Page 1

enCoRe™ USB

CY7C63221/31A

1

CY7C63221A/31A

enCoRe™ USB

Low-speed USB Peripheral Controller

Cypress Semiconductor Corporation • 3901 North First Street • San Jose, CA 95134 • 408-943-2600

Document #: 38-08028 Rev. *B Revised Sep 16, 2004

Page 2

FOR

FOR

enCoRe™ USB

CY7C63221/31A

TABLE OF CONTENTS

1.0 FEATURES .....................................................................................................................................5

2.0 FUNCTIONAL OVERVIEW ............................................................................................................. 6

2.1 enCoRe USB - The New USB Standard ....................................................................................6

3.0 LOGIC BLOCK DIAGRAM .............................................................................................................7

4.0 PIN CONFIGURATIONS .................................................................................................................7

5.0 PIN ASSIGNMENTS .......................................................................................................................7

6.0 PROGRAMMING MODEL ...............................................................................................................8

6.1 Program Counter (PC) ...............................................................................................................8

6.2 8-bit Accumulator (A) .................................................................................................................8

6.3 8-bit Index Register (X) ..............................................................................................................8

6.4 8-bit Program Stack Pointer (PSP) ............................................................................................ 8

6.5 8-bit Data Stack Pointer (DSP) ..................................................................................................9

6.6 Address Modes ..........................................................................................................................9

6.6.1 Data .................................................................................................................................................. 9

6.6.2 Direct ................................................................................................................................................ 9

6.6.3 Indexed ............................................................................................................................................ 9

7.0 INSTRUCTION SET SUMMARY ...................................................................................................10

8.0 MEMORY ORGANIZATION ..........................................................................................................11

8.1 Program Memory Organization ................................................................................................11

8.2 Data Memory Organization ......................................................................................................12

8.3 I/O Register Summary .............................................................................................................13

9.0 CLOCKING ....................................................................................................................................14

9.1 Internal/External Oscillator Operation ......................................................................................15

9.2 External Oscillator ....................................................................................................................15

10.0 RESET .........................................................................................................................................16

10.1 Low-voltage Reset (LVR) .......................................................................................................16

10.2 Brown-out Reset (BOR) .........................................................................................................16

10.3 Watchdog Reset (WDR) ........................................................................................................17

11.0 SUSPEND MODE ........................................................................................................................17

11.1 Clocking Mode on Wake-up from Suspend ...........................................................................18

11.2 Wake-up Timer ......................................................................................................................18

12.0 GENERAL PURPOSE I/O PORTS .............................................................................................19

12.1 Auxiliary Input Port .................................................................................................................21

13.0 USB SERIAL INTERFACE ENGINE (SIE) .................................................................................22

13.1 USB Enumeration ..................................................................................................................23

13.2 USB Port Status and Control .................................................................................................23

14.0 USB DEVICE ...............................................................................................................................25

14.1 USB Address Register ...........................................................................................................25

14.2 USB Control Endpoint ............................................................................................................25

14.3 USB Non-Control Endpoints ..................................................................................................26

14.4 USB Endpoint Counter Registers ..........................................................................................27

Document #: 38-08028 Rev. *B Page 2 of 50

Page 3

FOR

FOR

enCoRe™ USB

CY7C63221/31A

15.0 USB REGULATOR OUTPUT ......................................................................................................27

16.0 PS/2 OPERATION .......................................................................................................................28

17.0 12-BIT FREE-RUNNING TIMER .................................................................................................28

18.0 PROCESSOR STATUS AND CONTROL REGISTER ...............................................................29

19.0 INTERRUPTS ..............................................................................................................................31

19.1 Interrupt Vectors ....................................................................................................................31

19.2 Interrupt Latency ....................................................................................................................32

19.3 Interrupt Sources ...................................................................................................................32

20.0 USB MODE TABLES ..................................................................................................................36

21.0 REGISTER SUMMARY ...............................................................................................................41

22.0 ABSOLUTE MAXIMUM RATINGS .............................................................................................42

23.0 DC CHARACTERISTICS ............................................................................................................42

24.0 SWITCHING CHARACTERISTICS .............................................................................................44

25.0 ORDERING INFORMATION .......................................................................................................47

26.0 PACKAGE DIAGRAMS .............................................................................................................47

Document #: 38-08028 Rev. *B Page 3 of 50

Page 4

FOR

FOR

enCoRe™ USB

CY7C63221/31A

LIST OF FIGURES

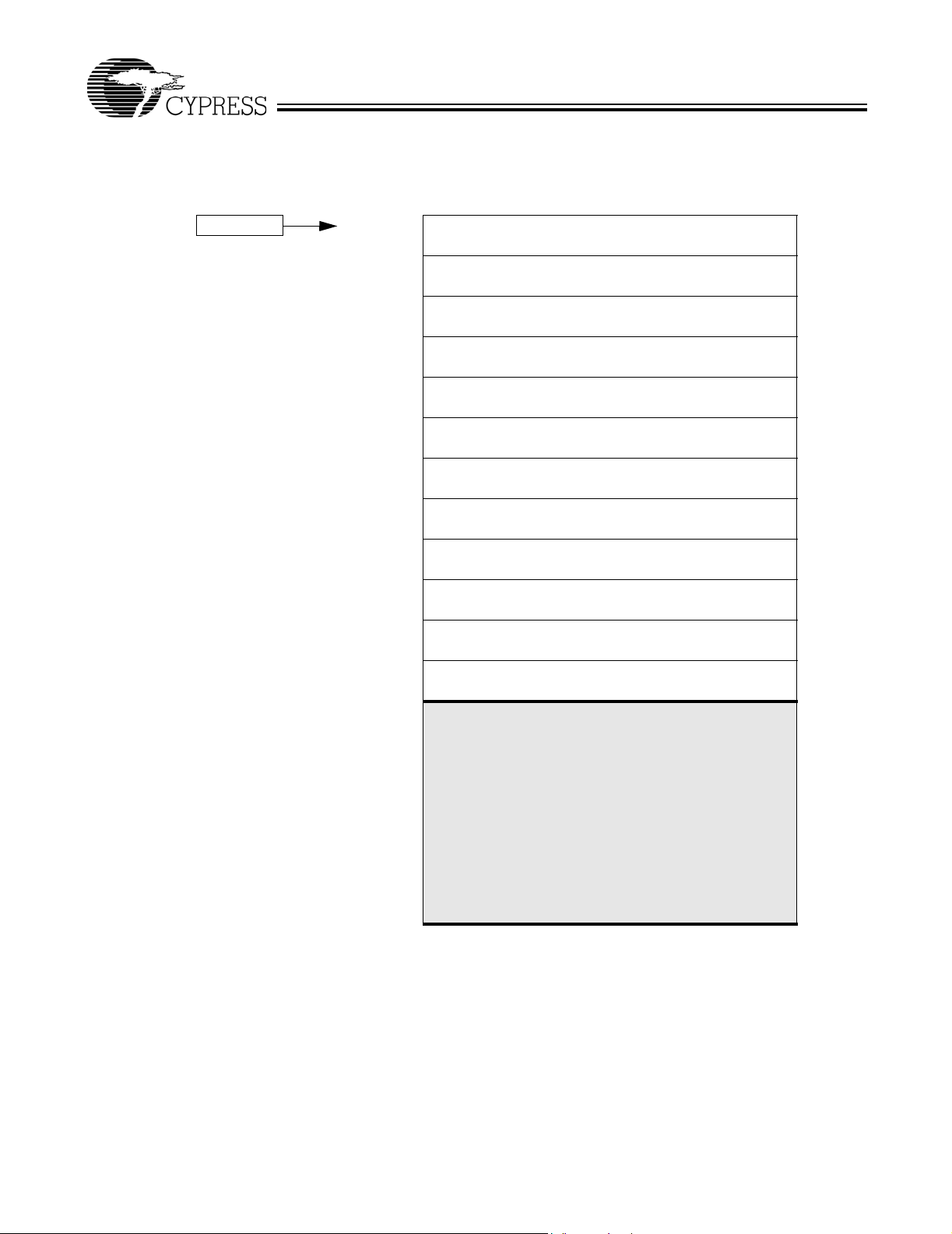

Figure 8-1. Program Memory Space with Interrupt Vector Table ........................................................ 11

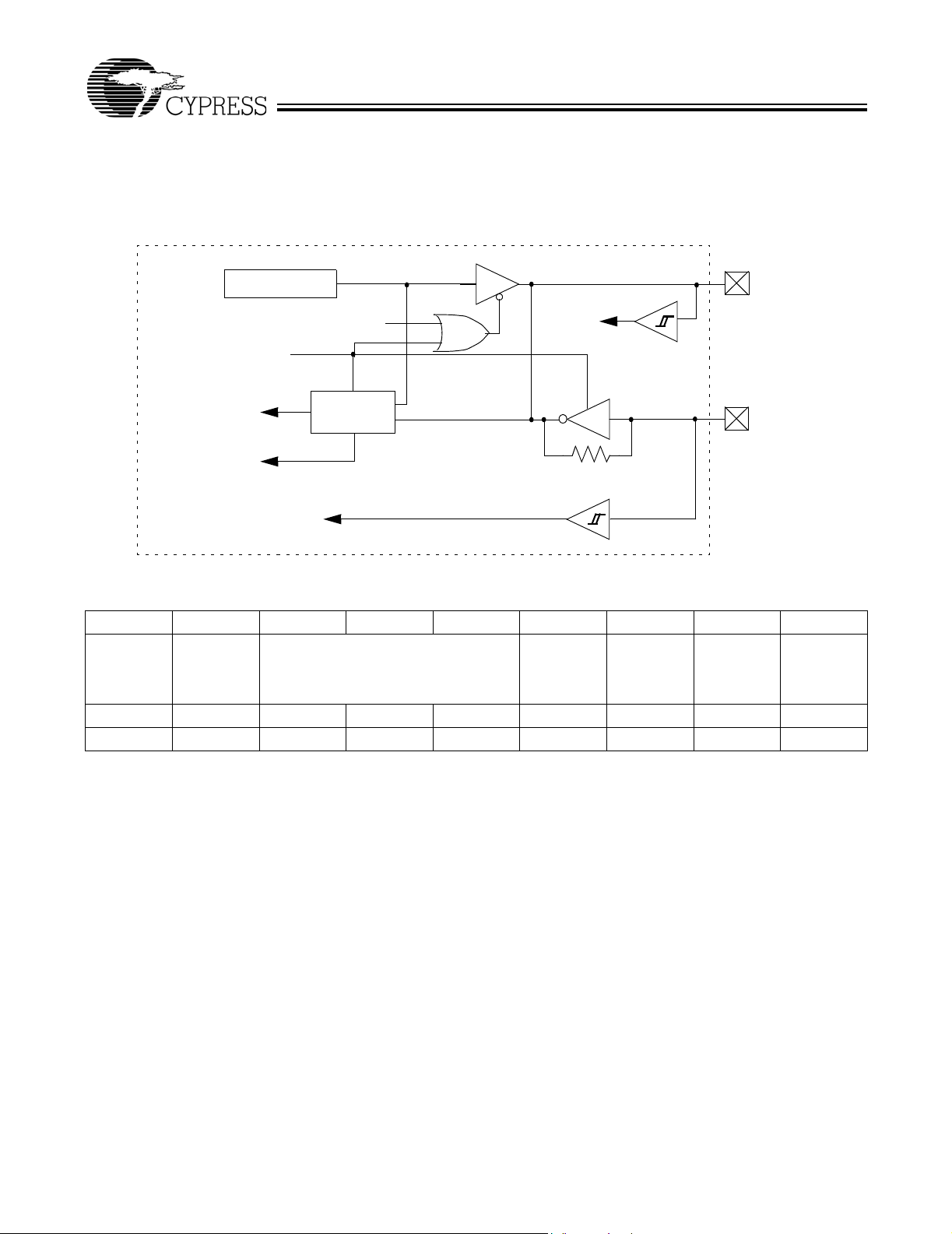

Figure 9-1. Clock Oscillator On-chip Circuit ......................................................................................... 14

Figure 9-2. Clock Configuration Register (Address 0xF8) ................................................................... 14

Figure 10-1. Watchdog Reset (WDR, Address 0x26) .......................................................................... 17

Figure 12-1. Block Diagram of GPIO Port (one pin shown) ................................................................. 19

Figure 12-2. Port 0 Data (Address 0x00) .............................................................................................19

Figure 12-3. Port 1 Data (Address 0x01) .............................................................................................20

Figure 12-4. GPIO Port 0 Mode0 Register (Address 0x0A) ................................................................. 20

Figure 12-5. GPIO Port 0 Mode1 Register (Address 0x0B) ................................................................. 20

Figure 12-6. GPIO Port 1 Mode0 Register (Address 0x0C) ................................................................ 20

Figure 12-7. GPIO Port 1 Mode1 Register (Address 0x0D) ................................................................ 21

Figure 12-8. Port 2 Data Register (Address 0x02) ..............................................................................22

Figure 13-1. USB Status and Control Register (Address 0x1F) .......................................................... 23

Figure 14-1. USB Device Address Register (Address 0x10) ...............................................................25

Figure 14-2. Endpoint 0 Mode Register (Address 0x12) ..................................................................... 25

Figure 14-3. USB Endpoint EP1 Mode Registers (Address 0x14) ......................................................26

Figure 14-4. Endpoint 0 and 1 Counter Registers (Addresses 0x11 and 0x13) .................................. 27

Figure 16-1. Diagram of USB - PS/2 System Connections ................................................................. 28

Figure 17-1. Timer LSB Register (Address 0x24) ................................................................................29

Figure 17-2. Timer MSB Register (Address 0x25) ............................................................................... 29

Figure 17-3. Timer Block Diagram .......................................................................................................29

Figure 18-1. Processor Status and Control Register (Address 0xFF) ................................................. 29

Figure 19-1. Global Interrupt Enable Register (Address 0x20) ............................................................ 32

Figure 19-2. Endpoint Interrupt Enable Register (Address 0x21) ........................................................ 33

Figure 19-3. Interrupt Controller Logic Block Diagram ........................................................................ 34

Figure 19-4. Port 0 Interrupt Enable Register (Address 0x04) ............................................................ 34

Figure 19-5. Port 1 Interrupt Enable Register (Address 0x05) ............................................................ 34

Figure 19-6. Port 0 Interrupt Polarity Register (Address 0x06) ............................................................ 35

Figure 19-7. Port 1 Interrupt Polarity Register (Address 0x07) ............................................................ 35

Figure 19-8. GPIO Interrupt Diagram ..................................................................................................35

Figure 24-1. Clock Timing ....................................................................................................................45

Figure 24-2. USB Data Signal Timing ..................................................................................................45

Figure 24-3. Receiver Jitter Tolerance ................................................................................................45

Figure 24-4. Differential to EOP Transition Skew and EOP Width ...................................................... 46

Figure 24-5. Differential Data Jitter ...................................................................................................... 46

LIST OF TABLES

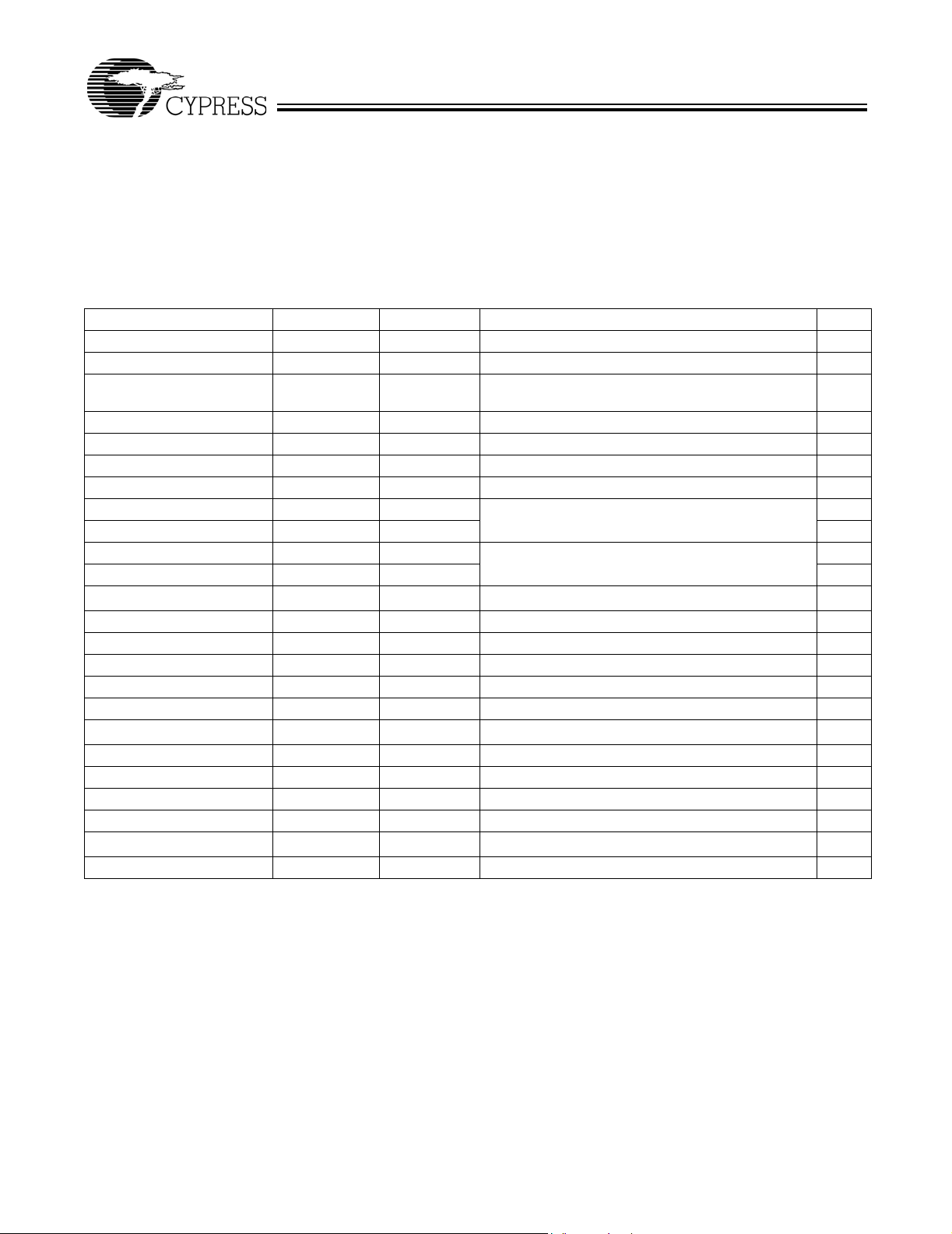

Table 8-1. I/O Register Summary ........................................................................................................13

Table 11-1. Wake-up Timer Adjust Settings ........................................................................................ 18

Table 12-1. Ports 0 and 1 Output Control Truth Table ........................................................................21

Table 13-1. Control Modes to Force D+/D– Outputs ...........................................................................24

Table 19-1. Interrupt Vector Assignments ...........................................................................................31

Table 20-1. USB Register Mode Encoding for Control and Non-Control Endpoint .............................36

Table 20-2. Decode table for Table 20-3: “Details of Modes for Differing Traffic Conditions” ............. 38

Table 20-3. Details of Modes for Differing Traffic Conditions .............................................................. 39

Table 26-1. CY7C63221A-XC Probe Pad Coordinates in microns ((0,0) to bond pad centers) .......... 48

Document #: 38-08028 Rev. *B Page 4 of 50

Page 5

FOR

FOR

enCoRe™ USB

CY7C63221/31A

1.0 Features

• enCoRe™ USB - enhanced Component Reduction

— Internal oscillator eliminates the need for an external crystal or resonator

— Interface can auto-configure to operate as PS/2 or USB without the need for external components to switch between

modes (no GPIO pins needed to manage dual mode capability)

— Internal 3.3V regulator for USB pull-up resistor

— Configurable GPIO for real-world interface without external components

• Flexible, cost-effective solution for applications that combine PS/2 and low-speed USB, such as mice, gamepads,

joysticks, and many others

• USB Specification Compliance

— Conforms to USB Specification, Version 2.0

— Conforms to USB HID Specification, Version 1.1

— Supports 1 low-speed USB device address

— Supports 1 control endpoint and 1 data endpoint

— Integrated USB transceiver

— 3.3V regulated output for USB pull-up resistor

• 8-bit RISC microcontroller

— Harvard architecture

— 6-MHz external ceramic resonator or internal clock mode

— 12-MHz internal CPU clock

— Internal memory

— 96 bytes of RAM

— 3 Kbytes of EPROM

— Interface can auto-configure to operate as PS/2 or USB

— No external components for switching between PS/2 and USB modes

• I/O ports

— Up to 10 versatile General Purpose I/O (GPIO) pins, individually configurable

— High current drive on any GPIO pin: 50 mA/pin current sink

— Each GPIO pin supports high-impedance inputs, internal pull-ups, open drain outputs, or traditional CMOS outputs

— Maskable interrupts on all I/O pins

— XTALIN, XTALOUT and VREG can be configured as additional input pins

• Internal low-power wake-up timer during suspend mode

— Periodic wake-up with no external components

• Optional 6-MHz internal oscillator mode

— Allows fast start-up from suspend mode

• Watchdog timer (WDT)

• Low-voltage Reset at 3.75V

• Internal brown-out reset for suspend mode

• Improved output drivers to reduce EMI

• Operating voltage from 4.0V to 5.5VDC

• Operating temperature from 0 to 70 degrees Celsius

• available in DIE form or 16-pin PDIP

• available in 18-pin SOIC, 18-pin PDIP

• Industry-standard programmer support

Document #: 38-08028 Rev. *B Page 5 of 50

Page 6

FOR

FOR

enCoRe™ USB

CY7C63221/31A

2.0 Functional Overview

2.1 enCoRe USB - The New USB Standard

Cypress has reinvented its leadership position in the low-speed USB market with a new family of innovative microcontrollers.

Introducing...enCoRe™ USB—“enhanced Component Reduction.” Cypress has leveraged its design expertise in USB solutions

to create a new family of low-speed USB microcontrollers that enables peripheral developers to design new products with a

minimum number of components. At the heart of the Cypress enCoRe USB technology is the breakthrough design of a crystalless oscillator. By integrating the oscillator into the chip, an external crystal or resonator is no longer needed. We have also

integrated other external components commonly found in low-speed USB applications such as pull-up resistors, wake-up circuitry,

and a 3.3V regulator. All of this adds up to a lower system cost.

The family is comprised of 8-bit RISC One Time Programmable (OTP) microcontrollers. The instruction set has been optimized

specifically for USB and PS/2 operations, although the microcontrollers can be used for a variety of other embedded applications.

The features up to 10 general-purpose I/O (GPIO) pins to support USB, PS/2 and other applications. The I/O pins are grouped

into two ports (Port 0 to 1) where each pin can be individually configured as inputs with internal pull-ups, open drain outputs, or

traditional CMOS outputs with programmable drive strength of up to 50 mA output drive. Additionally, each I/O pin can be used

to generate a GPIO interrupt to the microcontroller.

The microcontrollers feature an internal oscillator. With the presence of USB traffic, the internal oscillator can be set to precisely

tune to USB timing requirements (6 MHz ±1.5%). This clock generator has been optimized to reduce clock-related noise

emissions (EMI), and provides the 6-MHz and 12-MHz clocks that remain internal to the microcontroller. When using the internal

oscillator, XTALIN and XTALOUT can be configured as additional input pins that can be read on port 2. Optionally, an external 6MHz ceramic resonator can be used to provide a higher precision reference if needed.

The is offered with 3 Kbytes of EPROM to minimize cost, and has 96 bytes of data RAM for stack space, user variables, and

USB endpoint FIFOs.

The family includes low-voltage reset logic, a watchdog timer, a vectored interrupt controller, and a 12-bit free-running timer. The

low-voltage reset (LVR) logic detects when power is applied to the device, resets the logic to a known state, and begins executing

instructions at EPROM address 0x0000. LVR will also reset the part when V

watchdog timer can be used to ensure the firmware never gets stalled for more than approximately 8 ms.

The microcontroller supports 7 maskable interrupts in the vectored interrupt controller. Interrupt sources include the USB BusReset, the 128-µs and 1.024-ms outputs from the free-running timer, two USB endpoints, an internal wake-up timer and the GPIO

port. The timers bits cause periodic interrupts when enabled. The USB endpoints interrupt after USB transactions complete on

the bus. The GPIO port has a level of masking to select which GPIO inputs can cause a GPIO interrupt. For additional flexibility,

the input transition polarity that causes an interrupt is programmable for each GPIO pin. The interrupt polarity can be either rising

or falling edge.

The free-running 12-bit timer clocked at 1 MHz provides two interrupt sources as noted above (128 µs and 1.024 ms). The timer

can be used to measure the duration of an event under firmware control by reading the timer at the start and end of an event,

and subtracting the two values.

The CY7C63221/31A includes an integrated USB serial interface engine (SIE). The hardware supports one USB device address

with two endpoints. The SIE allows the USB host to communicate with the function integrated into the microcontroller. A 3.3V

regulated output pin provides a pull-up source for the external USB resistor on the D– pin. When using an external voltage

regulator VREG can be configured as an input pin that can be read on port 2 (P2.0).

The USB D+ and D– USB pins can alternately be used as PS/2 SCLK and SDATA signals, so that products can be designed to

respond to either USB or PS/2 modes of operation. PS/2 operation is supported with internal pull-up resistors on SCLK and

SDATA, the ability to disable the regulator output pin, and an interrupt to signal the start of PS/2 activity. No external components

are necessary for dual USB and PS/2 systems, and no GPIO pins need to be dedicated to switching between modes. Slow edge

rates operate in both modes to reduce EMI.

drops below the operating voltage range. The

CC

Document #: 38-08028 Rev. *B Page 6 of 50

Page 7

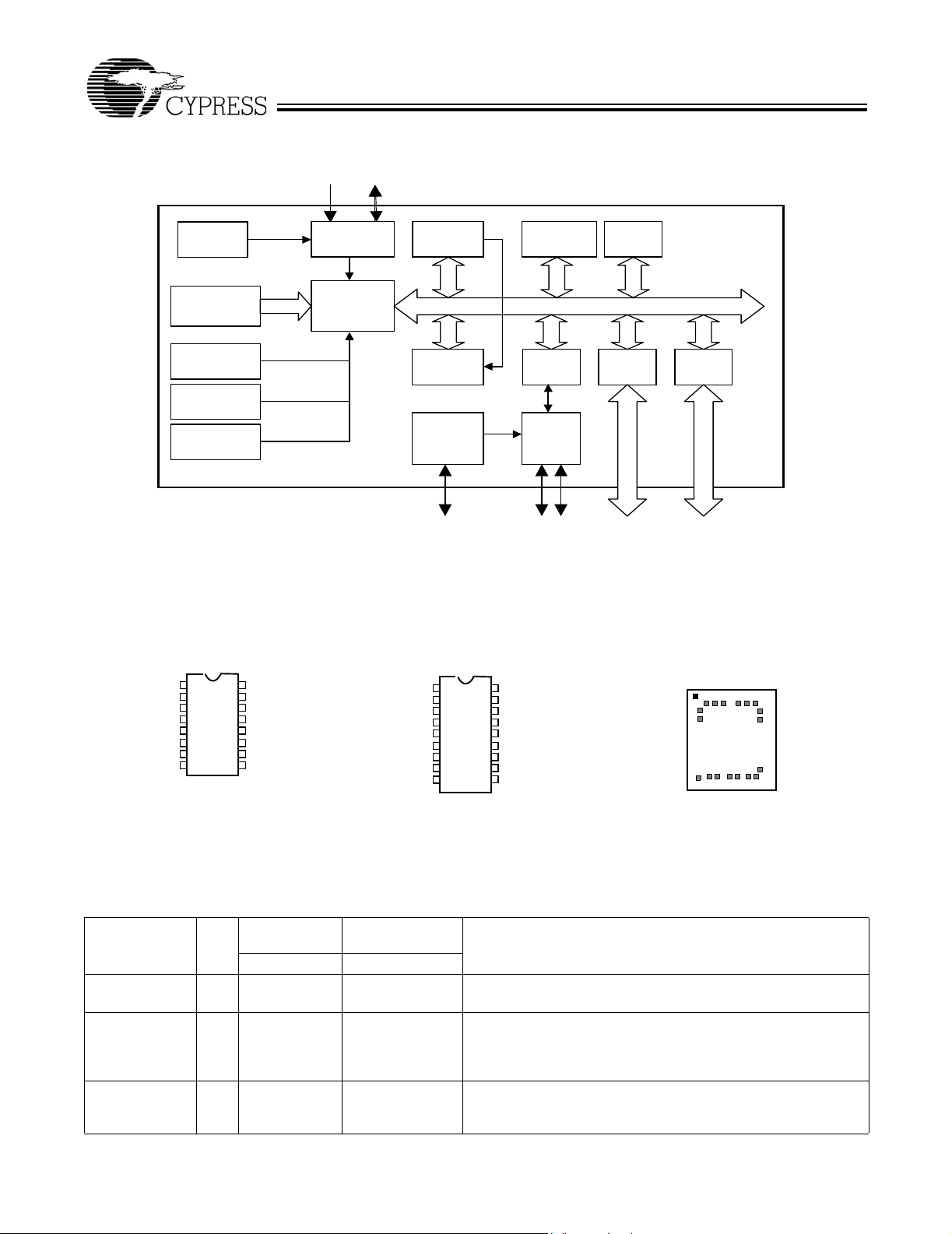

3.0 Logic Block Diagram

FOR

FOR

enCoRe™ USB

CY7C63221/31A

XTALIN/P2.1

XTALIN/P2.1 XTALOUT

Internal

Oscillato r

EPROM

3 Kbytes

Brown-Out

Reset

Watch Dog

Timer

Low Voltage

Reset

4.0 Pin Configurations

CY7C63221A

16-pin PDIP

P0.0

P0.1

P0.2

P0.3

V

SS

V

PP

VREG/P2.0

XTALIN/P2.1

1

2

3

4

5

6

7

8

P0.4

16

15

P0.5

P0.6

14

P0.7

13

12

D+/SCLK

11

D–/SDATA

10

V

XTALOUT/P2.2

9

CC

XTALOUT/P2.2

Xtal

Oscillato r

8-bit

RISC

Core

Wake-Up

Timer

Interrupt

Controller

3.3V

Regulator

RAM

96 Bytes

USB

Engine

USB &

PS/2

Xcvr

12-bit

Timer

Port 0

GPIO

VREG/P2.0 D+ D- P0.0-P0.7 P1.0-P1.1

(Top View)

CY7C63231A

18-pin SOIC/PDIP

P0.0

1

P0.1

2

P0.2

3

P0.3

4

P1.0

5

6

V

SS

7

V

PP

VREG/P2.0

XTALIN/P2.1

8

9

P0.4

18

17

P0.5

P0.6

16

P0.7

15

P1.1

14

13

D+/SCLK

12

D–/SDATA

V

11

XTALOUT/P2.2

10

CC

CY7C63221A-XC/XWC

DIE

P0.3

P1.0

Vss

Port 1

GPIO

4

5

6

3 P0.2

2 P0.1

7 8 9

Vpp

VREG/P2.0

1 P0.0

18 P0.4

101112

XTALIN/P2.1

XTALOUT/P2.2

17 P0.5

Vcc

16 P0.6

15

14

13

D-/SDATA

P0.7

P1.1

D+/SCLK

5.0 Pin Assignments

CY7C63231A/

CY7C63221A-XC

Name I/O

D–/SDATA,

D+/SCLK

P0[7:0] I/O 1, 2, 3, 4,

I/O 11

12

13, 14, 15, 16

12

13

1, 2, 3, 4,

15, 16, 17, 18

USB differential data lines (D– and D+), or PS/2 clock and data

signals (SDATA and SCLK)

GPIO Port 0 capable of sinking up to 50 mA/pin, or sinking

controlled low or high programmable current. Can also source

2 mA current, provide a resistive pull-up, or serve as a highimpedance input.

P1[1:0] I/O NA 5,14 IO Port 1 capable of sinking up to 50 mA/pin, or sinking controlled

low or high programmable current. Can also source 2 mA current,

provide a resistive pull-up, or serve as a high-impedance input.

Document #: 38-08028 Rev. *B Page 7 of 50

Description16-Pin 18-Pin/Pad

Page 8

FOR

FOR

enCoRe™ USB

CY7C63221/31A

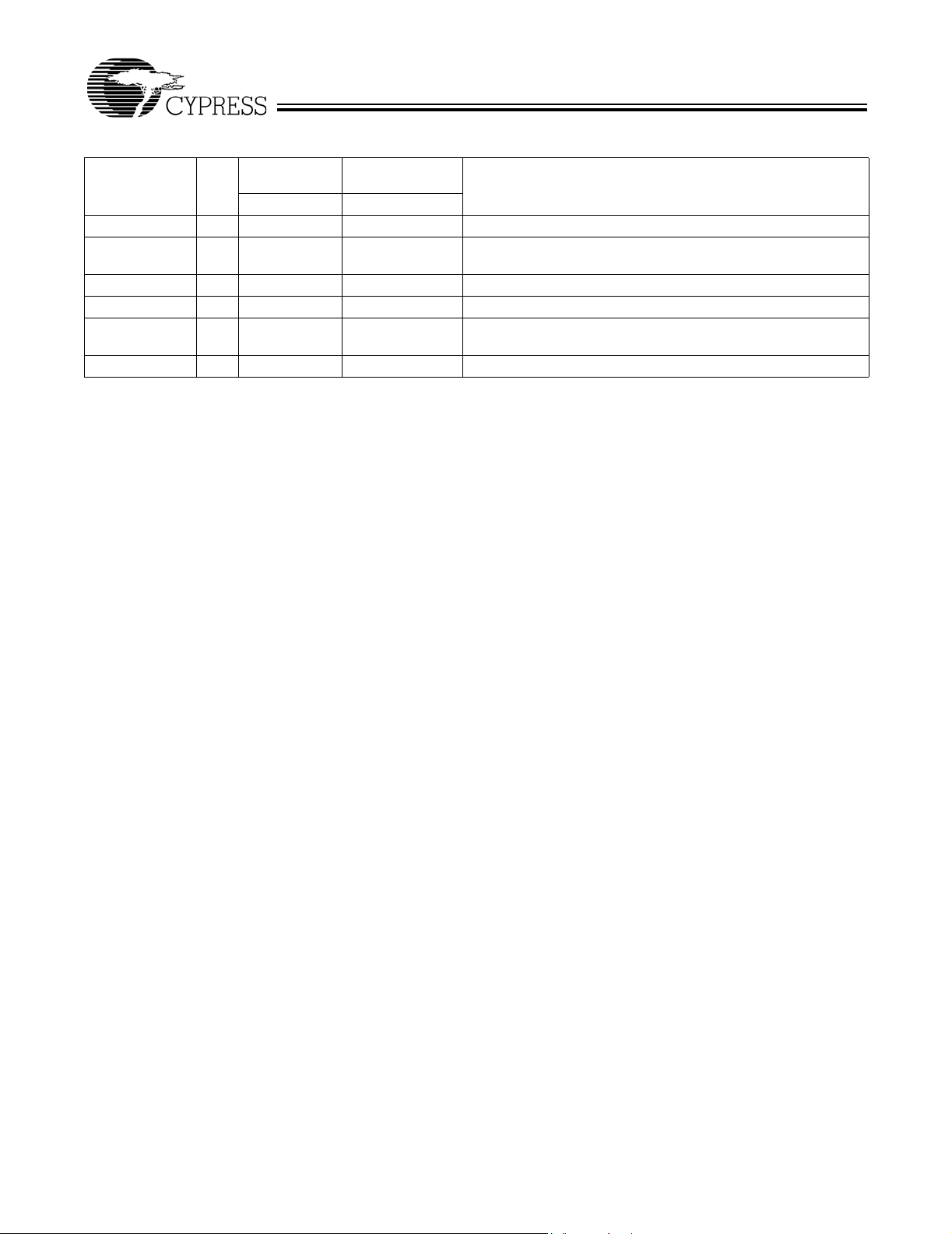

5.0 Pin Assignments (continued)

CY7C63231A/

CY7C63221A-XC

Name I/O

XTALIN/P2.1 IN 8 9 6-MHz ceramic resonator or external clock input, or P2.1 input

XTALOUT/P2.2 IN 9 10 6-MHz ceramic resonator return pin or internal oscillator output,

or P2.2 input

V

PP

V

CC

VREG/P2.0 7 8 Voltage supply for 1.3-kΩ USB pull-up resistor (3.3V nominal).

V

SS

6 7 Programming voltage supply, ground for normal operation

10 11 Voltage supply

Also serves as P2.0 input.

5 6 Ground

6.0 Programming Model

Refer to the CYASM Assembler User’s Guide for more details on firmware operation with the microcontrollers.

6.1 Program Counter (PC)

The 14-bit program counter (PC) allows access for 3 Kbytes of EPROM using the architecture. The program counter is cleared

during reset, such that the first instruction executed after a reset is at address 0x0000. This is typically a jump instruction to a

reset handler that initializes the application.

The lower 8 bits of the program counter are incremented as instructions are loaded and executed. The upper 6 bits of the program

counter are incremented by executing an XPAGE instruction. As a result, the last instruction executed within a 256-byte “page”

of sequential code should be an XPAGE instruction. The assembler directive “XPAGEON” will cause the assembler to insert

XPAGE instructions automatically. As instructions can be either one or two bytes long, the assembler may occasionally need to

insert a NOP followed by an XPAGE for correct execution.

The program counter of the next instruction to be executed, carry flag, and zero flag are saved as two bytes on the program stack

during an interrupt acknowledge or a CALL instruction. The program counter, carry flag, and zero flag are restored from the

program stack only during a RETI instruction.

Please note the program counter cannot be accessed directly by the firmware. The program stack can be examined by reading

SRAM from location 0x00 and up.

Note that there are restrictions in using the JMP, CALL, and INDEX instructions across the 4-KB boundary of the program memory.

Refer to the CYASM Assembler User’s Guide for a detailed description.

Description16-Pin 18-Pin/Pad

6.2 8-bit Accumulator (A)

The accumulator is the general-purpose, do-everything register in the architecture where results are usually calculated.

6.3 8-bit Index Register (X)

The index register “X” is available to the firmware as an auxiliary accumulator. The X register also allows the processor to perform

indexed operations by loading an index value into X.

6.4 8-bit Program Stack Pointer (PSP)

During a reset, the program stack pointer (PSP) is set to zero. This means the program “stack” starts at RAM address 0x00 and

“grows” upward from there. Note that the program stack pointer is directly addressable under firmware control, using the MOV

PSP,A instruction. The PSP supports interrupt service under hardware control and CALL, RET, and RETI instructions under

firmware control.

During an interrupt acknowledge, interrupts are disabled and the program counter, carry flag, and zero flag are written as two

bytes of data memory. The first byte is stored in the memory addressed by the program stack pointer, then the PSP is incremented.

The second byte is stored in memory addressed by the program stack pointer and the PSP is incremented again. The net effect

is to store the program counter and flags on the program “stack” and increment the program stack pointer by two.

The return from interrupt (RETI) instruction decrements the program stack pointer, then restores the second byte from memory

addressed by the PSP. The program stack pointer is decremented again and the first byte is restored from memory addressed

by the PSP. After the program counter and flags have been restored from stack, the interrupts are enabled. The effect is to restore

the program counter and flags from the program stack, decrement the program stack pointer by two, and re-enable interrupts.

Document #: 38-08028 Rev. *B Page 8 of 50

Page 9

FOR

FOR

enCoRe™ USB

CY7C63221/31A

The call subroutine (CALL) instruction stores the program counter and flags on the program stack and increments the PSP by two.

The return from subroutine (RET) instruction restores the program counter, but not the flags, from program stack and decrements

the PSP by two.

6.5 8-bit Data Stack Pointer (DSP)

The data stack pointer (DSP) supports PUSH and POP instructions that use the data stack for temporary storage. A PUSH

instruction will pre-decrement the DSP, then write data to the memory location addressed by the DSP. A POP instruction will read

data from the memory location addressed by the DSP, then post-increment the DSP.

During a reset, the Data Stack Pointer will be set to zero. A PUSH instruction when DSP equals zero will write data at the top of

the data RAM (address 0xFF). This would write data to the memory area reserved for a FIFO for USB endpoint 0. In non-USB

applications, this works fine and is not a problem.

For USB applications, the firmware should set the DSP to an appropriate location to avoid a memory conflict with RAM dedicated

to USB FIFOs. Since there are only 80 bytes of RAM available (except Endpoint FIFOs) the DSP should be set between 0x00

and 0x4Fh. The memory requirements for the USB endpoints are shown in Section 8.2. For example, assembly instructions to

set the DSP to 20h (giving 32 bytes for program and data stack combined) are shown below:

MOV A,20h ; Move 20 hex into Accumulator (must be D8h or less to avoid USB FIFOs)

SWAP A,DSP ; swap accumulator value into DSP register

6.6 Address Modes

The microcontroller supports three addressing modes for instructions that require data operands: data, direct, and indexed.

6.6.1 Data

The “Data” address mode refers to a data operand that is actually a constant encoded in the instruction. As an example, consider

the instruction that loads A with the constant 0x30:

• MOV A, 30h

This instruction will require two bytes of code where the first byte identifies the “MOV A” instruction with a data operand as the

second byte. The second byte of the instruction will be the constant “0xE8h”. A constant may be referred to by name if a prior

“EQU” statement assigns the constant value to the name. For example, the following code is equivalent to the example shown

above:

• DSPINIT: EQU 30h

• MOV A,DSPINIT

6.6.2 Direct

“Direct” address mode is used when the data operand is a variable stored in SRAM. In that case, the one byte address of the

variable is encoded in the instruction. As an example, consider an instruction that loads A with the contents of memory address

location 0x10h:

• MOV A, [10h]

In normal usage, variable names are assigned to variable addresses using “EQU” statements to improve the readability of the

assembler source code. As an example, the following code is equivalent to the example shown above:

• buttons: EQU 10h

• MOV A,[buttons]

6.6.3 Indexed

“Indexed” address mode allows the firmware to manipulate arrays of data stored in SRAM. The address of the data operand is

the sum of a constant encoded in the instruction and the contents of the “X” register. In normal usage, the constant will be the

“base” address of an array of data and the X register will contain an index that indicates which element of the array is actually

addressed:

• array: EQU 10h

•MOV X,3

• MOV A,[x+array]

This would have the effect of loading A with the fourth element of the SRAM “array” that begins at address 0x10h. The fourth

element would be at address 0x13h.

Document #: 38-08028 Rev. *B Page 9 of 50

Page 10

FOR

FOR

enCoRe™ USB

CY7C63221/31A

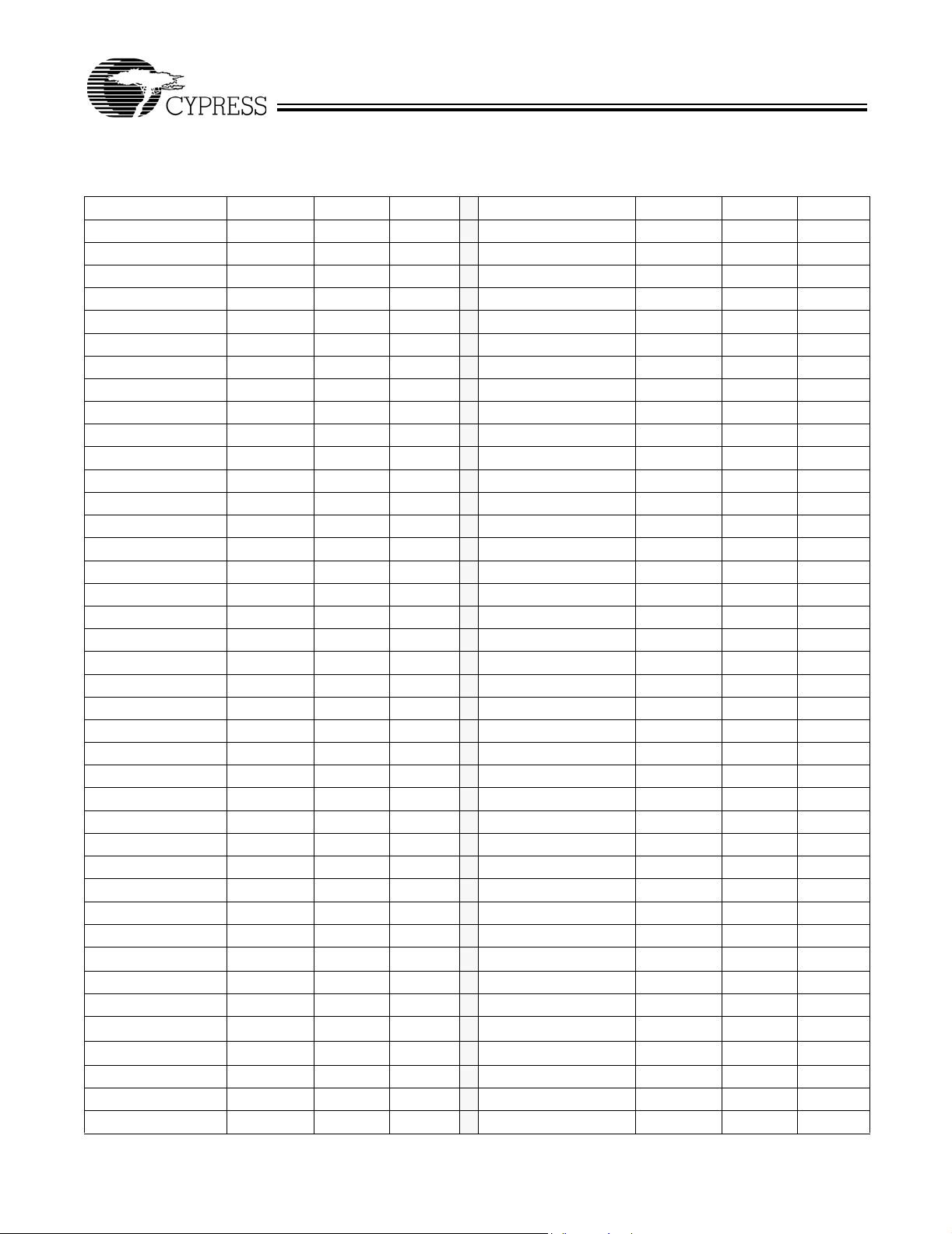

7.0 Instruction Set Summary

Refer to the CYASM Assembler User’s Guide for detailed information on these instructions. Note that conditional jump instructions

(i.e. JC, JNC, JZ, JNZ) take 5 cycles if jump is taken, 4 cycles if no jump.

MNEMONIC Operand Opcode Cycles

HALT 00 7 NOP 20 4

ADD A,expr data 01 4

ADD A,[expr] direct 02 6 INC X x 22 4

ADD A,[X+expr] index 03 7

ADC A,expr data 04 4 INC [X+expr] index 24 8

ADC A,[expr] direct 05 6 DEC A acc 25 4

ADC A,[X+expr] index 06 7

SUB A,expr data 07 4 DEC [expr] direct 27 7

SUB A,[expr] direct 08 6 DEC [X+expr] index 28 8

SUB A,[X+expr] index 09 7

SBB A,expr data 0A 4 IOWR expr address 2A 5

SBB A,[expr] direct 0B 6 POP A 2B 4

SBB A,[X+expr] index 0C 7

OR A,expr data 0D 4 PUSH A 2D 5

OR A,[expr] direct 0E 6 PUSH X 2E 5

OR A,[X+expr] index 0F 7

AND A,expr data 10 4 SWAP A,DSP 30 5

AND A,[expr] direct 11 6 MOV [expr],A direct 31 5

AND A,[X+expr] index 12 7

XOR A,expr data 13 4 OR [expr],A direct 33 7

XOR A,[expr] direct 14 6 OR [X+expr],A index 34 8

XOR A,[X+expr] index 15 7

CMP A,expr data 16 5 AND [X+expr],A index 36 8

CMP A,[expr] direct 17 7 XOR [expr],A direct 37 7

CMP A,[X+expr] index 18 8

MOV A,expr data 19 4

MOV A,[expr] direct 1A 5

MOV A,[X+expr] index 1B 6

MOV X,expr data 1C 4 ASR 3C 4

MOV X,[expr] direct 1D 5 RLC 3D 4

reserved 1E

XPAGE 1F 4 RET 3F 8

MOV A,X 40 4

MOV X,A 41 4 EI 72 4

MOV PSP,A 60 4

CALL addr 50 - 5F 10

JMP addr 80-8F 5

CALL addr 90-9F 10

JZ addr A0-AF 5 (or 4)

JNZ addr B0-BF 5 (or 4)

MNEMONIC Operand Opcode Cycles

INC A acc 21 4

INC [expr] direct 23 7

DEC X x 26 4

IORD expr address 29 5

POP X 2C 4

SWAP A,X 2F 5

MOV [X+expr],A index 32 6

AND [expr],A direct 35 7

XOR [X+expr],A index 38 8

IOWX [X+expr] index 39 6

CPL 3A 4

ASL 3B 4

RRC 3E 4

DI 70 4

RETI 73 8

JC addr C0-CF 5 (or 4)

JNC addr D0-DF 5 (or 4)

JACC addr E0-EF 7

INDEX addr F0-FF 14

Document #: 38-08028 Rev. *B Page 10 of 50

Page 11

FOR

FOR

8.0 Memory Organization

8.1 Program Memory Organization

After reset Address

14-bit PC 0x0000 Program execution begins here after a reset.

enCoRe™ USB

CY7C63221/31A

0x0002 USB Bus Reset interrupt vector

0x0004 128-µs timer interrupt vector

0x0006 1.024-ms timer interrupt vector

0x0008 USB endpoint 0 interrupt vector

0x000A USB endpoint 1 interrupt vector

0x000C Reserved

0x000E Reserved

0x0010 Reserved

0x0012 Reserved

0x0014 GPIO interrupt vector

0x0016 Wake-up interrupt vector

0x0018 Program Memory begins here

0x0BDF 3 KB PROM ends here (3K - 32 bytes). See Note 1 below

Figure 8-1. Program Memory Space with Interrupt Vector Table

Note:

1. The upper 32 bytes of the 3K PROM are reserved. Therefore, user’s program must not over-write this space.

Document #: 38-08028 Rev. *B Page 11 of 50

Page 12

FOR

FOR

enCoRe™ USB

CY7C63221/31A

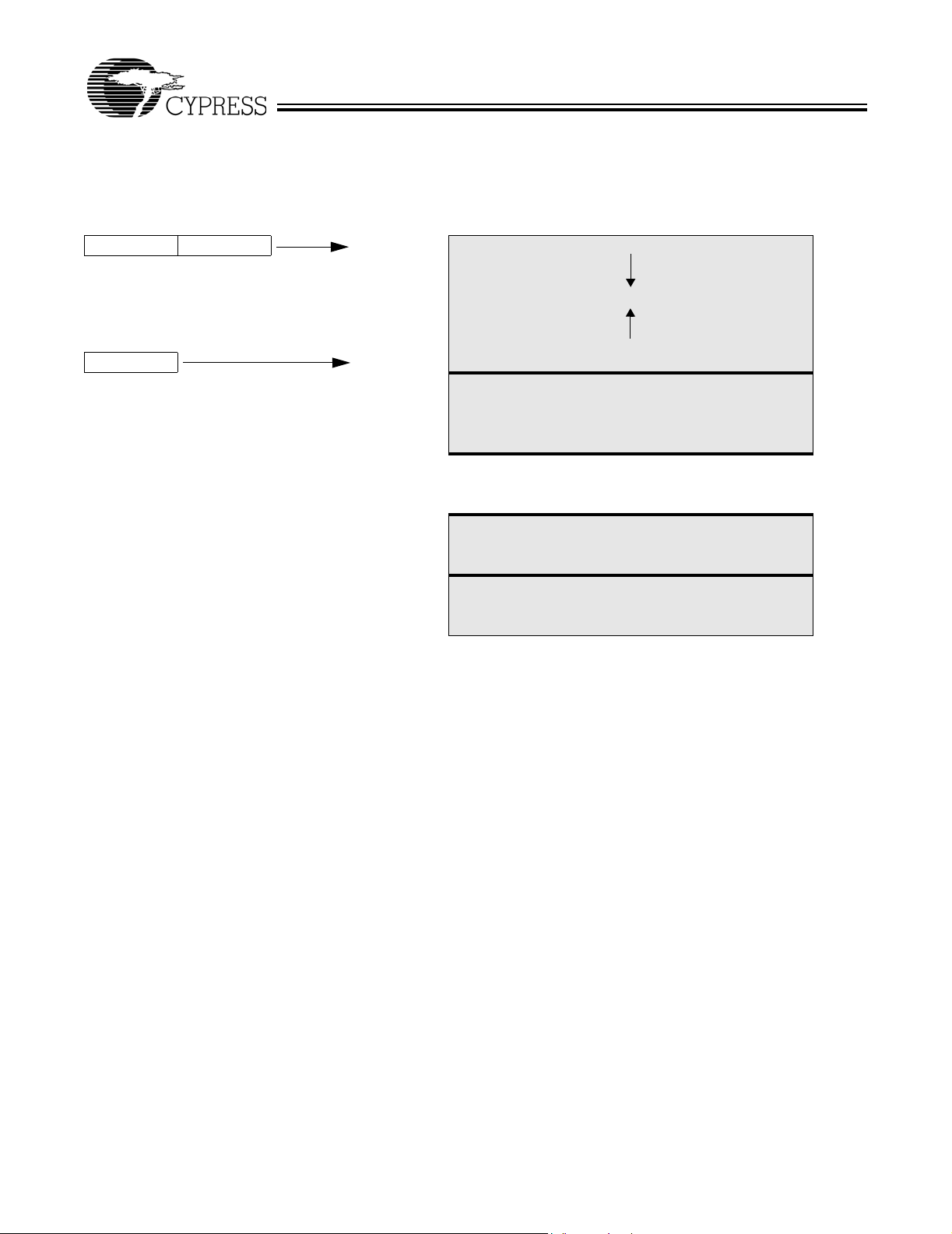

8.2 Data Memory Organization

The microcontroller provides 96 bytes of data RAM. In normal usage, the SRAM is partitioned into four areas: program stack,

data stack, user variables and USB endpoint FIFOs as shown below:

After reset Address

8-bit DSP 8-bit PSP 0x00 Program Stack Growth

(User’s firmware

moves DSP)

8-bit DSP User selected Data Stack Growth

User Variables

0x4F

0xF0

0xF8

Top of RAM Memory 0xFF

USB FIFO for Address A endpoint 1

USB FIFO for Address A endpoint 0

Document #: 38-08028 Rev. *B Page 12 of 50

Page 13

FOR

FOR

enCoRe™ USB

CY7C63221/31A

8.3 I/O Register Summary

I/O registers are accessed via the I/O Read (IORD) and I/O Write (IOWR, IOWX) instructions. IORD reads the selected port into

the accumulator. IOWR writes data from the accumulator to the selected port. Indexed I/O Write (IOWX) adds the contents of X

to the address in the instruction to form the port address and writes data from the accumulator to the specified port. Note that

specifying address 0 with IOWX (e.g., IOWX 0h) means the I/O port is selected solely by the contents of X.

Note: All bits of all registers are cleared to all zeros on reset, except the Processor Status and Control Register (Figure 18-

1). All registers not listed are reserved, and should never be written by firmware. All bits marked as reserved should always be

written as 0 and be treated as undefined by reads.

Table 8-1. I/O Register Summary

Register Name I/O Address Read/Write Function Fig.

Port 0 Data 0x00 R/W GPIO Port 0 12-2

Port 1 Data 0x01 R/W GPIO Port 1 12-3

Port 2 Data 0x02 R Auxiliary input register for D+, D–, VREG, XTALIN,

XTALOUT

Port 0 Interrupt Enable 0x04 W Interrupt enable for pins in Port 0 19-4

Port 1 Interrupt Enable 0x05 W Interrupt enable for pins in Port 1 19-5

Port 0 Interrupt Polarity 0x06 W Interrupt polarity for pins in Port 0 19-6

Port 1 Interrupt Polarity 0x07 W Interrupt polarity for pins in Port 1 19-7

Port 0 Mode0 0x0A W Controls output configuration for Port 0 12-4

Port 0 Mode1 0x0B W 12-5

Port 1 Mode0 0x0C W Controls output configuration for Port 1 12-6

Port 1 Mode1 0x0D W 12-7

USB Device Address 0x10 R/W USB Device Address register 14-1

EP0 Counter Register 0x11 R/W USB Endpoint 0 counter register 14-4

EP0 Mode Register 0x12 R/W USB Endpoint 0 configuration register 14-2

EP1 Counter Register 0x13 R/W USB Endpoint 1 counter register 14-4

EP1 Mode Register 0x14 R/W USB Endpoint 1 configuration register 14-3

USB Status & Control 0x1F R/W USB status and control register 13-1

Global Interrupt Enable 0x20 R/W Global interrupt enable register 19-1

Endpoint Interrupt Enable 0x21 R/W USB endpoint interrupt enables 19-2

Timer (LSB) 0x24 R Lower 8 bits of free-running timer (1 MHz) 17-1

Timer (MSB) 0x25 R Upper 4 bits of free-running timer 17-2

WDR Clear 0x26 W Watch Dog Reset clear -

Clock Configuration 0xF8 R/W Internal / External Clock configuration register 9-2

Processor Status & Control 0xFF R/W Processor status and control 18-1

12-8

Document #: 38-08028 Rev. *B Page 13 of 50

Page 14

FOR

FOR

enCoRe™ USB

CY7C63221/31A

9.0 Clocking

The chip can be clocked from either the internal on-chip clock, or from an oscillator based on an external resonator/crystal, as

shown in Figure 9-1. No additional capacitance is included on chip at the XTALIN/OUT pins. Operation is controlled by the Clock

Configuration Register, Figure 9-2.

Internal Osc

Int Clk Output Disable

Port 2.2

XTALOUT

Ext Osc Enable

Clk2x (12 MHz)

(to Microcontroller)

Clock

Doubler

XTALIN

Clk1x (6 MHz)

(to USB SIE)

Port 2.1

Figure 9-1. Clock Oscillator On-chip Circuit

Bit # 76543210

Bit Name Ext. Clock

Resume

Delay

Wake-up Timer Adjust Bit [2:0] Low-voltage

Reset

Disable

Precision

USB

Clocking

Enable

Internal

Clock

Output

Disable

External

Oscillator

Enable

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Reset 00000000

Figure 9-2. Clock Configuration Register (Address 0xF8)

Bit 7: Ext. Clock Resume Delay

External Clock Resume Delay bit selects the delay time when switching to the external oscillator from the internal oscillator

mode, or when waking from suspend mode with the external oscillator enabled.

1 = 4 ms delay.

0 = 128 µs delay.

The delay gives the oscillator time to start up. The shorter time is adequate for operation with ceramic resonators, while the

longer time is preferred for start-up with a crystal. (These times do not include an initial oscillator start-up time which depends

on the resonating element. This time is typically 50–100 µs for ceramic resonators and 1–10 ms for crystals). Note that this

bit only selects the delay time for the external clock mode. When waking from suspend mode with the internal oscillator (Bit 0

is LOW), the delay time is only 8 µs in addition to a delay of approximately 1 µs for the oscillator to start.

Bit [6:4]: Wake-up Timer Adjust Bit [2:0]

The Wake-up Timer Adjust Bits are used to adjust the Wake-up timer period.

If the Wake-up interrupt is enabled in the Global Interrupt Enable Register, the microcontroller will generate wake-up interrupts

periodically. The frequency of these periodical wake-up interrupts is adjusted by setting the Wake-up Timer Adjust Bit [2:0],

as described in Section 11.2. One common use of the wake-up interrupts is to generate periodical wake-up events during

suspend mode to check for changes, such as looking for movement in a mouse, while maintaining a low average power.

Bit 3: Low-voltage Reset Disable

When V

microcontroller enters a partial suspend state for a period of t

drops below V

CC

(see Section 23.0 for the value of V

LVR

) and the Low-voltage Reset circuit is enabled, the

LVR

(see Section 24.0 for the value of t

START

START

). Program

Document #: 38-08028 Rev. *B Page 14 of 50

Page 15

FOR

FOR

enCoRe™ USB

CY7C63221/31A

execution begins from address 0x0000 after this t

executes code. See Section 10.1 for more details.

1 = Disables the LVR circuit.

0 = Enables the LVR circuit.

Bit 2: Precision USB Clocking Enable

The Precision USB Clocking Enable only affects operation in internal oscillator mode. In that mode, this bit must be set to

1 to cause the internal clock to automatically precisely tune to USB timing requirements (6 MHz ±1.5%). The frequency

may have a looser initial tolerance at power-up, but all USB transmissions from the chip will meet the USB specification.

1 = Enabled. The internal clock accuracy is 6 MHz ±1.5% after USB traffic is received.

0 = Disabled. The internal clock accuracy is 6 MHz ±5%.

Bit 1: Internal Clock Output Disable

The Internal Clock Output Disable is used to keep the internal clock from driving out to the XTALOUT pin. This bit has no effect

in the external oscillator mode.

1 = Disable internal clock output. XTALOUT pin will drive HIGH.

0 = Enable the internal clock output. The internal clock is driven out to the XTALOUT pin.

Bit 0: External Oscillator Enable

At power-up, the chip operates from the internal clock by default. Setting the External Oscillator Enable bit HIGH disables the

internal clock, and halts the part while the external resonator/crystal oscillator is started. Clearing this bit has no immediate

effect, although the state of this bit is used when waking out of suspend mode to select between internal and external clock.

In internal clock mode, XTALIN pin will be configured as an input with a weak pull-down and can be used as a GPIO input

(P2.1).

1 = Enable the external oscillator. The clock is switched to external clock mode, as described in Section 9.1.

0 = Enable the internal oscillator.

delay period. This provides time for VCC to stabilize before the part

START

9.1 Internal/External Oscillator Operation

The internal oscillator provides an operating clock, factory set to a nominal frequency of 6 MHz. This clock requires no external

components. At power-up, the chip operates from the internal clock. In this mode, the internal clock is buffered and driven to the

XTALOUT pin by default, and the state of the XTALIN pin can be read at Port 2.1. While the internal clock is enabled, its output

can be disabled at the XTALOUT pin by setting the Internal Clock Output Disable bit of the Clock Configuration Register.

Setting the External Oscillator Enable bit of the Clock Configuration Register HIGH disables the internal clock, and halts the part

while the external resonator/crystal oscillator is started. The steps involved in switching from Internal to External Clock mode are

as follows:

1. At reset, chip begins operation using the internal clock.

2. Firmware sets Bit 0 of the Clock Configuration Register. For example,

mov A, 1h ; Set Bit 0 HIGH (External Oscillator Enable bit). Bit 7 cleared gives faster start-up

iowr F8h ; Write to Clock Configuration Register

3. Internal clocking is halted, the internal oscillator is disabled, and the external clock oscillator is enabled.

4. After the external clock becomes stable, chip clocks are re-enabled using the external clock signal. (Note that the time for the

external clock to become stable depends on the external resonating device; see next section.)

5. After an additional delay the CPU is released to run. This delay depends on the state of the Ext. Clock Resume Delay bit of

the Clock Configuration Register. The time is 128 µs if the bit is 0, or 4 ms if the bit is 1.

6. Once the chip has been set to external oscillator, it can only return to internal clock when waking from suspend mode. Clearing

bit 0 of the Clock Configuration Register will not re-enable internal clock mode until suspend mode is entered. See Section

11.0 for more details on suspend mode operation.

If the Internal Clock is enabled, the XTALIN pin can serve as a general-purpose input, and its state can be read at Port 2, Bit 1

(P2.1). Refer to Figure 12-8 for the Port 2 Data Register. In this mode, there is a weak pull-down at the XTALIN pin. This input

cannot provide an interrupt source to the CPU.

9.2 External Oscillator

The user can connect a low-cost ceramic resonator or an external oscillator to the XTALIN/XTALOUT pins to provide a precise

reference frequency for the chip clock, as shown in Figure 9-1. The external components required are a ceramic resonator or

crystal and any associated capacitors. To run from the external resonator, the External Oscillator Enable bit of the Clock Configuration Register must be set to 1, as explained in the previous section.

Document #: 38-08028 Rev. *B Page 15 of 50

Page 16

FOR

FOR

enCoRe™ USB

CY7C63221/31A

Start-up times for the external oscillator depend on the resonating device. Ceramic-resonator-based oscillators typically start in

less than 100 µs, while crystal-based oscillators take longer, typically 1 to 10 ms. Board capacitance should be minimized on the

XTALIN and XTALOUT pins by keeping the traces as short as possible.

An external 6-MHz clock can be applied to the XTALIN pin if the XTALOUT pin is left open.

10.0 Reset

The USB Controller supports three types of resets. The effects of the reset are listed below. The reset types are:

1. Low-voltage Reset (LVR)

2. Brown-out Reset (BOR)

3. Watchdog Reset (WDR)

The occurrence of a reset is recorded in the Processor Status and Control Register (Figure 18-1). Bits 4 (Low-voltage or Brownout Reset bit) and 6 (Watchdog Reset bit) are used to record the occurrence of LVR/BOR and WDR respectively. The firmware

can interrogate these bits to determine the cause of a reset.

The microcontroller begins execution from ROM address 0x0000 after a LVR, BOR, or WDR reset. Although this looks like

interrupt vector 0, there is an important difference. Reset processing does NOT push the program counter, carry flag, and zero

flag onto program stack. Attempting to execute either a RET or RETI in the reset handler will cause unpredictable execution

results.

The following events take place on reset. More details on the various resets are given in the following sections.

1. All registers are reset to their default states (all bits cleared, except in Processor Status and Control Register).

2. GPIO and USB pins are set to high-impedance state.

3. The VREG pin is set to high-impedance state.

4. Interrupts are disabled.

5. USB operation is disabled and must be enabled by firmware if desired, as explained in Section 14.1.

6. For a BOR or LVR, the external oscillator is disabled and Internal Clock mode is activated, followed by a time-out period t

for V

to stabilize. A WDR does not change the clock mode, and there is no delay for VCC stabilization on a WDR. Note that

CC

the External Oscillator Enable (Bit 0, Figure 9-2) will be cleared by a WDR, but it does not take effect until suspend mode is

entered.

7. The Program Stack Pointer (PSP) and Data Stack Pointer (DSP) reset to address 0x00. Firmware should move the DSP for

USB applications, as explained in Section 6.5.

8. Program execution begins at address 0x0000 after the appropriate time-out period.

START

10.1 Low-voltage Reset (LVR)

When V

the point where V

of t

START

wait for V

As long as the LVR circuit is enabled, this reset sequence repeats whenever the V

be disabled by firmware by setting the Low-voltage Reset Disable bit in the Clock Configuration Register (Figure 9-2). In addition,

the LVR is automatically disabled in suspend mode to save power. If the LVR was enabled before entering suspend mode, it

becomes active again once the suspend mode ends.

When LVR is disabled during normal operation (e.g., by writing ‘0’ to the Low-voltage Reset Disable bit in the Clock Configuration

Register), the chip may enter an unknown state if V

normal operation. If LVR is disabled (e.g., by firmware or during suspend mode), a secondary low-voltage monitor, BOR, becomes

active, as described in the next section. The LVR/BOR Reset bit of the Processor Status and Control Register (Figure 18-1), is

set to ‘1’ if either a LVR or BOR has occurred.

is first applied to the chip, the internal oscillator is started and the Low-voltage Reset is initially enabled by default. At

CC

(see Section 24.0 for the value of t

to stabilize before it begins executing code from address 0x0000.

CC

has risen above V

CC

(see Section 23.0 for the value of V

LVR

). During this t

START

drops below V

CC

START

), an internal counter starts counting for a period

LVR

time, the microcontroller enters a partial suspend state to

pin voltage drops below V

CC

. Therefore, LVR should be enabled at all times during

LVR

. The LVR can

LVR

10.2 Brown-out Reset (BOR)

The Brown-out Reset (BOR) circuit is always active and behaves like the POR. BOR is asserted whenever the V

the device is below an internally defined trip voltage of approximately 2.5V. The BOR re-enables LVR. That is, once V

and trips BOR, the part remains in reset until V

resumes, and the microcontroller starts executing code from address 0x00 after the t

In suspend mode, only the BOR detection is active, giving a reset if V

suspended and code is not executing, this lower reset voltage is safe for retaining the state of all registers and memory. Note that

rises above V

CC

. At that point, the t

LVR

drops below approximately 2.5V. Since the device is

CC

delay occurs before normal operation

START

delay.

START

in suspend mode, LVR is disabled as discussed in Section 10.1.

Document #: 38-08028 Rev. *B Page 16 of 50

voltage to

CC

CC

drops

Page 17

FOR

FOR

enCoRe™ USB

CY7C63221/31A

10.3 Watchdog Reset (WDR)

The Watchdog Timer Reset (WDR) occurs when the internal Watchdog timer rolls over. Writing any value to the write-only

Watchdog Reset Register at address 0x26 will clear the timer. The timer will roll over and WDR will occur if it is not cleared within

t

(see Figure 10-1) of the last clear. Bit 6 (Watchdog Reset bit) of the Processor Status and Control Register is set to record

WATCH

this event (see Section 18.0 for more details). A Watchdog Timer Reset lasts for typically 2–4 ms after which the microcontroller

begins execution at ROM address 0x0000.

t

WATCH = 10.1 to

WDR

14.6 ms

(at F

OSC

= 6 MHz)

2–4 ms

At least 10.1 ms

since last write to WDR

WDR goes HIGH

for 2–4 ms

Execution begins at

ROM Address 0x0000

Figure 10-1. Watchdog Reset (WDR, Address 0x26)

11.0 Suspend Mode

The parts support a versatile low-power suspend mode. In suspend mode, only an enabled interrupt or a LOW state on the

D–/SDATA pin will wake the part. Two options are available. For lowest power, all internal circuits can be disabled, so only an

external event will resume operation. Alternatively, a low-power internal wake-up timer can be used to trigger the wake-up

interrupt. This timer is described in Section 11.2, and can be used to periodically poll the system to check for changes, such as

looking for movement in a mouse, while maintaining a low average power.

The is placed into a low-power state by setting the Suspend bit of the Processor Status and Control Register (Figure 18-1). All

logic blocks in the device are turned off except the GPIO interrupt logic, the D–/SDATA pin input receiver, and (optionally) the

wake-up timer. The clock oscillators, as well as the free-running and watchdog timers are shut down. Only the occurrence of an

enabled GPIO interrupt, wake-up interrupt, SPI slave interrupt, or a LOW state on the D–/SDATA pin will wake the part from

suspend (D– LOW indicates non-idle USB activity). Once one of these resuming conditions occurs, clocks will be restarted and

the device returns to full operation after the oscillator is stable and the selected delay period expires. This delay period is

determined by selection of internal vs. external clock, and by the state of the Ext. Clock Resume Delay as explained in Section 9.0.

In suspend mode, any enabled and pending interrupt will wake the part up. The state of the Interrupt Enable Sense bit (Bit 2,

Figure 18-1) does not have any effect. As a result, any interrupts not intended for waking from suspend should be disabled through

the Global Interrupt Enable Register and the USB End Point Interrupt Enable Register (Section 19.0).

If a resuming condition exists when the suspend bit is set, the part will still go into suspend and then awake after the appropriate

delay time. The Run bit in the Processor Status and Control Register must be set for the part to resume out of suspend.

Once the clock is stable and the delay time has expired, the microcontroller will execute the instruction following the I/O write that

placed the device into suspend mode before servicing any interrupt requests.

To achieve the lowest possible current during suspend mode, all I/O should be held at either V

bit interrupts (Figure 19-4 and Figure 19-5) should be disabled for any pins that are not being used for a wake-up interrupt. This

should be done even if the main GPIO Interrupt Enable (Figure 19-1) is off.

Typical code for entering suspend is shown below:

... ; All GPIO set to low-power state (no floating pins, and bit interrupts disabled unless using for wake-up)

... ; Enable GPIO and/or wake-up timer interrupts if desired for wake-up

... ; Select clock mode for wake-up (see Section 11.1)

mov a, 09h ; Set suspend and run bits

iowr FFh ; Write to Status and Control Register - Enter suspend, wait for GPIO/wake-up interrupt or USB activity

nop ; This executes before any ISR

... ; Remaining code for exiting suspend routine

or ground. In addition, the GPIO

CC

11.1 Clocking Mode on Wake-up from Suspend

When exiting suspend on a wake-up event, the device can be configured to run in either Internal or External Clock mode. The

mode is selected by the state of the External Oscillator Enable bit in the Clock Configuration Register (Figure 9-2). Using the

Document #: 38-08028 Rev. *B Page 17 of 50

Page 18

FOR

FOR

enCoRe™ USB

CY7C63221/31A

Internal Clock saves the external oscillator start-up time and keeps that oscillator off for additional power savings. The external

oscillator mode can be activated when desired, similar to operation at power-up.

The sequence of events for these modes is as follows:

Wake in Internal Clock Mode:

1. Before entering suspend, clear bit 0 of the Clock Configuration Register. This selects Internal clock mode after suspend.

2. Enter suspend mode by setting the suspend bit of the Processor Status and Control Register.

3. After a wake-up event, the internal clock starts immediately (within 2 µs).

4. A time-out period of 8 µs passes, and then firmware execution begins.

5. At some later point, to activate External Clock mode, set bit 0 of the Clock Configuration Register. This halts the internal clocks

while the external clock becomes stable. After an additional time-out (128 µs or 4 ms, see Section 9.0), firmware execution

resumes.

Wake in External Clock Mode:

1. Before entering suspend, the external clock must be selected by setting bit 0 of the Clock Configuration Register. Make sure

this bit is still set when suspend mode is entered. This selects External clock mode after suspend.

2. Enter suspend mode by setting the suspend bit of the Processor Status and Control Register.

3. After a wake-up event, the external oscillator is started. The clock is monitored for stability (this takes approximately 50–100

µs with a ceramic resonator).

4. After an additional time-out period (128 µs or 4 ms, see Section 9.0), firmware execution resumes.

11.2 Wake-up Timer

The wake-up timer runs whenever the wake-up interrupt is enabled, and is turned off whenever that interrupt is disabled.

Operation is independent of whether the device is in suspend mode or if the global interrupt bit is enabled. Only the Wake-up

Timer Interrupt Enable bit (Figure 19-1) controls the wake-up timer.

Once this timer is activated, it will give interrupts after its time-out period (see below). These interrupts continue periodically until

the interrupt is disabled. Whenever the interrupt is disabled, the wake-up timer is reset, so that a subsequent enable always

results in a full wake-up time.

The wake-up timer can be adjusted by the user through the Wake-up Timer Adjust bits in the Clock Configuration Register

(Figure 9-2). These bits clear on reset. In addition to allowing the user to select a range for the wake-up time, a firmware algorithm

can be used to tune out initial process and operating condition variations in this wake-up time. This can be done by timing the

wake-up interrupt time with the accurate 1.024-ms timer interrupt, and adjusting the Timer Adjust bits accordingly to approximate

the desired wake-up time.

Table 11-1. Wake-up Timer Adjust Settings

Adjust Bits [2:0]

(Bits [6:4] in Figure 9-2) Wake-up Time

000 (reset state) 1 * t

001 2 * t

010 4 * t

011 8 * t

100 16 * t

101 32 * t

110 64 * t

111 128 * t

See Section 24.0 for the value of t

WAKE

WAKE

WAKE

WAKE

WAKE

WAKE

WAKE

WAKE

WAKE

Document #: 38-08028 Rev. *B Page 18 of 50

Page 19

FOR

FOR

enCoRe™ USB

CY7C63221/31A

12.0 General Purpose I/O Ports

Ports 0 and 1 provide up to 10 versatile GPIO pins that can be read or written (the number of pins depends on package type).

V

GPIO

Mode

2

CC

Q3

GPIO

Internal

Data Bus

Data

Out

Register

Q1

Control

14 kΩ

Pin

Port Write

Interrupt

Polarity

Interrupt

Enable

Port Read

Interrupt

Logic

Threshold Select

Q2

To Interrupt

Controller

Figure 12-1. Block Diagram of GPIO Port (one pin shown)

Port 0 is an 8-bit port; Port 1 contains 2 bits, P1.1–P1.0 in the and CY7C63221A-XC parts. Each bit can also be selected as an

interrupt source for the microcontroller.

The data for each GPIO pin is accessible through the Port Data Register. Writes to the Port Data Register store outgoing data

state for the port pins, while reads from the Port Data Register return the actual logic value on the port pins, not the Port Data

Register contents.

Each GPIO pin is configured independently. The driving state of each GPIO pin is determined by the value written to the pin’s

Data Register and by two associated pin’s Mode0 and Mode1 bits.

The Port 0 Data Register is shown in Figure 12-2, and the Port 1 Data Register is shown in Figure 12-3. The Mode0 and Mode1

bits for the two GPIO ports are given in Figure 12-4 through Figure 12-7.

Bit # 76543210

Bit Name P0

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Reset 00000000

Figure 12-2. Port 0 Data (Address 0x00)

Bit [7:0]: P0[7:0]

1 = Port Pin is logic HIGH

0 = Port Pin is logic LOW

Document #: 38-08028 Rev. *B Page 19 of 50

Page 20

FOR

FOR

enCoRe™ USB

CY7C63221/31A

Bit # 76543210

Bit Name Reserved P1[1:0]

Notes Pins 1:0 in all parts

Read/Write ------R/WR/W

Reset 00000000

Figure 12-3. Port 1 Data (Address 0x01)

Bit [7:2]: Reserved

Bit [1:0]: P1[1:0]

1 = Port Pin is logic HIGH

0 = Port Pin is logic LOW

Bit # 76543210

Bit Name P0[7:0] Mode0

Read/Write WWWWWWWW

Reset 00000000

Figure 12-4. GPIO Port 0 Mode0 Register (Address 0x0A)

Bit [7:0]: P0[7:0] Mode 0

1 = Port Pin Mode 0 is logic HIGH

0 = Port Pin Mode 0 is logic LOW

Bit # 76543210

Bit Name P0[7:0] Mode1

Read/Write WWWWWWWW

Reset 00000000

Figure 12-5. GPIO Port 0 Mode1 Register (Address 0x0B)

Bit [7:0]: P0[7:0] Mode 1

1 = Port Pin Mode 1 is logic HIGH

0 = Port Pin Mode 1 is logic LOW

Bit #76543210

Bit Name Reserved P1[1:0] Mode0

Read/Write ------WW

Reset 00000000

Figure 12-6. GPIO Port 1 Mode0 Register (Address 0x0C)

Bit [7:2]: Reserved

Bit [1:0]: P1[1:0] Mode 0

1 = Port Pin Mode 0 is logic HIGH

0 = Port Pin Mode 0 is logic LOW

Document #: 38-08028 Rev. *B Page 20 of 50

Page 21

FOR

FOR

enCoRe™ USB

CY7C63221/31A

Bit #76543210

Bit Name Reserved P1[1:0] Mode1

Read/Write ------WW

Reset 00000000

Figure 12-7. GPIO Port 1 Mode1 Register (Address 0x0D)

Bit [7:2]: Reserved

Bit [1:0]: P1[1:0] Mode 1

1 = Port Pin Mode 1 is logic HIGH

0 = Port Pin Mode 1 is logic LOW

Each pin can be independently configured as high-impedance inputs, inputs with internal pull-ups, open drain outputs, or traditional CMOS outputs with selectable drive strengths.

The driving state of each GPIO pin is determined by the value written to the pin’s Data Register and by its associated Mode0 and

Mode1 bits. Table 12-1 lists the configuration states based on these bits. The GPIO ports default on reset to all Data and Mode

Registers cleared, so the pins are all in a high-impedance state. The available GPIO output drive strength are:

• Hi-Z Mode (Mode1 = 0 and Mode0 = 0)

Q1, Q2, and Q3 (Figure 12-1) are OFF. The GPIO pin is not driven internally. Performing a read from the Port Data Register

return the actual logic value on the port pins.

• Low Sink Mode (Mode1 = 1, Mode0 = 0, and the pin’s Data Register = 0)

Q1 and Q3 are OFF. Q2 is ON. The GPIO pin is capable of sinking 2 mA of current.

• Medium Sink Mode (Mode1 = 0, Mode0 = 1, and the pin’s Data Register = 0)

Q1 and Q3 are OFF. Q2 is ON. The GPIO pin is capable of sinking 8 mA of current.

• High Sink Mode (Mode1 = 1, Mode0 = 1, and the pin’s Data Register = 0)

Q1 and Q3 are OFF. Q2 is ON. The GPIO pin is capable of sinking 50 mA of current.

• High Drive Mode (Mode1 = 0 or 1, Mode0 = 1, and the pin’s Data Register = 1)

Q1 and Q2 are OFF. Q3 is ON. The GPIO pin is capable of sourcing 2 mA of current.

• Resistive Mode (Mode1 = 1, Mode0 = 0, and the pin’s Data Register = 1)

Q2 and Q3 are OFF. Q1 is ON. The GPIO pin is pulled up with an internal 14-kΩ resistor.

Note that open drain mode can be achieved by fixing the Data and Mode1 Registers LOW, and switching the Mode0 register.

Input thresholds are CMOS, or TTL as shown in the table (See Section 23.0 for the input threshold voltage in TTL or CMOS

modes). Both input modes include hysteresis to minimize noise sensitivity. In suspend mode, if a pin is used for a wake-up

interrupt using an external R-C circuit, CMOS mode is preferred for lowest power.

Table 12-1. Ports 0 and 1 Output Control Truth Table

Data Register Mode1 Mode0 Output Drive Strength Input Threshold

0

1 Hi-Z TTL

0

1 High Drive CMOS

0

1 Resistive CMOS

0

1 High Drive CMOS

00

Medium (8 mA) Sink CMOS

01

10

11

Hi-Z CMOS

Low (2 mA) Sink CMOS

High (50 mA) Sink CMOS

12.1 Auxiliary Input Port

Port 2 serves as an auxiliary input port as shown in Figure 12-8. The Port 2 inputs all have TTL input thresholds.

Document #: 38-08028 Rev. *B Page 21 of 50

Page 22

FOR

FOR

enCoRe™ USB

CY7C63221/31A

Bit #76543210

Bit Name Reserved D+ (SCLK)

Stat e

Read/Write --RR-RRR

Reset 00000000

Figure 12-8. Port 2 Data Register (Address 0x02)

Bit [7:6]: Reserved

Bit [5:4]: D+ (SCLK) and D- (SDATA) States

The state of the D+ and D– pins can be read at Port 2 Data Register. Performing a read from the port pins returns their logic

values.

1 = Port Pin is logic HIGH

0 = Port Pin is logic LOW

Bit 3: Reserved

D– (SDATA)

State

Reserved P2.2

(Internal

Clock Mode

Only)

P2.1

(Internal

Clock Mode

Only)

P2.0

VREG Pin

State

Bit 2: P2.2 (Internal Clock Mode Only)

In the Internal Clock mode, the XTALOUT pin can serve as a general purpose input, and its state can be read at Port 2, Bit 2

(P2.2). See Section 9.1 for more details.

1 = Port Pin is logic HIGH

0 = Port Pin is logic LOW

Bit 1: P2.1 (Internal Clock Mode Only)

In the Internal Clock mode, the XTALIN pin can serve as a general purpose input, and its state can be read at Port 2, Bit 1

(P2.1). See Section 9.1 for more details.

1 = Port Pin is logic HIGH

0 = Port Pin is logic LOW

Bit 0: P2.0/ VREG Pin State

In PS/2 mode, the VREG

1 = Port Pin is logic HIGH

0 = Port Pin is logic LOW

pin can be used as an input and its state can be read at port P2.0. Section 15.0 for more details.

13.0 USB Serial Interface Engine (SIE)

The SIE allows the microcontroller to communicate with the USB host. The SIE simplifies the interface between the microcontroller and USB by incorporating hardware that handles the following USB bus activity independently of the microcontroller:

• Translate the encoded received data and format the data to be transmitted on the bus.

• CRC checking and generation. Flag the microcontroller if errors exist during transmission.

• Address checking. Ignore the transactions not addressed to the device.

• Send appropriate ACK/NAK/STALL handshakes.

• Token type identification (SETUP, IN, or OUT). Set the appropriate token bit once a valid token is received.

• Place valid received data in the appropriate endpoint FIFOs.

• Send and update the data toggle bit (Data1/0).

• Bit stuffing/unstuffing.

Firmware is required to handle the rest of the USB interface with the following tasks:

• Coordinate enumeration by decoding USB device requests.

• Fill and empty the FIFOs.

• Suspend/Resume coordination.

• Verify and select Data toggle values.

Document #: 38-08028 Rev. *B Page 22 of 50

Page 23

FOR

FOR

enCoRe™ USB

CY7C63221/31A

13.1 USB Enumeration

A typical USB enumeration sequence is shown below. In this description, ‘Firmware’ refers to embedded firmware in the

controller.

1. The host computer sends a SETUP packet followed by a DATA packet to USB address 0 requesting the Device descriptor.

2. Firmware decodes the request and retrieves its Device descriptor from the program memory tables.

3. The host computer performs a control read sequence and Firmware responds by sending the Device descriptor over the USB

bus, via the on-chip FIFO.

4. After receiving the descriptor, the host sends a SETUP packet followed by a DATA packet to address 0 assigning a new USB

address to the device.

5. Firmware stores the new address in its USB Device Address Register after the no-data control sequence completes.

6. The host sends a request for the Device descriptor using the new USB address.

7. Firmware decodes the request and retrieves the Device descriptor from program memory tables.

8. The host performs a control read sequence and Firmware responds by sending its Device descriptor over the USB bus.

9. The host generates control reads from the device to request the Configuration and Report descriptors.

10.Once the device receives a Set Configuration request, its functions may now be used.

11.Firmware should take appropriate action for Endpoint 1 transactions, which may occur from this point.

13.2 USB Port Status and Control

USB status and control is regulated by the USB Status and Control Register as shown in Figure 13-1.

Bit # 76543210

Bit Name PS/2 Pull-up

Enable

Read/Write R/W R/W R/W - R/W R/W R/W R/W

Reset 00000000

Bit 7: PS/2 Pull-up Enable

This bit is used to enable the internal PS/2 pull-up resistors on the SDATA and SCLK pins. Normally the output high level on

these pins is V

or if the Device Address is enabled (bit 7 of the USB Device Address Register, Figure 14-1).

, but note that the output will be clamped to approximately 1 Volt above V

CC

1 = Enable PS/2 pull-up resistors. The SDATA and SCLK pins are pulled up internally to V

5kΩ (see Section 23.0 for the value of R

0 = Disable PS/2 pull-up resistors.

Bit 6: VREG Enable

A 3.3V voltage regulator is integrated on chip to provide a voltage source for a 1.5-kΩ pull-up resistor connected to the D– pin

as required by the USB Specification. Note that the VREG output has an internal series resistance of approximately 200Ω, the

external pull-up resistor required is approximately 1.3-kΩ (see Figure 16-1).

1 = Enable the 3.3V output voltage on the VREG pin.

0 = Disable. The VREG pin can be configured as an input.

VREG

Enable

USB Reset-

PS/2 Activity

Reserved USB

Bus Activity

Interrupt

Mode

Figure 13-1. USB Status and Control Register (Address 0x1F)

REG

with two resistors of approximately

CC

PS2

).

D+/D- Forcing Bit

if the VREG Enable bit is set,

Bit 5: USB-PS/2 Interrupt Select

This bit allows the user to select whether an USB bus reset interrupt or a PS/2 activity interrupt will be generated when the

interrupt conditions are detected.

1 = PS/2 interrupt mode. A PS/2 activity interrupt will occur if the SDATA pin is continuously LOW for 128 to 256 µs.

0 = USB interrupt mode (default state). In this mode, a USB bus reset interrupt will occur if the single ended zero (SE0, D–

and D+ are LOW) exists for 128 to 256 µs.

See Section 19.0 for more details.

Bit 4: Reserved. Must be written as a ‘0’.

Document #: 38-08028 Rev. *B Page 23 of 50

Page 24

FOR

FOR

enCoRe™ USB

CY7C63221/31A

Bit 3: USB Bus Activity

The Bus Activity bit is a “sticky” bit that detects any non-idle USB event has occurred on the USB bus. Once set to HIGH by

the SIE to indicate the bus activity, this bit retains its logical HIGH value until firmware clears it. Writing a ‘0’ to this bit clears

it; writing a ‘1’ preserves its value. The user firmware should check and clear this bit periodically to detect any loss of bus

activity. Firmware can clear the Bus Activity bit, but only the SIE can set it. The 1.024-ms timer interrupt service routine is

normally used to check and clear the Bus Activity bit.

1 = There has been bus activity since the last time this bit was cleared. This bit is set by the SIE.

0 = No bus activity since last time this bit was cleared (by firmware).

Bit [2:0]: D+/D– Forcing Bit [2:0]

Forcing bits allow firmware to directly drive the D+ and D– pins, as shown in Table 13-1. Outputs are driven with controlled

edge rates in these modes for low EMI. For forcing the D+ and D– pins in USB mode, D+/D– Forcing Bit 2 should be 0. Setting

D+/D– Forcing Bit 2 to ‘1’ puts both pins in an open-drain mode, preferred for applications such as PS/2 or LED driving.

Table 13-1. Control Modes to Force D+/D– Outputs

D+/D– Forcing Bit [2:0] Control Action Application

000 Not forcing (SIE controls driver) Any Mode

001 Force K (D+ HIGH, D– LOW) USB Mode

010 Force J (D+ LOW, D– HIGH)

011 Force SE0 (D– LOW, D+ LOW)

100 Force D– LOW, D+ LOW PS/2 Mode

101 Force D– LOW, D+ HiZ

110 Force D– HiZ, D+ LOW

111 Force D– HiZ, D+ HiZ

Note:

2. For PS/2 operation, the D+/D- Forcing Bit [2:0] = 111b mode must be set initially (one time only) before using the other PS/2 force modes.

[2]

Document #: 38-08028 Rev. *B Page 24 of 50

Page 25

FOR

FOR

enCoRe™ USB

CY7C63221/31A

14.0 USB Device

The supports one USB Device Address with two endpoints: EP0 and EP1.

14.1 USB Address Register

The USB Device Address Register contains a 7-bit USB address and one bit to enable USB communication. This register is

cleared during a reset, setting the USB device address to zero and marking this address as disabled. Figure 14-1 shows the

format of the USB Address Register.

Bit # 76543210

Bit Name Device

Address

Enable

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Reset 00000000

Figure 14-1. USB Device Address Register (Address 0x10)

In either USB or PS/2 mode, this register is cleared by both hardware resets and the USB bus reset. See Section 19.3 for more

information on the USB Bus Reset - PS/2 interrupt.

Device Address Bit

Bit 7: Device Address Enable

This bit must be enabled by firmware before the serial interface engine (SIE) will respond to USB traffic at the address specified

in Bit [6:0].

1 = Enable USB device address.

0 = Disable USB device address.

Bit [6:0]: Device Address Bit[6:0]

These bits must be set by firmware during the USB enumeration process (i.e., SetAddress) to the non-zero address assigned

by the USB host.

14.2 USB Control Endpoint

All USB devices are required to have an endpoint number 0 (EP0) that is used to initialize and control the USB device. EP0

provides access to the device configuration information and allows generic USB status and control accesses. EP0 is bidirectional,

as the device can both receive and transmit data. EP0 uses an 8-byte FIFO at SRAM locations 0xF8-0xFF, as shown in

Section 8.2.

The EP0 endpoint mode register uses the format shown in Figure 14-2.

Bit # 76543210

Bit Name SETUP

Received

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Reset 00000000

IN

Received

Figure 14-2. Endpoint 0 Mode Register (Address 0x12)

OUT

Received

ACKed

Transaction

Mode Bit

The SIE provides a locking feature to prevent firmware from overwriting bits in the USB Endpoint 0 Mode Register. Writes to the

register have no effect from the point that Bit[6:0] of the register are updated (by the SIE) until the firmware reads this register.

The CPU can unlock this register by reading it.

Because of these hardware-locking features, firmware should perform an read after a write to the USB Endpoint 0 Mode Register

and USB Endpoint 0 Count Register (Figure 14-4) to verify that the contents have changed as desired, and that the SIE has not

updated these values.

Bit [7:4] of this register are cleared by any non-locked write to this register, regardless of the value written.

Bit 7: SETUP Received

1 = A valid SETUP packet has been received. This bit is forced HIGH from the start of the data packet phase of the SETUP

transaction until the start of the ACK packet returned by the SIE. The CPU is prevented from clearing this bit during this interval.

Document #: 38-08028 Rev. *B Page 25 of 50

Page 26

FOR

FOR

enCoRe™ USB