Page 1

CS5516

CS5520

16-Bit/20-Bit Bridge Transducer A/D Converter

Features

l On-chip Instrume nta t ion Amplifier

l On-chip Programmable Gain Amplifier

l On-Chip 4-Bit D/A For Offset Removal

l Dynamic Excitation Options

l Linearity Error: ±0.0015% FS

- 20-Bit No Missing Codes

l CMRR at 50/60 Hz > 200 dB

l System Calibration Capability with calibration

read/write option

l 3, 4 or 5 wire Serial Communications Port

l Low Power Consumption: 40 mW

- 10 µW Standby Mode for Portable applications

Description

The CS5516 and CS5520 are complete solutions for digitizing low le vel signals from strain gauge s, load cells,

and pressure transducers. Any family of mV output

transducers, includi ng those requiring bridge excitat ion,

can be interfaced directly to the CS5516 or CS5520. The

devices offer an on-chi p software p rogramm able instrumentation amplifier block, choice of DC or AC bridge

excitation, and software selectable reference and signal

demodulation.

The CS5516 uses delta-sigma modulation to achieve

16-bit resolution at outpu t word rates up to 60 Hz. The

CS5520 achieves 20 -bit resolution at word rates u p to

60 Hz.

The CS5516 and CS5520 sample at a rate set by the

user in the form of eith er an external CMOS clock or a

crystal. On-chi p digital filtering provides rejec tion of all

frequencies above 12 Hz for a 4.096 MHz clock.

The CS5516 and CS5520 includ e system calibrat ion to

null offset and gain errors in the input channel. The digital values assoc iate d wi th the sys tem calibration can b e

written to, or read from, the calibration RAM locations at

any time via the serial commun ications port. The 4-bit

DC offset D/A converter, in conjunction with digital correction, is initially used to zero the input offset value.

I

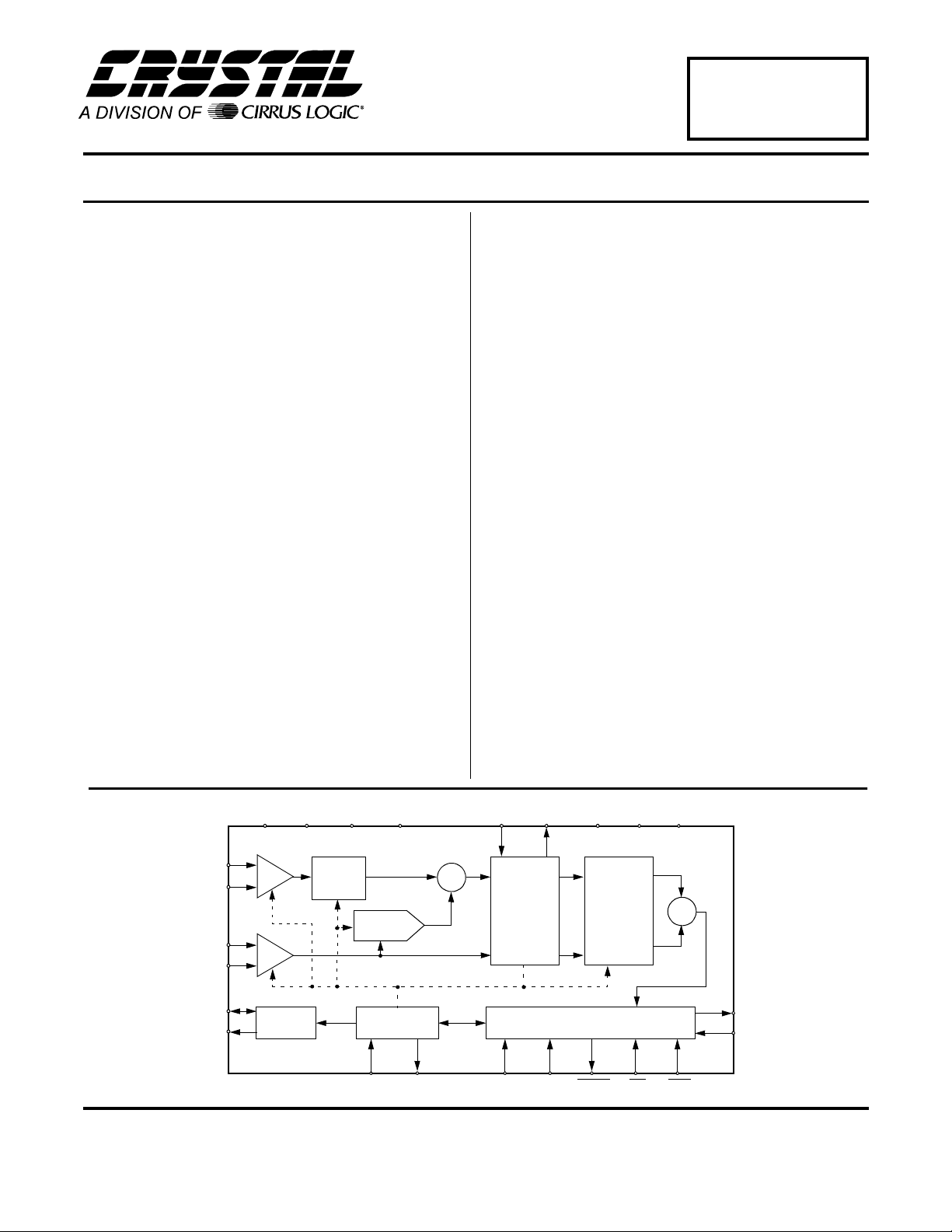

9$9$$*1'$*1'

;

;

%ULGJH

6\QF

*DLQ

%ORFN

$,1

$,1

95()

95()

%;

%;

Cirrus Logic, Inc.

Crystal Semiconductor Products Division

P.O. Box 17847, Austin, Texas 78760

(512) 445 7222 FAX: (512) 445 7581

http://www.crystal.com

ELW'$

&RQYHUWHU

&DOLEUDWLRQ

;,1;287

ORDERING INFORMATION

See page 29.

0'590'599'9''*1'

,1 287

Σ

&KDQQHO

'HOWD6LJPD

0RGXODWRU

,1 287

602'(6&/.'5'<&6567

Copyright Cirrus Logic, Inc. 1997

(All Rights Reserved)

&KDQQHO

),5

)LOWHU

6HULDO,QWHUIDFH

÷

62'

6,'

MAR ‘95

DS74F1

1

Page 2

CS5516

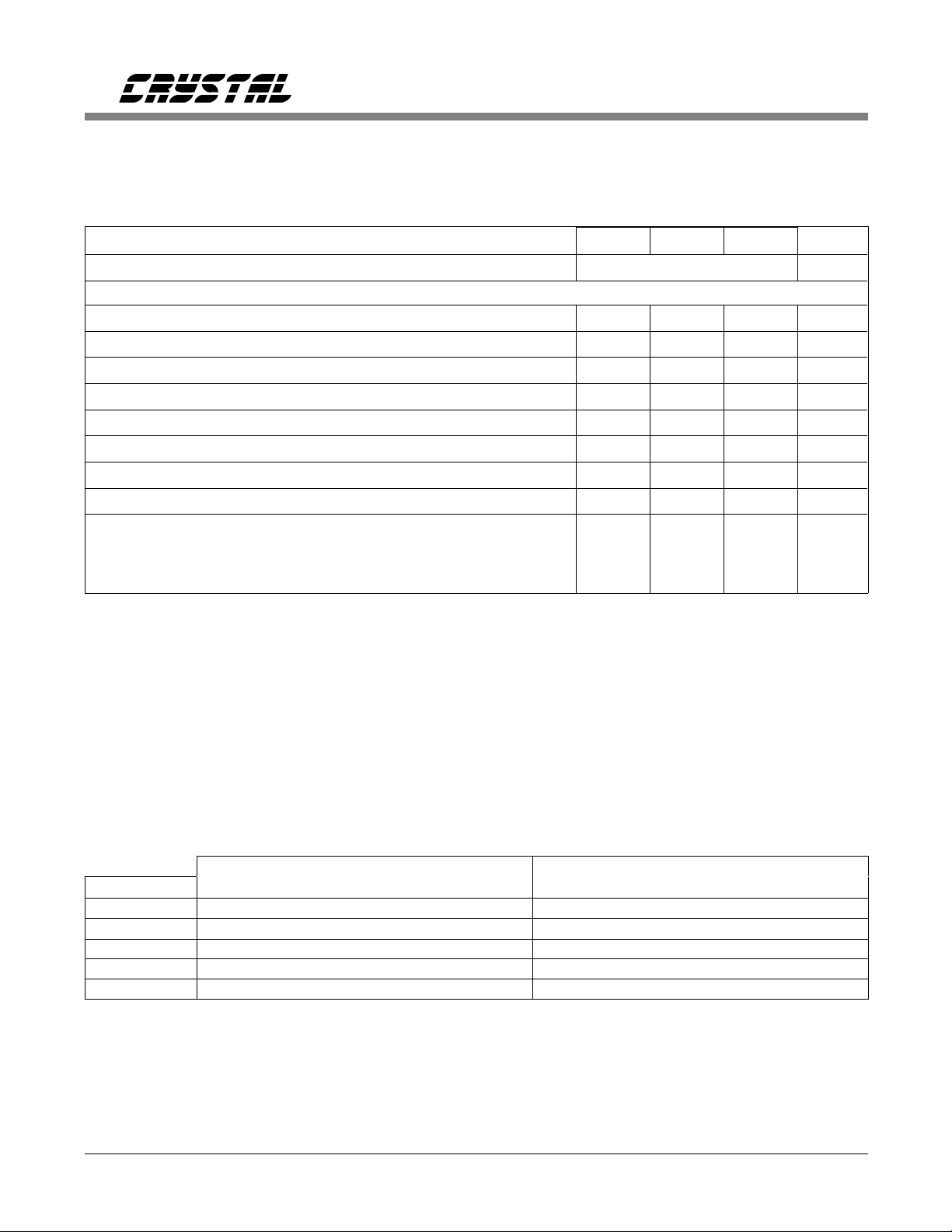

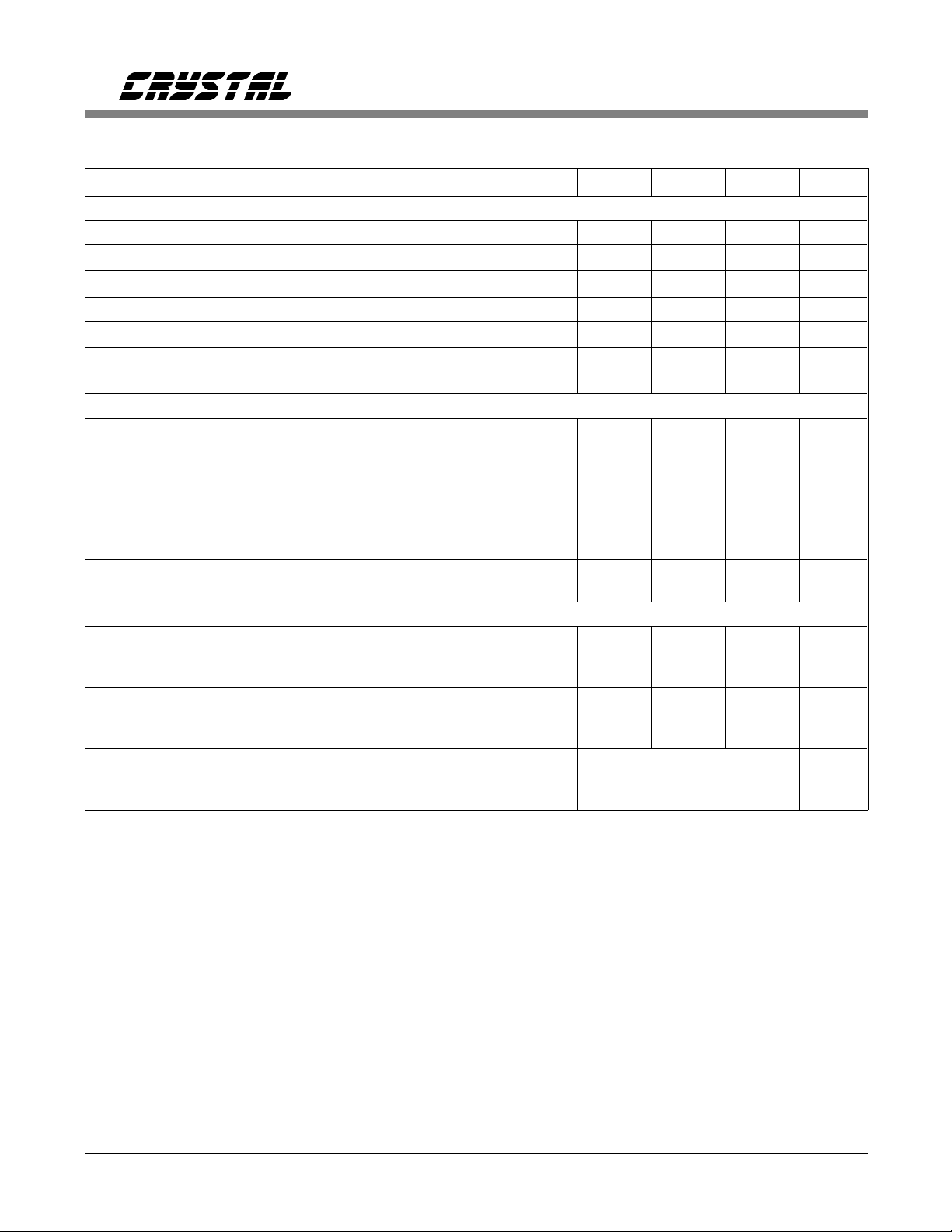

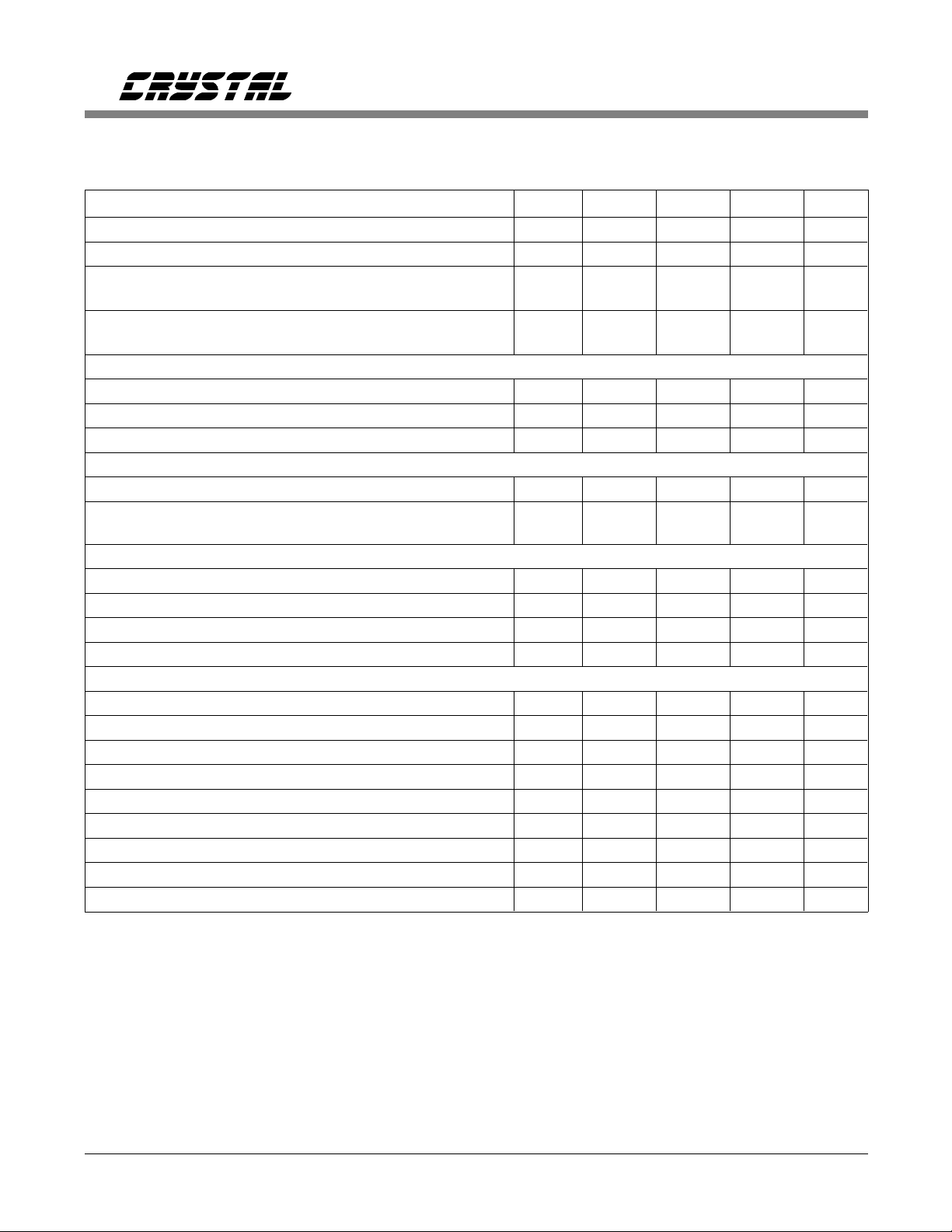

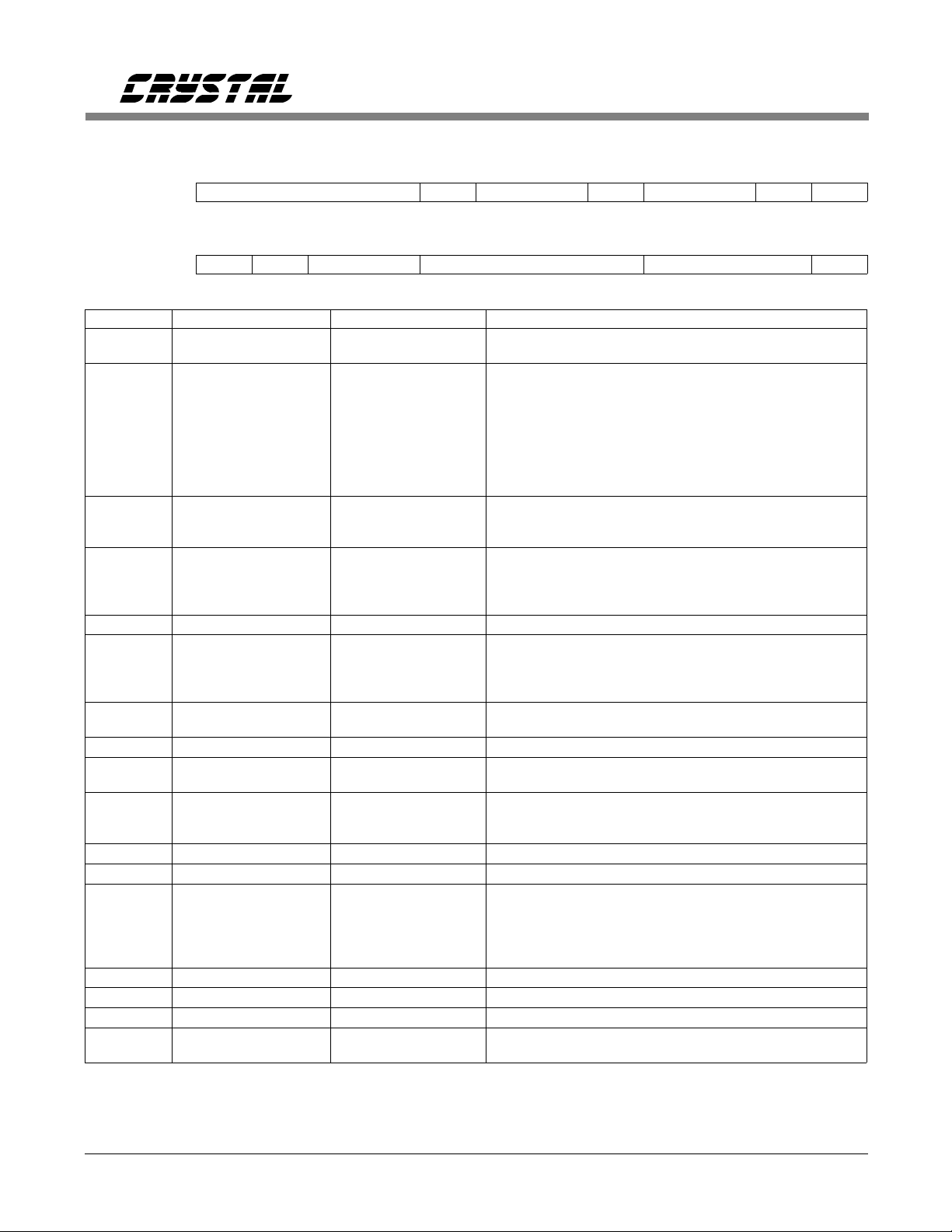

ANALOG CHARACTERISTICS (T

VREF= 2.5V (externa l differen tial volt age across VREF+ an d VREF-); f

AC Excitation 300 Hz; Gain = 25; Bipolar Mode; R

A

= T

source

MIN

to T

; VA+, VD+, MDRV+ = 5V; VA-, VD- = -5V;

MAX

= 4.9152 MHz ;

CLK

= 300Ω with a 4.7nF to AGND at AIN (see Note 1);

unless otherwise specified.)

Parameter* Min Typ Max Units

Specified Temperature Range -40 to +85

°

C

Accuracy

Linearity Error - 0.0015 0.003

Differential Nonlinearity Unipolar Gain Error (Note 2) Bipolar Gain Error (Note 2) Unipolar/Bipolar Gain Drift Unipolar Offset (Note 2) Bipolar Offset (Note 2) Offset Drift Noise (Referred to Input) Gain = 25 (25 x 1)

Gain = 50 (25 x 2)

Gain = 100 (25 x 4)

Gain = 200 (25 x 8)

-

-

-

-

±

0.25

±

±

±

±

±

±

0.005

250

200

150

150

±

0.5

8

8

1

1

1

±

31

±

31

-

±

2

±

2

-

-

-

-

-

±

%FS

LSB

16

ppm

ppm

ppm/°C

LSB

16

LSB

16

µV/°

C

nVrms

nVrms

nVrms

nVrms

Notes: 1. The AIN and VREF pins present a very high input resistance at dc and a minor dynamic load which

scales to the master clock fr equency. Both source r esistance and shunt capac itance are therefore

critical in determining the source impedance requirements of the CS5516 and CS5520 at these pins.

2. Applies after system calibration at the temperature of interest.

Unipolar Mode Bipolar Mode

µ

V

LSB’s % FS ppm FS LSB’s % FS ppm FS

0.4 0.26 0.0004 4 0.13 0.0002 2

0.76 0.50 0.0008 8 0.26 0.0004 4

1.52 1.00 0.0015 15 0.50 0.0008 8

3.04 2.00 0.0030 30 1.00 0.0015 15

6.08 4.00 0.0061 61 2.00 0.0030 30

VREF = 2.5V PGA gain = 1

CS5516; 16-Bit Unit Conversion Factors

* Refer to the Specification Definitions immediately following the Pin Description Section.

Specifications are subject to change without notice.

2 DS74F1

Page 3

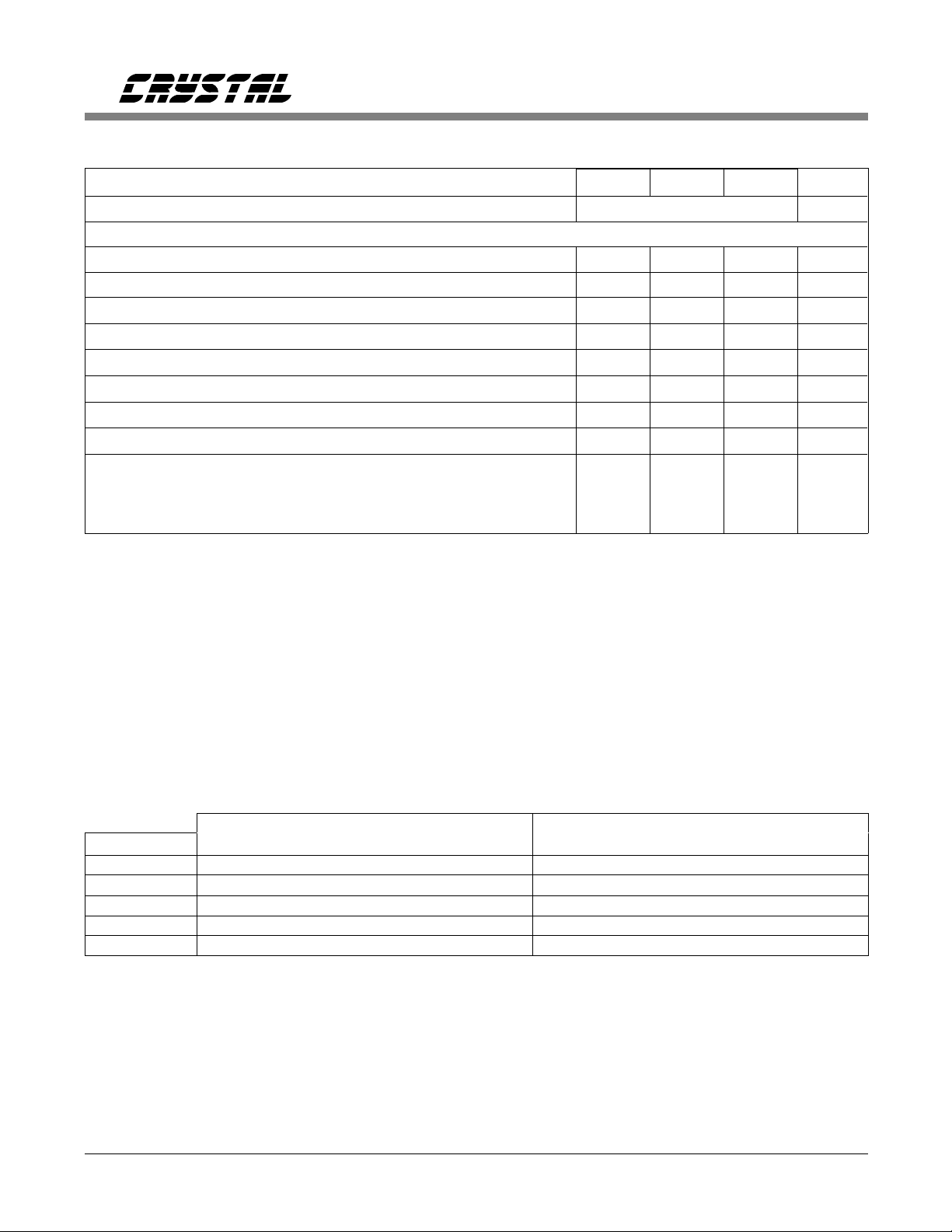

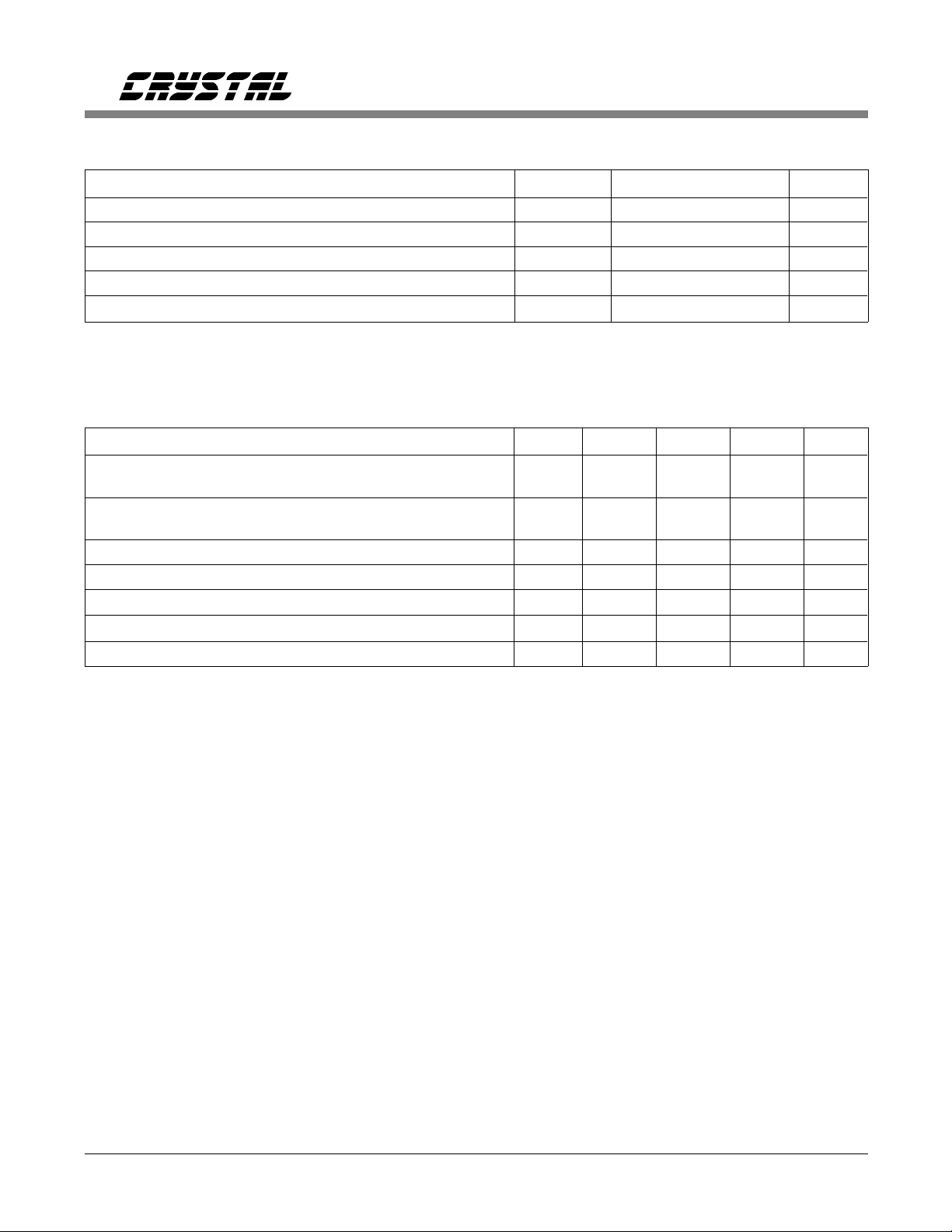

ANALOG CHARACTERISTICS (continued)

Parameter* Min Typ Max Units

CS5520

Specified Temperature Range -40 to +85

°

C

Accuracy

Linearity Error - 0.0007 0.0015

Differential Nonlinearity (No Missing Codes) 20 - - Bits

Unipolar Gain Error (Note 2) Bipolar Gain Error (Note 2) Unipolar/Bipolar Gain Drift Unipolar Offset (Note 2) Bipolar Offset (Note 2) Offset Drift Noise (Referred to Input) Gain = 25 (25 x 1)

Gain = 50 (25 x 2)

Gain = 100 (25 x 4)

Gain = 200 (25 x 8)

-

-

-

-

±

±

±

±

±

±

0.005

250

200

150

150

4

4

1

4

4

±

24

±

24

-

±

8

±

8

-

-

-

-

-

±

%FS

ppm

ppm

ppm/°C

LSB

LSB

µV/°

nVrms

nVrms

nVrms

nVrms

20

20

C

Unipolar Mode Bipolar Mode

µ

V

0.025 0.26 0.0000238 0.25 0.13 0.0000119 0.125

0.047 0.50 0.0000477 0.50 0.26 0.0000238 0.25

0.095 1.00 0.0000954 1.0 0.50 0.0000477 0.50

0.190 2.00 0.0001907 2.0 1.00 0.0000954 1.0

0.380 4.00 0.0003814 4.0 2.00 0.0001907 2.0

* Refer to the Specification Definitions immediately following the Pin Description Section.

DS74F1 3

LSB’s % FS ppm FS LSB’s % FS ppm FS

VREF = 2.5V PGA gain = 1

CS5520; 20-Bit Unit Conversion Factors

Specifications are subject to change without notice.

Page 4

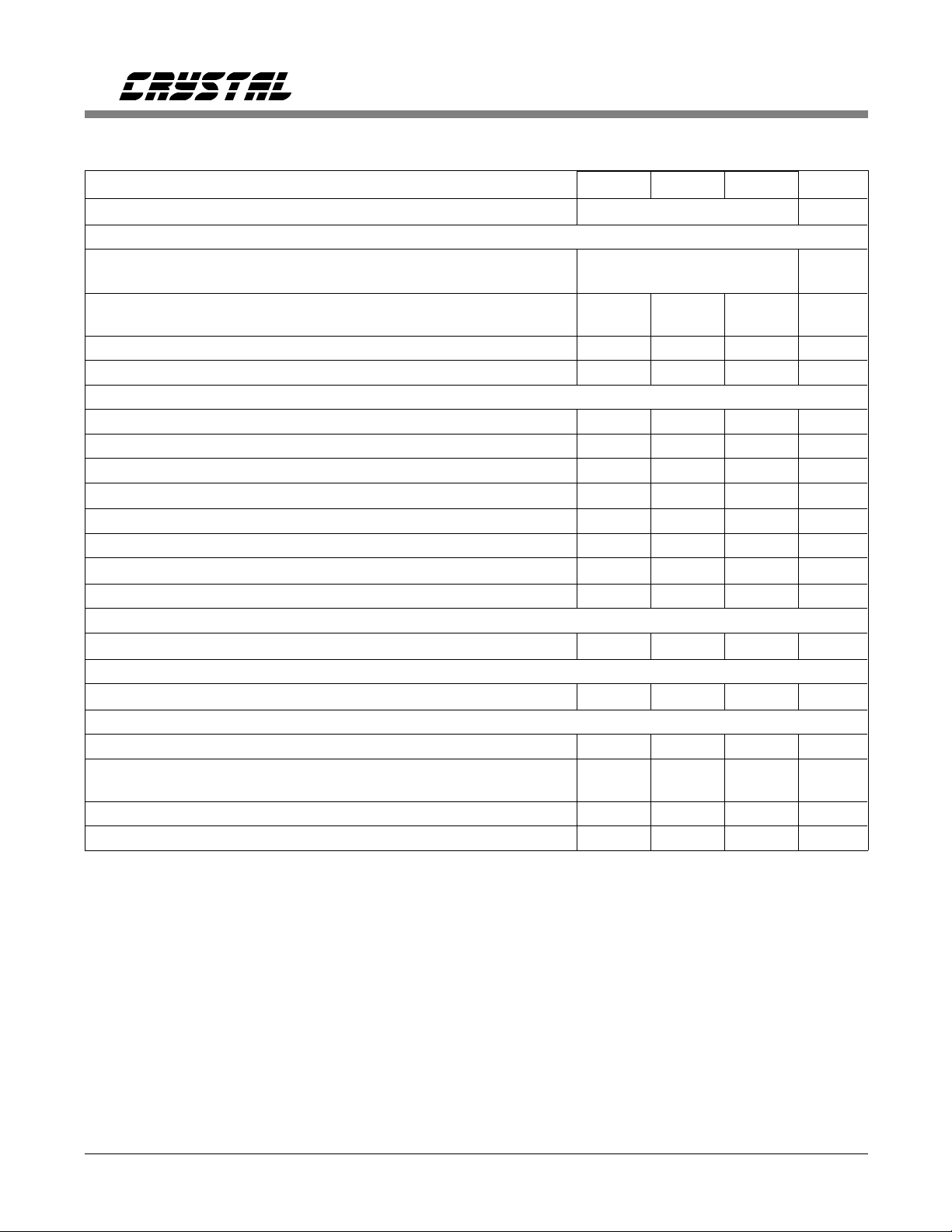

ANALOG CHARACTERISTICS (continued)

Parameter Min Typ Max Units

CS5516, CS5520

Specified Temperature Range -40 to +85

°

C

Analog Input

Analog Input Range Unipolar

Bipolar

Common Mode Rejection dc

50, 60 Hz

Input Capacitance - 5 - pF

Input Bias Current (Note 1) - 100 - pA

12.5, 25, 50, 100

±

12.5, ±25, ±50, ±100

-

-

165

200

mV

mV

-

-

dB

dB

Instrumentation Amplifier

Gain - 25 Bandwidth - 200 - kHz

Unity Gain Bandwidth - 5 - MHz

Output Slew Rate - 1.5 -

Noise @ 10 Hz BW - 100 - nV rms

Power Supply Rejection @ 50/60 Hz (Note 3) - 120 - dB

Common Mode Range (Note 4) -

Chopping Frequency - XIN/128 - Hz

±

3

-V

V/µsec

Programmable Gain Amplifier

Gain Tracking (Note 5) -

±

1

-%

4-Bit Offset Trim DAC

Accuracy -

±

5

-%

Voltage Reference Input

Range (Note 6) 2.0 2.5 3.8 V

Common Mode Rejection: dc

50, 60 Hz

Input Capacitance - 15 - pF

Input Bias Current (Note 1) - 10 - nA

Notes: 3. This includes the on-chip digital filtering.

4. The maximum magnitude of the differential input voltage, Vdiff(in) is determined by the following:

Vdiff(in) < 300 mV - |Vcm/12.5 | and should never exceed 300mV .

Vcm is the common mode voltage which is applied to the ins trumentation amplifier inputs.

The above equation should be used to calculate the allowable common mode voltage for a given

differential voltage applied to the firs t gain stage inputs. This limit ensures

that the instrumentation amplifier does not saturate.

5. Gain tracking accuracy can be significantly improved by uploading a calibrated gain word to the

gain register for each PGA gain s election.

6. The common mode voltage on the Voltage Reference Input, plus the reference range,

[(VREF+) - (VREF-)]/2, must not exceed ±3 volts.

-

-

60

200

-

-

dB

4 DS74F1

Page 5

CS5516, CS5520

ANALOG CHARACTERISTICS (continued)

Parameter Min Typ Max Units

Modulator Differential Voltage Reference

Nominal Output Voltage - 3.75 - V

Initial Output Voltage Tolerance -

Temperature Coefficient - 100 Line Regulation (4.75V < VA < 5.25V) - 0.5 - mV/V

Output Voltage Noise 0.1 to 15 Hz - 10 Output Current Drive: Source Current

Sink Current

-

-

±

100

-

-

Power Supplies

DC Power Supply Currents I

Power Dissipation: (Note 7)

Normal Operation

Standby Mode

Power Supply Rejection: dc Positive Supplies

dc Negative Supplies

I

A+

I

A-

D+

I

D-

-

-

-

-

-

-

-

-

2.7

-2.7

1.5

-0.6

37.5

10

100

95

System Calibration Specifications

Positive Full Scale Calibration Range (Note 8)

Unipolar Mode

Bipolar Mode

Maximum Ratiometric Offset Calibration Range (Note 8)

Unipolar Mode

Bipolar Mode

Differential Input Voltage Range (Notes 4, 8, 9, 10)

Unipolar Mode

Bipolar

Notes: 7. All outputs unloaded. All inputs CMOS levels.

8. T=VREF/(Gx25), where T is the full s cale span, where VREF i s the differential voltage ac ross

VREF+ and VREF- in volts, and G is the gain setting of the second gain block. G can be set

to 1, 2, 4, 8. This sets the overall gain to 25, 50, 100, 200. The gai n can then be fine tuned by

using the calibration of the full s cale point.

9. When calibrated.

10. V

is the offset corrected by the offset c alibration routine. V

offset

0.8T

0.8T

-2T

-2T

Voffset + (1.2T)

Voffset ± (1.2T)

offset

-

-

-

-

may be as large as 2T.

-mV

ppm/°C

µ

V

20

20

3.5

-3.5

2.2

-0.8

-

-

-

-

1.2T

1.2T

+2T

+2T

µ

µ

mA

mA

mA

mA

mW

µ

W

dB

dB

V

V

V

V

V

V

p-p

A

A

DS74F1 5

Page 6

DYNAMIC CHARACTERISTICS

Parameter Symbol Ratio Units

CS5516, CS5520

AIN and VREF Input Sampling Frequency f

Modulator Sampling Frequency f

Output Update Rate f

Filter Corner Frequency f

Settling Time to ±0.0007% (FS Step)

DIGITAL CHARACTERISTICS (T

= T

A

MIN

to T

MAX

is

s

out

-3dB

t

s

; VA+, VD+ = 5V ± 5%; VA-, VD- = -5V ± 5%;

DGND = 0) All measurements below are per formed under static conditions .

Parameter Symbol Min Typ Max Units

High-Level Input Voltage: XIN

All Pins Except XIN

Low-Level Input Voltage XIN

All Pins Except XIN

High-Level Output Voltage (Note 11) V

Low-Level Output Voltage l

= 1.6mA V

out

Input Leakage Current l

3-State Leakage Current l

Digital Output Pin Capacitance C

Notes: 11. I

= -100 µA. This guarantees the ability to drive one TTL load. (VOH = 2.4V @ I

out

V

V

V

V

IH

IH

IL

IL

(VD+)-1.0 - - V

OH

OL

in

OZ

out

f

/128 Hz

clk

f

/256 Hz

clk

f

/81,920 Hz

clk

f

/341,334 Hz

clk

4.5

2.0

-

-

6/f

out

-

-

-

-

-

-

0.5

0.8

s

V

V

V

V

--0.4V

-110

--

±

10

µ

A

µ

A

-9-pF

= -40 µA).

out

6 DS74F1

Page 7

CS5516, CS5520

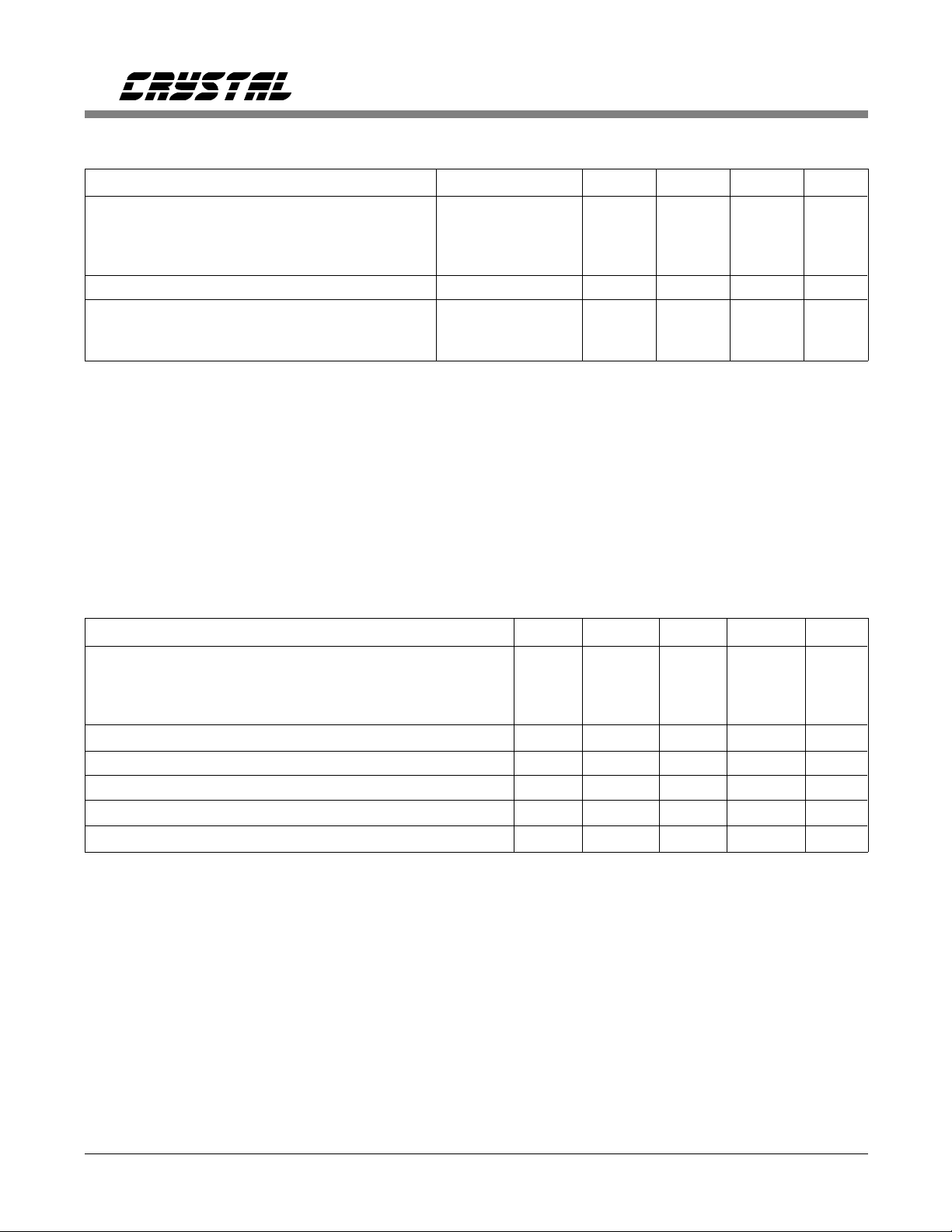

RECOMMENDED OPERATING CONDITIONS (AGND, DGND = 0V, see Note 12.)

Parameter Symbol Min Typ Max Units

DC Power Supplies: Positive Digital

Negative Digital

Positive Analog

Negative Analog

Differential Analog Reference Voltage (VREF+) - (VREF-) 2.0 2.5 3.8 V

Analog Input Voltage: (Note 13)

Unipolar

Bipolar

Notes: 12. All voltages with respect to ground.

13. The CS5516 and CS5520 can accept input voltages up to +T in unipolar mode and -T to +T in bipolar

mode where T=VREF/(Gx25). G is the gain setting at the second gain block . When the inputs exceed

these values, the CS5516 and CS5520 will output positive full scale for any input abov e T, and

negative full scale for inputs below AGND in unipolar and -T in bipolar mode. This applies when the

analog input does not exceed ±2T overrange.

VD+

VD-

VA+

VA-

VAIN

VAIN

4.5

-4.5

4.5

-4.5

0

-T

5.0

-5.0

5.0

-5.0

-

-

5.5

-5.5

5.5

-5.5

+T

+T

V

V

V

V

V

V

ABSOLUTE MAXIMUM RATINGS* (AGND, DGND = 0V, all voltages with respect to ground.)

Parameter Symbol Min Typ Max Units

DC Power Supplies: Positive Digital (Note 14)

Negative Digital

Positive Analog

Negative Analog

Input Current, Any Pin Except Supplies (Notes 15, 16) l

Analog Input Voltage AIN and VREF pins V

Digital Input Voltage V

Ambient Operating Temperature T

Storage Temperature T

Notes: 14. No pin should go more positive than ( VA+)+0.3V. VD+ must always be less than (VA+)+0.3 V,and

can never exceed 6.0V.

15. Applies to all pins inc luding continuous overvoltage condi tions at the analog input pi ns.

16. Transient currents of up to 100mA will not cause SCR latch-up. Max imum input current for a power

supply pin is ± 50 mA.

* WARNING: Operation beyond these limits may r esult in permanent damage to the device.

Normal operation is not guaranteed at these extremes.

VD+

VD-

VA+

VA-

in

INA

IND

A

stg

-0.3

-0.3

-0.3

+0.3

--

(VA-)-0.3 - (VA+)+0.3 V

-0.3 - (VD+)+0.3 V

-55 - 125

-65 - 150

-

-

-

-

(VA+)+0.3

-5.5

5.5

-5.5

±

10

mA

°

°

V

V

V

V

C

C

DS74F1 7

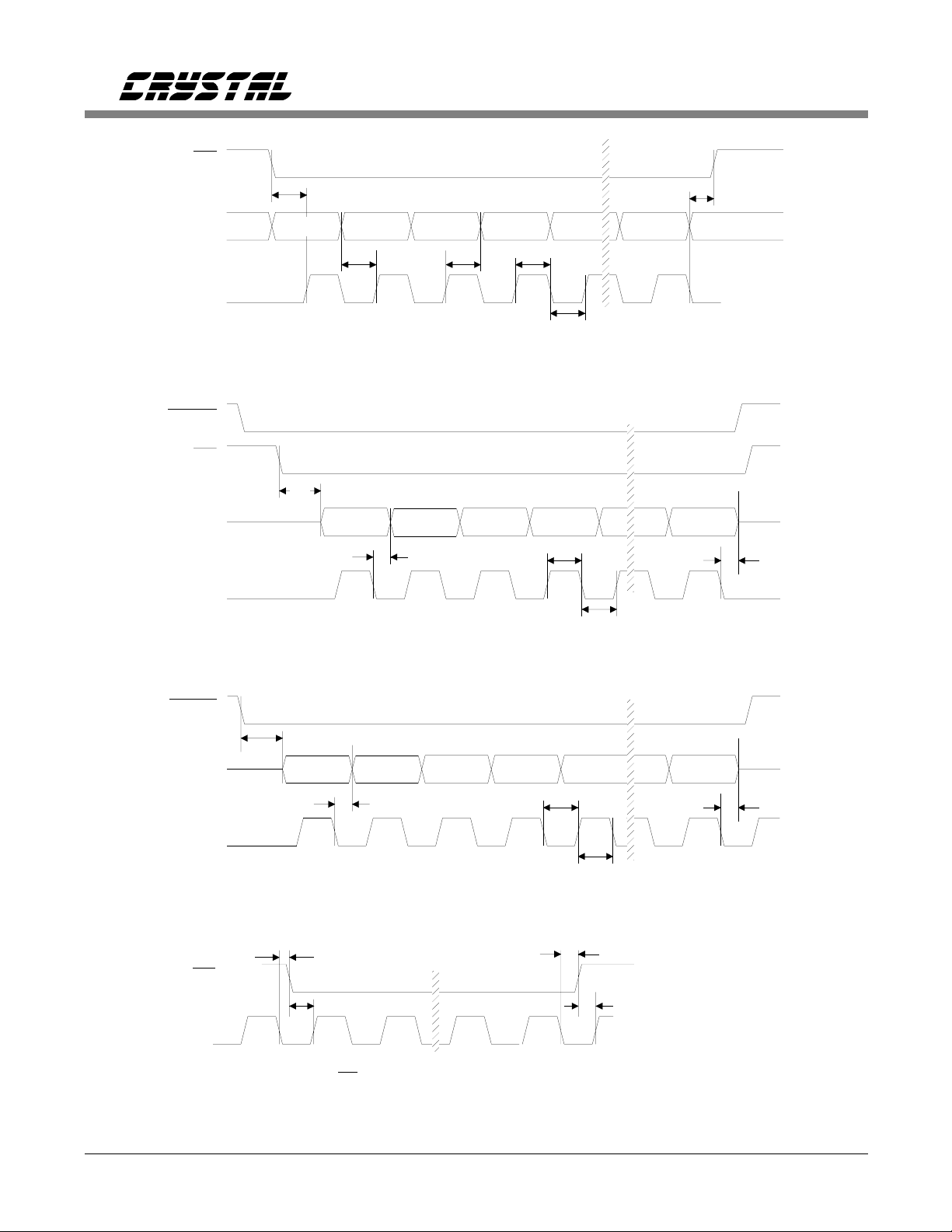

Page 8

CS

CS5516, CS5520

SID

SCLK

DRDY

CS

SOD

SCLK

MSB

t

7

t

3

MSB-1

t

4

SID Write Timing (Not to Scale)

MSB MSB-1

t

6

t

5

t

1

t

2

LSB

t

8

t

1

t

2

t

9

DRDY

SOD

SCLK

CS

SCLK

SOD Read Timing (Not to Scale)

t

10

MSB MSB-1

t

8

SOD Read Timing with CS = 0 (Not to Scale)

t

12

t

13

CS with Continuous SCLK (Not to Scale)

t

1

LSB

t

9

t

2

t

14

t

15

8 DS74F1

Page 9

CS5516, CS5520

SWITCHING CHARACTERISTICS (T

VA-, VD- = -5V±5%; Input Levels: Logic 0 = 0V, Logic 1 = VD+; C

A

= T

MIN

to T

VA+, VD+ = 5V ± 5%;

MAX;

= 50 pF)

L

Parameter Symbol Min Typ Max Units

Master Clock Frequency: Internal Oscillator / External Clock XIN 1.0 4.096 5.0 MHz

Master Clock Duty Cycle 40 - 60 %

Rise Times Any Digital Input (Note 18)

Any Digital Output

Fall Times Any Digital Input (Note 18)

Any Digital Output

t

t

rise

fall

-

-

-

-

50

50

-

-

1.0

-

1.0

-

µ

ns

µ

ns

Startup

Power-on Reset Period t

Oscillator Start-up Time X TAL = 4.9152 MHz(Note 19) t

RST Pulse Width t

por

ost

res

- 100 - ms

-60-ms

1/XIN - - ns

Serial Port Timing

Serial Clock Frequency SCLK - - 2.4 MHz

Serial Clock Pulse Width High

Pulse Width Low

t

1

t

2

200

200

-

-

-

-

ns

ns

SID Write Timing

CS Enable to Valid Latch Clock t

Data Set-up Time prior to SCLK rising t

Data Hold Time After SCLK Rising t

SCLK Falling Prior to CS Disable t

3

4

5

6

150 - - ns

50 - - ns

50 - - ns

50 - - ns

SOD Read Timing

CS to Data Valid t

SCLK Falling to New Data Bit t

SCLK Falling to SOD Hi-Z t

DRDY Falling to Valid Data (CS = 0) t

CS Rising to SOD Hi-Z t

CS Disable Hold Time t

CS Enable Set-up Time t

CS Enable Hold Time t

CS Disable Set-up Time t

7

8

9

10

11

12

13

14

15

- - 150 ns

- - 170 ns

- - 200 ns

- - 150 ns

- - 150 ns

50 - - ns

150 - - ns

50 - - ns

150 - - ns

Notes: 18. Specified using 10% and 90% points on waveform of interest. Output loaded wi th 50 pF.

19. Oscillator start-up time var ies with crystal par ameters. This specification does not apply when us ing

an external clock source.

s

s

DS74F1 9

Page 10

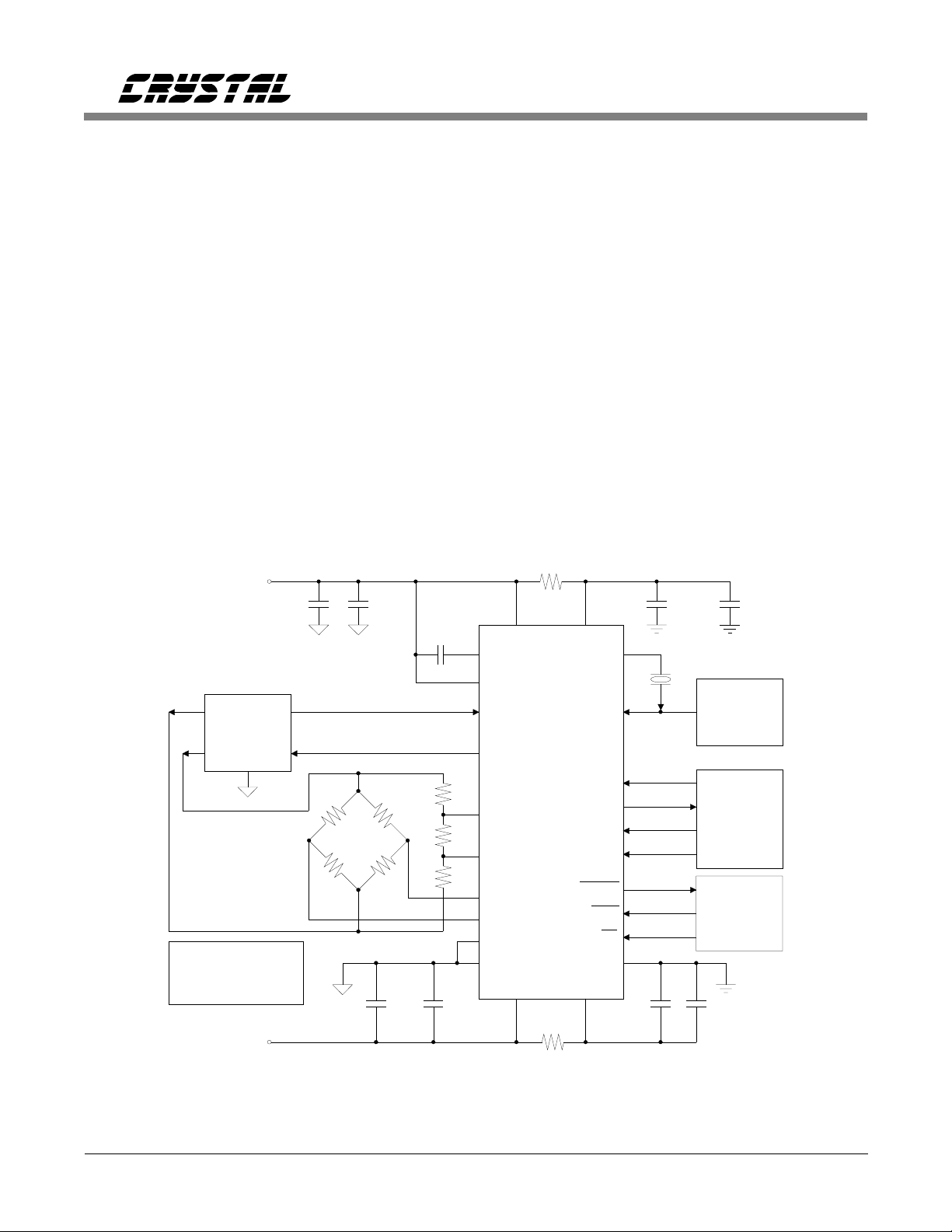

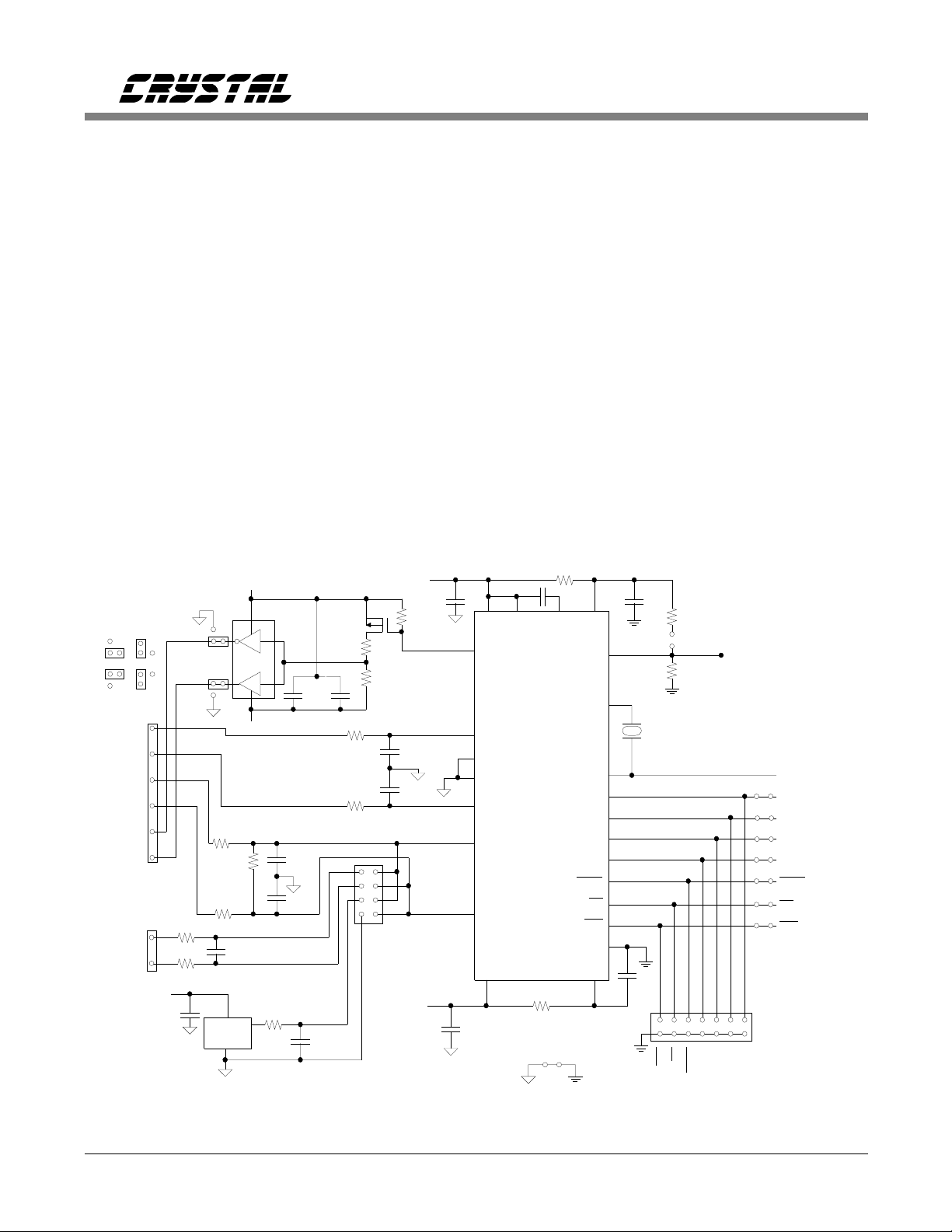

GENERAL DESCRIPTION

CS5516, CS5520

The CS5516 and CS5520 are monolithic CMOS

A/D converters which include an instrumentation

amplifier input, an on-chip programmable gain

amplifier, and a DAC for offset trimming.

While the devices are optimized for ratiometric

measurement of Wheatstone bridge applications,

they can be used for general purpose low-level

signal measurement.

Each of the devices includes a two-channel differential delta-sigma modulator (the signal

measurement input and the reference input are

digitized independently before a digital output

word is computed), a calibration microcontroller,

a two-channel digital filter, a programmable instrumentation amplifier block, a 4-bit DAC for

+5V

Analog

Supply

Bridge

Excitation

Supply

-

Unused logic inputs

must be connected

to DGND or VD+

-5V

Analog

Supply

0.1 µF1 µF1

1 µF

Excitation Supply

Synch. Signals

+

0.1 µF

1 µF 1 µF

coarse offset trimming, circuitry for generation

and demodulation of AC (actually switched DC)

bridge excitation, and a serial port. The CS5516

outputs 16-bit words; the CS5520 outputs 20-bit

words.

The CS5516/20 devices can measure either

unipolar or bipolar signals. Self-calibration is

utilized to maximize performance of the measurement system. To better understand the

capabilities of the CS5516/20, it is helpful to examine some of the error sources in bridge

measurement systems.

10

Ω

µ

F

Optional

Clock

Source

Serial

Data

Interface

Control

Logic

0.1 µF

2

1

12

11

9

10

6

7

5

8

320

10

VD+

SMODE

DGND

VD-

Ω

VA+

MDRVMDRV+

BX1

BX2

VREF+

VREF-

AIN+

AINAGND1

AGND2

VA-

CS5516

CS5520

XOUT

XIN

SCLK

SOD

SID

DRDY

RST

CS

214

0.1 µF

23

22

16

18

17

24

15

13

14

19

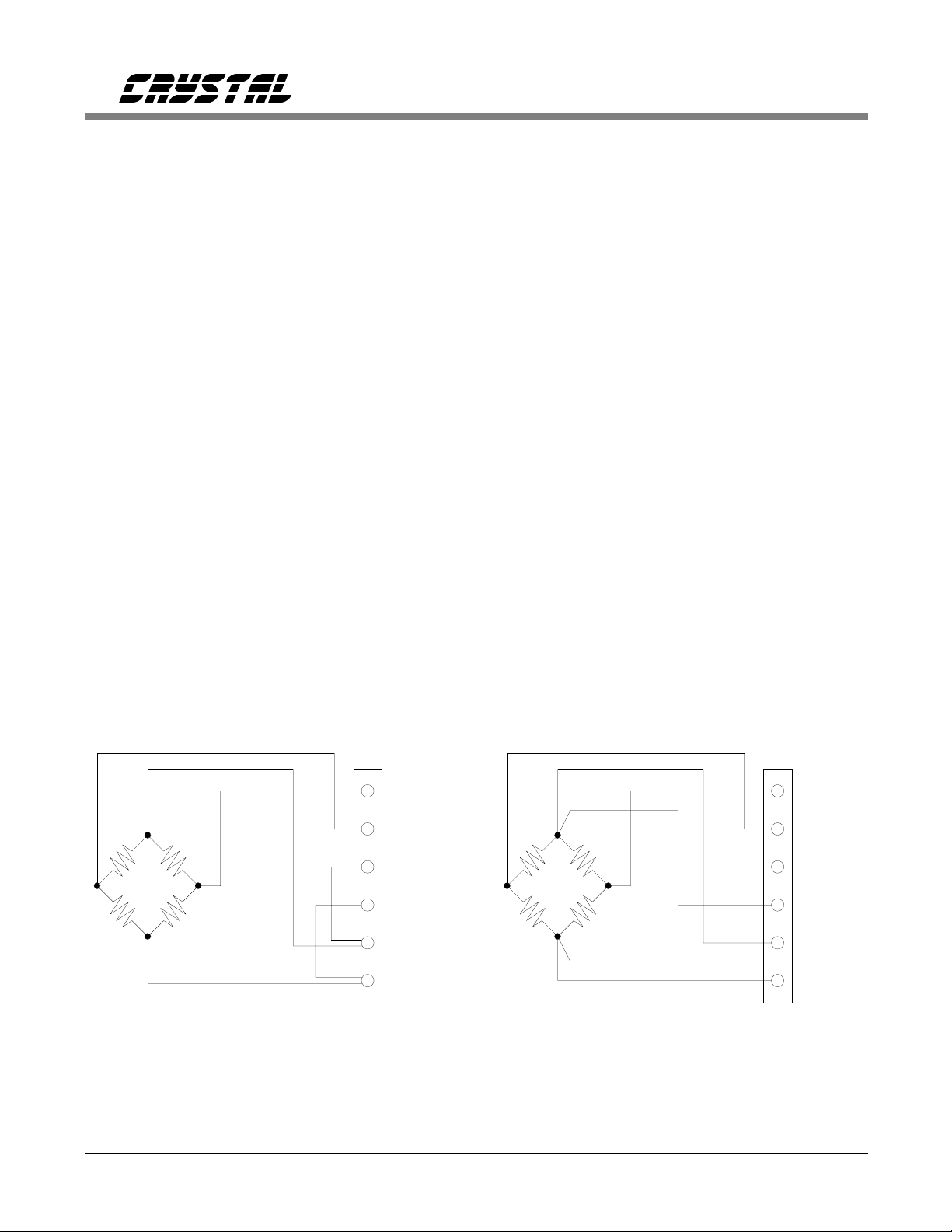

Figure 1. System Connection Diagram: AC Excitation Mode Using External Excitation

10 DS74F1

Page 11

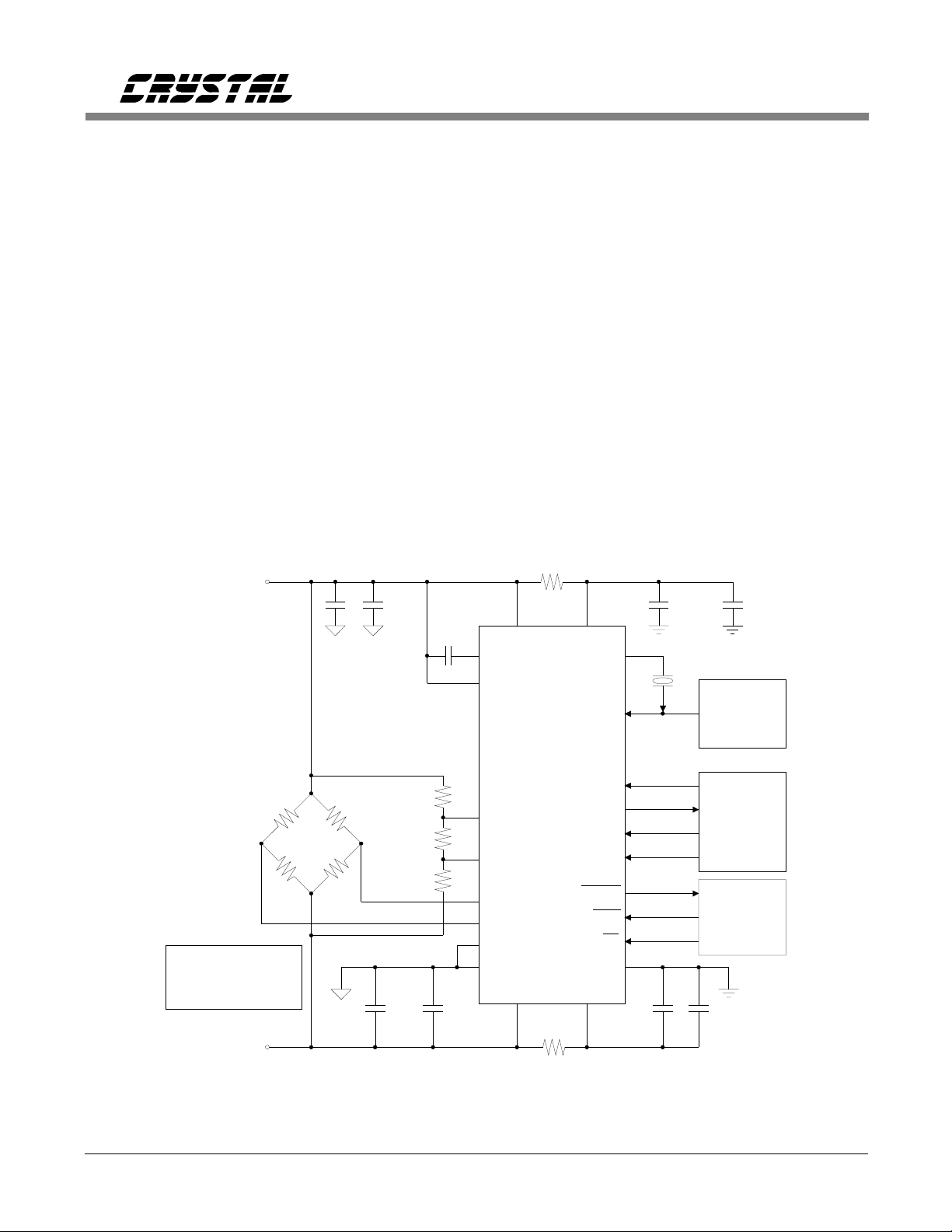

THEORY OF OPERATION

CS5516, CS5520

The front page of this data sheet illustrates the

block diagram of the CS5516 and CS5520 A/D

converter. The device includes an instrumentation amplifier with a fixed gain of 25. This

chopper-stabilized instrumentation amplifier is

followed by a programmable gain stage with

gain settings of 1, 2, 4, and 8. The sensitivity of

the input is a function of the programmable gain

setting and of the reference voltage connected

between the VREF+ and VREF- pins of the device. The full scale of the converter is VREF/( G

x 25) in unipolar, or ±VREF/(G x 25) in bipolar,

where VREF is the reference voltage between

the VREF+ and VREF- pins, G is the gain setting of the programmable gain amplifier, and 25

is the gain of the instrumentation amplifier.

+5V

Analog

Supply

-

Unused logic inputs

must be connected

to DGND or VD+

-5V

Analog

Supply

0.1 µF1 µF1

1 µF

+

0.1 µF

1 µF 1 µF

After the programmable gain block, the output

of a 4-bit DAC is combined with the input signal. The DAC can be used to add or subtract

offset from the analog input signal. Offsets as

large as ±200 % of full scale can be trimmed

from the input signal.

The CS5516 and CS5520 are optimized to perform ratiometric measurement of bridge-type

transducers. The devices support dc bridge excitation or two modes of ac (switched dc) bridge

excitation. In the switched-dc modes of operation the converter fully demodulates both the

reference voltage and the analog input signal

from the bridge.

10

Ω

µ

F

Optional

Clock

Source

Serial

Data

Interface

Control

Logic

2

1

9

10

6

7

5

8

320

10

VD+

SMODE

DGND

VD-

Ω

VA+

MDRVMDRV+

CS5516

CS5520

VREF+

VREF-

AIN+

AINAGND1

AGND2

VA-

XOUT

XIN

SCLK

SOD

SID

DRDY

RST

CS

214

0.1 µF

23

22

16

18

17

24

15

13

14

19

0.1 µF

Figure 2. System Connection Diagram: DC Excitation Mode (EXC bit = 0), F1 = F0 = 0.

DS74F1 11

Page 12

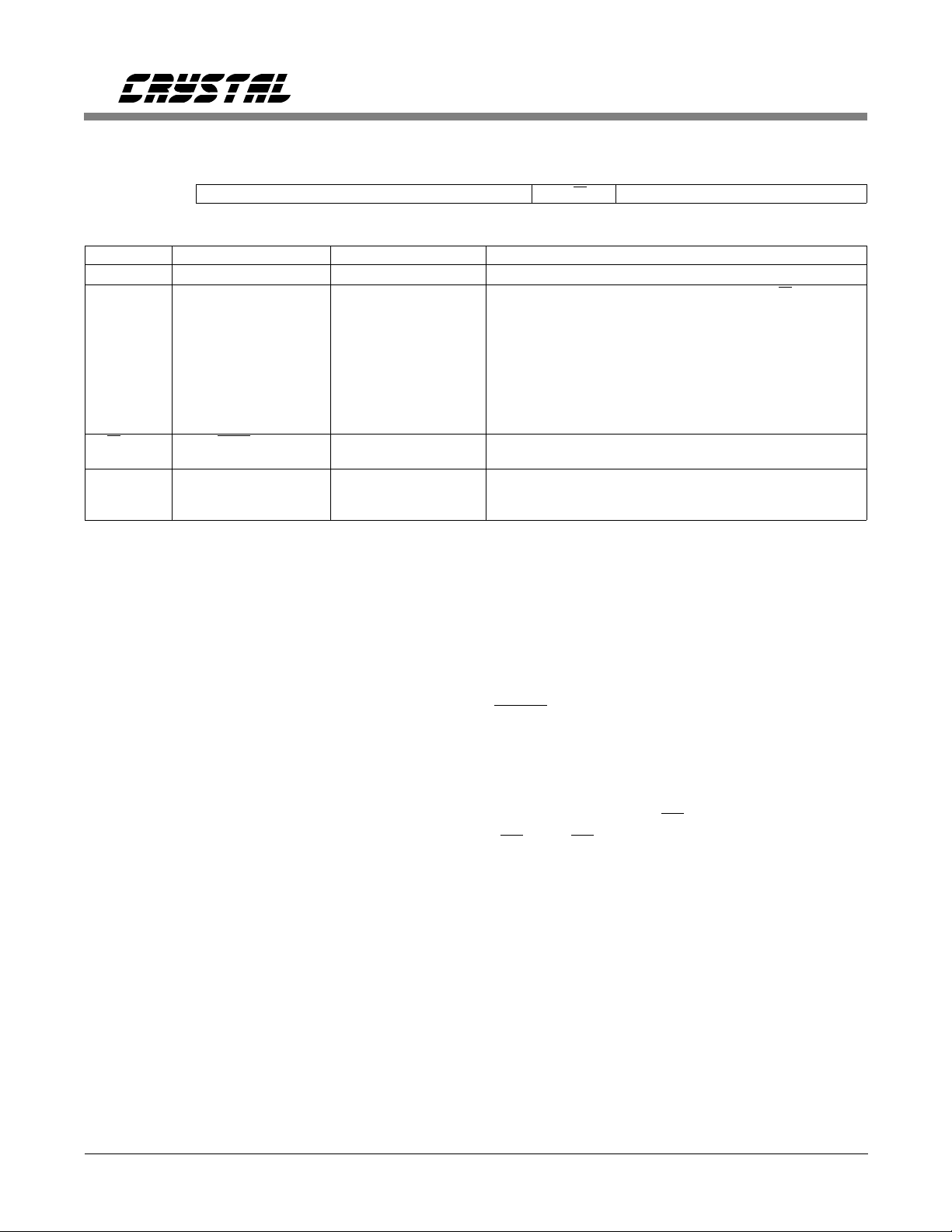

Command Register

D7 D6 D5 D4 D3 D2 D1 D0

1 RSB2 RSB1 RSB0 R/

BIT NAME VALUE FUNCTION

D7 D7 1 Must always be logic 1

RSB2-0 Register Select Bit

000

001

010

011

100

101

110

111

R/W R ead/Write 0

D2

D1

D0

D2

D1

D0

1

0

0

0

Selects Re gister to be Read o r Writte n per R/

CONVERSION DATA (read only )

CONFIGURATION

GAIN

DAC

RATIOMETRIC OFFSET

NON-RATIOMETRIC OFFSET - AIN

NON-RATIOMETRIC OFFSET - VREF

NOT USED

Write to the registe r selected by th e RSB2-0 bi ts

Read from the regi ster selec ted by the RS B2-0 bits

Not Used

Not Used

Not Used

W0 0 0

CS5516, CS5520

W bit

Table 1. CS5516 and CS5520 Commands

The CS5516/20 includes a microcontroller which

manages operation of the chip. Included in the

microcontroller are eight different registers associated with the operation of the device. An 8-bit

command register is used to interpret instructions received via the serial port. When power

is applied, and the device has been re set, the serial port is initialized into the command mode.

In this mode it is waiting to receive an 8-bit

command via its serial port. The first 8 bits into

the serial port are placed into the command register. Table 1 lists all the valid command words

for reading from or writing to internal registers

of the converter. Once a valid 8-bit command

word has been received and decoded, the serial

port goes into data mode. In data mode the next

24 serial clock pulses shift data either into or out

of the serial port. When writing data to the port,

the data may immediately follow the command

word. When reading data from the port, the user

must pause after clocking in the 8-bit command

word to allow the microcontroller time to decode

the command word, access the appropriate regis-

ter to be read, and present its 24-bit word to the

port. The microcontroller will signal when the

24-bit read data is available by causing the

DRDY pin to go low.

The user must write or read the full 24-bit word

except in the case of reading conversion data. In

read data conversion mode, the user may read

less than 24 bits if CS is then made inactive

(CS = 1). CS going inactive releases user control

over the port and allows new data updates to the

port.

The user can instruct the on-chip microcontroller

to perform certain operations via the configuration register. Whenever a new word is written

to the 24-bit configuration register, the microcontroller then decodes the word and executes

the configuration register instructions. Table 2

illustrates the bits of the configuration register.

The bits in the configuration register will be discussed in various sections of this data sheet.

12 DS74F1

Page 13

Configuration Register

D23 D22 D21 D20 D19 D18 D17 D16 D15 D14 D13 D12

Register

Reset (R)

Register

Reset (R)

DAC3 DAC2 DAC1 DAC0 EXC F1 F0 D16 G1 G0 U/B D12

000000000000

D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

A/S EC D9 D8 CC3 CC2 CC1 CC0 D3 D2 D1 RF

000000000000

CS5516, CS5520

BIT NAME VALUE FUNCTION

DAC3 DAC Sign Bit 0

1

DAC2-0 DAC Bits 000

001

010

011

100

101

110

111

EXC E xcitatio n: Internal

External

F1-F0 Select Frequenc y 00

D16 D16 0

G1-G0 Select PGA Gain 00

U/B Select Unipolar/B ipo-

lar Mode

D12 D12 0

A/S Awake/ Sleep 0

EC Execute Cali bration 0

D9 D9 0

D8 D8 0

CC3-CC0 Calibration Control Bits 0000

D3 D3 0

D2 D2 0

D1 D2 0

RF Reset Filter 0

0

1

01

10

11

10

01

11

0

1

1

1

1000

0100

0010

0001

1

1

R

Add Offset

Subtract Offset This bit is read only

R

25% Offset

50% Offset

75% Offset

100% Offset These bits are read only

125% Offset

150% Offset

175% Offset

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

BX1 and BX2 outp uts are de termi ned by bits F1 and F0

BX1 is an input which determines the phase of the

demodulation clock and the BX2 output

Excitation on BX1 & BX2 is dc. BX1=0 V, BX2=+5 V

Excitation Frequency on BX1 & BX2 is XIN/8192 Hz

Excitation Frequency on BX1 & BX2 is XIN/16384 Hz

Excitation Frequency on BX1 & BX2 is XIN/4096 Hz

Must always be logic 0

Gain = 1 (X25)

Gain = 2 (X25)

Gain = 4 (X25)

Gain = 8 (X25)

Bipolar Measureme nt Mode

Unipolar Measurement Mode

Must always be logic 0

Awake Mode

Sleep Mode

Calibration not active

Perform calibratio n select ed by CC 3-CC0 bi ts. EC bi t

must be written back to "0" after calibration is completed

Must always be logic 0

Must always be logic 0

No calibration to be performed

Calibrate non-ratiometric offset, VREF

Calibrate non-ratiometric offset, AIN

Calibrate ratiometric offset, AIN

Calibrate gain, AIN

Must always be logic 0

Must always be logic 0

Must always be logic 0

Normal operation

Reset Filter

2

2

Notes:1.Reset State

2.A write to these bits does not change the register bit values. These bits are just a mirror of the DAC register contents.

Table 2. Configuration Register

DS74F1 13

Page 14

CS5516, CS5520

System Initialization

Whenever power is applied to the

CS5516/CS5520 A/D converters, the devices

must be reset to a known condition before

proper operation can occur. The internal reset is

applied after power is established and lasts for

approximately 100 ms. The RST pin can also be

used to establish a reset condition. The reset signal should remain low for at least one XIN clock

cycle to ensure adequate reset time. It is recommended that the RST pin be used to reset the

converter if the power supplies rise very slowly

or with poor startup characteristics. The RST

signal can be generated by a microcontroller output, or by use of an R-C circuit.

The reset function initializes the configuration

register and all five of the calibration registers;

and places the microcontroller in command

mode ready to accept a command from the serial

port. Whenever the device is reset the DRDY

pin will be set to a logic 1 and the on-chip registers are initia lized to t he following s tates:

Configuration 000000(H)

Calibration registers:

DAC 000000(H)

Gain 800000(H)

AIN Ratiometric Offset 000000(H)

AIN Non-ratiometric Offset 000000(H)

VREF Non-ratiometric Offset 000000(H)

CALIBRATION

After the CS5516/20 is reset, the device is functional and can perform measurements without

being calibrated. The converter will utilize the

initialized values of the calibration registers to

calculate output words.

The converter uses the two outputs (AIN &

VREF) of the dual channel converter along with

the contents of the calibration registers to compute the conversion data word. The following

equation indicates the computation.

D

− R1

R0 = R4 [[

Where R0 is the output data, D

D

VREF

AIN

− R2

] − R3]

and D

AIN

VREF

are the digital output words from the AIN and

VREF digital filter channels, and R1, R2, R3

and R4 are the contents of the following calibration registers:

R1 = AIN non-ratiometric offset

R2 = VREF non-ratiometric offset

R3 = AIN ratiometric offset

R4 = Gain

The computed output word, R0, is a two’s complement number.

Calibration minimizes the errors in the converted

output data. If calibration has not been performed, the measurements will include offset

and gain errors of the entire system.

The converter may be calibrated each time it is

powered up, or calibration words from a previous calibration may be uploaded into the

appropriate calibration registers from some type

of E2PROM by the system microcontroller.

The converter uses five different registers to

store specific calibration information. Each of

the calibration registers stores information pertinent to correcting a specific source of error

associated with either the converter or with the

input transducer and its wiring. The method by

14 DS74F1

Page 15

CS5516, CS5520

Configuration Register

EC CC3 CC2 CC1 CC0

11000 VREF Non-ratiometric Offset 573,440/fclk

10100 AIN Non-ratiometric Offset 573,440/fclk

10010 AIN Ratiometric Offset 2,211,840/fclk

10001 AIN System Gain 573,440/fclk

11100VREF & AIN Non-ratiometric Offset 573,440/fclk

0XXXX End Calibration -

DRDY remains high through calibration sequence. In all modes, DRDY falls immediately upon completion of the calibration

sequence.

Table 3. CS5516/CS5520 Calibration Control

which calibration is initiated is common to each

of the calibration registers. The configuration

register controls the execution of the calibration

process. Bits CC3--CC0 in the configuration

register determine which type of calibration will

be performed and which of the five calibration

registers will be affected. On the falling edge of

the 24th SCLK, the configuration word will be

latched into the configuration register and the se-

formed. The calibration steps should be performed in the following sequence. If the user

determines that non-ratiometric offset calibration is important, the non-ratiometric offset

errors of the VREF and AIN input channels

should be calibrated first. Then the ratiometric

offset of the AIN channel should be calibrated.

And finally, the AIN channel gain should be

calibrated.

CAL Type Calibration Time

lected calibration will be executed. The time

required to perform a calibration is listed in Table 3. The DRDY pin will remain a logic 1

during calibration, and will go low when the

calibration step is completed.

The serial port should not be accessed while a

calibration is in progress. The EC bit of the

configuration register remains a logic 1 until it is

overwritten by a new configuration word (EC =

0). Consequently, if EC is left active, any write

(the falling edge of the 24th SCLK) to any register inside the converter will cause a re-execution

of the calibration sequence. This occurs because

the internal microcontroller executes the contents

of the configuration register every time the 24th

SCLK falls after writing a 24-bit word to any

internal register. To be certain that calibrations

will not be re-executed each time a new word is

written or read via the serial port, the EC bit of

Non-ratiometric Errors

To calibrate out the VREF and AIN

non-ratiometric errors, the input channels to the

VREF path into the converter and the AIN path

into the converter must be grounded (this may

occur at the pins of the IC, or at the bridge excitation as shown in Figure 3.). Then the EC,

CC2 and CC3 bits of the configuration register

must be set to logic 1. The converter will then

perform a non-ratiometric calibration and place

BX1

BX2

CS5516

CS5520

VREF+

VREF-

AIN+

+

1A*1B*

-

the configuration register must be written back

to a logic 0 after the final calibration step has

been completed.

The CC3--CC0 bits of the configuration register

determine the type of calibration to be per-

*Note: The bridge can be grounded with a

Figure 3. Non-ratiometric System Calibration using

AIN-

relay or with jumpers to perform

non-ratiometric calibration.

Internal Excitation

DS74F1 15

Page 16

CS5516, CS5520

the proper 24 bit calibration words in the VREF

and AIN non-ratiometric registers. Note that the

two non-ratiometric offsets can be calibrated simultaneously or independently, but they must be

calibrated prior to the other calibration steps if

non-ratiometric offset calibration is to be used. If

the effects of the non-ratiometric errors are not

significant enough to affect the user application,

they can be left uncalibrated (after a reset, the

non-ratiometric offset registers will contain

000000(H)).

Ratiometric Offset

Once the non-ratiometric errors have been calibrated, the ratiometric offset error of the AIN

channel should be calibrated next. To perform

this calibration step, a reference voltage must be

applied to the VREF+ and VREF- pins. Then,

place "zero" weight on the scale platform. This

will result in an offset voltage into the converter

which will represent the offset of the bridge, the

wiring, and the AIN input of the converter itself.

A configuration word with the EC and CC1 bits

set to logic 1 is then written into the configuration register. During the ratiometric offset

calibration of AIN the microcontroller first uses

a successive approximation algorithm to compute the correct values for the DAC3-DAC0 bits

of the DAC register. This accommodates any

large offsets on the AIN input signal. Once the

four DAC bits are computed, this amount of offset is removed from the input signal. The

microcontroller then computes the appropriate

24 bit number to place in the AIN ratiometric

offset register to calibrate out the remaining offset not removed by the DAC.

Gain

After the AIN ratiometric offset has been calibrated, the next step is to perform a gain

calibration. Gain calibration is performed with

"full scale" weight on the scale platform. The

EC and CC0 bits of the configuration register

are set to logic 1. The gain calibration of the

AIN channel is the final calibration step. After

DRDY falls to signal the completion of this calibration step, the EC bit of the configuration

register must be set back to logic 0 to terminate

the calibration mode.

Limitation s in Calib ration Range

There are five calibration registers in the converter. There are two non-ratiometric offset

calibration registers, one for the AIN input and

one for the VREF input; one 4-bit offset trim

DAC; one ratiometric offset calibration register

for the AIN input; and one gain calibration register. After the non-ratiometric offsets are

calibrated, an LSB in either of the 24-bit non-ratiometric calibration registers represents 2

-23

proportion of an internally-scaled MDRV

(Modulator Differential Reference Voltage). At

the MDRV+ and MDRV- pins, the MDRV has a

nominal value of 3.75 volts. This voltage is internally scaled to a nominal 2.5 volts (never less

than 2.4 volts) for use with the non-ratiometric

calibration. The two non-ratiometric calibration

words are stored in 2’s complement form with

one count equal to slightly less than 300 nV at

the input of the internal A/D converter. For the

AIN channel this will be scaled down by the

gain of the instrumentation amplifier (X25) and

the PGA gain. For a PGA gain = 1, one count of

a non-ratiometric register will represent slightly

less than 12 nV. Non-ratiometric offset at the

VREF input cannot exceed ± 2.4 volts to be

within calibration range of the converter. Nonratiometric offset to be calibrated by the AIN

channel cannot exceed ± 2.4 volts divided by the

channel gain. With a PGA gain = 1, the maximum non-ratiometric offset which can be

calibrated on the AIN channel cannot exceed

± 96 mV.

When the ratiometric offset is calibrated, the 4bit DAC coarsely trims offset from the analog

signal. The ratiometric offset which remains is

finely trimmed after the signal has been converted; using the contents of the ratiometric

offset register for digital correction. The DAC

16 DS74F1

Page 17

CS5516, CS5520

bits can be manipulated by the user to add or

subtract offset up to 200 percent of the nominal

input signal. The AIN ratiometric offset register

can be manipulated to add or subtract offset

equal to the maximum differential input signal

into the X2 5 amplifier. An LSB in the ra tiometric offset register represents 2

-23

proportion of

the voltage input across the VREF+ and VREFpins at the internal input to the AIN channel

A/D converter. This will be scaled down by the

AIN channel gain when calculated relative to the

instrumentation amplifier input. For example,

with a VREF = 2.5 V, the PGA gain = 1, one

count of the ratiometric offset register would

represent about 12 nV at the instrumentation amplifier input. The proportion remains ratiometric

even if the VREF voltage should change. The

24-bit register content is stored in 2’s complement form.

Manipulation of the DAC or ratiometric offset

register allows the user to shift the transfer function to allow for load cell creep or load cell zero

drift.

The gain calibration is performed last. The contents of the gain register spans from 2

-23

to 2 as

shown in Table 4. After gain calibration has

been performed, the numeric value in the gain

register should not exceed the range of 0.8 to

1.2. The gain calibration range is ± 20 % of the

nominal value of 1.0. The nominal value of 1.0

is for an input span dictated by the VREF voltage, the PGA gain, and the X25 instrumentation

gain. The converter may operate with gain slope

factors from 0.5 to 2.0 (decimal), but when the

slope exceeds 1.2 the converter output code

computation may lack adequate resolution and

result in missing codes in the transfer function.

Internal circuitry may saturate for large signals

which would calibrate to a gain factor less than

0.8.

In a typical weigh scale application, the

CS5516/CS5520 will be calibrated in combination with a load cell at the factory. Once

calibrated, the calibration words are off-loaded

from the converter and stored in E2PROM.

When powered-up in the field the calibration

words are up-loaded into the appropriate registers. This is viable because the AIN and VREF

input to the converter are "chopper-stabilized"

and maintain excellent stability when subjected

to changes in temperature.

Programmable Gain Amplifier

The programmable gain amplifier inside the

CS5516/20 offers gains of 1, 2, 4, and 8. This is

in addition to the fixed gain of × 25 in the input

instrumentation amplifier. The gain tracking of

the PGA is about one percent between ranges.

The user can remove this error by performing a

gain calibration at the factory with a full scale

signal on each range. The gain calibration word

for each gain range can be off-loaded into

E2PROM and uploaded into the gain register

whenever a new gain setting is selected for the

PGA. Gain stability over temperature for the

converter itself is approximately 1 ppm/°C when

the device is used ratiometrically.

Serial Interface Modes

The CS5516/20 support either 5, 4 or 3 pin serial interfacing. The SMODE pin sets the

operating mode of the serial interface. With

SMODE = 0, the device assumes the user is operating with either a 5 or 4 wire interface. The

five wire mode includes SOD, SID, SCLK,

DRDY, and CS. In the four wire mode, CS is

connected to DGND as a logic 0. The user

would then interface to the SOD, SID, SCLK,

and DRDY pins.

DS74F1 17

Page 18

AIN and VREF Non-Ratiometric Offset Registers

MSB LSB

Register

Reset (R)

0

2

000000 000000

-1

2

-2

2

-3

2

-4

2

-5

2

-18

2

≈

CS5516, CS5520

-19

2

-20

2

-21

2

-22

2

-23

2

One LSB represents 2

-23

proportion of th e internal MDRV (≈2.5 Volts)

DAC Register

D23 D22 D21 D20 D19 D18 D17 D16 D15 D14 D13 D12

Register

Reset (R)

Register

Reset (R)

BIT NAME VALUE FUNCTION

DAC3 DAC Sign Bit 0

DAC2-0 DAC Bits 000

Bits

D19 to D0

DAC3 DAC2 DAC1 DAC0 EXC F1 F0 D16 G1 G0 U/B D12

000000000000

D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

A/S EC D9 D8 CC3 CC2 CC1 CC0 D3 D2 D1 RF

000000000000

1

1

R

Add Offset

Subtract Offset

R

001

010

011

100

101

110

111

0

R

25% Offset

50% Offset

75% Offset

100% Offset

125% Offset

150% Offset

175% Offset

These bits mi rror t he

Configuration Register

read only

2

Note: 1. Reset State

2. A write to these bi ts does not ch ange the regis ter bit valu es.

AIN Ratiometric Offset Register

MSB LSB

Register

Reset (R)

One LSB represents 2

0

2

000000 000000

-1

2

-2

2

-3

2

-4

2

-5

2

-18

2

-19

2

-20

2

-21

2

≈

-23

proportion of the voltage [<(VREF+) - (VREF-)>/GAIN] where GAIN = 25 X PGA Gain

-22

2

-23

2

GAIN Register

MSB LSB

Register

Reset (R)

The gain reg ister span f rom 0 t o (2-2

0

2

100000 000000

18 DS74F1

-1

2

-2

2

-3

2

-4

2

-5

2

-18

2

-19

2

-20

2

-21

2

-22

2

-23

2

≈

-23

). After Reset the MSB=1, all other bits are 0.

Table 4. Calibration Registers

Page 19

CS5516, CS5520

Reading a register in the converter requires a

command word to be written to the SID pin.

For example, to read the conversion data register, the following command sequence should be

performed. First, the command word 88(H)

would be issued to the port. In the 5 wire interface mode, this would involve activating CS

low, followed by 8 SCLKs (note that SCLK

must always start low and transition from low to

high to latch the transmit data, and then back

low again) to input the 8-bit command word. CS

must be low for the serial port to recognize

SCLKs during a write or a read, but it is actually

the first rising SCLK during command time that

gives the user control over the port. After writing the command word, the user must pause and

wait until the CS5520 presents the selected register data to the serial port. The DRDY signal

will fall when the data is available. When reading the conversion data register, it may take up

to 112,000 XIN clock cycles for DRDY to fall

after the 88(H) command word is recognized.

See Figure 4 for an illustration of command and

data word ti ming.

The conversion data register is actually the accumulator of the post-processor which computes

the output data. At the end of each filter convolution cycle, the internal microcontroller checks

to see if a read conversion data register command has been interpreted. If so, it transfers the

accumulator result to the serial port.

Whenever registers other than the conversion

data register are read, the DRDY pin will fall

within 256 XIN clock cycles (62.5 µs with

XIN = 4.096 MHz) after the command word is

recognized. When DRDY falls, 24 SCLKs are

then issued to the port to read the 24-bit output

data word. DRDY will return high after all 24

bits have been clocked out. The SOD pin will be

in a Hi-Z state whenever CS is high, or after all

24 output data bits have been clocked out of the

port.

The CS5516/20 is designed such that it can output conversion data words continuously, without

issuing a new command word prior to each data

read. Under the following circumstances, continuous conversion data can be read from the

port after issuing only one 88(H) command

word. Once the command to read the conversion

data register is issued, DRDY must be allowed

to go low, after which 24 SCLKs are issued to

read the data. This will cause DRDY to return

high.

The converter will continue to output conversion

words at the update rate as long as a different

command word is not started prior to DRDY

falling again. The user is not required to read

every output word to remain in the continuous

update mode. DRDY will toggle high, and then

low as each new output word becomes available.

If a command word is issued immediately after a

data word is read, the converter will end the read

conversion mode. Figure 5 illustrates the continuous data mode.

The user should perform all data reads and command writes within 51,000 XIN clock cycles

after DRDY falls to avoid ambiguity as to who

controls the serial port.

If SMODE = 1 (tied to VD+), the interface operates as a 3 wire interface using only SOD, SID,

and SCLK. In the 3 wire mode CS must be tied

to DGND. DRDY operates normally but is not

used. Instead, the DRDY signal modifies the

behavior of the SOD signal, allowing it to signal

to the user when data is available. To read data

from the converter requires a command word to

be written to the SID pin. The SOD output is

normally high (never Hi-Z). When output data

is available, the SOD signal will go low. The

user would then issue 8 SCLKs to the SCLK pin

to clear this data ready signal. On the falling

edge of the 8th SCLK the SOD pin will present

the first bit of the 24-bit output word. 24 SCLKs

are then issued to read the data. Then SOD will

go high. SID should remain low whenever the

DS74F1 19

Page 20

CS

SCLK

CS5516, CS5520

SID

CS

SCLK

SID

DRDY

SOD

Command Time

8 SCLKs

Command Time

8 SCLKs

MSB

SID Write

t *

d

MSB

SOD Read (4 or 5 Wire)

LSB

Data Time

24 SCLKs

LSB

Data Time

24 SCLKs

SCLK

SID

81,920 XIN

Clock Cycles

LSB

SOD falls if

Command

was 88(H)

SOD

Command Time

8 SCLKs

t *

d

8 SCLKs Clear DRDY

SOD Read (3 Wire)

MSB

Data Time

24 SCLKs

Figure 4. Command and Data Word Timing

*See text for t

time.

d

20 DS74F1

Page 21

CS5516, CS5520

SID pin is not being written. When reading

SOD, SCLK cannot be continuous but must

burst one clock cycle per bit.

The continuous read conversion data mode is

also functional in the 3-wire interface mode. Issue one 88(H) command word to the converter.

Then wait for SOD to go low. Issue 8 SCLKs to

clear the data ready function. The MSB data bit

will then appear on the SOD pin. Issue 24

SCLKs to read the conversion word. At the falling edge of the 24th SCLK SOD will return

high. SOD will go low at the next DRDY falling

time to indicate a new conversion word. Eight

SCLKs must again be issued to clear the data

ready function before clocking out the data conversion word. The SOD pin will continue to

toggle low each time a word is available even if

the conversion data is not read. To terminate the

continuous conversion mode, input an 8-bit command word immediately after reading a

conversion word.

The user should perform all data reads and command writes within 51,000 XIN clock cycles

after SOD falls to avoid ambiguity as to who

controls the serial port.

Serial Port Initialization

If for any reason the off-chip microcontroller

fails to know whether the serial port of the

CS5516/20 is in data mode or command mode,

the following initialization procedure can be issued to the port to force the CS5516/20 into the

command mode. Write 128 or more 1’s to the

SID pin. Then issue a single 0 to the SID pin.

The port will then be initialized into the command mode and will be waiting for an 8-bit

command word.

Bridge Excitation Options

The CS5516/CS5520 A/D converters are optimized for Wheatstone bridge applications. The

converters support either dc or ac (switched dc)

bridge excitation.

DC Bridge Excitation

The CS5516/CS5520 can be configured for dc

bridge excitation in either of two ways. The

EXC bit of the configuration register can be set

for either internal or for external excitation. If

set to internally-controlled mode (EXC = 0), the

F1 and F0 bits must be set to logic 0s. In this

condition, the bridge can be excited from a dc

supply with a resistor divider to develop the appropriate reference voltage for the VREF+ and

VREF- pins. Note that the bridge excitation

Port Access Period

Valid 51,000

XIN Clock Cycles

CS

SCLK

8 SCLKs 24 SCL Ks 24 SCLKs

SID

8 Data Bits

DRDY

SOD

Figure 5. Continuous Read Conversion Data Mode (4 or 5 Wire)

DS74F1 21

81,920 XIN

Clock Cycles

24 Data Bits

24 Data Bits

Page 22

CS5516, CS5520

should not be applied prior to the

CS5516/CS5520 being powered-up. With EXC,

F1, and F0 set to logic 0, the BX1 output will be

logic 0 (0 volts) and the BX2 output will be a

logic 1 (+5 volts).

A second method for configuring the converter

for dc excitation is by setting EXC = 1, and

pulling up BX1 (pin 12) to VD+ (pin 20)

through a resistor. This sets the converter for

use with external excitation which uses the

BX1 pin as an input to set the excitation frequency. With BX1 = VD+, the external

excitation frequency is zero, or dc.

AC Bridge Excitation

AC bridge excitation involves using a clock signal to generate a square wave which repetitively

reverses the excitation polarity on the bridge. To

excite the bridge dynamically requires some type

of bridge driver external to the CS5516/CS5520

converter. This driver is driven by a square wave

clock. The source of this clock depends upon

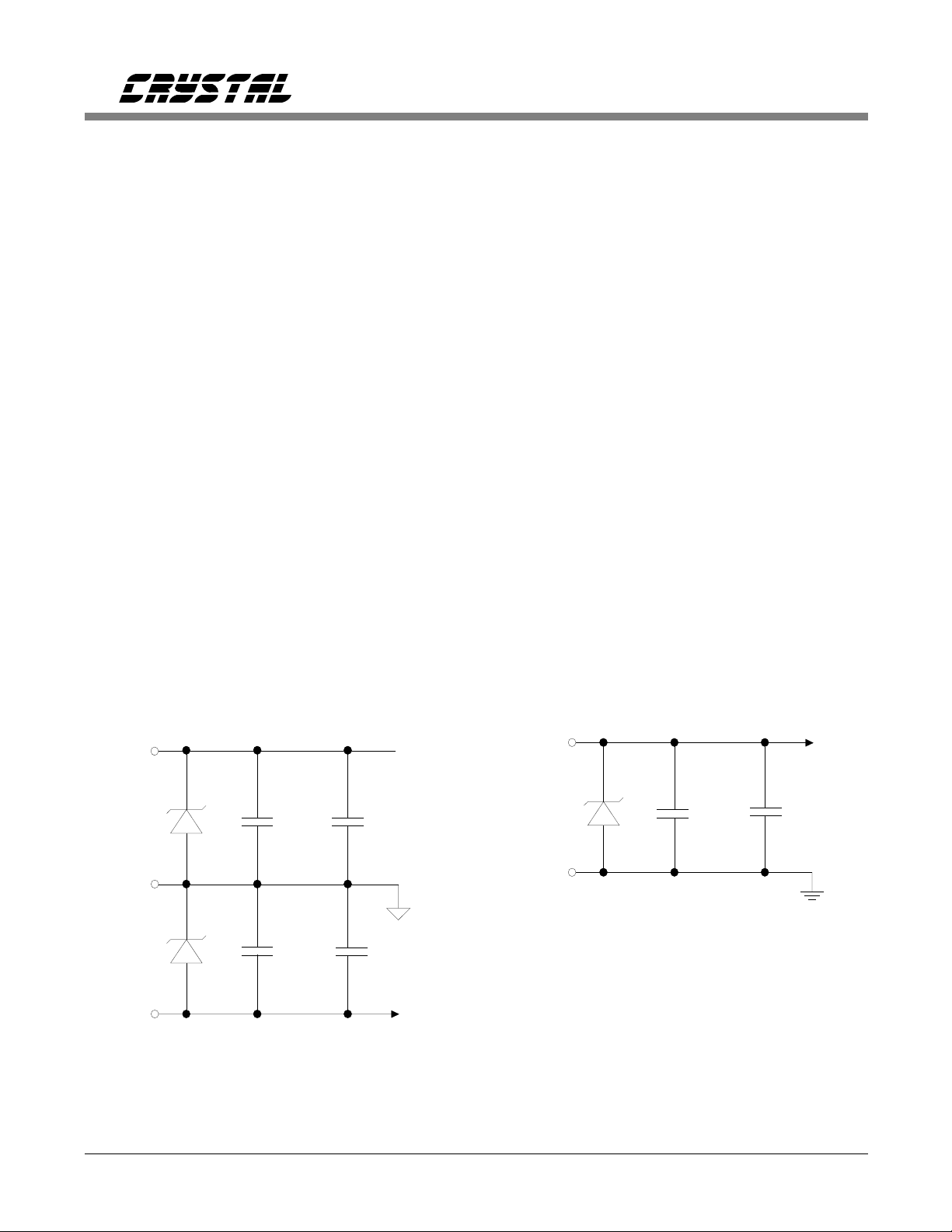

whether the converter is set for internal excitation or for external excitation. Figure 6

illustrates a sample bridge drive circuit when operating in the internal AC excitation mode.

+5V

+

-5V

EXC+

EXC-

10 µF0.1 µF

+5V

-5V

+5V

-5V

+5V

0V

100 k

BX2

TP0610

10 k

10 k

Figure 6. Sample AC Bridge Driver

2

4

-5V

6

7

5

MICREL

3

MIC4428 or

MIC4425

Using internal excitation involves setting the

EXC bit of the configuration register to 0, and

setting th e F1 and F 0 bits to sele ct the excitat ion

frequency for the bridge. In this mode the excitation frequency is a sub-multiple of the XIN

clock frequency. The excitation clock is output

from the BX1 and BX2 pins of the converter in

the form of a two-phase non-overlapping clock.

The converter is capable of demodulating this

clocked excitation. But only if the signals into

the AIN+ and VREF+ pins of the converter are

in phase with the demodulation clock inside the

converter (see Figure 7). The non-overlapping

clock signals from BX1 and BX2 are CMOS

level outputs (0 to VD+ volts) and are capable

of driving one TTL load. A buffer amplifier

MUST be used to drive the bridge.

BX1 (Out)

t

d

BX2 (Out)

Demod Clock

(Internal)

Note: The signals from the bridge into AIN+ and

VREF+ of the converter must be in phase

with the demodulation clock.

t is 1 cycle of XIN clock.

d

Figure 7. Internal Excitation Clock Phasing

t

d

Whenever the internal mode is used for dynamic

bridge excitation the signals are non-overlapping. The non-overlapping time is one XIN

clock cycle.

The converter can also be configured to provide

dynamic bridge excitation when operating in the

external-controlled bridge excitation mode. With

the EXC bit of the configuration register set to

logic 1, the BX1 pin becomes an input which

determines the bridge excitation frequency and

phase. BX1 should be near 50% duty cycle. The

user can select the excitation frequency with the

following restrictions. The excitation frequency

must be synchronous with the XIN frequency of

the converter and must be chosen using the following equation:

F

= (N × XIN)

exc

⁄

81,920

where N is an integer and lies in the range including 1 to 160. F

is the desired bridge

exc

excitation frequency. Other asynchronous fre-

22 DS74F1

Page 23

CS5516, CS5520

quencies are possible but may introduce a jitter

component in the BX output signals. It is desirable not to choose an excitation frequency

where interference components are present,

su ch as 50 Hz or 60 Hz or their harmonics. The

XIN frequency can be divided down using a

counter IC external to the A/D converter. F

exc

would be input to the BX1 pin of the converter

to synchronize the internal operations of the amplifiers and synchronous detection circuitry and

to generate a clock output from the BX2 pin.

The BX2 output is then used to drive the bridge

amplifier with a signal of proper phase for detection by the converter. Figure 8 indicates the

necessary phase of the signals to ensure proper

demodulation.

BX1 (In)

t

dd

BX2 (Out)

Demod Clock

(Internal)

Note: The signals from the bridge into AIN+ and

VREF+ of the converter must be in phase

with the demodulation clock.

t

≤

64/XIN

dd

Figure 8. External Excitation Clock Phasing

verter and the VREF+/VREF- leads to the converter are filtered, care should be exercised in

the choice of components. With either dc or ac

excitation, one should limit any input filtering

resistors on AIN to below 1 kΩ. Values greater

than this will degrade noise performance of the

converter. In ac excitation applications, any filtering must be broadband enough that the

switched dc excitation signal can settle within 10

µsecs. Failure to meet this settling requirement

will affect measurement accuracy. Figure 9 illustrates acceptable filter components for ac

excitation. If only differential filtering is required, a single capacitor can be placed between

AIN+ and AIN- (and VREF+ and VREF-) in

place of two capacitors to ground.

AIN+

AIN-

7.5k

7.5k

5k

300

300

470 pF

470 pF

0.0047 µF

0.0047 µF

VREF+

VREF-

AIN+

AIN-

CS5516

or

CS5520

EXC+

EXC-

Figure 9. AIN and VREF Input Filter Components

Whenever the dynamic excitation clock output

Voltage Reference Considerations

from either the BX1 and BX2 pins (during internal excitation) or from the BX2 pin (during

external excitation) changes states, the converter

waits 64 XIN cycles before sampling the AIN

and VREF signal inputs. The delay allows some

time for the signal to settle from the modulation

event.

The CS5516/20 include an on-chip voltage reference which is output on the MDRV- and

referenced from the MDRV+ pin. The converter

is designed to be operated as a ratiometric measurement device. The 2-channel delta-sigma

converter uses the internal MDVR (Modulator

Differential Voltage Reference) as its reference.

Input Filtering

Since the MDVR is used for converting both the

AIN and VREF signals at the same time, the ab-

Some load cells are located a distance from the

input to the converter. Under these conditions,

separate twisted pair cabling is recommended for

the excitation drive to the bridge, the excitation

sense leads (if used), and for the AIN±/ΑΙΝ−

signal leads. If the AIN+/AIN- leads to the con-

DS74F1 23

solute value of the MDVR and its tempco are

not important when the CS5516/20 is used in the

ratiometric measurement mode. The voltage reference output, MDVR-, should be decoupled

using a 1 µF capacitor which is connected to the

MDRV+ supply line. Voltage reference decou-

Page 24

CS5516, CS5520

pling is shown on the system connection diagrams.

If absolute measurements are to be made by the

CS5516/20, then a precision reference should be

input into the VREF+ and VREF- terminals.

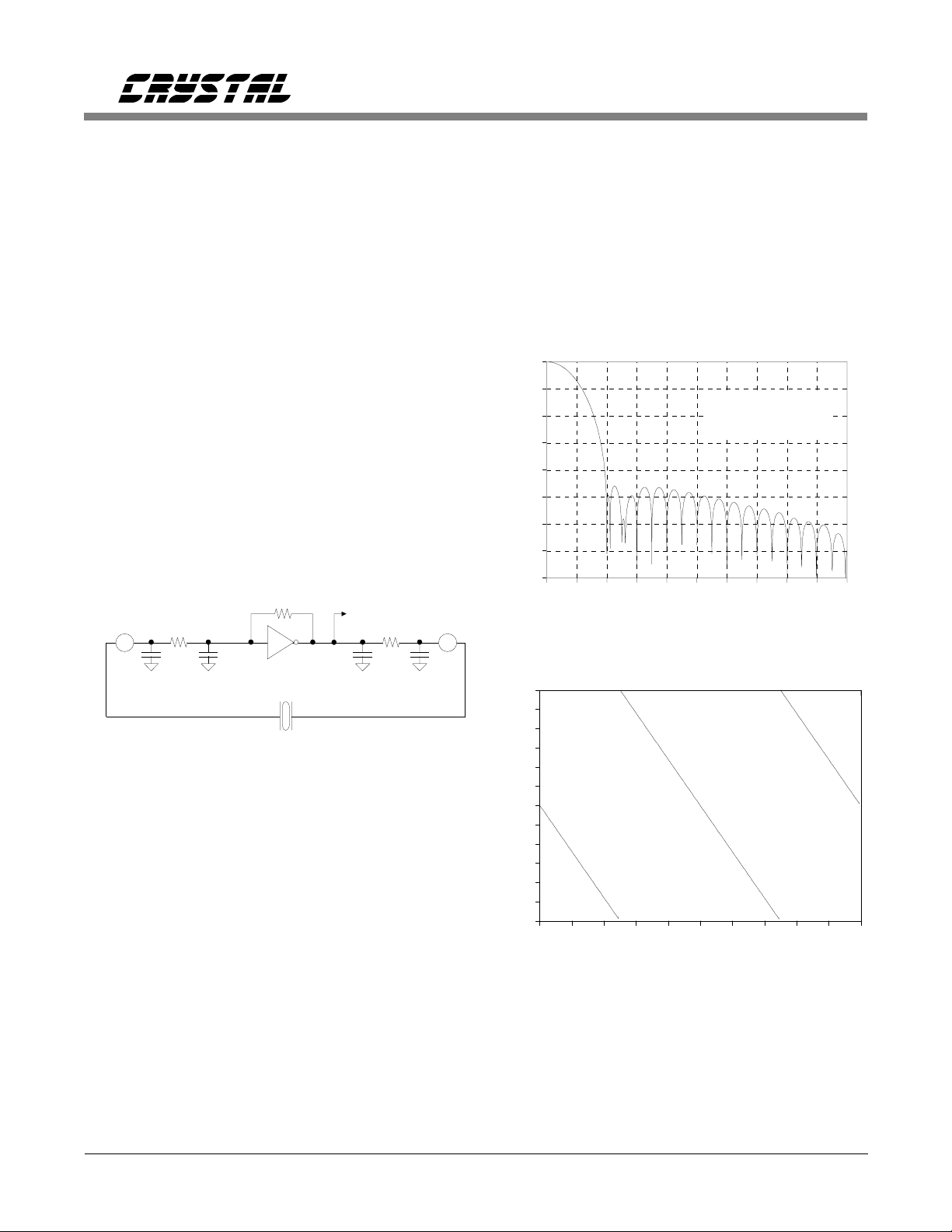

Clock Generator

The CS5516/20 includes a gate which can be

connected as a crystal oscillator to provide the

master clock to run the chip. Alternatively, an

external (CMOS compatible) clock can be input

into the XIN pin. Figure 10 illustrates a simple

model for the on-chip gate oscillator. The onchip oscillator is designed to typically operate

with crystal frequencies between 4.0 and 5.0

MHz without additional loading capacitors. If

other crystal frequencies, or if ceramic resonators are used, additional loading capacitance may

be necessary.

>1M

XIN

400

1pF 5pF

g ≅ 2000 umhos

m

External XTAL

Figure 10. On-Chip Gate Oscillator Model

To Internal circuitry

400

5pF 1pF

XOUT

2322

The XOUT pin can be used to drive one CMOS

gate for system clock requirements. Be sure to

include the gate’s input capacitance and stray capacitance as part of the loading capacitance for

the resonating element.

Digital Filter

The CS5516/20 is optimized to operate with clock

frequencies of 4.096 MHz or 4.9152 MHz. These

result in the filter having a 3dB bandwidth of 12

Hz or 15 Hz, with output word rates of 50 or

60Hz. The rejection at 50Hz ± 3Hz is 70 dB minimum with a 4.096 MHz clock. Similar rejection is

obtained at 60 Hz with a 4.9152 MHz clock.

The digital filter has a deep notch in its transfer

function at 50 Hz (XIN = 4.096 MHz) or 60 Hz

(XIN = 4.9152 MHz) but other XIN frequencies

can be used. The filter transfer function will

scale proportionally. Figure 11 shows the transfer function of the filter when operated at three

different frequencies. With a 3.579 MHz XIN,

the filter offers greater than 90 dB rejection of

both 50 and 60 Hz.

0

-20

-40

-60

-80

-100

Magnitude (dB)

-120

-140

-160

0

0

0

21.8

25

30

43.7

50

60

Input Frequency (Hz)

87.3

100

120

(1) XIN = 3.579 MHz

(2) XIN = 4.096 MHz

(3) XIN = 4.915 MHz

131.0

150

180

174.7

200

240

218.5

250

300

Figure 11. Filter Magnitude Response

180

Phase (degrees)

-120

-150

-180

150

120

-30

-60

-90

90

60

30

0

0 5

10

XIN = 4.096 MHz

15 20 25 30 35 40 45 50

Input Frequency (Hz)

Figure 12. Filter Phase Response.

The output word rate of the converter scales

with the XIN clock rate and is set by the ratio of

XIN/81,920; or 50 Hz for XIN = 4.096 MHz. If

very narrow signal bandwidths, such as 3 Hz,

are desired, averaging of the output words is recommended.

24 DS74F1

Page 25

CS5516, CS5520

The digital filter computes a new output data

word every 81,920 XIN clock cycles. If the input experiences a large change in amplitude, the

PGA gain is changed, or the DAC calibration

registers are changed, it may take up to six filter

cycles (81,920 X 6 clock cycles) for the filter to

compute an output word which is fully settled to

the input signal.

Output Coding

The CS5516/20 converters output data in binary

format when operating in unipolar mode and in

two’s complement when operating in bipolar

mode. Table 5 illustrates the output coding for

the converters. Note that when reading conversion data from the converter the data word is

output MSB or sign bit first. Falling edges on

SCLK advance the data word to the next lower

bit.

The output conversion words from both the

CS5516 and the CS5520 are 24 bits long. The

CS5516 has 16 data bits followed by 8 flag bits

(all identical). The CS5520 has 20 data bits followed by 4 flag bits (all identical). To read the

conversion data, including the error flag information will require at least 17 SCLKs for the

CS5516 and at least 21 SCLKs for the CS5520.

Under normal operating conditions, the flag bits

will be zeroes. The flag bits will be set to all

ones whenever an overrange condition exists.

Under large overrange conditions where the input signal exceeds the nominal full scale input

by approximately two times (for example:

50 mV input when the nominal full scale input

is set-up for 25 mV), the converter may be unable to compute a proper output code. In this

condition flag bits will be set to all 1s but the

conversion data may be a value other than full

scale plus or minus.

After the converter is first powered-up, a RST is

issued, or the device comes out of the SLEEP

mode, the first conversion data read may

erroneously have its error flag bits set to "1".

Synchronizing Multiple Converters

Multiple converters can be made to output their

conversion words at the same time if they are

operated from the same clock signal at XIN. To

synchronize multiple converters requires that

they all have their RF bit of the configuration

register written to a logic 1 and then back to 0.

The filters will be allowed to start convolutions

after the falling edge of the 24th SCLK used to

write the RF bit to the configuration register.

Unipolar Inpu t

Voltage

>(VFS-1.5 LSB) FFFF >(VFS-1.5 LSB) 7FFF >(VFS-1.5 LSB) FFFFF >(VFS-1.5 LSB) 7FFFF

VFS-1.5 LSB

VFS/2-0.5 LSB

+0.5 LSB

<(+0.5 LSB) 0000 <(-VFS+0.5 LSB) 8000 <(+0.5 LSB) 00000 <(-VFS+0.5 LSB) 80000

Note: VFS in the table equals the full scale voltage between +VREF/(G x 25) and ground for unipolar mode; and

between ±VREF/(G x 25) for bipolar mode. The signal input to the A/D section of the converter has been

amplified by th e instrumen tation ampl ifier (x25 ) and the PGA gain, G (1, 2, 4, or 8). See text ab out error

flags under over range cond itions.

DS74F1 25

Offset

Binary

FFFF

-----

FFFF

8000

-----

7FFF

0001

-----

0000

CS5516 Output Coding CS5520 Out put Coding

Bipolar Inp ut

Voltage

VFS-1.5 LSB

-0.5 LSB

-VFS+0.5 L SB

Table 5. Output Coding for the CS5516/20 Converters.

Two’s

Complement

7FFF

-----

7FFE

0000

-----

FFFF

8001

-----

8000

Unipolar Input

Voltage

VFS-1.5 LSB

VFS/2-0.5 LSB

+0.5 LSB

Offset

Binary

FFFFF

-----

FFFFE

80000

-----

7FFFF

00001

-----

00000

Bipolar Inp ut

Voltage

VFS-1.5 LSB

-0.5 LSB

-VFS+0.5 LSB

Two’s

Complement

7FFFF

-----

7FFFE

00000

-----

FFFFF

80001

-----

80000

Page 26

The filter will start a new convolution on the

next rising edge of the XIN clock after the 24th

SCLK falls.

CS5516, CS5520

140

120

Sleep Mode

The CS5516/20 configuration register has an

A/S bit which allows the users to put the device

in a sleep condition to lower quiescent power.

Upon reset the A/S bit device is set to a logic 0

which places the device in the ’awake’ condition. Writing a 1 to the A/S bit will shutdown

most of the chip, including the oscillator. It is

desirable to use the following sequence when

coming out of sleep. Write a logic 0 to the A/S

bit of the configuration register. In the same

configuration word write a logic 1 to the RF bit

of the configuration register. Then wait until it is

certain that the oscillator has started. After the

oscillator has started or a clock present on the

XIN pin, set the RF bit back to 0. The user

should then wait at least 6 output word update

periods before expecting a valid output data

word.

100

80

60

40

20

0

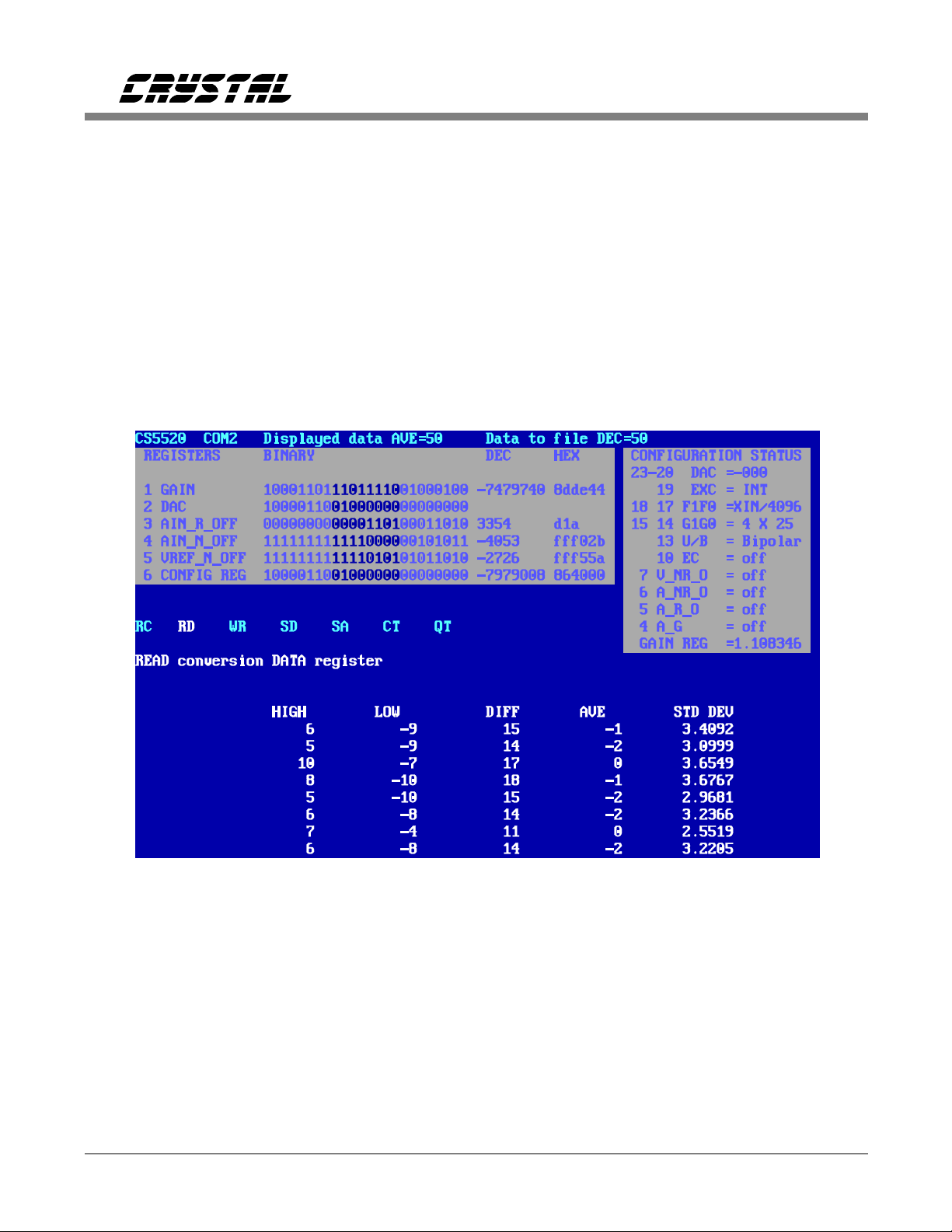

Figure 13. CS5520 Noise Histogram.

012345678-1-2-3-4-5-6-7-8

Noise Performance

Typical noise performance for the converter is

listed in the specification tables for each PGA

gain. Figure 13 illustrates a noise histogram for

1000 output conversions from the CS5520. The

data for the histogram was collected using the

CDB5520 evaluation board; with VREF at 2.5

volts, PGA = 4, bipolar mode. The data shows

the standard deviation of the data set is 3.2

LSBs. One LSB is equivalent to [VREF X 2(bipolar)]/ [Inst amp gain X PGA gain X number

of codes] or (2.5 X 2)/ (25 X 4 X 2E20) = 47.7

nV. One standard deviation is equivalent to rms

if the data is Normal or Gaussian. The rms noise

presented by the plot is 153 nV, which is in

good agreement with the typical noise specification of 150 nV for a PGA gain of 4.

Applicatio ns

See the Application Notes section of the databook.

Schematic & Layout Review Service

Confirm Optimum

Confirm Optimum

Schematic & Layout

Schematic & Layout

Before Building Your Board.

Before Building Your Board.

For Our Free Review Service

For Our Free Review Service

Call Applications Engineering.

Call Applications Engineering.

Call:(512) 445-7222

26 DS74F1

Page 27

PIN DESCRIPTIONS

CS5516, CS5520

Modulator Diff. Voltage Ref + MDRV+ SMODE Serial Interface Mode

Modulator Diff. Voltage Ref - MDRV- XOUT Crystal Out

Positive Analog Power VA+ XIN Crystal In

Negative Analog Power VA- VD- Negative Digital Power

Analog Ground One AGND1 VD+ Positive Digital Power

Analog In + AIN+ DGND Digital Gr ound

Analog In - AIN- SOD Serial Output Data

Analog Ground Two AGND2 SID Serial Input Data

Voltage Ref In + VREF+ SCLK Serial Clock Input

Voltage Ref In - VREF-

Bridge Excite 2 BX2

Bridge Excite 1 BX1

1

2

3

4

5

6

7

8

9

10

11

12

24

23

22

21

20

19

18

17

16

15

DRDY Data Ready

14

CS Chip Select

13

RST Reset

Power Supply Connections

VD+ - Positive Digital Power, PIN 20.

Positive digital supply voltage. Nominally +5 volts.

VD- - Negative Digital Power, PIN 21.

Negative digital supply voltage. Nominally -5 volts.

DGND - Digital Ground, PIN 19.

Digital ground.

VA+ - Positive Analog Power, PIN 3.

Positive analog supply voltage. Nominally +5 volts.

VA- - Negative Analog Power, PIN 4.

Negative analog supply voltage. Nominally -5 volts.

AGND1, AGND2 - Analog Ground, PINS 5, 8.

Analog ground.

Clock Generator

XIN; XOUT - Crystal In; Crystal Out, Pins 22, 23

An internal gate is connected to these pins enabling the use of either a crystal or a ceramic

resonator to provide the master clock for the device. Alternatively, an external (CMOS

compatible) clock can be input to the XIN pin as the master clock for the device.

DS74F1 27

Page 28

Digital Inputs

RST - Reset, PIN 13.

Reset pin initializes all calibration registers to a known condition and places the serial port into

the command mode.

CS - Chip Select, PIN 14.

An input which can be enabled by an e xternal device to gain control over the serial port. When

this pin is high, SOD is in a high impedance state if SMODE = 0.

SCLK - Serial Data Clock, PIN 16.

A clock signal at this pin determines the output rate of the data from the SOD pin and the input

data rate on the SID pin.

SID - Serial Input Data, PIN 17.

This pin is used for inputting command and configuration words or inputting calibration words.

Data is input at a rate determined by SCLK. SID is in a don’t care state when no data is being

clocked in.

CS5516, CS5520

SMODE - Serial Interface Mode, PIN 24.

Selects the operating mode of the serial port. When low the serial port operates in the 5 or 4

wire interface mode. When high the chip will enter the 3 wire interface mode.

Analog Inputs

AIN+ and AIN- - Analog Inputs, PINS 6, 7.

The analog input signals from the transducer. These are true differential inputs.

VREF+ and VREF- - Voltage Reference Inputs, PINS 9,10.

These are the differential analog reference voltage inputs.

MDRV+ - Modulator Differential Voltage Reference, PIN 1.

Positive terminal of the internal differential voltage reference which can be tied to the positive

supply (VA+) or ground (AGND).

MDRV- - Modulator Differential Voltage Reference, PIN 2.

This is the -3.75V modulator differential voltage reference output and can be used to generate

an analog reference. Note this is with refere nce to the MDRV+ pin.

28 DS74F1

Page 29

Digital Outputs

BX1 and BX2 - AC Bridge Excitation Signals, PINS 12, 11.

These can be buffered to drive the transducer or used as synchronizing signals for a transducer

drive circuit. BX1 and BX2 are 0 to +5V signals.

DRDY - Data Ready, PIN 15.

DRDY goes low every 81,920 cycles of XIN (when in read conversion data mode) to indicate

that new data has been placed in the output port. DRDY goes high when all the serial port data

is clocked out, when the serial port is being updated with new data, when a calibration is in

progress, or when the device is in SLEEP.

SOD - Serial Output Data, PIN 18.

Data from the serial port will be output from this pin at a rate determined by SCLK . The data

will either be conversion data, or, calibration values, dependent upon the command word that

has been previously input on the SID pin. The SOD pin furnishes a high impedance output

state when not transmitting data (SMODE = 0).

CS5516, CS5520

ORDERING GUIDE

Model Number Linearity Error (Max) Temperature Range Package

CS5516-AP 0.003% -40°C to +85°C 24-pin 0.3" Plastic DIP

CS5516-AS 0.003% -40°C to +85°C 24-pin 0.3" SOIC

CS5520-BP 0.0015% -40°C to +85°C 24-pin 0.3" Plastic DIP

CS5520-BS 0.0015% -40°C to +85°C 24-pin 0.3" SOIC

DS74F1 29

Page 30

SPECIFICATION DEFINITIONS

Linearity Error

The deviation of a code from a straight line which extends between two fixed points on the

A/D converter transfer function. In unipolar mode, the straight line extends from one point

located 1⁄2 LSB below the first code transition, one count above all zeros; to the second point

located 1⁄2 LSB beyond the code transition to all ones. In bipolar mode, the straight line extends

from one point located 1⁄2 LSB beyond the code transition to all ones, passing through a point

1

⁄2 LSB below code 8000(H) (16-bit); 80000(H) (20-bit); extending to beyond negative full

scale. Units are in percent of full-sca le.

Differential Nonlinearity

The deviation of a code’s width from the ideal width. Units in LSBs.

Full Scale Error

The deviation of the last code transition form the ideal [{(VREF+)-(VREF-)}-3⁄2 LSB]. Units

are in LSBs.

CS5516, CS5520

Unipolar Offset

The deviation of the first code transition from the ideal (1⁄2 LSB above AGND) when in

unipolar mode (BP/UP low). Units are in LSBs.

Bipolar Offset

The deviation of the mid-scale transition (011...111 to 100...000) from the ideal (1⁄2 LSB below

AGND) when in bipolar mode (BP/UP high). Units are in LSBs.

30 DS74F1

Page 31

CDB5516

CDB5520

CS5516 and CS5520 ADC Evaluation Board

Features

l On-board microcontroller

l RS232 Serial Communicationswith host PC

l Supports either AC or DC bridge drive

l On-board bridge driver

l Supports ratiometric or absolute

measurements

l Evaluation software included

I

Load

Cell

AIN+

CS5516

CS5520

Description

The CDB5516 and CDB5520 provide quick and easy

evaluation of the CS5516 and CS5520 bridge transducer

A/D converters. Direct connection of the bridge to the

evaluation board is provided.

The board also contains a microcontroller, with firmware