Page 1

CRF-22010-TB

© Cree, Inc. 2003 Specifications subject to change without notice

Rev 1.01 - March 28, 2003 http://www.cree.com/

Evaluation Board for CRF-22010

Version A (Narrowband)

Features

• Ready-to-Go RF Amplifier

• Requires Two Power Supplies

• Externally Adjustable Gate Bias Voltage

• Solderless Transistor Changeout

• Includes Heat Sink, Fan, and Wiring Harness

• Designed for Narrowband Operation

Description

Cree’s CRF-22010-TB-A is a complete 10 watt RF single band power amplifier. The evaluation board is pretuned

for a specified frequency (generally between 1.8 and 2.2 GHz) and is supplied with CRF-22010 silicon carbide

MESFETs in the 101 style flange-mount package. The CRF-22010-TB-A requires a positive 48 VDC drain power

supply and a negative adjustable gate power supply (capable of providing up to -15 VDC) for operation. This board

will assist the designer in testing and evaluating the CRF-22010.

1

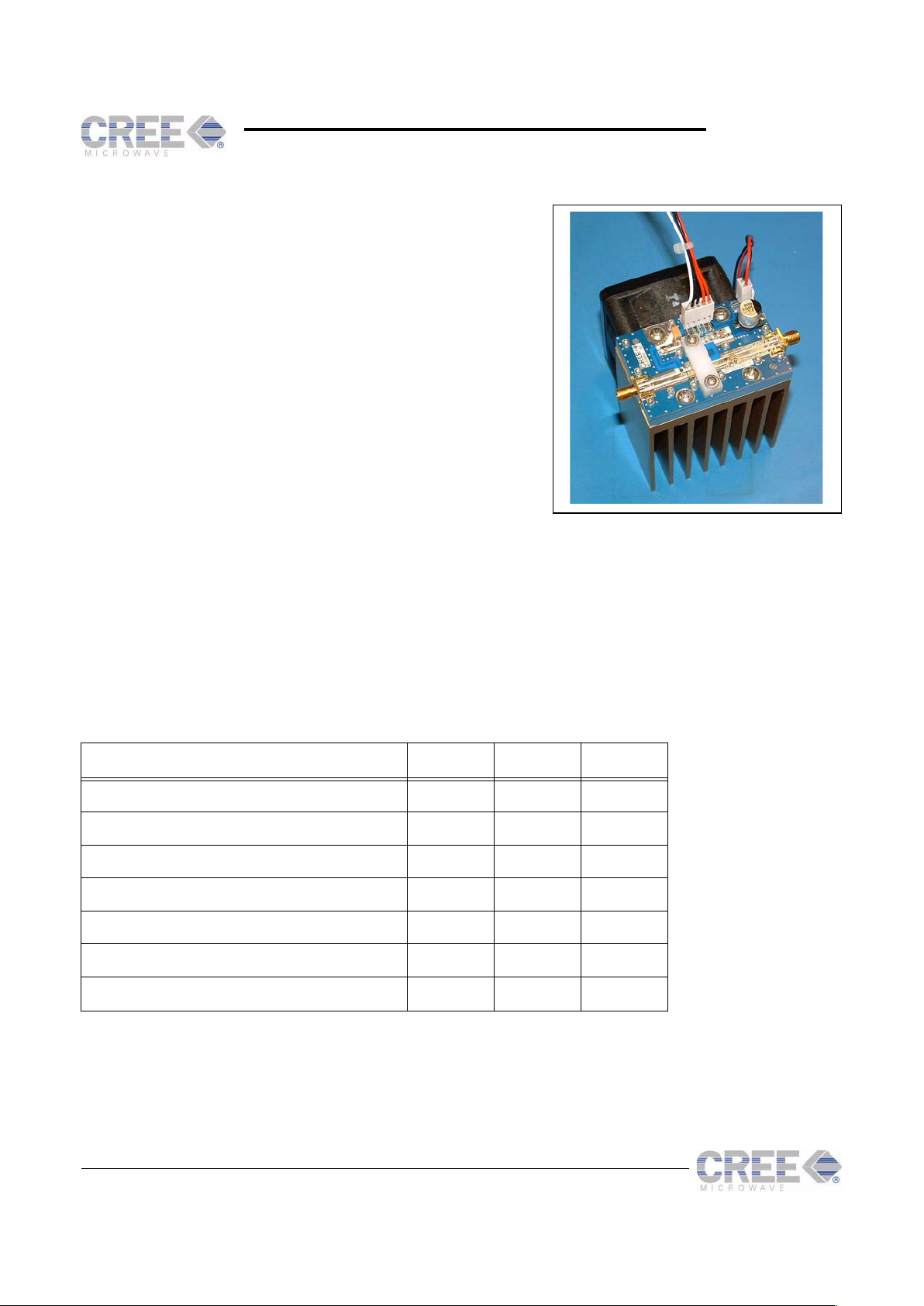

Amplifier and carrier without heatsink and fan assembly

Absolute Maximum Ratings (not simultaneous) at 25°C

Parameter Symbol Rating Units

Drain Supply Voltage V

DSMAX

50 VDC

Drain Supply Current I

DSMAX

+2 ADC

Gate Supply Voltage V

GSMAX

-15 VDC

Gate Supply Current I

GSMAX

0.1 ADC

Total Device Dissipation P

D

66 W

Storage Temperature T

STG

125 °C

Thermal Resistance, Junction to Base

1

R

qJB

4.5 °C/W

Page 2

CRF-22010-TB

© Cree, Inc. 2003 Specifications subject to change without notice

2 http://www.cree.com/

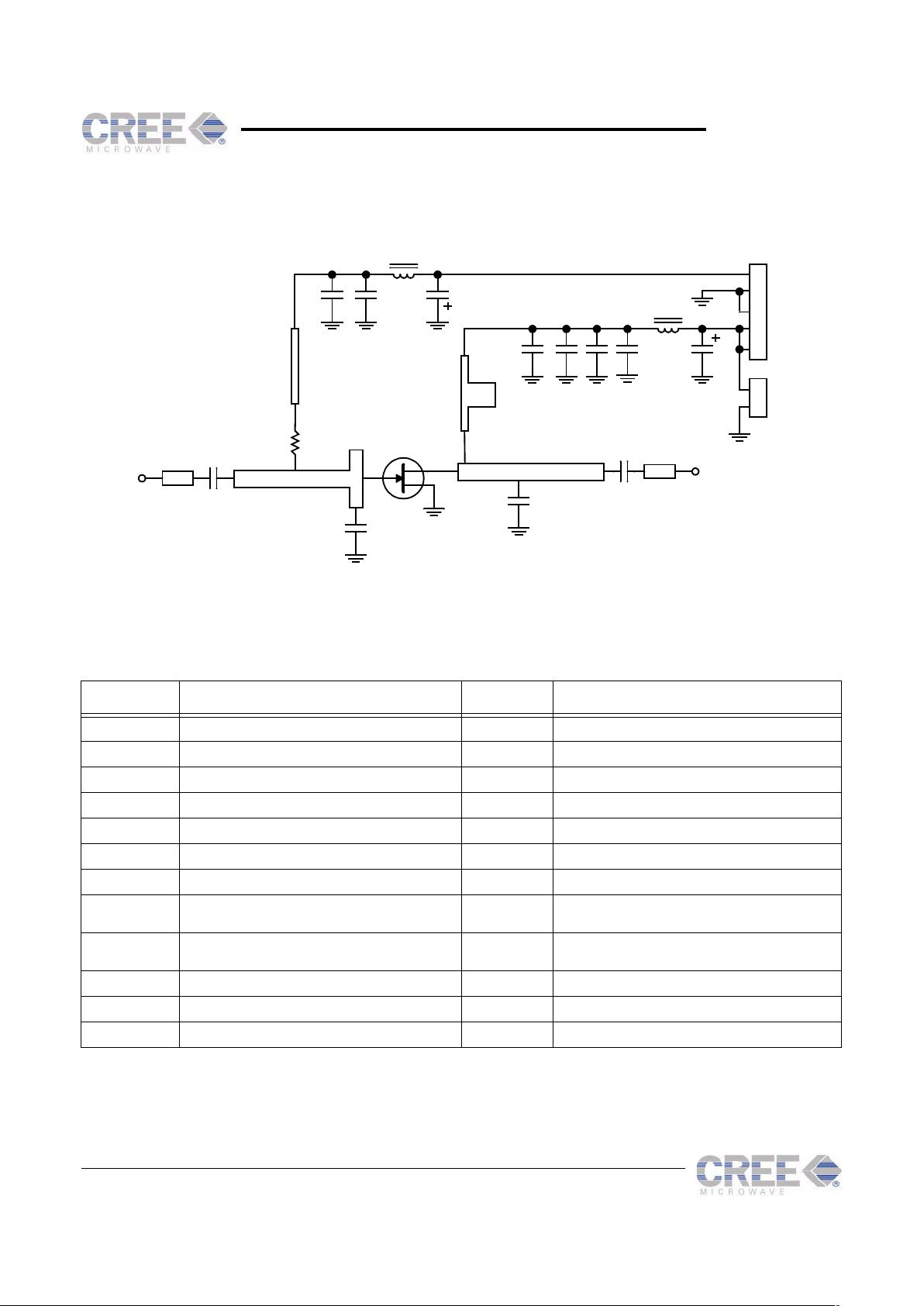

Schematic (Rev. A)

Parts List

Note: Some values may differ due to substitution in the event of temporarily unavailable parts

Designator Value Designator Value

R1 39 W, 0.1 W, 0805 Chip Resistor C1, C2, C3, C6 27 pF, 100V Ceramic Capacitor, ATC 12061C104MAT2A

L1 Ferrite, 80 ohms, Steward HI1206K101R C4 0.1 uF, 25V, 0805 Ceramic Capacitor

L2 Ferrite, Murata BLM21P220SG C5 10 uF, 25V Tantalum Capacitor

J1, J2 Flange Mount SMA Female Connector C7 2.2 nF, 100V Ceramic Capacitor, AVX 08051C222MAT2A

J3 5-pin Molex Male Connector C8 10 nF, 100V, 0805 Ceramic Capacitor

J4 2-pin Molex Male Connector C9 0.1 uF, 100V, 1206 Ceramic Capacitor

Q1 CRF-22010 C10 33 uF, 100V, Aluminum Electrolytic Capacitor

Substrate Rogers RO4003, e

r

=3.38, h=32 mil C11 3.3 pF, 150V Porcelain Capacitor, ATC

100B3R3OBW500X (exact value depends on tuning)

Heatsink Thermalloy 74605 Extrusion, 2 in long C12 2.2 pF, 150V Porcelain Capacitor, ATC

100B2R2OBW500X (exact value depends on tuning)

Fan Comair-Rotron FS48B3, 60 mm, 48V, 0.05 A, 18 cfm

V_DD

C1

C2

C3

C6 C9

C8

L1

C10

J4

J3

C7

C11

C12

C5

L2

J1

RF

IN

J2

RF

OUT

Q1

R1

V_GG

C4

FAN+

FAN-

GND

GND

V_DD

2

1

5

4

3

2

1

Page 3

CRF-22010-TB

Specifications subject to change without notice© Cree, Inc. 2003

http://www.cree.com/3

Layout

Operating Instructions

As per normal RF amplifier operation, observe correct polarity . Do not power up the evaluation board

unless the RF input and output ports are properly terminated.

The CRF-22010-TB-A is supplied fully assembled but without any transistors installed; since they are ESD-sensitive devices, they are packaged separately in protective packaging. The test board is only designed for use with

the flange style package. To install a transistor, remove the plastic clamp. Place the transistor into the cavity with

the angled gate lead towards the input connector J1. Use the two 2-56 hex screws and washers to attach the

flange to the board. Replace the clamp and retighten to effect positive contact between the circuit’s microstrip

lines and the part’s leads. Reverse this procedure to remove the device.

The evaluation board is fastened to an aluminum carrier to provide heat spreading and sinking, but this thermal

mass is not a sufficient heat sink for extended (i.e., for more than 30 seconds) operation. An optional heatsink and

fan assembly is supplied with the fixture. A thermal compound such as Wakefield #120-2 should be used at the

carrier-to-heatsink interface to ensure adequate heat transfer. Thermal compound should be used sparingly in

order to minimize the thermal drop across the interface; refer to manufacturer instructions for proper application of

thermal compound. Failure to provide adequate heatsinking will result in RF performance degradation and/

or component failure.

Q1

R1

L1

L2

C1

C2

C3

C4

J1

RF IN

J2

RF OUT

J4

FAN

J3

DC SUPPLY

C11

C5

C6

C7 C8

C9

C10

C12

Page 4

CRF-22010-TB

© Cree, Inc. 2003 Specifications subject to change without notice

4 http://www.cree.com/

Handle and test the board in an ESD-protected environment. With all power off, connect the RF and DC cables.

Standard SMA cables will mate to the RF input and output connectors. Connect an external 48 VDC power supply

to the board’s GROUND and DRAIN plugs. The supply should be capable of supplying 1.5 A minimum. Connect

an external adjustable supply to the board’s GROUND and GATE plugs. Observe correct polarity: the GATE

voltage is negative with respect to ground, and the DRAIN voltage is positive with respect to ground. Observe

proper supply sequencing: the negative gate voltage must be turned on before the positive drain voltage.

Adjust the gate voltage so that the CRF-22010 will be operating Class A at V

DS

= 48 V and IDS ~ 500 mA for initial

checkout.

Connect a 20 dBm, 2.0 GHz source to RF IN and measure output power at RF OUT. The 1 dB gain compression

point should be reached with an input power of 27 dBm to 30 dBm.

Note that, for convenience, the fan uses the board’s 48VDC supply through J4. For monitoring drain current from

the V_DD supply lead, the fan should either be disconnected and supplied separately, or its operating current

should be determined without a transistor installed in the fixture and then subtracted from later measured current

values.

Theory of Operation

Refer to the schematic presented earlier. This circuit is intended only for test and evaluation purposes; it is

not a complete, ready-for-production amplifier.

C1 and C2 are DC blocking capacitors. C11 and the transmission line to which it is connected constitute the input

match. This matching network transforms 50W to the desired source impedance (see the CRF-22010 data sheet).

Likewise C12 and the transmission line to which it is connected transform the desired load impedance to 50W.

These are lowpass matching structures, and they perform impedance matching in the desired band, but they only

give a high-Q, narrowband match. Gate bias is provided through a typical l/4 line; R1 helps to isolate and stabilize

the amplifier. C3 and C4 terminate the line in an RF short, and L1 and C5 provide further supply isolation. Drain

bias is provided through a l/4 line also, but the combination of C8-C10, L2, and the stub in the drain supply line

provide both an RF short and a termination with good video bandwidth. DC is supplied to the test board through

J3, and the fan draws its power through J4.

Some typical swept power and frequency measurements of an evaluation board are presented on the next page.

These data are measured using a typical evaluation board with a typical transistor.

Page 5

CRF-22010-TB

Specifications subject to change without notice© Cree, Inc. 2003

http://www.cree.com/5

Typical Performance at V

DS

= 48V, I

DQ

= 500mA

Swept CW Data vs Frequency

5

6

7

8

9

10

11

12

13

14

15

1.7 1.8 1.9 2 2.1 2.2 2.3

Frequency (GHz)

Gain (dB)

32

33

34

35

36

37

38

39

40

41

42

P1dB (dBm)

Swept CW Data vs Power at 1900 MHz

22

24

26

28

30

32

34

36

38

40

42

10 12 14 16 18 20 22 24 26 28 30 32

Pin (dBm)

Pout (dBm)

0.00

4.00

8.00

12.00

16.00

20.00

24.00

28.00

32.00

36.00

40.00

h

(Drain Efficiency) (%)

Page 6

CRF-22010-TB

© Cree, Inc. 2003 Specifications subject to change without notice

6 http://www.cree.com/

Disclaimer: Specifications are subject to change without notice. Cree, Inc. believes the information contained

within this data sheet to be accurate and reliable. However, no responsibility is assumed by Cree for its use or for

any infringement of patents or other rights of third parties which may result from its use. No license is granted by

implication or otherwise under any patent or patent rights of Cree. Cree makes no warranty, representation or

guarantee regarding the suitability of its products for any particular purpose. “Typical” parameters are the average

values expected by Cree in large quantities and are provided for information purposes only. These values can and

do vary in different applications, and actual performance can vary over time. All operating parameters should be

validated by customer’s technical experts for each application. Cree products are not designed, intended, or

authorized for use as components in applications intended for surgical implant into the body or to support or sustain life, in applications in which the failure of the Cree product could result in personal injury or death, or in applications for the planning, construction, maintenance or direct operation of a nuclear facility. CREE is a trademark of

Cree, Inc.

Contact Information:

Cree, Inc.

4600 Silicon Drive

Durham, NC 27703

919-313-5300 [sales]

919-313-5451 [fax]

Sales Email: sales@cree.com

Web: http://www.cree.com/

Loading...

Loading...