Page 1

Octal T1/E1/J1 Line Interface Unit

00000

00000

00000

00000

00000

00000

00000

00000

00000

00000

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

CS61884

Features

Industry Standard Footprint

Octal E1/T1/J1 Short-haul Line Interface Unit

Low Power

No External Component Changes for

100 Ω/120 Ω/75 Ω Operation

Pulse Shapes can be customized by the user

Internal AMI, B8ZS, or HDB3 Encoding/Decoding

LOS Detection per T1.231, ITU G.775, ETSI 300-233

G.772 Non-Intrusive Monitoring

G.703 BITS Clock Recovery

Crystal-less Jitter Attenuation

Serial/Parallel Microprocessor Control Interfaces

Transmitter Short Circuit Current Limiter (<50mA)

TX Drivers with Fast High-Z and Power Down

JTAG Boundary Scan compliant to IEEE 1149.1

144-Pin LQFP or 160-Pin BGA Package

ORDERING INFORMATION

CS61884-IQ 144-pin LQFP

CS61884-IB 160-pin FBGA

Description

The CS61884 is a full-featured Octal E1/T1/J1 shorthaul LIU that supports both 1.544 Mbps or 2.048 Mbps

data transmission. Each channel provides crystal-less

jitter attenuation that complies with the most stringent

standards. Each channel also provides internal

AMI/B8ZS/HDB3 encoding/decoding. To support enhanced system diagnostics, channel zero can be

configured for G.772 non-intrusive monitoring of any of

the other 7 channels’ receive or transmit paths.

The CS61884 makes use of ultra low power matched impedance transmitters and receivers to reduce power

beyond that achieved by traditional driver designs. By

achieving a more precise line match, this technique also

provides superior return loss characteristics. Additionally, the internal line matching circuitry reduces the

external component count. All transmitters have controls

for independent power down and High-Z.

Each receiver provides reliable data recovery with over

12 dB of cable attenuation. The receiver also incorporates LOS detection compliant to the most recent

specifications.

Note: Click on any text in blue to go to cross-references.

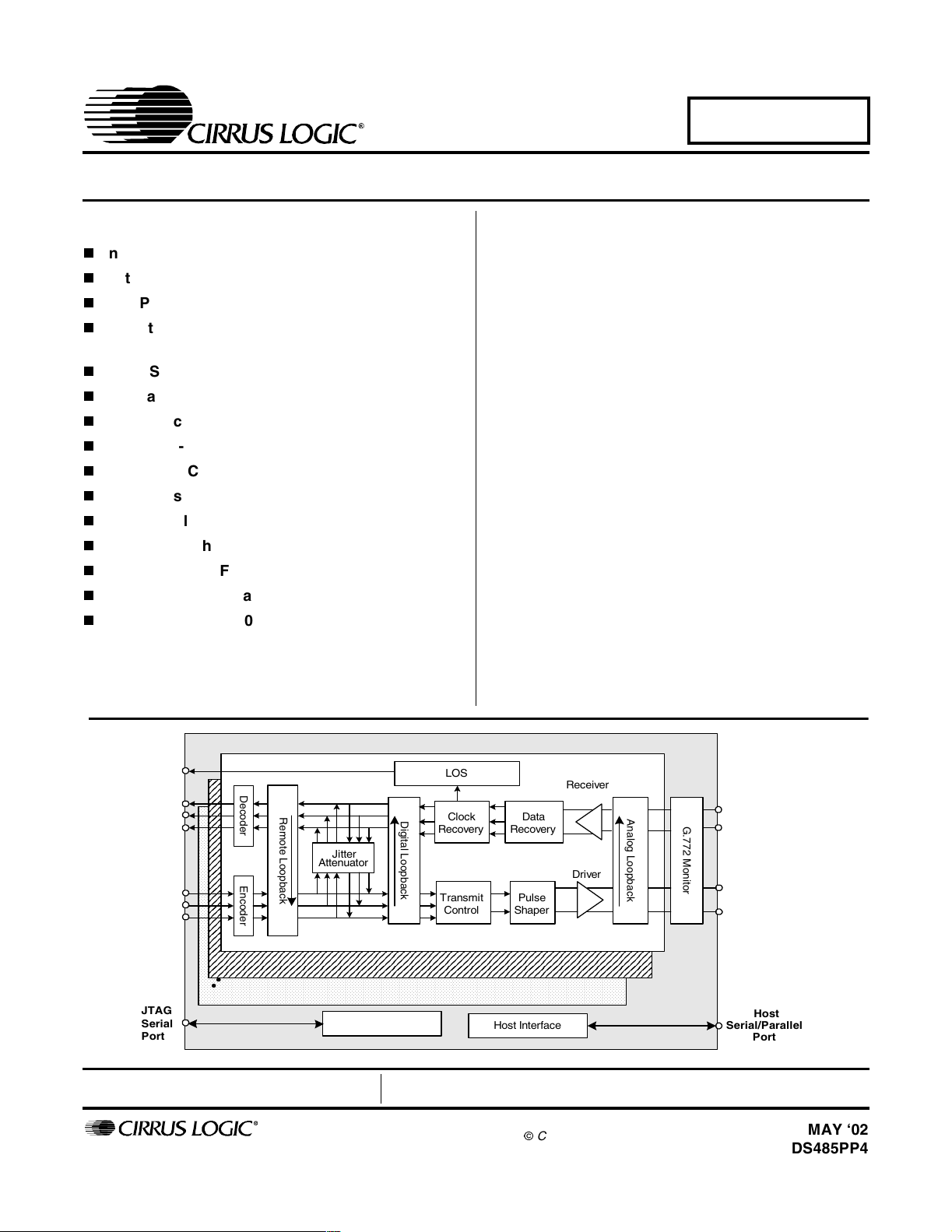

LOS

00000000000000000000000000000000000000000000000000000000000000000000000000

00000000000000000000000000000000000000000000000000000000000000000000000000

Decoder

00000000000000000000000000000000000000000000000000000000000000000000000000

RCLK

RPOS

RNEG

TCLK

TPOS

TNEG

00000000000000000000000000000000000000000000000000000000000000000000000000

00000000000000000000000000000000000000000000000000000000000000000000000000

000000000000000000000000000000000000000000000000000000000000000000

00000000000000000000000000000000000000000000000000000000000000000000000000

00000000000000000000000000000000000000000000000000000000000000000000000000

00000000000000000000000000000000000000000000000000000000000000000000000000

000000000000000000000000000000000000000000000000000000000000000000

00000000000000000000000000000000000000000000000000000000000000000000000000

00000000000000000000000000000000000000000000000000000000000000000000000000

00000000000000000000000000000000000000000000000000000000000000000000000000

000000000000000000000000000000000000000000000000000000000000000000

00000000000000000000000000000000000000000000000000000000000000000000000000

00000000000000000000000000000000000000000000000000000000000000000000000000

00000000000000000000000000000000000000000000000000000000000000000000000000

000000000000000000000000000000000000000000000000000000000000000000

00000000000000000000000000000000000000000000000000000000000000000000000000

00000000000000000000000000000000000000000000000000000000000000000000000000

00000000000000000000000000000000000000000000000000000000000000000000000000

000000000000000000000000000000000000000000000000000000000000000000

00000000000000000000000000000000000000000000000000000000000000000000000000

00000000000000000000000000000000000000000000000000000000000000000000000000

00000000000000000000000000000000000000000000000000000000000000000000000000

000000000000000000000000000000000000000000000000000000000000000000

00000000000000000000000000000000000000000000000000000000000000000000000000

00000000000000000000000000000000000000000000000000000000000000000000000000

00000000000000000000000000000000000000000000000000000000000000000000000000

000000000000000000000000000000000000000000000000000000000000000000

00000000000000000000000000000000000000000000000000000000000000000000000000

00000000000000000000000000000000000000000000000000000000000000000000000000

00000000000000000000000000000000000000000000000000000000000000000000000000

000000000000000000000000000000000000000000000000000000000000000000

00000000000000000000000000000000000000000000000000000000000000000000000000

00000000000000000000000000000000000000000000000000000000000000000000000000

00000000000000000000000000000000000000000000000000000000000000000000000000

000000000000000000000000000000000000000000000000000000000000000000

00000000000000000000000000000000000000000000000000000000000000000000000000

00000000000000000000000000000000000000000000000000000000000000000000000000

1

00000000000000000000000000000000000000000000000000000000000000000000000000

000000000000000000000000000000000000000000000000000000000000000000

0

Encoder

Remote Loopback

Jitter

Attenuator

7

JTAG

Serial

Port

JTAG Interface

Preliminary Product Information

P.O. Box 17847, Austin, Texas 78760

(512) 445 7222 FAX: (512) 445 7581

http://www.cirrus.com

LOS

Digital Loopback

Clock

Recovery

Recovery

Data

Receiver

Analog Loopback

G.772 Monitor

RTIP

RRING

Driver

Transmit

Control

Pulse

Shaper

Host Interface

This document contains information for a new product.

Cirrus Logic reserves the right to modify this product without notice.

CopyrightCirrus Logic, Inc. 2002

(All Rights Reserved)

TTIP

TRING

Host

Serial/Parallel

Port

DS485PP4

MAY ‘02

1

Page 2

CS61884

TABLE OF CONTENTS

1. PINOUT - LQFP ........................................................................................................................................ 7

2. PINOUT - FBGA ........................................................................................................................................ 8

3. PIN DESCRIPTIONS ................................................................................................................................. 9

3.1 Power Supplies .................................................................................................................................. 9

3.2 Control .............................................................................................................................................. 10

3.3 Address Inputs/Loopbacks ............................................................................................................... 14

3.4 Cable Select ..................................................................................................................................... 15

3.5 Status ............................................................................................................................................... 15

3.6 Digital Rx/Tx Data I/O ....................................................................................................................... 16

3.7 Analog RX/TX Data I/O .................................................................................................................... 19

3.8 JTAG Test Interface ......................................................................................................................... 21

3.9 Miscellaneous ................................................................................................................................... 21

4. OPERATION ........................................................................................................................................... 22

5. POWER-UP ............................................................................................................................................. 22

6. MASTER CLOCK .................................................................................................................................... 22

7. G.772 MONITORING ............................................................................................................................... 22

8. BUILDING INTEGRATED TIMING SYSTEMS (BITS) CLOCK MODE .................................................. 23

9. TRANSMITTER ....................................................................................................................................... 24

9.1 Bipolar Mode .................................................................................................................................... 25

9.2 Unipolar Mode .................................................................................................................................. 25

9.3 RZ Mode ........................................................................................................................................... 25

9.4 Transmitter Powerdown / High-Z ...................................................................................................... 25

9.5 Transmit All Ones (TAOS) ................................................................................................................ 25

9.6 Automatic TAOS ............................................................................................................................... 26

9.7 Driver Failure Monitor ....................................................................................................................... 26

9.8 Driver Short Circuit Protection .......................................................................................................... 26

10. RECEIVER ............................................................................................................................................ 26

10.1 Bipolar Output Mode ...................................................................................................................... 26

10.2 Unipolar Output Mode .................................................................................................................... 26

10.3 RZ Output Mode ............................................................................................................................. 27

10.4 Receiver Powerdown/High-Z .......................................................................................................... 27

Contacting Cirrus Logic Support

For a complete listing of Direct Sales, Distributor, and Sales Representative contacts, visit the Cirrus Logic web site at:

http://www.cirrus.com/corporate/contacts/sales.cfm

IMPORTANT NOTICE

"Preliminary" product inf ormation describes products that are in production, but for which full characterization data is not yet available. "Advance" product inf ormation describes products that are i n development and subject to development changes. Cirrus Logic, I nc. and its subsidiaries ("Cirrus") believe that the information contained in this document is accurate and reliable. However, the information is subject to change without notice and is provided "AS IS" without warranty

of any kind (express or implied). Customers are advised to obtain the latest version of relevant information to verify, before placing orders, that information being

relied on is current and complete. All products are sold subject to the terms and conditions of sale supplied at the time of order acknowledgment, including those

pertaining to warranty, patent infringement, and l imitation of liability. No responsibil ity is assumed by Ci rrus f or the use of this information, including use of this

information as the basis for manufacture or sale of any items, or for i nfringement of patents or other rights of third parties. This document is the property of Cir rus

and by furnishi ng this information, Cirrus grants no license, express or implied under any patents, mask work rights, copyrights, trademarks, trade secrets or

other intellectual property rights. Cirr us owns the copyrights of the i nformation contained herein and gives consent for copies to be made of the information only

for use within your or ganization with respect to Cirrus integrated circui ts or ot her parts of Cir rus. This consent does not ext end to other copying such as copying

for general distribution, advertising or pr omotional purposes, or for creating any work for resale.

An export permit needs to be obtained from the competent authorities of the Japanese Government if any of the products or technologies described in thismaterial and controll ed under the "Foreign Exchange and Forei gn Trade Law" i s to be exported or taken out of Japan. An export l icense and/or quota needs to be

obtained from the competent authorities of the Chinese Government if any of the products or technologies describe d in this material is subject to the PRC Foreign

Trade Law and i s to be exported or taken out of the PRC.

CERTAIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF DEATH, PERSONAL INJURY, OR SEVERE

PROPERTY OR ENVIRONMENTAL DAMAGE ("CRITICAL APPLICATIONS"). CIRRUS PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER CRITICAL APPLICATIONS. INCLUSION OF CIRRUS PRODUCTS

IN SUCH APPLICATIONS IS UNDERSTOOD TO BE FULLY AT THE CUSTOMER'S RISK.

Cirrus Logic, Cirrus, and the Ci rrus Logi c logo designs are trademarks of Cirrus Logic, Inc. All other brand and product names in thi s document may be trademarks or service marks of their respective owners.

2 DS485PP4

Page 3

CS61884

10.5 Loss-of-Signal (LOS) .......................................................................................................................27

10.6 Alarm Indication Signal (AIS) ..........................................................................................................28

11. JITTER ATTENUATOR .........................................................................................................................28

12. OPERATIONAL SUMMARY ..................................................................................................................29

12.1 Loopbacks .......................................................................................................................................29

12.2 Analog Loopback ............................................................................................................................29

12.3 Digital Loopback ..............................................................................................................................30

12.4 Remote Loopback ...........................................................................................................................30

13. HOST MODE ..........................................................................................................................................32

13.1 SOFTWARE RESET ....................................................................................................................... 32

13.2 Serial Port Operation .......................................................................................................................32

13.3 Parallel Port Operation ....................................................................................................................33

13.4 Register Set ....................................................................................................................................34

14. REGISTER DESCRIPTIONS .................................................................................................................35

14.1 Revision/IDcode Register (00h) ......................................................................................................35

14.2 Analog Loopback Register (01h) .....................................................................................................35

14.3 Remote Loopback Register (02h) ...................................................................................................35

14.4 TAOS Enable Register (03h) ..........................................................................................................35

14.5 LOS Status Register (04h) ..............................................................................................................35

14.6 DFM Status Register (05h) .............................................................................................................35

14.7 LOS Interrupt Enable Register (06h) ...............................................................................................36

14.8 DFM Interrupt Enable Register (07h) ..............................................................................................36

14.9 LOS Interrupt Status Register (08h) ................................................................................................36

14.10 DFM Interrupt Status Register (09h) .............................................................................................36

14.11 Software Reset Register (0Ah) .....................................................................................................36

14.12 Performance Monitor Register (0Bh) ............................................................................................36

14.13 Digital Loopback Reset Register (0Ch) .........................................................................................37

14.14 LOS/AIS Mode Enable Register (0Dh) ..........................................................................................37

14.15 Automatic TAOS Register (0Eh) ...................................................................................................37

14.16 Global Control Register (0Fh) .......................................................................................................38

14.17 Line Length Channel ID Register (10h) .........................................................................................38

14.18 Line Length Data Register (11h) ...................................................................................................39

14.19 Output Disable Register (12h) .......................................................................................................39

14.20 AIS Status Register (13h) ............................................................................................................. 39

14.21 AIS Interrupt Enable Register (14h) ..............................................................................................39

14.22 AIS Interrupt Status Register (15h) ...............................................................................................40

14.23 AWG Broadcast Register (16h) .....................................................................................................40

14.24 AWG Phase Address Register (17h) ............................................................................................40

14.25 AWG Phase Data Register (18h) ..................................................................................................40

14.26 AWG Enable Register (19h) ..........................................................................................................40

14.27 AWG Overflow Interrupt Enable Register (1Ah) ............................................................................41

14.28 AWG Overflow Interrupt Status Register (1Bh) .............................................................................41

14.29 JA Error Interrupt Enable Register (1Ch) ......................................................................................41

14.30 JA Error Interrupt Status Register (1Dh) .......................................................................................41

14.31 Bits Clock Enable Register (1Eh) ..................................................................................................41

14.32 Reserved Register (1Fh) ...............................................................................................................41

14.33 Status Registers ............................................................................................................................42

14.33.1 Interrupt Enable Registers ...................................................................................................42

14.33.2 Interrupt Status Registers ....................................................................................................42

15. ARBITRARY WAVEFORM GENERATOR ............................................................................................43

16. JTAG SUPPORT ....................................................................................................................................45

16.1 TAP Controller .................................................................................................................................45

16.1.1 JTAG Reset ...........................................................................................................................45

DS485PP4 3

Page 4

CS61884

16.1.2 Test-Logic-Reset ................................................................................................................... 45

16.1.3 Run-Test-Idle ........................................................................................................................ 45

16.1.4 Select-DR-Scan .................................................................................................................... 46

16.1.5 Capture-DR ........................................................................................................................... 46

16.1.6 Shift-DR ................................................................................................................................ 46

16.1.7 Exit1-DR ................................................................................................................................ 46

16.1.8 Pause-DR ............................................................................................................................. 46

16.1.9 Exit2-DR ................................................................................................................................ 46

16.1.10 Update-DR .......................................................................................................................... 46

16.1.11 Select-IR-Scan .................................................................................................................... 47

16.1.12 Capture-IR .......................................................................................................................... 47

16.1.13 Shift-IR ................................................................................................................................ 47

16.1.14 Exit1-IR ............................................................................................................................... 47

16.1.15 Pause-IR ............................................................................................................................. 47

16.1.16 Exit2-IR ............................................................................................................................... 47

16.1.17 Update-IR ........................................................................................................................... 47

16.2 Instruction Register (IR) ................................................................................................................. 47

16.2.1 EXTEST ................................................................................................................................ 47

16.2.2 SAMPLE/PRELOAD ............................................................................................................. 47

16.2.3 IDCODE ................................................................................................................................ 47

16.2.4 BYPASS ............................................................................................................................... 47

16.3 Device ID Register (IDR) ................................................................................................................ 48

17. BOUNDARY SCAN REGISTER (BSR) ................................................................................................ 48

18. APPLICATIONS .................................................................................................................................... 51

18.1 Transformer specifications ............................................................................................................. 53

18.2 Crystal Oscillator Specifications ..................................................................................................... 53

18.3 Designing for AT&T 62411 ............................................................................................................. 53

18.4 Line Protection ............................................................................................................................... 53

19. CHARACTERISTICS AND SPECIFICATIONS ..................................................................................... 54

19.1 Absolute Maximum Ratings ............................................................................................................ 54

19.2 Recommended Operating Conditions ............................................................................................ 54

19.3 Digital Characteristics ..................................................................................................................... 55

19.4 Transmitter Analog Characteristics ................................................................................................ 55

19.5 Receiver Analog Characteristics .................................................................................................... 56

19.6 Jitter Attenuator Characteristics ..................................................................................................... 57

19.7 Master Clock Switching Characteristics .........................................................................................59

19.8 Transmit Switching Characteristics ................................................................................................ 59

19.9 Receive Switching Characteristics ................................................................................................. 59

19.10 Switching Characteristics - Serial Port ......................................................................................... 61

19.11 Switching Characteristics - Parallel Port (Multiplexed Mode) ...................................................... 62

19.12 Switching Characteristics- Parallel Port (Non-multiplexed Mode) ............................................... 65

19.13 Switching Characteristics - JTAG ................................................................................................. 68

20. COMPLIANT RECOMMENDATIONS AND SPECIFICATIONS ........................................................... 69

21. FBGA PACKAGE DIMENSIONS .......................................................................................................... 70

22. LQFP PACKAGE DIMENSIONS ..................................................................................................... 71

4 DS485PP4

Page 5

CS61884

LIST OF FIGURES

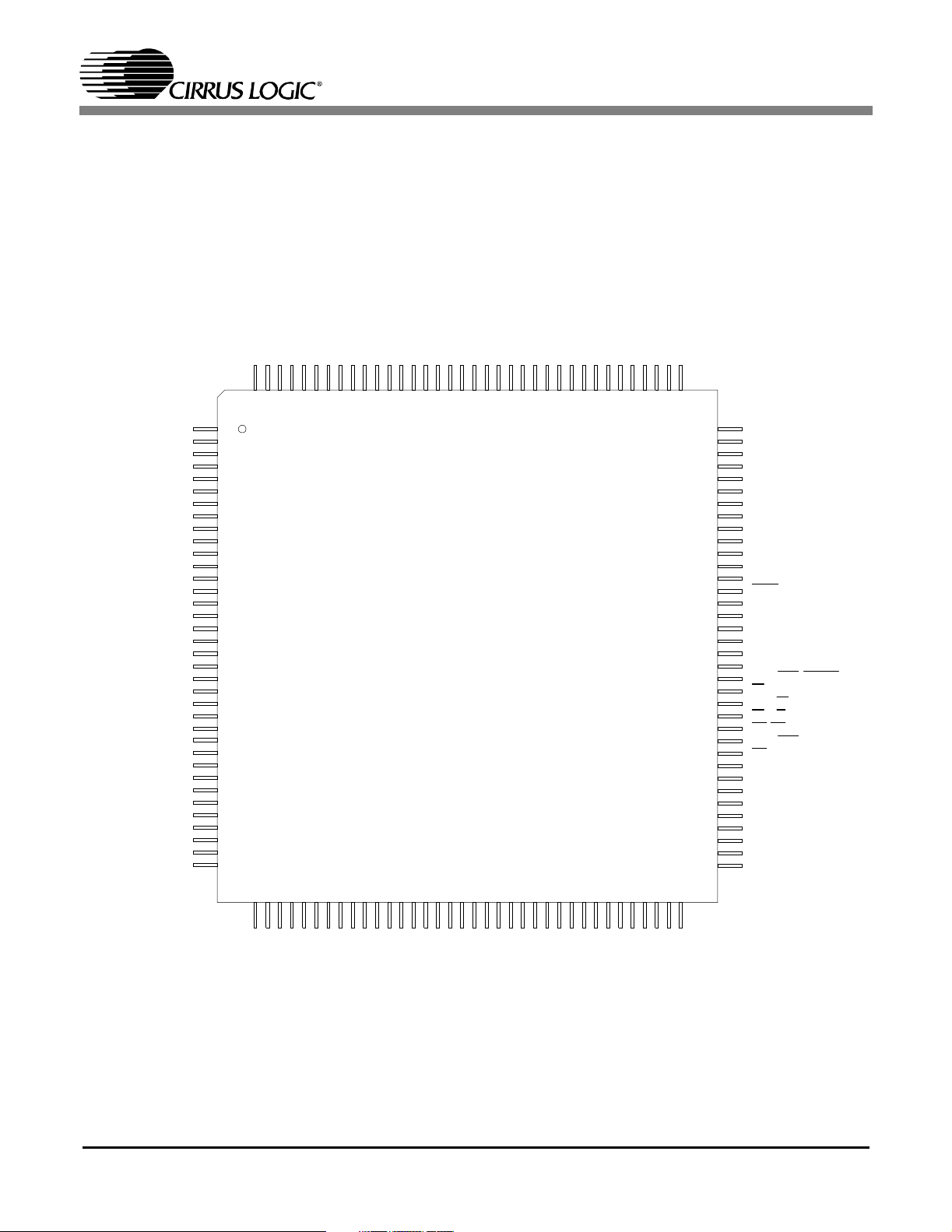

Figure 1. CS61884 144-Pin Outs ....................................................................................................... 7

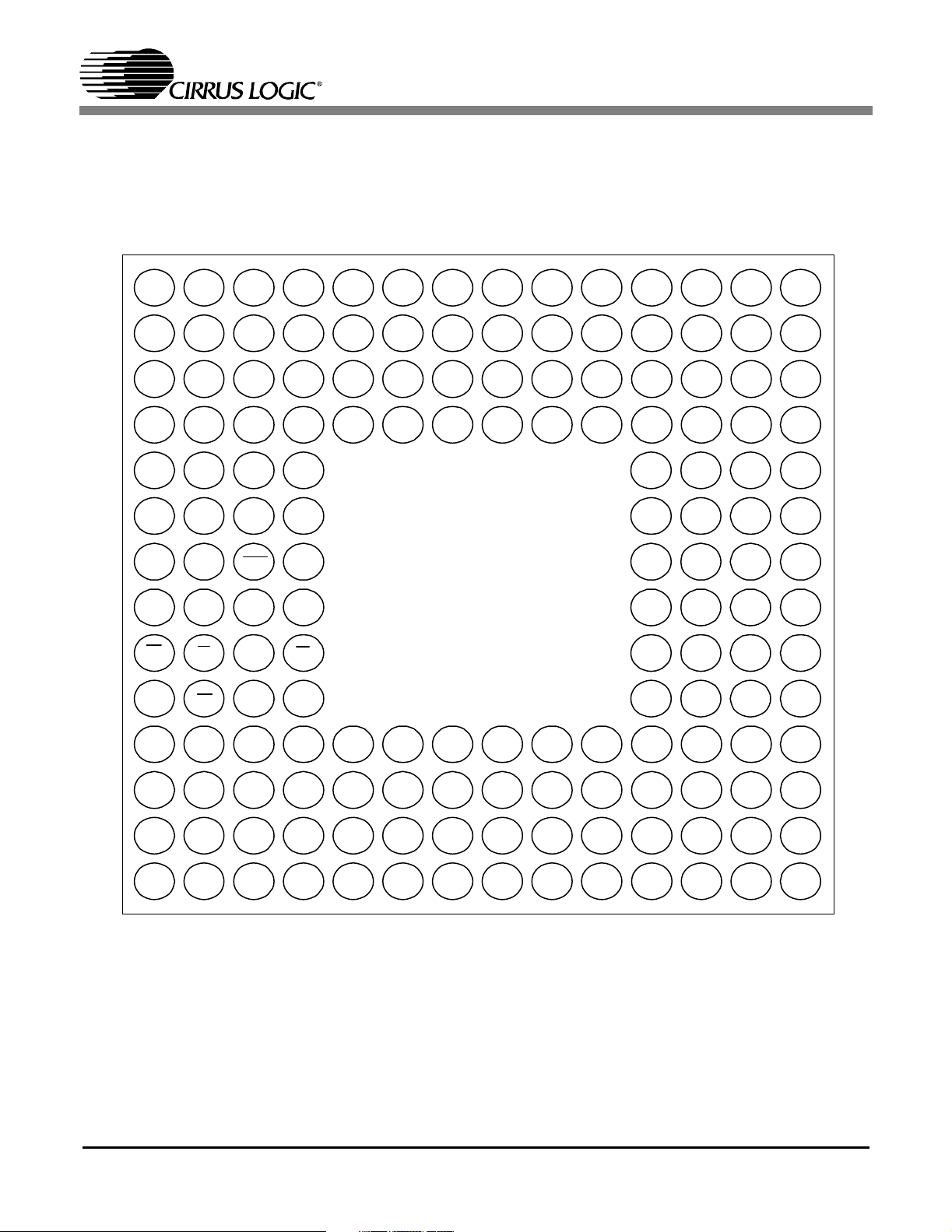

Figure 2. CS61884 160-Ball FBGA Pin Outs .................................................................................... 8

Figure 3. G.703 BITS Clock Mode in NRZ Mode .......................................................................... 23

Figure 4. G.703 BITS Clock Mode in RZ Mode ............................................................................. 23

Figure 5. G.703 BITS Clock Mode in Remote Loopback ............................................................... 23

Figure 6. Pulse Mask at T1/J1 Interface .......................................................................................... 24

Figure 7. Pulse Mask at E1 Interface .............................................................................................. 24

Figure 8. Analog Loopback Block Diagram .................................................................................... 30

Figure 9. Analog Loopback with TAOS Block Diagram ................................................................ 30

Figure 10. Digital Loopback Block Diagram .................................................................................. 31

Figure 11. Digital Loopback with TAOS ........................................................................................ 31

Figure 12. Remote Loopback Block Diagram ................................................................................. 31

Figure 13. Serial Read/Write Format (SPOL = 0) ........................................................................... 33

Figure 14. Arbitrary Waveform UI .................................................................................................. 43

Figure 15. Test Access Port Architecture ........................................................................................ 45

Figure 16. TAP Controller State Diagram ....................................................................................... 46

Figure 17. Internal RX/TX Impedance Matching ............................................................................ 51

Figure 18. Internal TX, External RX Impedance Matching ............................................................ 52

Figure 19. Jitter Transfer Characteristic vs. G.736, TBR 12/13 & AT&T 62411 ........................... 58

Figure 20. Jitter Tolerance Characteristic vs. G.823 & AT&T 62411 ............................................ 58

Figure 21. Recovered Clock and Data Switching Characteristics ................................................... 60

Figure 22. Transmit Clock and Data Switching Characteristics ...................................................... 60

Figure 23. Signal Rise and Fall Characteristics ............................................................................... 60

Figure 24. Serial Port Read Timing Diagram .................................................................................. 61

Figure 25. Serial Port Write Timing Diagram ................................................................................. 61

Figure 26. Parallel Port Timing - Write; Intel Multiplexed Address / Data Bus Mode ................... 63

Figure 27. Parallel Mode Port Timing - Read; Intel Multiplexed Address / Data Bus Mode ........ 63

Figure 28. Parallel Port Timing - Write in Motorola Multiplexed Address / Data Bus .................. 64

Figure 29. Parallel Port Timing - Read in Motorola Multiplexed Address / Data Bus ................... 64

Figure 30. Parallel Port Timing - Write in Intel Non-Multiplexed Address / Data Bus Mode ....... 66

Figure 31. Parallel Port Timing - Read in Intel Non-Multiplexed Address / Data Bus Mode ........ 66

Figure 32. Parallel Port Timing - Write in Motorola Non-Multiplexed Address / Data Bus Mode 67

Figure 33. Parallel Port Timing - Read in Motorola Non-Multiplexed Address / Data Bus Mode . 67

Figure 34. JTAG Switching Characteristics .................................................................................... 68

DS485PP4 5

Page 6

CS61884

LIST OF TABLES

Table 1. Operation Mode Selection ................................................................................................. 10

Table 2. Mux/Bits Clock Selection .................................................................................................. 11

Table 3. Cable Impedance Selection ................................................................................................ 15

Table 4. G.772 Address Selection ....................................................................................................22

Table 5. Hardware Mode Line Length Configuration Selection ...................................................... 25

Table 6. Jitter Attenuator Configurations .........................................................................................28

Table 7. Operational Summary ........................................................................................................ 29

Table 8. Host Control Signal Descriptions ...................................................................................... 32

Table 9. Host Mode Register Set ..................................................................................................... 34

Table 10. JTAG Instructions ............................................................................................................ 47

Table 11. Boundary Scan Register ................................................................................................... 48

Table 12. Transformer Specifications .............................................................................................. 53

6 DS485PP4

Page 7

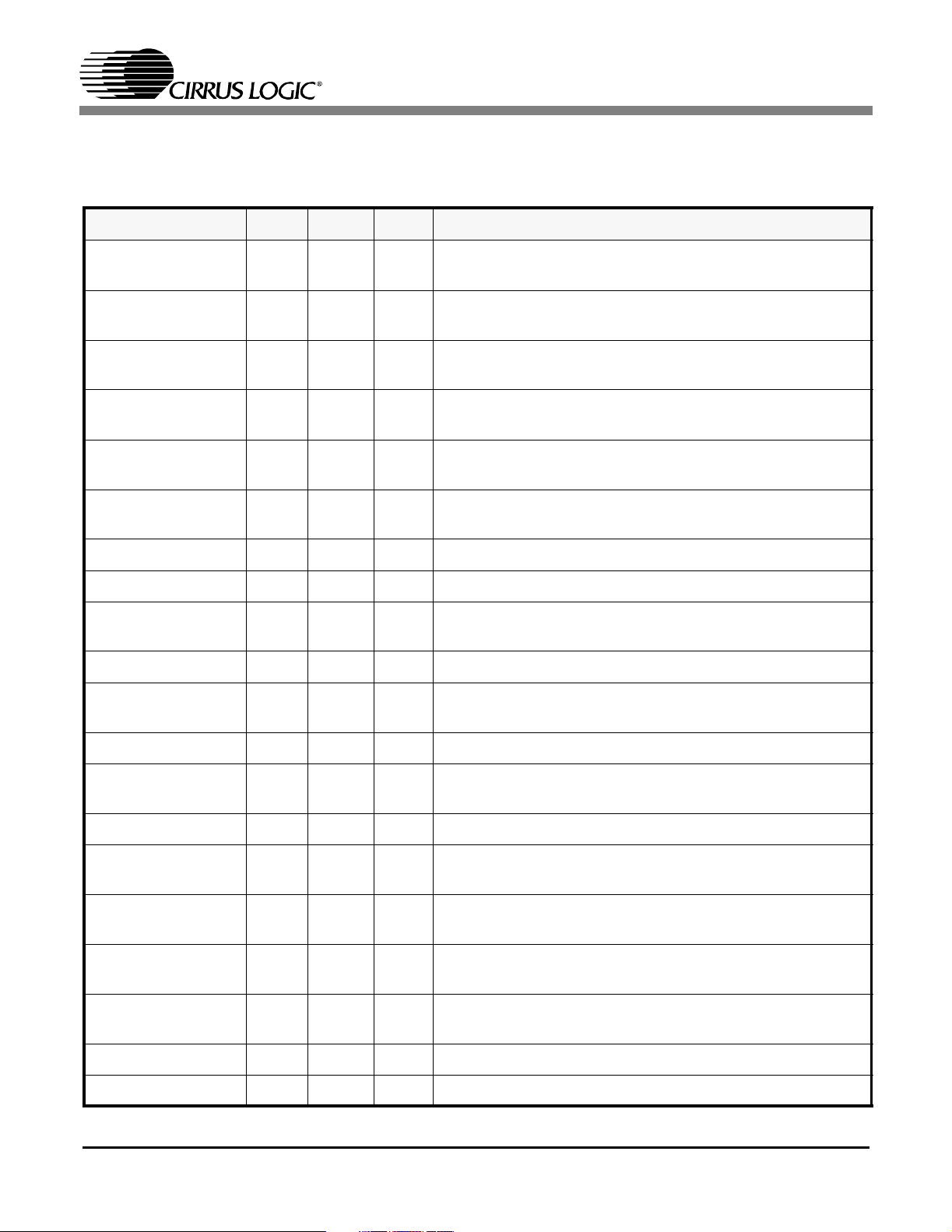

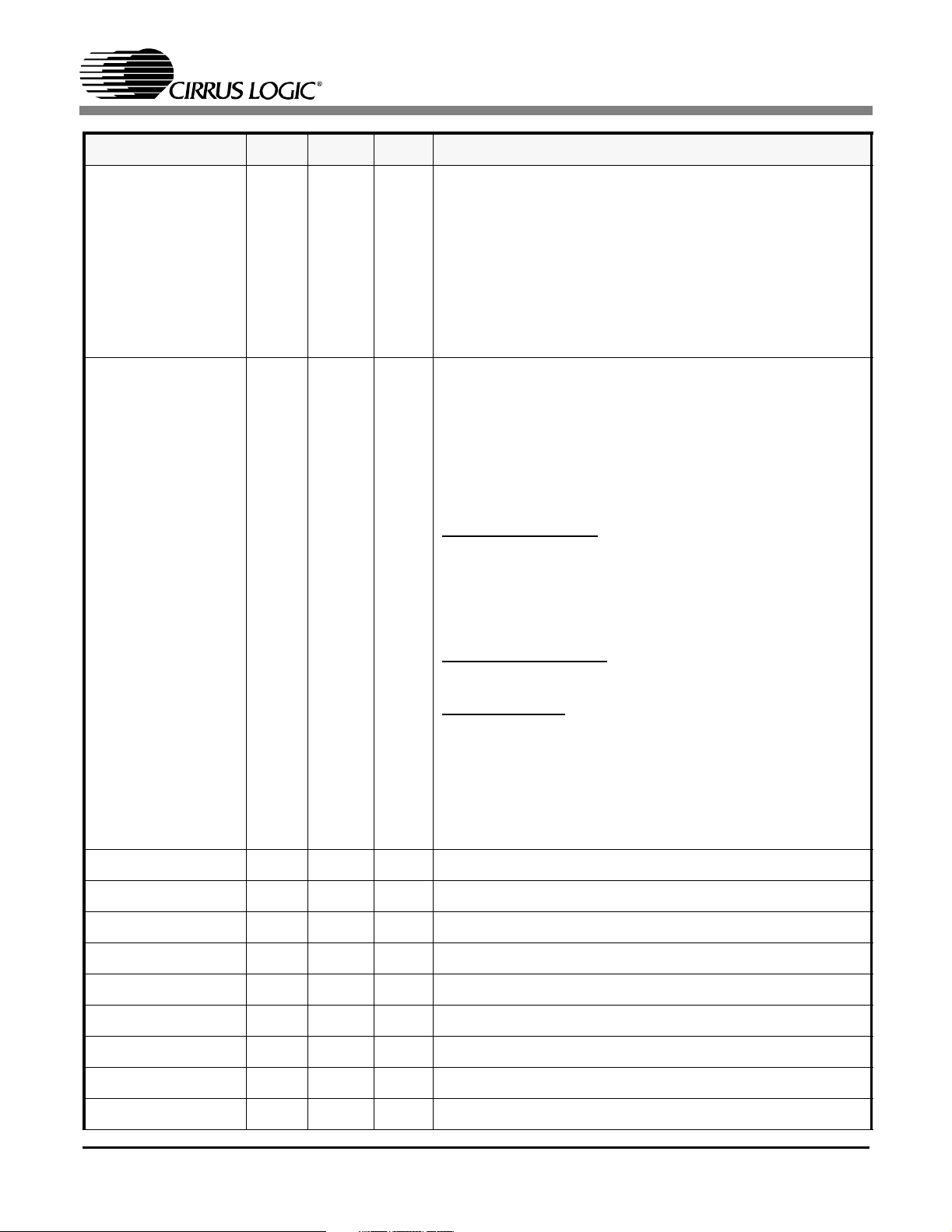

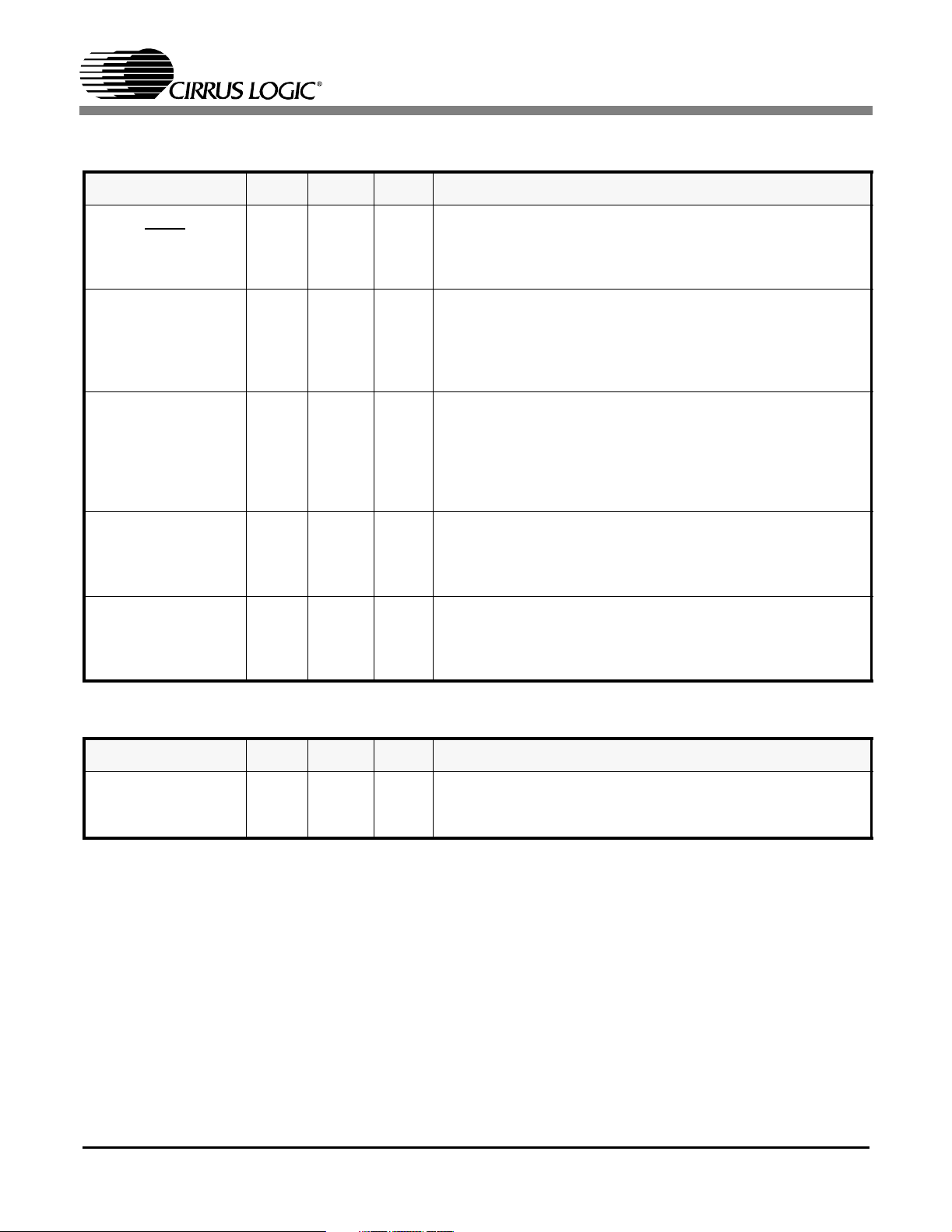

1. PINOUT - LQFP

TPOS7/TDATA7

TCLK7

LOS6

RNEG6/BPV6

RPOS6/RDATA6

RCLK6

TNEG6/UBS6

TPOS6/TDATA6

TCLK6

MCL K

MOD E

A4

A3

A2

A1

A0

VCCIO

GNDIO

RV0+

RGND0

LOOP0/D0

LOOP1/D1

LOOP2/D2

LOOP3/D3

LOOP4/D4

LOOP5/D5

LOOP6/D6

LOOP7/D7

TCLK1

TPOS1/TDATA1

TNEG1/UBS1

RCLK1

RPOS1/RDATA1

RNEG1/BPV1

LOS1

TCLK0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

TNEG7/UBS7

144

RCLK7

RPOS7/RDATA7

143

142

CS61884

RNEG7/BPV7

LOS7

RTIP7

RRING7

TV+7

TTIP7

TRING7

TGND7

RRING6

RTIP6

TGND6

TRING6

TTIP6

TV+6

RTIP5

RRING5

TV+5

TTIP5

TRING5

TGND5

RRING4

RTIP4

TGND4

TRING4

TTIP4

TV+4

CLKE

TXOE

LOS4

RNEG4/BPV4

RPOS4/RDATA4

RCLK4

TNEG4/UBS4

118

116

115

140

139

138

137

136

141

135

134

133

132

131

130

129

127

126

125

124

123

122

120

128

121

119

CS6188 4

144-Pin

LQFP

(Top View)

117

114

113

112

111

110

109

108

107

106

105

104

103

102

101

100

99

98

97

96

95

94

93

92

91

90

89

88

87

86

85

84

83

82

81

80

79

78

77

76

75

74

73

TPOS4/TDATA4

TCLK4

LOS5

RNEG5/BPV5

RPOS5/RDATA5

RCLK5

TNEG5/UBS5

TPOS5/TDATA5

TCLK5

TDI

TDO

TCK

TMS

TRST

REF

CBLSEL

VCCIO

GNDIO

RV1+

RGND1

INTL/MOT/CODEN

CS/JASEL

ALE/AS/SCLK/LEN2

RD/RW/LEN1

WR/DS/SDI/LEN0

RDY/ACK/SDO

INT

TCLK2

TPOS2/TDATA2

TNEG2/UBS2

RCLK2

RPOS2/RDATA2

RNEG2/BPV2

LOS2

TCLK3

TPOS3/TDATA3

37

3839414243

40

RCLK0

TNEG0/USB0

TPOS0/TDATA0

RPOS0/RDATA0

47

444546

TV+0

LOS0

RNEG0/BPV0

MUX/BITSEN0

484950

TTIP0

RTIP0

TGND0

TRING0

525354

51

TGND1

TRING1

RRING0

TV+1

TTIP1

5556575859

TV+2

RTIP1

RRING1

TTIP2

61

60

RTIP2

TGND2

TRING2

RRING2

626364

TGND3

TRING3

TTIP3

65

TV+3

66

67

RTIP3

RRING3

6869707172

LOS3

RCLK3

RNEG3/RBPV3

RPOS3/RDATA3

TNEG3/UBS3

Figure 1. CS61884 144-Pin Outs

DS485PP4 7

Page 8

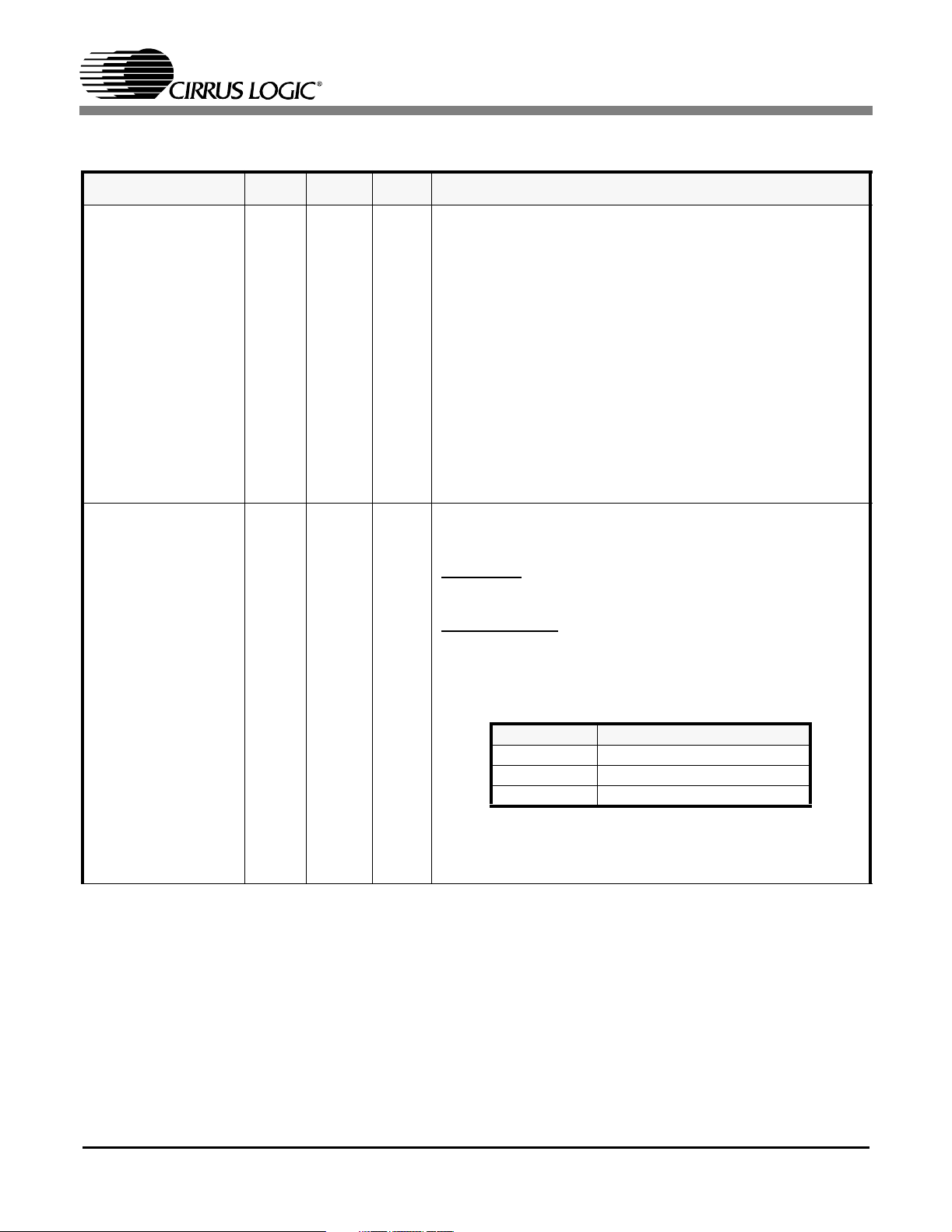

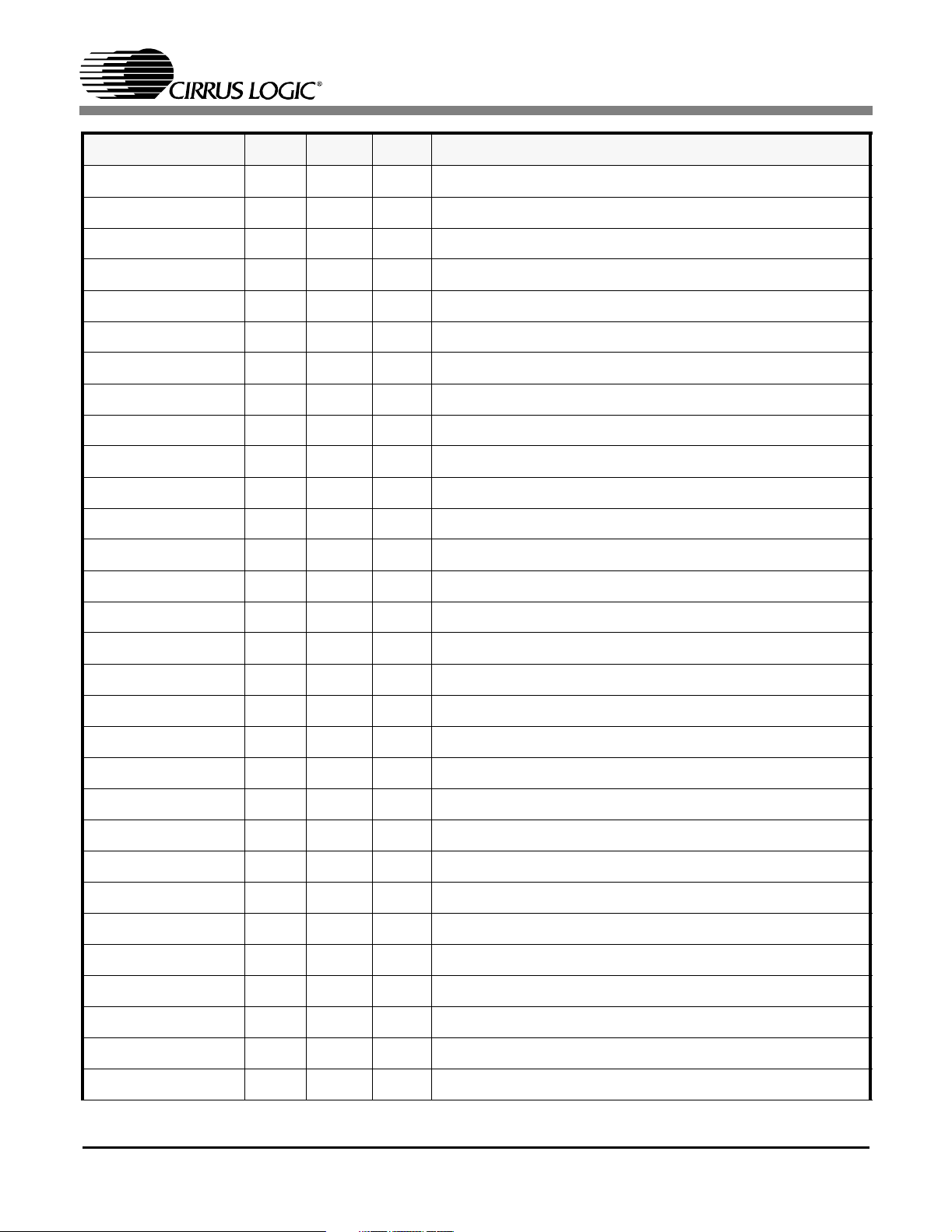

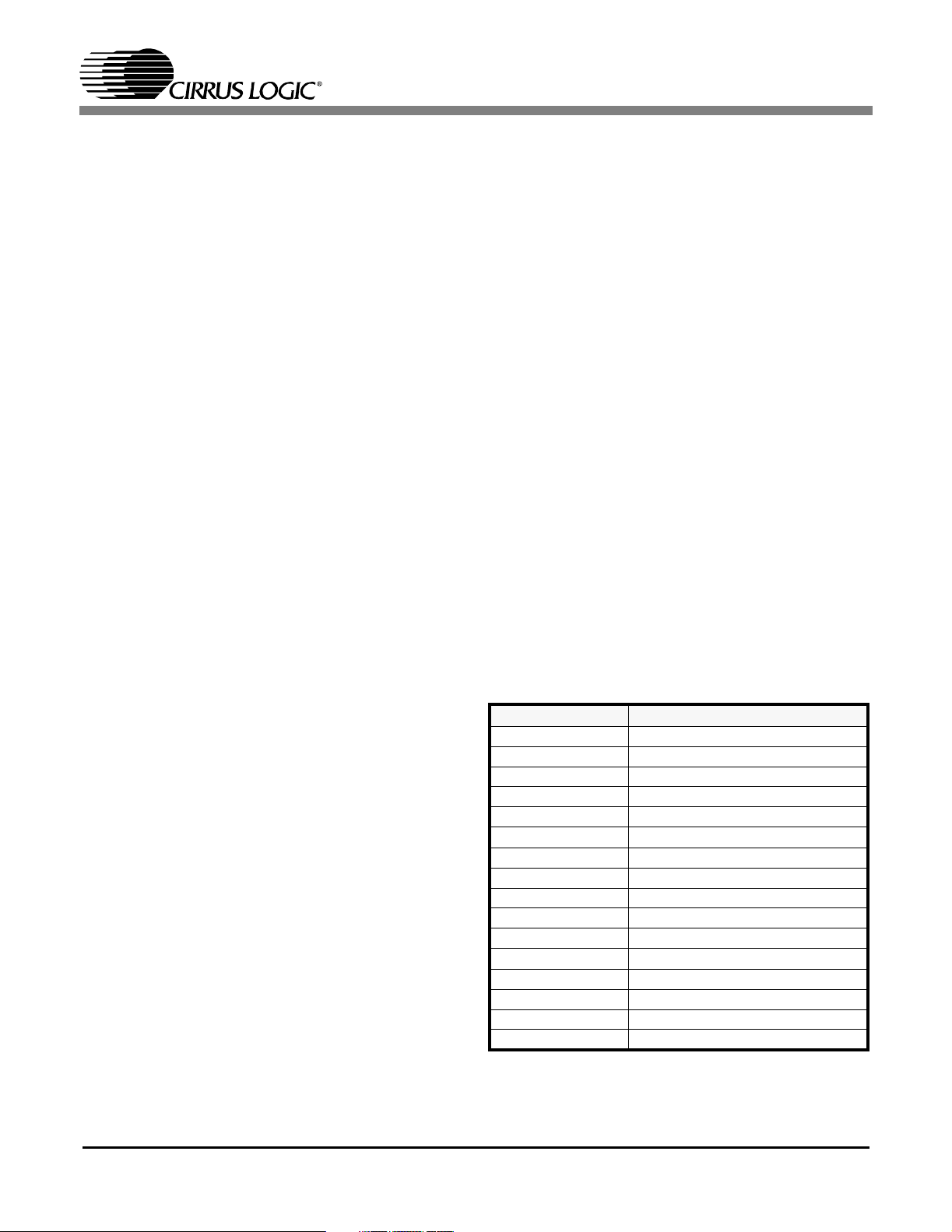

2. PINOUT - FBGA

CS61884

1234567891011121314

G

4

4

5

5

TCK

RPOS

TPOS

RPOS

TPOS

CLKE

CBLSEL

RCLK

A

TCLK

B

RCLK

C

TCLK

D

E

TXOE

F

VCCIO

4

4

5

5

TDO

RNEG

TNEG

RNEG

TNEG

TRST

4

4

5

5

LOS

TDI

TVCC

TVCC

TVCC

TVCC

5

GNDIO

4

4

5

5

LOS

4

TMS

TRING

4

TTIP

4

TRING

5

TTIP

5

TGND

4

TGND

4

TGND

5

TGND

5

RTIP

RRING

RTIP

RRING

RTIP

4

4

5

5

7

RRING

7

RTIP

6

RRING

6

CS61884

TGND

7

TGND

7

TGND

6

TGND

6

TRING

TTIP

TRING

TTIP

TVCC

7

TVCC

7

TVCC

6

TVCC

6

GNDIO

7

6

6

LOS

7

A4

RNEG

7

TNEG

RNEG

TNEG

LOS

A3

A0

RPOS

7

TPOS

7

RPOS

6

TPOS

6

MODE

6

LOOP

RCLK

7

TCLK

7

RCLK

6

TCLK

6

MCLK

A2

A1

VCCIO

0

A

7

B

7

C

6

D

6

E

F

G

160 FBGA

RGND

INTL

ALE

LOS

2

CS

LOS

1

3

(Bottom View)

WR

REF

RD

INT

RV1+

H

J

RDY

K

RGND

0

LOOP

3

LOS

0

LOOP

1

LOOP

4

LOS

1

LOOP

2

LOOP

5

MUX

RV0+

LOOP

6

LOOP

7

H

J

K

TVCC

2

TVCC

2

TVCC

3

TVCC

3

TTIP

2

TRING

2

TTIP

3

TRING

3

TGND

2

TGND

2

TGND

3

TGND

3

RRING

2

2

RRING

3

3

2

RTIP

2

3

RTIP

3

RRING

1

RTIP

1

RRING

0

RTIP

0

TGND

1

TGND

1

TGND

0

TGND

0

TTIP

1

TRING

1

TTIP

0

TRING

0

TVCC

1

TVCC

1

TVCC

0

TVCC

0

TNEG

1

RNEG

1

TNEG

0

RNEG

0

TPOS

1

RPOS

1

TPOS

0

RPOS

0

TCLK

1

RCLK

1

TCLK

0

RCLK

0

L

M

N

P

M

TCLK

L

RCLK

TCLK

N

RCLK

P

TPOS

2

RPOS

2

TPOS

3

RPOS

3

TNEG

2

RNEG

2

TNEG

3

RNEG

3

1234567891011121314

Figure 2. CS61884 160-Ball FBGA Pin Outs

8 DS485PP4

Page 9

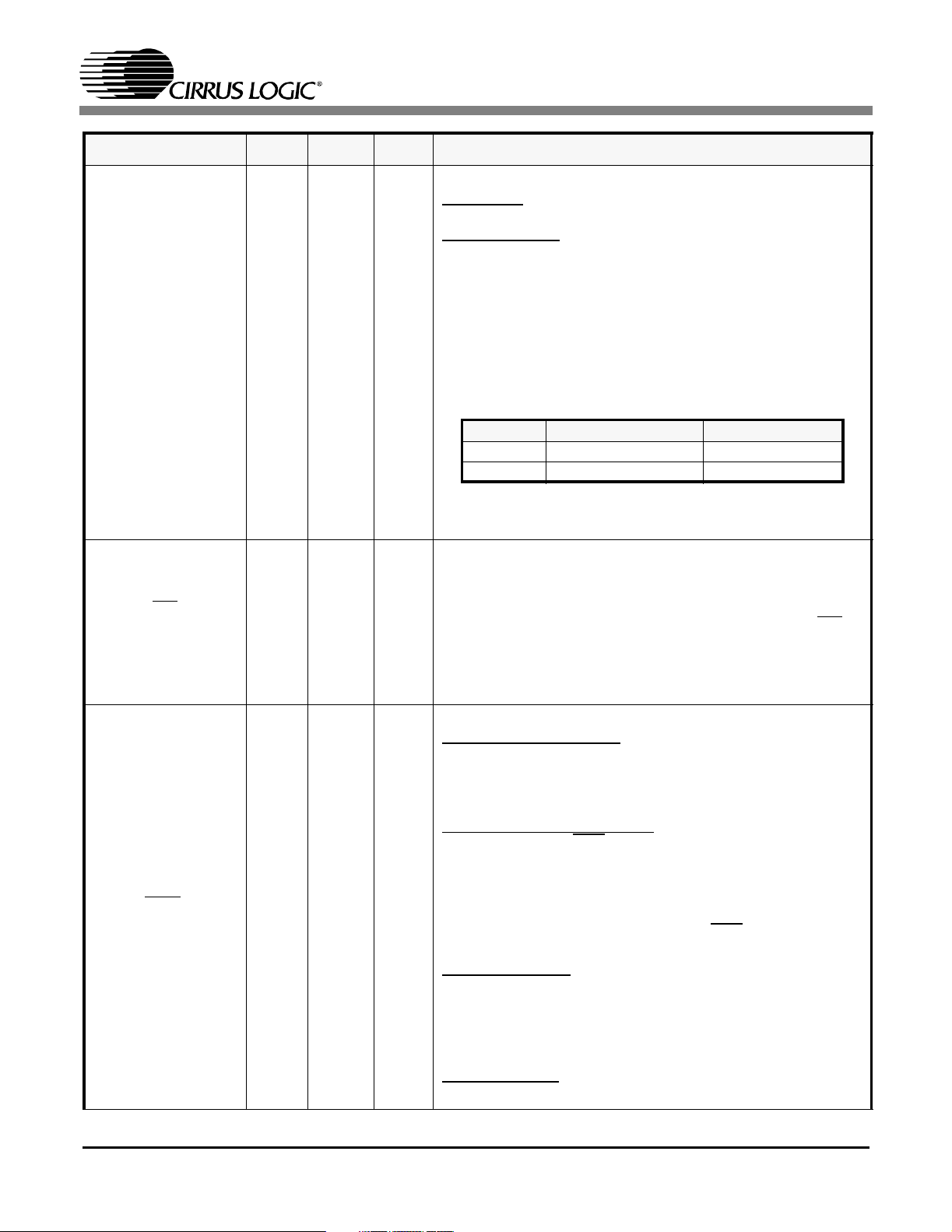

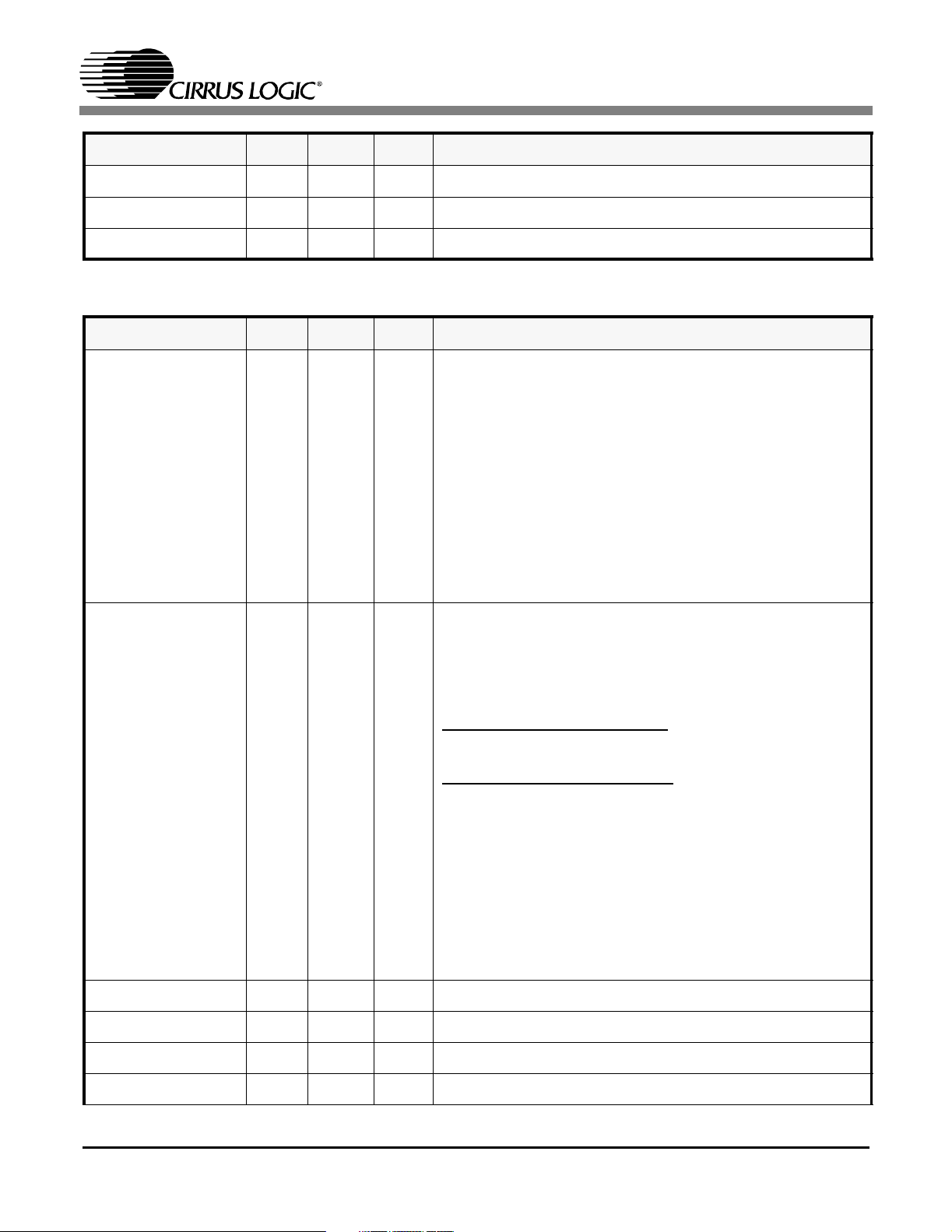

3. PIN DESCRIPTIONS

3.1 Power Supplies

SYMBOL LQFP FBGA TYPE DESCRIPTION

CS61884

17

VCCIO

GNDIO 18

RV0+

RV1+

RGND0

RGND1

TV+0 44 N4, P4 Power Supply, Transmit Driver 0

TGND0 47 N6, P6 Ground, Transmit Driver 0

TV+1 53 L4, M4 Power Supply, Transmit Driver 1

TGND1 50 L6, M6 Ground, Transmit Driver 1

TV+2 56 L11

TGND2 59 L9, M9 Ground, Transmit Driver 2

TV+3 65 N11

92

91

19

90

20

89

G1

G14

G4

G11

H1

H14

H4

H11

M11

P11

Power Supply, Digital Interface: Power supply for digital

interface pins; typically 3.3V.

Ground, Digital Interface:

Power supply ground for the digital interface; typically 0 Volts

Power Supply, Core Circuitry: Power supply for all sub-circuits except the transmit driver; typically +3.3 Volts

Ground, Core Circuitry:

Ground for sub-circuits except the TX driver; typically 0 Volts

Power supply for transmit driver 0; typically +3.3 Volts

Power supply ground for transmit driver 0; typically 0 Volts

Power Supply, Transmit Driver 2

Power Supply, Transmit Driver 3

TGND3 62 N9, P9 Ground, Transmit Driver 3

TV +4 116 A11

B11

TGND4 119 A9, B9 Ground, Transmit Driver 4

TV+5 125 C11

D11

TGND5 122 C9,

D9

TV+6 128 C4,

D4

TGND6 131 C6,

D6

TV+7 137 A4, B4 Power Supply, Transmit Driver 7

TGND7 134 A6, B6 Ground, Transmit Driver 7

DS485PP4 9

Power Supply, Transmit Driver 4

Power Supply, Transmit Driver 5

Ground, Transmit Driver 5

Power Supply, Transmit Driver 6

Ground, Transmit Driver 6

Page 10

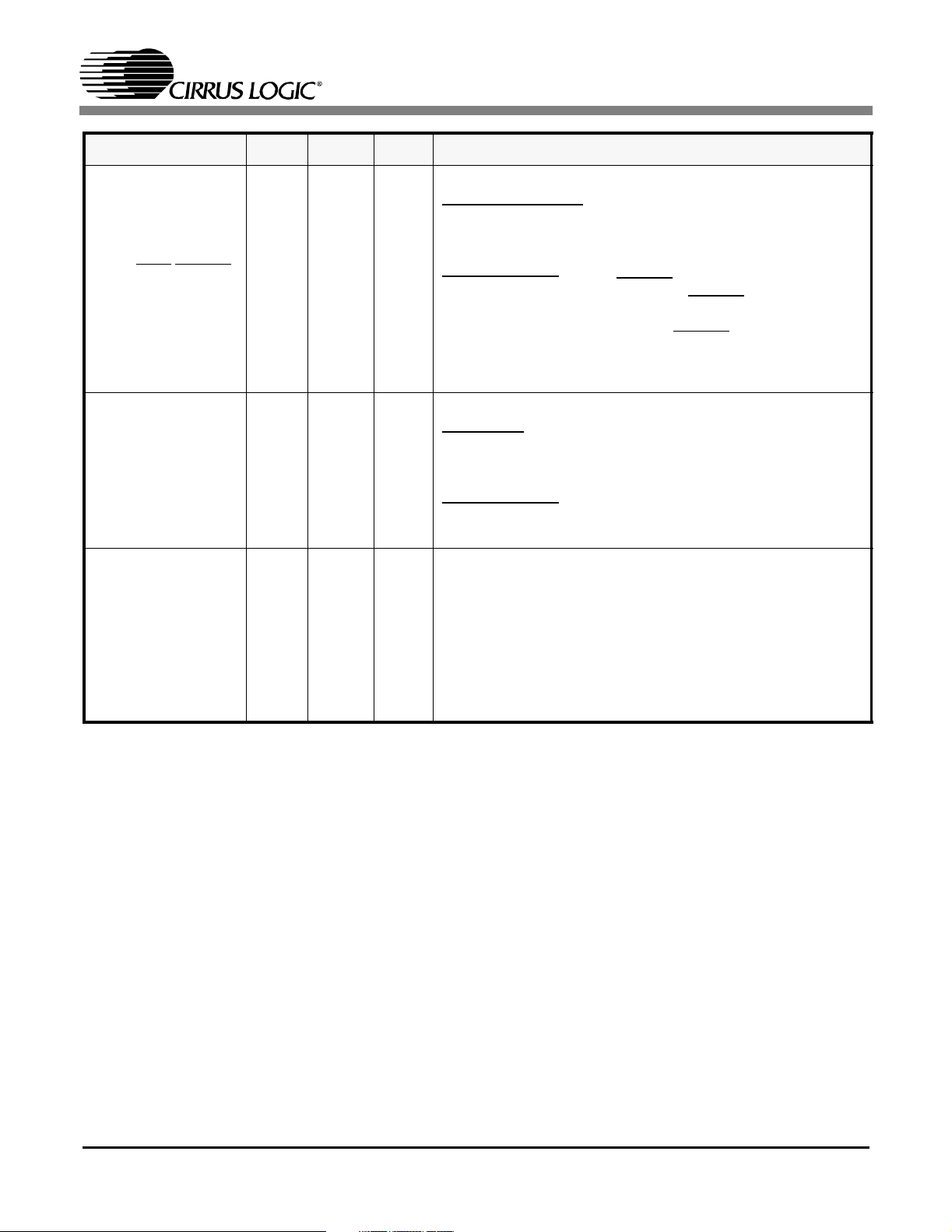

3.2 Control

SYMBOL LQFP FBGA TYPE DESCRIPTION

MCLK 10 E1 I

MODE 11 E2 I

CS61884

Master Clock Input

This pin is a free running reference clock that should be

either 1.544 MHz for T1/J1 or 2.048 MHz for E1 operation.

This timing reference is used as follows:

- Timing reference for the clock recovery and jitter attenuation circuitry.

- RCLK reference during Loss of Signal (LOS) conditions

- Transmit clock reference during Transmit all Ones (TAOS)

condition

- Wait state timing for microprocessor interface

- When this pin is held “High”, the PLL clock recovery circuit is disabled. In this mode, the CS61884 receivers

function as simple data slicers.

- When this pin is held “Low”, the receiver paths are powered down and the output pins RCLK, RPOS, and RNEG

are High-Z.

Mode Select

This pin is used to select whether the CS61884 operates in

Serial host, Parallel host or Hardware mode.

Host Mode

serial or a parallel microprocessor interface (Refer to HOST

MODE (See Section 13 on page 32).

Hardware Mode

and the device control/status are provided through the pins

on the device.

- The CS61884 is controlled through either a

- The microprocessor interface is disabled

Table 1. Operation Mode Selection

Pin State OPERATING Mode

LOW Hardware Mode

HIGH Parallel Host Mode

VCCIO/2 Serial Host Mode

NOTE: For serial host mode connect this pin to a resistor

divider consisting of two 10KΩ resistors between

VCCIO and GNDIO.

10 DS485PP4

Page 11

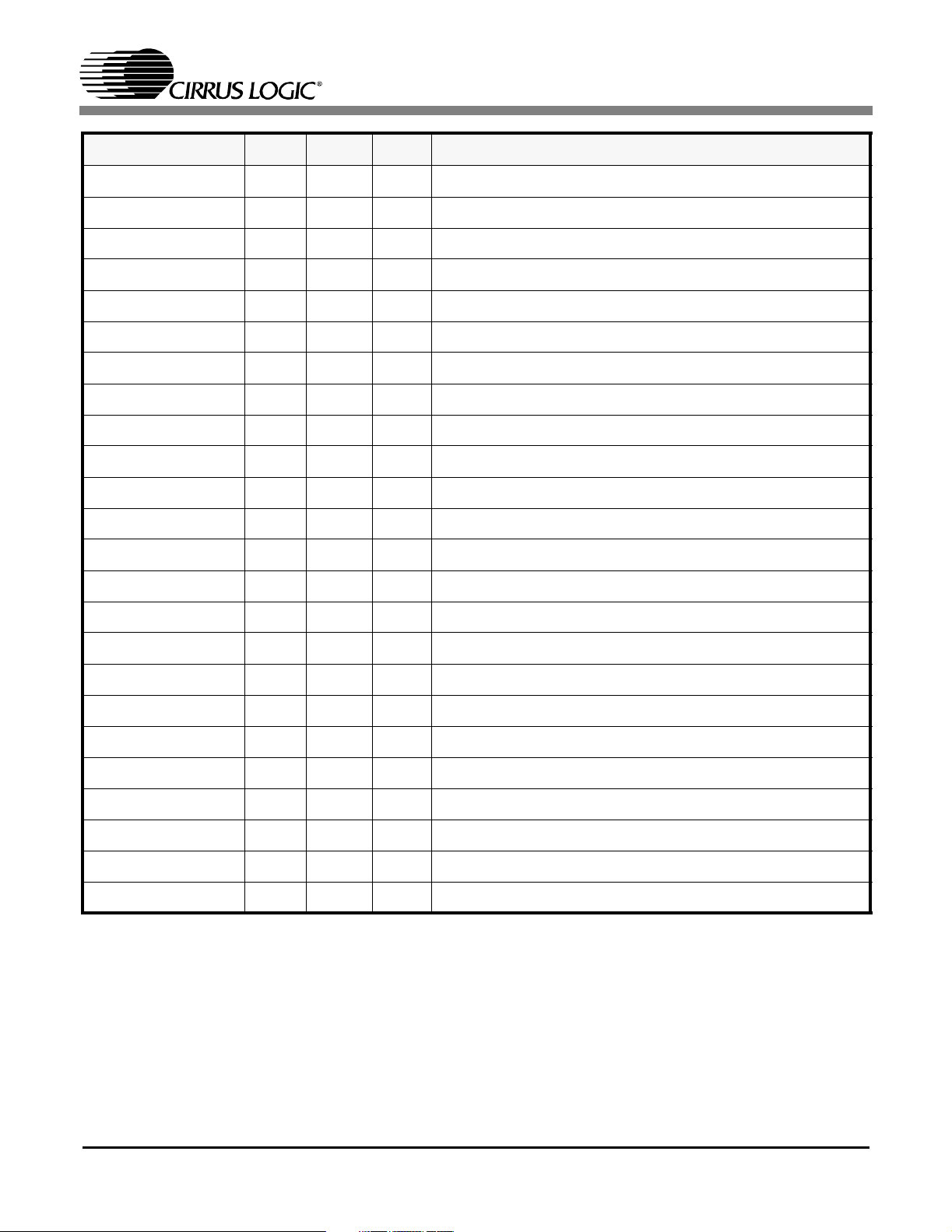

SYMBOL LQFP FBGA TYPE DESCRIPTION

Multiplexed Interface/Bits Clock Select

MUX/BITSEN0 43 K2 I

Host Mode

face for multiplexed or non-multiplexed operation.

Hardware mode

a G.703 BITS Clock recovery channel (Refer to BUILDING

INTEGRATED TIMING SYSTEMS (BITS) CLOCK MODE

(See Section 8 on page 23). Channel 1 through 7 are not

affected by this pin during hardware mode. During host

mode the G.703 BITS Clock recovery function is enabled by

the Bits Clock Enable Register (1Eh) (See Section 14.31

on page 41).

-This pin configures the microprocessor inter-

- This pin is used to enable channel 0 as

Table 2. Mux/Bits Clock Selection

Pin State Parallel Host Mode Hardware Mode

HIGH multiplexed BITS Clock ON

LOW non multiplexed BITS Clock OFF

NOTE: The MUX pin only controls the BITS Clock function in

Hardware Mode

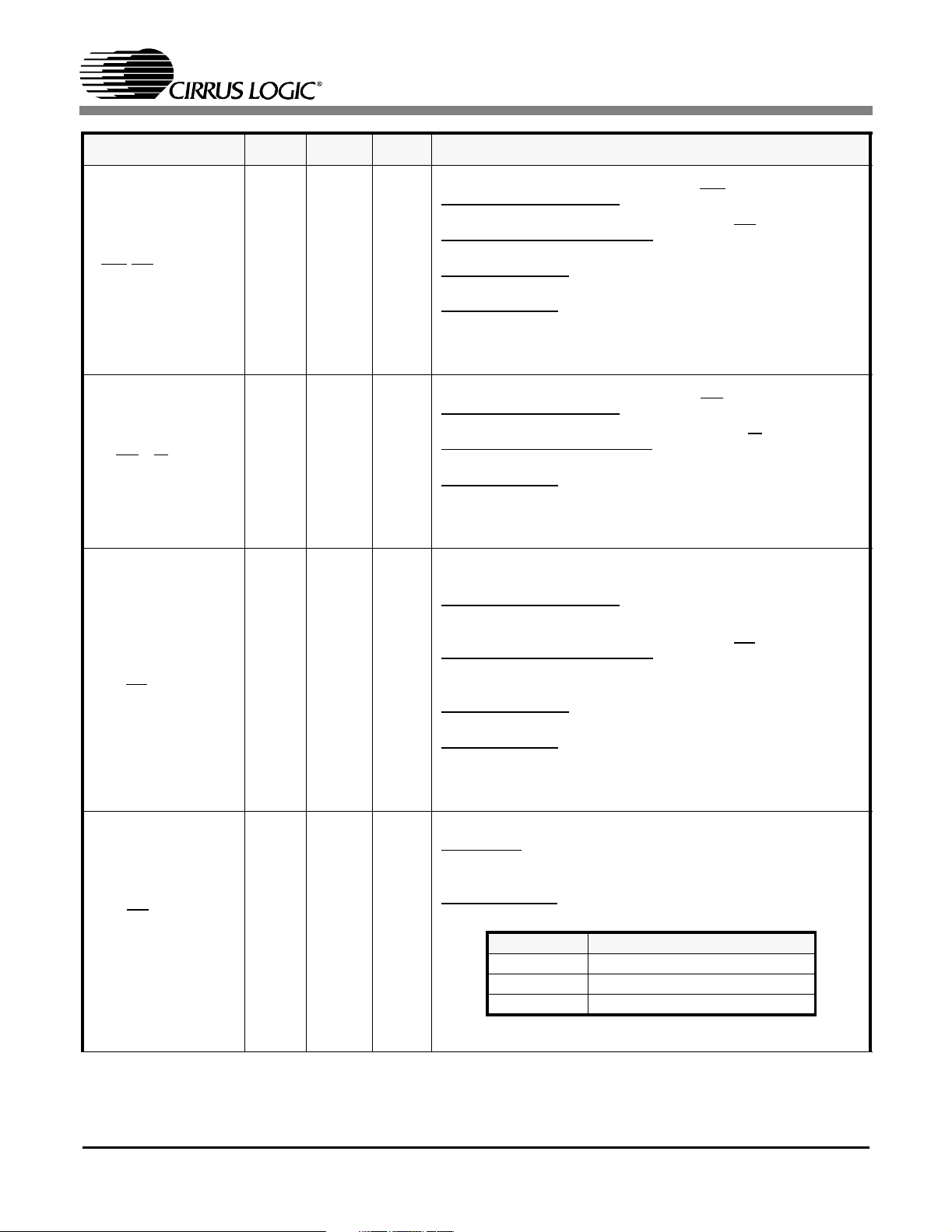

CS61884

INT

RDY/ACK

82 K13 O

/SDO 83 K14 O

Interrupt Output

This active low output signals the host processor when one

of the CS61884’s internal status register bits has changed

state. When the status register is read, the interrupt is

cleared. The various status changes that would force INT

active are maskable via internal interrupt enable registers.

NOTE: This pin is an open drain output and requires a 10 kΩ

pull-up resistor.

Data Transfer Acknowledge/Ready/Serial Data Output

IntelParallelHostMode

access, RDY is asserted “Low” to acknowledge that the device has been accessed. An asserted “High” acknowledges

that data has been written or read. Upon completion of the

bus cycle, this pin High-Z.

Motorola Parallel Host Mode

operation this pin “ACK

data on the bus is valid. An asserted “Low” on this pin during a write operation acknowledges that a data transfer to

the addressed register has been accepted. Upon completion of the bus cycle, this pin High-Z.

NOTE: Wait state generation via RDY/ACK

RZ mode (No Clock Recovery).

Serial Host Mode

configured for serial bus operation, “SDO” is used as a serial data output. This pin is forced into a high impedance

state during a serial write access. The CLKE pin controls

whether SDO is valid on the rising or falling edge of SCLK.

Upon completion of the bus cycle, this pin High-Z.

Hardware Mode

open.

- When the microprocessor interface is

- This pin is not used and should be left

- During a read or write register

- During a data bus read

” is asserted “High” to indicate that

is disabled in

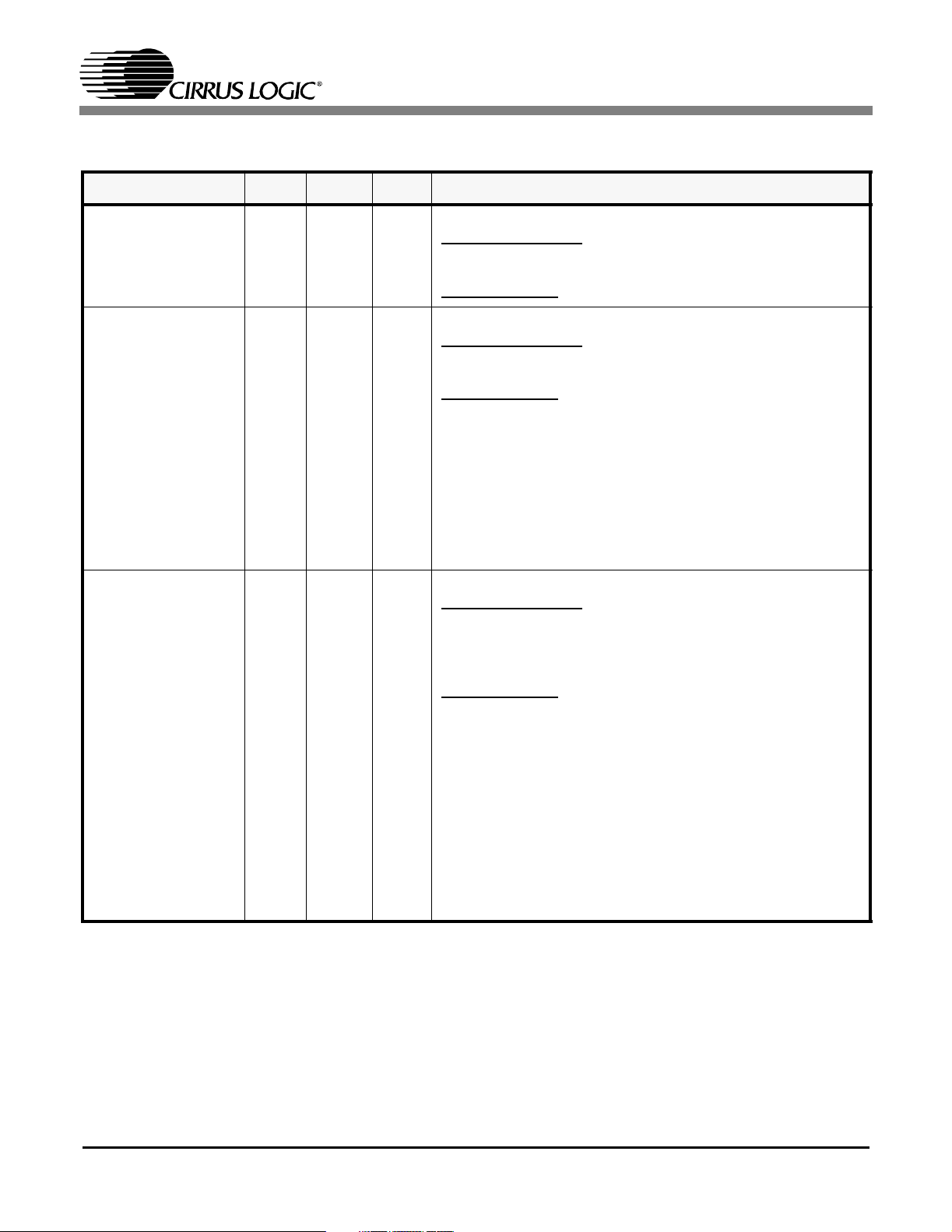

DS485PP4 11

Page 12

SYMBOL LQFP FBGA TYPE DESCRIPTION

Data Strobe/ Write Enable/Serial Data/Line Length Input

WR/DS/SDI/LEN0 84 J14 I

RD

/RW/LEN1 85 J13 I

IntelParallelHostMode

write enable.

Motorola Parallel Host Mode

a data strobe input.

Serial Host Mode

data input.

Hardware Mode

pulse shapes for both E1 and T1/J1 modes. This pin also

selects which mode is used E1 or T1/J1 (Refer to Ta b le 5

on page 25).

Read/Write/ Read Enable/Line Length Input

IntelParallelHostMode

read enable.

Motorola Parallel Host Mode

the read/write input signal.

Hardware Mode

pulse shapes for both E1 and T1/J1 modes. This pin also

selects which mode is used E1 or T1/J1 (Refer to Ta b le 5

on page 25).

- This pin “SDI” functions as the serial

- As LEN0, this pin controls the transmit

- As LEN1, this pin controls the transmit

- This pin “WR” functions as a

- This pin “RD” functions as a

CS61884

- This pin “DS“ functions as

- This pin “R/W” functions as

ALE/AS

CS

/SCLK/LEN2 86 J12 I

/JASEL 87 J11 I

Address Latch Enable/Serial Clock/Address Strobe/Line

Length Input

IntelParallelHostMode

Address Latch Enable when configured for multiplexed address/data operation.

Motorola Parallel Host Mode

the active “low” address strobe when configured for multiplexed address/data operation.

Serial Host Mode

used for data I/O on SDI and SDO.

Hardware Mode

pulse shapes for both E1 and T1/J1 modes. This pin also

selects which mode is used E1 or T1/J1 (Refer to Ta b le 5

on page 25).

Chip Select Input/Jitter Attenuator Select

Host Mode

cesses to the microprocessor interface in either serial or

parallel mode.

Hardware Mode

Attenuator.

- This active low input is used to enable ac-

Pin State Jitter Attenuation Position

LOW Transmit Path

HIGH Receive Path

OPEN Disabled

- This pin “SCLK” is the serial clock

- As LEN2, this pin controls the transmit

- This pin controls the position of the Jitter

- This pin “ALE” functions as the

- This pin “AS” functions as

12 DS485PP4

Page 13

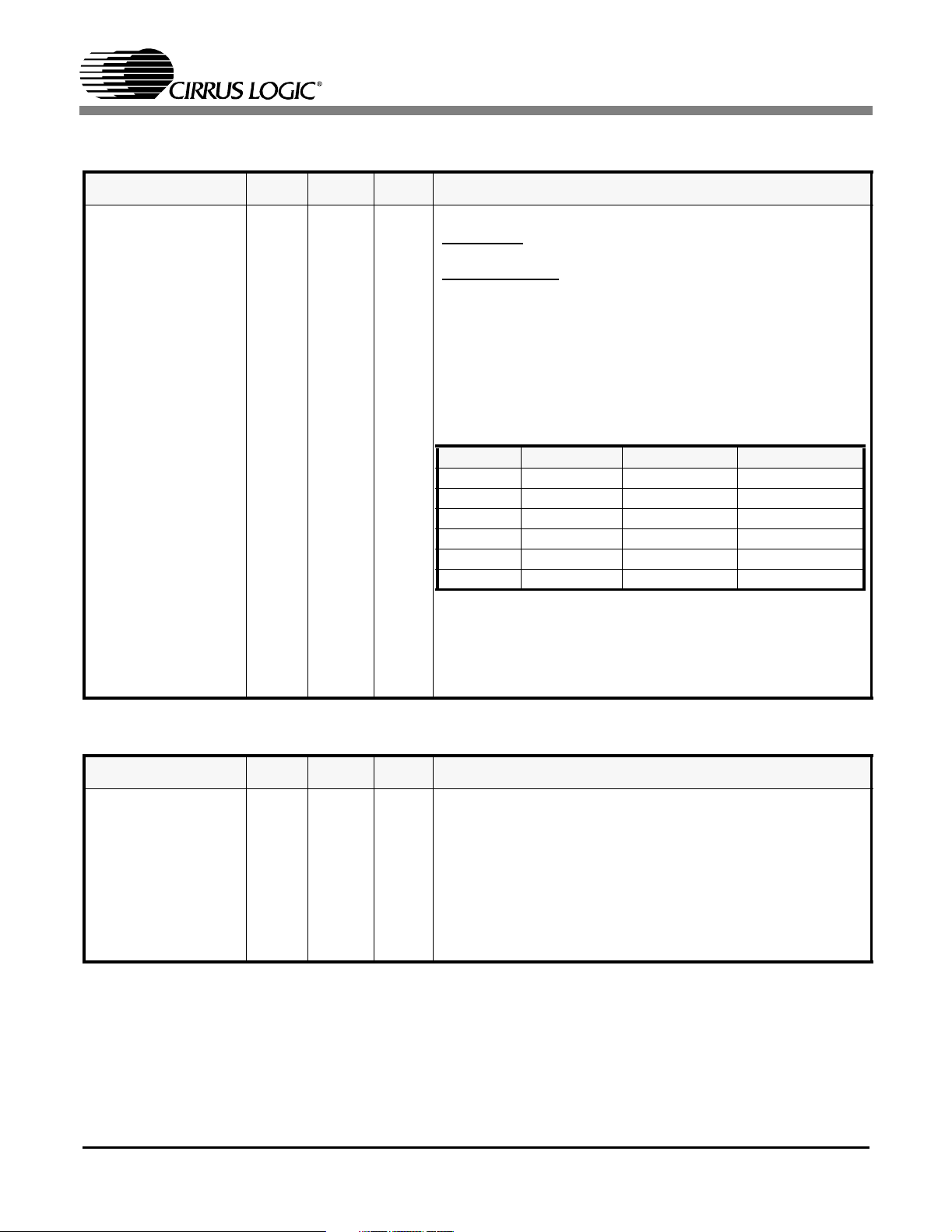

SYMBOL LQFP FBGA TYPE DESCRIPTION

Motorola/Intel/Coder Mode Select Input

INTL/MOT/CODEN 88 H12 I

TXOE 114 E14 I

Parallel Host Mode

cessor interface is configured for operation with Motorola

processors. When this pin is “High” the microprocessor interface is configured for operation with Intel processors.

Hardware Mode

polar operation, this pin, CODEN

encoding/decoding function. When CODEN

B8ZS/HDB3 encoders/decoders are enabled for T1/J1 or

E1 operation respectively. When CODEN

coding/decoding is activated. This is done for all eight

channels.

Transmitter Output Enable

Host mode

dividual drivers can be set to a high impedance state via

the Output Disable Register (12h) (See Section 14.19 on

page 39).

Hardware Mode

TX drivers are forced into a high impedance state. All other

internal circuitry remains active.

- Operates the same as in hardware mode. In-

- When this pin is “Low” the micropro-

- When the CS61884 is configured for uni-

- When TXOE pin is asserted Low, all the

CS61884

, configures the line

is low,

is high, AMI en-

CLKE 115 E13 I

Clock Edge Select

In clock/data recovery mode, setting CLKE “high” will cause

RPOS/RNEG to be valid on the falling edge of RCLK and

SDOtobevalidontherisingedgeofSCLK.WhenCLKEis

set “low”, RPOS/RNEG is valid on the rising edge of RCLK,

and SDO is valid on the falling edge of SCLK. When the

part is operated in data recovery mode, the RPOS/RNEG

output polarity is active “high” when CLKE is set “high” and

active “low” when CLKE is set “low”.

DS485PP4 13

Page 14

3.3 Address Inputs/Loopbacks

SYMBOL LQFP FBGA TYPE DESCRIPTION

A4 12 F4 I

A3

A2

A1

A0

13

14

15

16

F3

F2

F1

G3

Address Selector Input

Parallel Host Mode

mode operation, this pin function as the address 4 input for

the parallel interface.

Hardware Mode

Non-Intrusive Monitoring/Address Selector Inputs

Parallel Host Mode

mode operation, these pins function as address A[3:0] inputs for the parallel interface.

Hardware Mode

tion during non-intrusive monitoring. In non-intrusive

I

monitoring mode, receiver 0’s input is internally connected

to the transmit or receive ports on one of the other 7 chan-

I

nels. The recovered clock and data from the selected port

are output on RPOS0/RNEG0 and RCLK0. Additionally, the

I

data from the selected port can be output on

TTIP0/TRING0 by activating the remote loopback function

I

for channel 0 (Refer to Performance Monitor Register

(0Bh) (See Section 14.12 on page 36).

- During non-multiplexed parallel host

- The A4 pin must be tied low at all times.

- During non-multiplexed parallel host

- The A[3:0] pins are used for port selec-

CS61884

LOOP0/D0

LOOP1/D1

LOOP2/D2

LOOP3/D3

LOOP4/D4

LOOP5/D5

LOOP6/D6

LOOP7/D7

21

22

23

24

25

26

27

28

G2

H3

H2

J4

J3

J2

J1

K1

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

Loopback Mode Selector/Parallel Data Input/Output

Parallel Host Mode

terface mode, these pins function as the bi-directional 8-bit

data port. When operating in multiplexed microprocessor interface mode, these pins function as the address and data

inputs/outputs.

Hardware Mode

- No Loopback - The CS61884 is in a normal operating

state when LOOP is left open (unconnected) or tied to

VCCIO/2.

- Local Loopback - When LOOP is tied High, data transmitted on TTIP and TRING is looped back into the analog

input of the corresponding channel’s receiver and output on

RPOS and RNEG. Input Data present on RTIP and RRING

is ignored.

- Remote Loopback - When LOOP is tied Low the recovered clock and data received on RTIP and RRING is looped

back for transmission on TTIP and TRING. Data on TPOS

and TNEG is ignored.

- In non-multiplexed microprocessor in-

14 DS485PP4

Page 15

3.4 Cable Select

SYMBOL LQFP FBGA TYPE DESCRIPTION

CS61884

Cable Impedance Select

Host Mode

normal operation.

Hardware Mode

LEN control pins (Refer to Ta bl e 5 , “Hardware Mode Line

Length Configuration Selection,” on page 25)tosettheline

impedance for all eight receivers and transmitters. This pin

also selects whether or not all eight receivers use an internal or external line matching network (Refer to the Table

below for proper settings).

- The input voltage to this pin does not effect

- Thispinisusedincombinationwiththe

3.5

CBLSEL 93 G13 I

E1/T1/J1 CBLSEL Transmitters Receivers

NOTE: Refer to Figure 17 on page 51 and Figure 18 on

Table 3. Cable Impedance Selection

T1/J1 No Connect 100 Ω Internal Internal

T1/J1 HIGH 100 Ω Internal Internal

T1/J1 LOW 100 Ω Internal External

E1 No Connect 120 Ω Internal Inter or Ext

E1 HIGH 75 Ω Internal Internal

E1 LOW 75 Ω Internal External

page 52 for appropriate external line matching com-

ponents. All transmitters use internal matching networks.

Status

SYMBOL LQFP FBGA TYPE DESCRIPTION

Loss of Signal Output

LOS0

LOS1

LOS2

LOS3

LOS4

LOS5

LOS6

LOS7

42

35

75

68

113

106

3

140

K4

K3

K12

K11

E11

E12

E3

E4

O

O

The LOS output pins can be configured to indicate a loss of

O

signal (LOS) state that is compliant to either T1.231, ITU

O

G.775 or ETSI 300 233. These pins are asserted “High” to

O

indicate LOS. The LOS output returns low when an input

O

signal is present for the time period dictated by the associ-

O

ated specification (Refer to Loss-of-Signal (LOS) (See

O

Section 10.5 on page 27)).

DS485PP4 15

Page 16

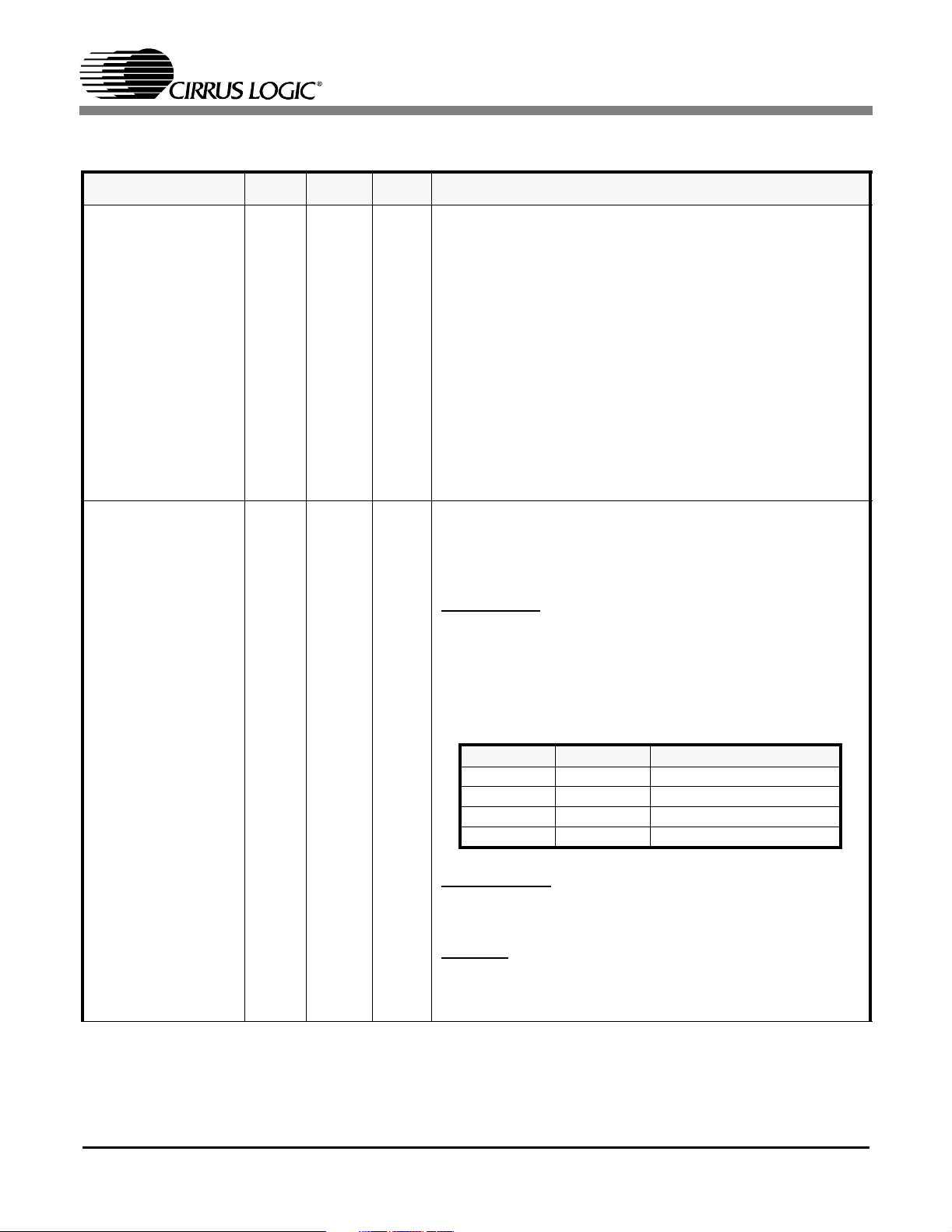

3.6 Digital Rx/Tx Data I/O

SYMBOL LQFP FBGA TYPE DESCRIPTION

TCLK0 36 N1 I

CS61884

Transmit Clock Input Port 0

- When TCLK is active, the TPOS and TNEG pins function

as NRZ inputs that are sampled on the falling edge of

TCLK.

- If MCLK is active, TAOS will be generated when TCLK is

held High for 16 MCLK cycles.

NOTE: MCLK is used as the timing reference during TAOS

and must have the appropriate stability.

-IfTCLKisheldHighintheabsenceofMCLK,theTPOS

and TNEG inputs function as RZ inputs. In this mode, the

transmit pulse width is set by the pulse-width of the signal

input on TPOS and TNEG. To enter this mode, TCLK must

be held high for at least 12 µS.

- If TCLK is held Low, the output drivers enter a low-power,

high impedance state.

Transmit Positive Pulse/Transmit Data Input Port 0

Transmit Negative Pulse/Unipolar-Bipolar Select Port 0

The function of the TPOS/TDATA and TNEG/UBS inputs

are determined by whether Unipolar, Bipolar or RZ input

mode has been selected.

Bipolar Mode

TNEG are sampled on the falling edge of TCLK and transmitted onto the line at TTIP and TRING respectively. A

“High” input on TPOS results in transmission of a positive

pulse; a “High” input on TNEG results in a transmission of a

negative pulse. The translation of TPOS/TNEG inputs to

TTIP/TRING outputs is as follows:

- In this mode, NRZ data on TPOS and

TPOS0/TDATA0

TNEG0/UBS

16 DS485PP4

37

38

N2

N3

I

I

TPOS TNEG OUTPUT

0 0 Space

1 0 Positive Mark

0 1 Negative Mark

1 1 Space

Unipolar mode

TNEG/UBS “High” for more than 16 TCLK cycles, when

MCLK is present. The falling edge of TCLK samples a unipolar data steam on TPOS/TDATA.

RZ Mode

absence of MCLK. In this mode, the duty cycle of the

TPOS and TNEG inputs determine the pulse width of the

output signal on TTIP and TRING.

- Unipolar mode is activated by holding

- To activate RZ mode tie TCLK “High” with the

Page 17

SYMBOL LQFP FBGA TYPE DESCRIPTION

Receive Clock Output Port 0

- When MCLK is active, this pin outputs the recovered clock

from the signal input on RTIP and RRING. In the event of

LOS, the RCLK output transitions from the recovered clock

RCLK0 39 P1 O

RPOS0/RDATA0

RNEG0/BPV0

40

41

P2

P3

to MCLK.

- If MCLK is held “High”, the clock recovery circuitry is disabled and the RCLK output is driven by the XOR of RNEG

and RPOS.

- If MCLK is held “Low”, this output is in a high-impedance

state.

Receive Positive Pulse/ Receive Data Output Port 0

Receive Negative Pulse/Bipolar Violation Output Port 0

The function of the RPOS/RDATA and RNEG/BPV outputs

are determined by whether Unipolar, Bipolar, or RZ input

mode has been selected. During LOS, the RPOS/RNEG

outputs will remain active.

NOTE: The RPOS/RNEG outputs can be High-Z by holding

MCLK Low.

Bipolar Output Mode

O

tion, NRZ Data is recovered from RTIP/RRING and output

on RPOS/RNEG. A high signal on RPOS or RNEG corre-

O

spond to the receipt of a positive or negative pulse on

RTIP/RRING respectively. The RPOS/RNEG outputs are

valid on the falling or rising edge of RCLK as configured by

CLKE.

Unipolar Output Mode

the recovered data is output on RDATA. The decoder signals bipolar Violations on the RNEG/BPV pin.

RZ Output Mode

output RZ data recovered by slicing the signal present on

RTIP/RRING. A positive pulse on RTIP with respect to

RRING generates a logic 1 on RPOS; a positive pulse on

RRING with respect to RTIP generates a logic 1 on RNEG.

The polarity of the output on RPOS/RNEG is selectable using the CLKE pin. In this mode, external circuitry is used to

recover clock from the received signal.

- When configured for Bipolar opera-

- When unipolar mode is activated,

- In this mode, the RPOS/RNEG pins

CS61884

TCLK1 29 L1 I Transmit Clock Input Port 1

TPOS1/TDATA1 30 L2 I Transmit Positive Pulse/Transmit Data Input Port 1

TNEG1/UBS1 31 L3 I Transmit Negative Pulse/Unipolar-Bipolar Select Port 1

RCLK1 32 M1 O Receive Clock Output Port 1

RPOS1/RDATA1 33 M2 O Receive Positive Pulse/ Receive Data Output Port 1

RNEG1/BPV1 34 M3 O Receive Negative Pulse/Bipolar Violation Output Port 1

TCLK2 81 L14 I Transmit Clock Input Port 2

TPOS2/TDATA2 80 L13 I Transmit Positive Pulse/Transmit Data Input Port 2

TNEG2/UBS2 79 L12 I Transmit Negative Pulse/Unipolar-Bipolar Select Port 2

DS485PP4 17

Page 18

CS61884

SYMBOL LQFP FBGA TYPE DESCRIPTION

RCLK2 78 M14 O Receive Clock Output Port 2

RPOS2/RDATA2 77 M13 O Receive Positive Pulse/ Receive Data Output Port 2

RNEG2/BPV2 76 M12 O Receive Negative Pulse/Bipolar Violation Output Port 2

TCLK3 74 N14 I Transmit Clock Input Port 3

TPOS3/TDATA3 73 N13 I Transmit Positive Pulse/Transmit Data Input Port 3

TNEG3/UBS3 72 N12 I Transmit Negative Pulse/Unipolar-Bipolar Select Port 3

RCLK3 71 P14 O Receive Clock Output Port 3

RPOS3/RDATA3 70 P13 O Receive Positive Pulse/ Receive Data Output Port 3

RNEG3/BPV3 69 P12 O Receive Negative Pulse/Bipolar Violation Output Port 3

TCLK4 107 B14 I Transmit Clock Input Port 4

TPOS4/TDATA4 108 B13 I Transmit Positive Pulse/Transmit Data Input Port 4

TNEG4/UBS4 109 B12 I Transmit Negative Pulse/Unipolar-Bipolar Select Port 4

RCLK4 110 A14 O Receive Clock Output Port 4

RPOS4/RDATA4 111 A13 O Receive Positive Pulse/ Receive Data Output Port 4

RNEG4/BPV4 11 2 A12 O Receive Negative Pulse/Bipolar Violation Output Port 4

TCLK5 100 D14 I Transmit Clock Input Port 5

TPOS5/TDATA5 101 D13 I Transmit Positive Pulse/Transmit Data Input Port 5

TNEG5/UBS5 102 D12 I Transmit Negative Pulse/Unipolar-Bipolar Select Port 5

RCLK5 103 C14 O Receive Clock Output Port 5

RPOS5/RDATA5 104 C13 O Receive Positive Pulse/ Receive Data Output Port 5

RNEG5/BPV5 105 C12 O Receive Negative Pulse/Bipolar Violation Output Port 5

TCLK6 9 D1 I Transmit Clock Input Port 6

TPOS6/TDATA6 8 D2 I Transmit Positive Pulse/Transmit Data Input Port 6

TNEG6/UBS6 7 D3 I Transmit Negative Pulse/Unipolar-Bipolar Select Port 6

RCLK6 6 C1 O Receive Clock Output Port 6

RPOS6/RDATA6 5 C2 O Receive Positive Pulse/ Receive Data Output Port 6

RNEG6/BPV6 4 C3 O Receive Negative Pulse/Bipolar Violation Output Port 6

TCLK7 2 B1 I Transmit Clock Input Port 7

TPOS7/TDATA7 1 B2 I Transmit Positive Pulse/Transmit Data Input Port 7

TNEG7/UBS7 144 B3 I Transmit Negative Pulse/Unipolar-Bipolar Select Port 7

18 DS485PP4

Page 19

CS61884

SYMBOL LQFP FBGA TYPE DESCRIPTION

RCLK7 143 A1 O Receive Clock Output Port 7

RPOS7/RDATA7 142 A2 O Receive Positive Pulse/ Receive Data Output Port 7

RNEG7/BPV7 141 A3 O Receive Negative Pulse/Bipolar Violation Output Port 7

3.7 Analog RX/TX Data I/O

SYMBOL LQFP FBGA TYPE DESCRIPTION

Transmit Tip Output Port 0

Transmit Ring Output Port 0

TTIP and TRING pins are the differential outputs of the

transmit driver. The driver internally matches impedances

for E1 75 Ω, E1 120 Ω and T1/J1 100 Ω lines requiring only

TTIP0

TRING0

45

46

N5

P5

a1:2transformer.TheCBLSELpinisusedtoselectthe

O

appropriate line matching impedance only in “Hardware”

mode. In host mode, the appropriate line matching imped-

O

ance is selected by the Line Length Data Register (11h)

(See Section 14.18 on page 39).

NOTE: TTIP and TRING are forced to a high impedance state

when the TCLK pin is “Low” for over 12µSorthe

TXOE pin is forced “Low”.

Receive Tip Input Port 0

Receive Ring Input Port 0

RTIP and RRING are the differential line inputs to the receiver. The receiver uses either Internal Line Impedance or

External Line Impedance modes to match the line imped-

RTIP0

RRING0

TTIP1 52 L5 O Transmit Tip Output Port 1

48

49

P7

N7

ances for E1 75Ω, E1 120Ω or T1/J1 100Ω modes.

I

Internal Line Impedance Mode

same external resistors to match the line impedance (Refer

I

to Figure 17 on page 51).

External Line Impedance Mode

ent external resistors to match the line impedance (Refer to

Figure 18 on page 52).

- In host mode, the appropriate line impedance is selected

by the Line Length Data Register (11h) (See Section

14.18 on page 39).

- In hardware mode, the CBLSEL pin in combination with

the LEN pins select the appropriate line impedance. (Refer

to Table 3 on page 15 for proper line impedance settings).

NOTE: Data and clock recovered from the signal input on

these pins are output via RCLK, RPOS, and RNEG.

- The receiver uses the

- The receiver uses differ-

TRING1 51 M5 O Transmit Ring Output Port 1

RTIP1 55 M7 I Receive Tip Input Port 1

RRING1 54 L7 I Receive Ring Input Port 1

DS485PP4 19

Page 20

SYMBOL LQFP FBGA TYPE DESCRIPTION

TTIP2 57 L10 O Transmit Tip Output Port 2

TRING2 58 M10 O Transmit Ring Output Port 2

RTIP2 60 M8 I Receive Tip Input Port 2

RRING2 61 L8 I Receive Ring Input Port 2

TTIP3 64 N10 O Transmit Tip Output Port 3

TRING3 63 P10 O Transmit Ring Output Port 3

RTIP3 67 P8 I Receive Tip Input Port 3

RRING3 66 N8 I Receive Ring Input Port 3

TTIP4 117 B10 O Transmit Tip Output Port 4

TRING4 118 A10 O Transmit Ring Output Port 4

RTIP4 120 A8 I Receive Tip Input Port 4

RRING4 121 B8 I Receive Ring Input Port 4

CS61884

TTIP5 124 D10 O Transmit Tip Output Port 5

TRING5 123 C10 O Transmit Ring Output Port 5

RTIP5 127 C8 I Receive Tip Input Port 5

RRING5 126 D8 I Receive Ring Input Port 5

TTIP6 129 D5 O Transmit Tip Output Port 6

TRING6 130 C5 O Transmit Ring Output Port 6

RTIP6 132 C7 I Receive Tip Input Port 6

RRING6 133 D7 I Receive Ring Input Port 6

TTIP7 136 B5 O Transmit Tip Output Port 7

TRING7 135 A5 O Transmit Ring Output Port 7

RTIP7 139 A7 I Receive Tip Input Port 7

RRING7 138 B7 I Receive Ring Input Port 7

20 DS485PP4

Page 21

3.8 JTAG Test Interface

SYMBOL LQFP FBGA TYPE DESCRIPTION

TRST

TMS 96 F11 I

TCK 97 F14 I

TDO 98 F13 O

95 G12 I

CS61884

JTAG Reset

This active Low input resets the JTAG controller. This input

is pulled up internally and may be left as a NC when not

used.

JTAG Test Mode Select Input

This input enables the JTAG serial port when active High.

This input is sampled on the rising edge of TCK. This input

is pulled up internally and may be left as a NC when not

used.

JTAG Test Clock

Data on TDI is valid on the rising edge of TCK. Data on

TDO is valid on the falling edge of TCK. When TCK is

stopped high or low, the contents of all JTAG registers remain unchanged. Tie pin low through a 10 KΩ resistor

when not used.

JTAG Test Data Output

JTAG test data is shifted out of the device on this pin. Data

is output on the falling edge of TCK. Leave as NC when not

used.

TDI 99 F12 I

3.9 Miscellaneous

SYMBOL LQFP FBGA TYPE DESCRIPTION

REF 94 H13 I Reference Input

JTAG Test Data Input

JTAG test data is shifted into the device using this pin. The

pin is sampled on the rising edge of TCK. TDI is pulled up

internally and may be left as a NC when not used.

This pin must be tied to ground through 13.3 KΩ 1% resistor. This pin is used to set the internal current level.

DS485PP4 21

Page 22

CS61884

4. OPERATION

The CS61884 is a full featured line interface unit

for up to eight E1/T1/J1 lines. The device provides

an interface to twisted pair or co-axial media. A

matched impedance technique is employed that reduces power and eliminates the need for matching

resistors. As a result, the device can interface directly to the line through a transformer without the

need for matching resistors on the transmit side.

The receive side uses the same resistor values for

all E1/T1/J1 settings.

5. POWER-UP

On power-up, the device is held in a static state until the power supply achieves approximately 70%

of the power supply voltage. Once the power supply threshold is passed, the analog circuitry is calibrated, the control registers are reset to their default

settings, and the various internal state machines are

reset. The reset/calibration process completes in

about 30 ms.

6. MASTER CLOCK

7. G.772 MONITORING

The receive path of channel zero of the CS61884

can be used to monitor the receive or transmit paths

of any of the other channels. The signal to be monitored is multiplexed to channel zero through the

G.772 Multiplexer. The multiplexer and channel

zero then form a G.772 compliant digital Protected

Monitoring Point (PMP). When the PMP is connected to the channel, the attenuation in the signal path is

negligible across the signal band. The signal can be

observed using RPOS, RNEG, and RCLK of channelzeroorbyputtingchannelzeroinremoteloopback, the signal can be observed on TTIP and

TRING of channel zero.

The G.772 monitoring function is available during

both host mode and hardware mode operation. In

host modes, individual channels are selected for

monitoring via the Performance Monitor Regis-

ter (0Bh) (See Section 14.12 on page 36)). In hard-

ware mode, individual channels are selected

through the A3:A0 pins (Refer to Table 4 below for

address settings).

The CS61884 requires a 2.048 MHz or 1.544 MHz

reference clock with a minimum accuracy of ±100

ppm. This clock may be supplied from internal system timing or a CMOS crystal oscillator and input

to the MCLK pin.

The receiver uses MCLK as a reference for clock

recovery, jitter attenuation, and the generation of

RCLK during LOS. The transmitter uses MCLK as

the transmit timing reference during a blue alarm

transmit all ones condition. In addition, MCLK

provides the reference timing for wait state generation.

In systems with a jittered transmit clock, MCLK

should not be tied to the transmit clock, a separate

crystal oscillator should drive the reference clock

input. Any jitter present on the reference clock will

not be filtered by the jitter attenuator and can cause

the CS61884 to operate incorrectly.

Table 4. G.772 Address Selection

Address [A3:A0] Channel Selection

0000 Monitoring Disabled

0001 Receiver Channel # 1

0010 Receiver Channel # 2

0011 Receiver Channel # 3

0100 Receiver Channel # 4

0101 Receiver Channel # 5

0110 Receiver Channel # 6

0111 Receiver Channel # 7

1000 Monitoring Disabled

1001 Transmitter Channel # 1

1010 Transmitter Channel # 2

1011 Transmitter Channel # 3

1100 Transmitter Channel # 4

1101 Transmitter Channel # 5

1110 Transmitter Channel # 6

1111 Tr a n smitte r Chan n el # 7

NOTE: In hardware mode the A4 pin must be tied low

at all times.

22 DS485PP4

Page 23

8. BUILDING INTEGRATED TIMING SYSTEMS (BITS) CLOCK MODE

CS61884

This mode is used to enable one or more channels

as a stand-alone timing recovery unit used for

G.703 Clock Recovery.

In hardware mode, BITS Clock mode is selected by

pulling the MUX pin “HIGH”. This enables only

channel zero as a stand-alone timing recovery unit,

no other channel can be used as a timing recovery

unit.

RCLK

RTIP

CS61884

RPOS

One Receiver

RNEG

RRING

Figure 3. G.703 BITS Clock Mode in NRZ Mode

In host mode, each channel can be setup as an independent G.703 timing recovery unit, through the

Bits Clock Enable Register (1Eh) (See Section

14.31 on page 41), setting the desired bit to “1” enables BITS Clock mode for that channel. The following diagrams show how the BITS clock

function operates.

0.1µF

R1

RECEIVE

LINE

R2

T1 1:2

RCLK

RPOS

RNEG

TCLK

TPOS

TNEG

RCLK

CS61884

RPOS

One Receiver

RNEG

Figure 4. G.703 BITS Clock Mode in RZ Mode

CS61884

One Channel

REMOTE

LOOPBACK

RTIP

RRING

TTIP

TRING

RTIP

RRING

0.1µF

0.1µF

R1

R2

R1

RECEIVE

LINE

R2

T1 1:2

RECEIVE

LINE

T1 1:2

TRANMIT

LINE

T1 1:2

Figure 5. G.703 BITS Clock Mode in Remote Loopback

DS485PP4 23

Page 24

CS61884

9. TRANSMITTER

The CS61884 contains eight identical transmitters

that each use a low power matched impedance driver to eliminate the need for external load matching

resistors, while providing superior return loss. As a

result, the TTIP/TRING outputs can be connected

directly to the transformer allowing one hardware

circuit for 100 Ω (T1/J1), 120 Ω (E1), and 75 Ω

(E1) applications.

Digital transmit data is input into the CS61884

through the TPOS/TNEG input pins. These pins accept data in one of three formats: unipolar, bipolar,

or RZ. In either unipolar or bipolar mode, the

CS61884 internally generates a pulse shape compliant to the ANSI T1.102 mask for T1/J1 or the

G.703 mask for E1 (Refer to Figure 6 and

Figure 7). The pulse shaping applied to the transmit

data can be selected in hardware mode or in host

mode.

In hardware mode, the pulse shape is selected for

all channels via the LEN[2:0] pins (Refer to

Table 5 on page 25). This sets the pulse shape for

all eight transmitters to one of the prestored line

lengths. The CBLSEL pin in combination with the

LEN[2:0] pins set the line impedance for all eight

channels. The CBLSEL pin also selects between

E1 120Ω or E1 75Ω modes, when the LEN pins are

configured for E1 operation mode.

In host mode, the pulse shape for each channel can

be set independently, during NRZ operation mode,

for proper clock recovery and jitter attenuation. In

RZ Mode each channel can be set to either T1/J1 or

E1, when there is no Mclk present (Refer to RZ

Mode (See Section 9.3 on page 25).

pedance for both the receiver and the transmitter of

the addressed channel.

NOTE: In host mode the CBLSEL pin is not used.

Normalized

Amplitude

1.0

0.5

0

Output Pulse

Shape

-0.5

0 250 750 1000

Figure 6. Pulse Mask at T1/J1 Interface

Percent of

nominal peak

voltage

120

110

100

90

80

50

500

TIME (nanoseconds)

269 ns

244 ns

194 ns

ANSI T1.102,

AT&T CB 119

Specifications

To select the standard pulse shapes, the channels

are selected individually using the Line Length

Channel ID Register (10h) (See Section 14.17 on

page 38), then the LEN[3:0] bits in the Line

Length Data Register (11h) (See Section 14.18 on

page 39) are set for the desired line length for that

10

0

-10

-20

Figure 7. Pulse Mask at E1 Interface

219 ns

488 ns

Nominal Pulse

channel. The LEN bits select the line type and im-

24 DS485PP4

Page 25

CS61884

The CS61884 also allows the user to customize the

transmit pulse shapes to compensate for non-standard cables, transformers, or protection circuitry.

For further information on the AWG Refer to Ar-

bitrary Waveform Generator (SeeSection15on

page 43).

For more information on the host mode registers,

refer to Register Descriptions (See Section 14 on

page 35).

9.1 Bipolar Mode

Bipolar mode provides transparent operation for

applications in which the line coding function is

performed by an external framing device. In this

mode, the falling edge of TCLK samples NRZ data

on TPOS/TNEG for transmission on TTIP/TRING.

9.2 Unipolar Mode

In unipolar mode, the CS61884 is configured such

that transmit data is encoded using B8ZS, HDB3,

or AMI line codes. This mode is activated by holding TNEG/UBS “High” for more than 16 TCLK

cycles. Transmit data is input to the part via the

TPOS/TDATA pin on the falling edge of TCLK.

When operating the part in hardware mode, the

CODEN pin is used to select between B8ZS/HDB3

or AMI encoding. During host mode operation, the

line coding is selected via the Global Control Reg-

ister (0Fh) (See Section 14.16 on page 38).

NOTE: The encoders/decoders are selected for all

eight channels in both hardware and host

mode.

9.3 RZ Mode

In RZ mode, the internal pulse shape circuitry is

bypassed and RZ data driven into TPOS/TNEG is

transmitted on TTIP/TRING. In this mode, the