Page 1

Features

■ Programmable Fixed

Frequency

■ Programmable FET Non-

overlap

■ Enable Lead

■ 12V Fixed Auxiliary

Supply Control

■ Under and Overvoltage

Shutdown

■ Output Undervoltage

Protection with Timer

■ Master/Slave Clock

Syncing Capability

■ Sync Frequency Range

Detection

■ 80ns PWM Propagation

Delay

■ 20mA 5V Reference

Output

■ Small 24 lead SSOP

Package

■ Controlled Hiccup Mode

Package Options

CS5106

Multi-Feature, Synchronous plus Auxiliary

PWM Controller

CS5106

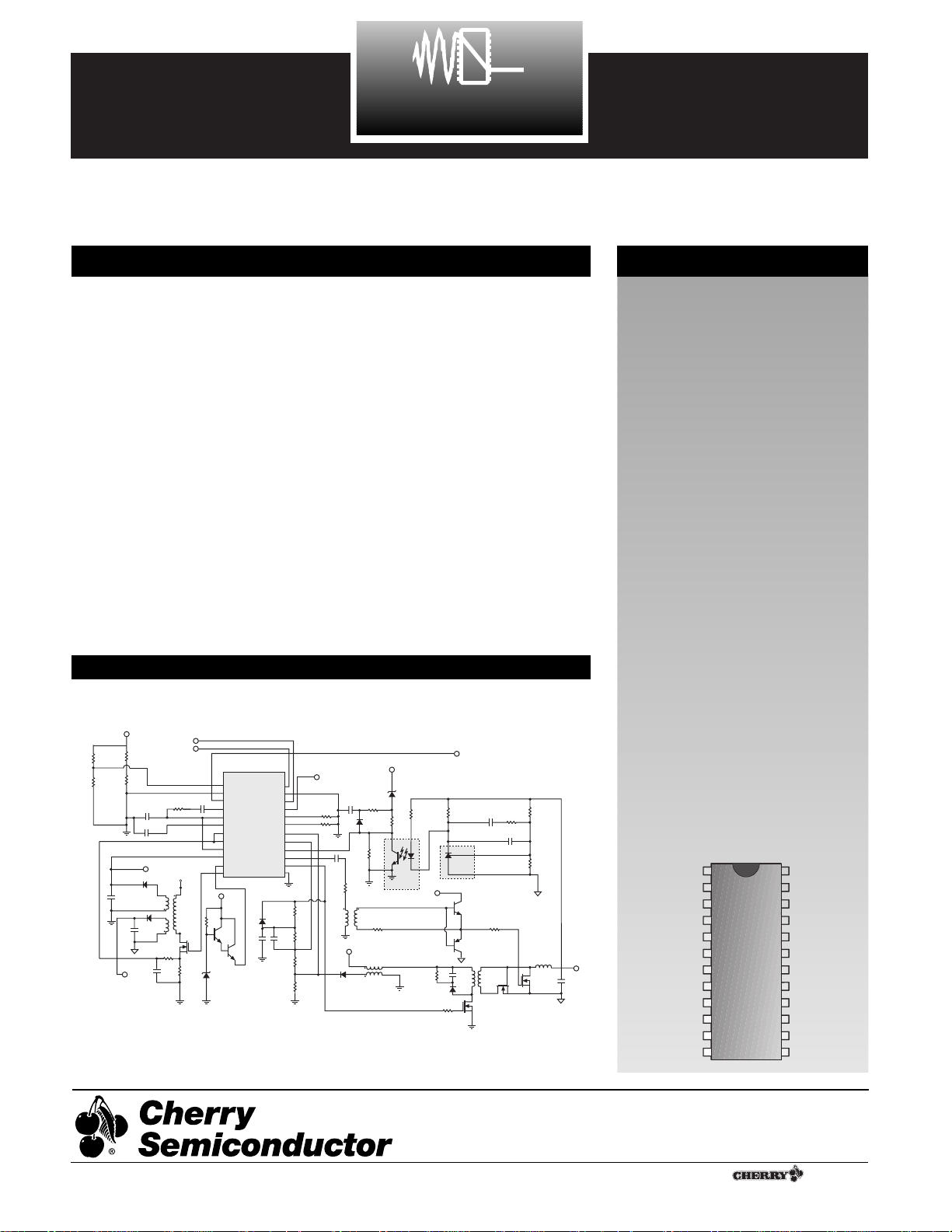

Description

The CS5106 is a fixed frequency,

current mode controller with one

single NFET driver and one dual

FET, synchronous driver. The synchronous driver allows for

increased efficiency of the main isolated power stage and the single

driver allows the designer to develop auxiliary supplies for controller

power as well as secondary side

house keeping. In addition,

because the synchronous drivers

have programmable FET non-overlap, the CS5106 is an ideal controller for soft-switched converter

topologies.

The CS5106 is specifically designed

for isolated topologies where speed,

flexibility, reduced size and

reduced component count are

requirements. The controller contains the following features:

Undervoltage Shutdown,

Overvoltage Shutdown,

Programmable Frequency,

Programmable Synchronous NonOverlap Time, Master/Slave

Clocking with Frequency Range

Detection, Enable, Output

Undervoltage Protection with

Timer, 20mA 5V Output, 80ns

PWM propagation delay, and

Controlled Hiccup Mode.

The CS5106 has junction temperature and supply ranges of -40ûC to

125ûC and 9V to 16V respectively

and is available in the 24 lead SSOP

package.

Applications Diagram

24 Lead SSOP

1

UVSD

OVSD

OAM

OAOUT

V

5REF

OUVDELAY

I

LIM1

RAMP1

V

FB1

V

SS

V

CC

GATE1

ENABLE

PROGRAM

SYNC

IN

SYNC

OUT

FADJ

DLYSET

I

LIM2

RAMP2

V

FB2

V

DD

GATE2B

GATE2

Rev. 10/27/98

48V to 3.3V Forward Converter with Synchronous Rectifiers

Cherry Semiconductor Corporation

2000 South County Trail, East Greenwich, RI 02818

Tel: (401)885-3600 Fax: (401)885-5786

Email: info@cherry-semi.com

Web Site: www.cherry-semi.com

A Company

¨

V

IN

C5

V

C1

C2

V

D1

D2

AUXS

SYNC

ENABLE

R4

AUXP

V

T1

R5

C7

IN

CS5106

UVSD

ENABLE

PROGRAM

OVSD

V

SYNC

5REF

C3

IN

V

R8

Q1

R6

IN

D6

OAM

OA

OUVDELAY

I

LIM1

RAMP1

V

V

V

GATE1

Q2

SYNC

OUT

FADJ

OUT

DLYSET

I

LIM2

RAMP2

V

FB1

FB2

GATE2B

SS

GATE2

CC

V

D3

C10

C9

R27

R1

R2

R3

C4

V

R13

AUXP

OUT

D5

C6

R7

R20

R15

D8

R14

C8

CNY17-4

T4

R26

V

IN

T3

D4

R23

SYNC

IN

R24

R25

DD

R9

R10

R11

R12

V

5REF

R21

R18

R17

C13

R19

L1

Q5

Q4

R16

C14

TL431

V

AUXS

Q7

Q6

T2

C11

D7

Q3

R22

V

MAIN

C12

1

Page 2

CS5106

2

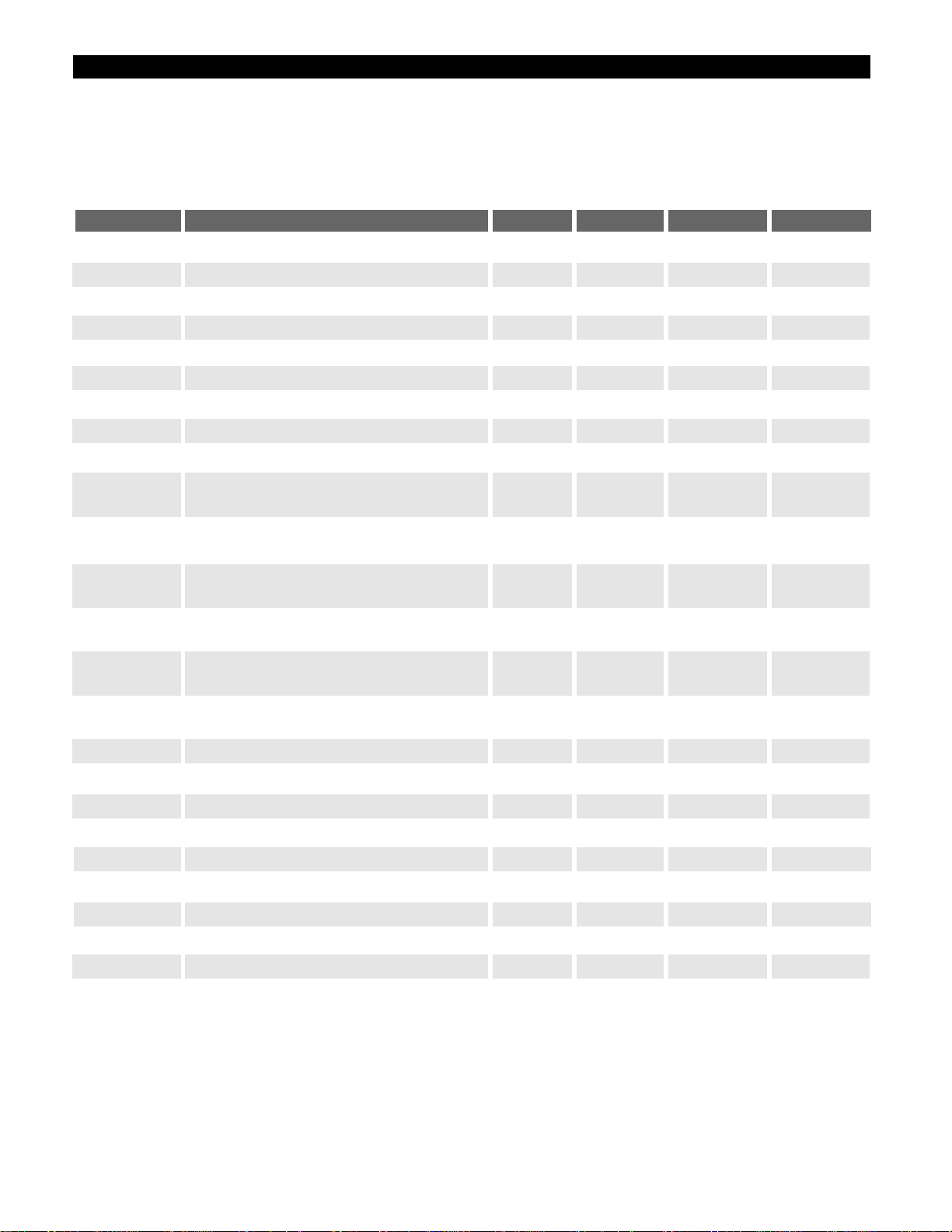

Absolute Maximum Ratings

Lead Symbol Lead Name

V

MAX

V

MIN

I

SOURCE

I

SINK

UVSD Undervoltage Shutdown Input 6V -0.3V 1mA N/A

OVSD Overvoltage Shutdown Input 6V -0.3V 1mA N/A

V

5REF

5V Reference Output 6V -0.3V 150mA 25mA

OAM Error Amp Minus Input 6V -0.3V 250µA 1.2mA

OAOUT Error Amp Output 6V -0.3V 300µA 100mA

OUVDELAY Output Overcurrent Timer Capacitor 6V -0.3V 15µA N/A

I

LIM1

Auxiliary Primary Side Current Limit Input 6V -0.3V 10µA N/A

RAMP1 Auxiliary Primary Side Current Ramp Input 6V -0.3V 10µA N/A

V

FB1

Auxiliary Voltage Feedback Input 6V -0.3V 5µA 100µA

V

SS

Bootstrapped Power Input 20V -0.3V 2µA 0.5A Peak

300mA DC

V

CC

Main Power Input 20V -0.3V See Note 1 0.5A Peak

300mA DC

GATE1 Auxiliary FET Driver Output 20V -0.3V 0.5A Peak 0.5Peak

100mA DC 100mA DC

Gnd Ground 0V 0V 0.5A Peak N/A

300mA DC

GATE2 Synchronous FET Driver Output 20V -0.3V 0.5A Peak 0.5APeak

100mA DC 100mA DC

GATE2B Synchronous FET Driver Output B 20V -0.3V 0.5A Peak 0.5A Peak

100mA DC 100mA DC

V

FB2

Synchronous Voltage Feedback Input 6V -0.3V 10µA 100µA

RAMP2 Synchronous Primary Side Current Ramp Input 6V -0.3V 10µA N/A

I

LIM2

Synchronous Primary Side Current Limit Input 6V -0.3V 10µA N/A

DLYSET Gate Non-Overlap Programming Input 2.5V -0.3V 125µA N/A

FADJ Frequency Programming Input 2.5V -0.3V 125µA N/A

SYNC

OUT

Clock Master Output 6V -0.3V 50mA 100mA

SYNC

IN

Clock Slave Input 6V -0.3V N/A 1mA

PROGRAM Enable Programming Input 16V -0.3V 30µA N/A

ENABLE Enable Input 16V -0.3V 300µA N/A

Note 1: Current out of V

CC

is not limited. Care should be taken to prevent shorting VCCto Ground.

Operating Junction Temperature, TJ..................................................................................................................................... 150¡C

Operating Temperature Range, TA...............................................................................................................................-40 to 85¡C

Storage Temperature Range, TS...................................................................................................................................-65 to 150¡C

ESD (Human Body Model).........................................................................................................................................................2kV

Lead Temperature Soldering: Reflow (SMD styles only).............................................60 sec. max above 183¡C, 230¡C peak

Page 3

CS5106

3

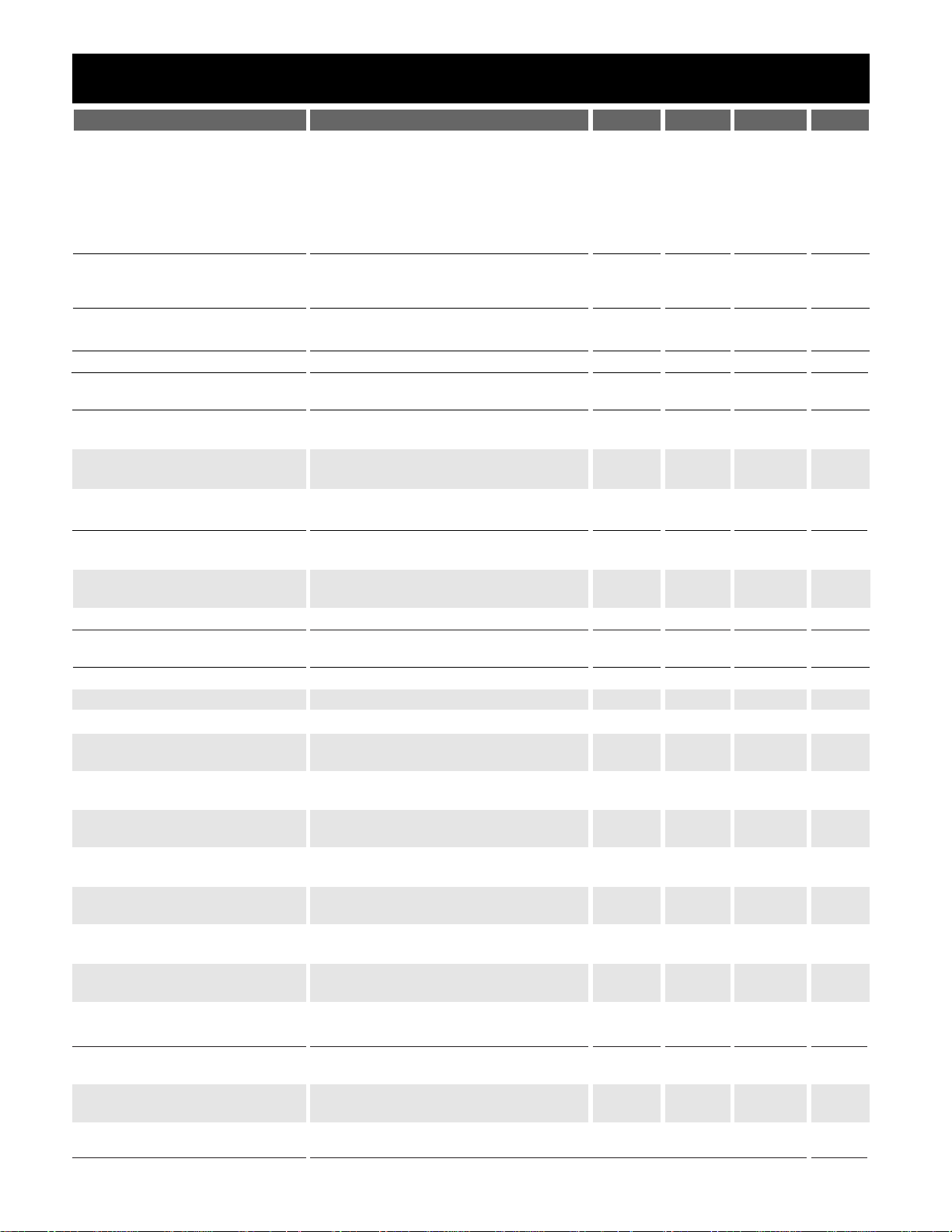

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Electrical Characteristics: TJ = -40¡C to 125¡C, V

SS

= 9 to 16V, V

5REFILOAD

= 2mA, SYNC

OUT

Free Running, unless other-

wise specified. For All Specs: UVSD=6V, OVSD = 0V, ENABLE = 0V, I

LIM(1,2)

= 0,V

FB(1,2)

= 3V,R

FADJ

= R

DLYSET

= 27.4k½.

■ V

SS

Supply Current Measure current into VSSwhen 16.00 23.00 mA

V

5REFILOAD

=0mA. 9V ² VSS² 13V.

Measure current into VSSwhen 16.00 25.00 mA

V

5REFILOAD

=0mA. 13V < VSS² 16V.

Measure current into VSSwhen 16.00 30.00 mA

V

5REFILOAD

=0mA. 16V < VSS² 20V.

■ Low V

CC

Supply Current Float VSS. Set VCC=7V & measure 1.50 3.50 mA

VCCcurrent while V

5REFILOAD

=0mA.

■ V

SS

TO VCCDIODE

Diode ON Voltage Measure VSS- VCC. 0.20 0.75 1.00 V

■ Reference

5V Internal Voltage Reference Measure V

REF

voltage when 4.85 5.00 5.15 V

I

REF

=0 and I

REF

=20 mA.

V

REF

OK Threshold Adjust V

REF

from 4.8V-4.0V until 4.30 4.55 4.70 V

PWM1,2 goes low.

■ Low V

CC

Lockout

VCCTurnon Threshold Voltage VCCincreasing until ICC> 3.5mA 7.00 7.25 7.50 V

V

5REFILOAD

= 0mA

VCCTurnoff Threshold Voltage VCCdecreasing until ICC< 3.5mA 6.30 6.70 7.10 V

V

5REFILOAD

= 0mA

Hysteresis Turnon - Turnoff 0.40 0.55 0.70 V

■ Clock

Operating Frequency1 Measure frequency from SYNC

OUT

. 485.0 512.0 540.0 kHz

SYNCINInput Impedance Measure input impedance. 7.00 15.00 k½

SYNC

OUT

Output Low Voltage R

LOAD

= 2k½ to V

5REF

1.00 1.50 V

SYNC

OUT

Output High R

LOAD

= 2k½ to Gnd 3.50 4.20 V

Voltage

SYNCINDetect Frequency Verify SYNC

OUT

= SYNCIN, 425.0 555.0 kHz

R

LOAD

= 2k½ to Gnd

Max. Low SYNC Rej. Frequency Verify SYNC

OUT

= FCLK when 340.0 kHz

R

LOAD

= 2k½ to Gnd.

Min. High SYNC Rej. Frequency Verify SYNC

OUT

= FCLK when 690 kHz

R

LOAD

= 2k½ to Gnd.

SYNCINInput Threshold Functional Testing 0.90 1.85 2.90 V

Voltage Verify FCLK from 1.0V to 2.8V.

Main PWM Clock Pulse (GBD) - CLPH1

Width One Shot Pulse Width 80.0 100.0 120.0 ns

Aux PWM Clock Pulse (GBD) -CLPH2

Width One Shot Pulse Width 80.0 100.0 120.0 ns

■ Bias Supply Error Amplifier

Output Low Voltage V

SS

> 12.6V. Measure OAOUT 43.0 85.0 mV

voltage when sinking 1.0 mA.

Output High Voltage V

SS

< 11.4V. Measure OAOUT 4.55 4.75 V

voltage when sourcing 150µA.

Output High Source Current V

SS

< 11.4V. Measure OAOUT source 150.0 225.0 300.0 µA

current when OAOUT = 0.5V.

Page 4

CS5106

4

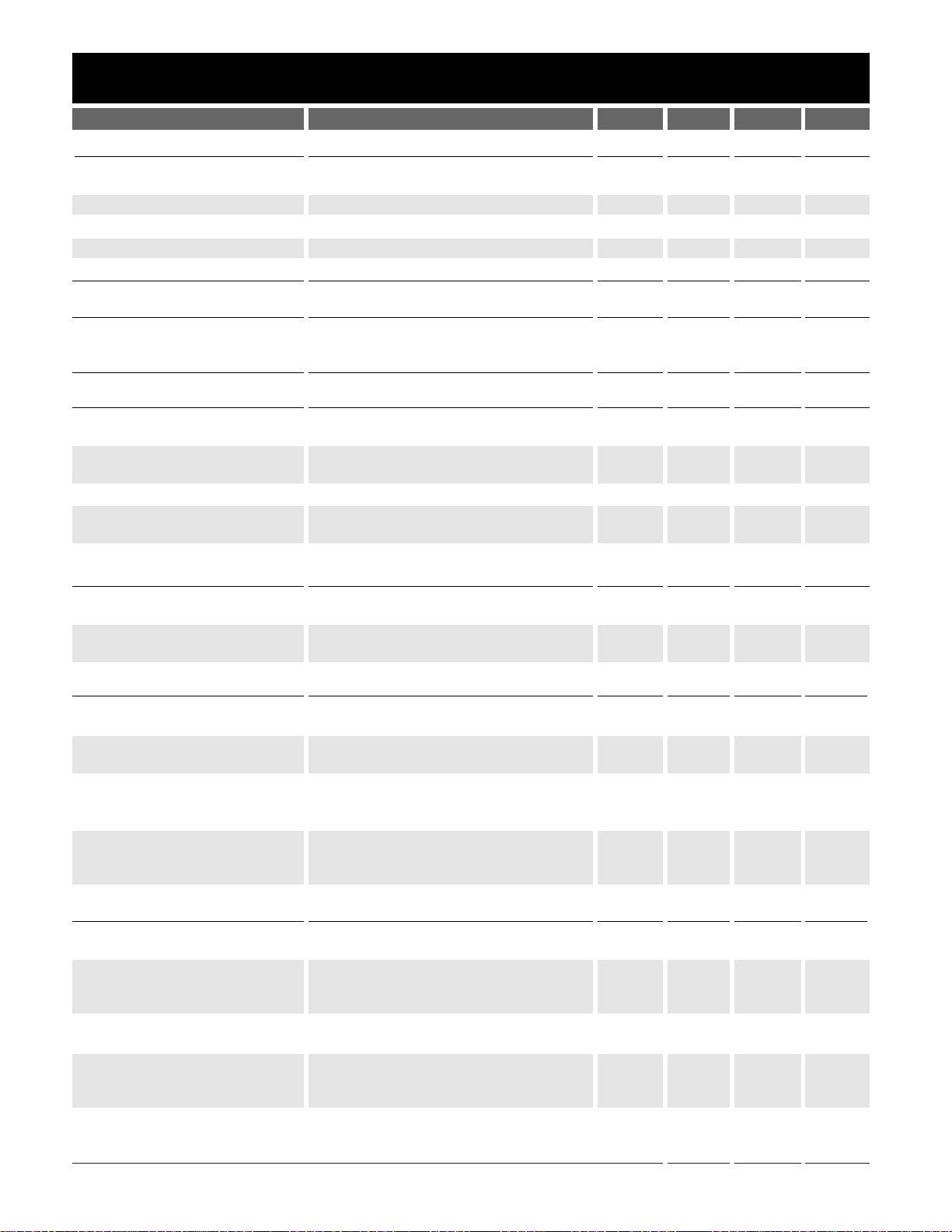

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Electrical Characteristics: TJ = -40¡C to 125¡C, V

SS

= 9 to 16V, V

5REFILOAD

= 2mA, SYNC

OUT

Free Running, unless other-

wise specified. For All Specs: UVSD=6V, OVSD = 0V, ENABLE = 0V, I

LIM(1,2)

= 0,V

FB(1,2)

= 3V,R

FADJ

= R

DLYSET

= 27.4k½.

■ Bias Supply Error Amplifier: continued

Output Low Sink Current V

SS

> 12.6V. Measure OAOUT sink 3.0 20.0 50.0 mA

current when OAOUT = 2.5V.

VSSSet Point Adjust VSSuntil OAOUT goes low. 11.60 12.25 12.80 V

Large Signal Gain (GBD) 15.00 V/mV

Unity Gain Bandwidth (GBD) 1.00 MHz

Common Mode Input Range (GBD) 1.00 2.00 V

■ V

SS

Voltage

VSSReset Voltage Toggle ENABLE between Gnd & VCC,

then adjust VSSfrom 2.0V-0.8V until

OAOUT goes high. 1.00 1.40 1.80 V

■ Undervoltage Lockout

UVSD Turn On Adjust UVSD from 4.7V-5.3V 4.80 5.00 5.10 V

Threshold Voltage until GATE 1, 2 goes high.

UVSD Turn Off Threshold Adjust UVSD from 5.1V-4.3V 4.45 4.70 4.95 V

Voltage until GATE 1, 2 goes low.

Hysteresis Turnon - Turnoff 0.20 0.27 0.40 V

UVSD Input Bias Current Set UVSD=0V. Measure Current 0.20 0.50 µA

out of UVSD lead.

■ Overvoltage Lockout

OVSD Threshold Voltage Adjust OVSD from 4.7V-5.3V 4.85 5.00 5.15 V

until GATE 1, 2 goes low.

OVSD Input Bias Current Set OVSD=0V. Measure Current out 0.20 0.50 µA

of OVSD lead.

■ ENABLE & PROGRAM

ENABLE Lead Output Current Measure current out of 100.0 266.0 500.0 µA

ENABLE when ENABLE = 0V.

PROGRAM Lead Output Measure current out of 20.0 60.0 100.0 µA

Current PROGRAM when PROGRAM = 0V.

PROGRAM Threshold ENABLE = Gnd. Adjust 1.20 1.40 1.60 V

Voltage PROGRAM from 1.0V - 1.8V

until GATE 1, 2 goes high.

ENABLE Threshold Voltage PROGRAM = Gnd. 1.20 1.40 1.60 V

Adjust ENABLE from 1.0V - 1.8V

until GATE 1, 2 goes high.

■ Output Undervoltage Delay

OUVDELAY Charging Set OUVDELAY = 1V, V

FB1

= 4.4V 7.50 10.00 12.50 µA

Current Measure OUVDELAY I

CHARGE

.

OUVDELAY Latchoff Voltage Toggle ENABLE between Gnd & VCC, 4.80 5.00 5.20 V

then adjust OUVDELAY from

4.7V - 5.3V until GATE 1, 2, goes low.

OUVDELAY Set Current OUVDELAY = VOCLO + 50mV 0.50 1.00 mA

Measure current into OUVDELAY.

V

FB1

Charge Threshold VSS=1V. Toggle ENABLE between 4.05 4.22 4.40 V

Gnd & VCC, adjust V

FB1

from 3.8V - 4.6V

until GATE 1, 2 goes low.

V

FB2

Charge Threshold V

SS

= 1V. Toggle ENABLE between 3.90 4.15 4.35 V

Gnd & VCC, adjust V

FB2

from 3.8V - 4.6V

until GATE 1, 2 goes low.

Page 5

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

CS5106

5

Electrical Characteristics: TJ = -40¡C to 125¡C, V

SS

= 9 to 16V, V

5REFILOAD

= 2mA, SYNC

OUT

Free Running, unless other-

wise specified. For All Specs: UVSD=6V, OVSD = 0V, ENABLE = 0V, I

LIM(1,2)

= 0,V

FB(1,2)

= 3V,R

FADJ

= R

DLYSET

= 27.4k½.

■ Current Limit Circuits

I

LIM1

Current Limit Threshold Adjust I

LIM1

from 1.0V - 1.3V until 1.16 1.24 1.30 V

Voltage GATE1 goes low.

I

LIM1

Short Circuit Threshold Adjust I

LIM1

from 1.30V - 1.50V until 1.35 1.44 1.51 V

Voltage GATE1 skips 2-cycles with reference

to SYNC

OUT.

I

LIM1

Input Bias Current Set I

LIM1

=0V. Measure current 0.50 5.00 µA

out of I

LIM1

lead.

I

LIM2

Current Limit Adjust I

LIM2

from 1.0V - 1.3V until 1.16 1.24 1.30 V

Threshold V GATE2 goes low.

I

LIM2

Short Circuit Adjust I

LIM2

from 1.30V - 1.50V until 1.35 1.44 1.51 V

Threshold Voltage GATE2 skips 2-cycles with reference

to SYNC

OUT

.

I

LIM2

Input Bias Current Set I

LIM 2

= 0V. Measure current out 0.50 5.00 µA

of I

LIM2

lead.

■ Voltage Feedback Control

RAMP1 Offset Voltage V

FB1

=0V. Adjust RAMP1 from 0V - 0.3V 0.08 0.13 0.20 V

until GATE1 goes low. Measure V

RAMP1

.

RAMP1 Input Bias Current Set RAMP1 = 0V. Measure Current 0.50 5.00 µA

out of RAMP1 lead.

RAMP2 Offset Voltage V

FB2

= 0V. Adjust RAMP2 from 0.08 0.13 0.20 V

0V-3V until GATE2 goes low.

Measure V

RAMP2

.

RAMP2 Input Bias Current Set RAMP2 = 0V. Measure Current

out of RAMP2 lead. 0.50 5.00 µA

V

FB1

Input Impedance Measure input impedance. 60.0 120.0 220.0 k½

V

FB2

Input Impedance Measure Input impedance. 60.0 120.0 220.0 k½

■ Gate1,2,2B Output Voltages V

SS

= 12V. V

CC

= V

SS

- V

DON

GATE1 Low State PROGRAM = 0V. Measure GATE1 0.15 0.80 V

voltage when sinking 1mA.

GATE2 Low State PROGRAM = 0V. Measure GATE2 0.18 0.80 V

voltage when sinking 1mA.

GATE2B Low State PROGRAM = 0V. Measure GATE2B 0.18 0.80 V

voltage when sinking 1mA.

GATE2B High State Measure V

CC

- GATE2B voltage 1.65 2.00 V

when sourcing 1mA.

GATE2 High State Measure VCC- GATE2 voltage 1.65 2.00 V

when sourcing 1mA.

GATE1 High State Measure V

CC

- GATE1 voltage 1.65 2.00 V

when sourcing 1mA.

■ Propagation Delays

I

LIM1

Delay to Output GATE1 Measure delay from I

LIM1

going 80.0 120.0 ns

high to GATE1 going low.

I

LIM2

Delay to Output GATE2 Measure delay from I

LIM2

going 80.0 100.0 ns

high to GATE2 going low.

RAMP1 Delay to Output GATE1 Measure delay from RAMP1 going 80.0 115.0 ns

high to GATE1 going low.

RAMP2 Delay to Output GATE2 Measure delay from RAMP2 going 80.0 100.0 ns

high to GATE2 going low.

Page 6

Package Lead Description

CS5106

6

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Electrical Characteristics: TJ = -40¡C to 125¡C, V

SS

= 9 to 16V, V

5REFILOAD

= 2mA, SYNC

OUT

Free Running, unless other-

wise specified. For All Specs: UVSD=6V, OVSD = 0V, ENABLE = 0V, I

LIM(1,2)

= 0,V

FB(1,2)

= 3V,R

FADJ

= R

DLYSET

= 27.4k½.

PACKAGE LEAD # LEAD SYMBOL FUNCTION

■ GATE 2, 2B Non-Overlap Delay

GATE2 Turn-on Delay Measure delay from GATE2B going low 20.0 45.0 70.0 ns

from GATE2B @1.7V to GATE2 going high @1.7V.

GATE2B Turn-on Delay Measure delay from GATE2 going low 20.0 45.0 70.0 ns

from GATE2 @1.7V to GATE2B going high @1.7V.

■ GATE 1, 2, 2B Rise & Fall Times V

SS

=12V,VCC=VSS-V

DON

GATE1 Rise Time Measure GATE1 Rise Time from 50.0 80.0 ns

90% to 10%. C

LOAD

= 150pF.

GATE1 Fall Time Measure GATE1 Fall Time from

10% to 90%. C

LOAD

= 150pF. 30.0 60.0 ns

GATE2 Rise Time Measure GATE2 Rise Time from

90% to10%. C

LOAD

= 50pF. 50.0 80.0 ns

GATE2 Fall Time Measure GATE2 Fall Time from

10% to 90%. C

LOAD

= 50pF. 15.0 30.0 ns

GATE2B Rise Time Measure GATE2B Rise Time from

90% to10%. C

LOAD =

50pF. 50.0 80.0 ns

GATE2B Fall Time Measure GATE2B Fall Time from

10% to 90%. C

LOAD

= 50pF. 15.0 30.0 ns

1 UVSD Undervoltage shutdown lead. Typically this lead is connected through a

resistor divider to the main high voltage (VIN) line. If the voltage on this lead

is less than 5V then a fault is initiated such that GATE1, GATE2 and GATE2B

go low.

2 OVSD Overvoltage shutdown lead. Typically this lead is connected through a resistor

divider to the main high voltage (VIN) line. If the voltage on this lead exceeds

5V then a fault is initiated such that GATE1, GATE2 and GATE2B go low.

3V

5REF

5V reference output lead. Capable of 20mA nominal output. If this lead falls

to 4.5V, a fault is initiated such that GATE1, GATE2 and GATE2B go low.

4 OAM Auxiliary error amplifier minus input. This lead is compared to 1.2V nominal

on the auxiliary error amp plus lead and represents the VSSvoltage divided

by ten.

5 OAOUT Auxiliary error amplifier output lead. Source current 300µA max.

6 OUVDELAY Output undervoltage timing capacitor lead. If the controlled output voltages

of either the main or the auxiliary supply are such that either V

FB1

or V

FB2

is

greater that 4.1V nominal, then capacitor from OUVDELAY to ground will

begin charging. If the over voltage duration is such that the OUVDELAY

voltage exceeds 5V, then a fault will be initiated such that GATE1, GATE2

and GATE2B will go low.

7I

LIM1

Pulse by pulse over current protection lead for the auxiliary PWM. A voltage

exceeding 1.2V nominal on I

LIM1

will cause GATE1 to go low. A voltage

exceeding 1.4V nominal on I

LIM1

will cause GATE1 to go low for at least two

clock cycles.

8 RAMP1 Current Ramp Input Lead for the Auxiliary PWM. A voltage which is linear

with respect to current in the primary side of the auxiliary trans former is

usually represented on this lead. A voltage exceeding V

FB1

- 0.13 on RAMP1

will cause GATE1 to go low.

Page 7

CS5106

7

PACKAGE LEAD # LEAD SYMBOL FUNCTION

Package Lead Description: continued

9V

FB1

Voltage Feedback Lead for the Auxiliary PWM. A voltage which represents

the auxiliary power supply output voltage is fed to this lead. A voltage less

than RAMP1+0.13 on V

FB1

will cause GATE1 to go low.

10 V

SS

VSSpower/feedback input lead. See VCCfor description of power operation.

In addition, this lead is fed to a divide by ten resistor divider and compared to

1.2V nominal at the positive side of the error amplifier.

11 V

CC

V

CC

power input lead. This input runs off a Zener referenced supply until

VSS> VCC. Then an internal diode which runs between VSSand VCCturns on

and all main power is derived from VSS.

12 GATE1 Auxiliary PWM gate drive lead. This output normally drives the FET which

drives the auxiliary transformer.

13 Gnd Ground lead.

14 GATE2 Synchronous PWM gate drive lead. This output normally drives the FET

which drives the main transformer.

15 GATE2B Synchronous PWM gate drive lead. This output normally drives the FET for

the gate drive transformer used for synchronous rectification.

16 V

FB2

Voltage feedback lead for the synchronous PWM. A voltage which represents

the main power supply output voltage is fed to this lead. A voltage less than

RAMP2+0.13 on V

FB2

will cause GATE2 to go low and GATE2B to go high.

17 RAMP2 Current ramp input lead for the synchronous PWM. A voltage which is linear

with respect to current in the primary side of the main trans former is usually

represented on this lead. A voltage exceeding V

FB2

- 0.13 on RAMP2 will

cause GATE2 to go low and GATE2B to go high.

18 I

LIM2

Pulse by pulse over current protection lead for the synchronous PWM. A voltage exceeding 1.2V nominal on I

LIM2

will cause GATE2 to go low and GATE2B

to go high. A voltage exceeding 1.4V nominal on I

LIM2

will cause GATE2 to go

low and GATE2B to go high for at least two clock cycles.

19 DLYSET GATE2, GATE2B non-overlap time adjustment lead. A 27k½ resistor from

DLYSET to ground sets the non-overlap time to 45ns nominal.

20 FADJ Frequency adjustment lead. A 27k½ resistor from FADJ to ground sets the

clock frequency to 512kHz nominal.

21 SYNC

OUT

Clock output lead. This is a 50% duty cycle, 1V to 5V pulse whose rising edge

is in phase with GATE1. This signal can be used to synchronize other power

supplies.

22 SYNC

IN

Clock synchronization lead. The internal clock frequency can be adjusted

+10%, -15% by the onset of positive edges of an external clock occurring on the

SYNCINlead. If the external clock frequency is out side the internal clock frequency by +25%, -35% the external clock is ignored and the internal clock free

runs.

23 PROGRAM ENABLE programming input. See ENABLE for programming states. PRO-

GRAM has at least 20µA min. of available source current.

24 ENABLE PWM enable input. If PROGRAM is HIGH then a LOW on ENABLE will

allow GATE1, GATE2 and GATE2B to switch. If PROGRAM is LOW then a

HIGH on ENABLE will allow GATE1, GATE2 and GATE2B to switch. If

ENABLE is left floating, it will pull up to a HIGH level. ENABLE has at least

100µA (min) of available source current.

Page 8

CS5106

8

Block Diagram

OUVDELAY

Theory of Application

Powering the IC

The IC has one supply, V

CC

, and one Ground lead. If VSSis

used for a bootstrapped supply the diode between VSSand

VCCis forward biased, and the IC will derive its power

from VSS. The internal logic monitors the supply voltage,

VCC. During abnormal operating conditions, all GATE

drivers are held in a low state. The CS5106 requires 1.5mA

nominal of startup current.

Startup

Assume the part is enabled and there are no over voltage

or under voltage faults present. Also, assume that all auxiliary and main regulated output voltages start at 0V. An

8V, Zener referenced supply is typically applied to VCC.

When VCCexceeds 7.5V, the 5V reference is enabled and

the OSC begins switching. If the V

5REF

lead is not exces-

sively loaded such that V

5REF

< 4.5V nominal, ÔV

REF

OKÕ

goes ÔhighÕ and ÔRUN1Õ will go ÔhighÕ, releasing GATE1

from its low state. After GATE1 is released, it begins

switching according to conditions set by the auxiliary control loop and the auxiliary supply, VSSbegins to rise.

When VSS> VCC+ V(D1), P1 turns on and ÔRUN2Õ goes

ÔhighÕ, releasing GATE2 and GATE2B from their low state.

GATE2 and GATE2B begin switching according to conditions set by the main control loop and the main regulated

output begins to rise. See startup waveforms in Figure 1.

Soft Start

Soft start for the auxiliary power supply is accomplished

by placing a capacitor between OAOUT and Ground. The

error amplifier has 200µA of nominal of source current and

is ideal for setting up a Soft Start condition for the auxiliary

regulator. Care should be taken to make sure that the soft

start timing requirements are not in conflict with any transient load requirements for the auxiliary supply as large

capacitors on OAOUT will slow down the loop response.

Also, the Soft start capacitor must be chosen such that during start or restart, both outputs will come into regulation

before the OUVDELAY timer trips. Soft Start for the main

supply is accomplished by charging soft start capacitor C6

through D5 and R7 at start up. After the main supply has

come into regulation C6 continues to charge and is disconnected from the feedback loop by D8.

Theory of Operation

OAOUT

OAM

V

V

V

5REF

RAMP1

V

GATE1

Gnd

I

SS

FB1

LIM1

V

+

V

VREF

=5V

2R

RUN1

RSFF

Q

R

F4

S

Reset

Dominant

G14

CC

5V

V

-

C2

Output

Undervoltage

Timer

V

4.5

R

+

G5

G6

Comparator

REFOK

-

C9

+

V

V

REF

Aux.PWM

Comparator

G10

Aux. Current

Limit Comparator

CLOCK

Skip2B

Skip Two

Clock Pulses

Aux. 2nd Current

Threshold Comparator

RUN 2

OK

C10

C12

SET

C16

C4

C7

-

+

-

+

+

-

RSFF

RQ

F1

S

Set Dominant

+

-

1.4V

-

V

+

1.2V

V

1.4V

V

V

REFOK

Fault Latch

RSFF

QR

RUN 1

T

PERIOD

+

V

-

C11

+

-

C13

+

CLOCK

Skip Two

Clock Pulses

SET

-

C17

+

Main 2nd Current

Threshold Comparator

F2

Reset

Dominant

+

1.5V

A2

-

Main PWM

Comparator

G11

Main Current

Limit Comparator

Skip2B

S

CLK1

CLK2

IFSET

V

G18

SS

SYNC

OSC

SYNC

R

Dominant

G15

G4

IDSET

RSFF

R

F3

S

Reset

+

FREQ

C1

-

-

C3

+

-

C5

+

-

C8

+

TFF

Q

T1

G1

G3

ENABLE

V

Restart

SS

Comparator

+

A2

-

1.4V

V

IN

OUT

G7

Under Voltage

Comparator

Over Voltage

Comparator

Sync Detection

G8

Comparator

FREQ

TOO HIGH

TOO LOW

1.4V

5V

V

V

PROGRAM

ENABLE

UVSD

OVSD

SYNC

IN

SYNC

OUT

DYLSET

+

0.13V

V

2R

RUN2

G12

G16

1.7V

DRIVER

DRIVER

+

Q

Q

G17

G13

C14

RUN2

C15

DELAY

+

-

DELAY

-

+

FADJ

RAMP2

V

FB2

GATE2

GATE2B

V

I

LIM2

Aux. Error Amp

+

A1

D1

P1

CC

+

START

STOP

V

DRIVER

-

7.4/6.8V

0.13V

-

100k

45k

RUN1

G9

5k

ENABLE

V

+

V

1.2V

REF

Page 9

CS5106

9

Figure 1: Startup waveforms.

Voltage and Current Ramp PWM Comparator Inputs

(V

FB1,2

and RAMP1,2 leads)

C10 and C11 are the PWM comparators for the auxiliary

and main supplies. The feedback voltage (VFB) is divided

by three and compared with a linear, voltage representation of the current in the primary side of the transformer

(RAMP). When the output of the feedback comparator

goes ÔhighÕ, a reset signal is sent to the PWM flip-flop and

the GATE driver is driven ÔlowÕ. A 130mV offset on the

RAMP leads allows the drivers to go to 0% duty cycle in

the presence of light loads.

Feedback Voltage for GATE1 Driver (V

FB1

)

Typically the output of the auxiliary error amplifier (A1) is

tied to V

FB1

. The VSSoutput is programmed to 12V by a

10:1 resistive divider on the negative input of the error

amplifier and a fixed 1.2V reference on the positive input

of the error amplifier.

Pulse by Pulse Over Current Protection and Hiccup

Mode (I

LIM1,2

leads)

C12 and C13 are the pulse by pulse current limit comparators for the auxiliary and main supplies. When the current

in the primary side of the transformer increases such that

the voltage across the current sense resistor exceeds 1.2V

nominal, the output of the current limit comparator goes

ÔhighÕ and a reset signal is sent to the PWM flip-flop and

the GATE driver is driven ÔlowÕ.

C16 and C17 are the second threshold, pulse by pulse current limit comparators for the auxiliary and main supplies.

If the current in the primary side of the transformer

increases so quickly that the current sense voltage is not

limited by C12 or C13 and the voltage across the current

sense resistor exceeds 1.4V, the second threshold comparator will trip a delay circuit and force the GATE driver stage

to go low and stay low for the next two clock cycles.

Undervoltage and Overvoltage Thresholds

C5 and C8 are the undervoltage and overvoltage detection

comparators. Typically, these inputs are tied across the

middle resistor in a three resistor divider with the top

resistor to VINand bottom resistor to Ground. The under

voltage comparator has 200mV of built in hysteresis with

respect to a direct input on the UVSD lead. The under volt-

age comparator has its positive input referenced to 5V

while the over voltage comparator has its negative input

referenced to 5V. The output of both comparators are

ORed at (G4) with the over current and enable inputs. The

output of G4 feeds the input to the fault latch (F2).

PROGRAM and ENABLE Leads

The PROGRAM lead controls the polarity of the ENABLE

lead. If the PROGRAM lead is ÔhighÕ or floating, the GATE

outputs will go low if the ENABLE input is tied ÔhighÕ or

floating. If the PROGRAM lead is tied low, the GATE outputs will go low if the ENABLE input is tied ÔlowÕ. If the

part is then enabled after switching the outputs low, the

part will restart according to the procedure outlined in the

ÒStartupÓ section.

FAULT Logic

If a V

REF

, UVSD or OVSD fault occurs at any time, G4

resets the fault latch (F2). RUN1 goes low and all gate

drivers cease switching and return to their ÔlowÕ state.

When RUN1 goes low, the output of the auxiliary op-amp

(A1) discharges the soft start capacitor and holds it low

while RUN1 is low. If the fault condition is removed before

the OUVDELAY timer is tripped, the IC will restart the

power supplies when VSS< 1.4V. If the OUVDELAY timer

trips, the power supply must be restarted as explained in

the following section.

Output Undervoltage Delay Timer for the Main and

Auxiliary Regulated Outputs

C7 and C4 are the output under voltage monitor comparators for the auxiliary and main supplies. If a regulated output drops such that its associated VFBvoltage exceeds 4.1V,

the output undervoltage monitor comparator goes ÔhighÕ

and the OUVDELAY capacitor begins charging from 0V. A

timing relation is set up by a 10µA nominal current source,

the OUVDELAY capacitor and a 5V fault threshold at the

input of C2 (see Figure 2). If any regulated output drops

and stays low for the entire charge time of the OUVDELAY

capacitor, a fault is triggered and all GATE drivers will go

into a low state.

Once this fault is triggered, the IC will restart the power

supplies only if the OUVDELAY fault is reset and ENABLE

or UVSD is toggled while VSS< 1.4V. To reset the OUVDELAY fault, both the VFBinputs must be less than 4.1V. In

the application circuit shown, V

FB1

is brought low by

OAOUT when RUN1 stops the oscillators. V

FB2

is brought

low when V

AUXP

bleeds down and the V

FB2

opto-isolator is

no longer powered.

Figure 2: OUVDELAY Time vs. OUVDELAY Capacitance

7.5V

Theory of Application: continued

V

V

REF,VREF(OK)

CC

,RUN1

CLK1

GATE1

V

FB1

RAMP1

V

RUN2

CLK2

GATE2

GATE2B

V

FB2

RAMP2

SS

VSS > V

CC

1000

100

10

TIME (ms)

1

0.1

0.01

0.1 10

1 100 1000

CAPACITANCE (nF)

Page 10

FADJ and DLYSET Leads

Amplifier A2 and transistor N3 create a current source follower whose output is FADJ. An external resistor from

FADJ to ground completes the loop. The voltage across the

resistor is set by a buffered, trimmed, precision reference.

In this fashion, an accurate current is created which is used

to charge and discharge an internal capacitor thereby creating an oscillator with a tight frequency tolerance. For FADJ

resistor value selection, see Figure 3. Transistor N2 is in

parallel with N3 and is used to created an independent current across the resistor from DLYSET to ground. This current is used to program the GATE non-overlap delay

blocks in the main PWM drivers. For DLYSET resistor

value selection, see Figure 4.

Figure 3: SYNC

OUT

Frequency vs. FADJ Resistors

Figure 4: GATE Non-Overlap Time vs. DLYSET Resistance

Oscillator

The oscillator generates two clock signals which are 180

degrees out of phase with respect to time. One clock signal

feeds the main driver and the other feeds the auxiliary

driver. Because the drivers are never turned on at the same

time, ground noise and supply noise is minimized. The

clock signals are actually 100ns pulse spikes. These spikes

create a narrow driver turn-on window. This narrow window prevents the driver from spurious turn on in the middle of a clock cycle. The oscillator can be synchronized by

an external clock (slave) or drive the clocks of other con-

trollers (master). See Figure 5 for the relationship between

SYNC, CLK, and GATE waveforms.

Figure 5: SYNC, GATE and CLOCK waveforms.

SYNCINand SYNC

OUT

Leads

Multiple supplies can be synchronized to one supply by

using the SYNC leads. The SYNCINand SYNC

OUT

pulses

are always 180 degrees out of phase. The SYNCINinput is

always in phase with the clock signal for the main driver

and the SYNC

OUT

output is always in phase with the clock

signal for the auxiliary driver. If the IC is being used as a

slave, the incoming frequency must be within +10%, -20%

of the programmed frequency set by its own FADJ resistor.

If the frequency on the SYNCINlead is outside the internal

frequency by +25%, -35%, the SYNCINinput will be

ignored. If the SYNC signal stops while the power supplies

are in synchronized operation, the synchronized supplies

will stop and restart free running. If the SYNCINsignal

drifts out of frequency specification while the power supplies are in synchronized operation, the synchronized supplies will begin to free run without restarting.

Slope Compensation

DC-DC converters with current mode control require slope

compensation to avoid instability at duty cycles greater

than 50%. A slope is added to the current sense waveform

(or subtracted from the voltage waveform) that is equal to

a percentage (75% typical) of the down slope of the inductor current. In the application diagram shown, the bootstrap (flyback) transformer inductance can be chosen so

that the duty cycle never exceeds 50% and therefore does

not require slope compensation. The buck indicator in the

forward converter would typically be chosen to work in

continuous conduction mode with a maximum duty cycle

of 50-60% and would require slope compensation. Slope

compensation is accomplished as follows: R9 and C9 form

a ramp waveform rising each time GATE 2 turns on. C9 is

discharged through D3 to the same level each cycle regardless of duty cycle. R10 and R11 are chosen to control the

amount of slope compensation. C10 provides filtering for

noise and turn-on spikes. To calculate the required slope

compensation, calculate the buck indicator down current

and the corresponding voltage slope at the current sense

resistor - R12.

The buck inductor down slope is:

Inductor_Slope =

)

A

µs

(

V

OUT

+ V

Q5

L1(µH)

SYNC

OUT

CLK1

GATE1

CLK2

GATE2

GATE2B

SYNC

IN

Time (ns)

Resistance (kW)

80

70

60

50

40

30

20

10

0

01051520253035404550

Theory of Application: continued

CS5106

10

1100

1000

900

800

700

600

500

400

Frequency (kHz)

300

200

100

0

010203040

Resistance kW

60

50

70

80

Page 11

CS5106

11

The equivalent down slope at the current sense resistor for

this application circuit is:

Slope @ R12 = Inductor_Slope ´´´R12

After choosing R9 and C9 to generate a ramp with a time

constant of about 5 times the oscillator period, R10 and R11

can be chosen for the voltage at RAMP2 to be 1.75 of the

voltage across R12.

Synchronous Rectification

Synchronous rectification was chosen to reduce losses in

the forward converter. Improvements in efficiency will be

most significant in low voltage, medium and high current

converters where improvement in conduction loss offsets

any added losses for gate drive.

In the application circuit Q4 is turned on and off by the forward transformer. Q5 is turned on and off through pulse

transformer T4 and the gate driver formed by Q6 and Q7.

Because Q4 and Q5 are driven through different types of

components, differences in propagation delay must be considered. The DLYSET resistor should be chosen to avoid

shoot-through or excessive off time.

Gate Drive Capability

All GATE drive outputs have nominal peak currents of

0.5A. See Figures 6 and 7 for typical rise and fall times.

Figure 6: Typical GATE2, 2B switching times.

Figure 7: Typical GATE1 switching times.

Design Considerations

The circuit board should utilize high frequency layout

techniques to avoid pulse width jitter and false triggering

of high impedance inputs. Ground plane(s) should be

employed. Signal grounds and power grounds should be

run separately. Portions of the circuit with high slew rates

or current pulses should be segregated from sensitive

areas. Shields and decoupling capacitors should be used as

required.

Special care should be taken to prevent coupling between

the SYNC leads and the surrounding leads. Depending on

the circuit board layout and component values, decoupling

capacitors or reduction in resistor values might be required

to reduce noise pick-up on the FADJ and DLYSET resistors.

Decoupling capacitors or active pull-up/down might be

required to prevent false triggering of the ENABLE and

PROGRAM leads.

Time (ns)

Load Capacitance (pF)

60

50

40

30

20

10

0

50

Rise Time

Fall Time

70

1500500 1000 2000200

Time (ns)

Load Capacitance (pF)

70

60

50

40

30

20

10

0

Rise Time

Fall Time

50 100 500 1000 2000200

)

V

µs

(

NP

T3

NS

T3

NS

T2

NP

T2

Theory of Application: continued

Page 12

12

Thermal Data 24 Lead SSOP

R

QJC

typ 23 ûC/W

R

QJA

typ 117 ûC/W

Rev. 10/27/98 © 1999 Cherry Semiconductor Corporation

Package Specification

PACKAGE DIMENSIONS IN mm (INCHES)

D

Lead Count Metric English

Max Min Max Min

24 Lead SSOP 8.50 7.90 .335 .311

PACKAGE THERMAL DATA

CS5106

Ordering Information

Part Number Description

CS5106LSW24 24 Lead SSOP

CS5106LSWR24 24 Lead SSOP (tape & reel)

Cherry Semiconductor Corporation reserves the right to

make changes to the specifications without notice. Please

contact Cherry Semiconductor Corporation for the latest

available information.

Seating Plane

0.65 (.026) BSC

0.38 (.015)

0.22 (.009)

D

0.25 (.010)

0.05 (.002)

1.88 (.074)

1.62 (.064)

2.13 (.084) MAX

1.03 (.041)

0.77 (.030)

8.20 (.323)

7.40 (.291)

0.20 (.008)

0.09 (.004)

5.60 (.220)

5.00 (.197)

See

DETAIL A

Parting Line

DETAIL A

REF: JEDEC MO-150

SSOP (SW); 5.3mm Body

Loading...

Loading...