Page 1

V

CC

BIAS

UVLO

SS

Gnd

GATE

IS

V

FB

R8

0.39Ω

Q2

IRFR220

R5

17.4k

C2

1.5µF,

100V

C1

0.1µF,

100V

R2

200k

10µH

36-75V

IN

L1

R1

510k

Q1

ZVN3310A

T1

D1

MBRD360CT

R3

47Ω

R6

1k

C3

.022µF

C6

.01µF

R7

30.1k

C5

47µF,

10V

ISOLATED

RTN

5V

OUT

ENABLE

48VRTN

D4

R4

10Ω

BAS16LT1

C4

0.47µF,

25V

C8

1000pF

C7

0.1µF

TPS5908

U2

R9

10.0k

C9

1000pF

CS5124

CTX15-14514

Features

■ Line UVLO Monitoring

■ Low Current Sense

Voltage for Resistive

Current Sensing

■ External Synchronization

to Higher or Lower

Frequency Oscillator

(CS5126 Only)

■ Bias for Start up Circuitry

(CS5124 Only)

■ Thermal Shutdown

■ Sleep On/Off Pin

■ Soft Start Timer

■ Leading Edge Blanking

■ Direct Optocoupler

Interface

■ 90ns Propagation Delay

■ 35ns Driver Rise and Fall

Times

■ Sleep Mode

Package Options

CS5124/6

High Performance, Integrated Current Mode

PWM Controllers

CS5124/6

Description

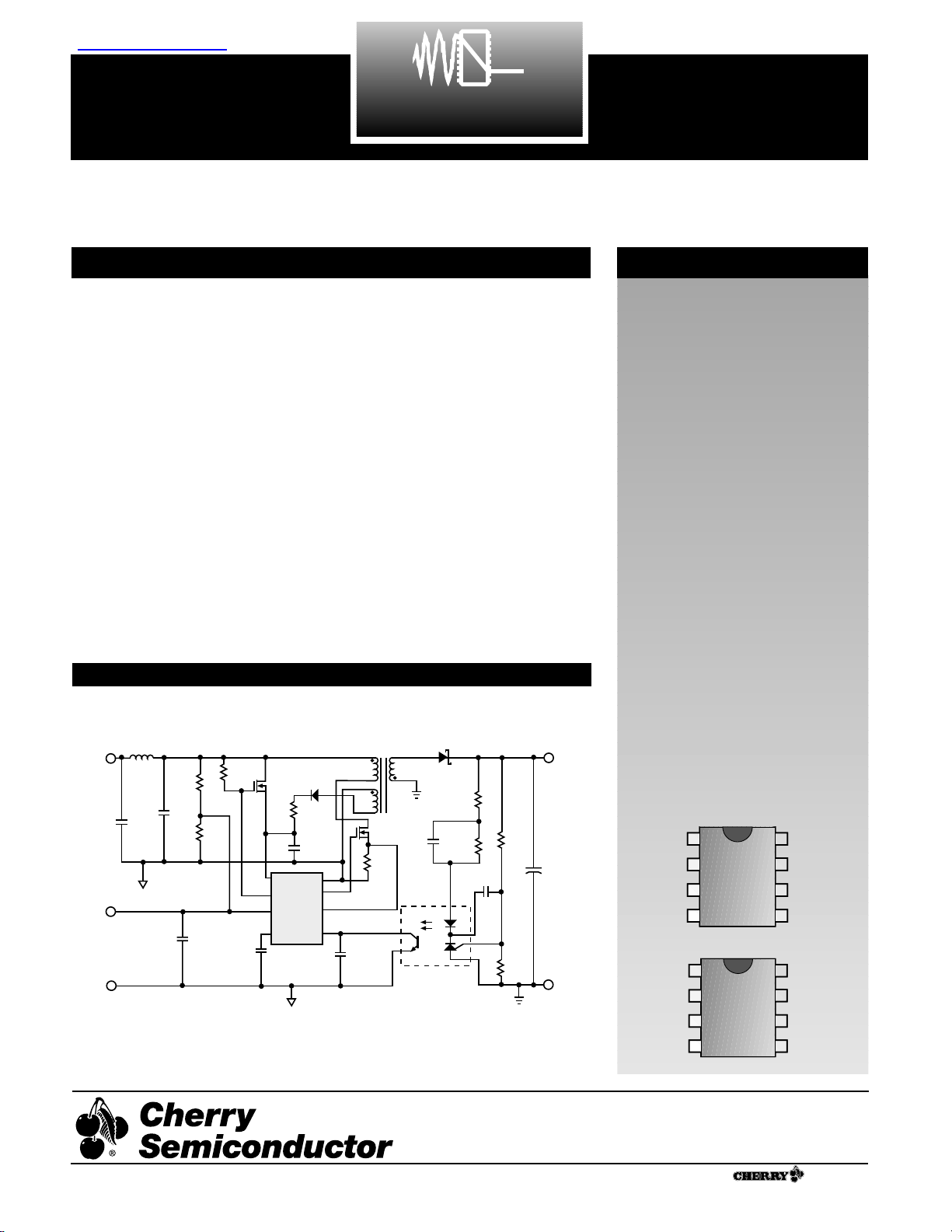

Applications Diagram

8 Lead SO Narrow

1

V

CC

BIAS

UVLO

SS

Gnd

GATE

I

SENSE

V

FB

Cherry Semiconductor Corporation

2000 South County Trail, East Greenwich, RI 02818

Tel: (401)885-3600 Fax: (401)885-5786

Email: info@cherry-semi.com

Web Site: www.cherry-semi.com

A Company

®

Rev. 3/12/99

Gnd

UVLO

V

CC

SYNC

SS

GATE

I

SENSE

V

FB

CS5124

CS5126

48V to 5V, 1A flyback converter using the CS5124

The CS5124/6 is a fixed frequency

current mode controller designed

specifically for DC-DC converters

found in the telecommunications

industry. The CS5124/6 integrates

many commonly required current

mode power supply features and

allows the power supply designer to

realize substantial cost and board

space savings. The product matrix is

as follows:

CS5124: 400kHz w/V

BIAS

Pin,

195mV first current sense threshold

CS5126: 200kHz w/SYNC Pin,

335mV first current sense threshold

The CS5124/6 integrates the following features: Internal Oscillator, Slope

Compensation, Sleep On/Off, Under

Voltage Lock Out, Thermal

Shutdown, Soft Start Timer, Low

Voltage Current Sense for Resistive

Sensing, Second Current Threshold

for Pulse by Pulse Over Current

Protection, a Direct Optocoupler

Interface and Leading Edge Current

Blanking.

The CS5124/6 has supply range of

7.7V to 20V and is available in 8 pin

SO narrow package.

查询CS5124供应商

1

1

Page 2

Pin Symbol Lead Name

V

MAX

V

MIN

I

SOURCE

I

SINK

V

CC

VCCPower Input 20V -0.3V 1mA 1.5A Peak

200mA DC

SYNC (CS5126) Clock Synchronization Input 20V -0.3V 1mA 1mA

V

BIAS

(CS5124) VCCClamp Output 20V -0.3V 1mA 1mA

UVLO UVLO Shutdown Input 6V -0.3V 1mA 1mA

SS Soft Start Capacitor Input 6V -0.3V 1mA 2mA

V

FB

Voltage Feed Back Input 6V -0.3V 3mA 20mA

I

SENSE

Current Sense Input 6V -0.3V 1mA 1mA

GROUND Ground 0V 0V 1.5A peak 1mA

200mA DC

GATE Gate Drive Output 20V -0.3V 1.5A Peak 1.5A Peak

200mA DC 200mA DC

Operating Junction Temperature, T

J

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-40 to 135°C

Storage Temperature Range, TS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-40 to 150°C

ESD (Human Body Model) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2kV

ESD (Machine Model) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .200V

Lead Temperature Soldering:

Reflow (SMD styles only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60 sec. max above 183°C, 230°C peak

CS5124/6

2

Absolute Maximum Ratings

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Electrical Characteristics: -40°C ≤ TJ ≤ 125°C, -40°C ≤ TA ≤ 105°C, 7.60V ≤ V

CC

≤ 20V, UVLO = 3.0V, I

SENSE

= 0V,

C

V(CC)

= 0.33µF, C

GATE

= 1nF (ESR = 10Ω), CSS= 470pF C

V(FB)

= 100pF, unless otherwise stated.

■ General

ICCOperating - V

GATE

not switching. 10 13 mA

ICCat VCCLow VCC= 6V 500 750 µA

ICCSleep V

UVL

= 1V 210 275 µA

■ Low V

CC

Lockout

VCCTurn-on Threshold Voltage 7.2 7.7 8.3 V

VCCTurn-off Threshold Voltage 6.8 7.3 7.8 V

VCCHysteresis 350 425 500 mV

■ UVLO

Sleep Threshold Voltage UVLO decreasing 1.5 1.8 2.3 V

Sleep Threshold Voltage UVLO increasing 1.88 2.45 V

Sleep Hysteresis 35 85 150 mV

UVLO Turn-off (Note 1) 2.3 2.45 2.6 V

Threshold Voltage

UVLO Turn-on (Note 1) 2.50 2.63 2.76 V

Threshold Voltage

UVLO Hysteresis Turn-on – Turnoff (-40°C ≤ TJ≤ 100°C) 170 185 200 mV

(Note 1)

UVLO Hysteresis Turn-on – Turnoff (100°C ≤ TJ≤ 125°C) 50 185 400 mV

(Note 1)

UVLO Input Bias Current -1 1 µA

UVLO Clamp With UVLO sinking 1mA. 5 7.5 12 V

Page 3

CS5124/6

3

Electrical Characteristics: -40°C ≤ TJ ≤ 125°C, -40°C ≤ TA ≤ 105°C, 7.60V ≤ V

CC

≤ 20V, UVLO = 3.0V, I

SENSE

= 0V,

C

V(CC)

= 0.33µF, C

GATE

= 1nF (ESR = 10Ω), CSS= 470pF C

V(FB)

= 100pF, unless otherwise stated.

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

■ V

CC

Clamp and BIAS Pin CS5124 Only. Connect an NFET as follows: BIAS = G, VCC= S, V

IN

= D.

VCCClamp Voltage 36V ≤ VIN≤ 60V, 220nF ≤ 7.275 7.9 8.625 V

CSS≤ 500nF, R = 500k

BIAS Minimum Voltage Measure Voltage on BIAS with: 1.6 2.8 4 V

10V ≤ VCC≤ 20V and 50µA ≤ I

BIAS

≤ 1mA

BIAS Clamp With BIAS pin sinking 1mA 12 15 20 V

■ 200kHz Oscillator CS5126 Only

Operating Frequency 175 200 225 kHz

Max Duty Cycle Clamp 78 82.5 85 %

Slope Compensation 12 18 23 mV/µs

(Normal operation)

Slope Compensation

(Synchronized operation) (Note 1) 7 12 16 mV/µs

SYNC Input Threshold Voltage 1 2 3 V

SYNC Input Impedance Measured with SYNC = 1V &10V 50 120 230 kΩ

■ 400kHz Oscillator CS5124 Only

Operating Frequency 360 400 440 kHz

Max Duty Cycle Clamp 80.0 82.5 85.0 %

Slope Compensation 15 21 26 mV/µs

■ Soft Start

Soft Start Charge Current 7 10 13 µA

Soft Start Discharge Current 0.5 10.0 mA

VSSVoltage when V

FB

V

FB

= 300mV 1.40 1.62 1.80 V

Begins to Rise

Peak Soft Start Charge Voltage 4.7 4.9 V

Valley Soft Start Discharge Voltage 200 275 400 mV

■ Current Sense CS5124 Only

First Current Sense Threshold At max duty cycle. 170 195 215 mV

Second Current Sense Threshold 250 275 315 mV

I

SENSE

to GATE Prop. Delay 0 to 700mV pulse into I

SENSE

60 90 130 ns

(after blanking time)

Leading Edge Blanking Time 0 to 400mV pulse into I

SENSE

90 130 180 ns

Internal Offset (Note 1) 60 mV

■ Current Sense CS5126 Only

First Current Sense Threshold At max duty cycle 300 335 360 mV

Second Current Sense 485 525 575 mV

Threshold

I

SENSE

to GATE Prop. Delay 0 to 800mV pulse into I

SENSE

60 90 130 ns

(after blanking time)

Leading Edge Blanking Time 0 to 550mV pulse into I

SENSE

110 175 210 ns

Internal Offset (Note 1) 125 mV

Page 4

Package Lead Description

PACKAGE LEAD # LEAD SYMBOL FUNCTION

CS5124/6

4

Electrical Characteristics: -40°C ≤ TJ ≤ 125°C, -40°C ≤ TA ≤ 105°C, 7.60V ≤ V

CC

≤ 20V, UVLO = 3.0V, I

SENSE

= 0V,

C

V(CC)

= 0.33µF, C

GATE

= 1nF (ESR = 10Ω), CSS= 470pF C

V(FB)

= 100pF, unless otherwise stated.

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

8 Lead SO Narrow

CS5124 CS5126

11 VCCVCCPower Input Pin.

2 - BIAS VCCClamp Output Pin. This pin will control the gate of an N-channel MOS-

FET that in turn regulates VCC. This pin is internally clamped at 15V when

the IC is in sleep mode.

- 3 SYNC Clock Synchronization Pin. A positive edge will terminate the current PWM

cycle. Ground this pin when it is not used.

3 2 UVLO Sleep and under voltage lockout pin. A voltage greater than 1.8V causes the

chip to "wake up" however the GATE remains low. A voltage greater than

2.6V on this pin allows the output to switch.

4 4 SS Soft Start Capacitor Pin. A capacitor placed between SS and GROUND is

charged with 10µA and discharged with 10mA. The Soft Start capacitor controls both soft-start time and hiccup mode frequency.

55 VFBVoltage Feedback Pin. The collector of an optocoupler is typically tied to this

pin. This pin is pulled up internally by a 4.3kΩ resistor to 5V and is clamped

internally at 2.9V(2.65V). If VFBis pulled > 4V, the oscillator is disabled and

GATE will stay high. If the VFBpin is pulled < 0.49V, GATE will stay low.

66I

SENSE

Current Sense Pin. This pin is connected to the current sense resistor on the

primary side. If VFBis floating, the GATE will go low if I

SENSE

= 195mV

(335mV). If I

SENSE

> 275mV (525mV), Soft Start will be initiated.

7 7 GATE Gate Drive Output Pin. Capable of driving a 3nF load. GATE is nominally

clamped to 13.5V.

8 8 Gnd Ground Pin.

■ Voltage Feedback

V

FB

Pull-up Res. 2.9 4.3 8.1 kΩ

VFBClamp Voltage CS5124 Only 2.63 2.90 3.15 V

VFBClamp Voltage CS5126 Only 2.40 2.65 2.90 V

VFBFault Voltage Threshold 460 490 520 mV

■ Output Gate Drive

Maximum Sleep VCC= 6.0V, I

OUT

= 1mA 1.2 2.0 V

Pull-down Voltage

GATE High (AC) Series resistance < 1Ω (Note 1) VCC-1 VCC-0.5 V

GATE Low (AC) Series resistance < 1Ω (Note 1) 0.0 0.5 V

GATE High Clamp Voltage VCC= 20V 11.0 13.5 16.0 V

Rise Time Measure GATE rise time, 45 65 ns

1V < GATE < 9V; V

CC

=12V

Fall Time Measure GATE fall time, 25 55 ns

9V > GATE > 1V; V

CC

= 12V

■ Thermal Shutdown

Thermal Shutdown Temperature (Note 1) (GATE low) 135 150 165 °C

Thermal Enable Temperature (Note 1) (GATE switching) 100 125 150 °C

Thermal Hysteresis (Note 1) 15 25 35 °C

Notes

1. Not tested in production. Specification is guaranteed by design.

Page 5

CS5124/6

5

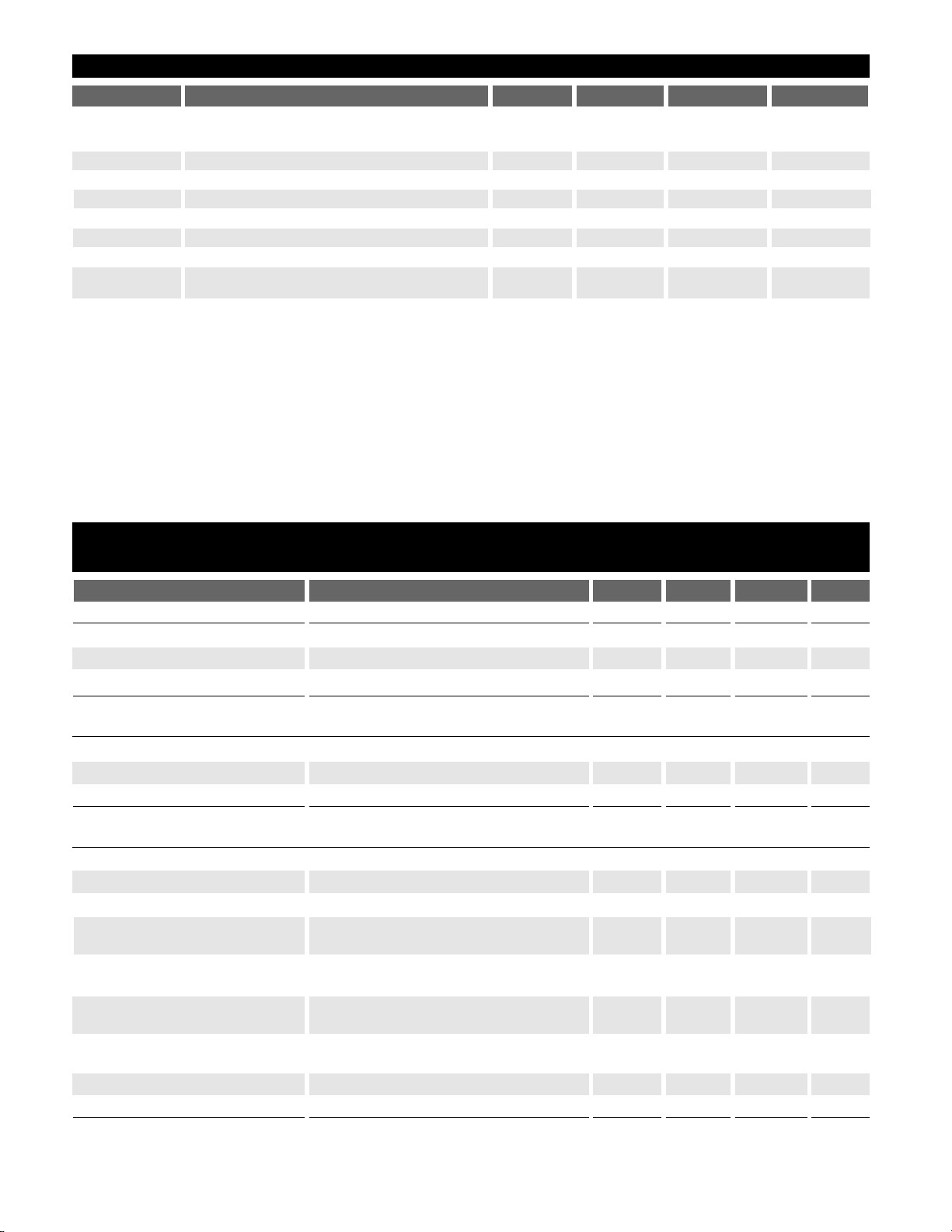

Block Diagram

V

Theory of Operation

Powering the IC

V

CC

can be powered directly from a regulated supply

and requires 500µA of start-up current. The CS5124/6

includes a line bias pin (BIAS) that can be used to control a

series pass transistor for operation over a wide input voltage. The BIAS pin will control the gate voltage of an Nchannel MOSFET placed between V

IN

and VCCto regulate

V

CC

at 8V.

VCCand UVLO Pins

The UVLO pin has three different modes; low power shutdown, Line UVLO, and normal operation. To illustrate

how the UVLO pin works; assume that VIN, as shown in

the application schematic, is ramped up starting at 0V with

the UVLO pin open. The SS and I

SENSE

pins also start at 0V.

While the UVLO is below 1.8V, the IC will remain in a low

current sleep mode and the BIAS pin of the CS5124 is internally clamped to a maximum of 15V. When the voltage on

the UVLO pin rises to between 1.8V and 2.6V the reference

for the VCCUVLO is enabled and VCCis regulated to 8V by

the BIAS pin (CS5124 only), but the IC remains in a UVLO

state and the output driver does not switch. When the

UVLO pin exceeds 2.6V and the VCCpin exceeds 7.7V, the

GATE pin is released from a low state and can begin

switching based on the comparison of the I

SENSE

and V

FB

pins. The Soft Start capacitor begins charging from 0V at

10µA. As the capacitor charges, a buffered version of the

capacitor voltage appears on the V

FB

pin and the VFBvoltage begins to rise. As VFBrises the duty cycle increases

until the supply comes into regulation.

Soft Start

Soft Start is accomplished by clamping the V

FB

pin 1.32V

below the SS pin during normal start up and during restart

after a fault condition. When the CS5124/6 starts, the Soft

Start capacitor is charged from a 10µA source from 0V to

4.9V. The VFBpin follows the Soft Start pin offset by –1.32V

until the supply comes into regulation or until the Soft

Start error amp is clamped at 2.9V (2.65V for the CS5126).

During fault conditions the Soft Start capacitor is discharged at 10mA.

Fault Conditions

The CS5124/6 recognizes the following faults: UVLO off,

Thermal Shutdown, V

REF(OK)

, and Second Current

Threshold. Once a fault is recognized, fault latch F2 is set

and the IC immediately shuts down the output driver and

discharges the Soft Start capacitor. Soft Start will begin

only after all faults have been removed and the Soft Start

capacitor has been discharged to less than 0.275V. Each

fault will be explained in the following sections.

CC

UVLO

BIAS

(CS5124 ONLY)

SS

UVLO COMP

V

CC

+

-

+

V

7.7 V/7.275V

TSHUT

150°C/125°C

+

LINE AMP

LINE UVLO COMP

+

2.62 V/2.45V

V

V

1.91 V/1.83V

-

+

2.0V

+

REMOTE

(SLEEP) COMP

+

-

V

CC

2.9 R

R

+

V

G2

ENABLE

-

V

REFOK

+

+

V

SOFT START LATCH

F2

G5

S

R

SET DOMAIN

SS COMP

275mV

{CS5126 ONLY}

SYNC

V

CC

V

= 5V

REF

V5

REF

10µA

Q

+

+

V

V5

REF

{2.65V}

2.90V

+

OSC

RAMP

2ND I

+

1.32V

V

DIS

V

G3

COMP

V

FB

PWM COMP

+

{525mV}

-

275mV

+

COMP

V

V5

R

F1

S

RESET DOMAIN

+

+

V

+

+

V

{125mV}

60mV

BLANK

G6

REF

Q

490mV

G1

{85 mV/us}

170mV us

{1/5}

1/10

÷

1000Ω

BLANKING

S

R

F3

G7

+

-

Q

SS AMP

DRIVER

V5

REF

4500Ω

GATE

V

FB

I

SENSE

Gnd

Page 6

CS5124/6

6

Theory of Operation: continued

Application Information

Under Voltage Lockout (UVLO)

The UVLO pin is tied to typically the midpoint of a resistive divider between V

IN

and GROUND. During a start up

sequence, this pin must be above 2.6V in order for the IC to

begin normal operation. If the IC is running and this pin is

pulled below 1.8V, F2 shuts down the output driver and

discharges the Soft Start capacitor in order to insure proper

start-up. If the UVLO pin is pulled high again before the

Soft Start capacitor discharges, the IC will complete the

Soft Start discharge and, if no other faults are present, will

immediately restart the power supply. If the UVLO pin

stays low, then it will enter either the low current sleep

mode or the UVLO state depending on the level of the

UVLO pin.

Thermal Shutdown

If the IC junction temperature exceeds approximately

150°C the thermal shutdown circuit sets F2, which shuts

down the output driver and discharges the Soft Start

capacitor. If no other faults are present the IC will initiate

Soft Start when the IC junction temperature has been

reduced by 25°C.

V

REF(OK)

V

REF(OK)

is an internal monitor that insures the internal

regulator is running before any switching occurs. This

function does not trip the fault comparator like the other

fault functions. To insure that Soft Start will occur at low

line conditions the UVLO divider should be set up so that

the VCCUVLO comparator turns on before the LINE

UVLO comparator.

Second Threshold Comparator

Since the maximum dynamic range of the I

SENSE

signal in

normal operation is 195mV (335mV for the CS5126), any

voltage exceeding this threshold on the I

SENSE

pin is considered a fault and the PWM cycle is terminated. The 2nd

I

COMP

compares the I

SENSE

signal with a 275mV (525mV

for the CS5126) threshold. If the I

SENSE

voltage exceeds the

second threshold, F2 is set, the driver turns off, and the

soft-start capacitor discharges. After the Soft Start capacitor

has discharged to less than 0.275V Soft Start will begin. If

the fault condition has been removed the supply will operate normally. If the fault remains the supply will operate in

hiccup mode until the fault condition is removed.

VFBComparator

The VFBcomparator detects when the output voltage is too

high. When the regulated output voltage is too high, the

feedback loop will drive VFBlow. If VFBis less than 0.49V

the output of the VFBcomparator will go high and shut the

output driver off.

Oscillator

The internally trimmed, 400kHz (CS5124) or 200kHz

(CS5126) provides the slope compensation ramp as well as

the pulse for enabling the output driver.

PWM Comparator and Slope Compensation

The CS5124/6 provides a fixed internal slope compensation ramp that is subtracted from the feedback signal. The

pwm comparator compares peak primary current to a portion of the difference of the feedback voltage and slope

compensation ramp. The 170mV/µs (85mV/µs for the

CS5126) slope compensation ramp is subtracted from the

voltage feedback signal internally. The difference signal is

then divided by ten (five for the CS5126) before the PWM

comparator to provide high noise rejection with a low voltage across the current sense network. (The effective ramp

is 21mV/µs for the CS5124, and 18mV/µs for the CS5126).

A 60mV (125mV for the CS5126) nominal offset on the positive input to the PWM comparator allows for operation

with the I

SENSE

pin at, or even slightly below Gnd.

A 4.3kΩ pull-up resistor internally connected to a 5V nomi-

nal reference provides the bias current to for an opto-coupler connection to the VFBpin.

UVLO and Thermal Shutdown Interaction

The UVLO pin and thermal shutdown circuit share the

same internal comparator. During high temperature operation (TJ>100°C) the UVLO pin will interact with the thermal shutdown circuit. This interaction increases the turnon threshold (and hysteresis) of the UVLO circuit. If the

UVLO pin shuts down the IC during high temperature

operation, higher hysteresis (see hysteresis specification)

might be required to enable the IC.

BIAS Pin (CS5124 Only)

The bias pin can be used to control V

CC

as shown in the

main application diagram. In order to provide adequate

phase margin for the bias control loop, the pole created by

the series pass transistor and the VCCbypass capacitor

should be kept above 10kHz. The frequency of this pole

can be calculated by Formula (1).

Pole

Frequency = (1)

Transconductance of pass Transistor

2 × π × C

V(CC)

Page 7

CS5124/6

7

Application Information: continued

The Line BIAS pin shows a significant change in the regulated V

CC

voltage when sinking large currents. This will

show up as poor line regulation with a low value pull-up

resistor. Typical regulated VCCvs BIAS pin sink current is

shown in Figure 1.

Figure 1. Regulated VCCvs BIAS Sink Current

Clock Synchronization Pin (CS5126 Only)

The CS5126 can be synchronized to signals ranging from

30% slower to several times faster than the internal oscillator frequency. If the part is synchronized to a fast signal,

maximum duty cycle will be reduced as the frequency

increases as shown in Figure 2.

Figure 2: CS5126 Maximum Duty Cycle vs Frequency (Synchronized

Operation)

If the converter is initially free running and a sync signal is

applied, the current oscillator cycle will terminate and the

oscillator will lock on to the sync signal. The SYNC pin

works with a positive edge triggered signal. When the sync

signal transitions high the current PWM cycle terminates

and a new cycle begins as shown in Figure 3. The typical

phase lag between the rising edge of the SYNC signal and

the rising edge of the Gate is shown in Figure 4. When this

pin is held high or low the internal clock determines the

oscillator frequency.

Figure 3. Synchronized Operation

Figure 4 : Typical Phase Lag between SYNC and GATE on.

Gate Drive

Rail to rail gate driver operation can be obtained (up to

13.5V) over a range of MOSFET input capacitance if the

gate resistor value is kept low. Figure 5 shows the high

gate drive level vs. the series gate resistance with VCC= 8V

driving an IRF220.

Figure 5. Gate Drive vs Gate Resistor Driving an IRF220 (VCC= 8V)

8.3

8.2

8.1

CC

V

8

7.9

5µ 10µA20µA50µA 100µA 200µA

Bias Current (I

BIAS

)

SYNC

OSC

GATE

140

130

120

110

100

Phase Lag°

90

80

70

200kHz 300kHz 400kHz 500kHz 600kHz

0.82

125°C

0.77

Maximum Duty Cycle

0.72

200kHz

300kHz 400kHz 500kHz 600kHz

Frequency

25°C

-40°C

8.5

8

7.5

7

Peak Voltage

6.5

6

0 0.3 0.5 2.5 5 11

Gate Resistor Value

Page 8

Application Information: continued

CS5124/6

8

A large negative dv/dt on the power MOSFET drain will

couple current into the gate driver through the gate to

drain capacitance. If this current is kept within absolute

maximum ratings for the GATE pin it will not damage the

IC. However if a high negative dv/dt coincides with the

start of a PWM duty cycle, there will be small variations in

oscillator frequency due to current in the controller substrate. If required, this can be avoided by choosing the

transformer ratio and reset circuit so that a high dv/dt

does not coincide with the start of a PWM cycle, or by

clamping the negative voltage on the GATE pin with a

schottky diode

First Current Sense Threshold

During normal operation the peak primary current is controlled by the level of the VFBpin (as determined by the

control loop) and the current sense network. Once the signal on the I

SENSE

pin exceeds the level determined by V

FB

pin the pwm cycle terminates. During high output currents

the VFBpin will rise until it reaches the VFBclamp. The first

current sense threshold determines the maximum signal

allowed on the I

SENSE

pin before the PWM cycle is terminated. Under this condition the maximum peak current is

determined by the VFBClamp, the slope compensation

ramp, the PWM comparator offset voltage and the PWM

on time. The nominal first current threshold varies with on

time and can be calculated from Formulas (2) & (3) below.

CS5124

1st Threshold = – 60mV (2)

CS5126

1st Threshold = – 125mV (3)

When the output current is high enough for the I

SENSE

pin

to exceed the first threshold, the pwm cycle terminates

early and the converter begins to function more like a current source. The current sense network must be chosen so

that the peak current during normal operation does not

exceed the first current sense threshold.

Second Current Sense Threshold

The second threshold is intended to protect the converter

from over-heating by switching to a low duty cycle mode

when there are abnormally high fast rise currents in the

converter. If the second current sense threshold is tripped,

the converter will shut off and restart in Soft Start mode

until the high current condition is removed. The dead time

after a second threshold over-current condition will primarily be determined by the time required to charge the

Soft Start cap from 0.275V nominal to 1.32V.

The second threshold will only be reached when a high

dv/dt is present at the current sense pin. The signal must

be fast enough to reach the second threshold before the

first threshold turns off the driver. This will normally happen if the forward inductor saturates or when there is a

shorted load.

Excessive filtering of the current sense signal, a low value

current sense resistor, or even an inductor that does not

saturate during heavy output currents can prevent the second threshold from being reached. In this case the first current sense threshold will trip during each cycle of high output current conditions. The first threshold will limit output

current but some components, especially the output rectifier, can overheat due to higher than normal average output

current.

Slope Compensation

Current mode converters operating at duty cycles in excess

of 50% require an artificial ramp to be added to the current

waveform or subtracted from the feedback waveform. For

the current loop to be stable the artificial ramp must be

equivalent to at least 50% of the inductor current down

slope and is typically chosen between 75 % to 100% of the

inductor down current down slope.

To choose an inductor value such that the internal slope

compensation ramp will be equal to a certain fraction of

the inductor down current slope use the Formula (4).

× (V

OUT

+ V

RECTIFIER)

××

R

I(SENSE)

× Slope Value Factor = Inductor Value (H) (4)

Calculating the nominal inductor value for an artificial

ramp equivalent to 100% of the current inductor down

slope at CS5126 nominal conditions, a 5V output, a 200mΩ

current sense resistor and a 4:1 transformer ratio yields

× (5V + 0.3V) × × 0.2Ω × 1 = 13.2 µH

To check that the slope compensation ramp will be greater

than 50% of the inductor down under all conditions, substitute the minimum internal slope compensation value

and use 0.5 for the slope compensation value. Then check

that the actual inductor value will always be greater than

the inductor value calculated.

During synchronized operation of the CS5126 the slope

compensation ramp is reduced by 33%. If the CS5126 will

1

4

1

20mV/µs

N

SECONDARY

N

PRIMARY

1

Internal Ramp

2.65V – 85mV/µs × T

ON

5

2.9V – 170mV/µs × T

ON

10

Page 9

9

CS5124/6

be used in synchronized operation, the inductor value

should be recalculated to work with the slope compensation ramp reduced to 67% of the normal value.

Powering the CS5124/6 from a Transformer Winding

There are numerous ways to power the CS5124/6 from a

transformer winding to enable the converter to be operated

at high efficiency over a wide input range. Two ways are

shown in the application circuits.

The CS5124 application circuit (main application diagram)

is a flyback converter that uses a second flyback winding

to power VCC. R4 improves VCCregulation with load

changes by snubbing the turn off spike. Once the turn off

spike has subsided the voltage of this winding is voltage

proportional to the voltage on the main flyback winding.

This voltage is regulated because the main winding is

clamped by the regulated output voltage.

In the CS5126 application circuit (below) an extra winding

is added to the forward inductor to power VCC. This winding is phased to conduct during the off time of the forward

converter and performs the same function as the flyback

winding above.

A flyback winding from a forward transformer can also be

used to power VCC. Ideally the transformer volt-second

product of a forward converter would be constant over the

range of line voltages and load currents; and the transformer inductance could be chosen to store the required

level of energy during each cycle to power VCC. Even

though the flyback energy is not directly regulated it

would remain constant. Unfortunately in a real converter

there are many non-ideal effects that degrade regulation.

Transformer inductance varies, converter frequency varies,

energy stored in primary leakage inductance varies with

output current, stray transformer capacitances and various

parasitics all effect the level of energy available for VCC. If

too little energy is provided to VCC, the bootstrapping circuit must provide power and efficiency will be reduced. If

too much energy is provided VCCrises and may damage

the controller. If this approach is taken the circuit must be

carefully designed and component values must be controlled for good regulation.

Application Information: continued

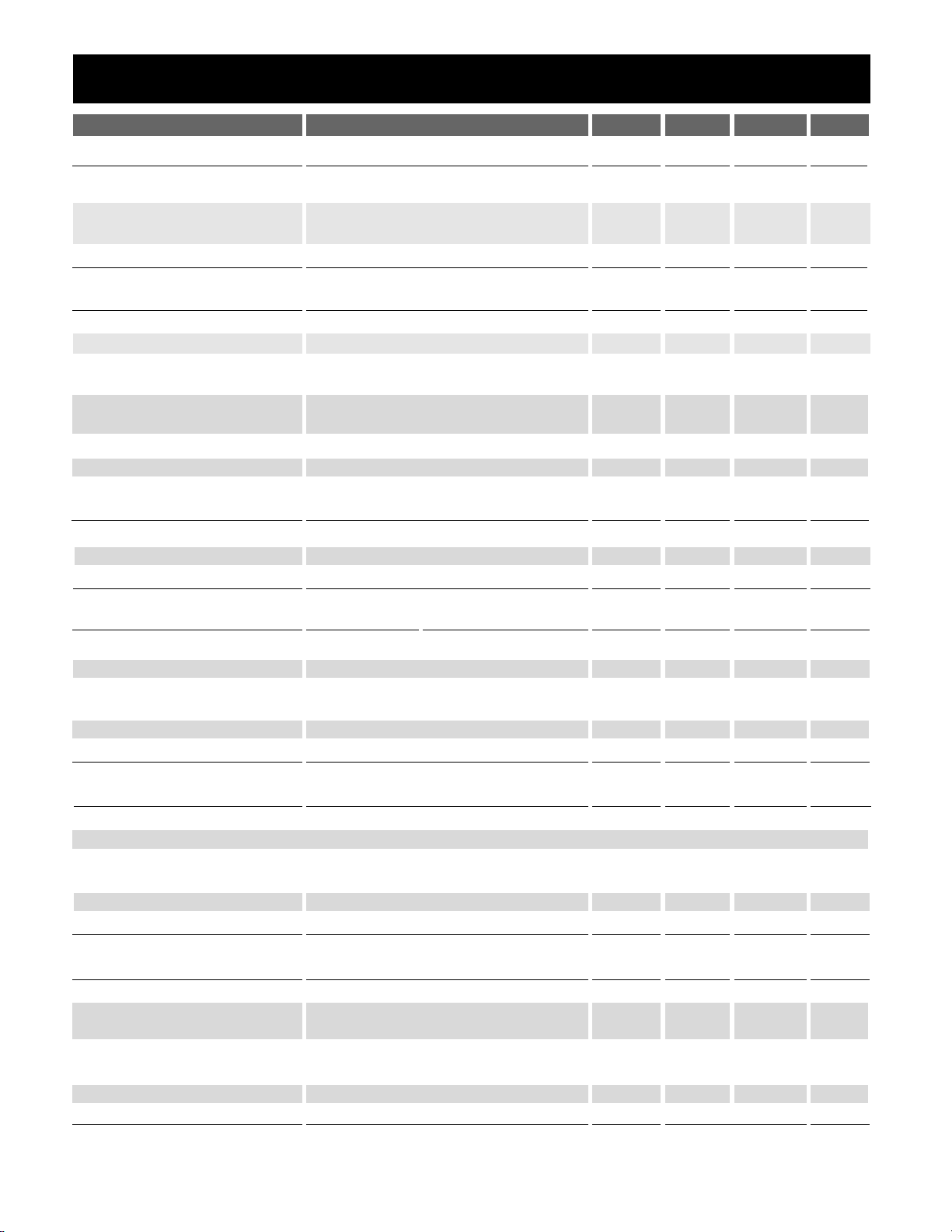

Additional Application Diagram

48V to 5V, 5A forward converter using the CS5126

C3

L1

10µH

1.5µF,

100V

C2

1.5µF,

100V

R9

10k

1000pF

C1

C4

R2

200k

R6

17.4k

R10

10k

R1

39k

1µF,

25V

D3

11V

C5

0.1µF

C11

F2T493

D2

MMBD6100L

V

UVLO

SYNC

SS

CS5126

Q1

CC

36-75V

0.2µF, 100V

ENABLE

48VRTN

IN

SYNC

Gnd

GATE

V

C6

390pF

IS

FB

CTX15-14526

Q2

IRF634

C10

1000pF

T2

R4

0.2Ω

1/4W

MBRB2060CT

TPS5908

C12

.01µF

U2

CTX15-14527

T1

R7

2k

C9

.01µF

R3

30.1k

R8

10.0k

C7

47µF

5V

OUT

ISOLATED

RTN

C8

47µF

Page 10

CS5124/6

10

© 1999 Cherry Semiconductor CorporationRev. 3/12/99

Part Number Description

CS5124XD8 8 Lead SO Narrow

CS5124XDR8 8 Lead SO Narrow (tape & reel)

CS5126XD8 8 Lead SO Narrow

CS5126XDR8 8 Lead SO Narrow (tape & reel)

Thermal Data 8L SO Narrow

R

ΘJC

typ 45 ˚C/W

R

ΘJA

typ 165 C/W

D

Lead Count Metric English

Max Min Max Min

8 Lead SO Narrow 5.00 4.80 .197 .189

Package Specification

PACKAGE DIMENSIONS IN mm (INCHES)

PACKAGE THERMAL DATA

Ordering Information

Cherry Semiconductor Corporation reserves the right to

make changes to the specifications without notice. Please

contact Cherry Semiconductor Corporation for the latest

available information.

Surface Mount Narrow Body (D); 150 mil wide

1.27 (.050) BSC

0.51 (.020)

0.33 (.013)

6.20 (.244)

5.80 (.228)

4.00 (.157)

3.80 (.150)

1.57 (.062)

1.37 (.054)

D

0.25 (0.10)

0.10 (.004)

1.75 (.069) MAX

1.27 (.050)

0.40 (.016)

REF: JEDEC MS-012

0.25 (.010)

0.19 (.008)

Loading...

Loading...