Page 1

The CS403 is a linear regulator specially designed as a post regulator.

The CS403 provides low noise, low

drift, and high accuracy to

improve the performance of a

switching power supply. It is ideal

for applications requiring a highly

efficient and accurate linear regulator. The active RESET makes the

device particularly well suited to

supply microprocessor based systems. The PNP-NPN output stage

assures a low dropout voltage

without requiring excessive supply

current. Its features include low

dropout (1V typically) and low

supply drain (4mA typical with

I

OUT

= 500mA).

The CS403 design optimizes supply rejection by switching the

internal reference from the supply

input to the regulator output as

soon as the nominal output voltage

is reached.

1

Features

■ 5V ±5% Output Voltage

■ Low Drift

■ High Efficiency

■ Short Circuit Protection

■ Active Delayed Reset

■ Noise Immunity on Reset

■ 750mA Output Current

Package Options

5 Lead TO-220

Tab (Gnd)

1

CS403

5V, 750mA Linear Regulator

with RESET

CS403

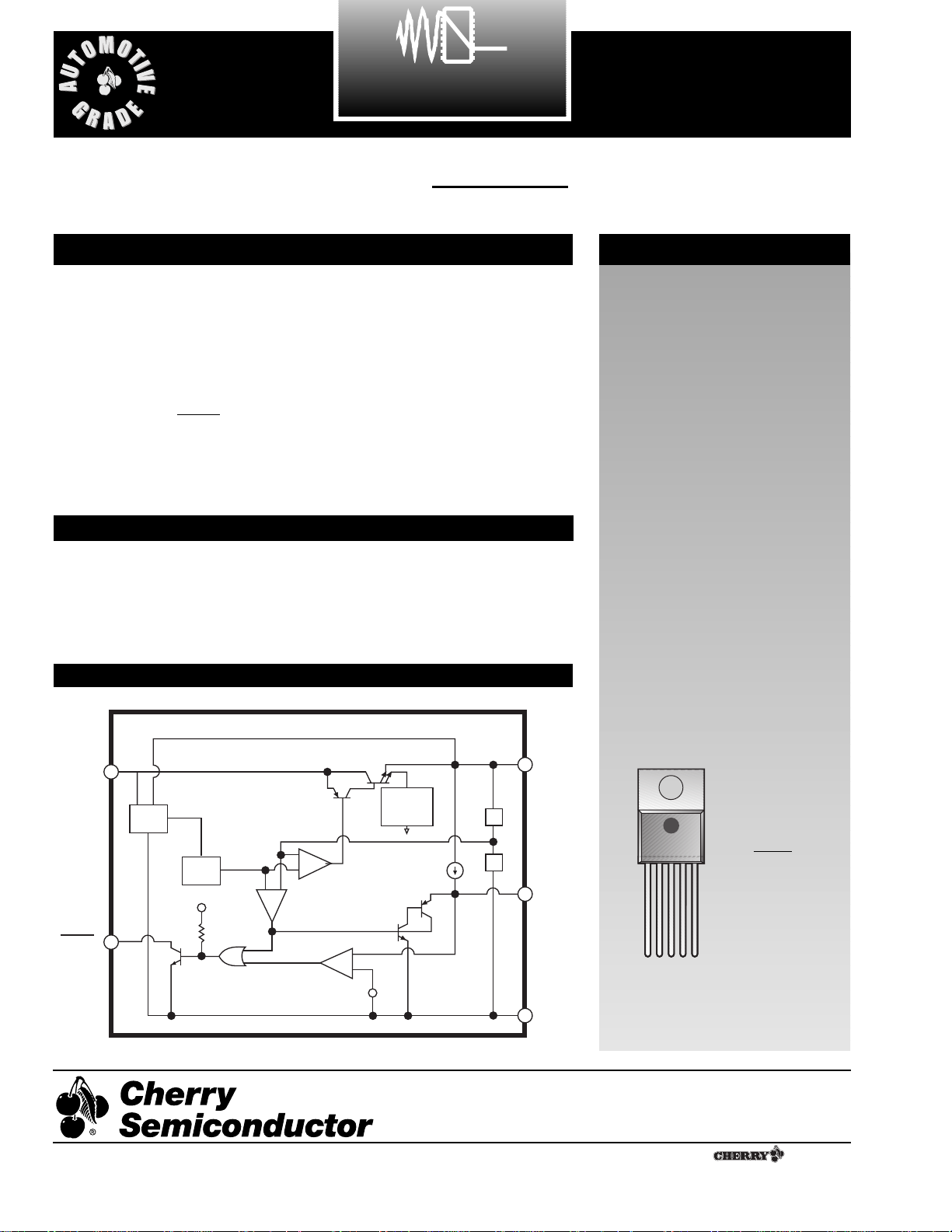

Block Diagram

Absolute Maximum Ratings

Forward Input Voltage ..................................................................................18V

Operating Junction Temperature, T

J

..............................................-40 to 150ûC

Storage Temperature........................................................................-55 to 150ûC

Lead Temperature Soldering

Wave Solder (through hole styles only)..........10 sec. max, 260¡C peak

Description

1. V

IN

2. RESET

3. Gnd

4. Delay

5. V

OUT

Rev. 2/18/98

Cherry Semiconductor Corporation

2000 South County Trail, East Greenwich, RI 02818

Tel: (401)885-3600 Fax: (401)885-5786

Email: info@cherry-semi.com

Web Site: www.cherry-semi.com

A Company

¨

V

IN

RESET

Start

REF

TO V

OUT

+-

Comparator

+

-

Error Amp

Low Voltage

INHIBIT

Comparator

Delay

V

OUT

Output

Current

Limit

I

CHARGE

SCR

Latch

-

+

V

CMP

Delay

Gnd

Page 2

2

CS403

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Electrical Characteristics : Refer to the test circuit, -40¡C ² T

C

² 125¡C, -40 ² TJ² 150¡C, 7V ² VIN² 10V unless otherwise specified

td = Cdx V

DTC/Ich

= C

Delay

x 2.105(typical)

where:

t

d

= Time delay

C

d

= Value of external charging capacitor (see test circuit).

V

DTC

= Delay threshold charge

I

ch

= Reset delay capacitor charging current.

Output Voltage, V

OUT

VIN= 8.5V, I

OUT

= 250mA

TJ= 25¡C 4.95 5.00 5.05 V

100mA ² I

OUT

² 750mA 4.85 5.00 5.15

Operating Input Voltage 100 to 750mA -0.75 18.0 V

Load Regulation 100mA ² I

OUT

² 750mA, VIN= 8.5V 30 100 mV

Dropout Voltage I

OUT

= 750mA 1.4 1.8 V

Quiescent Current I

OUT

= 0mA 3 4 mA

I

OUT

= 750mA 5 25 mA

PSRR I

OUT

-250mA f = 120Hz 70 dB

C

OUT

= 10µF, VIN= 8.5V±V

pp

Output Short Circuit Current 1 A

Reset Output Voltage IR= 1.6mA 1.0 ² V

OUT

² 4.75V 0.08 0.40 V

Reset Output Leakage Current V

OUT

in regulation 0 50 µA

Delay Time for Reset Output Cd= 100nF 10 20 30 ms

Reset Threshold: V

RTH

V

OUT

Increasing V

OUT

-0.04 V

V

RTL

V

OUT

Decreasing 4.75 V

Threshold Hysteresis 10 50 mV

Delay, V

DTC

Charge 3.7 4.0 4.4 V

Delay, V

DTD

Discharge 3.1 3.5 3.9 V

Delay Hysteresis, V

DH

200 500 1000 mV

Reset Delay Capacitor 10 20 40 µA

Charging Current, I

CH

Reset Delay Capacitor 0.6 1.2 V

Discharge Voltage, V

DIS

Package Lead Description

PACKAGE LEAD # LEAD SYMBOL FUNCTION

5 Lead TO-220

1V

IN

Input voltage.

2 CMOS compatible output lead. goes low whenever V

OUT

falls out of regulation.

3 Gnd Ground connection.

4 Delay Timing capacitor for function.

5V

OUT

Regulated output voltage, 5V (typ).

RESET

RESETRESET

Page 3

0

Output Current (mA), I

OUT

Dropout Voltage (V)

1.2

1.0

0.8

0.6

0.4

0.2

0.0

100 200 300 400 500

TA = -40ûC

TA = 25ûC

-40

Junction Temperature (ûC), T

J

V

OUT

(V)

5.02

4.95

5.01

5.00

4.99

4.98

4.97

4.96

0 40 80 120 150

I

OUT

= 250mA

3

CS403

Typical Performance Characteristics

10.0

0.0

0.0

V

IN

Supply Current (mA)

V

OUT

VO

IQ

1.5

2.5

3.5

4.5

5.5

2.0 4.0 6.0 8.0

0.0

6.0

10.0

14.0

18.0

22.0

Output Voltage vs. Junction Temperature

Dropout Voltage vs. Output Current Over Temperature

Output Voltage vs. V

IN

, I

Q

RESET

(1) - No Delay Capacitor.

(2) - With Delay Capacitor.

(3) - Max. Reset Voltage (<1.0V)

(1)

(2)

(2)

V

RT(ON)

V

OUT

(3)

V

RT(OFF)

V

DH

V

DTD

V

DTC

Delay

V

RL

V

RH

V

DIS

T

Delay

Reset Circuit Waveform

Page 4

The CS403 function is very precise, has hysteresis

on both the and Delay comparators, a latching

Delay capacitor discharge circuit, and operates down to

1V.

The circuit output is an open collector type with

ON and OFF parameters as specified. The output

NPN transistor is controlled by the two circuits described

(see Block Diagram).

This circuit monitors output voltage, and when output

voltage is below the specified minimum, causes the

output transistor to be in the ON (saturation) state.

When the output voltage is above the specified level, this

circuit permits the output transistor to go into the

OFF state if allowed by the reset Delay circuit.

This circuit provides a programmable (external capacitor)

delay on the output lead. The Delay lead provides

source current to the external delay capacitor only when

the Low Voltage Inhibit circuit indicates that output voltage is above V

RT(ON)

. Otherwise, the Delay lead sinks current to ground (used to discharge the Delay capacitor).

The discharge current is latched ON when the output voltage is below V

RT(OFF)

, or when the voltage on the Delay

capacitor is above V

DIS

. In other words, the Delay capacitor is fully discharged any time the output voltage falls

out of regulation, even for a short period of time. This feature ensures a controlled pulse is generated following detection of an error condition. The circuit allows

the output transistor to go to the OFF (open) state

only when the voltage on the Delay lead is higher than

V

DIS

.

RESET

RESET

RESET

Reset Delay Circuit

RESET

RESET

Low Voltage Inhibit Circuit

RESET

RESET

RESET

RESET

4

CS403

Application Notes

The output or compensation capacitor helps determine

three main characteristics of a linear regulator: start-up

delay, load transient response and loop stability.

The capacitor value and type should be based on cost,

availability, size and temperature constraints. A tantalum

or aluminum electrolytic capacitor is best, since a film or

ceramic capacitor with almost zero ESR, can cause instability. The aluminum electrolytic capacitor is the least

expensive solution, but, if the circuit operates at low temperatures (-25¡C to -40¡C), both the value and ESR of the

capacitor will vary considerably. The capacitor manufacturers data sheet usually provides this information.

The value for the output capacitor C

OUT

shown in the test

and applications circuit should work for most applications, however it is not necessarily the optimized solution.

To determine an acceptable value for C

OUT

for a particular

application, start with a tantalum capacitor of the recommended value and work towards a less expensive alternative part.

Step 1: Place the completed circuit with a tantalum capacitor of the recommended value in an environmental chamber at the lowest specified operating temperature and

monitor the outputs with an oscilloscope. A decade box

connected in series with the capacitor will simulate the

higher ESR of an aluminum capacitor. Leave the decade

box outside the chamber, the small resistance added by

Stability Considerations

Test Circuit

C1*

100nF

V

IN

Gnd

Delay

V

OUT

CS403

C2**

C

OUT

=10mF to

100mF

100nF

C

d

RESET

C1* is required if the regulator is far from the power source filter.

C

2

** is required for stability

Circuit Description

Page 5

5

the longer leads is negligible.

Step 2: With the input voltage at its maximum value,

increase the load current slowly from zero to full load

while observing the output for any oscillations. If no oscillations are observed, the capacitor is large enough to

ensure a stable design under steady state conditions.

Step 3: Increase the ESR of the capacitor from zero using

the decade box and vary the load current until oscillations

appear. Record the values of load current and ESR that

cause the greatest oscillation. This represents the worst

case load conditions for the regulator at low temperature.

Step 4: Maintain the worst case load conditions set in step

3 and vary the input voltage until the oscillations increase.

This point represents the worst case input voltage conditions.

Step 5: If the capacitor is adequate, repeat steps 3 and 4

with the next smaller valued capacitor. A smaller capacitor will usually cost less and occupy less board space. If

the output oscillates within the range of expected operating conditions, repeat steps 3 and 4 with the next larger

standard capacitor value.

Step 6: Test the load transient response by switching in

various loads at several frequencies to simulate its real

working environment. Vary the ESR to reduce ringing.

Step 7: Remove the unit from the environmental chamber

and heat the IC with a heat gun. Vary the load current as

instructed in step 5 to test for any oscillations.

Once the minimum capacitor value with the maximum

ESR is found, a safety factor should be added to allow for

the tolerance of the capacitor and any variations in regulator performance. Most good quality aluminum electrolytic

capacitors have a tolerance of ± 20% so the minimum

value found should be increased by at least 50% to allow

for this tolerance plus the variation which will occur at

low temperatures. The ESR of the capacitor should be less

than 50% of the maximum allowable ESR found in step 3

above.

The maximum power dissipation for a single output regulator (Figure 1) is:

P

D(max)

= {V

IN(max)

- V

OUT(min)

}

I

OUT(max)

+ V

IN(max)IQ

(1)

where:

V

IN(max)

is the maximum input voltage,

V

OUT(min)

is the minimum output voltage,

I

OUT(max)

is the maximum output current, for the applica-

tion, and

IQis the quiescent current the regulator consumes at

I

OUT(max)

.

Once the value of P

D(max)

is known, the maximum permis-

sible value of R

QJA

can be calculated:

R

QJA

=

(2)

The value of R

QJA

can then be compared with those in

the package section of the data sheet. Those packages

with R

QJA

's less than the calculated value in equation 2

will keep the die temperature below 150¡C.

In some cases, none of the packages will be sufficient to

dissipate the heat generated by the IC, and an external

heatsink will be required.

Figure 1: Single output regulator with key performance parameters

labeled.

A heat sink effectively increases the surface area of the

package to improve the flow of heat away from the IC and

into the surrounding air.

Each material in the heat flow path between the IC and the

outside environment will have a thermal resistance. Like

series electrical resistances, these resistances are summed

to determine the value of R

QJA

.

R

QJA

= R

QJC

+ R

QCS

+ R

QSA

(3)

where

R

QJC

= the junctionÐtoÐcase thermal resistance,

R

QCS

= the caseÐtoÐheatsink thermal resistance, and

R

QSA

= the heatsinkÐtoÐambient thermal resistance.

R

QJC

appears in the package section of the data sheet. Like

R

QJA

, it is a function of package type. R

QCS

and R

QSA

are

functions of the package type, heatsink and the interface

between them. These values appear in heat sink data

sheets of heat sink manufacturers.

Heat Sinks

150¡C - T

A

P

D

Calculating Power Dissipation

in a Single Output Linear Regulator

Application Notes

CS403

I

V

IN

IN

Regulator

Control

Features

}

Smart

I

Q

I

OUT

V

OUT

Page 6

Part Number Description

CS403GT5 TO-220 Straight

CS403GTVA5 TO-220 Vertical

CS403GTHA5 TO-220 Horizontal

6

Rev. 2/18/98

CS403

Ordering Information

Thermal Data TO-220

R

QJC

typ 4.1 ûC/W

R

QJA

typ 50 ûC/W

Package Specification

PACKAGE THERMAL DATA

PACKAGE DIMENSIONS IN mm(INCHES)

© 1999 Cherry Semiconductor Corporation

Cherry Semiconductor Corporation reserves the

right to make changes to the specifications without

notice. Please contact Cherry Semiconductor

Corporation for the latest available information.

5 Lead TO-220 (T) Straight

2.87 (.113)

2.62 (.103)

6.93(.273)

6.68(.263)

9.78 (.385)

10.54 (.415)

1.02(.040)

0.63(.025)

1.83(.072)

1.57(.062)

0.56 (.022)

0.36 (.014)

2.92 (.115)

2.29 (.090)

1.40 (.055)

1.14 (.045)

4.83 (.190)

4.06 (.160)

6.55 (.258)

5.94 (.234)

14.22 (.560)

13.72 (.540)

1.02 (.040)

0.76 (.030)

3.71 (.146)

3.96 (.156)

14.99 (.590)

14.22 (.560)

5 Lead TO-220 (TVA) Vertical

1.68

(.066) typ

1.70 (.067)

7.51 (.296)

1.78 (.070)

4.34 (.171)

0.56 (.022)

0.36 (.014)

1.40 (.055)

1.14 (.045)

4.83 (.190)

4.06 (.160)

14.99 (.590)

14.22 (.560)

2.92 (.115)

2.29 (.090)

.94 (.037)

.69 (.027)

8.64 (.340)

7.87 (.310)

6.80 (.268)

10.54 (.415)

9.78 (.385)

2.87 (.113)

2.62 (.103)

6.55 (.258)

5.94 (.234)

3.96 (.156)

3.71 (.146)

5 Lead TO-220 (THA) Horizontal

0.81(.032)

1.70 (.067)

6.81(.268)

1.40 (.055)

1.14 (.045)

5.84 (.230)

6.60 (.260)

6.83 (.269)

0.56 (.022)

0.36 (.014)

10.54 (.415)

9.78 (.385)

6.55 (.258)

5.94 (.234)

3.96 (.156)

3.71 (.146)

1.68

(.066)

TYP

14.99 (.590)

14.22 (.560)

2.77 (.109)

2.29 (.090)

2.92 (.115)

4.83 (.190)

4.06 (.160)

2.87 (.113)

2.62 (.103)

Loading...

Loading...