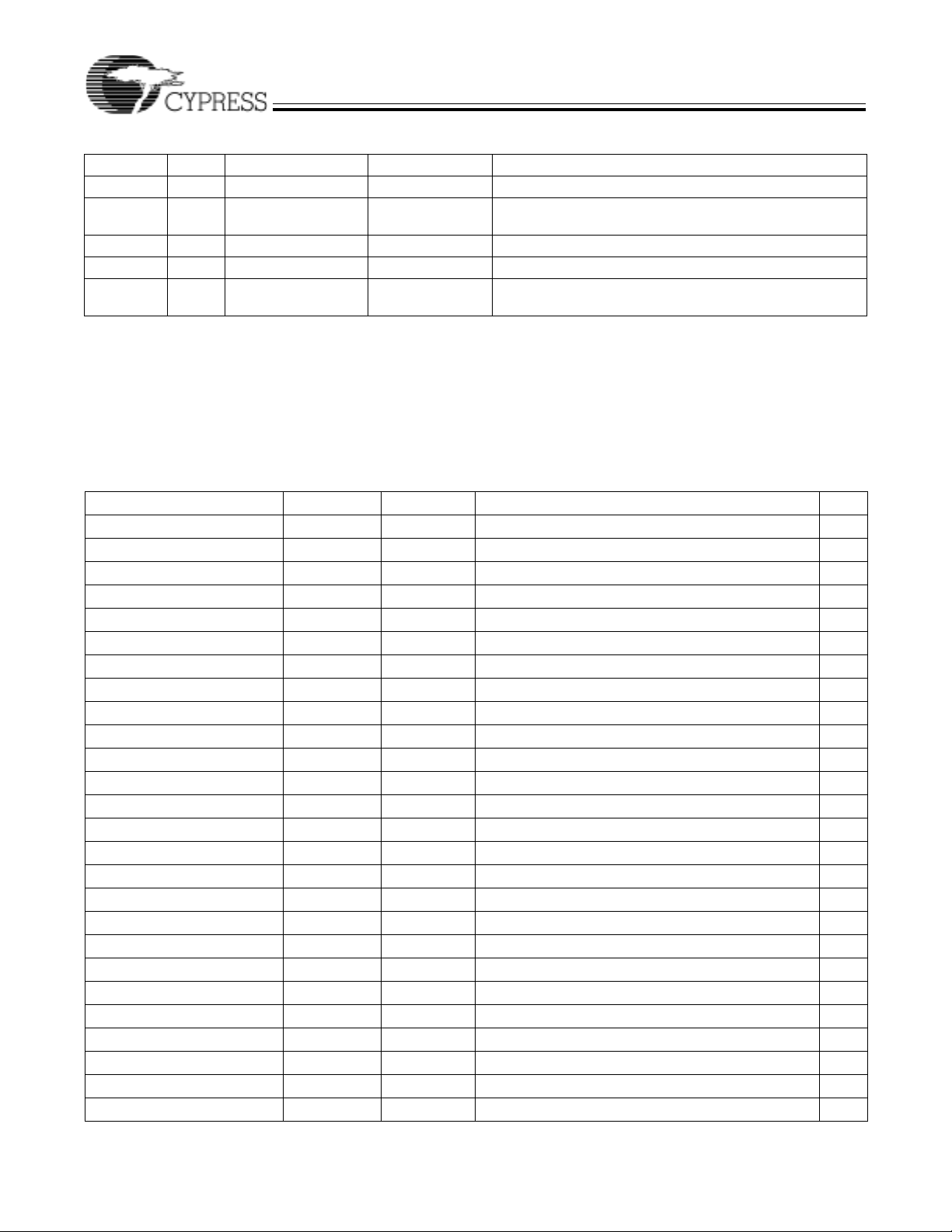

Table 4-1. Pin Assignments

Name I/O 48-pin 28-pin Description

D+[0], D–[0] I/O 7, 8 5, 6 Upstream port, USB differential data.

D+[1], D–[1] I/O 10, 11 7, 8 Downstream Port 1, USB differential data.

D+[2], D–[2] I/O 13, 14 9, 10 Downstream Port 2, USB differential data.

D+[3], D– [3] I/ O 41, 42 23, 24 Downstream Port 3, US B differential data.

D+[4], D– [4] I/ O 38, 39 21, 22 Downstream Port 4, US B differential data.

D+[5], D–[5] I/O 35, 36 Downstream Port 5, USB differential data.

D+[6], D–[6] I/O 31, 32 Downstream Port 6, USB differential data.

D+[7], D–[7] I/O 18, 19 Downstream Port 7, USB differential data.

P0 I/O P1[7:0]

21, 25, 22, 26, 23, 27,

24, 28

P1 I/O P1[7:4,2:0]

5, 44, 4, 45; 46, 3, 47

P2 I/O P2[7:3]

20, 30, 17,33, 15

P3 I/O P3[1:0]

6, 43

XTAL

IN

IN 2 2 6-MHz crystal or external clock input.

P1[7:0]

11, 15, 12, 16, 13,

17, 14, 18

P1[2:0]

25, 27, 26

GPIO Port 0 capable of sinking 7 mA (typical).

GPIO Port 1 capable of sinking 7 mA (typical).

GPIO Port 2 capable of sinking 12 mA (typical).

GPIO Port 3, capable of sinking 12 mA (typical).

Document #: 38-08002 Rev. *B Page 9 of 51

Page 10

CY7C6501

3

3

Table 4-1. Pin Assignments (continued)

Name I/O 48-pin 28-pin Description

XTAL

OUT

V

PP

V

CC

GND 9, 16, 34, 40 4, 20 Ground.

V

REF

4.2 I/O Register Summary

I/O registers are accessed v ia the I/O Read (IORD) a nd I/O W rite (IOWR , IOWX) instructi ons. IORD reads data from the sel ected

port into the accumu lator . IOWR perform s the revers e; it wri tes dat a from the a ccumulator to the sel ected por t. Indexed I/O W rite

(IOWX) adds the co ntent s of X to t he add ress in th e ins tructio n to form the p ort add ress a nd wri tes da ta from th e acc umula tor t o

the specified port. Specifying address 0 (e.g., IOWX 0h) means the I/O register is selected solely by the contents of X.

All undefined registers are reserved. Do not write to reserved registers as this may cause an undefined operation or increased

current consumption during operation. When writing to registers with reserved bits, the reserved bits must be written with ‘0.’

Table 4-2. I/O Register Summary

Port 0 Data 0x00 R/W GPIO Port 0 Data 18

Port 1 Data 0x01 R/W GPIO Port 1 Data 17

Port 2 Data 0x02 R/W GPIO Port 2 Data 17

Port 3 Data 0x03 R/W GPIO Port 3 Data 19

Port 0 Interrupt Enable 0x04 W Interrupt Enable for Pins in Port 0 19

Port 1 Interrupt Enable 0x05 W Interrupt Enable for Pins in Port 1 19

Port 2 Interrupt Enable 0x06 W Interrupt Enable for Pins in Port 2 19

Port 3 Interrupt Enable 0x07 W Interrupt Enable for Pins in Port 3 19

GPIO Configuration 0x08 R/W GPIO Port Configurations 18

2

C Configuration 0x09 R/W I2C Position Configuration 20

I

USB Device Address A 0x10 R/W USB Device Address A 36

EP A0 Counter Register 0x11 R/W USB Address A, Endpoint 0 Counter 38

EP A0 Mode Register 0x12 R/W USB Address A, Endpoint 0 Configuration 37

EP A1 Counter Register 0x13 R/W USB Address A, Endpoint 1 Counter 38

EP A1 Mode Register 0x14 R/W USB Address A, Endpoint 1 Configuration 38

EP A2 Counter Register 0x15 R/W USB Address A, Endpoint 2 Counter 38

EP A2 Mode Register 0x16 R/W USB Address A, Endpoint 2 Configuration 38

USB Status & Control 0x1F R/W USB Upstream Port Traffic Status and Control 35

Global Interrupt Enable 0x20 R/W Global Interrupt Enable 25

Endpoint Interrupt Enable 0x21 R/W USB Endpoint Interrupt Enables 26

Interrupt Vector 0x23 R Pending Interrupt Vector Read/Clear 27

Timer (LSB) 0x24 R Lower Eight Bits of Free-running Timer (1 MHz) 20

Timer (MSB) 0x25 R Upper Four Bits of Free-running Timer 20

WDR Clear 0x26 W Watchdog Reset Clear 17

2

C Control & Sta tus 0x28 R/W I2C Status and Control 21

I

2

C Data 0x29 R/W I2C Data 23

I

OUT 1 1 6-MHz crystal out.

29 19 Programming voltage supply, tie to ground during normal

operation.

48 28 Voltage supply.

IN 12, 37 3 External 3.3V supply voltage for the down stream dif ferential

data output buffers and the D+ pull up.

Register Name I/O Address Read/Write Function Page

CY7C6511

Document #: 38-08002 Rev. *B Page 10 of 51

Page 11

CY7C6501

3

3

Table 4-2. I/O Register Summary (continued)

Register Name I/O Address Read/Write Function Page

Reserved 0x30 Reserved

Reserved 0x31 Reserved

Reserved 0x32 Reserved

Reserved 0x38-0x3F Reserved

USB Device Address B 0x40 R/W USB Device Address B (not used in 5-endpoint mod e) 36

EP B0 Counter Register 0x41 R/W USB Address B, Endpoint 0 Counter 38

EP B0 Mode Register 0x42 R/W USB Address B, Endpoint 0 Configuration, or

USB Address A, Endpoint 3 in 5-endpoint mode

EP B1 Counter Register 0x43 R/W USB Address B, Endpoint 1 Counter 38

EP B1 Mode Register 0x44 R/W USB Address B, Endpoint 1 Configuration, or

USB Address A, Endpoint 4 in 5-endpoint mode

Hub Port Connect Status 0x48 R/W Hub Downstream Port Connect Status 31

Hub Port Enable 0x49 R/W Hub Downstream Ports Enable 32

Hub Port Speed 0x4A R/W Hub Downstream Ports Speed 31

Hub Port Control (Ports [4:1]) 0x4B R/W Hub Downstream Ports Control (Ports [4:1]) 33

Hub Port Control (Ports [7:5]) 0x4C R/W Hub Downstream Ports Control (Ports [7:5]) 33

Hub Port Suspend 0x4D R/W Hub Downstream Port Suspend Control 34

Hub Port Resume Status 0x4E R Hub Downstream Ports Resume Status 35

Hub Ports SE0 Status 0x4F R Hub Downstream Ports SE0 Status 33

Hub Ports Data 0x50 R Hub Downstream Ports Differential Data 34

Hub Downstream Force Low 0x51 R/W Hub Downstream Ports Force LOW (Ports [1:4]) 33

Hub Downstream Force High 0x52 R/W Hub Downstream Ports Force HIGH (Ports [5:7]) 33

Processor Status & Control 0xFF R/W Microprocessor Status and Control Register 24

CY7C6511

37

38

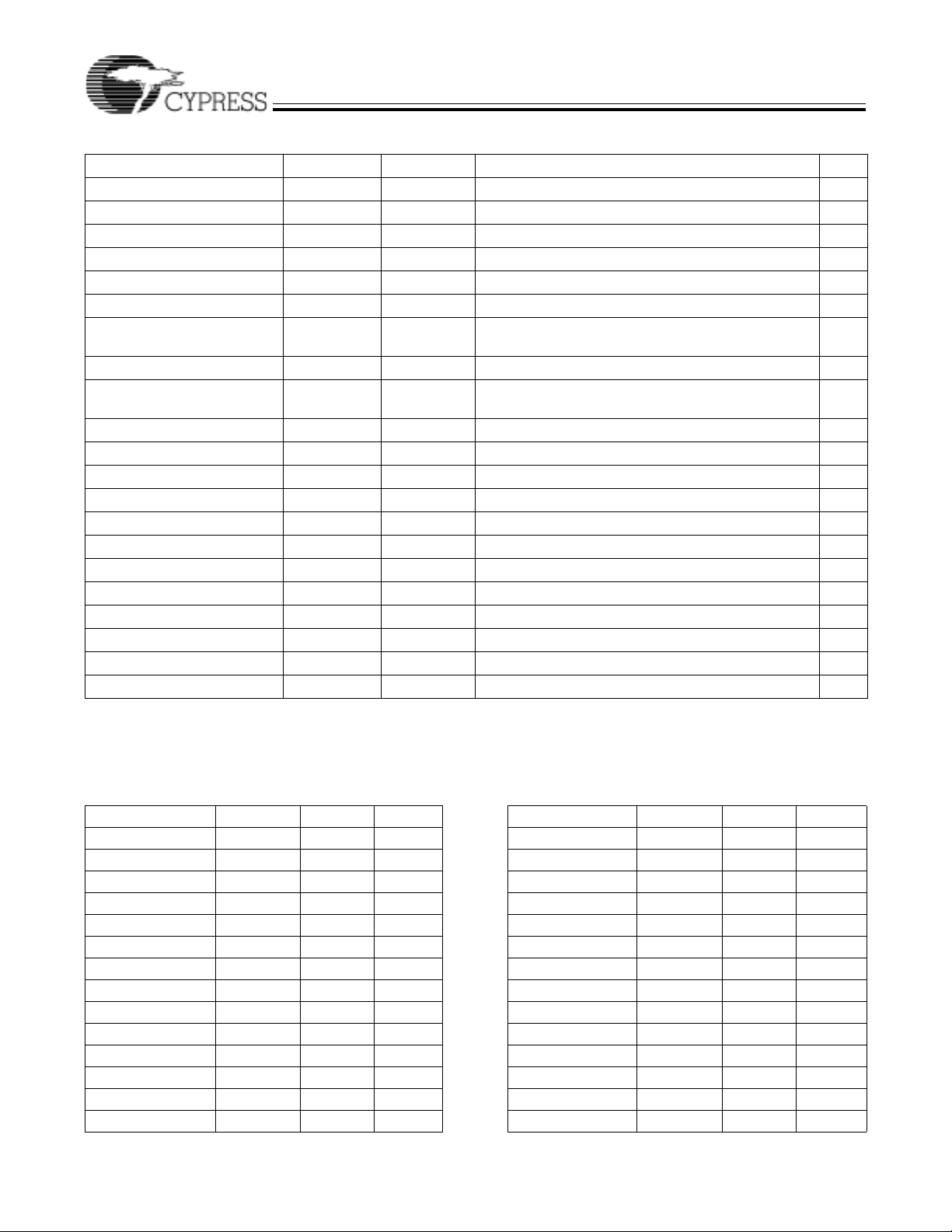

4.3 Instruction Set Summary

Refer to the CYASM Assembler User’s Guide for more details. Note that conditional jump instructions (i.e. JC, JNC, JZ, JNZ)

take five cycles if jump is taken, four cycles if no jump.

Table 4-3. Instruction Set Summary

MNEMONIC operand opcode cycles MNEMONIC operand opcode cycles

HALT 00 7 NOP 20 4

ADD A,expr data 01 4 INC A acc 21 4

ADD A,[expr] direct 02 6 INC X x 22 4

ADD A,[X+expr] index 03 7 INC [expr] direct 23 7

ADC A,expr data 04 4 INC [X+expr] index 24 8

ADC A,[expr] direct 05 6 DEC A acc 2 5 4

ADC A,[X+expr] index 06 7 DEC X x 26 4

SUB A,expr data 07 4 DEC [expr] direct 27 7

SUB A,[expr] direct 08 6 DEC [X+expr] index 28 8

SUB A,[X+expr] index 09 7 IORD expr address 29 5

SBB A,expr data 0A 4 IOWR expr address 2A 5

SBB A,[expr] direct 0B 6 POP A 2B 4

SBB A,[X+expr] index 0C 7 POP X 2C 4

OR A,expr data 0D 4 PUSH A 2D 5

Document #: 38-08002 Rev. *B P age 11 of 51

Page 12

CY7C6501

3

3

Table 4-3. Instruction Set Summary (continued)

MNEMONIC operand opcode cycles MNEMONIC operand opcode cycles

OR A,[expr] direct 0E 6 PUSH X 2E 5

OR A,[X+expr] index 0F 7 SWAP A,X 2F 5

AND A,expr data 10 4 SWAP A,DSP 30 5

AND A,[expr] direct 11 6 MOV [expr],A direct 31 5

AND A,[X+expr] index 12 7 MOV [X+expr],A index 32 6

XOR A,expr data 13 4 OR [ex pr],A direct 33 7

XOR A,[expr] direct 14 6 OR [X+expr],A index 34 8

XOR A,[X+expr] index 15 7 AND [expr],A direct 35 7

CMP A,expr data 16 5 AND [X+expr],A index 36 8

CMP A,[expr] direct 17 7 XOR [expr],A direct 37 7

CMP A,[X+expr] index 18 8 XOR [X+expr],A index 38 8

MOV A,expr data 19 4 IOWX [X+expr] index 39 6

MOV A,[expr] direct 1A 5 CPL 3A 4

MOV A,[X+expr] index 1B 6 ASL 3B 4

MOV X,expr data 1C 4 ASR 3C 4

MOV X,[expr] direct 1D 5 RLC 3D 4

reserved 1E RRC 3E 4

XPAGE 1F 4 RET 3F 8

MOV A,X 40 4 DI 70 4

MOV X,A 41 4 EI 72 4

MOV PSP,A 60 4 RETI 73 8

CALL addr 50-5F 10 JC addr C0-CF 5 (or 4)

JMP addr 80-8F 5 JNC addr D0-DF 5 (or 4)

CALL addr 90-9F 10 JACC addr E0-EF 7

JZ addr A0-AF 5 (or 4) INDEX addr F0-FF 14

JNZ addr B0-BF 5 (or 4)

CY7C6511

5.0 Programming Model

5.1 14-bit Program Counter

The 14-bit Program Counter (PC) allows access to up to 8 KB of PROM available with the CY7C65x13 architecture. The top

32 bytes of the ROM in the 8K part are re serve d for testing purposes. The program c ounter is clea red during re set, su ch that the

first instruction e xecuted a fter a res et is a t addres s 0x0 000h. Typically, this is a jum p ins tructio n to a res et han dler tha t initializes

the application (see Interrupt Vectors on page 27).

The lower eight bits of the program counter are incremented as instructions are loaded and executed. The upper six bits of the

program counter are increm ented by executing an XP AGE instructi on. As a result, the las t instruction exec uted within a 256-by te

“page” of sequen tial cod e should be an XPAGE instruction. The assemble r directive “XPAGEON” causes the as sembler to insert

XPAGE instructions au tomatical l y. Because instructions can be either one or two bytes lon g, the assembler may occasionally

need to insert a NOP followed by an XPAGE to execute correctly.

The address of the next ins truction to be execute d, the carry fl ag, and the zero fl ag are save d as two bytes on the progra m stack

during an interrupt acknowledge or a CALL instruction. The program counter, carry flag, and zero flag are restored from the

program stack during a RETI instruction. Only the program counter is restored during a RET instruction.

The program counter ca nnot be accesse d direct ly by the firm ware . The progr am st ack can be exam ined by read in g SRAM from

location 0x00 and up.

Document #: 38-08002 Rev. *B Page 12 of 51

Page 13

3

3

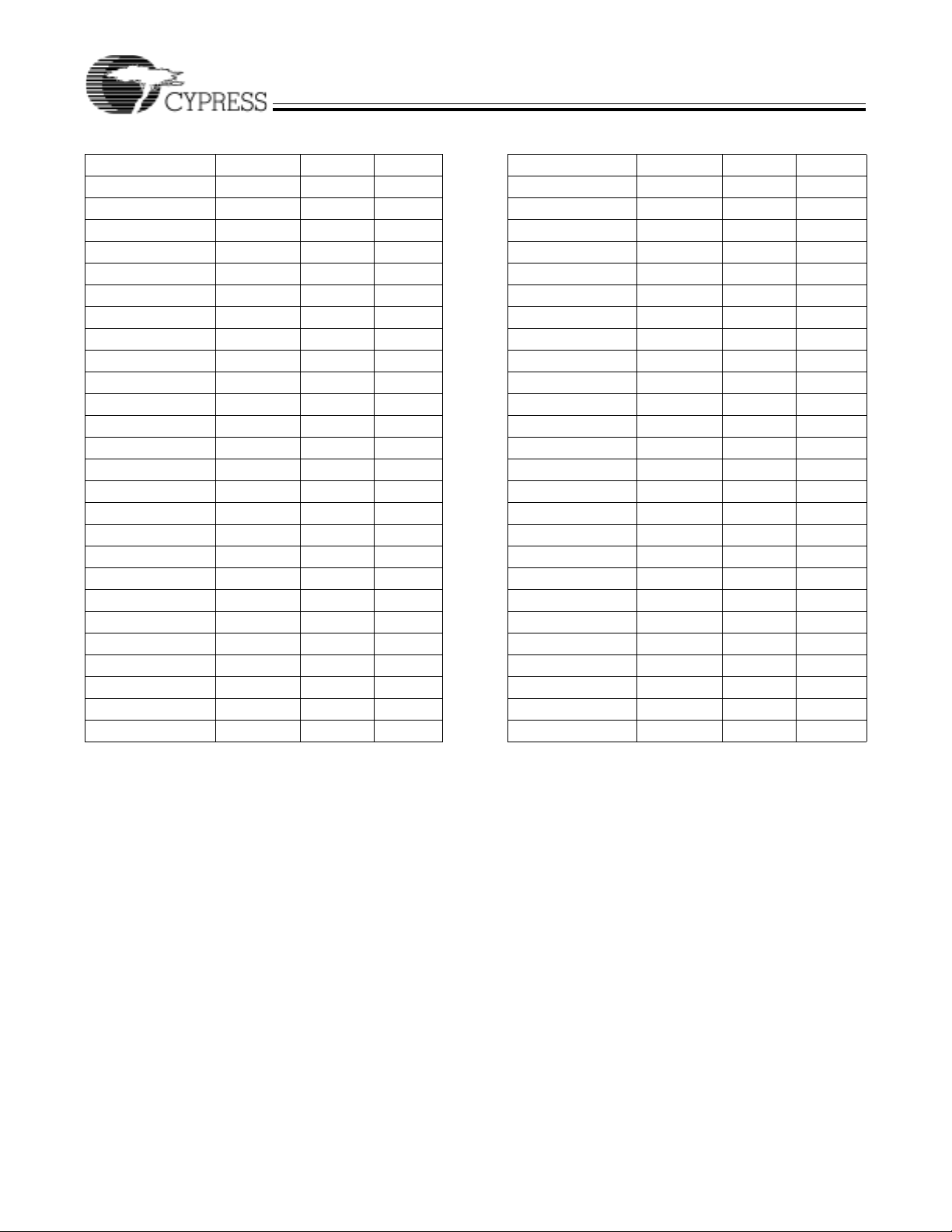

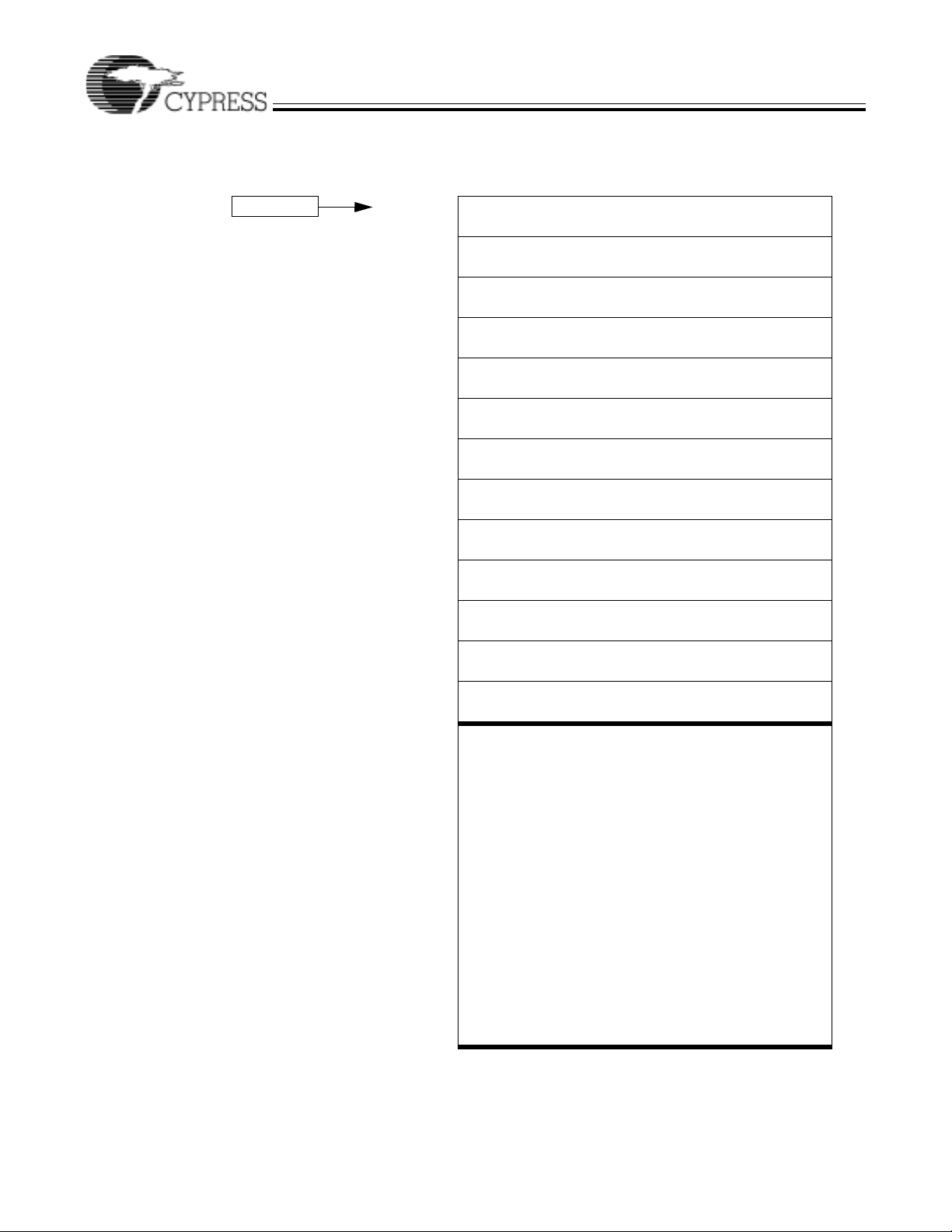

5.1.1 Program Memory Organization

after reset Address

14-bit PC 0x0000 Program execution begins here after a reset

0x0002 USB Bus Reset interrupt vector

0x0004 128-µs timer interrupt vector

0x0006 1.024-ms timer interrupt vector

0x0008 USB address A endpoint 0 interrupt vector

0x000A USB address A endpoint 1 interrupt vector

0x000C USB address A endpoint 2 interrupt vector

0x000E USB address B endpoint 0 interrupt vector

CY7C6501

CY7C6511

0x0010 USB address B endpoint 1 interrupt vector

0x0012 Hub interrupt vector

0x0014 Reserved

0x0016 GPIO interrupt vector

0x0018

0x001A Program Memory begi ns here

I2C interrupt vector

0x1FDF (8 KB -32) PROM ends here (CY7C65013, CY7C65113)

Figure 5-1. Program Memory Space with Interrupt Vector Table

Note that

Document #: 38-08002 Rev. *B Page 13 of 51

the upper 32 bytes of the 8K PROM are reserved. Therefore, user’s program must not overwrite this space.

Page 14

CY7C6501

3

3

5.2 8-bit Accumulator (A)

The accumulator is the general-purpose register for the microcontroller.

5.3 8-bit Temporary Register (X)

The “X” register is available to the firmware for temporary st orage of intermediate resul ts. The microcontroller can perform indexed

operations based on the value in X. Refer to Section 5.6.3 for additional information.

5.4 8-bit Program Stack Pointer (PSP)

During a reset, the Program Stack Pointer (PSP) is set to 0x00 and “grows” upward from this address. The PSP may be set by

firmware, using the MOV PSP,A instruction. The PSP supports interrupt service under hardware control and CALL, RET, and

RETI instructions under firmware control. The PSP is not readable by the firmware.

During an interrupt a ck nowl edge, interrupts are dis abl ed and the 14-bit program coun ter, carry flag, and zero flag are written as

two bytes of dat a memory . The first byte is stored in the me mory addresse d by the PSP, then the PSP is increm ented. The second

byte is stored in memory addressed by the PSP, and the PSP is incremented again. The overall effect is to store the program

counter and flags on the program “stack” and increment the PSP by two.

The Return From Interr upt (RETI) instruc tion decrem ents the PSP, then restores the second byt e from memor y addressed by the

PSP . The PSP is decremented again and the first byte is restored from memory ad dressed by the PSP. After the program counter

and flags have b een rest ored from s tack, th e interrupt s are enab led. The o verall ef fect is t o restore the program counter and flags

from the program stack, decrement the PSP by two, and re-enable interrupts.

The Call Subroutine (CALL) instruction stor es the prog ram coun ter and fla gs on the prog ram st ac k and inc rem en t s the PSP by

two.

The Return From Subroutine (RET) instruction restores the program counter but not the flags from the program stack and

decrements the PSP by two.

CY7C6511

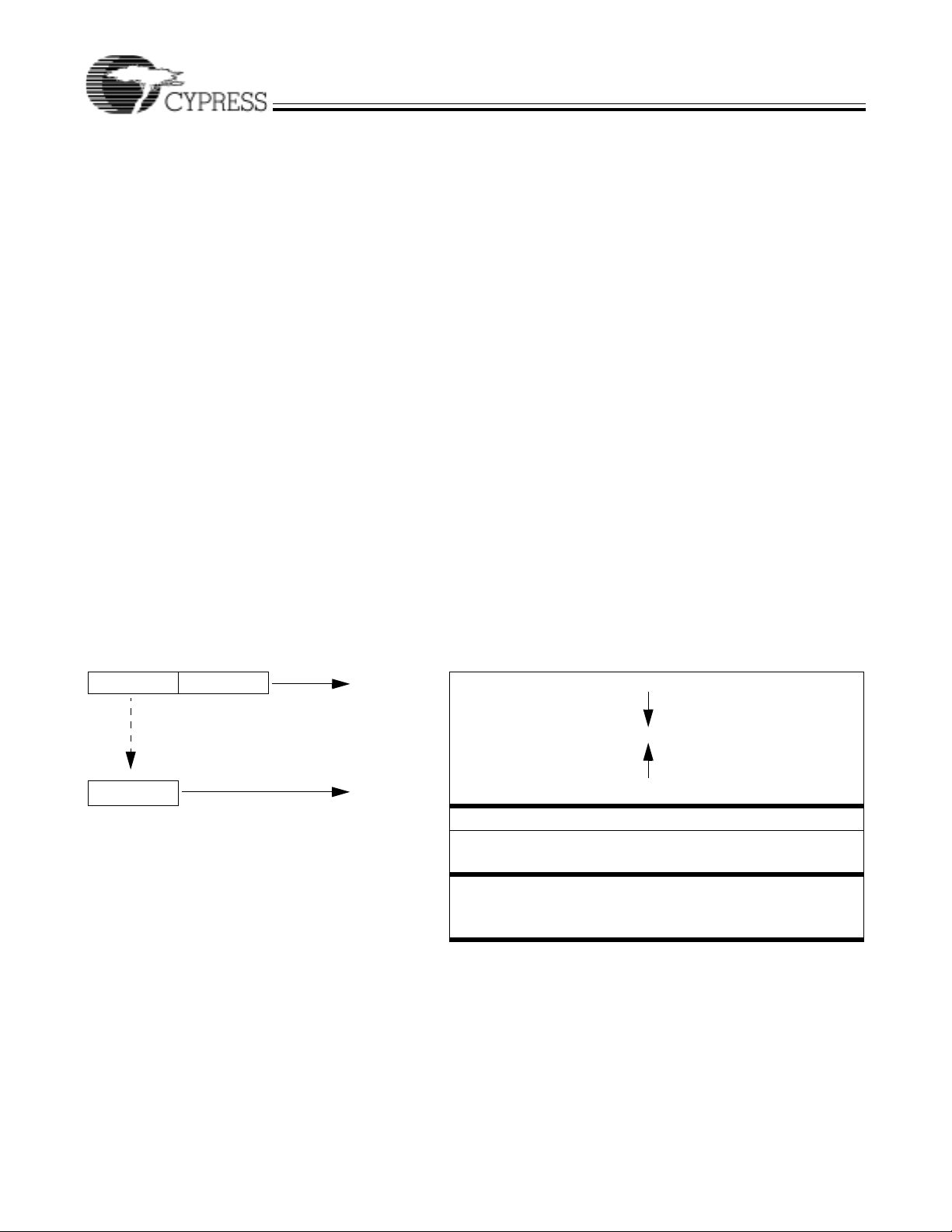

5.4.1 Data Memory Organization

The CY7C65x13 microcontrollers provide 256 bytes of data RAM. Normally, the SRAM is partitioned into four areas: program

stack, user va riables, data s tack, and USB e ndpoint FIFOs. The following is one ex ample of where the program stack, dat a stack ,

and user variables areas could be located.

After reset Address

8-bit DSP 8-bit PSP 0x00 Program Stack Growth

(Move DSP

8-bit DSP

Notes:

1. Refer to Section 5.5 for a description of DSP.

2. Endpoint sizes are fixed by the Endpoint Size Bit (I/O register 0x1F, Bit 7). See Table17-1.

[1]

)

user selected Data Stack Growth

User variables

USB FIFO space for up to tw o Address es and f ive endp oint s

0xFF

[2]

Document #: 38-08002 Rev. *B Page 14 of 51

Page 15

CY7C6501

3

3

5.5 8-bit Data Stack Pointer (DSP)

The Data Stack Pointer (DSP) supports PUSH and POP instructions that use the data stack for temporary storage. A PUSH

instruction pre-decrements the DSP, then writes data to the memory location addressed by the DSP. A POP instruction reads

data from the memory location addressed by the DSP, then post-increments the DSP.

During a reset, the DSP is reset to 0x00. A PUSH instruction when DSP equals 0x00 writes data at the top of the data RAM

(address 0xFF). This writes dat a to the memory area res erved fo r USB en dp oin t FIFO s. There fore , the DSP shou ld b e ind ex ed

at an appropriate memory location that does not compromise the Program Stack, user-de fin ed me mory (variables), or the USB

endpoint FIFOs.

For USB applications , the firmware s hould set the DSP to an appropri ate location to avoid a mem ory conflict w ith RAM dedic ated

to USB FIFOs. The me mo ry requirements for the U SB en dpo ints are described in Sec t io n 1 7.2. Exa mp le as se mbl y ins truc ti ons

to do this with two device addresses (FIFOs begin at 0xD8) are shown below:

MOV A,20h ; Move 20 hex into Accumulator (must be D8h or less)

SWAP A,DSP ; swap accumulator value into DSP register.

5.6 Address Modes

The CY7C65013 and CY 7C65113 microcontrollers support three addressin g modes for ins tructions that require da ta opera nds::

data, direct, and indexed.

5.6.1 Data (Immediate)

“Data” address m ode refers t o a data operand th at is actuall y a cons tant en coded in t he instruc tion. As an example, c onsider th e

instruction that loads A with the constant 0xD8:

• MOV A, 0D8h.

This instruction requires two bytes of code where the first byte identifies the “MOV A” instruction with a data operand as the

second byte. The second byte of the instruction is the constant “0xD8.” A constant may be referred to by name if a prior “EQU”

statement assigns the constant value to the name. For example, the following code is equivalent to the example shown above:

• DSPINIT: EQU 0D8h

• MOV A, DSPINIT.

CY7C6511

5.6.2 Direct

“Direct” address mode is used when the data operand is a variable stored in SRAM. In that case, the one byte address of the

variable is encode d in the instruction. As an example, consider an ins truction that loads A with the c onte nt s of memory address

location 0x10:

• MOV A, [10h].

Normally , varia ble names ar e assigned to va riable address es using “EQU” st atements to improve the re adability of th e assembler

source code. As an example, the following code is equivalent to the example shown above:

• buttons: EQU 10h

• MOV A, [buttons].

5.6.3 Indexed

“Indexed” address mode allows the firmware to manipulate arrays of data stored in SRAM. The address of the data operand is

the sum of a constan t encoded in the instru ction and the con tents of the “X” register . Norma lly , the co nstant is th e “base” address

of an array of data and the X register contains an index that indicates which element of the array is actually addressed:

• array: EQU 10h

•MOV X, 3

• MOV A, [X+array].

This would have the effect of loading A with the fourth element of the SRAM “array” that begins at address 0x10. The fourth

element would be at address 0x13.

Document #: 38-08002 Rev. *B Page 15 of 51

Page 16

3

3

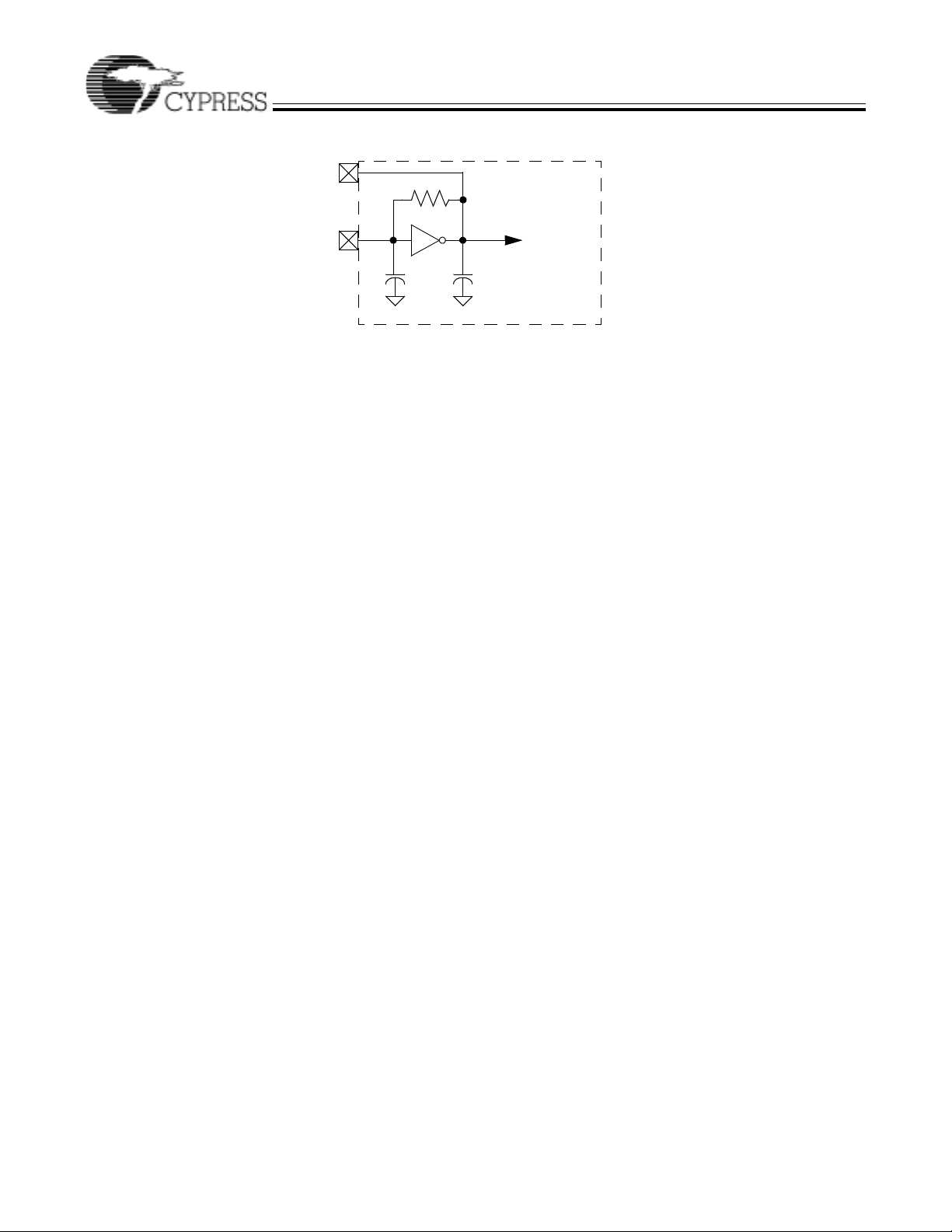

6.0 Clocking

XTALOUT

(pin 1)

CY7C6501

CY7C6511

XTALIN

(pin 2)

30 pF

Figure 6-1. Clock Oscillator On-Chip Circuit

The XTALIN and XTALOUT are the clock pins to the microcontroller. The user can connect an external oscillator or a crystal to

these pins. When u si ng an ex ternal crystal, kee p PC B trac es b etw ee n t he ch ip leads and cryst al as s hort as p os si ble (l ess t han

2 cm). A 6-MHz fundament al frequency p arallel resonan t crystal can be c onnected to these p ins to provide a refe rence frequency

for the internal PLL. The two int ernal 30-pF lo ad caps app ear in series to the externa l cryst al and would be equivalen t to a 15-pF

load. Therefore, the crystal must have a required load capacitance of about 15–18 pF. A ceramic resonator does not allow the

microcontroller to meet the timing specifications of full speed USB and therefore a ceramic resonator is not recommended with

these parts.

An external 6-MHz clock can be applied to the XTALIN pin if the XTALOUT pin is left open. Grounding the XTALOUT pin when

driving XTALIN with an oscillator does not work because the internal clock is effectively shorted to ground.

To Internal PLL

30 pF

7.0 Reset

The CY7C65x13 supports two resets: POR and WDR. Each of these resets causes:

• all registers to be restored to their default states

• the USB device addresses to be set to 0

• all interrupts to be disabl ed

• the PSP and DSP to be set to memory address 0x00.

The occurrence of a reset is recorded in the Processor Status and Control Register, as described in Section. Bits 4 and 6 are

used to record the occurrence of POR and WDR respectively. Firmware can interrogate these bits to determine the cause of a

reset.

Program execution st arts at ROM address 0x000 0 af ter a re set . Although this looks like int errup t ve cto r 0, the re is an imp ort a n t

difference. Reset processing does NOT push the program counter, carry flag, and zero flag onto program stack. The firmware

reset handler shou ld configure the hardw are before t he “main” loop of code. Attempting to execute a R ET or RETI in the firmw are

reset handler causes unpredictable execution results.

7.1 Power-on Reset

When VCC is first applied to the c hip, th e POR si gnal is asse rted and the C Y7C65x13 enters a “sem i-susp end” st ate . Durin g the

semi-suspend st ate, which i s diff erent from the suspend sta te defined i n the USB spec ification , the osci llator and al l other bl ocks

of the part are functional, except for the CPU. This semi-suspend time ensures that both a valid V

the internal PLL has time to stabilize before full operation begins. When the V

oscillator is st able, the POR is d easserted and th e on-chip timer st arts countin g. The first 1 ms of s uspend time is no t interruptible,

and the semi-suspe nd state conti nues for an addition al 95 ms unless the count is bypasse d by a USB Bus Reset on the up stream

port. The 95 ms provides time for V

If a USB Bus Reset occurs on the upstream port during the 95 ms semi-suspend time, the semi-suspend state is aborted and

program execution begins immediately from address 0x0000. In this case, the Bus Reset interrupt is pending but not serviced

until firmware sets the USB Bus Reset Interrupt Enable bit (Bit 0, Figure 14-1) and enables interrupts with the EI command.

The POR signal is asserte d whenever V

again. Behavior is the same as described above.

Document #: 38-08002 Rev. *B Page 16 of 51

to stabilize at a valid operating voltage before the chip executes code.

CC

drops below approxim ately 2.5V , and remains ass erted until VCC rises above this level

CC

has risen above approximately 2.5V, and the

CC

level is reached and that

CC

Page 17

CY7C6501

3

3

7.2 Watchdog Reset

The WDR occurs when the internal Watchd og Tim er rolls over . W riting any value to the write -only W atchdog Rese t Clear Registe r

(Figure 7-1) clears the timer. The timer rolls ov er a nd WD R oc c urs if it is not cleared within t

23.0 for the value of t

register content s are set to 01 0X0001 by the WDR) . A Watch dog Timer Reset lasts fo r 2 ms, after which the microcontrolle r begins

execution at ROM address 0x0000.

). Bit 6 of the Processor Status and Control Register (Figure13-1) is set to record this event (the

WATCH

of the last clear (s ee Sec tion

WATCH

CY7C6511

t

WATCH

Last write to

Watchdog Timer

Register

Figure 7-1. Watchdog Reset (Address 0x26)

The USB transmitter is disabled by a Watchdog Reset because the USB Device Address Registers are cleared (see Section

17.1). Otherwise, the USB Controller would respond to all address 0 transactions.

It is possible for the WDR bit of the Processor Status and Control Register (Figure 13-1) to be set following a POR event. If a

firmware interrogates th e Processor St atus and Control Register for a set condition on the WDR bit, the WD R bit should be ignored

if the POR bit is set (Bit 3 of the Processor Status and Control Register).

No write to WDT

register, so WDR

goes HIGH

2 ms

Execution begins at

Reset Vector 0x0000

8.0 Suspend Mode

The CY7C65x13 can be placed into a low-power state by setting the Suspend bit of the Processor Status and Control register.

All logic blocks in the device are turned off except the GPIO interrupt logic and the USB receiver. The clock oscillator and PLL,

as well as the free-running and Watchdog timers, are shut down. Only the occurrence of an enabled GPIO interrupt or non-idle

bus activity at a USB upstream or downstream port wakes the part out of suspend. The Run bit in the Processor Status and

Control Register must be set to resume a part out of suspend.

The clock oscillator res tarts immediately after ex it ing suspend mode. The microco ntroller returns to a fully functi on al state 1 ms

after the oscillator is st able. The microcontroller executes the instruction follow ing the I/O write that placed the device into suspend

mode before servicing any interrupt requests.

The GPIO interrupt allo ws the controller to wak e-up periodically and poll system component s while maintain ing a very low average

power consumption. To achieve the lowest possible current during suspend mode, all I/O should be held at V

This also applies to internal port pins that may not be bonded in a particular package.

Typical code for entering suspend is shown below:

... ; All GPIO set to low-power state (no floating pins)

... ; Enable GPIO interrupts if desired for wake-up

mov a, 09h ; Set suspend and run bits

iowr FFh ; Write to Status and Control Register – Enter suspend, wait for USB activity (or GPIO Interrupt)

nop ; This executes before any ISR

... ; Remaining code for exiting suspend routine.

or Gnd. Note:

CC

Document #: 38-08002 Rev. *B Page 17 of 51

Page 18

3

3

9.0 General-purpose I/O Ports

V

CY7C6501

CY7C6511

CC

Q1

14 kΩ

Q3*

Q2

*Port 0,1,2: Low I

Port 3: High I

sink

GPIO

PIN

sink

OE

Internal

Data Bus

Port Write

Port Read

Reg_Bit

STRB

(Latch is Transparent)

Interrupt

Enable

Interrupt

Controller

GPIO

CFG

Data

Out

Latch

Data

In

Latch

Data

Interrupt

Latch

mode

2-bits

Control

Control

Figure 9-1. Block Diagram of a GPIO Pin

There are up to 32 GPIO pins (P0[7:0], P1[7:4,2:0], P2[7:3], and P3[1:0]) for the hardware interface. The number of GPIO pins

depends on package type. See Se ction 3.0 for the port pi ns avai labil ity on dif fere nt pa ckage typ es. Each port can be configu red

as inputs with inte rnal pull -up s, open drain outp uts , or traditi onal C MOS outputs. Port 3 offers a higher cu rrent driv e, with t ypical

current sink capability of 12 mA. The data for each GPIO port is accessible through the data registers. Port data registers are

shown in Figure 9-2 through Figure 9-5, and are set to 1 on reset

.

Port 0 Data Address 0x00

Bit # 76543210

Bit Name P0.7 P0.6 P0.5 P0.4 P0.3 P0.2 P0.1 P0.0

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Reset 11111111

Figure 9- 2. Port 0 Data

Port 1 Data Address 0x01

Bit # 76543210

Bit Name P1.7 P1.6 P1.5 P1.4 Reserved P1.2 P1.1 P1.0

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Reset 11111111

Figure 9-3. Port1 Data

Port 2 Data Address 0x02

Bit # 76543210

Bit Name P2.7 P2.6 P2.5 P2.4 P2.3 Reserved Reserved Reserved

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Reset 11111111

Figure 9- 4. Port 2 Data

Document #: 38-08002 Rev. *B Page 18 of 51

Page 19

CY7C6501

3

3

Port 3 Data Address 0x03

Bit # 76543210

Bit Name Reserved Reserved Re served Reserved Reserved Reserved P3.1 P3.0

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Reset 11111111

Figure 9- 5. Port 3 Data

Special care should be t aken w ith any unu sed GPIO dat a bit s. An unused GPIO dat a bit, eithe r a pin on the ch ip or a port bit that

is not bonded on a particular package, must not be left floating when the device enters the suspend state. If a GPIO data bit is

left floating, the leakage current caused by the floating bit may violate the suspend current limitation specified by the USB

Specifications. If a ‘1’ is written to the unused data bit and the port is configured with open drain outputs, the unused data bit

remains in an indeterminate state. Therefore, if an unused port bit is programmed in open-drain mode, it must be written with a

‘0.’ Notice that the CY7C65113 always requires that P1[7:3], P2[7:0], and P3[7:0 ] be wr itte n with a ‘0 .’ Wh en the CY7 C65013 is

used, the P1[3], P2[2:0], and P3[7:2] should be written with a ‘0.’

A read from a GPIO port always returns the present state of the voltage at the pin, independent of the settings in the Port Data

Registers. During reset, all of the GPIO pins are set to a high-impedance input state. Writing a ‘0’ to a GPIO pin drives the pin

LOW. In this state, a ‘0’ is always read on that GPIO pin unless an external source overdrives the internal pull-down device.

9.1 GPIO Configuration Port

Every GPIO port can be progra mmed as inputs w ith internal pull-u ps, outputs LO W or HIGH, or Hi-Z (floating , the pin is not driven

internally). In addition, the interrupt polarity for each port can be programmed. The Port Configuration bits (Figure 9-6) and the

Interrupt Enable bit (Figure 9-7 through Figure 9-10) determine the interrupt polarity of the port pins

.

GPIO Configuration Address 0x08

Bit # 76543210

Bit Name Port 3

Config Bit 1

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Reset 00000000

Port 3

Config Bit 0

Port 2

Config Bit 1

Figure 9-6. GPIO Configuration Register

Port 2

Config Bit 0

Port 1

Config Bit 1

Port 1

Config Bit 0

Config Bit 1

CY7C6511

Port 0

Port 0

Config Bit 0

As shown in Table 9-1 below, a positi ve polarity on an input pin repre sents a rising edge interrupt (LO W to HIGH), and a negative

polarity on an input pin represents a falling edge interrupt (HIGH to LOW).

The GPIO interrupt is generated when all of the following conditions are met: the Interrupt Enable bit of the associated Port

Interrupt Enable Register is enabled, the GPIO Interrupt Enable bit of the Global Interrupt Enable Register (Figure 14-1) is

enabled, the Interrup t Enable Sense (bi t 2, Figure 13-1) is set, and the GPIO pin of the po rt sees an eve nt matching th e interrupt

polarity.

The driving stat e of ea ch GPIO pin is determined by the valu e written to the pin’s Dat a Reg is ter ( Figure 9-2 through Figure 9-5)

and by its associated Port Configuration bits as shown in the GPIO Configuration Register (Figure 9-6). These ports are

configured on a per-port basis, so all pins in a given port are configured together. The possible port configurations are detailed

in Table 9-1. As shown in this table below, when a GPIO port is configured with CMOS outputs, interrupts from that port are

disabled.

During reset, all of the bits in the GPIO Configuration Register are written with ‘0’ to select Hi-Z mode for all GPIO ports as the

default configuration.

Document #: 38-08002 Rev. *B Page 19 of 51

Page 20

CY7C6501

3

3

Table 9-1. GPIO Port Output Control Truth Table and Interrupt Polarity

Port Config Bit 1 Port Config Bit 0 Data Register Output Drive Strength Interrupt Enable Bit I nterrupt Polarity

1 1 0 Output LOW 0 Disabled

1 Resistive 1 – (Falling Edge)

1 0 0 Output LOW 0 Disabled

1 Output HIGH 1 Disabled

0 1 0 Output LOW 0 Disabled

1 Hi-Z 1 – (Falling Edge)

0 0 0 Output LOW 0 Disabled

1 Hi-Z 1 + (Rising Edge)

Q1, Q2, and Q3 discussed below are the transistors referenced in Figure 9-2. The available GPIO drive strength are:

• Output LOW Mode: The pin’s Data Register is set to ‘0.’

Writing ‘0’ to the pi n’s Data Regi ster puts the p in in ou tput LO W mod e, reg ardless of th e cont ents of th e Port Config urat ion

Bits[1:0]. In this mode, Q1 and Q2 are OFF. Q3 is ON. The GPIO pin is driven LOW through Q3.

• Output HIGH Mode: The pin’s Data Register is set to 1 and the Port Configuration Bits[1:0] is set to ‘10.’

In this mode, Q1 and Q3 are OFF. Q2 is ON. The GPIO is pulled up through Q2. The GPIO pin is capable of sourcing... of

current.

• Resistive Mode: The pin’s Data Register is set to 1 and the Port Configuration Bits[1:0] is set to ‘11.’

Q2 and Q3 are O FF. Q1 is ON. The GPIO p in is p ull ed up w ith a n i nte rnal 1 4kΩ re sistor. In resistive mode, t he pin m ay s er v e

as an input. Reading the pin’s Data Register returns a logic HIGH if the pin is not driven LOW by an external source.

• Hi-Z Mode: The pin’s Data Register is set to1 and Port Configuration Bits[1:0] is set either ‘00’ or ‘01.’

Q1, Q2, and Q3 are all OFF. The GPIO pin is not driven internally. In this mode, the pin may serve as an input. Reading the

Port Data Register returns the actual logic value on the port pins.

CY7C6511

9.2 GPIO Interrupt Enable Ports

Each GPIO pin can be individually enabled or disabled as an interrupt source. The Port 0–3 Interrupt Enable Registers provide

this feature with an Interrupt Enable bit for each GPIO pin.

During a reset, GPIO interrupts are disabled by clearing all of the GPIO Interrupt Enable bits. Writing a ‘1’ to a GPIO Interrupt

Enable bit enables GPIO interrupts from the corresponding input pin. All GPIO pins share a common interrupt, as discussed in

Section 14.7

.

Port 0 Interrupt Enable Address 0x04

Bit # 76543210

Bit Name P0.7 Intr

Enable

Read/WriteWWWWWWWW

Reset 00000000

Port 1 Interrupt Enable Address 0x05

Bit # 76543210

Bit Name P1.7 Intr

Enable

Read/WriteWWWWWWWW

Reset 00000000

P0.6 Intr

Enable

P1.6 Intr

Enable

P0.5 Intr

Enable

Figure 9-7. Port 0 Interrupt Enable

P1.5 Intr

Enable

Figure 9-8. Port 1 Interrupt Enable

P0.4 Intr

Enable

P1.4 Intr

Enable

P0.3 Intr

Enable

Reserved P0.2 Intr

P0.2 Intr

Enable

Enable

P0.1 Intr

Enable

P1.1 Intr

Enable

P0.0 Intr

Enable

P1.0 Intr

Enable

Document #: 38-08002 Rev. *B Page 20 of 51

Page 21

CY7C6501

3

3

Port 2 Interrupt Enable Address 0x06

Bit # 76543210

Bit Name P0.7 Intr

Enable

Read/WriteWWWWWWWW

Reset 00000000

Port 3 Interrupt Enable Address 0x07

Bit # 76543210

Bit Name Reserved Reserved Reserved Reserved Re served Reserved P3.1 Intr

Read/WriteWWWWWWWW

Reset 00000000

10.0 12-bit Free-Running Timer

The 12-bit timer operates with a 1 -µs tick, provides two interrupts (128µs and 1.02 4m s) an d all ows th e firm ware to dire ctl y time

events that are up to 4 ms in duration. The lower eight bits of the timer can be read directly by the firmware. Reading the lower

eight bits latch es the upper four bit s into a tempora ry register . When the firmwa re reads the upper fo ur bits of the timer , it is actually

reading the count stored in the temporary register. The effect of this is to ensure a stable 12-bit timer value can be read, even

when the two reads are separated in time.

Timer LSB Address 0x24

Bit # 76543210

Bit Name Timer Bit 7 TimerBit 6 Timer Bit 5 Timer Bit 4 Timer Bit 3 Timer Bit 2 Timer Bit 1 Timer Bit 0

Read/WriteRRRRRRRR

Reset 00000000

P0.6 Intr

Enable

P0.5 Intr

Enable

Figure 9-9. Port 2 Interrupt Enable

Figure 9-10. Port 3 Interrupt Enable

Figure 10-1. Timer LSB Register

P0.4 Intr

Enable

P0.3 Intr

Enable

Reserved Reserved Reserved

CY7C6511

Enable

P0.3 Intr

Enable

Bit [7:0]: Timer lower eight bits.

Timer MSB Address 0x25

Bit # 76543210

Bit Name Reserved Reserved Reserved Reserved Timer Bit 11 Timer Bit 10 Timer Bit 9 Timer Bit 8

Read/Write – – – – R R R R

Reset 00000000

Figure 10-2. Timer MSB Register

Bit [3:0]: Timer higher nibble

Bit [7:4]: Reserved.

Document #: 38-08002 Rev. *B Page 21 of 51

Page 22

CY7C6501

3

3

1.024-ms interrupt

µ

s interrupt

128-

CY7C6511

10 9 7856432

1 011

1 MHz clock

L1 L0L2L3

D3 D2 D1 D0 D7 D6 D5 D4 D3 D2 D1 D0

8

Figure 10-3. Timer Block Diagram

11.0 I2C Configuration Register

Internal hardware support s communi cation with extern al devices thro ugh an I2C-compatible int erface. I2C-compatibl e functio n is

discussed in det ail in Sec tion 12.0.

locations of the SCL (clock) and SDA (data) pins, either on Port 1 or Port 2 as shown in Table 11-1. These bits are cleared on

reset. When the GPIO is configu r ed for I

pull-up resistors on SCL and SDA is recommended

.

I2C Configuration Address 0x09

Bit # 76543210

Bit Name I

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Reset 00000000

Table 11-1. I2C Port Configuration

2

I

C Position (Bit7, Figure 11-1)I

2

C Position Reserved Reserved Reserved Reserved Reserved I2C Port

Don’t Care 1 I

00I

10I

[3]

The I2C Position bit (Bit 7, Figure 11-1) and I2C Port Width bit (Bit 1, Figure 11-1) select the

2

C function, the internal pull up s on the pin s are disabl ed. Ad diti on of an ex tern al w ea k

2

Figure 11-1. I

2

C Configuration Register

C Port Width (Bit1, Figure 11-1)I

To Timer Registers

Width

2

C Position

2

C on P2[1:0], 0:SCL, 1:SDA

2

C on P1[1:0], 0:SCL, 1:SDA

2

C on P2[1:0], 0:SCL, 1:SDA

Reserved

12.0 I2C-compatible Controller

The I2C-compatible block provides a versatile two-wire communication with external devices, supporting master, slave, and

multi-master modes of operation. The I2C-comp atible block functi ons by handling the low-l evel signaling in hardw are, and issuing

interrupts as needed to allow firmware to take appropriate action during transactions. While waiting for firmware response, the

hardware keeps the I2C-compatible bus idle if necessary.

The I2C-compatible block generates an interrupt to the microcontroller at the end of each received or transmitted byte, when a

stop bit is detected by the slave w hen in receive mode, or when arb itratio n is lost. D etai ls of the interrupt respons es are gi ven in

Section 14.8.

2

The I2C-compatibl e interface consist s of two registers, an I

(Figure 12-2). The I2C Data Register is imp lemen ted as sep arate r ead and writ e regis ters. G eneral ly, the I2C Sta tus an d Contro l

Register should o nly be m onitored a fter the I

read misleading bit status if a transaction is underway.

Note:

2

C-compatible function must be separately enabled, as described in Section 12.0.

3. I

Document #: 38-08002 Rev. *B Page 22 of 51

2

C interrupt, as all b its are valid at th at time. Po lling thi s registe r at other t imes could

C Data Register (Figure 12-1) and an I2C St atus and Contro l Register

Page 23

CY7C6501

3

3

CY7C6511

The I2C clock (SCL) is connected to bit 0 of either GPIO port 1 or GPIO port 2, and the I2C SDA data is connected to bit 1 of

either GPIO port 1 or GPIO port 2. The port selection is determined by settings in the I

2

C Port Configuration Register (Section

11.0). Once the I2C-compatible fun ctionali ty is enable d by setting the I2C Enable bit of the I2C Stat us and Control Register (bit 0,

Figure 12-2), the two LSB ([1:0]) of the correspondi ng GP IO port is pl aced in Op en D rain m ode, re gardle ss of the setti ngs of the

GPIO Configuration Register. In Open Drain mode, the GPIO pin outputs LOW if the pin’s Data Register is ‘0’, and the pin is in

Hi-Z mode if the pin’s Data Register is ‘1’. The electrical characteristics of the I

GPIO ports 1 and 2. Note that the I

All control of the I

2

C clock (SCL) and data (SDA) lines is performed by the I2C-compatible block.

(max) is 2 mA @ V

OL

= 2.0V for ports 1 and 2.

OL

2

C-compatible interface is the same as that of

I2C Data Address 0x29

Bit # 76543210

2

Bit Name I

C Data 7 I2C Data 6 I2C Data 5 I2C Data 4 I2C Data 3 I2C Data 2 I2C Data 1 I2C Data 0

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Reset XXXXXXXX

2

C Data Register

Bits [7..0] : I

2

C Data

Figure 12-1. I

Contains the 8-bit data on the I2C Bus.

2

I

C Status and Control Address 0x28

Bit # 76543210

2

Bit Name MSTR Mode Continue/BusyXmit Mode ACK Addr ARB

Lost/Restart

Received

Stop

C Enable

I

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Reset 00000000

2

Figure 12-2. I

2

The I

C Status and Control register bits are defined in Table 12-1, with a more detailed descripti on followi ng.

Table 12-1. I

2

C Status and Control Register Bit Definitions

C Status and Control Register

Bit Name Description

2

0I

C Enable When set to ‘1’, the I2C-compatible function is enabled. When cleared, I2C GPIO pins operate

normally.

2

1 Received Stop Reads 1 only in slave rec eive mo de, whe n I

C Stop bit detec ted (unle ss firmwa re did n ot ACK the

last transaction).

2 ARB Lost/Restart Reads 1 to indicate master has lost arbitration. Reads 0 otherwise.

Write to 1 in master mode to perform a restart sequence (also set Continue bit).

3 Addr Reads 1 during first byte after start/restart in slave mode, or if master loses arbitration.

Reads 0 otherwise. This bit should always be written as 0.

4 ACK In receive mode, write 1 to generate ACK, 0 for no ACK.

In transmit mode, reads 1 if ACK was received, 0 if no ACK received.

5 Xmit Mode Write to 1 for transmit mode, 0 for receive mode.

6 Continue/Busy Write 1 to indicate ready for next transaction.

Reads 1 when I

2

C-compatible block is busy with a transaction, 0 when transaction is complete.

7 MSTR Mode Write to 1 for master mode, 0 for slave mode. This bit is cleared if master loses arbitration.

Clearing from 1 to 0 generates Stop bit.

Bit 7 : MSTR Mode

2

Setting this bit to 1 causes the I

C-compatible block to initiate a master mode transaction by sending a start bit and

transmitting the first data byte from the data register (this typically holds the target address and R/W bit). Subsequent bytes

are initiated by setting the Continue bit, as described below.

Clearing this bit (set to 0) causes the GPIO pins to operate normally.

2

In master mode, the I

C-compatible block generates the clock (SCK), and drives the data line as required depending on

transmit or receive state. The I2C-compatible block performs any required arbitration and clock synchronization. IN the

event of a loss of arbitration, this MSTR bit is cleared, the ARB Lost bit is set, and an interrupt is generated by the

Document #: 38-08002 Rev. *B Page 23 of 51

Page 24

CY7C6501

3

3

microcontroller. If the chip is the target of an external master that wins arbitration, then the interrupt is held off until the

transaction from the external master is completed.

2

When MSTR Mode is cleared from 1 to 0 by a firmware write, an I

Bit 6 : Continue/Busy

This bit is written by the fi rmware to ind icate that t he firmware is ready for th e next byte t ransaction to begin. In other words,

the bit has respon ded to a n interru pt reque st and has c ompleted the require d updat e or read of the d ata registe r. During a

read this bit indicates if the hardware is busy and is lo cking out additi onal writes to the I

locking allows the hardware to compl ete c ert a in op erations that may requi re an ex ten ded period of time. F oll owin g an I

interrupt, the I2C-compatible block does not return to the Busy state until firmware sets the Continue bit. This allows the

firmware to make one control register write without the need to check the Busy bit.

Bit 5 : Xmit Mode

This bit is set by firmware to enter transmit mode and perform a data transmit in master or slave mode. Clearing this bit

sets the part i n rece ive m ode. Fi rmwa re gene rally d etermi nes th e val ue of th is bit from th e R/W bi t asso ciate d wit h the I

address packet. Th e Xmit Mode bit st ate is ignored whe n initially wri ting the MSTR Mode or th e Restart bit s, as these ca ses

always cause transmit mode for the first byte.

Bit 4 : ACK

This bit is set or cleared by firmware during receive operation to indicate if the hardware should generate an ACK signal

2

on the I

time. During transmits (Xmit Mode = 1), this bit should be cleared.

Bit 3 : Addr

This bit is set by the I

The Addr bit is cleared whe n the firmwa re se ts the Continue bit. This bit allows the firmware to re cogni ze w hen the mas ter

has lost arbitration, and in slave mode it allows the firmware to recognize that a start or restart has occurred.

Bit 2 : ARB Lost/Restart

This bit is valid as a status bit (ARB Lost) after master mode transactions. In master mode, set this bit (along with the

Continue and MSTR Mo de bit s) to pe rform an I

to the data regist er before setting the C ontinue bit. To prevent false ARB Lost signal s, the Restart bi t is cleared by h ardware

during the restart sequence.

Bit 1 : Receive Stop

This bit is set when the slave is in receive mode and detects a stop bit on the bus. The Receive Stop bit is not set if the

firmware terminates the I

e.g., in receive mode if firmware se ts the Continue bit and clears the ACK bit.

Bit 0 : I

Set this bit to overri de GPIO definition with I

these pins are free to fun ction as G PIO s. In I

of the GPIO configuration setting.

C-compatible bus. W riting a 1 to this bit genera tes an ACK (SDA LOW) on the I2C -comp atib le bus at the ACK bit

2

C-compatible block during the first byte of a slave receive transaction, after an I2C start or restart.

2

C restart sequence. The I2C target address for the restart must be written

2

C transaction by not acknowledging the previous byte transmitted on the I2C-compatible bus,

2

C Enable

2

C-compatible fu nction on the t wo I2C-compatible p ins. When this bit is cleared,

2

C-compatible m ode , the t wo pin s op era te in open drain mode, independent

C Stop bit is generated.

2

C St atus and Control register. This

CY7C6511

2

C

2

C

13.0 Processor Status and Control Register

Processor Status and Control Address 0xFF

Bit # 76543210

Bit Name IRQ

Pending

Read/Write R R/W R/W R/W R/W R R/W R/W

Reset 00010001

Bit 0: Run

This bit is manipulated by the HALT instruction. When Halt is executed, all the bits of the Processor Status and Control

Register are cleared to 0. Since the run bit is clea red, the processor stops at the end of the current in struction. The process or

remains halted until an appropriate reset occurs (power-on or Watchdog). This bit should normally be written as a ‘1.’

Bit 1: Reserved

Bit 1 is reserved and must be written as a zero.

Bit 2: Interrupt Enable Sense

Document #: 38-08002 Rev. *B Page 24 of 51

Watchdog

Reset

Figure 13-1. Processor Status and Control Register

USB Bus

Reset

Interrupt

Power-on

Reset

Suspend Interrupt

Enable

Reserved Run

Sense

Page 25

CY7C6501

3

3

This bit indicates w h eth er i nter r upts are enabled or dis abl ed. Firm w are has no di rec t c ontro l o ve r thi s b it a s wr i tin g a ze ro

or one to this bit position has no effect on interrupts. A ‘0’ indicates that interrupts are masked off and a ‘1’ indicates that

the interrupts are enab led. This bit is further gated with th e bit settings of the Glob al Interrupt Enable Registe r (Figure 14-1)

and USB End Point Interrupt Enable Register (Figure14-2). Instructions DI, EI, and RETI manipulate the state of this bit.

Bit 3: Suspend

Writing a ‘1’ to the Suspend bit halts the processor and cause the microcontroller to enter the suspend mode that significantly reduces power consumption. A pending, enabled interrupt or USB bus activity causes the device to come out of

suspend. After coming out of suspend, the devic e resumes firmware ex ecution at the in struction follow ing the IOWR which

put the part into suspend. An IOWR attempting to put the part into suspend is ignored if USB bus activity is present. See

Section 8.0 for more details on suspend mode operation.

Bit 4: Power-on Reset

The Power-on Reset is set to ‘1’ during a power-on reset. The firmware can check bits 4 and 6 in the reset handler to

determine whether a res et was ca used by a power-o n condi tion or a Watchdog timeout. A PO R event m ay be fo llowed b y

a Watchdog reset before firmware begins executing, as explained below.

Bit 5: USB Bus Reset Interrupt

The USB Bus Reset Interrupt bit is set when the USB Bus Reset is detec te d on receiv in g a USB Bus Rese t sig nal on the

upstream port. The USB Bus Reset signal is a single-ended zero (SE0) that lasts from 12 to 16 µs. An SE0 is defined as

the condition in which both the D+ line and the D– line are LOW at the same time. .

Bit 6: Watchdog Reset

The Watchdog Reset is set during a reset initiated by the Watchdog Timer. This indicates the Watchdog Timer went for

more than t