Page 1

1

Features

■ Linear Regulator

5V ± 2% @ 100mA

■ Switching Regulator

1.4A Peak Internal

Switch

120kHz Maximum

Switching Frequency

5V to 26V Operating

Supply Range

■ Smart Functions

Watchdog

■ Protection

Overtemperature

Current Limit

ENABLE

RESET

Package Options

24 Lead SO Wide

(Internally Fused Leads)

CS5112

1.4A Switching Regulator with 5V, 100mA Linear

Regulator with Watchdog, RESET and ENABLE

V

REG

V

LIN

I

BIAS

Gnd

Gnd

Gnd

Gnd

RESET

C

Delay

WDI

C

OSC

V

IN

NC

NC

V

SW

Gnd

Gnd

Gnd

Gnd

V

FB1

V

FB2

SELECT

COMP

ENABLE

CS5112

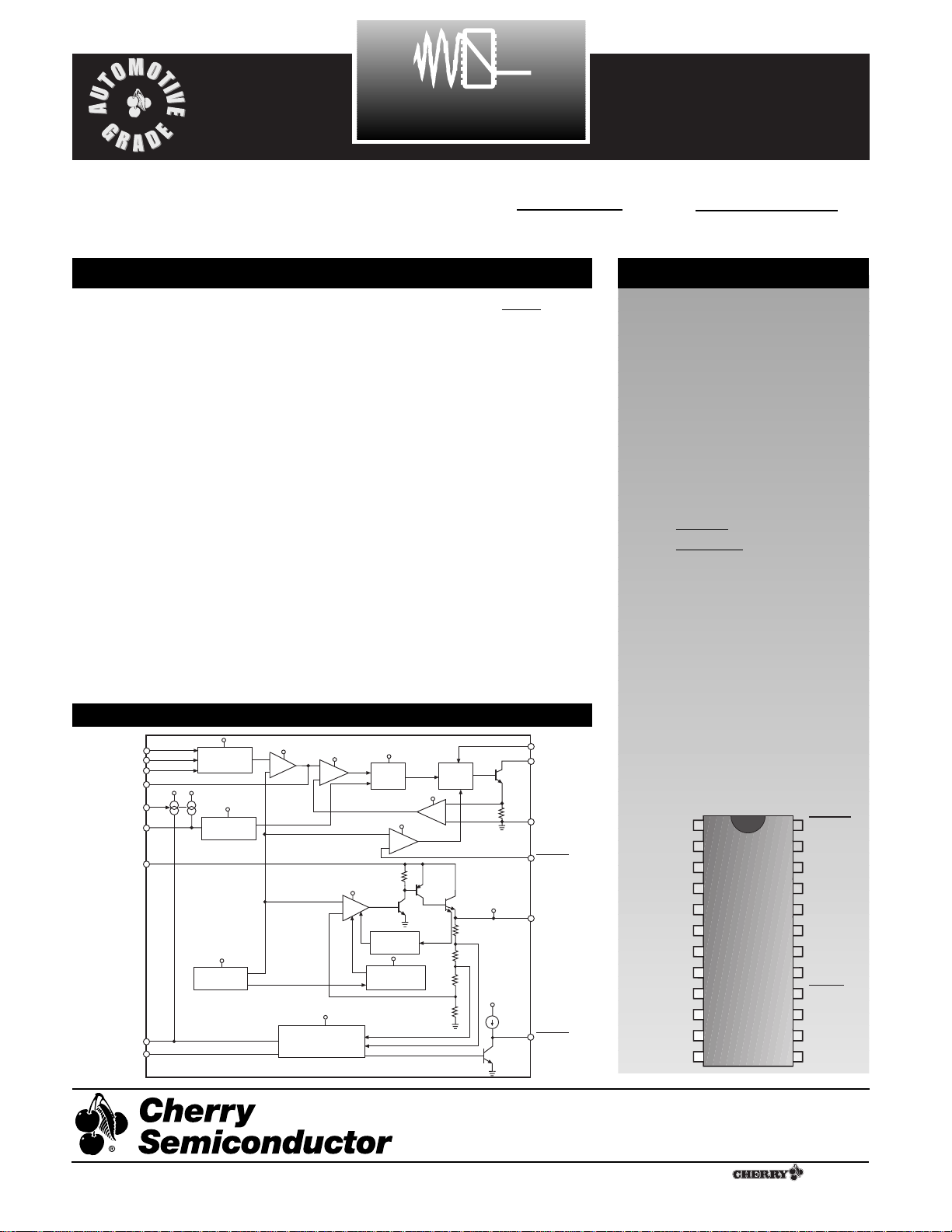

Description

Over

Temperature

V

IN

Linear

Error Amplifier

1.25V

V

REG

1.4A

V

SW

COMP

V

FB1

V

FB2

SELECT

V

LIN

I

BIAS

C

DELAY

RESET &

Watchdog Timer

Current

Limit

WDI

C

OSC

Base

Drive

RESET

Gnd

Bandgap

Reference

Oscillator

Multiplexer

+

-

COMP

Logic

+

-

+

-

+

Switcher Shutdown

Switcher

Error Amplifier

Current Sense Amplifier

ENABLE

Block Diagram

A Company

¨

Rev. 4/22/99

Cherry Semiconductor Corporation

2000 South County Trail, East Greenwich, RI 02818

Tel: (401)885-3600 Fax: (401)885-5786

Email: info@cherry-semi.com

Web Site: www.cherry-semi.com

The CS5112 is a dual output power supply integrated circuit. It contains a 5V

±2%, 100mA linear regulator, a watchdog

timer, a linear output voltage monitor to

provide a Power On Reset (POR) and a

1.4A current mode PWM switching regulator.

The 5V linear regulator is comprised of

an error amplifier, reference, and supervisory functions. It has low internal supply current consumption and provides

1.2V (typical) dropout voltage at maximum load current.

The watchdog timer circuitry monitors

an input signal (WDI) from the microprocessor. It responds to the falling

edge of this watchdog signal. If a correct

watchdog signal is not received within

the externally programmable time, a

reset signal is issued.

The externally programmable active

reset circuit operates correctly for an output voltage (V

LIN

) as low as 1V. During

power up, or if the output voltage shifts

below the regulation limit, toggles low and remains low for the duration

of the delay after proper output voltage

regulation is restored. Additionally a reset

pulse is issued if the correct watchdog is

not received within the programmed

time. Reset pulses continue until the correct watchdog signal is received. The

reset pulse width and frequency, as well

as the Power On Reset delay, are set by

one external RC network.

The current mode PWM switching regulator is comprised of an error amplifier

with selectable feedback inputs, a current sense amplifier, an adjustable oscillator, and a 1.4A output power switch

with anti-saturation control. The switching regulator can be configured in a

variety of topologies.

The CS5112 is load dump capable and

has protection circuitry which includes

current limit on the linear and switcher

outputs, and an overtemperature limiter.

RESET

1

Page 2

2

CS5112

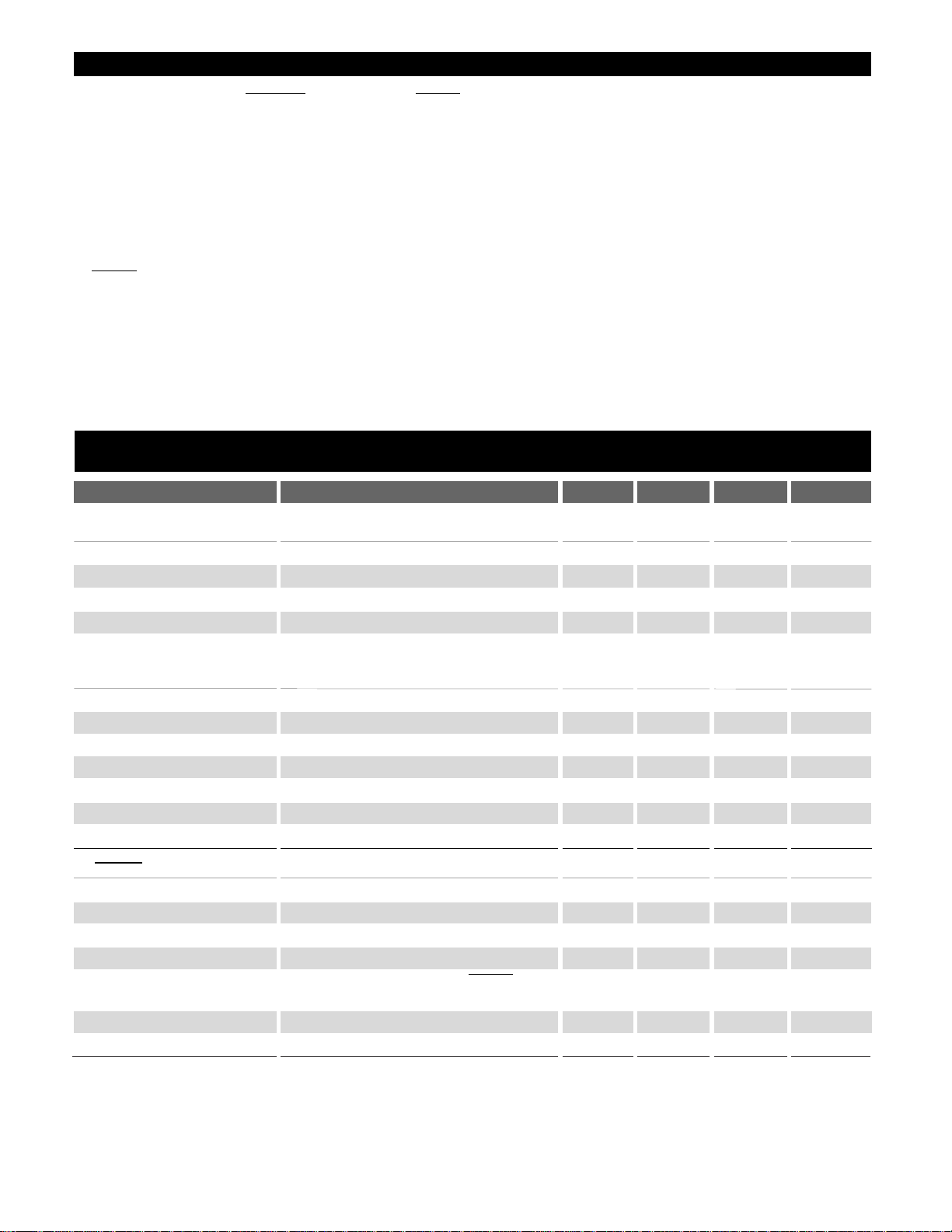

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Absolute Maximum Ratings

Logic Inputs/Outputs ( , SELECT, WDI, ) ................................................................................-0.3V to V

LIN

V

LIN

................................................................................................................................................................................-0.3V to 10V

VIN, V

REG:

DC Input Voltage .................................................................................................................................................-0.3V to 26V

Peak Transient Voltage (26V Load Dump @ 14V VIN)....................................................................................-0.3V to 40V

VSWPeak Transient Voltage .....................................................................................................................................................54V

C

OSC

, C

Delay

, COMP,V

FB1

, V

FB2

..................................................................................................................................-0.3V to V

LIN

Power Dissipation.............................................................................................................................................Internally Limited

V

LIN

Output Current ........................................................................................................................................Internally Limited

VSWOutput Current .........................................................................................................................................Internally Limited

Output Sink Current ..................................................................................................................................................5mA

ESD Susceptibility (Human Body Model)..............................................................................................................................2kV

ESD Susceptibility (Machine Model).....................................................................................................................................200V

Storage Temperature...................................................................................................................................................-65 to 150¡C

Lead Temperature Soldering: Reflow (SMD styles only) ..........................................60 sec. max above 183¡C, 230¡C peak

RESET

RESETENABLE

Electrical Characteristics: 5V ² V

IN

² 26V and -40¡C ² TJ ² 150¡C, -40¡C ² TA² 85¡C, C

OUT

= 100µF (ESR²8½),

C

Delay

= 0.1µF, R

BIAS

= 64.9k½, C

OSC

= 390 pF, C

COMP

= 0.1µF; unless otherwise specified.

■ General

I

IN

Off Current 6.6V ² VIN² 26V, I

SW

= 0A 2.0 mA

IINOn Current 6.6V ² VIN² 26V, I

SW

= 1.4A 30 70 mA

I

REG

Current I

LIN

= 100mA, 6.6V ² V

REG

² 26V 6 mA

Thermal Limit Guaranteed by design 160 210 ¡C

■ 5V Regulator Section

V

LIN

Output Voltage 6.6V ² V

REG

² 26V, 1mA ² I

LIN

² 100mA 4.9 5.0 5.1 V

Dropout Voltage (V

REG

- V

LIN

) @ I

LIN

= 100mA 1.2 1.5 V

Line Regulation 6.6V ² V

REG

² 26V, I

LIN

= 5mA 5 25 mV

Load Regulation V

REG

= 19V, 1mA ² I

LIN

² 100mA 5 25 mV

Current Limit 6.6V ² V

REG

² 26V 120 mA

DC Ripple Rejection 14V ² V

REG

² 24V 60 75 dB

■ Section

Low Threshold (V

RTL

)V

LIN

Decreasing 4.05 4.25 4.45 V

High Threshold (V

RTH

)V

LIN

Increasing 4.20 4.45 4.70 V

Hysteresis V

RTH

- V

RTL

140 190 240 mV

Active High V

LIN

> V

RTH

, I

RESET

= -25µA V

LIN

- 0.5 V

Active Low V

LIN

= 1V, 10k½ pullup from to V

LIN

0.4 V

V

LIN

= 4V, I

RESET

= 1mA 0.7 V

Delay Invalid WDI 6.25 8.78 11.0 ms

Power On Delay V

LIN

crossing V

RTH

6.25 ms

RESET

RESET

Page 3

3

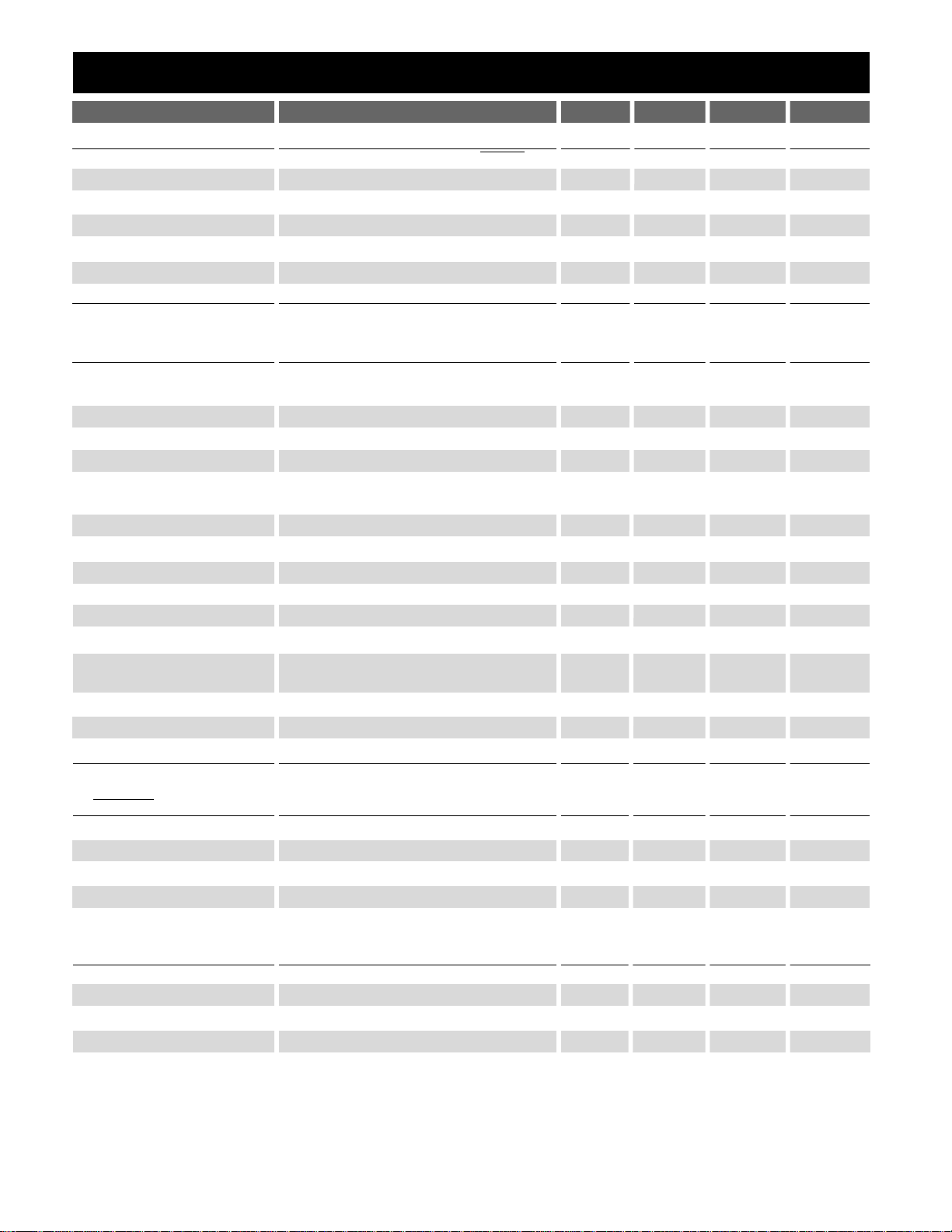

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

CS5112

■ Watchdog Input (WDI)

VIH Peak WDI needed to activate 2.0 V

VIL 0.8 V

Hysteresis Note 1 25 50 mV

Pull-Up Resistor WDI=0V 20 50 100 k½

Low Threshold 6.25 8.78 11.0 ms

Floating Input Voltage 3.5 V

WDI Pulse Width 5µs

■ Switcher Section

Minimum Operating 5.0 V

Input Voltage

Switching Frequency Refer to Figure 1d. 80 95 110 kHz

Switch Saturation Voltage ISW= 1.4A 0.7 1.1 1.6 V

Output Current Limit 1.4 2.5 A

Max Switching Frequency V

SW

= 7.5V with 50½ load, 120 kHz

Refer to Figure 1d.

V

FB1

Regulation Voltage 1.206 1.25 1.294 V

V

FB2

Regulation Voltage 1.206 1.25 1.294 V

V

FB1

, V

FB2

Input Current V

FB1

= V

FB2

= 5V 1 µA

Oscillator Charge Current C

OSC

= 0V 35 40 45 µA

Oscillator Discharge Current C

OSC

= 4V 270 320 370 µA

C

Delay

Charge Current C

Delay

= 0V 35 40 45 µA

Switcher Max Duty Cycle VSW= 5V with 50½ load, 72 85 95 %

V

FB1

= V

FB2

= 1V

Current Sense Amp Gain ISW= 2.3A 7

Error Amp DC Gain 67 dB

Error Amp Transconductance 2700 µA/V

■ Input

VIL 0.8 1.24 V

VIH 1.30 2.0 V

Hysteresis 60 mV

Input Impedance 10 20 40 k½

■ Select Input

VIL (Selects V

FB1

) 4.9 ² V

LIN

² 5.1 0.8 1.25 V

VIH (Selects V

FB2

) 4.9 ² V

LIN

² 5.1 1.25 2.0 V

SELECT Pull-Up SELECT = 0V 10 24 50 k½

Floating Input Voltage 3.5 4.5 V

Note 1: Guaranteed by Design, not 100% tested in production.

ENABLE

RESET

Electrical Characteristics: 5V ² V

IN

² 26V and -40¡C ² TJ ² 150¡C, -40¡C ² TA² 85¡C, C

OUT

= 100µF (ESR²8½),

C

Delay

= 0.1µF, R

BIAS

= 64.9k½, C

OSC

= 390 pF, C

COMP

= 0.1µF; unless otherwise specified.

Page 4

4

Typical Performance Characteristics

0A 20mA 40mA 60mA 80mA 100mA

3.5mA

4.0mA

4.5mA

I

LIN

I

REG

- I

LIN

-30mA

-40mA

0A 0.5A

I

SW

-20mA

-10mA

0A

1.0A 1.5A 2.0A

I

IN

I

SW

0A 0.5A 1.0A 1.5A 2.0A

0.4V

0.0V

0.6V

0.8V

1.2V

1.0V

V

SW

0.2V

1.4V

Package Lead Description

PACKAGE LEAD # LEAD SYMBOL FUNCTION

CS5112

Figure 1a. 5V Regulator Bias Current vs. Load Current. Figure 1b. Supply Current vs. Switch Current.

Figure 1c. Switch Saturation Voltage.

Figure 1d. Oscillator Frequency (kHz) vs. C

OSC

(pF), assuming R

BIAS

=

64.9k½.

24 Lead SO Wide

1V

IN

Supply Voltage.

2, 3 NC No connection.

4V

SW

Collector of NPN power switch for switching regulator section.

5,6,7,8,17,18,19,20 Gnd Connected to the heat removing leads.

9V

FB1

Feedback input voltage 1 (referenced to 1.25V)

10 V

FB2

Feedback input voltage 2 (referenced to 1.25V)

11 SELECT Logic level input that selects either V

FB1

or V

FB2

. An open selects

V

FB2

. Connect to Gnd to select V

FB1

.

12 COMP Output of the transconductance error amplifier.

13 C

OSC

A capacitor connected to Gnd sets the switching frequency.

Refer to Figure 1d.

14 WDI Watchdog input. Active on falling edge.

15 C

Delay

A capacitor connected to Gnd sets the Power On Reset and

Watchdog time.

16 output. Active low if V

LIN

is below the regulation limit.

If watchdog timeout is reached, a reset pulse train is issued.

21 I

BIAS

A resistor connected to Gnd sets internal bias currents as well as

the C

OSC

and C

Delay

charge currents.

22 V

LIN

Regulated 5V output from the linear regulator section.

23 V

REG

Input voltage to the linear regulator and the internal supply circuitry.

24 Logic level input to shut down the switching regulator.

ENABLE

RESETRESET

180

160

140

120

100

80

60

40

Frequency (kHz)

20

0

0

500 1500 2500

1000

C

OSC

2000 3000

(pF)

Page 5

Circuit Description

CS5112

5

The 5V linear regulator consists of an error amplifier,

bandgap voltage reference, and a composite pass transistor.

The 5V linear regulator circuitry is shown in Figure 2.

When an unregulated voltage greater than 6.6V is applied

to the V

REG

input, a 5V regulated DC voltage will be pre-

sent at V

LIN

. For proper operation of the 5V linear regula-

tor, the I

BIAS

lead must have a 64.9k½ pull down resistor to

ground. A 100µF or larger capacitor with an ESR <8½

must be connected between V

LIN

and ground. To operate

the 5V linear regulator as an independent regulator (i.e.

separate from the switching supply), the input voltage

must be tied to the V

REG

lead.

As the voltage at the V

REG

input is increased, Q1is turned

on. Q1provides base drive for Q2which in turn provides

base current for Q3. As Q3is turned on, the output voltage,

V

LIN

, begins to rise as Q3Õs output current charges the out-

put capacitor, C

OUT

. Once V

LIN

rises to a certain level, the

error amplifier becomes biased and provides the appropriate amount of base current to Q1. The error amplifier monitors the scaled output voltage via an internal voltage

divider, R2through R5, and compares it to the bandgap

voltage reference. The error amplifier output or error signal is an output current equal to the error amplifierÕs input

differential voltage times the transconductance of the

amplifier. Therefore, the error amplifier varies the base

current to Q1, which provides bias to Q2and Q3, based on

the difference between the reference voltage and the

scaled V

LIN

output voltage.

The watchdog timer circuitry monitors an input signal

(WDI) from the microprocessor. It responds to the falling

edge of this watchdog signal which it expects to see within

an externally programmable time (see Figure 3).

The watchdog time is given by:

t

WDI

= 1.353 ´ C

DelayRBIAS

Using C

Delay

= 0.1µF and R

BIAS

= 64.9k½ gives a time ranging from 6.25ms to 11ms assuming ideal components. Based

on this, the software must be written so that the watchdog

arrives at least every 6.25ms. In practice, the tolerance of

C

Delay

and R

BIAS

must be taken into account when calculat-

ing the minimum watchdog time (t

WDI

).

Figure 3. Timing diagram for normal regulator operation.

Figure 4. Timing diagram when WDI fails to appear within the preset

time interval, t

WDI

.

V

LIN

WDI

RESET

V

REG

t

POR

A

B

A: Watchdog waiting for

low-going transition on

WDI

50% Duty

Cycle

B: RESET stays low for

t

WDI

time.

Control Functions

5V Linear Regulator

Over

Temperature

Linear

Error

Amplifier

1.25V

V

REG

V

LIN

C

delay

RESET &

Watchdog Timer

Current

Limit

WDI

RESET

Bandgap

Reference

+

-

I

BIAS

R

BIAS

64.9kW

R

1

R

2

R

3

R

4

R

5

C

OUT

= 100mF

ESR < 8W

Q

1

Q

2

Q

3

Figure 2. Block diagram of 5V linear regulator portion of the CS5112.

V

RESET

REG

WDI

V

LIN

t

POR

Normal Operation

Page 6

6

Circuit Description: continued

CS5112

If a correct watchdog signal is not received within the

specified time a reset pulse train is issued until the correct

watchdog signal is received. The nominal reset signal in

this case is a 5 volt square wave with a 50% duty cycle as

shown in Figure 4.

The signal frequency is given by:

f

RESET

=

The Power On Reset (POR) and low voltage use

the same circuitry and issue a reset when the linear output

voltage is below the regulation limit. After V

LIN

rises

above the minimum specified value, remains low

for a fixed period t

POR

as shown in Figure 5.

The POR delay (t

POR

) is given by:

t

POR

= 1.353 ´ C

Delay RBIAS

Figure 5a. The power on reset time interval (t

POR

) begins when V

LIN

rises above 4.45V (typical).

Figure 5b. signal is issued whenever V

LIN

falls below 4.25V

(typical).

The current mode PWM switching voltage regulator contains an error amplifier with selectable feedback inputs, a

current sense amplifier, an adjustable oscillator and a 1.4A

output power switch with antisaturation control. The

switching regulator and external components, connected

in a boost configuration, are shown in Figure 6.

The switching regulator begins operation when V

REG

and

VINare raised above 5 volts. V

REG

is required since the

switching supplyÕs control circuitry is powered through

V

LIN

. VINsupplies the base drive to the switcher output

transistor.

The output transistor turns on when the oscillator starts to

charge the capacitor on C

OSC

. The output current will

develop a voltage drop across the internal sense resistor

(RS). This voltage drop produces a proportional voltage at

the output of the current sense amplifier, which is compared to the output of the error amplifier. The error amplifier generates an output voltage which is proportional to

the difference between the scaled down output boost voltage (V

FB1

or V

FB2

)

and the internal bandgap voltage reference. Once the current sense amplifier output exceeds the

error amplifierÕs output voltage, the output transistor is

turned off.

The energy stored in the inductor during the output transistor on time is transferred to the load when the output

transistor is turned off. The output transistor is turned

back on at the next rising edge of the oscillator. On a cycle

by cycle basis, the current mode controller in a discontinuous mode of operation charges the inductor to the appropriate amount of energy, based on the energy demand of

the load. Figure 7 shows the typical current and voltage

waveforms for a boost supply operating in the discontinuous mode.

NOTES:

1. Refer to Figure 1d to determine oscillator frequency.

2. The switching regulator can be disabled by providing a

logic high at the input.

3. The boost output voltage can be controlled dynamically

by the feedback select input. If select is open, V

FB2

is

selected. If select is low, then V

FB1

is selected.

The current out of V

LIN

is sensed in order to limit excessive power dissipation in the linear output transistor over

the output range of 0V to regulation. Also, the current into

VSWis sensed in order to provide the current limit function in the switcher output transistor.

If the die temperature is increased above 160¡C, either due

to excessive ambient temperature or excessive power dissipation, the drive to the linear output transistor is

reduced proportionally with increasing die temperature.

Therefore, V

LIN

will decrease with increasing die temperature above 160¡C. Since the switcher control circuitry is

powered through V

LIN

, the switcher performance, includ-

ing current limit, will be affected by the decrease in V

LIN

.

Protection Circuitry

ENABLE

Current Mode PWM Switching Circuitry

RESET

RESET

RESET

1

2(t

WDI

)

RESET

V

LIN

4.45V

4.25V

RESET

V

R

V

R

PEAK

LO

t

POR

V

LIN

5V

4.25V

RESET

5V

t

POR

Page 7

7

Application Notes

CS5112

Circuit Description: continued

Figure 6: Block diagram of the 1.4A current mode control switching regulator portion of the CS5112 in a boost configuration.

V

OUT

R

1

V

FB1

V

FB2

R

2

R

3

V

R2

R

EQ

{

Figure 8. Feedback sense

resistor divider connected

between V

OUT

and ground.

-1

V

OUT

V

FB1

This section outlines a procedure for designing a boost switching power supply operating in the discontinuous mode.

Step 1

Determine the output power required by the load.

P

OUT

= I

OUTVOUT

(1)

Step 2

Choose C

OSC

based on the target oscillator frequency with an

external resistor value, R

BIAS

= 64.9k½. (See Figure 1d).

Figure 7: Voltage and current waveforms for boost topology in CS5112.

Step 3

Next select the output voltage feedback sense resistor

divider as follows (Figure 8).

For V

FB1

active, choose a value for R1and then solve for

REQwhere:

REQ=

.

(3a)

For V

FB2

active, find:

V

FB1

= V

OUT

, (3b)

and then calculate R2where:

R2= =

. (3c)

Then find R3, where:

R3= REQ- R2. (3d)

V

FB1

-

V

FB2

V

FB1/REQ

V

R2

I

R2

)

R

EQ

R1+ R

EQ

(

R

1

0

V

SW

V

IN

V

SAT

t

0

I

SW

I

Peak

t

0

I

D

I

Peak

t

V

OUT

Design Procedure for Boost Topology

V

IN

1.4A

V

SW

COMP

V

FB1

V

FB2

SELECT

V

LIN

I

BIAS

C

OSC

Gnd

Bandgap

Reference

Oscillator

+

Switcher Shutdown

Switcher

Error

Amplifier

Current Sense Amplifier

ENABLE

Multiplexer

+

-

+

-

COMP

Base Drive

Logic

R

BIAS

64.9kW

R

S

R

3

R

2

R

1

1.25V

V

OUT

C

OUT

Page 8

8

Application Notes: continued

CS5112

Step 4

Determine the maximum on time at the minimum oscillator frequency and VIN. For discontinuous operation, all of

the stored energy in the inductor is transferred to the load

prior to the next cycle. Since the current through the

inductor cannot change instantaneously and the inductance is constant, a volt-second balance exists between the

on time and off time. The voltage across the inductor during the on cycle is VINand the voltage across the inductor

during the off cycle is V

OUT

- VIN. Therefore:

VINton= (V

OUT-VIN)toff

(4a)

where the maximum on time is:

t

on(max)

Å . (4b)

Step 5

Calculate the maximum inductance allowed for discontinuous operation:

L

(max)

= (5)

where h = efficiency.

Usually h = 0.75 is a good starting point. The ICÕs power

dissipation should be calculated after the peak current has

been determined in Step 6. If the efficiency is less than

originally assumed, decrease the efficiency and recalculate

the maximum inductance and peak current.

Step 6

Determine the peak inductor current at the minimum

inductance, minimum VINand maximum on time to make

sure the inductor current doesnÕt exceed 1.4A.

Ipk=

(6)

Step 7

Determine the minimum output capacitance and maximum ESR based on the allowable output voltage ripple.

C

OUT(min)

=

(7a)

ESR

(min)

=

(7b)

In practice, it is normally necessary to use a larger capacitance value to obtain a low ESR. By placing capacitors in

parallel, the equivalent ESR can be reduced.

Step 8

Compensate the feedback loop to guarantee stability

under all operating conditions. To do this, we calculate the

modulator gain and the feedback resistor network attenuation and set the gain of the error amplifier so that the

overall loop gain is 0dB at the crossover frequency, f

CO

. In

addition, the gain slope should be -20dB/decade at the

crossover frequency.

The low frequency gain of the modulator (i.e. error amplifier output to output voltage) is:

=

Ã

,

(8a)

where

I

pk(max)

=

=

=2.3A.

The V

OUT/VEA

transfer function has a pole at:

fp= 1/(¹R

LoadCOUT

) , (8b)

and a zero due to the output capacitorÕs ESR at:

fz= 1/(2¹ESR C

OUT

). (8c)

Since the error amplifier reference voltage is 1.25V, the

output voltage must be divided down or attenuated

before being applied to the input of the error amplifier.

The feedback resistor divider attenuation is:

.

The error amplifier in the CS5112 is an operational transconductance amplifier (OTA), with a gain given by:

G

OTA

= gmZ

OUT

(8d)

where:

gm = . (8e)

For the CS5112, gm = 2700µA/V typical.

One possible error amplifier compensation scheme is

shown in Figure 9. This gives the error amplifier a gain

plot as shown in Figure 10.

For the error amplifier gain shown in Figure 10, a low frequency pole is generated by the error amplifier output

impedance and C

1

. This is shown by the line AB with a 20dB/decade slope in Figure 12. The slope changes to zero

at point B due to the zero at:

fz= 1/(2¹R4C1). (8f)

Figure 9. RC network used to compensate the error amplifier (OTA).

ÆI

OUT

ÆV

IN

1.25V

V

OUT

(2.4V)/(7)

150m½

V

EA(max)/GCSA

R

S

R

Load

Lf

2

I

pk(max)

V

EA(max)

ÆV

OUT

ÆV

EA

ÆV

ripple

I

pk

I

pk

8fÆV

ripple

V

IN(min)ton(max)

L

(min)

f

SW(min)VIN2(min)ton2(max)

2 P

OUT

/h

]

1

f

SW(min)

[

]

1 -

V

IN(min)

V

OUT(max)

[

V

OUT

R

V

1

FB1

R

2

V

FB2

R

3

1.25V

M

U

X

+

Ð

Error

Amplifier

C

C

2

1

R

4

SELECT

Page 9

9

CS5112

Application Notes: continued

Linear Regulator Output Current vs. Input Voltage

* Subjecting the CS5112 to these conditions will exceed the maximum total power that the part can handle, thereby forcing it into thermal limit.

Figure 10. Bode plot of error amplifier (OTA) gain and modulator gain

added to the feedback resistor divider attenuation.

A pole at point C:

fp= 1/(¹R4C2), (8g)

offsets the zero set by the ESR of the output capacitors.

An alternative scheme uses a single capacitor as shown in

Figure 11, to roll the gain off at a relatively low frequency.

Figure 11. A typical application diagram with external components configured in a boost topology.

Step 9

Finally the watchdog timer period and Power on Reset

time is determined by:

t

Delay

= 1.353 ´ C

DelayRBIAS

. (9)

V

IN

NC

NC

V

SW

Gnd

Gnd

Gnd

Gnd

V

FB1

V

FB2

SELECT

COMP

V

REG

V

LIN

I

BIAS

Gnd

Gnd

Gnd

Gnd

C

Delay

WDI

C

OSC

R

BIAS

= 64.9kW

100mF

ESR<8W

0.1mF

C

COMP

0.33mF

L=33mH

V

IN

C

OUT

88mF

(2)

100kW

946W

7.5kW

R

1

R

2

R

3

C

delay

390pF

C

OSC

CS5112

RESET

ENABLE

(1)

V

OUT

= 18V, Select > 2V

V

OUT

= 16V, Select < 0.8V

MICROPROCESSOR

5V

Pole due to error amplifier

output impedance and C

1

G

0

fz = 1/2pR4C

1

+G

B

A

C

fP = 1/p R

LoadCOUT

error amplifier gain

f

CO

fz = 1/2p ESR C

OUT

fP = 1/pR4C

2

-20dB/dec

-G

Gain (dB)

modulator gain + feedback resistor divider attenuation

Worst Case Switcher Worst Case Switcher

Linear Power Power Available Power Available

V

REG

V

IN

I

LIN

Dissipation (QJA= 55¡C/W) (QJA= 35¡C/W)

(V) (V) (mA) (W) (W) (W)

20 14 25 0.44 0.74 1.42

20 14 50 0.83 0.35 1.03

20 14 75 1.22 * 0.64

20 14 100 1.60 * 0.26

25 14 25 0.60 0.58 1.26

25 14 50 1.11 0.07 0.75

25 14 75 1.62 * 0.24

25 14 100 2.14 * *

Figure 12: The shaded area shows the safe operating area of the CS5112 as a function of I

LIN

, V

REG

, and QJA. Refer to the table below for typical

loads and voltages.

100

75

(mA)

50

LIN

I

25

0

05

QJA = 55°C/W

= 14V

V

IN

Max Total Power = 1.18W

10 20 25

15 30

V

(V)

REG

100

75

(mA)

50

LIN

I

25

0

05

QJA = 35°C/W

V

IN

Max Total Power = 1.86W

= 14V

10 20 25

15 30

V

(V)

REG

Page 10

10

Part Number Description

CS5112EDWF24 24 Lead SO Wide

(internally fused leads)

CS5112EDWFR24 24 Lead SO Wide

(internally fused leads) (tape & reel)

Rev. 4/22/99

Thermal 24 Lead SO Wide

Data (internally fused leads)

R

QJC

typ 9 ûC/W

R

QJA

typ 55 ûC/W

Package Specification

PACKAGE THERMAL DATA

Ordering Information

D

Lead Count Metric English

Max Min Max Min

24 Lead SO Wide 15.60 15.20 .614 .598

(internally fused leads)

PACKAGE DIMENSIONS IN mm (INCHES)

CS5112

© 1999 Cherry Semiconductor Corporation

Cherry Semiconductor Corporation reserves the right to

make changes to the specifications without notice. Please

contact Cherry Semiconductor Corporation for the latest

available information.

Surface Mount Wide Body (DW); 300 mil wide

1.27 (.050) BSC

7.60 (.299)

7.40 (.291)

10.65 (.419)

10.00 (.394)

D

0.32 (.013)

0.23 (.009)

1.27 (.050)

0.40 (.016)

REF: JEDEC MS-013

2.49 (.098)

2.24 (.088)

0.51 (.020)

0.33 (.013)

2.65 (.104)

2.35 (.093)

0.30 (.012)

0.10 (.004)

Loading...

Loading...