Page 1

1

Features

■

Direct Sensor Input

■

High Output Torque

■

Low Pointer Flutter

■

High Input Impedance

■ Overvoltage Protection

■ Return to Zero

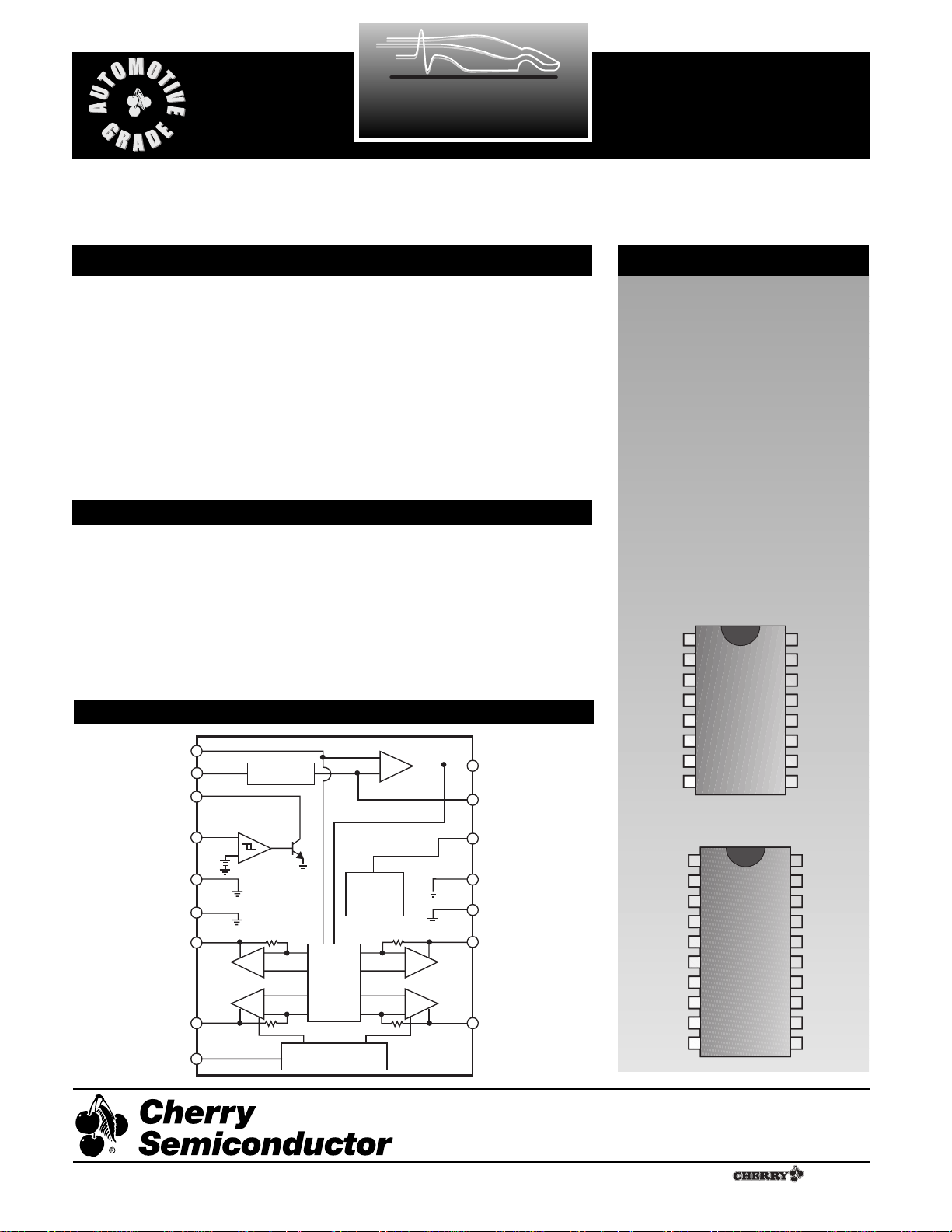

Package Options

16 Lead PDIP

(internally fused leads)

20 Lead SOIC

(internally fused leads)

CS8190

Precision Air-Core Tach/Speedo Driver

with Return to Zero

1

CP+

2

3

4

5

6

7

8

SQ

OUT

FREQ

IN

Gnd

Gnd

COS+

16

15

14

13

12

11

10

CP-

F/V

OUT

V

REG

Gnd

Gnd

SIN+

9

COS- SIN-

17

18

V

CC

BIAS

19

20

Gnd

Gnd

Gnd

Gnd

CS8190

Description

The CS8190 is specifically designed

for use with air-core meter movements. The IC provides all the functions necessary for an analog

tachometer or speedometer. The

CS8190 takes a speed sensor input

and generates sine and cosine related output signals to differentially

drive an air-core meter.

Many enhancements have been

added over industry standard

tachometer drivers such as the

CS289 or LM1819. The output utilizes differential drivers which eliminates the need for a zener reference

and offers more torque. The device

withstands 60V transients which

decreases the protection circuitry

required. The device is also more

precise than existing devices allowing for fewer trims and for use in a

speedometer.

Block Diagram

Absolute Maximum Ratings

Supply Voltage (<100ms pulse transient) .........................................VCC= 60V

(continuous)..............................................................VCC= 24V

Operating Temperature .............................................................Ð40¡C to +105¡C

Storage Temperature..................................................................Ð40¡C to +165¡C

Junction Temperature .................................................................Ð40¡C to+150¡C

ESD (Human Body Model) .............................................................................4kV

Lead Temperature Soldering

Wave Solder(through hole styles only).............10 sec. max, 260¡C peak

Reflow (SMD styles only).............60 sec. max above 183¡C, 230¡C peak

A Company

¨

Rev. 11/21/96

Cherry Semiconductor Corporation

2000 South County Trail, East Greenwich, RI 02818

Tel: (401)885-3600 Fax: (401)885-5786

Email: info@cherry-semi.com

Web Site: www.cherry-semi.com

BIAS

SQ

FREQ

CP+

OUT

IN

Gnd

Gnd

Charge Pump

Input

Comp.

+

Ð

Voltage

Regulator

V

REG

7.0V

+

Ð

F/V

CP-

V

Gnd

Gnd

OUT

REG

1

CP+

2

SQ

OUT

Gnd

Gnd

COS+

COS-

V

3

IN

4

5

6

7

8

CC

FREQ

16

15

14

13

12

11

10

9

CP-

F/V

V

REG

Gnd

Gnd

SINE+

SINE-

BIAS

OUT

COS

COS

+

Output

-

V

CC

COS

Ð

+

+

Ð

Func.

Gen.

High Voltage

Protection

Ð

+

SINE

Output

+

Ð

SINE+

SINE-

Page 2

2

Electrical Characteristics:

-40¡C ² TA² 85¡C, 8.5V ² VCC² 15V unless otherwise specified.

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

CS8190

■ Supply Voltage Section

I

CC

Supply Current VCC= 16V, -40¡C, No Load 50 125 mA

VCCNormal Operation Range

8.5 13.1 16.0 V

■ Input Comparator Section

Positive Input Threshold 1.0 2.0 3.0 V

Input Hysteresis 200 500 mV

Input Bias Current * 0V ² V

IN

² 8V -10 -80 µA

Input Frequency Range 0 20 KHz

Input Voltage Range in series with 1k½ -1 V

CC

V

Output V

SAT

ICC= 10mA 0.15 0.40 V

Output Leakage V

CC

= 7V 10 µA

Low V

CC

Disable Threshold 7.0 8.0 8.5 V

Logic 0 Input Voltage 1 V

* Note: Input is clamped by an internal 12V Zener.

■ Voltage Regulator Section

Output Voltage 6.25 7.00 7.50 V

Output Load Current 10 mA

Output Load Regulation 0 to 10 mA 10 50 mV

Output Line Regulation 8.5V ² V

CC

² 16V 20 150 mV

Power Supply Rejection V

CC

= 13.1V, 1Vp/p 1kHz 34 46 dB

■ Charge Pump Section

Inverting Input Voltage 1.5 2.0 2.5 V

Input Bias Current 40 150 nA

V

BIAS

Input Voltage 1.5 2.0 2.5 V

Non Invert. Input Voltage I

IN

= 1mA 0.7 1.1 V

Linearity* @ 0, 87.5, 175, 262.5, + 350Hz -0.10 0.28 +0.70 %

F/V

OUT

Gain @ 350Hz, CT= 0.0033µF, RT= 243k½ 7 10 13 mV/Hz

Norton Gain, Positive I

IN

= 15µA 0.9 1.0 1.1 I/I

Norton Gain, Negative I

IN

= 15µA 0.9 1.0 1.1 I/I

* Note: Applies to % of full scale (270¡)

■ Function Generator Section: -40¡ ² T

A

² 85¡C, VCC= 13.1V unless otherwise noted.

Return to Zero Threshold T

A

= 25¡C 5.2 6.0 7.0 V

Differential Drive Voltage 8.5V ² V

CC

² 16V 5.5 6.5 7.5 V

(V

COS

+ - V

COS

-) Q = 0¡

Differential Drive Voltage 8.5V ² V

CC

² 16V 5.5 6.5 7.5 V

(V

SIN

+ - V

SIN

-) Q = 90¡

Differential Drive Voltage 8.5V ² V

CC

² 16V -7.5 -6.5 -5.5 V

(V

COS

+ - V

COS

-) Q = 180¡

Differential Drive Voltage 8.5V ² V

CC

² 16V -7.5 -6.5 -5.5 V

(V

SIN

+ - V

SIN

-) Q = 270¡

Differential Drive Current 8.5V ² V

CC

² 16V 33 42 mA

Zero Hertz Output Angle -1.5 0.0 1.5 deg

Page 3

3

PACKAGE LEAD # LEAD SYMBOL FUNCTION

CS8190

Electrical Characteristics:

continued

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Package Lead Description

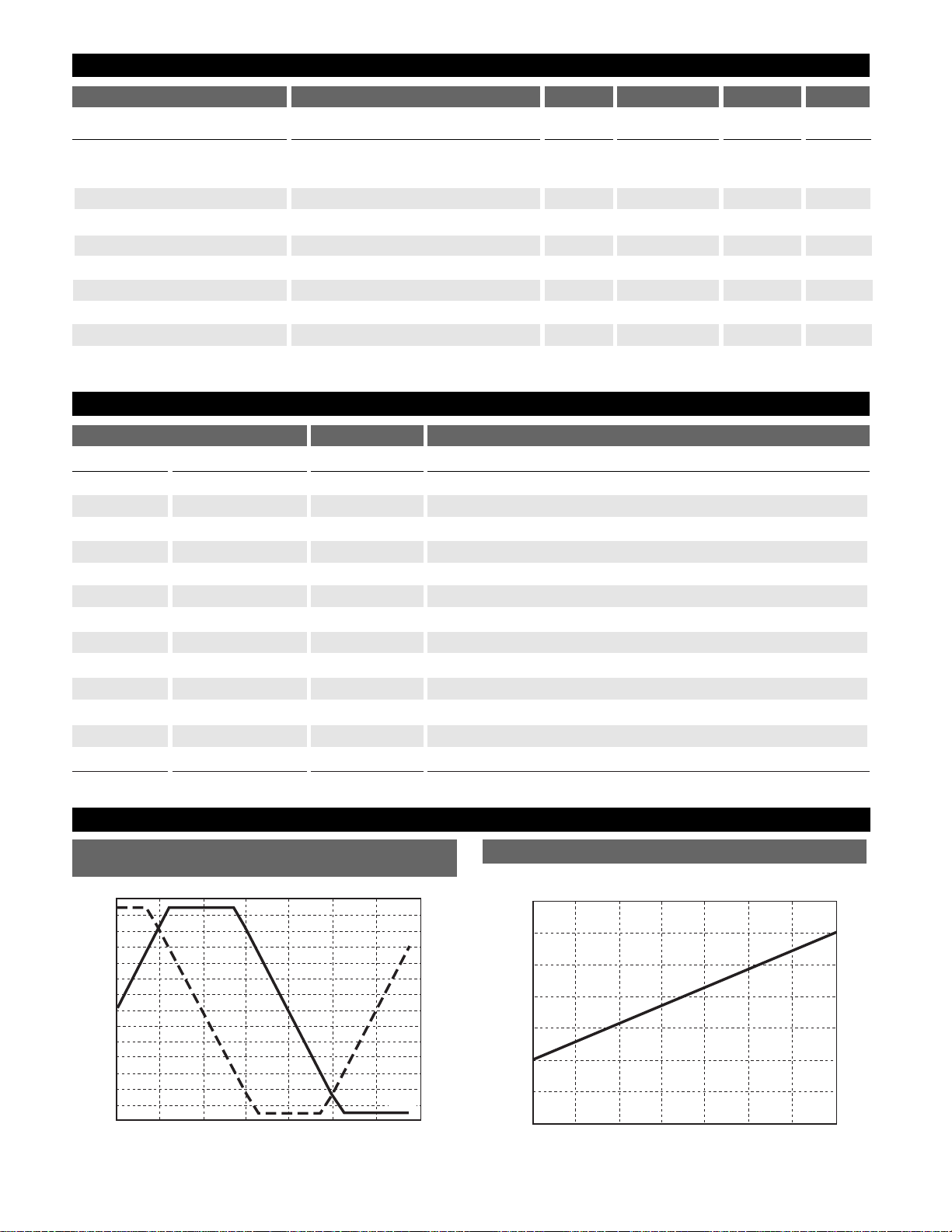

Typical Performance Characteristics

0 45 90 135 180 225 270 315

Output Voltage (V)

Degrees of Deflection (°)

7

6

5

4

3

2

1

0

-1

-2

-3

-4

-5

-6

-7

COS

SIN

045

90

135 180 225 270 315

F/V Output (V)

Frequency/Output Angle (°)

7

6

5

4

3

2

1

0

Figure 2: Charge Pump Output Voltage vs Output Angle

Figure 1: Function Generator Output Voltage

vs Degrees of Deflection

F/V

OUT

= 2.0V + 2 FREQ ´ CT´ RT´ (V

REG

- 0.7V)

■ Function Generator Section: continued

Function Generator Error * V

CC

= 13.1V -2 0 +2 deg

Reference Figures 1 - 4 Q = 0¡ to 305¡

Function Generator Error 13.1V ² V

CC

² 16V -2.5 0 +2.5 deg

Function Generator Error 13.1V ² V

CC

² 11V -1 0 +1 deg

Function Generator Error 13.1V ² V

CC

² 9V -3 0 +3 deg

Function Generator Error 25¡C ² T

A

² 80¡C -3 0 +3 deg

Function Generator Error 25¡C ² T

A

² 105¡C -5.5 0 +5.5 deg

Function Generator Error Ð40¡C ² T

A

² 25¡C -3 0 +3 deg

Function Generator Gain T

A

= 25¡C, Q vs F/V

OUT

60 77 95 ¡/V

* Note: Deviation from nominal per Table 1 after calibration at 0 and 270¡.

16L 20L

1 1 CP+ Positive input to charge pump.

22SQ

OUT

Buffered square wave output signal.

3 3 FREQ

IN

Speed or rpm input signal.

4, 5, 12, 13 4 - 7, 14 - 17 Gnd Ground Connections.

6 8 COS+ Positive cosine output signal.

7 9 COS- Negative cosine output signal.

810VCCIgnition or battery supply voltage.

9 11 BIAS Test point or zero adjustment.

10 12 SIN- Negative sine output signal.

11 13 SIN+ Positive sine output signal.

14 18 V

REG

Voltage regulator output.

15 19 F/V

OUT

Output voltage proportional to input signal frequency.

16 20 CP- Negative input to charge pump.

Page 4

4

00

1 1.09

2 2.19

3 3.29

4 4.38

5 5.47

6 6.56

7 7.64

8 8.72

9 9.78

10 10.84

11 11.90

12 12.94

13 13.97

14 14.99

15 16.00

16 17.00

17 17.98

18 18.96

19 19.92

20 20.86

21 21.79

22 22.71

23 23.61

24 24.50

25 25.37

26 26.23

27 27.07

28 27.79

29 28.73

30 29.56

31 30.39

32 31.24

33 32.12

34 33.04

35 34.00

36 35.00

37 36.04

38 37.11

39 38.21

40 39.32

41 40.45

42 41.59

43 42.73

44 43.88

45 45.00

50 50.68

55 56.00

60 60.44

65 64.63

70 69.14

75 74.00

80 79.16

85 84.53

90 90.00

95 95.47

100 100.84

105 106.00

110 110.86

115 115.37

120 119.56

125 124.00

130 129.32

135 135.00

140 140.68

145 146.00

150 150.44

155 154.63

160 159.14

165 164.00

170 169.16

175 174.33

180 180.00

185 185.47

190 190.84

195 196.00

200 200.86

205 205.37

210 209.56

215 214.00

220 219.32

225 225.00

230 230.58

235 236.00

240 240.44

245 244.63

250 249.14

255 254.00

260 259.16

265 264.53

270 270.00

275 275.47

280 280.84

285 286.00

290 290.86

295 295.37

300 299.21

305 303.02

Ideal Q Nominal Ideal Q Nominal Ideal Q Nominal Ideal Q Nominal Ideal Q Nominal Ideal Q Nominal

Degrees Q Degrees Degrees Q Degrees Degrees Q Degrees Degrees Q Degrees Degrees Q Degrees Degrees Q Degrees

Typical Performance Characteristics continued

CS8190

Nominal Angle vs. Ideal Angle (After calibrating at 180¡)

+7V

Ð7V

(V

COS+

) - (V

COS-

)

7V

Angle

-7V

Q

(V

SINE+

) - (V

SINE-

)

]

V

SIN+

Ð V

SIN-

V

COS+

Ð V

COS-

Q = ARCTAN

[

-1.50

Deviation (°)

0 45 90 135 180 225 270 315

-1.25

-1.00

-0.75

-0.50

-0.25

0.00

0.25

0.50

0.75

1.00

1.25

1.50

Theoretical Angle (°)

Figure 4: Nominal Output Deviation

Figure 3: Output Angle in Polar Form

Ideal Angle (Degrees)

Nominal Angle (Degrees)

0

5

10

15

20

25

30

35

40

45

1 5 9 13 17 21 25 29 33 37 41 45

Ideal Degrees

Nominal Degrees

Table 1: Function Generator Output Nominal Angle vs. Ideal Angle (After calibrating at 270¡)

Note: Temperature, voltage, and nonlinearity not included.

Note: Temperature, voltage, and nonlinearity not included.

Page 5

5

The CS8190 is specifically designed for use with air-core

meter movements. It includes an input comparator for

sensing an input signal from an ignition pulse or speed

sensor, a charge pump for frequency to voltage conversion, a bandgap voltage regulator for stable operation,

and a function generator with sine and cosine amplifiers

to differentially drive the motor coils.

From the simplified block diagram of Figure 5A, the

input signal is applied to the FREQINlead, this is the

input to a high impedance comparator with a typical positive input threshold of 2.0V and typical hysteresis of

0.5V. The output of the comparator, SQ

OUT

, is applied to

the charge pump input CP+ through an external capacitor

CT. When the input signal changes state, CTis charged

or discharged through R3 and R4. The charge accumulated on CTis mirrored to C4 by the Norton Amplifier circuit comprising of Q1, Q2 and Q3. The charge pump output voltage, F/V

OUT

, ranges from 2V to 6.3V depending

on the input signal frequency and the gain of the charge

pump according to the formula:

F/V

OUT

= 2.0V + 2 ´ FREQ ´ CT´ RT´ (V

REG

Ð 0.7V)

RTis a potentiometer used to adjust the gain of the F/V

output stage and give the correct meter deflection. The

F/V output voltage is applied to the function generator

which generates the sine and cosine output voltages. The

output voltage of the sine and cosine amplifiers are

derived from the on-chip amplifier and function generator circuitry. The various trip points for the circuit (i.e., 0¡,

90¡, 180¡, 270¡) are determined by an internal resistor

divider and the bandgap voltage reference. The coils are

differentially driven, allowing bidirectional current flow

in the outputs, thus providing up to 305¡ range of meter

deflection. Driving the coils differentially offers faster

response time, higher current capability, higher output

voltage swings, and reduced external component count.

The key advantage is a higher torque output for the

pointer.

The output angle, Q, is equal to the F/V gain multiplied

by the function generator gain:

Q = A

F/V

´ AFG,

where:

AFG= 77¡/V (typ)

The relationship between input frequency and output

angle is:

Q = AFG´ 2 ´ FREQ ´ CT´ RT´ (V

REG

Ð 0.7V)

or, Q = 970 ´ FREQ ´ CT´ R

T

The ripple voltage at the F/V converterÕs output is determined by the ratio of CTand C4 in the formula:

ÆV =

Ripple voltage on the F/V output causes pointer or needle flutter, especially at low input frequencies.

The response time of the F/V is determined by the time

constant formed by RTand C4. Increasing the value of C4

will reduce the ripple on the F/V output but will also

increase the response time. An increase in response time

causes a very slow meter movement and may be unacceptable for many applications.

The CS8190 has an undervoltage detect circuit that disables the input comparator when VCCfalls below

8.0V(typical). With no input signal the F/V output voltage decreases and the needle moves towards zero. A second undervoltage detect circuit at 6.0V(typical) causes the

function generator to generate a differential SIN drive

voltage of zero volts and the differential COS drive voltage to go as high as possible. This combination of voltages (Figure 1) across the meter coil moves the needle to

the 0¡ position. Connecting a large capacitor(> 2000µF) to

the VCClead (C2 in Figure 6) increases the time between

these undervoltage points since the capacitor discharges

slowly and ensures that the needle moves towards 0¡ as

opposed to 360¡. The exact value of the capacitor depends

on the response time of the system,the maximum meter

deflection and the current consumption of the circuit. It

should be selected by breadboarding the design in the lab.

Design Example

Maximum meter Deflection = 270¡

Maximum Input Frequency = 350Hz

1. Select RTand C

T

Q = A

GEN

´ Æ

F/V

Æ

F/V

= 2 ´ FREQ ´ CT´ RT´ (V

REG

Ð 0.7V)

Q = 970 ´ FREQ ´ CT´ R

T

Let CT= 0.0033µF, Find R

T

RT=

RT= 243k½

RTshould be a 250k½ potentiometer to trim out any inaccuracies due to IC tolerances or meter movement pointer

placement.

2. Select R3 and R4

Resistor R3 sets the output current from the voltage regulator. The maximum output current from the voltage regulator is 10mA, R3 must ensure that the current does not

exceed this limit.

Choose R3 = 3.3k½

The charge current for CTis:

= 1.90mA

C1 must charge and discharge fully during each cycle of

the input signal. Time for one cycle at maximum frequency is 2.85ms. To ensure that CTis discharged, assume that

the (R3 + R4) CTtime constant is less than 10% of the

minimum input frequency pulse width.

T = 285µs

Choose R4 = 1k½.

Charge time: T = R3 ´ C

T

= 3.3k½ ´ 0.0033µF = 10.9µs

Discharge time:T = (R3 + R4)C

T

= 4.3k½ ´ 0.0033µF = 14.2µs

V

REG

Ð 0.7V

3.3k½

270¡

970 ´ 350Hz ´ 0.0033µF

C

T(VREG

Ð 0.7V)

C4

Circuit Description and Application Notes

CS8190

Page 6

6

3. Determine C4

C4 is selected to satisfy both the maximum allowable ripple voltage and response time of the meter movement.

C4 =

With C4 = 0.47µF, the F/V ripple voltage is 44mV.

The last component to be selected is the return to zero

capacitor C2. This is selected by increasing the input signal frequency to its maximum so the pointer is at its maximum deflection and removing the power from the circuit. C2 should be large enough to ensure that the pointer

always returns to the 0¡ position rather than 360¡ under

all operating conditions.

Figure 7 shows how the CS8190 and the CS8441 are used

to produce a Speedometer and Odometer circuit.

CT(V

REG

Ð 0.7V)

V

RIPPLE(MAX)

CS8190

Circuit Description and Application Notes: continued

+

Ð

R

T

C4

CPÐ

+

Ð

F/V

OUT

F to V

2.0V

Q2

Q1

Q3

0.25V

CP+

R4C

T

VC(t)

+Ð

R3

V

REG

SQ

OUT

Q

SQUARE

2.0V

FREQ

IN

Figure 5A: Partial Schematic of Input and Charge Pump

Figure 5B: Timing Diagram of FREQINand I

CP

V

CC

IN

OUT

0

V

REG

FREQ

SQ

0

I

CP+

V

CP+

0

T

PW T-PW

Page 7

7

Speedometer/Odometer or Tachometer Application

CS8190

In some cases a designer may wish to use the CS8190 only

as a driver for an air-core meter having performed the F/V

conversion elsewhere in the circuit.

Figure 8 shows how to drive the CS8190 with a DC voltage

ranging from 2V to 6V. This is accomplished by forcing a

voltage on the F/V

OUT

lead. The alternative scheme shown

in Figure 9 uses an external op amp as a buffer and operates over an input voltage range of 0V to 4V.

Figure 8. Driving the CS8190 from an external DC voltage.

An alternative solution is to use the CS4101 which has a

separate function generator input lead and can be driven

directly from a DC source.

Figure 9. Driving the CS8190 from an external DC voltage using an Op

Amp Buffer.

Figure 6

R1 - 3.9, 500mW

R2 - 10k½

R3 - 3k½

R4 - 1k½

R

T

- Trim Resistor ±20 PPM/DEG. C

C1 - 0.1µF

C2 - 1. Stand alone Speedo or Tach with return to Zero, 2000µF

2. With CS8441 application, 10µF

C3 - 0.1µF

C4 - 0.47µF

C

T

- 0.0033µF, ±30 PPM/¡C

D1 - 1A, 600 PIV

D2 - 50V, 500mW Zener

Note 1: C2 (> 2000µF) is needed if return to zero function is required.

Note 2: The product of C4 and R4 have a direct effect on gain and

therefore directly effect temperature compensation.

Note 3: C4 Range; 20pF to .2µF.

Figure 7

Note 4: R4 Range; 100k½ to 500k½.

Note 5: The IC must be protected from transients above 60V and reverse

battery conditions.

Note 6: Additional filtering on the FREQ

IN

lead may be required.

R4

R3

C

Speedo

Input

Battery

Gnd

R2

R1D1

T

C3

C1D2

C2

CP+

CP+

1

SQ

2

FREQ

3

Gnd

4

Gnd

5

COS+

6

COS-

7

V

8

COSINE SINE

CC

OUT

Air Core

Gauge

IN

200W

CP-

F/V

OUT

V

REG

Gnd

Gnd

SINE+

CS8190

SINE-

BIAS

16

15

14

13

12

11

10

9

C4

Speedometer

R4

R3

C

R

T

+

Speedo

Input

Battery

Gnd

R2

R1D1

T

C3

C1D2

C2

CP+

CP+

1

SQ

2

FREQ

3

Gnd

4

Gnd

5

COS+

6

COS-

7

V

8

COSINE SINE

1

CC

OUT

IN

Air Core

Gauge

200W

CP-

F/V

OUT

V

REG

Gnd

Gnd

SINE+

CS8190

SINE-

BIAS

16

15

14

13

12

11

10

9

CS8441

Air Core

Stepper Motor

200W

C4

Speedometer

Odometer

R

T

+

VREG

100kW

V

IN

2V to 6V DC

10kW

N/C

-

CP

BIAS

F/VOUT

CS8190

-

+

CS8190

100kW

100kW

V

IN

0V to 4V DC

100kW

+

-

100kW

10kW

BIAS

-

CP

F/VOUT

+

-

Page 8

8

CS8190

Part Number Description

CS8190ENF16 16L PDIP (internally fused leads)

CS8190EDWF20 20L SOIC (internally fused leads)

CS8190EDWFR20 20L SOIC (internally fused leads)

(tape & reel)

Rev. 11/21/96

D

Lead Count Metric English

Max Min Max Min

16L PDIP* 19.69 18.67 .775 .735

20L SOIC* 13.00 12.60 .512 .496

Ordering Information

Thermal Data 16L PDIP* 20L SOIC*

R

QJC

typ 15 9 ûC/W

R

QJA

typ 50 55 ûC/W

Package Specification

PACKAGE DIMENSIONS IN mm (INCHES)

PACKAGE THERMAL DATA

© 1999 Cherry Semiconductor Corporation

Cherry Semiconductor Corporation reserves the

right to make changes to the specifications without

notice. Please contact Cherry Semiconductor

Corporation for the latest available information.

Plastic DIP (N); 300 mil wide

0.39 (.015)

MIN.

2.54 (.100) BSC

1.77 (.070)

1.14 (.045)

D

Some 8 and 16 lead

packages may have

1/2 lead at the end

of the package.

All specs are the same.

.203 (.008)

.356 (.014)

REF: JEDEC MS-001

3.68 (.145)

2.92 (.115)

8.26 (.325)

7.62 (.300)

7.11 (.280)

6.10 (.240)

.356 (.014)

.558 (.022)

Surface Mount Wide Body (DW); 300 mil wide

1.27 (.050) BSC

7.60 (.299)

7.40 (.291)

10.65 (.419)

10.00 (.394)

D

0.32 (.013)

0.23 (.009)

1.27 (.050)

0.40 (.016)

REF: JEDEC MS-013

2.49 (.098)

2.24 (.088)

0.51 (.020)

0.33 (.013)

2.65 (.104)

2.35 (.093)

0.30 (.012)

0.10 (.004)

*Internally Fused Leads

Loading...

Loading...