Page 1

Features

■ V

2

™

Control Topology

■ Dual N Channel Design

■ 100ns Controller Transient

Response

■ Excess of 1Mhz Operation

■ 5 Bit DAC with 1% Tolerance

■ Power Good Output With

Internal Delay

■ Enable Input Provides

Micropower Shutdown Mode

■ Complete Pentium

®

II System

Requires 18 Components

■ 5V and 12V Operation

■ Adaptive Voltage Positioning

■ Remote Sense Capability

■ Current Sharing Capability

■ V

CC

Monitor

■ Hiccup Mode Short Circuit

Protection

■ Overvoltage Protection (OVP)

■ Programmable Soft Start

■ 150ns PWM Blanking

■ 65ns FET Non-Overlap

■ 40ns Gate Rise and Fall Times

(3.3nF load)

Package Options

CS5165

Fast, Precise 5-Bit Synchronous Buck Controller

for the Next Generation Low Voltage Pentium® II Processors

CS5165

Description

The CS5165 synchronous 5-bit NFET

buck controller is optimized to manage

the power of the next generation

Pentium

®

II processors. It’s V

2

™

control

architecture delivers the fastest transient

response (100ns), and best overall voltage

regulation in the industry today. It’s feature rich design gives end users the maximum flexibility to implement the best

price/performance solutions for their end

products.

The CS5165 has been carefully crafted to

maximize performance and protect the

processor during operation. It has a 5-bit

DAC on board that holds a ±1% tolerance

over temperature. Its on board programmable soft start insures a control

start up, and the FET nonoverlap circuitry ensures that both FETs do not conduct

simultaneously.

The on board oscillator can be programmed up to 1MHz to give the designer maximum flexibility in choosing exter-

nal components and setting systems costs.

The CS5165 protects the processor during

potentially catastrophic events like overvoltage (OVP) and short circuit. The OVP

feature is part of the V

2

™

architecture and

does not require any additional components. During short circuit, the controller

pulses the MOSFETs in a “hiccup” mode

(3% duty cycle) until the fault is removed.

With this method, the MOSFETs do not

overheat or self destruct.

The CS5165 is designed for use in both

single processor desktop and multiprocessor workstation and server applications. The CS5165’s current sharing capability allows the designer to build multiple parallel and redundant power solutions for multiprocessor systems.

The CS5165 contains other control and

protection features such as Power Good,

ENABLE, and adaptive voltage positioning. It is available in a 16 lead SOIC wide

body package.

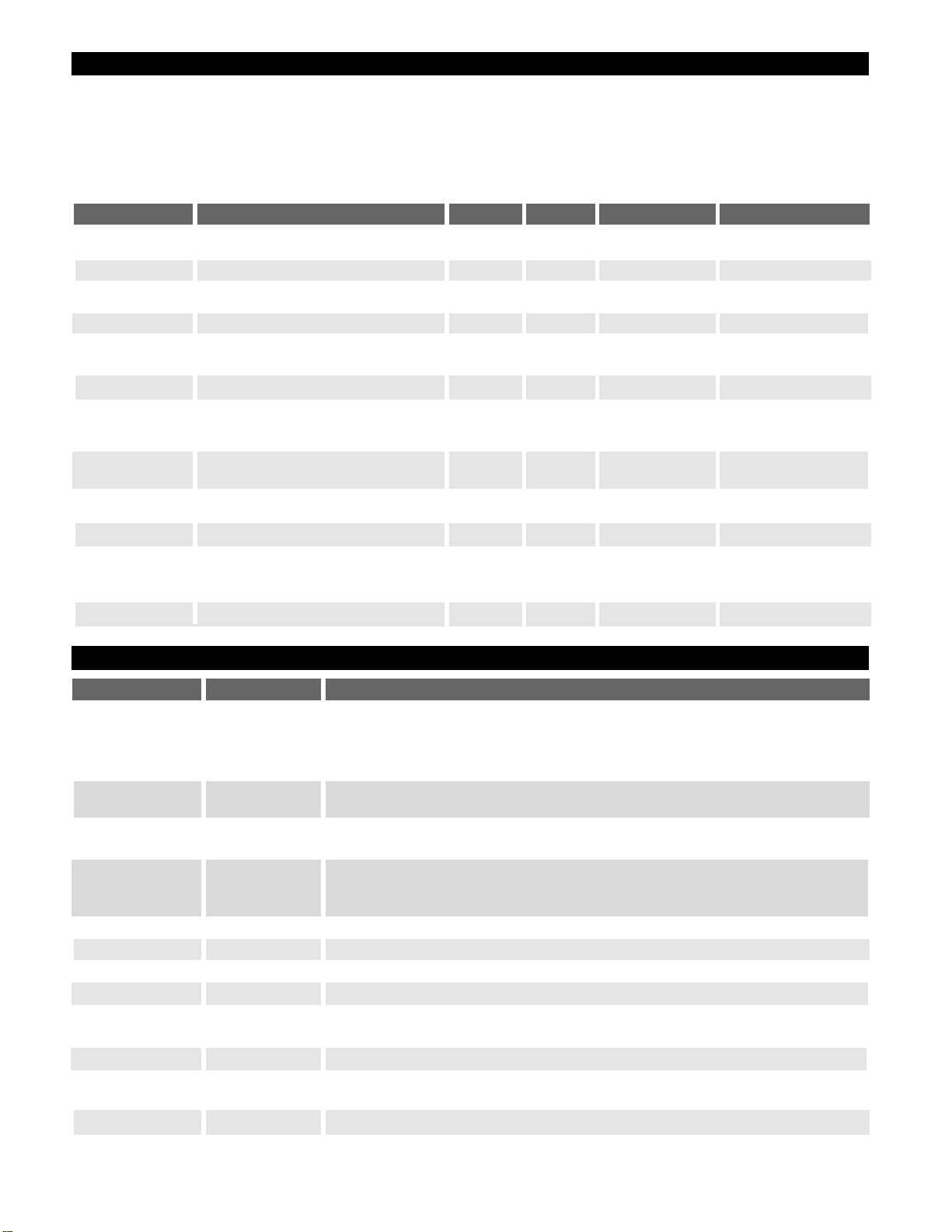

Application Diagram

16 Lead SO WIDE

1

V

ID0

V

ID1

V

ID2

V

ID3

ENABLE

C

OFF

SS

V

ID4

V

FB

COMP

LGnd

PWRGD

GATE(L)

PGnd

GATE(H)

V

CC

V2is a trademark of Switch Power, Inc.

Pentium is a registered trademark of Intel Corporation.

5V to 2.8V @ 14.2A for 300MHz Pentium

®

II

Rev. 6/28/99

Cherry Semiconductor Corporation

2000 South County Trail, East Greenwich, RI 02818

Tel: (401)885-3600 Fax: (401)885-5786

Email: info@cherry-semi.com

Web Site: www.cherry-semi.com

A Company

®

SS

0.1µF

0.1 µF

330pF

COMP

C

OFF

V

V

V

V

V

ID4

ID3

ID2

ID1

ID0

12V

1µF

V

CC

GATE(H)

CS5165

GATE(L)

PGnd

LGnd

V

FB

PWRGD

ENABLE

5V

1200µF/10V x 3

IRL3103

IRL3103

3.3K

1000pF

1.2µH

PCB

trace 6mΩ

1200µF

10V x 5

V

V

PWRGD

ENABLE

V

ID0

V

V

ID2

V

ID3

V

CC

SS

ID1

ID4

Pentium® II

System

1

Page 2

Absolute Maximum Ratings

Pin Symbol Pin Name

V

MAX

V

MIN

I

SOURCE

I

SINK

2

PACKAGE PIN # PIN SYMBOL FUNCTION

Package Pin Description

CS5165

V

CC

IC Power Input 16V -0.3V N/A 1.5A Peak

200mA DC

SS Soft Start Capacitor 6V -0.3V 200µA 10µA

COMP Compensation Capacitor 6V -0.3V 10mA 1mA

V

FB

Voltage Feedback Input 6V -0.3V 10µA 10µA

C

OFF

Off-Time Capacitor 6V -0.3V 1mA 50mA

V

ID0-4

Voltage ID DAC Inputs 6V -0.3V 1mA 10µA

GATE(H) High-Side FET Driver 16V -0.3V 1.5A Peak; 1.5A Peak;

200mA DC 200mA DC

GATE(L) Low-Side FET Driver 16V -0.3V 1.5A Peak; 1.5A Peak;

200mA DC 200mA DC

ENABLE Enable Input 6V -0.3V 100µA 1mA

PWRGD Power-Good Output 6V -0.3V 10µA 30mA

PGnd Power Ground 0V 0V 1.5A Peak N/A

200mA DC

LGnd Logic Ground 0V 0V 100mA N/A

Operating Junction Temperature, TJ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0° to 150°C

Lead Temperature Soldering:

Reflow (SMD styles only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60 sec max. above 183°C, 230°C Peak

Storage Temperature Range, TS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . −65°C to 150°C

ESD Susceptibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2kV

1,2,3,4,6 V

ID0-VID4

Voltage ID DAC inputs. These pins are internally pulled up to 5V if left open.

V

ID4

selects the DAC range. When V

ID4

is high (logic one), the Error Amp ref-

erence range is 2.14V to 3.54V with 100mV increments. When V

ID4

is low (logic

zero), the Error amp reference voltage is 1.34V to 2.09V with 50mV increments.

5 SS Soft Start Pin. A capacitor from this pin to LGnd sets the Soft Start and fault

timing.

7 C

OFF

Off-Time Capacitor Pin. A capacitor from this pin to LGnd sets both the normal and extended off time.

8 ENABLE Output Enable Input. This pin is internally pulled up to 1.8V. A logic Low

( < 0.8V) on this pin disables operation and places the CS5165 into a low current sleep mode.

9 V

CC

Input Power Supply Pin.

10 GATE(H) High Side Switch FET driver pin.

11 PGnd High Current ground for the GATE(H) and GATE(L) pins.

12 GATE(L) Low Side Synchronous FET driver pin.

13 PWRGD Power Good Output. Open collector output drives low when VFBis out of

regulation. Active when ENABLE input is low

14 LGnd Reference ground. All control circuits are referenced to this pin.

15 COMP Error Amp output. PWM Comparator reference input. A capacitor to LGnd

provides Error Amp compensation.

16 V

FB

Error Amp, PWM Comparator, and Low VFBComparator feedback input.

Page 3

CS5165

3

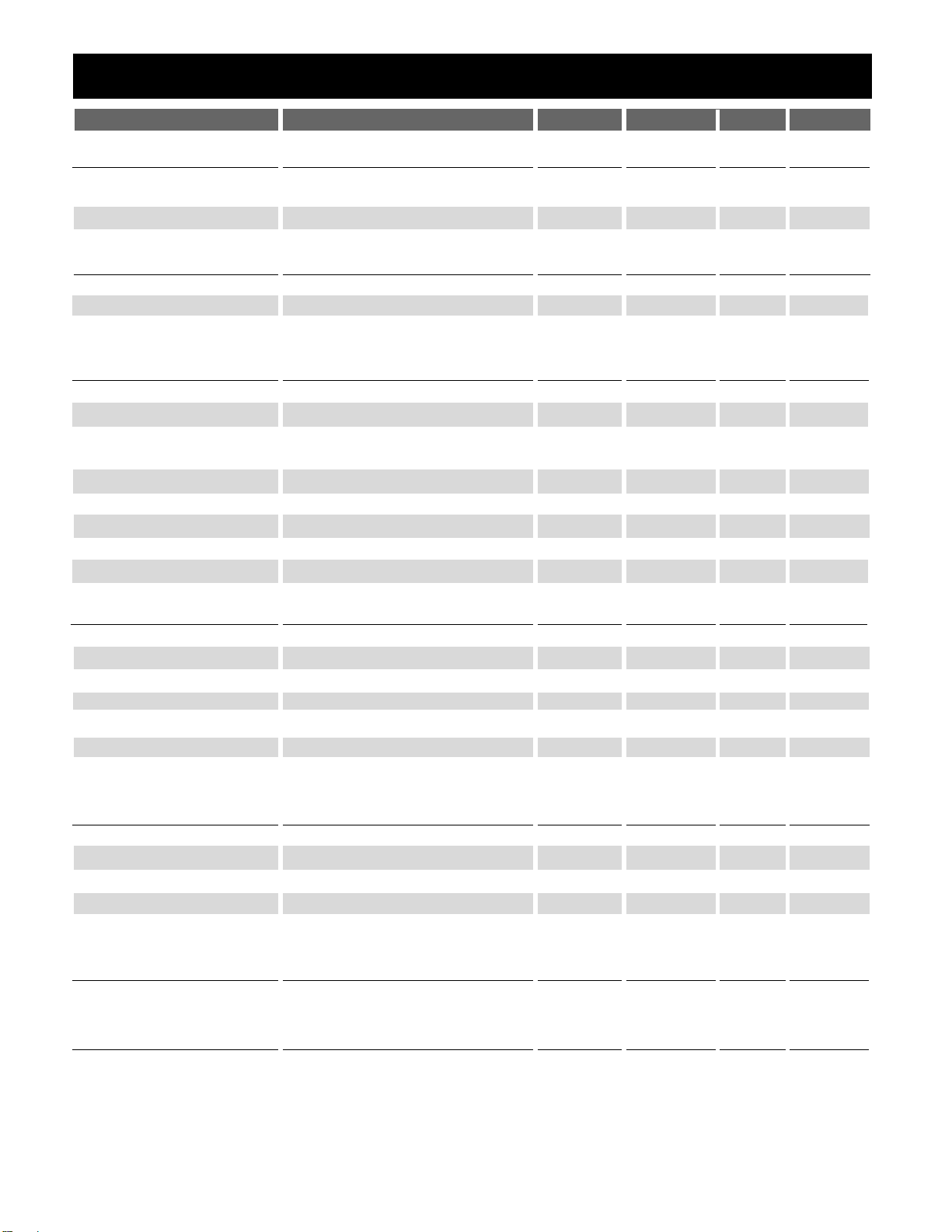

Electrical Characteristics: 0˚C < TA< 70˚C; 0˚C < TJ < 125˚C; 8V < VCC< 14V;

2.8V DAC Code (V

ID4=VID2=VID1=VID0

=1, V

ID3

= 0), C

GATE(H)

= C

GATE(L)

= 3.3nF, C

OFF

= 330pF, CSS= 0.1µF; Unless otherwise stated.

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

■ V

CC

Supply Current

Operating 1V < VFB< V

DAC

(max on-time) 12 20 mA

No Loads on Gate(H) and Gate(L)

Sleep Mode ENABLE = 0V 300 600 µA

■ VCCMonitor

Start Threshold GATE(H) Switching 3.75 3.95 4.15 V

Stop Threshold GATE(H) not switching 3.65 3.87 4.05 V

Hysteresis Start - Stop 80 mV

■ Error Amplifier

VFBBias Current VFB= 0V 0.1 1.0 µA

COMP Source Current COMP = 1.2V to 3.6V; VFB= 2.7V 15 30 60 µA

COMP CLAMP Voltage VFB= 2.7V, Adjust COMP voltage for 0.85 1.0 1.15 V

Comp current = 50µA

COMP Clamp Current COMP = 0V 0.4 1.0 1.6 mA

COMP Sink Current V

COMP

=1.2V; V

FB

= 3V; VSS> 2.5V 180 400 800 µA

Open Loop Gain Note 1 50 60 dB

Unity Gain Bandwidth Note 1 0.5 2 MHz

PSRR @ 1kHZ Note 1 60 85 dB

■ GATE(H) and GATE(L)

High Voltage at 100mA Measure VCC-GATE 1.2 2.0 V

Low Voltage at 100mA Measure GATE 1.0 1.5 V

Rise Time 1.6V < GATE < (V

CC

- 2.5V) 40 80 ns

Fall Time (V

CC

- 2.5V) > GATE > 1.6V 40 80 ns

GATE(H) to GATE(L) Delay GATE(H) < 2V, GATE(L) > 2V 30 65 100 ns

GATE(L) to GATE(H) Delay GATE(L) < 2V, GATE(H) > 2V 30 65 100 ns

GATE pull-down Resistance to PGnd (note 1) 20 50 115 kΩ

■ Fault Protection

SS Charge Time V

FB

= 0V 1.6 3.3 5.0 ms

SS Pulse Period VFB= 0V 25 100 200 ms

SS Duty Cycle (Charge Time/Period) × 100 1.0 3.3 6.0 %

SS Comp Clamp Voltage VFB= 2.7V, VSS= 0V 0.50 0.95 1.10 V

VFBLow Comparator Increase VFBtill no SS 0.9 1.0 1.1 V

pulsing and normal Off-time.

■ PWM Comparator

Transient Response V

FB

= 1.2 to 5V 500ns after 100 150 ns

GATE(H) (after Blanking time) to

GATE(H) = (VCC- 1V) to 1V

Page 4

CS5165

4

Electrical Characteristics: 0˚C < TA< 70˚C; 0˚C < TJ < 125˚C; 8V < VCC< 14V;

2.8V DAC Code (V

ID4=VID2=VID1=VID0

=1, V

ID3

= 0), C

GATE(H)

= C

GATE(L)

= 3.3nF, C

OFF

= 330pF, CSS= 0.1µF; Unless otherwise stated.

■ Voltage Identification DAC

Accuracy (all codes except 11111) Measure V

FB

= COMP (C

OFF

= 0V) -1 +1 %

V

ID4VID3VID2VID1VID0

25˚C ≤ TJ≤ 125˚C; VCC= 12V

1 0 0 0 0 3.505 3.540 3.575 V

1 0 0 0 1 3.406 3.440 3.474 V

1 0 0 1 0 3.307 3.340 3.373 V

1 0 0 1 1 3.208 3.240 3.272 V

1 0 1 0 0 3.109 3.140 3.171 V

1 0 1 0 1 3.010 3.040 3.070 V

1 0 1 1 0 2.911 2.940 2.969 V

1 0 1 1 1 2.812 2.840 2.868 V

1 1 0 0 0 2.713 2.740 2.767 V

1 1 0 0 1 2.614 2.640 2.666 V

1 1 0 1 0 2.515 2.540 2.565 V

1 1 0 1 1 2.416 2.440 2.464 V

1 1 1 0 0 2.317 2.340 2.363 V

1 1 1 0 1 2.218 2.240 2.262 V

1 1 1 1 0 2.119 2.140 2.161 V

0 0 0 0 0 2.069 2.090 2.111 V

0 0 0 0 1 2.020 2.040 2.060 V

0 0 0 1 0 1.970 1.990 2.010 V

0 0 0 1 1 1.921 1.940 1.959 V

0 0 1 0 0 1.871 1.890 1.909 V

0 0 1 0 1 1.822 1.840 1.858 V

0 0 1 1 0 1.772 1.790 1.808 V

0 0 1 1 1 1.723 1.740 1.757 V

0 1 0 0 0 1.673 1.690 1.707 V

0 1 0 0 1 1.624 1.640 1.656 V

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

■ PWM Comparator: continued

Minimum Pulse Width Drive VFB1.2 to 5V upon 50 150 250 ns

(Blanking Time) GATE(H) rising edge (> V

CC

-1V),

measure GATE(H ) pulse width

■ C

OFF

Normal Off-Time VFB= 2.7V 1.0 1.6 2.3 µs

Extended Off-Time VSS= VFB= 0V 5.0 8.0 12.0 µs

■ Time-Out Timer

Time-Out Time VFB= 2.7V, Measure

GATE(H ) Pulse Width 10 30 50 µs

Fault Duty Cycle V

FB

= 0V 30 50 70 %

■ Enable Input

ENABLE Threshold GATE(H) Switching 0.8 1.15 1.30 V

Shutdown delay (Note 1) ENABLE-to-GATE(H) < 2V 3 µs

Pull-up Current ENABLE = 0V 3 7 15 µA

Pull-up Voltage No load on ENABLE pin 1.30 1.8 3 V

Input Resistance ENABLE = 5V,

R = (5V-V

PULLUP

)/I

ENABLE

10 20 50 kΩ

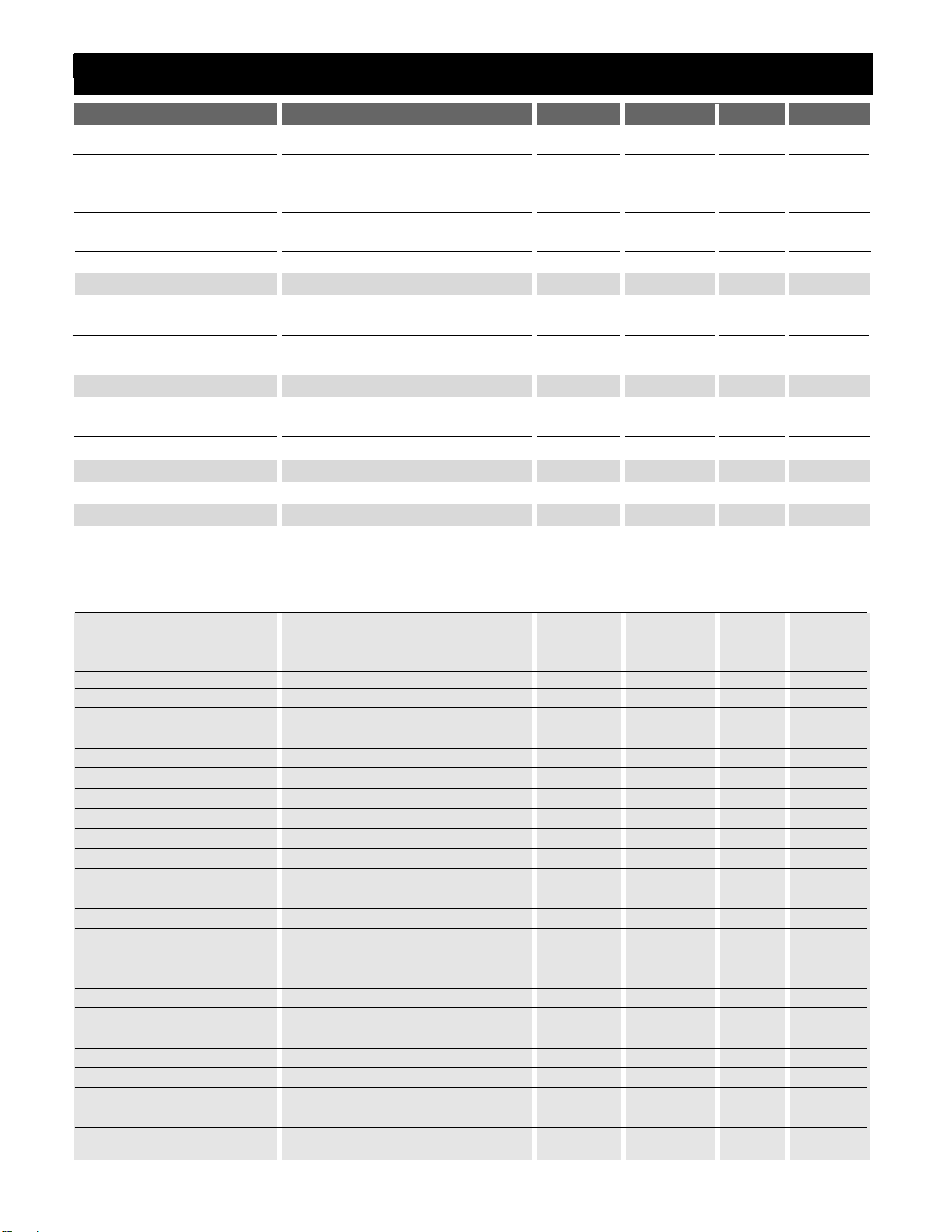

Page 5

CS5165

5

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

THRESHOLD ACCURACY

LOWER THRESHOLD UPPER THRESHOLD

MIN TYP MAX MIN TYP MAX UNIT

% of Nominal DAC Output -12 -8.5 -5 5 8.5 12 %

■ DAC CODE

V

ID4VID3VID2VID1VID0

1 0 0 0 0 3.115 3.239 3.363 3.717 3.841 3.965 V

1 0 0 0 1 3.027 3.148 3.268 3.612 3.732 3.853 V

1 0 0 1 0 2.939 3.056 3.173 3.507 3.624 3.741 V

1 0 0 1 1 2.851 2.965 3.078 3.402 3.515 3.629 V

1 0 1 0 0 2.763 2.873 2.983 3.297 3.407 3.517 V

1 0 1 0 1 2.675 2.782 2.888 3.192 3.298 3.405 V

1 0 1 1 0 2.587 2.690 2.793 3.087 3.190 3.293 V

1 0 1 1 1 2.499 2.599 2.698 2.982 3.081 3.181 V

1 1 0 0 0 2.411 2.507 2.603 2.877 2.973 3.069 V

1 1 0 0 1 2.323 2.416 2.508 2.772 2.864 2.957 V

1 1 0 1 0 2.235 2.324 2.413 2.667 2.756 2.845 V

1 1 0 1 1 2.147 2.233 2.318 2.562 2.647 2.733 V

1 1 1 0 0 2.059 2.141 2.223 2.457 2.539 2.621 V

1 1 1 0 1 1.971 2.050 2.128 2.352 2.430 2.509 V

1 1 1 1 0 1.883 1.958 2.033 2.250 2.322 2.397 V

0 0 0 0 0 1.839 1.912 1.986 2.195 2.268 2.341 V

0 0 0 0 1 1.795 1.867 1.938 2.142 2.213 2.285 V

0 0 0 1 0 1.751 1.821 1.810 2.090 2.159 2.229 V

0 0 0 1 1 1.707 1.775 1.843 2.037 2.105 2.173 V

0 0 1 0 0 1.663 1.729 1.796 1.985 2.051 2.117 V

0 0 1 0 1 1.619 1.684 1.748 1.932 1.996 2.061 V

0 0 1 1 0 1.575 1.638 1.701 1.880 1.942 2.005 V

0 0 1 1 1 1.531 1.592 1.653 1.827 1.888 1.949 V

V

ID4VID3VID2VID1VID0

0 1 0 1 0 1.574 1.590 1.606 V

0 1 0 1 1 1.525 1.540 1.555 V

0 1 1 0 0 1.475 1.490 1.505 V

0 1 1 0 1 1.426 1.440 1.455 V

0 1 1 1 0 1.376 1.390 1.405 V

0 1 1 1 1 1.327 1.340 1.353 V

1 1 1 1 1 1.223 1.247 1.273 V

Input Threshold V

ID4

, V

ID3

, V

ID2

, V

ID1

, V

ID0

1.000 1.250 2.400 V

Input Pull-up Resistance V

ID4

, V

ID3

, V

ID2

, V

ID1

, V

ID0

25 50 100 kΩ

Input Pull-up Voltage 4.85 5.00 5.15 V

■ Power Good Output

Low to High Delay V

FB

= (0.8 × V

DAC

) to V

DAC

30 65 110 µs

High to Low Delay VFB= V

DAC

to (0.8 × V

DAC

) 30 75 120 µs

Output Low Voltage V

FB

= 2.4V, I

PWRGD

= 500µA 0.2 0.3 V

Sink Current Limit V

FB

= 2.4V, PWRGD = 1V 0.5 4.0 15.0 mA

Electrical Characteristics: 0˚C < TA< 70˚C; 0˚C < TJ < 125˚C; 8V < VCC< 14V;

2.8V DAC Code (V

ID4=VID2=VID1=VID0

=1, V

ID3

= 0), C

GATE(H)

= C

GATE(L)

= 3.3nF, C

OFF

= 330pF, CSS= 0.1µF; Unless otherwise stated.

Page 6

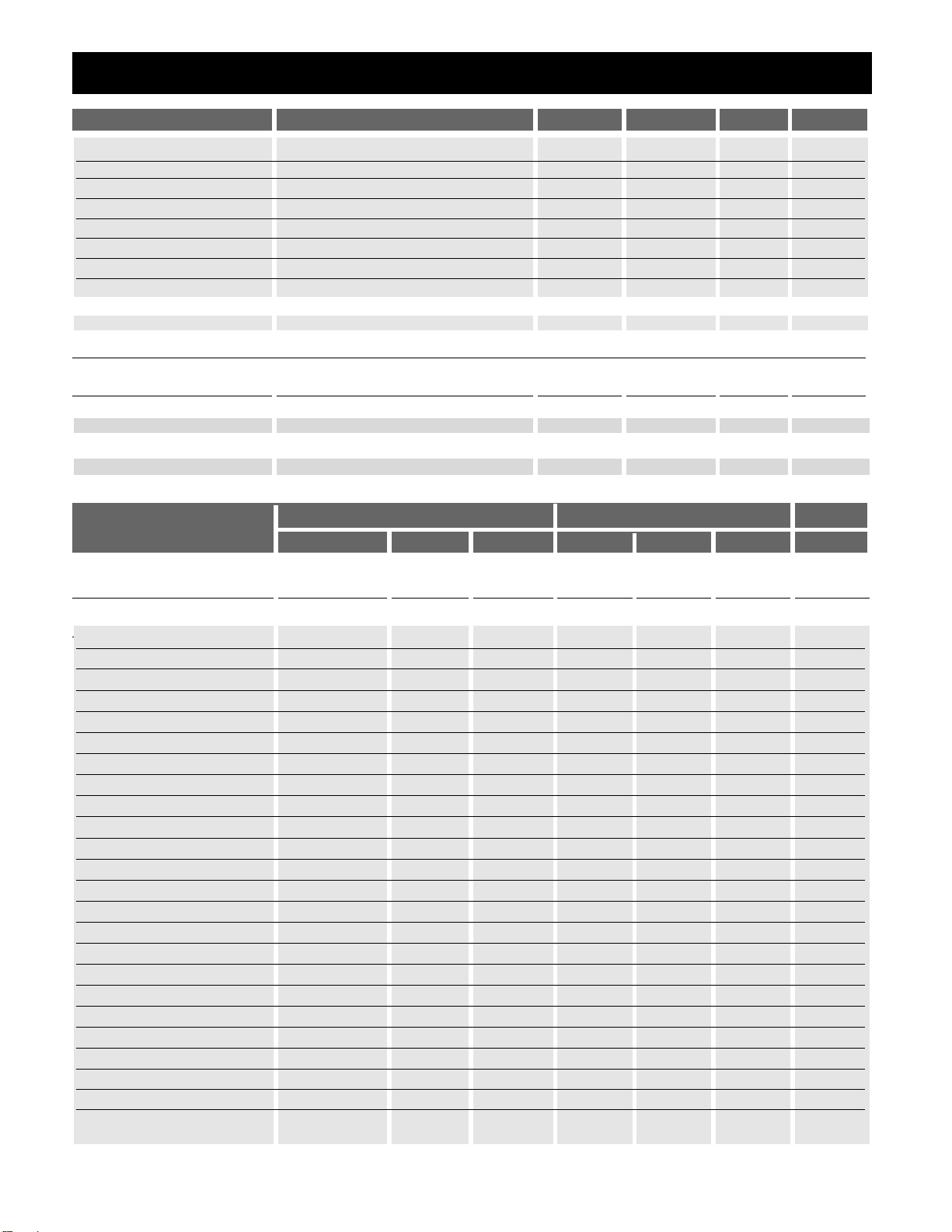

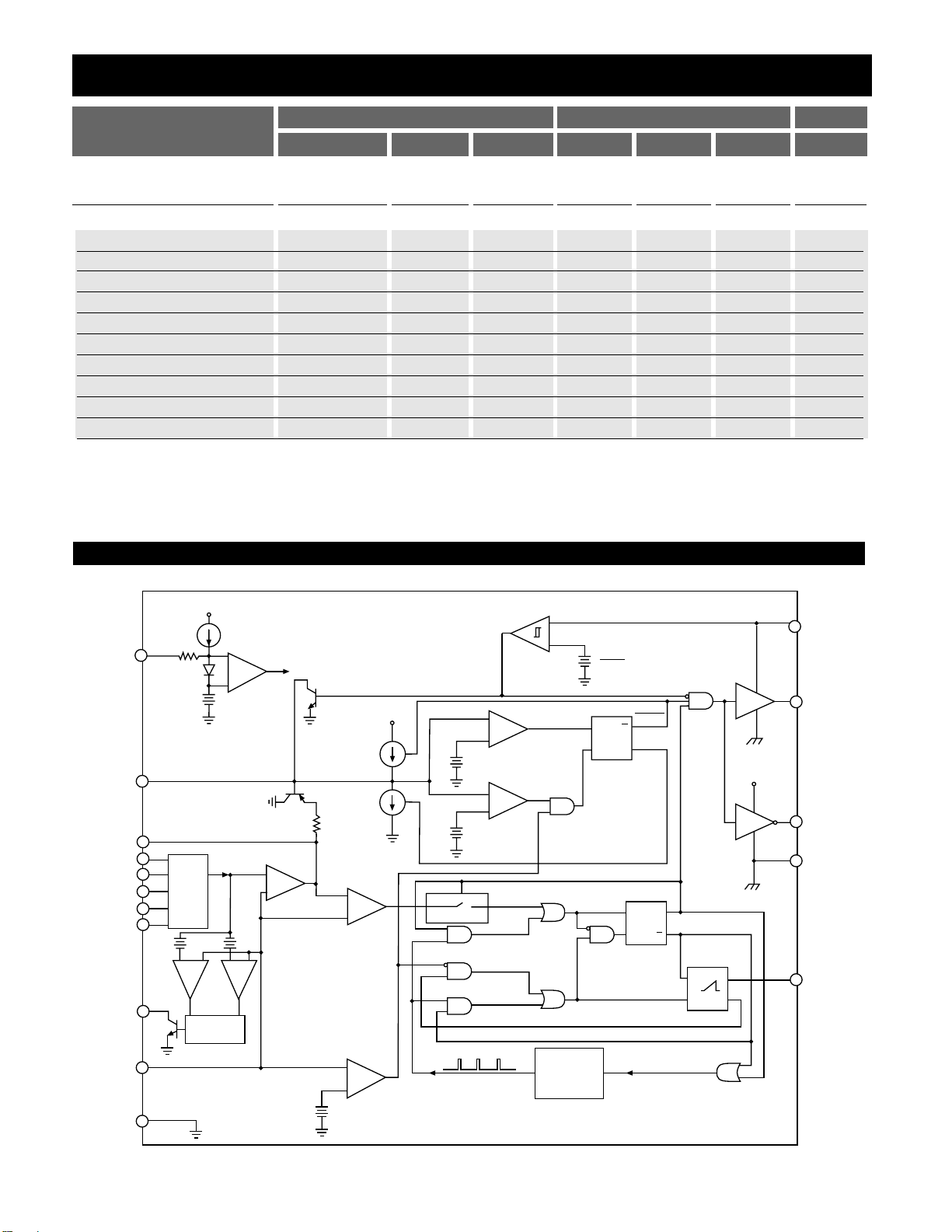

Block Diagram

6

CS5165

THRESHOLD ACCURACY

LOWER THRESHOLD UPPER THRESHOLD

MIN TYP MAX MIN TYP MAX UNITS

% of Nominal DAC Output -12 -8.5 -5 5 8.5 12 %

■ DAC CODE

V

ID4VID3VID2VID1VID0

0 1 0 0 0 1.487 1.546 1.606 1.775 1.834 1.893 V

0 1 0 0 1 1.443 1.501 1.558 1.722 1.779 1.837 V

0 1 0 1 0 1.399 1.455 1.511 1.670 1.725 1.781 V

0 1 0 1 1 1.355 1.409 1.463 1.617 1.671 1.724 V

0 1 1 0 0 1.311 1.363 1.416 1.565 1.617 1.669 V

0 1 1 0 1 1.267 1.318 1.368 1.512 1.562 1.613 V

0 1 1 1 0 1.223 1.272 1.321 1.460 1.508 1.557 V

0 1 1 1 1 1.179 1.226 1.273 1.407 1.454 1.501 V

1 1 1 1 1 1.097 1.141 1.185 1.309 1.353 1.397 V

Note 1: Guaranteed by design, not 100% tested in production.

Electrical Characteristics: 0˚C < TA< 70˚C; 0˚C < TJ < 125˚C; 8V < VCC< 14V;

2.8V DAC Code (V

ID4=VID2=VID1=VID0

=1, V

ID3

= 0), C

GATE(H)

= C

GATE(L)

= 3.3nF, C

OFF

= 330pF, CSS= 0.1µF; Unless otherwise stated.

ENABLE

SS

COMP

V

V

V

V

V

PWRGD

V

FB

LGnd

ID0

ID1

ID2

ID3

ID4

-8.5%

20k

1.25V

5 BIT

DAC

V

CC

+8.5%

-+-

65µs

Delay

7µA

-

+

Enable

Comparator

Error Amplifier

+

-

+

Circuit Bias

1V

60µA

2µA

-

+

PWM

Comparator

-

+

VFB Low

Comparator

Monitor

V

CC

5V

2.5V

PWM Comp

Blanking

0.7V

Off-Time

Extended

Off-Time

Timeout

-

+

+

-

Maximum

On-Time

Timeout

Normal

+

SS Low

Comparator

SS High

Comparator

Time Out

(30µs)

Timer

3.95V

3.87V

R

S

FAULT

Latch

Off-Time

Timeout

FAULT

Q

FAULT

Q

Q

R

S

Q

PWM

Latch

Edge Triggered

V

GATE(H) = ON

GATE(H) = OFF

C

OFF

One Shot

R

S

Q

CC

PGnd

V

CC

V

GATE(H)

V

GATE(L)

PGnd

C

OFF

Page 7

CS5165

7

V

2

™

Control Method

The V

2

™

method of control uses a ramp signal that is generated by the ESR of the output capacitors. This ramp is

proportional to the AC current through the main inductor

and is offset by the value of the DC output voltage. This

control scheme inherently compensates for variation in

either line or load conditions, since the ramp signal is generated from the output voltage itself. This control scheme

differs from traditional techniques such as voltage mode,

which generates an artificial ramp, and current mode,

which generates a ramp from inductor current.

Figure 1: V

2

™

Control Diagram

The V

2

™

control method is illustrated in Figure 1. The output voltage is used to generate both the error signal and

the ramp signal. Since the ramp signal is simply the output

voltage, it is affected by any change in the output regardless of the origin of that change. The ramp signal also contains the DC portion of the output voltage, which allows

the control circuit to drive the main switch to 0% or 100%

duty cycle as required.

A change in line voltage changes the current ramp in the

inductor, affecting the ramp signal, which causes the V

2

™

control scheme to compensate the duty cycle. Since the

change in inductor current modifies the ramp signal, as in

current mode control, the V

2

™

control scheme has the

same advantages in line transient response.

A change in load current will have an affect on the output

voltage, altering the ramp signal. A load step immediately

changes the state of the comparator output, which controls

the main switch. Load transient response is determined

only by the comparator response time and the transition

speed of the main switch. The reaction time to an output

load step has no relation to the crossover frequency of the

error signal loop, as in traditional control methods.

The error signal loop can have a low crossover frequency,

since transient response is handled by the ramp signal

loop. The main purpose of this “slow”feedback loop is to

provide DC accuracy. Noise immunity is significantly

improved, since the error amplifier bandwidth can be

rolled off at a low frequency. Enhanced noise immunity

improves remote sensing of the output voltage, since the

noise associated with long feedback traces can be effectively filtered.

Line and load regulation are drastically improved because

there are two independent voltage loops. A voltage mode

controller relies on a change in the error signal to compensate for a deviation in either line or load voltage. This

change in the error signal causes the output voltage to

change corresponding to the gain of the error amplifier,

which is normally specified as line and load regulation. A

current mode controller maintains fixed error signal under

deviation in the line voltage, since the slope of the ramp

signal changes, but still relies on a change in the error signal for a deviation in load. The V

2

™

method of control

maintains a fixed error signal for both line and load variation, since the ramp signal is affected by both line and load.

Constant Off-Time

To maximize transient response, the CS5165 uses a

Constant Off-Time method to control the rate of output

pulses. During normal operation, the Off-Time of the high

side switch is terminated after a fixed period, set by the

C

OFF

capacitor. To maintain regulation, the V

2

™

Control

Loop varies switch On-Time. The PWM comparator monitors the output voltage ramp, and terminates the switch

On-Time.

Constant Off-Time provides a number of advantages.

Switch duty Cycle can be adjusted from 0 to 100% on a

pulse-by pulse basis when responding to transient conditions. Both 0% and 100% Duty Cycle operation can be

maintained for extended periods of time in response to

Load or Line transients. PWM Slope Compensation to

avoid sub-harmonic oscillations at high duty cycles is

avoided.

Switch On-Time is limited by an internal 30µs (typical)

timer, minimizing stress to the Power Components.

Programmable Output

The CS5165 is designed to provide two methods for programming the output voltage of the power supply. A five

bit on board digital to analog converter (DAC) is used to

program the output voltage within two different ranges.

The first range is 2.14V to 3.54V in 100mV steps, the second

is 1.34V to 2.09V in 50mV steps, depending on the digital

input code. If all five bits are left open, the CS5165 enters

adjust mode. In adjust mode, the designer can choose any

output voltage by using resistor divider feedback to the

VFBpin, as in traditional controllers. The CS5165 is specifically designed to meet or exceed Intel’s Pentium® II specifications.

Start-up

Until the voltage on the V

CC

Supply pin exceeds the 3.95V

monitor threshold, the Soft Start and Gate pins are held

low. The Fault latch is Reset (no Fault condition). The output of the Error Amp (COMP) is pulled up to 1V by the

Comp Clamp. When the V

CC

pin exceeds the monitor

Theory Of Operation

Application Information

COMP

PWM

Comparator

+

C

–

Ramp Signal

Error

Signal

Error

Amplifier

GATE(H)

GATE(L)

E

Output

Voltage

Feedback

–

+

Reference

Voltage

Page 8

threshold, the GateH output is activated, and the Soft Start

Capacitor begins charging. The GateH output will remain

on, enabling the NFET switch, until terminated by either

the PWM Comparator, or the Maximum On-Time Timer.

If the Maximum On-Time is exceeded before the regulator

output voltage achieves the 1V level, the pulse is terminated. The GateH pin drives low, and the GateL pin drives

high for the duration of the Extended Off-Time. This time

is set by the Time-out Timer and is approximately equal to

the Maximum On-Time, resulting in a 50% Duty Cycle. The

GateL Pin will then drive low, the GateH pin will drive

high, and the cycle repeats.

When regulator output voltage achieves the 1V level present at the Comp pin, regulation has been achieved and

normal Off-Time will ensue. The PWM comparator terminates the switch On-Time, with Off-Time set by the C

OFF

Capacitor. The V

2

™

control loop will adjust switch Duty

Cycle as required to ensure the regulator output voltage

tracks the output of the Error Amp.

The Soft Start and Comp capacitors will charge to their

final levels, providing a controlled turn-on of the regulator

output. Regulator turn-on time is determined by the Comp

capacitor charging to its final value. Its voltage is limited

by the Soft Start Comp clamp and the voltage on the Soft

start pin.

Power Supply Sequencing

The CS5165 offers inherent protection from undefined

start-up conditions, regardless of the 12V and 5V supply

power-up sequencing. The turn-on slew rates of the 12V

and 5V power supplies can be varied over wide ranges

without affecting the output voltage or causing detrimental

effects to the buck regulator.

Figure 2: Demonstration board start up in response to increasing 12V

and 5V input voltages. Extended off time is followed by normal off

time operation when output voltage achieves regulation to the error

amplifier output.

Figure 3: Demonstration board start up waveforms.

Figure 4: Demonstration board enable start up waveforms.

Normal Operation

During Normal operation, Switch Off-Time is constant and

set by the C

OFF

capacitor. Switch On-Time is adjusted by

the V

2

™

Control loop to maintain regulation. This results

in changes in regulator switching frequency, duty cycle,

and output ripple in response to changes in load and line.

Output voltage ripple will be determined by inductor ripple current and the ESR of the output capacitors (see figures 5 & 6 ).

CS5165

8

Application Information: continued

Trace 1 Soft Start pin (2V/div)

Trace 2 COMP pin (error amplifier output) (1V/div)

Trace 4 Regulator output voltage (1V/div)

Trace 1 - Regulator Output Voltage (1V/div.)

Trace 2 - Inductor Switching Node (2V/div.)

Trace 3 - 12V input (V

Trace 4 - 5V Input (1V/div.)

) (5V/div.)

CC

Trace 1 - Regulator Output Voltage (1V/div.)

Trace 2 - Inductor Switching Node (5V/div.)

Page 9

Figure 5: Normal Operation showing Output Inductor Ripple Current

and Output Voltage Ripple, 0.5A Load, V

OUT

= +2.84V (DAC = 10111)

Figure 6: Normal Operation showing Output Inductor Ripple Current

and Output Voltage Ripple, I

LOAD

= 14A, V

OUT

= +2.84V (DAC = 10111)

Transient Response

The CS5165 V

2

™

Control Loop’s 100ns reaction time provides unprecedented transient response to changes in

input voltage or output current. Pulse-by-pulse adjustment

of duty cycle is provided to quickly ramp the inductor current to the required level. Since the inductor current cannot

be changed instantaneously, regulation is maintained by

the output capacitor(s) during the time required to slew the

inductor current.

Overall load transient response is further improved

through a feature called “Adaptive Voltage Positioning”.

This technique pre-positions the output capacitors voltage

to reduce total output voltage excursions during changes in

load.

Holding tolerance to 1% allows the error amplifiers reference voltage to be targeted +40mV high without compromising DC accuracy. A “Droop Resistor”, implemented

through a PC board trace, connects the Error Amps feedback pin (V

FB

) to the output capacitors and load and carries

the output current. With no load, there is no DC drop

across this resistor, producing an output voltage tracking

the Error amps, including the +40mV offset. When the full

load current is delivered, an 80mV drop is developed

across this resistor. This results in output voltage being offset -40mV low.

The result of Adaptive Voltage Positioning is that additional margin is provided for a load transient before reaching

the output voltage specification limits. When load current

suddenly increases from its minimum level, the output

capacitor is pre-positioned +40mV. Conversely, when load

current suddenly decreases from its maximum level, the

output capacitor is pre-positioned -40mV (see figures 7, 8,

and 9). For best Transient Response, a combination of a

number of high frequency and bulk output capacitors are

usually used.

If the Maximum On-Time is exceeded while responding to

a sudden increase in Load current, a normal off-time

occurs to prevent saturation of the output inductor.

Figure 7: Output Voltage Transient Response to a 14A load pulse,

V

OUT

= +2.84V (DAC = 10111).

CS5165

9

Application Information: continued

Trace 1 GATE (H) (10V/div)

Trace 2 Inductor Switching Node (5V/div)

Trace 3 Output Inductor Ripple Current (2A/div)

Trace 4 V

Trace 1 - GATE(H) (10/div)

Trace 2 - Inductor Switching Node (5V/div)

Trace 3 - Output Inductor Ripple Current (2A/div)

Trace 4 - V

ripple (20mV/div)

OUT

ripple (20mV/div)

OUT

Trace 3 -Load Current (5A/10mV/div)

Trace 4 - V

OUT

(100mV/div)

Page 10

Figure 8: Output Voltage Transient Response to a 14A load step, V

OUT

=

+2.84V(DAC = 10111).

Figure 9: Output Voltage Transient Response to a 14A load turn-off,

V

OUT

= +2.84V (DAC = 10111).

Short Circuit Protection

A lossless hiccup mode short circuit protection feature is

provided, requiring only the Soft Start capacitor to implement. If a short circuit condition occurs the VFBlow comparator sets the FAULT latch. This causes the top FET to

shut off, disconnecting the regulator from its input voltage.

The Soft Start capacitor is then slowly discharged by a 2µA

current source until it reaches its lower 0.7V threshold. The

regulator will then attempt to restart normally, operating

in its extended off time mode with a 50% duty cycle, while

the Soft Start capacitor is charged with a 60µA charge current.

If the short circuit condition persists, the regulator output

will not achieve the 1V low V

FB

comparator threshold

before the Soft Start capacitor is charged to its upper 2.5V

threshold. If this happens the cycle will repeat itself until

the short is removed. The Soft Start charge/discharge current ratio sets the duty cycle for the pulses (2µA/60µA =

3.3%), while actual duty cycle is half that due to the extended off time mode (1.65%).

This protection feature results in less stress to the regulator

components, input power supply, and PC board traces

than occurs with constant current limit protection (see

Figures 10 and 11).

If the short circuit condition is removed, output voltage

will rise above the 1V level, preventing the FAULT latch

from being set, allowing normal operation to resume.

Figure 10: Demonstration board hiccup mode short circuit protection.

Gate pulses are delivered while the Soft Start capacitor charges, and

cease during discharge.

Figure 11: Demonstration board Start up with regulator output shorted

to ground.

Protection and Monitoring Features

CS5165

10

Application Information: continued

Trace 1 - GATE(H) (10V/div)

Trace 2 - Inductor Switching Node (5V/div)

Trace 3 -Load Current (5A/div)

Trace 4 - V

(100mV/div)

OUT

Trace 1 - GATE(H) (10V/div)

Trace 2 - Inductor Switching Node (5V/div)

Trace 3 -Load Current (5A/div)

Trace 4 - V

(100mV/div)

OUT

Trace 4 - 5V Supply Voltage (2V/div.)

Trace 3 - Soft Start Timing Capacitor (1V/div.)

Trace 2 - Inductor Switching Node (2V/div.)

Trace 4 = 5V from PC Power Supply (2V/div.)

Trace 2 = Inductor Switching Node (2V/div.)

Page 11

Overvoltage Protection

Overvoltage protection (OVP) is provided as result of the

normal operation of the V

2

™

control topology and requires

no additional external components. The control loop

responds to an overvoltage condition within 100ns, causing

the top MOSFET to shut off, disconnecting the regulator

from its input voltage. The bottom MOSFET is then activated, resulting in a “crowbar” action to clamp the output

voltage and prevent damage to the load (see Figures 12

and 13). The regulator will remain in this state until the

overvoltage condition ceases or the input voltage is pulled

low. The bottom FET and board trace must be properly

designed to implement the OVP function. If a dedicated

OVP output is required, it can be implemented using the

circuit in figure 14. In this figure the OVP signal will go

high (overvoltage condition), if the output voltage (V

CORE

)

exceeds 20% of the voltage set by the particular DAC code

and provided that PWRGD is low. It is also required that

the overvoltage condition be present for at least the

PWRGD delay time for the OVP signal to be activated. The

resistor values shown in figure 14 are for V

DAC

= +2.8V

(DAC = 10111). The V

OVP

(overvoltage trip-point) can be

set using the following equation:

V

OVP

= V

BEQ3

(

1 +

)

Figure 12: OVP response to an input-to-output short circuit by immediately providing 0% duty cycle, crow-barring the input voltage to

ground.

Figure 13: OVP response to an input-to-output short circuit by pulling

the input voltage to ground.

Figure 14: Circuit to implement a dedicated OVP output using the

CS5165.

Output Enable Circuit

The Enable pin (pin 8) is used to enable or disable the regulator output voltage, and is consistent with TTL DC specifications. It is internally pulled-up. If pulled low (below

0.8V), the output voltage is disabled. At the same time the

Power Good and Soft Start pins are pulled low, so that

when normal operation resumes power-up of the CS5165

goes through the Soft Start sequence. Upon pulling the

Enable pin low, the internal IC bias is completely shut off,

resulting in total shutdown of the Controller IC.

Power Good Circuit

The Power Good pin (pin 13) is an open-collector signal

consistent with TTL DC specifications. It is externally

pulled -up, and is pulled low (below 0.3V) when the regulator output voltage typically exceeds ± 8.5% of the nominal output voltage. Maximum output voltage deviation

before Power Good is pulled low is ± 12%.

R2

R1

CS5165

11

Application Information: continued

Trace 4 = 5V from PC Power Supply (2V/div.)

Trace 1 = Regulator Output Voltage (1V/div.)

+5V

CS5165

PWRGD

10K

Q1

2N3906

+5V

5K

20K

10K

15K

56K

Q2

2N3904

V

CORE

R1

R2

Q3

2N3906

OVP

10K

Trace 4 = 5V from PC Power Supply (5V/div.)

Trace1 = Regulator Output Voltage (1V/div.)

Trace 2 = Inductor Switching Node (5V/div.)

Page 12

Figure 15: PWRGD signal becomes logic high as V

OUT

enters -8.5% of

lower PWRGD threshold, V

OUT

= +2.84V (DAC = 10111)

Figure 16: Power Good response to an out of regulation condition.

Figure 16 shows the relationship between the regulated

output voltage V

FB

and the Power Good signal. To prevent

Power Good from interrupting the CPU unnecessarily, the

CS5165 has a built-in delay to prevent noise at the VFBpin

from toggling Power Good. The internal time delay is

designed to take about 75µs for Power Good to go low and

65µs for it to recover. This allows the Power Good signal to

be completely insensitive to out of regulation conditions

that are present for a duration less than the built in delay

(see figure 17).

It is therefore required that the output voltage attains an

out of regulation or in regulation level for at least the builtin delay time duration before the Power Good signal can

change state.

Figure 17: Power Good is insensitive to out of regulation conditions

that are present for a duration less than the built in delay.

Selecting External Components

The CS5165 buck regulator can be used with a wide range

of external power components to optimize the cost and

performance of a particular design. The following information can be used as general guidelines to assist in their

selection.

NFET Power Transistors

Both logic level and standard FETs can be used. The reference designs derive gate drive from the 12V supply which

is generally available in most computer systems and utilize

logic level FETs. A charge pump may be easily implemented to support 5V only systems. Multiple FET’s may be paralleled to reduce losses and improve efficiency and thermal management.

Voltage applied to the FET gates depends on the application circuit used. Both upper and lower gate driver outputs

are specified to drive to within 1.5V of ground when in the

low state and to within 2V of their respective bias supplies

when in the high state. In practice, the FET gates will be

driven rail to rail due to overshoot caused by the capacitive

load they present to the controller IC. For the typical application where VCC= 12V and 5V is used as the source for

the regulator output current, the following gate drive is

provided:

V

GS (TOP)

= 12V - 5V = 7V, V

GS(BOTTOM)

= 12V (see Figure 18).

CS5165

12

Application Information: continued

Trace 2 - PWRGD (2V/div)

Trace 4 - V

Trace 1 PWRGD (2V/div)

Trace 4 VFB (1V/div)

OUT

(1V/div)

Trace 1 PWRGD (2V/div)

Trace 4 V

FB

(1V/div)

Page 13

13

Figure 18: Gate drive waveforms depicting rail to rail swing.

Figure 19: Normal Operation showing the guaranteed Non-Overlap

time between the High and Low - Side MOSFET Gate Drives, I

LOAD

=

14A.

The CS5165 provides adaptive control of the external NFET

conduction times by guaranteeing a typical 65ns non-overlap between the upper and lower MOSFET gate drive pulses. This feature eliminates the potentially catastrophic

effect of “shoot-through current”, a condition during

which both FETs conduct causing them to overheat, selfdestruct, and possibly inflict irreversible damage to the

processor.

The most important aspect of FET performance is RDSON,

which effects regulator efficiency and FET thermal management requirements.

The power dissipated by the MOSFETs may be estimated

as follows:

Switching MOSFET:

Power = I

LOAD

2

× RDSON× duty cycle

Synchronous MOSFET:

Power = I

LOAD

2

× RDSON× (1 - duty cycle)

Duty Cycle =

Off Time Capacitor (C

OFF

)

The C

OFF

timing capacitor sets the regulator off time:

T

OFF

= C

OFF

× 4848.5

The preceding equation for Duty Cycle can also be used to

calculate the regulator switching frequency and select the

C

OFF

timing capacitor:

C

OFF

=

where

period =

Schottky Diode for Synchronous FET

For synchronous operation, A Schottky diode may be

placed in parallel with the synchronous FET to conduct the

inductor current upon turn off of the switching FET to

improve efficiency. The CS5165 reference circuit does not

use this device due to its excellent design. Instead, the

body diode of the synchronous FET is utilized to reduce

cost and conducts the inductor current. For a design operating at 200kHz or so, the low non-overlap time combined

with Schottky forward recovery time may make the benefits of this device not worth the additional expense. The

power dissipation in the synchronous MOSFET due to

body diode conduction can be estimated by the following

equation:

Power = Vbd× I

LOAD

× conduction time × switching fre-

quency

Where Vbd= the forward drop of the MOSFET body diode.

For the CS5165 demonstration board:

Power = 1.6V × 14.2A × 100ns × 200kHz = 0.45W

This is only 1.1% of the 40W being delivered to the load.

1

switching frequency

Period × (1-Duty Cycle)

4848.5

V

OUT

+ (I

LOAD

× RDS

ON OF SYNCH FET

)

VIN+ (I

LOAD

× RDS

ON OF SYNCH FET

) - (I

LOAD

× RDS

ON OF SWITCH FET

)

Application Information: continued

CS5165

Trace 3 = GATE(H) (10V/div.)

GATE(H) - 5V

Trace 1=

Trace 4 =

Trace 2 = Inductor Switching Node (5V/div.)

Trace 1 - GATE(H) (5V/div)

Trace 2 - GATE(L) (5V/div)

GATE(L)

IN

(10V/div.)

Page 14

14

CS5165

“Droop” Resistor for Adaptive Voltage Positioning

Adaptive voltage positioning is used to help keep the output voltage within specification during load transients. To

implement adaptive voltage positioning a “Droop

Resistor” must be connected between the output inductor

and output capacitors and load. This resistor carries the full

load current and should be chosen so that both DC and AC

tolerance limits are met. An embedded PC trace resistor

has the distinct advantage of near zero cost implementation. However, this droop resistor can vary due to three

reasons: 1) the sheet resistivity variation causes the thickness of the PCB layer to vary. 2) the mismatch of L/W, and

3) temperature variation.

1) Sheet Resistivity

for one ounce copper, the thickness variation is

typically 1.15 mil to 1.35 mil. Therefore the error due to

sheet resistivity is:

= 16%

2) Mismatch due to L/W

The variation in L/W is governed by variations due to

the PCB manufacturing process that affect the

geometry and the power dissipation capability of the

droop resistor. The error due to L/W mismatch is

typically 1%

3) Thermal Considerations

Due to I2× R power losses the surface temperature of

the droop resistor will increase causing the resistance

to increase. Also, the ambient temperature variation

will contribute to the increase of the resistance,

according to the formula:

R = R

20

[1+ α20(Τ−20)]

where:

R

20

= resistance at 20˚C

α =

T= operating temperature

R = desired droop resistor value

For temperature T = 50˚C,

the % R change = 12%

Droop Resistor Tolerance

Tolerance due to sheet resistivity variation 16%

Tolerance due to L/W error 1%

Tolerance due to temperature variation 12%

Total tolerance for droop resistor 29%

In order to determine the droop resistor value the nominal

voltage drop across it at full load has to be calculated. This

voltage drop has to be such that the output voltage full

load is above the minimum DC tolerance spec.

V

DROOP(TYP)

=

Example: for a 300MHz Pentium

®

II, the DC accuracy spec

is 2.74 < V

CC(CORE)

< 2.9V, and the AC accuracy spec is

2.67V < V

CC(CORE)

<2.93V. The CS5165 DAC output voltage

is +2.812V < V

DAC

< +2.868V. In order not to exceed the DC

accuracy spec, the voltage drop developed across the resistor must be calculated as follows:

V

DROOP(TYP)

=

= = 56mV

With the CS5165 DAC accuracy being 1%, the internal error

amplifier’s reference voltage is trimmed so that the output

voltage will be 40mV high at no load. With no load, there is

no DC drop across the resistor, producing an output voltage tracking the error amplifier output voltage, including

the offset. When the full load current is delivered, a drop of

-56mV is developed across the resistor. Therefore, the regulator output is pre-positioned at 40mV above the nominal

output voltage before a load turn-on. The total voltage

drop due to a load step is ∆V-40mV and the deviation from

the nominal output voltage is 40mV smaller than it would

be if there was no droop resistor. Similarly at full load the

regulator output is pre-positioned at 16mV below the nominal voltage before a load turn-off. the total voltage

increase due to a load turn-off is ∆V-16mV and the deviation from the nominal output voltage is 16mV smaller than

it would be if there was no droop resistor. This is because

the output capacitors are pre-charged to value that is either

40mV above the nominal output voltage before a load turnon or, 16mV below the nominal output voltage before a

load turn-off (see figure 7).

Obviously, the larger the voltage drop across the droop

resistor ( the larger the resistance), the worse the DC and

load regulation, but the better the AC transient response.

Design Rules for Using a Droop Resistor

The basic equation for laying an embedded resistor is:

R

AR

= ρ × or R = ρ ×

L

(W × t)

L

A

2.812V-2.74V

1.3

[V

DAC(MIN)-VDC PENTIUM®II(MIN)

]

1+R

DROOP(TOLERANCE)

[V

DAC(MIN)-VDC(MIN)

]

1+R

DROOP(TOLERANCE)

0.00393

˚C

1.35 - 1.15

1.25

Application Information: continued

Page 15

15

Application Information: continued

where:

A= W × t = cross-sectional area

ρ= the copper resistivity (µΩ - mil)

L= length (mils)

W = width (mils)

t = thickness (mils)

For most PCBs the copper thickness, t, is 35µm (1.37 mils)

for one ounce copper. ρ = 717.86µΩ-mil

For a Pentium

®

II load of 14.2A the resistance needed to cre-

ate a 56mV drop at full load is:

R

DROOP

= = = 3.9mΩ

The resistivity of the copper will drift with the temperature

according to the following guidelines:

∆R = 12% @ T

A

= +50˚C

∆R = 34% @T

A

= +100˚C

Droop Resistor Width Calculations

The droop resistor must have the ability to handle the load

current and therefore requires a minimum width which is

calculated as follows (assume one ounce copper thickness):

W=

where:

W = minimum width (in mils) required for proper power

dissipation, and I

LOAD

Load Current Amps.

The Pentium

®

II maximum load current is 14.2A.

Therefore:

W = = 284 mils = 0.7213cm

Droop Resistor Length Calculation

L = = = 2113 mil = 5.36cm

Output Inductor

The inductor should be selected based on its inductance,

current capability, and DC resistance. Increasing the inductor value will decrease output voltage ripple, but degrade

transient response.

Inductor Ripple Current

Ripple current =

Example: V

IN

= +5V, V

OUT

= +2.8V, I

LOAD

= 14.2A, L = 1.2µH,

Freq = 200KHz

Ripple current = = 5.1A

Output Ripple Voltage

V

RIPPLE

= Inductor Ripple Current × Output Capacitor ESR

Example:

V

IN

= +5V, V

OUT

= +2.8V, I

LOAD

= 14.2A, L = 1.2µH,

Switching Frequency = 200KHz

Output Ripple Voltage = 5.1A × Output Capacitor ESR

(from manufacturer’s specs)

ESR of Output Capacitors to limit Output Voltage Spikes

ESR =

This applies for current spikes that are faster than regulator

response time. Printed Circuit Board resistance will add to

the ESR of the output capacitors.

In order to limit spikes to 100mV for a 14.2A Load Step,

ESR = 0.1/14.2 = 0.007Ω

Inductor Peak Current

Peak Current = Maximum Load Current +

()

Example: V

IN

= +5V, V

OUT

= +2.8V, I

LOAD

= 14.2A, L = 1.2µH,

Freq = 200KHz

Peak Current = 14.2A + (5.1/2) = 16.75A

A key consideration is that the inductor must be able to

deliver the Peak Current at the switching frequency without

saturating.

Response Time to Load Increase

(limited by Inductor value unless Maximum On-Time is

exceeded)

Response Time =

Example: V

IN

= +5V, V

OUT

= +2.8V, L = 1.2µH, 14.2A

change in Load Current

Response Time = = 7.7µs

1.2µH × 14.2A

(5V-2.8V)

L × ∆ I

OUT

(VIN-V

OUT

)

Ripple

Current

2

∆ V

OUT

∆ I

OUT

[(5V-2.8V)x 2.8V]

[200KHz × 1.2µH × 5V]

[(VIN- V

OUT

) × V

OUT

]

(

Switching Frequency × L × V

IN

)

0.0039 × 284 × 1.37

717.86

R

DROOP

× W × t

ρ

14.2A

0.05

I

LOAD

0.05

56mV

14.2A

56mV

I

OUT

CS5165

Page 16

16

CS5165

Response Time to Load Decrease

(limited by Inductor value)

Response Time =

Example: V

OUT

=+2.8V, 14.2A change in Load Current,

L = 1.2µH

Response Time = = 6.1µs

Input and Output Capacitors

These components must be selected and placed carefully to

yield optimal results. Capacitors should be chosen to provide acceptable ripple on the input supply lines and regulator output voltage. Key specifications for input capacitors

are their ripple rating, while ESR is important for output

capacitors. For best transient response, a combination of

low value/high frequency and bulk capacitors placed close

to the load will be required.

Thermal Considerations for Power MOSFETs and Diodes

In order to maintain good reliability, the junction temperature of the semiconductor components should be kept to a

maximum of 150°C or lower. The thermal impedance

(junction to ambient) required to meet this requirement can

be calculated as follows:

Thermal Impedance =

A heatsink may be added to TO-220 components to reduce

their thermal impedance. A number of PC board layout

techniques such as thermal vias and additional copper foil

area can be used to improve the power handling capability

of surface mount components.

EMI Management

As a consequence of large currents being turned on and off

at high frequency, switching regulators generate noise as a

consequence of their normal operation. When designing

for compliance with EMI/EMC regulations, additional

components may be added to reduce noise emissions.

These components are not required for regulator operation

and experimental results may allow them to be eliminated.

The input filter inductor may not be required because bulk

filter and bypass capacitors, as well as other loads located

on the board will tend to reduce regulator di/dt effects on

the circuit board and input power supply. Placement of the

power component to minimize routing distance will also

help to reduce emissions.

Layout Guidelines

When laying out the CPU buck regulator on a printed circuit board, the following checklist should be used to

ensure proper operation of the CS5165.

1) Rapid changes in voltage across parasitic capacitors and

abrupt changes in current in parasitic inductors are major

concerns for a good layout.

2) Keep high currents out of logic grounds.

3) Avoid ground loops as they pick up noise. Use star or

single point grounding. The source of the lower (synchronous FET) is an ideal point where the input and output GND planes can be connected.

4) For double-sided PCBs a single large ground plane is not

recommended, since there is little control of where currents

flow and the large surface area can act as an antenna.

5) Even though double sided PCBs are usually sufficient

for a good layout, four-layer PCBs are the optimum

approach to reducing susceptibility to noise. Use the two

internal layers as the +5V and GND planes, and the top

and bottom layers for the vias.

6) Keep the inductor switching node small by placing the

output inductor, switching and synchronous FETs close

together.

7) The FET gate traces to the IC must be as short, straight,

and wide as possible. Ideally, the IC has to be placed right

next to the FETs.

8) Use fewer, but larger output capacitors, keep the capacitors clustered, and use multiple layer traces with heavy

copper to keep the parasitic resistance low.

9) Place the switching FET as close to the +5V input capacitors as possible.

10) Place the output capacitors as close to the load

as possible.

11) Place the VFBfilter resistor in series with the

V

FB

pin (pin 16) right at the pin.

12) Place the V

FB

filter capacitor right at the VFBpin (pin

16).

13) The “Droop” Resistor (embedded PCB trace) has to be

wide enough to carry the full load current.

14) Place the VCCbypass capacitor as close as possible to

the V

CC

pin.

T

J(MAX)

- T

A

Power

Thermal Management

1.2µH × 14.2A

2.8V

L × Change in I

OUT

V

OUT

Application Information: continued

Page 17

17

9

Figure 24: Percent Output Error vs DAC Voltage Setting,

VCC= 12V, TA = 25˚C, V

ID4

= 0

Figure 25: Percent Output Error vs. DAC Output Voltage Setting

VCC= 12V, TA = 25˚C, V

ID4

= 1

Typical Performance Characteristics

Figure 22: GATE(H) &GATE(L) Falltime vs. Load Capacitance

Figure 23: DAC Output Voltage vs Temperature, DAC Code = 10111,

VCC= 12V

Figure 20: GATE(L) Risetime vs. Load Capacitance Figure 21: GATE(H) Risetime vs. Load Capacitance

CS5165

200

180

160

140

120

100

80

60

Risetime (ns)

40

VCC=12V

T

=25C˚

A

20

0

0 2000 4000 6000 8000 10000 12000 14000 16000

Load Capacitance (pF)

200

180

160

140

120

100

80

60

Falltime (ns)

40

VCC=12V

TA=25C˚

20

0

0 2000 4000 6000 8000 10000 12000 14000 16000

Load Capacitance (pF)

200

180

160

140

120

100

80

60

Risetime (ns)

40

20

0

0

0.04

0.02

0

-0.02

-0.04

-0.06

-0.08

DAC Output Voltage Deviation (%)

-0.1

0

2000 4000 6000 8000 10000 12000 14000 16000

Load Capacitance (pF)

Junction T emperature (˚C)

VCC=12V

T

=25C˚

A

12010080604020

0.04

0.02

0

-0.02

-0.04

-0.06

Output Error (%)

-0.08

-0.1

1.34 1.39 1.44 1.49 1.54 1.59 1.64 1.69 1.74 1.79 1.84 1.89 1.94 1.99 2.04 2.0

DAC Output Voltage Setting (V)

0.05

0

-0.05

-0.1

-0.15

Output Error (%)

-0.2

-0.25

2.14 2.24 2.34 2.44 2.54 2.64 2.74 2.84 2.94 3.04 3.14 3.24 3.34 3.44 3.54

DAC Output Voltage Setting (V)

Page 18

CS5165

Figure 26: +5V to +2.8V @ 14.2A for 300 MHz PentiumII

®

Additional Application Circuits

18

+5V

MBRS120

1µF

MBRS120

MBRS120

330pF

0.1µF

V

CC

V

ID0

V

ID1

V

ID2

V

ID3

V

ID4

C

OFF

SS

COMP

CS5165

ENABLE

PWRGD

0.1µF

1µF

V

GATEH

V

GATEL

PGND

V

LGND

1200uF/10V

x3

Si4410DY

1.2µH

Droop Resistor

(Embedded PCB trace)

6mΩ

Vcc

Si9410DY

1200µF/10V

x5

Vss

ENABLE

FB

3.3K

1000pF

PWRGD

PENTIUM

SYSTEM

®

II

VID4

VID3

VID2

VID1

VID0

Page 19

19

Thermal Data 16L

SO Wide

R

ΘJC

typ 23 ˚C/W

R

ΘJA

typ 105 ˚C/W

D

Lead Count Metric English

Max Min Max Min

16L SO Wide 10.50 10.10 .413 .398

Package Specification

PACKAGE DIMENSIONS IN mm (INCHES)

PACKAGE THERMAL DATA

Rev. 6/28/99

Ordering Information

Part Number Description

CS5165GDW16 16L SO Wide

CS5165GDWR16 16L SO Wide (tape & reel)

CS5165

© 1999 Cherry Semiconductor Corporation

Cherry Semiconductor Corporation reserves the

right to make changes to the specifications without

notice. Please contact Cherry Semiconductor

Corporation for the latest available information.

Surface Mount Wide Body (DW); 300 mil wide

7.60 (.299)

7.40 (.291)

0.51 (.020)

0.33 (.013)

1.27 (.050) BSC

10.65 (.419)

10.

00 (.394)

1.27 (.050)

0.40 (.016)

REF: JEDEC MS-013

0.32 (.013)

0.23 (.009)

2.49 (.098)

2.24 (.088)

2.65 (.104)

2.35 (.093)

D

0.30 (.012)

0.10 (.004)

Loading...

Loading...