Page 1

Features

■ Nonsynchronous Buck

Design

■ V

2

ª

Control Topology

■ 100ns Transient Loop

Response

■ Programmable Oscillator

Frequency

■ 30ns Typical Gate Rise

and 10ns Fall Times

(No Load)

■ Frequency

Synchronization Input

■ ENABLE Input Controls

Channel 2 Gate Driver

■ 5V/10mA Reference

Output

Package Option

CS5127

Dual Output Nonsynchronous Buck Controller

with Sync Function and Second Channel Enable

CS5127

Description

The CS5127 is a fixed frequency

dual output nonsynchronous buck

controller. It contains circuitry for

regulating two separate outputs.

Each output channel contains a

high gain error amplifier, a comparator and latch, and a totem-pole

output driver capable of providing

DC current of 100mA and peak current in excess of 0.5A. A common

oscillator controls switching for

both channels, and a sync lead is

provided to allow parallel supply

operation or shifting of the switching noise spectrum. An on-chip 5V

reference is capable of providing as

much as 10mA of current for external circuitry. The CS5127 also

contains two undervoltage lockout

circuits. The first lockout releases

when VINreaches 8.4V, while the

second lockout ensures that V

REF

is

higher than 3.6V. The outputs are

held in a low state until both lockouts have released. The controller is

configured to utilize the V

2

ª

control method to achieve the fastest

possible transient response and

best overall regulation. This dual

controller is a cost-effective solution for providing V

CORE

and V

IO

power solutions in computing

applications using a single controller. The CS5127 will operate

over an input voltage range of 9.4V

to 20V and is available in a 16 lead

wide body surface mount package.

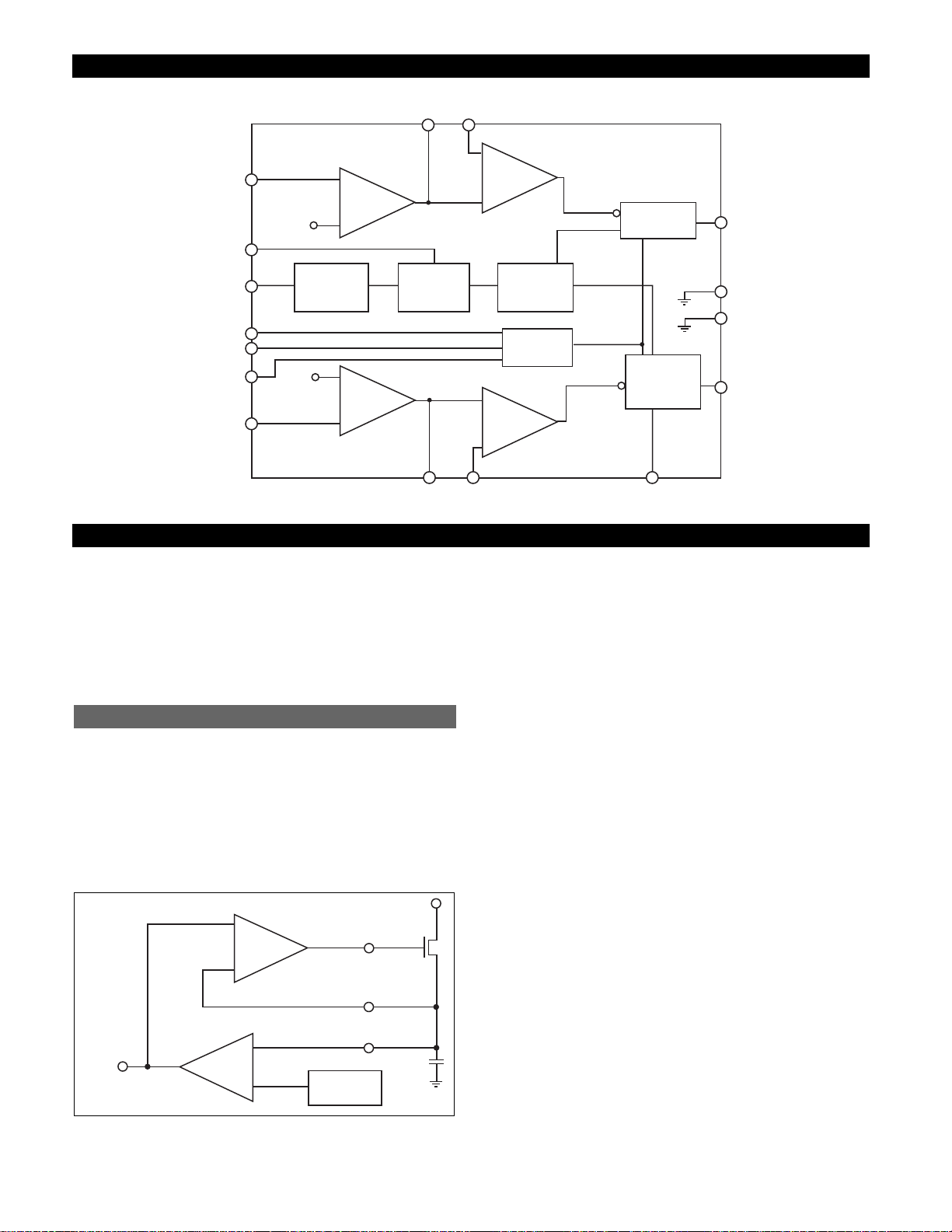

Applications Diagram

16 Lead SOIC Wide

1

C

T

SYNC

COMP2

PGND

COMP1

ENABLE

LGND

V

FB1

V

FB2

V

REF

V

IN

GATE1

GATE2

V

FFB1

V

FFB2

R

T

12V, 5V to 2.8V @ 7A and 3.3V @ 7A for 233MHz Pentium¨Processor with MMXª Technology

V2is a trademark of Switch Power, Inc.

Pentium is a registered trademark and MMX is a trademark of Intel Corporation

Rev. 11/3/98

Cherry Semiconductor Corporation

2000 South County Trail, East Greenwich, RI 02818

Tel: (401)885-3600 Fax: (401)885-5786

Email: info@cherry-semi.com

Web Site: www.cherry-semi.com

A Company

¨

C1, C2

2 x 680mF

R2

27k

5V

Q2

IRL3103S

D1

1N5821

+

Q1

FMMT2222ACT

R1

2.8V

20k

1540

1270

0.1mF

R4

R5

C7

330pF

C6

L1

5mH

+

C10, C11

2 x 680mF

C4, C5

+

C8

1mF

IRL3103S

1N5821

+5V

+

C9

0.1mF

Q3

L2

5mH

D2

C12, C13

2 x 680mF

+

SYNC

C

T

R

T

V

FB1

COMP1

V

FFB1

GATE1

LGnd

1mF

CS5127

C3

ENABLE

COMP2

GATE2

V

V

V

FFB2

PGnd

12V

+

2 x 680mF

V

IN

REF

FB2

R9

2k

R3

18k

3.3V

R7

2400

R8

1500

1

R6

1k

R10

20k

C14

330pF

C15

100mF

C16

100mF

C17

330pF

R11

20k

Page 2

CS5127

2

Absolute Maximum Ratings

Lead Symbol Lead Name

V

MAX

V

MIN

I

SOURCE

I

SINK

Operating Junction Temperature, TJ..................................................................................................................................... 150¡C

Storage Temperature Range, TS...................................................................................................................................-65 to 150¡C

ESD (Human Body Model).........................................................................................................................................................2kV

Lead Temperature Soldering: Reflow (SMD styles only).............................................60 sec. max above 183¡C, 230¡C peak

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Electrical Characteristics: 0¡C < TA< 70¡C; 0¡C < TJ< 125¡C; 9.4V < VIN< 20V; CT= 330 pF; RT= 27k½;

unless otherwise stated.

SYNC Oscillator Synchronization Input 5.5V -0.3V 5 mA 5 mA

CT Oscillator Integrating Capacitor 5.5V -0.3V 1mA 1mA

RT Oscillator Charge Current Resistor 5.5V -0.3V 1mA 1mA

V

FB1

, V

FB2

Voltage Feedback Inputs 5.5V -0.3V N/A N/A

COMP1, COMP2 Error Amplifier Outputs 7.5V -0.3V 2mA 50mA

V

FFB1

, V

FFB2

PWM Ramp Inputs 5.5V -0.3V 1mA 1mA

GATE1, GATE2 FET Gate Drive Outputs 20V -0.3V DC, 200mA DC, 200mA DC,

-2.0V for 1A peak 1A peak

t < 50ns (t < 100µs) (t < 100µs)

LGnd Reference Ground and IC Substrate 0V 0V 25 mA N/A

PGnd Power Ground 0V 0V 1A Peak, N/A

200mA DC

ENABLE Channel 2 Enable 5.5V -0.3V 1mA N/A

V

REF

Reference Voltage Output 5.5V -0.3V 150mA 5mA

(short circuit)

V

IN

Power Supply Input 20V -0.3V N/A 200mA DC,

1A peak

(t < 100µs)

■ Reference Section

V

REF

Output Voltage Room Temperature, 4.9 5.0 5.1 V

I

VREF

= 1mA, VIN= 12V

Line Regulation 1 20 mV

Load Regulation 1 mA < I

VREF

< 10 mA 15 26 mV

V

REF

Variation over Line, Load 4.85 5.15 V

and Temperature

Output Short Circuit Current 30 100 150 mA

■ Oscillator Section

Oscillator Frequency Variation 175 210 245 kHz

over Line and Temperature

Maximum Duty Cycle 80 90 98 %

Sync Threshold 0.8 1.6 2.4 V

Sync Bias Current V

SYNC

= 2.4V 170 250 µA

V

SYNC

= 5.0V 430 750

Sync Propagation Delay 230 ns

Page 3

CS5127

3

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Electrical Characteristics: 0¡C < TA< 70¡C; 0¡C < TJ< 125¡C; 9.4V < VIN< 20V; CT= 330 pF; RT= 27k½;

unless otherwise stated.

■ Error Amplifiers

VFBReference Voltage V

COMP

= V

VFB

1.245 1.275 1.300 V

Input Bias Current VFB= 1.275V 0.1 1.0 µA

Open Loop Gain 85 dB

Unity Gain Bandwidth 1.0 MHz

PSRR f = 120Hz 80 dB

COMP Source Current V

COMP

= 3V, V

VFB

= 1.1V 0.9 1.3 2.0 mA

COMP Sink Current V

COMP

= 1.2V, V

VFB

= 1.45V 10 16 24 mA

COMP Output Low Voltage V

VFB

= 1.45V, I

COMP

= 0.3 mA 0.50 0.85 1.00 V

■ PWM Comparators

V

FFB

Bias Current V

FFB

= 0 2.0 20 µA

Propagation Delay V

FFB

rising to V

GATE

falling 100 250 ns

Common Mode 2.9 3.3 V

Maximum Input Voltage

■ ENABLE Lead

ENABLE High Threshold channel 2 enabled 1.5 2.5 3.5 V

ENABLE Bias Current V

ENABLE

= 0 100 250 400 µA

■ Gate Driver Outputs

Output Low Saturation Voltage I

GATE

= 20 mA 0.1 0.4 V

I

GATE

= 100 mA 0.25 2.50 V

Output High Saturation Voltage I

GATE

= 20 mA 1.5 2.0 V

I

GATE

= 100 mA 1.6 3.0 V

Output Voltage under Lockout VIN= 6V, I

GATE

= 1 mA 0.1 0.2 V

Output Rise Time no load 30 ns

Output Fall Time no load 10 ns

■ Undervoltage Lockout

Turn On Threshold 7.4 8.4 9.4 V

Turn Off Threshold 6.8 7.8 8.8 V

■ Supply Current

Start Up Current VIN= 6V 0.4 0.8 mA

Operating Current VCT= 0V, no load 17.5 25 mA

Page 4

CS5127

4

Package Lead Description

PACKAGE LEAD # LEAD SYMBOL FUNCTION

16 Lead SO Wide

1 SYNC A pulse train on this lead will synchronize the oscillator. Sync threshold level

is 2.4V. Synchronization frequency should be at least 10% higher than the regular operating frequency. The sync feature is level sensitive.

2C

T

The oscillator integrating capacitor is connected to this lead.

3R

T

The oscillator charge current setting resistor is connected to this lead.

4V

FB1

The inverting input of the channel 1 error amplifier is brought out to this lead.

The lead is connected to a resistor divider which provides a measure of the

output voltage. The input is compared to a 1.275V reference, and channel 1

error amp output is used as the V

2

ª

PWM control voltage.

5 COMP1 Channel 1 error amp output and PWM comparator input.

6V

FFB1

This lead connects to the non-inverting input of the channel 1 PWM comparator.

7 GATE1 This lead is the gate driver for the channel 1 FET. It is capable of providing

nearly 1A of peak current.

8 LGND This lead provides a ÒquietÓ ground for low power circuitry in the IC. This

lead should be shorted to the PGND lead as close as possible to the IC for best

operating results.

9 PGND This lead is the power ground. It provides the return path for the FET gate dis-

charge. It should be shorted to the LGND lead as close as possible to the IC for

best operating results.

10 GATE2 This lead is the gate driver for the channel 2 FET. See GATE1 lead description

for more details.

11 V

FFB2

This lead connects to the non-inverting input of the channel 2 PWM comparator.

12 COMP2 Channel 2 error amp output and PWM comparator input.

13 V

FB2

Inverting input for the channel 2 error amp. See V

FBI

for more details.

14 ENABLE The regulator controlled by channel 2 may be turned on and off selectively by

the user. Pulling the ENABLE lead above 3.5V will turn channel 2 on. Setting

the ENABLE lead voltage below 1.5V guarantees that channel 2 is off.

15 V

REF

This lead is the output of a ± 3% reference. This reference drives most of the

on-chip circuitry, but will provide a minimum of 10 mA to external circuitry if

needed. The reference is inherently stable and does not require a compensation capacitor, but use of a decoupling capacitor will reduce noise in the IC.

16 V

IN

This lead is the power supply input to the IC. The maximum input voltage

that can be withstood without damage to the IC is 20V.

Page 5

CS5127

5

Theory of Operation

The CS5127 is a dual power supply controller that utilizes

the V

2

ª

control method. Two nonsynchronous V

2

ª

buck

regulators can be built using a single controller IC. This IC

is a perfect choice for efficiently and economically providing core power and I/O power for the latest

high-performance CPUs. Both switching regulators

employ a fixed frequency architecture driven from a

common oscillator circuit.

The V

2

ª

method of control uses a ramp signal generated

by the ESR of the output capacitors. This ramp is proportional to the AC current in the inductor and is offset by the

DC output voltage. V

2

ª

inherently compensates for variation in both line and load conditions since the ramp signal

is generated from the output voltage. This differs from traditional methods such as voltage mode control, where an

artificial ramp signal must be generated, and current mode

control, where a ramp is generated from inductor current.

Figure 1: V

2

ª

control diagram.

The V

2

ª

control method is illustrated in Figure 1. Both

the ramp signal and the error signal are generated by the

output voltage. Since the ramp voltage is defined as the

output voltage, the ramp signal is affected by any change

in the output, regardless of the origin of that change. The

ramp signal also contains the DC portion of the output

voltage, allowing the control circuit to drive the output

switch from 0% to about 90% duty cycle.

Changes in line voltage will change the current ramp in

the inductor, affecting the ramp signal and causing the

V

2

ª

control loop to adjust the duty cycle. Since a change

in inductor current changes the ramp signal, the V

2

ª

method has the characteristics and advantages of current

mode control for line transient response.

Changes in load current will affect the output voltage and

thus will also change the ramp signal. A load step will

immediately change the state of the comparator output

that controls the output switch. In this case, load transient

response time is limited by the comparator response time

and the transition speed of the switch. Notice that the reaction time of the V

2

ª

loop to a load transient is not

dependent on the crossover frequency of the error signal

loop. Traditional voltage mode and current mode methods

are dependent on the compensation of the error signal

loop.

The V

2

ª

error signal loop can have a low crossover frequency, since transient response is handled by the ramp

signal loop. The ÒslowÓ error signal loop provides DC

accuracy. Low frequency roll-off of the error amplifier

bandwidth will significantly improve noise immunity.

This also improves remote sensing of the output voltage,

since switching noise picked up in long feedback traces

can be effectively filtered.

V

2

ª

line and load regulation are dramatically improved

because there are two separate control loops. A voltage

V

2

ª

Control Method

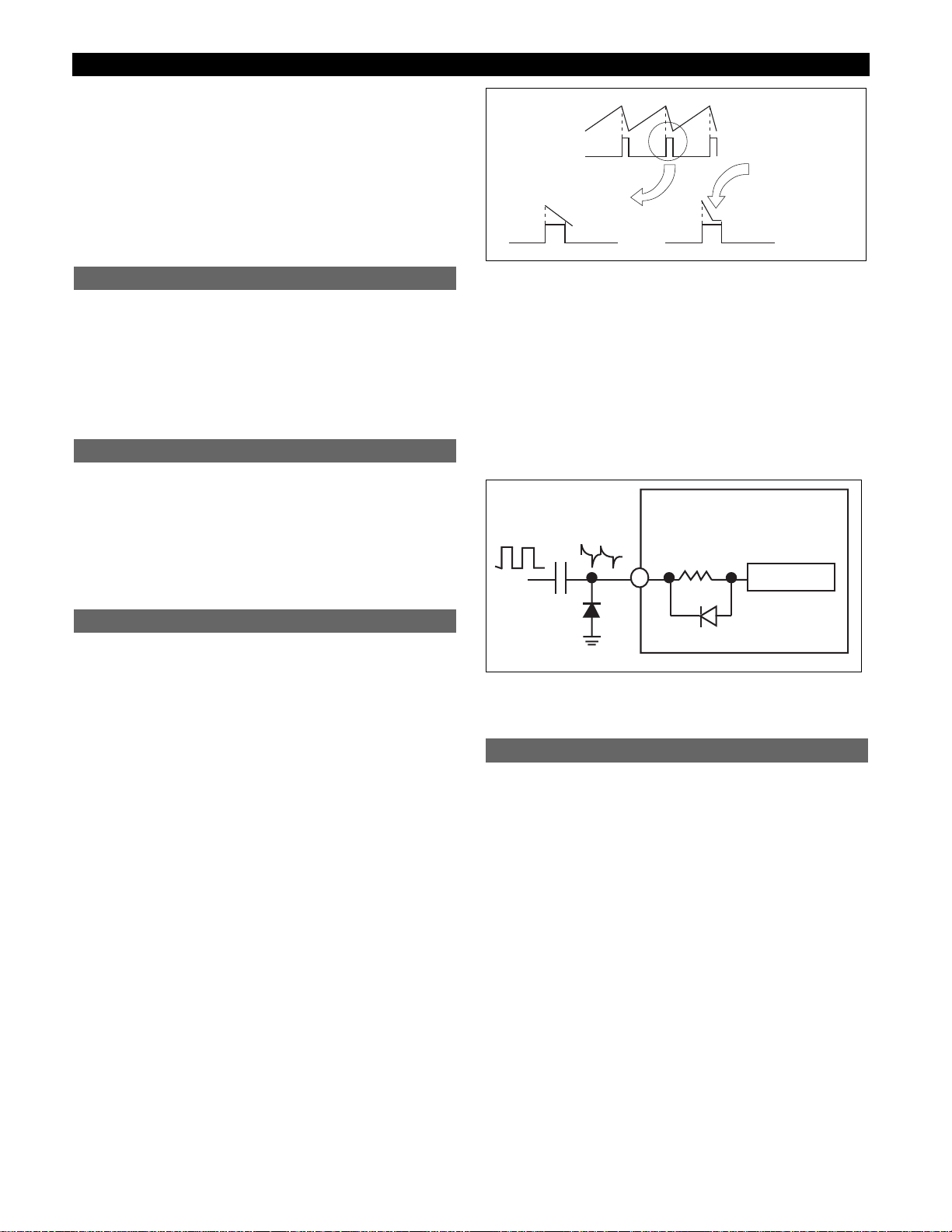

Block Diagram

V

FB1

V

REF

V

IN

SYNC

R

C

V

FB2

COMP1

V

FFB1

+

PWM

Comparator

-

Reference

Undervoltage

Lockout

Channel 2

Gate Driver

GATE1

LGND

1.275V

Undervoltage

Lockout

V

-

Error

Amplifier

+

IN

Bandgap

Voltage

Reference

PGND

T

T

1.275V

+

Error

Amplifier

-

Oscillator

-

PWM

Comparator

Channel 2

Gate Driver

GATE2

+

COMP2

+

PWM

Comparator

GATE

-

V

FFB

V

Reference

Voltage

FB

COMP

Ramp Signal

Error

Amplifier

+

Error Signal

-

V

FFB2

ENABLE

Page 6

CS5127

6

Theory of Operation: continued

mode controller relies on a change in the error signal to

indicate a change in the line and/or load conditions. The

error signal change causes the error loop to respond with a

correction that is dependent on the gain of the error amplifier. A current mode controller has a constant error signal

during line transients, since the slope of the ramp signal

will change in this case. However, regulation of load transients still requires a change in the error signal. V

2

ª

control maintains a fixed error signal for both line and

load variation, since the ramp signal is affected by both.

The CS5127 can be operated in voltage mode if necessary.

For example, if very small values of output ripple voltage

are required, V

2

ª

control may not operate correctly.

Details on how to choose the components for voltage

mode operation are provided in the section on V

FFB

com-

ponent selection.

As output line and load conditions change, the V

2

ª

control loop modifies the switch duty cycle to regulate the

output voltage. The CS5127 uses a fixed frequency architecture. Both output channels are controlled from a

common oscillator. The CS5127 can typically provide a

maximum duty cycle of about 90%.

It is sometimes desirable to shift the switching noise spectrum to different frequencies. A pulse train applied to the

SYNC lead will terminate charging of the C

T

lead capacitor

and pull the CTlead voltage to ground for the duration of

the positive pulse level. This reduces the period of oscillation and increases the switching frequency.

Synchronization must always be done at a frequency

higher than the typical oscillator frequency. Using a lower

frequency will lead to erratic operation and poor regulation. The SYNC pulse train frequency should be at least 10

% higher than the unsynchronized oscillator frequency.

Synchronizing the oscillator will also decrease the maximum duty cycle. If the nominal oscillator frequency is

200kHz, increasing the oscillator frequency by 10% (to

220kHz) will decrease the maximum duty cycle from a

typical of 90% to about 89%. Increasing the frequency by

25% (to 250kHz) will change the maximum duty cycle to

about 87%. A 50% increase (to 300kHz) gives a maximum

duty cycle of about 85%. The width of the SYNC pulse

should be slightly shorter than the duration of the falling

edge of the CTlead waveform (see Figure 2a) so the SYNC

pulse doesnÕt interfere with the oscillator function.

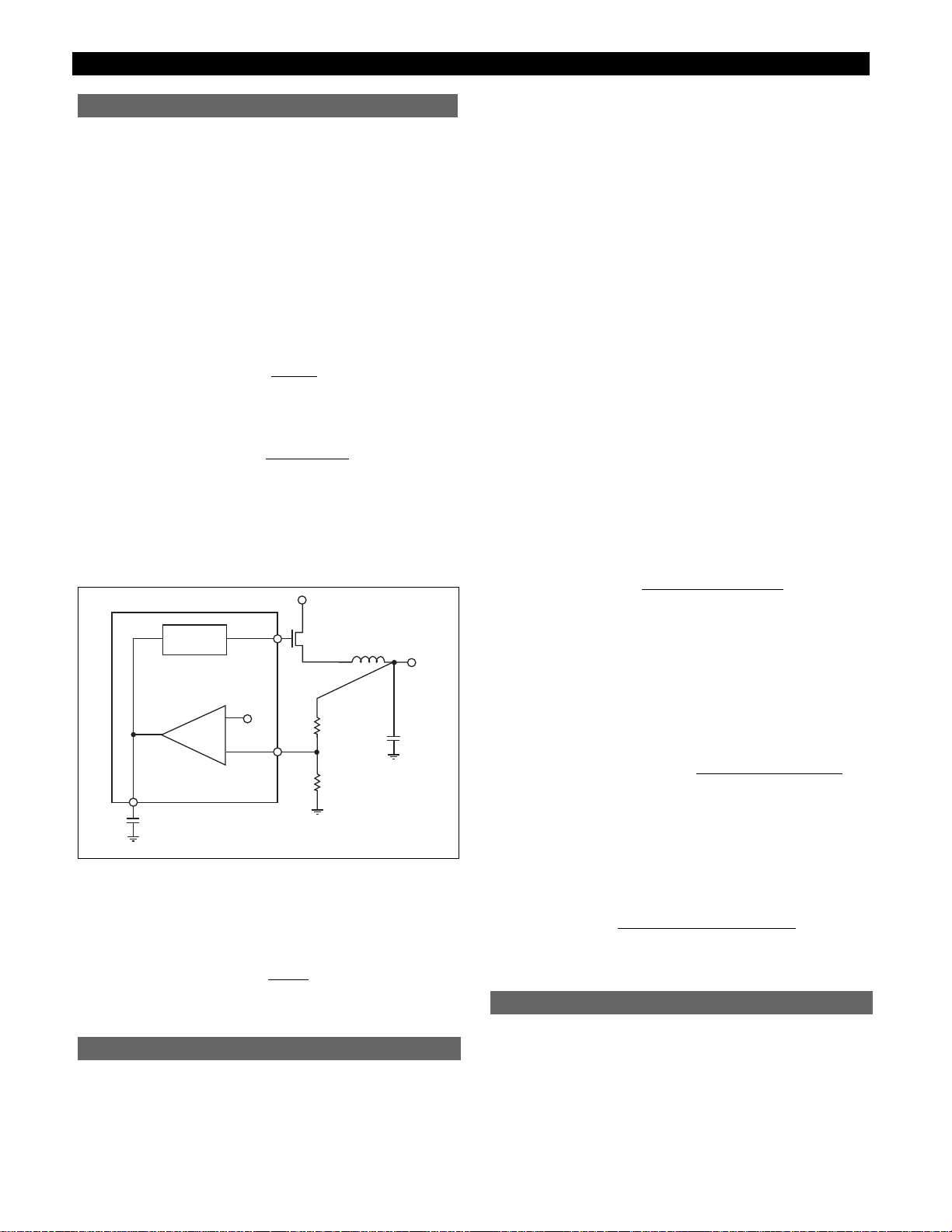

Figure 2a: Sync pulse duration vs. CTlead discharge time.

The best way to determine if the pulse width is sufficiently

short is to examine the CTlead waveform with an oscilloscope. If Òdead spotsÓ are observed in the CTlead waveform,

decreasing the SYNC pulse width should be considered.

Alternatively, the SYNC signal may be AC coupled through

a small capacitor. In this case, care must be taken to ensure

that current pulled out of the IC during the high-to-low transition of the SYNC signal is limited to less than 5mA.

Figure 2b: Capacitive coupling of the SYNC signal. The external diode

is used to clamp the IC substrate diode if I

SYNC

is greater than 5mA

during the negative portion of the input waveform.

The CS5127 has no on-board current limit circuitry. An

example current limit circuit is provided in the Additional

Application Circuits section of this data sheet.

Overcurrent Protection

Sync Function

Constant Frequency

Voltage Mode Control

CT Lead Waveform

Sync Lead Waveform

If the sync pulse is longer

than the C

lead discharge

T

time, a short Òdead spotÓ

will exist during which the

output driver is off.

SYNC

Oscillator

20k

2200p

Page 7

The feedback (V

FB)

leads are connected to external resistor

dividers to set the output voltage. The on-chip error amplifier is referenced to 1.275V, and the resistor divider values

are determined by selecting the desired output voltage

and the value of the divider resistor connected between

the VFBlead and ground.

Resistor R1 is chosen first based on a design trade-off of

system efficiency vs. output voltage accuracy. Low values

of divider resistance consume more current which decreases system efficiency. However, the VFBlead has a 1µA

maximum bias current which can introduce errors in the

output voltage if large resistance values are used. The

approximate value of current sinking through the resistor

divider is given by

I

V(FB)

=

The output voltage error that can be expected due to the

bias current is given by

Error Percentage = ´ 100%

where R1 is given in ohms. For example, setting R1 = 5K

yields an output voltage error of 0.39% while setting the

feedback divider current at 255µA. Larger currents will

result in reduced error.

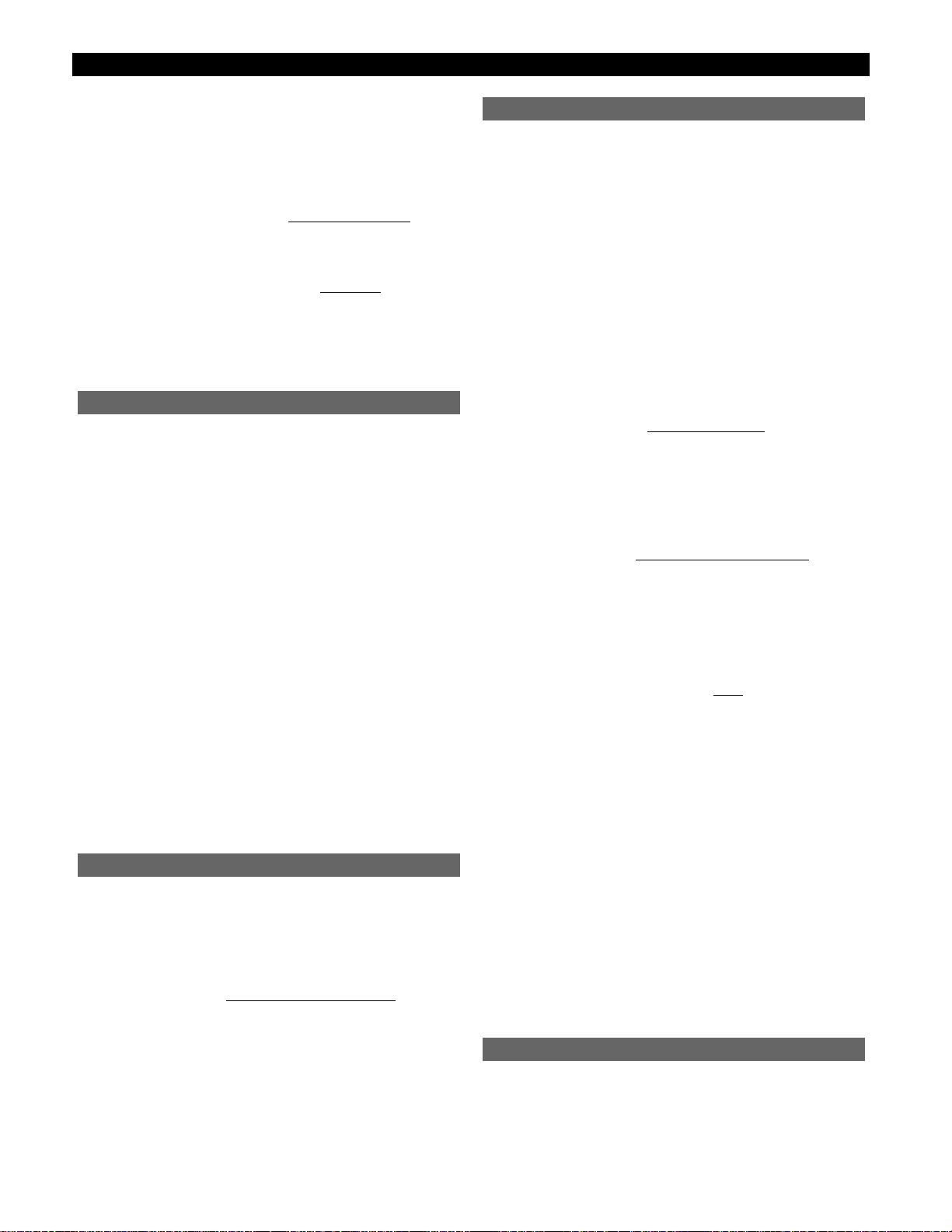

Figure 3: Feedback resistor divider.

R2 can be sized according to the following formula once

the desired output voltage and the value of R1 have been

determined:

R2 = R1 -1

There are many factors to consider when choosing the

inductor. Maximum load current, core losses, winding

losses, output voltage ripple, short circuit current, saturation, component height, EMI/EMC and cost are all

variables the designer must consider. Inductance values

between 1µH and 50µH are suitable for use with the CS5127.

Low values within this range minimize the component size

and improve transient response, but larger values reduce

ripple current. Choosing the inductor value requires the

designer to make some choices early in the design. Output

current, output voltage and the input voltage range should

be known in order to make a good choice.

The input voltage range is bracketed by the maximum and

minimum expected values of V

IN

. Most computer applications use a fairly well-regulated supply with a typical

output voltage tolerance on the order of ±5%. The values

of V

IN(MAX)

and V

IN(MIN)

are used to calculate peak current

and minimum inductance value, respectively. However, if

the supply is well-regulated, these calculations may both

be made using the typical input voltage value with very

little error.

Current in the inductor while operating in the continuous

current mode (CCM) is defined as the load current plus

the inductor ripple current:

IL= I

OUT

+ I

RIPPLE

The ripple current waveform is triangular, and the current

is a function of the voltage across the inductor, the switch

on-time and the inductor value. Switch on-time is the duty

cycle divided by the operating frequency, and duty cycle

can be defined as the ratio of V

OUT

to VIN, such that

I

RIPPLE

=

The peak current can be described as the load current plus

half of the ripple current. Peak current must be less than

the maximum rated switch current. This limits the maximum load current that can be provided. It is also

important that the inductor can deliver the peak current

without saturating.

I

OUT(MAX)

= I

SWITCH(MAX)

-

Since the peak inductor current must be less than or equal

to the peak switch current, the minimum value of inductance can be calculated:

L

MIN

=

The theoretical limit on load current transient response is a

function of the inductor value, the load transient and the

voltage across the inductor. In conventionally-controlled

regulators, the actual limit is the time required by the control loop. Conventional current-mode and voltage-mode

control loops adjust the switch duty cycle over many oscillator periods, often requiring tens or even hundreds of

Load Current Transient Response

(V

IN(MIN)

- V

OUT)VOUT

f ´ V

IN(MIN)

´ I

SWITCH(MAX)

(V

IN(MAX)

- V

OUT)VOUT

2f ´ L ´ V

IN(MAX)

(VIN- V

OUT)VOUT

f ´ L ´ V

IN

Selecting the Inductor

)

V

OUT

1.275

(

(1E - 6) ´ R1

1.275

1.275V

R1

Selection of Feedback Lead Divider Resistor Values

CS5127

7

Applications Information

Output

Driver

V

1.275V

+

-

COMP

V

FB

GATE

R2

R1

OUT

Page 8

CS5127

8

Applications Information: continued

microseconds to return to a steady-state. V

2

ª

control uses

the ripple voltage from the output capacitor and a ÒfastÓ

control loop to respond to load transients, with the result

that the transient response of the CS5127 is very close to

the theoretical limit. Response times are defined below.

t

RESPONSE(INCREASING)

=

t

RESPONSE(DECREASING)

=

Note that the response time to a load decrease is limited

only by the inductor value.

Inductor current rating is an important consideration. If

the regulated output is subject to short circuit or overcurrent conditions, the inductor must be sized to handle the

fault without damage. Sizing the inductor to handle fault

conditions within the maximum DC current rating helps to

ensure the coil doesnÕt overheat. Not only does this prevent damage to the inductor, but it reduces unwanted heat

generated by the system and makes thermal management

easier.

Selecting an open core inductor will minimize cost, but

EMI/EMC performance may be degraded. This is a tough

choice, since there are no guidelines to ensure these components will not prove troublesome.

Core materials influence the saturation current and saturation characteristics of the inductor. For example, a slightly

undersized inductor with a powdered iron core may provide satisfactory operation because powdered iron cores

have a ÒsoftÓ saturation curve compared to other core

materials.

Small physical size, low core losses and high temperature

operation will also increase cost. Finally, consider whether

an alternate supplier is an important consideration. All of

these factors can increase the cost of the inductor.

For light load designs, the CS5127 will operate in discontinuous current mode (DCM). In this regime, external

components can be smaller, since high power dissipation is

not an issue. In discontinuous mode, maximum output

current is defined as:

I

OUT(MAX)

=

where IPKis the maximum current allowed in the switch

FET.

Output capacitors are chosen primarily on the value of

equivalent series resistance, because this is what determines how much output ripple voltage will be present.

Most polarized capacitors appear resistive at the typical

oscillator frequencies of the CS5127. As a rule of thumb,

physically larger capacitors have lower ESR. The capacitorÕs value in µF is not of great importance, and values

from a few tens of µF to several hundreds of µF will work

well. Tantalum capacitors serve very well as output capacitors, despite their bad reputation for spectacular failure

due to excessive inrush current. This is not usually an issue

for output capacitors, because the failure is not associated

with discharge surges. Ripple current in the output capacitor is usually small enough that the ripple current rating is

not an issue. The ripple current waveform is triangular,

and the formula to calculate the ripple current value is:

I

RIPPLE

=

and output ripple voltage due to inductor ripple current is

given by:

V

RIPPLE(ESR)

=

A load step will produce an instantaneous change in

output voltage defined by the magnitude of the load step,

capacitor ESR and ESL.

DVO= (DIO´ ESD) + ESL

A good practice is to first choose the output capacitor to

accommodate voltage transient requirements and then to

choose the inductor value to provide an adequate ripple

voltage.

Increasing a capacitorÕs value typically reduces its ESR, but

there is a limit to how much improvement can be had. In

most applications, placing several smaller capacitors in

parallel will result in acceptable ESR while maintaining a

small PC board footprint. A warning is necessary at this

point. The V

2

ª

topology relies on the presence of some

amount of output ripple voltage being present to provide

the input signal for the ÒfastÓ control loop, and it is important that some ripple voltage be present at the lightest load

condition in normal operation to avoid subharmonic oscillation. Externally generated slope compensation can be

added to ensure proper operation.

The V

FFB

lead is tied to the PWM comparatorÕs non-inverting input, and provides the connection for the

externally-generated artificial ramp signal that is required

whenever duty cycle is greater than 50%.

Selecting the V

FFB

Lead Components

D

I

DT

(V

IN

- V

OUT

) ´ V

OUT

´ ESR

f ´ L ´ V

IN

(VIN- V

OUT)VOUT

f ´ L ´ V

IN

Selecting the Output Capacitor

(I

PK

)2f ´ L(VIN)

2V

OUT

´ (V

IN(MAX)

- V

OUT

)

Operating in Discontinuous Current Mode

Other Inductor Selection Concerns

L(ÆI

OUT

)

V

OUT

L(ÆI

OUT

)

(V

IN

- V

OUT

) ´ 0.85

Page 9

CS5127

Applications Information: continued

9

The DC voltage for the V

FFB

pin is usually provided from

the output voltage through an RC filter if V

OUT

is less than

3V. If V

OUT

is greater than 2.9V, a resistor divider from

V

OUT

is recommended for proper circuit bias due to the

common mode input range limitations of the PWM comparator. In most cases, the FB pin resistor divider can be

used for this purpose with very little error, but a separate

divider is recommended if high accuracy is required. The

filter network is typically composed of a 1K resistor (R

FFB

)

and a 330 pF capacitor (C

FFB

). This filter gives a 330 ns

time constant which is sufficient to remove switching

noise from the DC voltage. Note that in cases where a

resistor divider provides the ramp signal, the resistor

between V

OUT

and the V

FFB

pin serves as R

FFB

. An artificial

ramp signal is generated using an NPN transistor (Q1), a

small coupling capacitor (CC) and a second resistor (RR).

The NPN transistor collector is connected either to the

external 5V supply or to the ICÕs 5V on-chip reference. The

transistorÕs base is connected to the CT pin, and the ramp

on the CT pin is used to provide the artificial ramp. The

transistorÕs emitter is connected to the coupling capacitor.

The capacitor value should provide a low impedance at

the switching frequency. A 0.1 µF capacitor represents 6.4

ohms at 250 kHz. A resistor is placed in series between this

capacitor and the V

FFB

pin to set the amplitude of the ramp

signal.

Figure 4: Artificial ramp components CC, C

FFB

, RR and R

FFB

must be

provided for each channel if duty cycle for that channel exceeds 50%. Q1

and RE are common to both channels. DC voltage is shown supplied to

V

FFB

through the VFBresistor divider.

The amount of artificial ramp is dependent on oscillator

frequency, output voltage, output capacitor equivalent

series resistance (ESR), and inductor value. It also assumes

very small voltage fluctuations on the COMP pin. If the

added ramp is too small, it will not be sufficient to prevent

subharmonic oscillation. If the ramp is too large, V

2

ª

control will be defeated, and loop regulation will enter voltage

mode control. DC regulation will be adequate, but transient response will be degraded. However, this may be

desirable in cases where very low values of output ripple

voltage are desired.

The artificial ramp amplitude can be calculated as follows:

V

RAMP

=

if DC voltage is provided from the output, or

V

RAMP

=

if DC voltage is provided from a resistor divider as in

figure 5.

where R

ESR

is the equivalent series resistance in ohms of

the total output capacitance, V

OUT

is the output voltage in

volts and L

OUT

is the inductor value in Henries. The result

is V

RAMP

given in millivolts per oscillator period. This

value is the optimum amplitude for the artificial ramp.

Note that COMP pin voltage changes and output ripple

voltage must be added to the ramp amplitude for proper

operation.

Once the total ramp signal has been determined, the value

of the ramp resistor (RR) can be determined. The ramp

resistor and filter resistor R

FFB

create a resistor divider

between the output voltage and the artificial ramp voltage.

We can assume the output does not change, and that the

maximum input voltage to the divider is equal to the DC

output voltage plus the CT pin voltage swing of 2.1V. The

ramp amplitude on the filter capacitor is then the divider

output voltage:

V

RAMP

=

Rearranging, we have

RR = R

FFB

(

- 1

)

The schottky ÒcatchÓ diode must be capable of handling

the peak inductor current and must withstand a reverse

voltage at least equal to the value of VIN. Since the catch

diode only conducts during switch off-time, the average

current through the catch diode is defined as:

I

CATCH

= I

OUT

Minimizing the diode on-voltage will improve efficiency.

The on-chip oscillator frequency is set by two external

components. R

T

sets the oscillator charge current. It is connected to a voltage reference approximately equal to 2.5V.

The current generated in this fashion charges the CTcapacitor between threshold levels of 1.5V and 3.6V. C

T

capacitor discharge is done by a saturating NPN, and the

Selecting Oscillator Components RTand C

T

)

VIN- V

OUT

V

IN

(

Selecting the Catch Diode

2.1V

V

RAMP

(2.1V) (R

FFB

)

(RR + R

FFB

)

(R

ESR

) (V

OUT

)(R1)

2000 (L

OUT

) (R1 + R2)

(R

ESR

) (V

OUT

)

2000 (L

OUT

)

GATE

R2

V

5V

C

T

FB

V

FFB

V

OUT

+

Q1

RR

CT

CC

RE

C

FFB

R

FFB

R1

Page 10

discharge time is typically less than 10% of the charge

time. External components CT and RTallow the switching

frequency to be set by the user in the range between 10kHz

and 500kHz. CTcan be chosen first based on size and cost

constraints. For proper operation over temperature, the

value of RTshould be chosen within the range from 20k½

to 40k½. Any type of one-eighth watt resistor will be adequate. Larger values of RTwill decrease the maximum

duty cycle slightly. This occurs because the sink current on

the CTlead has an exponential relationship to the charge

current. Higher charge currents will discharge the CTlead

capacitor more quickly than lower currents, and a shorter

discharge time will result in a higher maximum duty

cycle.

Once the oscillator frequency and a value of CThave been

selected, the necessary value of RTcan be calculated as follows:

RT =

where f

OSC

is the oscillator frequency in hertz, CTis given

in farads, and the value of RTis given in ohms. ESR effects

are negligible since the charge and discharge currents are

fairly small, and any type of capacitor is adequate for CT.

As previously noted, the error amplifier does not contribute greatly to transient response, but it does influence

noise immunity. The fast feedback loop input is compared

against the COMP pin voltage. The DC bias to the V

FFB

pin

may be provided directly from the output voltage, or

through a resistor divider if output voltage is greater than

2.9V. The desired percentage value of DC accuracy translates directly to the V

FFB

pin, and the minimum COMP pin

capacitor value can be calculated:

C

COMP

=

If f

OSC

= 200kHz, V

FFB

DC bias voltage is 2.8V and toler-

ance is 0.1%, C

COMP

= 28.6µF. This is the minimum value

of COMP pin capacitance that should be used. It is a good

practice to guard band the tolerance used in the calculation. Larger values of capacitance will improve noise

immunity, and a 100µF capacitor will work well in most

applications.

The type of capacitor is not critical, since the amplifier

output sink current of 16mA into a fairly large value or

wide range of ESR will typically result in a very small DC

output voltage error. The COMP pin capacitor also determines the length of the soft start interval.

The input bypass capacitors minimize the ripple current in

the input supply, help to minimize EMI, and provide a

charge reservoir to improve transient response. The capacitor ripple current rating places the biggest constraint on

component selection. The input bypass capacitor network

should conduct all the ripple current. RMS ripple current

can be as large as half the load current, and can be calculated as:

I

RIPPLE(RMS)=IOUT

Peak current requirement, load transients, ambient operating temperature and product reliability requirements all

play a role in choosing this component. Capacitor ESR and

the maximum load current step will determine the maximum transient variation of the supply voltage during

normal operation. The drop in the supply voltage due to

load transient response is given as:

ÆV = I

RIPPLE(RMS)

´ ESR

The type of capacitor is also an important consideration.

Aluminum electrolytic capacitors are inexpensive, but they

typically have low ripple current ratings. Choosing larger

values of capacitance will increase the ripple current

rating, but physical size will increase as well. Size constraints may eliminate aluminum electrolytics fro

consideration. Aluminum electrolytics typically have

shorter operating life because the electrolyte evaporates

during operation. Tantalum electrolytic capacitors have

been associated with failure from inrush current, and manufacturers of these components recommended derating the

capacitor voltage by a ratio 2:1 in surge applications. Some

manufacturers have product lines specifically tested to

withstand high inrush current. AVX TPS capacitors are

one such product. Ceramic capacitors perform well, but

they are also large and fairly expensive.

At startup, output switching does not occur until two

undervoltage lockouts release. The first lockout monitors

the V

IN

lead voltage. No internal IC activity occurs until

VINlead voltage exceeds the VINturn-on threshold. This

threshold is typically 8.4V. Once this condition is met, the

on-chip reference turns on. As the reference voltage begins

to rise, a second undervoltage lockout disables switching

until V

REF

lead voltage is about 3.5V. The GATE leads are

held in a low state until both lockouts are released.

As switching begins, the VFBlead voltage is lower than the

output voltage. This causes the error amplifier to source

current to the COMP lead capacitor. The COMP lead voltage will begin to rise. As the COMP lead voltage begins to

rise, it sets the threshold level at which the rising V

FFB

lead

voltage will trip the PWM comparator and terminate

switch conduction. This process results in a soft start interval. The DC bias voltage on V

FFB

will determine the final

COMP voltage after startup, and the soft start time can be

approximately calculated as:

T

SOFT START

=

V

FFB

´ C

COMP

I

COMP(SOURCE)

Startup

V

OUT(VIN

- V

OUT

)

V

IN

2

Selecting the Input Bypass Capacitor

(16mA)(T

OSC

)

(V

FFB

DC Bias Voltage)(tolerance)

Selecting the Compensation Capacitor

1.88

(f

OSC

)(CT)

CS5127

10

Applications Information: continued

Page 11

Applications Information: continued

where T

SOFT START

is given in seconds if C

COMP

is given in

farads, I

COMP(SOURCE)

in amperes, and V

FFB

in volts. Note

that a design trade off will be made in choosing the value

of the COMP lead capacitor. Larger values of capacitance

will result in better regulation and improved noise immunity, but the soft start interval will be longer and capacitor

price may increase.

Figure 5: Measured performance of the CS5127 at start up.

C

COMP

=100µF, I

COMP(SOURCE)

=1.3mA, V

FFB

= 2.8V, T

SOFTSTART

= 0.22s.

During normal operation, the gate driver switching duty

cycle will remain approximately constant as the V

2

ª

control loop maintains the regulated output voltage under

steady state conditions. Changes in supply line or output

load conditions will result in changes in duty cycle to

maintain regulation.

Voltage Mode Operation

There are two methods by which a user can operate the

CS5127 in voltage mode. The first method is simple, but

the transient response is typically very poor. This method

uses the same components as V

2

ª

operation, but by

increasing the amplitude of the artificial ramp signal, V

2

ª

control is defeated and the controller operates in voltage

mode. Calculate RR using the formula above and divide

the value obtained by 10. This should provide an adequately large artificial ramp signal and cause operation

under voltage mode control. There may be some dependence on board layout, and further optimization of the

value for RR may be done empirically if required.

Voltage mode control may be refined by removing the

COMP pin capacitor and adding a two pole, one zero compensation network. Consider the system block diagram

shown in figure 6.

Figure 6: Voltage mode control equivalent circuit with two pole, one

zero compensation network.

VINis the switch supply voltage, R represents the load, RL

is the combined resistance of the FET RDS (on) and the

inductor DC resistance, L is the inductor value, C is the

output capacitance, RC is the output capacitor ESR, RA

and RB are the feedback resistors and VR is the peak to

peak amplitude of the artificial ramp signal at the V

FFB

pin. C1, C2, R1 and R2 are the components of the compensation network. Based on the application circuit from page

1, values for the 2.8V output equivalent circuit are:

VIN= 5V

R = 0.4½

RL = 0.02½

C = 1320µF

RC = 0.025½

RA = 1540½

RB = 1270½

L = 5µH

A resistor change is necessary to increase the artificial

ramp magnitude to V

FFB1

. Changing R10 from 20k to 2k

will give a peak to peak amplitude of about 2V. Thus, VR=

2V.

The transfer function from V

CONTROL

to V

OUT

is

=

´

Using the component values provided, this reduces to

1

V

R

R ´ V

IN

´ (sCRC+ 1)

s2LC (R + RC) + s[L + RLC(R + RC) + RCRC] + R + R

C

V

OUT

V

CONTROL

Voltage Mode Control

Normal Operation

11

CS5127

V

V

IN

CONTROL

LOGIC

PWM

V

CONTROL

L

V

FFB

COMP

R

L

C

R

C

V

R

C2

V

FB

EA

1.275V

OUT

R

A

R

R

B

R1

R2

C1

Page 12

CS5127

12

Applications Information: continued

The zero frequency due to the output capacitor ESR is

given as

= 4.8 kHz.

The double pole frequency of the power output stage is

= = 1.95 kHz.

The ESR zero approximately cancels one of the poles, and

the total phase shift is limited to 90. Bode plots are provided below.

Figure 7: Bode plot of gain response for V

OUT/VCONTROL

.

Figure 8: Bode plot of phase response for V

OUT/VCONTROL

.

This uncompensated system is stable, but the low gain will

result in poor DC accuracy, and the low cutoff frequency

will result in poor transient response. Note that we have

not yet included the gain factor from the feedback resistor

divider. This factor will further reduce the overall system

gain.

By adding the two pole, one zero compensation network

shown in figure 6, we can maximize the DC gain and push

out the crossover frequency. The transfer function for the

compensation network is

=

This can be rewritten in terms of pole and zero frequencies

and a gain constant A.

=

where

f

Z

=

fP= and A = R1 C2

Note that, due to the first s term in the denominator, a pole

is located at f = 0. This will provide the maximum DC

gain.

The optimum performance can be obtained by choosing f

Z

equal to the output double pole frequency and setting fPto

approximately half of the switching frequency. Gain factors can be chosen somewhat arbitrarily.

Values between

1E-6½F and 20E-6½F are practical. We then have a set of

equations that can be solved for component values:

C1 R1

=

[

-

]

, C1 R2 = , C2 =

Since there are only three equations, we must arbitrarily

choose one of the components. One option is to set the

value of R1 fairly large. This provides a high impedance

path between the VFBpin and the COMP pin.

For our design, we have fZ= the double pole frequency =

1.95 kHz and fP= f

OSC

/2 = 100kHz. LetÕs arbitrarily choose

R1 = 4.7K. Then we solve the first equation for C1 and

obtain C1 = 17nF. Use a standard value of 22 nF.

We next solve for R2. With C1 =22 nF, R2= 72½. Use a

standard value of 75½.

We can choose a gain factor from somewhere in the

middle of our range and solve for C2. If A = 10E-6½F, we

have

C2 = 2.1 nF. Use a standard value of 2.2 nF.

A

R1

1

2¹f

P

1

f

P

1

f

Z

1

2¹

1

2¹ C1R2

1

(2¹ C1 (R1 + R2))

s/(2¹fZ+ 1)

-A s ((s/2fP) + 1)

V

CONTROL

V

FB

s C1(R1 + R2) + 1

-s C2 R1(s C1 R2 + 1)

V

CONTROL

V

FB

R + R

1

LC(R + RC)

1

(2¹)

1

(2¹CRC)

1 + s(3.3E-5)

s2(2.772E-9) + s(2.902E-5) + 0.42

20

0

-20

Gain, (dB)

-40

-60.0

1

90

0

10

10210

Frequency (Hz)

3

4

10

5

10

6

10

10

7

-90

Phase, (degree)

-180

-270.0

1

10210

10

3

Frequency (Hz)

10

5

4

10

7

6

10

10

Page 13

Applications Information: continued

13

Now that we have the compensation components chosen,

we can put together a transfer function for the entire control loop. The transfer function is the product of the VOUT

to V

CONTROL

transfer function, the gain of the feedback

resistor divider and the negative inverse of the compensation loop transfer function. That is,

T

LOOP

= - (T

VC-VO

´ T

DIVIDER

´ T

COMPENSATION

)

or

T

LOOP

=

[]

´

[]

´

[]

´

[]

Bode plots for this transfer function are shown below.

Figure 9: Bode plot of gain response for compensated voltage mode

system.

Figure 10: Bode plot of phase response for compensated voltage mode

system.

Entering the loop transfer function in a mathematics program or a spreadsheet and evaluating the performance

from resulting Bode plots may help to further optimize the

compensation network component values.

Compensation may be further optimized by using a two

poleÐtwo zero compensation network as shown below.

Figure 11: Two poleÐtwo zero compensation network.

The two zeros are placed close to the resonant frequency of

the LC output circuit. That is,

ÅÅ

The two poles are placed near half the switching frequency, or

ÅÅ

The ENABLE lead controls operation of channel 2. Channel

2 operates normally if the ENABLE lead voltage is greater

than 3.5V. Setting the ENABLE lead voltage below 1.5V

will guarantee that channel 2 is disabled. In this case, the

GATE2 lead will be held low and no switching will occur.

This feature can be used to selectively power up or power

down circuitry that may not always need to be on. For

example, in a laptop computer, channel 1 could power the

microprocessor while channel 2 controlled the disk drive.

Channel 2 could be turned off if the drive was not in use.

Semiconductor components will deteriorate in high temperature environments. It is necessary to limit the junction

temperature of control ICs, power MOSFETs and diodes in

order to maintain high levels of reliability. Most semiconductor devices have a maximum junction temperature of

125¡C, and manufacturers recommend operating their

products at lower temperatures if at all possible.

Power dissipation in a semiconductor device results in the

generation of heat in the pin junctions at the surface of the

Thermal Management for Semiconductor Components

Channel 2 ENABLE Feature

1

2¹ R3 C2

1

2¹ C1 R1

f

SW

2

1

2¹ R3 C3

1

2¹ C1 R2

1

2¹ LC

sC1 (R1 + R2)+ 1

sC2 R1 (sC1 R2 + 1)

RB

RA + RB

1

V

R

R ´ V

IN

´ (sCRC+ 1)

s2LC (R + RC) + s[L + RLC(R + RC) + RCRC] + R + R

C

CS5127

C1

From V

OUT

R1

R2

V

FB

R3

C2

C3

COMP

100

60

20

Gain, (dB)

-20

-60.0

-100.0

1

10

90

0

-90

Phase, (degree)

-180

-270.0

1

10

10210

Frequency (Hz)

10210

Frequency (Hz)

3

3

5

4

10

10

5

4

10

10

7

6

10

10

6

10

10

7

Page 14

14

Applications Information: continued

IC. This heat is transferred to the surface of the IC package,

but a thermal gradient exists due to the thermal properties

of the package molding compound. The magnitude of this

thermal gradient is denoted in manufacturerÕs data sheets

as QJA, or junction-to-air thermal resistance. The on-chip

junction temperature can be calculated if Q

JA

, the air temperature at the ICÕs surface and the on-chip power

dissipation are known:

TJ = TA+ (QJA´ P)

TJand TA are given in degrees centigrade, P is IC power

dissipation in watts and QJAis thermal resistance in

degrees centigrade per watt. Junction temperature should

be calculated for all semiconductor devices to ensure they

are operated below the manufacturerÕs maximum junction

temperature specification. If any componentÕs temperature

exceeds the manufacturerÕs maximum specification, some

form of heatsink will be required.

Heatsinking will improve the thermal performance of any

IC. Adding a heatsink will reduce the magnitude of QJAby

providing a larger surface area for heat transfer to the surrounding air. Typical heat sinking techniques include the

use of commercial heatsinks for devices in TO-220 packages, or printed circuit board techniques such as thermal

bias and large copper foil areas for surface mount packages.

When choosing a heatsink, it is important to break Q

JA

into several different components.

QJA= QJC+ QCS+ Q

SA

where all components of Q

JA

are given in ¡C/W.

QJCis the thermal impedance from the junction to the sur-

face of the package case. This parameter is also included in

manufacturerÕs data sheets. Its value is dependent on the

mold compound and lead frames used in assembly of the

semiconductor device in question.

QCSis the thermal impedance from the surface of the case

to the heatsink. This component of the thermal impedance

can be modified by using thermal pads or thermal grease

between the case and the heat sink. These materials replace

the air gap normally found between heatsink and case with

a higher thermal conductivity path. Values of QCSare

found in catalogs published by manufacturers of heatsinks

and thermal compounds.

Finally, QSAis the thermal impedance from the heatsink to

ambient temperature. QSAis the important parameter

when choosing a heatsink. Smaller values of QSAallow

higher power dissipation without exceeding the maximum

junction temperature of the semiconductor device. Values

of QSAare typically provided in catalogs published by

heatsink manufacturers.

The basic equation for selecting a heatsink is

P

D

=

where PDis on-chip power dissipation in watts, TJis junction temperature in ¡C, TAis ambient temperature in¡C,

and thermal impedance QJC, QCS, and QSAare in¡C/W.

All these quantities can be calculated or obtained from data

sheets. The choice of a heatsink is based on the value of

QSArequired such that the calculated power dissipation

does not cause junction temperature to exceed the manufacturerÕs maximum specification.

Switching regulators generate noise a consequence of the

large values of current being switched on and off in normal

operation. Careful attention to layout of the printed circuit

board will usually minimize noise problems. Layout guidelines are provided in the next section. However, it may be

necessary in some cases to add filter inductors or bypass

capacitors to the circuitry to achieve the desired performance.

The following guidelines should be observed in the layout

of PC boards for the CS5127:

1. Connect the PGND lead to the external ground with a

wide metal trace.

2. Connect both LGND and PGND together with a wide

trace as close to the IC as possible.

3. Make all ground connections to a common ground

plane with as few interruptions as possible. Breaks in

the ground plane metal should be made parallel to an

imaginary line between the supply connections and the

load.

4. Connect the ground side of the COMP lead capacitors

back to LGND with separate traces.

5. Place the V

FFB

lead capacitors as close to the V

FFB

leads

as possible.

6. Place the 5V line bypass capacitors as close to the

switch FETs as possible.

7. Place the output capacitor network as close to the load

as possible.

8. Route the GATE lead signals to the FET gates with a

metal trace at least 0.025 inches wide.

9. Use wide straight metal traces to connect between the

5V line and FETs, between FETs and inductors and

between inductors and loads to minimize resistance in

the high current paths. Avoid sharp turns, loops and

long lengths.

Layout Considerations

EMI Management

T

J

- T

A

QJC+ QCS+ Q

SA

CS5127

Page 15

15

5V

Figure 12: Example external over voltage protection circuit. If V

OUT

exceeds V

OVP

, OVP out goes high. Resistor values shown above pro-

vide a +10% tolerance for a 3.3V output.

Figure 13: Example external Power GOOD circuit. P

GOOD(OUT)

is low

until V

OUT

exceeds V

PGOOD

. V

PGOOD

is typically chosen to be 10%

below nominal V

OUT

. Resistor values above provide a -10% tolerance

on V

OUT

=3.3V.

Figure 14: An external circuit can be built to provide an enable function for channel 1. The circuit shown above connects to the V

FB1

and

COMP1 pins as indicated. If the ENABLE1 signal is left floating or is

pulled high, channel 1 is enabled. If the ENABLE1 pin is pulled

below 1V, Q1 will conduct, and mirror Q3 pulls V

FFB1

up at the same

time as Q2 and Q4 pull COMP1 low. This will force GATE1 to go low

and turn off the switch FET. The circuit above will provide about

1mA of additional drive to the V

FFB1

pin components. This additional

current must be sufficient to pull V

FFB1

up to about 1V in order to

guarantee GATE1 is held low.

Additional Application Circuits

V

OVP

=

(R1 + R2)(0.65V)

R2

V

PGOOD

=

(R1 + R2)(0.65V)

R2

CS5127

5V

R3

V

OUT

R1

24K

R2

5K

10K

R4

10K

Q1

FMMT2222ACT

Q2

FMMT2907ACT

OVP OUT

5V

V

OUT

R1

6.3K

R2

1k

ENABLE 1

SIGNAL

Q1

FMMT2907ACT

Q2

FMMT2907ACT

R3

1K

Q3

FMMT2907ACT

TO COMP1

Q4

FMMT2222ACT

TO V

FFB1

PGOOD OUT

18K

R2

5K

R1

R3

10K

Q1

FMMT2222ACT

Q2

FMMT2222ACT

Page 16

Figure 15: CS5127 12V, 5V input to 2.8V @ 7A and 3.3V @ 7A Voltage Mode Control Application Circuit with External Soft Start.

Figure 16: CS5127 12V only to 2.8V @ 7A and 3.3V @ 7A Application Circuit.

Additional Application Circuits continued

16

CS5127

+5V +12V +5V

C1

680mF

C2

680mF

+

1UF

+C3

C4

680mF

C5

680mF

+

R1

3.3K

R2

100K

C6

390pF

R4

1540

R5

1270

C10

680mF

+

R7

10

2.8V 3.3V

C11

680mF

L1 5mH

R3

24K

IRL3103S

R6

2K

Q1

C14

0.2mF

D1

1N5821

7pF

R65

18K

C7

C50

0.22mF

C15

0.01mF

1

2

3

4

5

6

7

8

2N3906

Q4

m1

SYNC

CT

RT

V

FB1

COMP1

V

FFB1

GATE1

LGND

CS5127

V

V

REF

ENABLE

V

FB2

COMP2

V

FFB2

GATE2

PGND

16

IN

15

R48

100K

14

13

12

11

10

09

Q7

2N3906

C15

0.1mF

+12V

C16

0.22mF

C24

0.01mF

C52

7pF

R11

2.2K

Q2

IRL3103S

D2

1N5821

C17

0.2mF

+C8

1mF

L2

5mH

R10

C12

680UF

+

2K

R66

10

C13

680mF

R7

2400

R8

1500

C2

C1

680mF

680mF

C14

330PF

+

C18

0.1mF

50V

Q2

D1

1N5821

C15

100mF

1

2

3

4

5

6

7

8

m1

SYNC

CT

RT

V

FB1

COMP1

V

FFB1

GATE1

LGND

CS5127

2.8V

20K

R1

C6

0.1mF

R4

1540

1270

R5

Q1

FMMT2222ACT

C7

330PF

C10

680mF

+

R10

20K

R6

1K

L1

680mF

5mH

+

R2

27k

IRL3103S

V

REF

ENABLE

V

FB2

COMP2

V

FFB2

GATE2

PGND

D3

1N5818

D4

1N5818

V

IN

R12

30

C4

C5

680mF

D5

1N5248

L2

5mH

C12

680mFC11

R11

20K

680mF

0.1mF

680mF

+

C9

C13

+

3.3V

R7

2400

R8

R9

1500

2K

R3

18K

16

15

14

13

12

11

10

09

C8

1mF

C16

100mF

C3

10mF

IRL3103S

D2

1N5821

+

Q3

C17

330PF

Page 17

CS5127

Additional Application Circuits continued

17

Figure 17: 200kHz, V

2

ª

, 5V/12V input, 2.8V@ 7A and 3.3V @ 7A outputs with current limit.

Figure 18: CS5127 12V, 5V input to 2.8V @7A and 3.3V @ 7A Switching Regulator with External 1A, 2.5V Linear Output for Vclock.

+5V

+12V

+12V

+5V

+12V

R1

20K

2.8V

R4

1.54K

R5

1.27K

R69

10K

R70

20K

LM2903

U4A

C15

100mF

2N2907

1

2

3

4

5

6

7

8

C2

C1

680mF

680mF

Q1

FMMT2222ACT

C7

330PF

C6

0.1mF

C10

RDROOP

680mF

.008

+

+

C11

680mF

20K

R10

R6

1K

R66

R65

1M

1M

+

C24

0.1mF

-

R67

R68

15k

15k

Q2

IRL3103S

L1

5mH

C14

330PF

D1

1N5821

Q7

R73

1K

m1

SYNC

CT

RT

V

COMP1

V

GATE1

LGND

FB1

8

FFB1

CS5127

Q4

2N2907

R74

1K

V

ENABLE

COMP2

V

GATE2

PGND

V

REF

FFB2

R71

10K

R72

20K

LM2903

U4B

16

V

IN

15

14

13

FB2

12

11

10

09

+

-

C16

100mF

C25

0.1mF

D2

1N5821

C5

680mF

RDROOP

C4

680mF

C3

1mF

+

C9

0.1mF

C12

C13

680mF

680mF

.008

+

R11

20K

R8

1.50K

R7

2.40K

3.3V

R9

2K

R3

18K

R76

R75

1M

1M

R77

R78

15K

15K

+

C8

1mF

Q3

IRL3103S

L2

5mF

C17

330PF

2.8V

C3

1mF

V

V

REF

V

FB2

V

FFB2

GATE2

PGND

U2A

1/2 LM358

3

2

+12V

R17

2400

R18

2400

C4

680mF

+

16

IN

15

14

13

12

11

10

09

C16

100mF

C5

680mF

+

IRL3103S

D2

1N5821

+5V

+

C8

1mF

C9

L2

10mH

C12

680mFC11

0.1mF

C13

680mF

+

R11

20K

3.3V

R7

2400

R8

1500

R9

2K

R3

18K

Q3

C17

330pF

+5V

C1

C2

680mF

680mF

+

Q1

FMMT2222ACT

R1

20K

C6

0.1mF

R4

1540

R5

1270

C10

680mF

C7

330PF

+

R10

20K

R6

1K

L1

680mF

10mH

R2

27K

IRL3103S

C14

330pF

Q2

D1

1N5821

C15

100mF

Q4

IRL3103S

2.5V

C18

47mF

1

2

3

4

5

6

7

8

m1

SYNC

CT

RT

V

FB1

COMP1

V

FFB1

GATE1

LGND

CS5127

1

4

ENABLE

COMP2

8

+

-

Page 18

Figure 24: Oscillator Frequency vs RT,CT(VIN= 12V, T = 25C)

Figure 23: V

REF

Short Circuit Current vs Temperature.

18

Typical Performance Characteristics

Figure 19: V

REF

vs Temperature, 1mA Load.

Figure 21: V

REF

vs Temperature, 10mA Load.

Figure 20: Load Regulation vs Temperature 1mA to 10mA.

Figure 22: Line Regulation vs Temperature 9V to 20V.

CS5127

(V)

REF

V

5.005

5.004

5.003

5.002

5.001

5.000

18

16

14

12

Line Regulation (mV)

10

4.999

0

18

16

14

12

Load Regulation (mV)

10

8

10 20 30 40 50

0

10 20 30 40 50

Temperature (C)

Temperature (C)

60 70

7060

8

0

10 20 30 40 50

Temperature (C)

130

120

110

100

90

Short Circuit Current (mA)

80

70

0

10 20 30 40 50

Temperature(C)

60 70

60 70

4.992

4.990

4.998

4.988

VREF (V)

4.986

4.980

4.978

0

10 20 30 40 50

Temperature (C)

60 70

1.00E+06

5.00E+05

2.00E+05

1.00E+05

5.00E+04

Frequency (kHz)

2.00E+04

1.00E+04

20 22 26 28 30 34

24 32 38

3.3nF

RT (kW)

150pF

390pF

680pF

1.5nF

36 40

Page 19

Figure 27: Oscillator Duty Cycle vs CT, RT(VIN= 12V, T = 25C).

91.5

Figure 25: Oscillator Maximum Duty Cycle vs Temperature. Figure 28: SYNC Threshold vs Temperature.

Typical Performance Characteristics: continued

19

Figure 26: Oscillator Frequency vs Temperature. CT= 330pF, RT=27k

CS5127

Figure 30: VFBReference Voltage vs Temperature.

Figure 29: SYNC Input Current vs Temperature (V

SYNC

= 2.4V).

91.0

90.5

90.0

89.5

Maximum Duty Cycle (%)

89.0

88.5

010 304050 70

20 60

Temperature (C)

Sync Threshhold (V)

1.65

1.60

1.55

1.50

1.45

1.40

1.35

1.30

1.25

1.20

010 304050 70

20 60

Temperature (C)

210

208

206

204

Oscillator Frequency (kHz)

202

200

0

10 20 30 40 50

Temperature (C)

60 70

95

90

85

80

Duty Cycle (%)

75

70

20 22 26 28 30 34

24 32 38

RT (kW)

3.3nF

36 40

150pF

390pF

680pF

1.5nF

170

165

160

155

150

Sync Input Curernt (mA)

145

140

010 304050 70

20 60

Temperature (C)

1.2785

1.2780

1.2775

1.2770

1.2765

Reference Voltage (V)

FB

V

1.2760

1.2755

010 304050 70

20 60

Temperature (C)

Page 20

Figure 36: Error Amplifier Output Low Voltage (500µA) vs

Temperature.

Figure 35: Error Amplifier Source Current vs Temperature.

Figure 33: VFBBias Current vs Temperature.

Figure 31: Error Amplifier Gain vs Frequency. Figure 34: Error Amplifier Phase vs Frequency.

Figure 32: SYNC Input Current vs Temperature (V

SYNC

= 5V).

20

Typical Performance Characteristics: continued

CS5127

70

60

50

40

30

20

Gain (dB)

10

0

-10

-20

-30

1.00E +00

1.00E +01 1.00E +02 1.00E +03

1.00E +04 1.00E +05 1.00E +06 1.00E +07

Frequency (Hz)

225

180

135

90

45

0

Phase (degrees)

-45

1.00E+00

1.00E+01 1.00E+02 1.00E+03

Frequency (Hz)

1.00E+04

1.00E+05 1.00E+06 1.00E+07

450

430

410

390

Input Curernt (mA)

370

350

010 304050 70

20 60

Temperature (C)

0.105

0.103

0.101

0.099

Bias Current (mA)

FB

V

0.097

0.095

010 304050 70

20 60

Temperature (C)

1.310

1.305

1.300

1.295

1.290

Source Current (mA)

1.285

1.280

0

10 50 7020 40 40 60

Temperature (C)

0.90

0.85

0.80

0.75

Output Low Voltage (V)

0.70

0

10 50 7020 30 6040

Temperature (C)

Page 21

Figure 39: V

FFB

Bias Current vs Temperature.

3.37

Figure 37: PWM Comparator Maximum Common Mode Input Voltage

vs Temperature.

Figure 40: ENABLE Threshold vs Temperature.

Typical Performance Characteristics: continued

Figure 38: Error Amplifier Sink Current vs Temperature.

CS5127

Figure 41: ENABLE Bias Current vs Temperature.

Figure 42: GATE Low Voltage (100mA) vs Temperature.

21

2.28

3.35

3.33

3.31

3.29

Maximum Common Mode Voltage (V)

3.27

0

10 50 7020 30 6040

Temperature (C)

17.5

17.0

16.5

16.0

15.5

15.0

Sink Current (mA)

14.5

0

10 50 7020 30 6040

Temperature (C)

2.26

2.24

2.22

ENABLE Threshold (V)

2.20

0

10 50 7020 30 6040

Temperature (C)

280

270

260

250

240

230

220

ENABLE Bias Current (mA)

210

010 304050 70

20 60

Temperature (C)

1.07

1.06

1.05

1.04

1.03

Bias (mA)

1.02

FFB

V

1.01

1.00

0.99

0

10 20 30 40 50 60 70

Temperature (C)

215

210

205

200

195

GATE Low Voltage (mV)

190

185

180

010 304050 70

20 60

Temperature (C)

Page 22

Figure 48: Start-up Current vs Temperature.

Figure 47: VINStart-up Threshold vs Temperature.

Figure 44: GATE low voltage (20mA) vs Temperature.

Figure 45: GATE High Voltage (20mA) vs Temperature.

Figure 43: GATE High Voltage (100mA) vs Temperature. Figure 46: GATE Low Voltage (Lockout) vs Temperature.

22

Typical Performance Characteristics: continued

CS5127

1.70

1.65

18.0

17.5

1.60

1.55

1.50

GATE High Voltage (mV)

1.45

1.40

0

10

Temperature (C)

40

50 7020 30 60

17.0

16.5

16.0

Lockout Voltage (mV)

15.5

15.0

0

10 50 7020 30 6040

Temperature (C)

48

47

46

45

44

43

42

41

GATE Low Voltage (mV)

40

39

010 304050 70

20 60

Temperature (C)

8.615

8.613

8.611

8.609

Start up Threshold (V)

8.607

8.605

0

10

Temperature (C)

40

50 7020 30 60

1.60

1.55

1.50

1.45

1.40

1.35

1.30

GATE High Voltage (V)

1.25

1.20

010 304050 70

20 60

Temperature (C)

400

380

360

340

Start up Current (mA)

320

300

0

10

Temperature (C)

50 7020 30 60

40

Page 23

Figure 50: IC Supply Current vs Temperature. No Load on GATE pins.

RT= 27k, CT= 330pF

23

Typical Performance Characteristics: continued

7.924

Figure 49: VINShutdown Threshold vs Temperature.

CS5127

7.922

7.92

(V)

7.918

7.914

7.912

7.91

Shutdown Threshhold

7.908

7.906

0

10 20 30 40 50 60 70

Temperature (C)

18.5

18.0

17.5

17.0

16.5

IC Supply Current (mA)

16.0

15.5

0

10

Temperature (C)

40

50 7020 30 60

Page 24

24

Rev. 11/3/98

© 1999 Cherry Semiconductor Corporation

1.27 (.050) BSC

7.60 (.299)

7.40 (.291)

10.65 (.419)

10.00 (.394)

D

0.32 (.013)

0.23 (.009)

1.27 (.050)

0.40 (.016)

REF: JEDEC MS-013

2.49 (.098)

2.24 (.088)

0.51 (.020)

0.33 (.013)

2.65 (.104)

2.35 (.093)

0.30 (.012)

0.10 (.004)

Package Specification

PACKAGE DIMENSIONS IN mm (INCHES)

PACKAGE THERMAL DATA

Thermal Data 16 Lead SOIC Wide

R

QJC

typ 23 ûC/W

R

QJA

typ 105 ûC/W

D

Lead Count Metric English

Max Min Max Min

16 Lead SOIC Wide 10.50 10.10 .413 .398

Ordering Information

Part Number Description

CS5127GDW16 16 Lead SOIC Wide

CS5127GDWR16 16 Lead SOIC Wide (tape & reel)

Surface Mount Wide Body (DW); 300mil wide

Cherry Semiconductor Corporation reserves the

right to make changes to the specifications without

notice. Please contact Cherry Semiconductor

Corporation for the latest available information.

CS5127

Loading...

Loading...