Datasheet COP8SCR9HVA8, COP8SBR9LVA8, COP8SBR9KMT8, COP8SBR9IMT8, COP8SBR9HVA8 Datasheet (NSC)

...Page 1

COP8SBR9/COP8SCR9/COP8SDR9

8-Bit CMOS Flash Based Microcontroller with 32k

Memory, Virtual EEPROM and Brownout

1.0 General Description

The COP8SBR9/SCR9/SDR9 Flash based microcontrollers

are highly integrated COP8

Flash memory and advanced features including Virtual EEPROM, High Speed Timers, USART, and Brownout Reset.

Devices included in this datasheet:

Device

COP8SBR9 32k 1k 2.7V to 2.9V

COP8SCR9 32k 1k 4.17V to 4.5V

COP8SDR9 32k 1k No Brownout

™

Feature core devices, with 32k

Flash Program

Memory

(bytes)

RAM

(bytes)

Brownout

This single-chip CMOS device is suited for applications requiring a full featured, in-system reprogrammable controller

with large memory and low EMI. The same device is used for

development, pre-production and volume production with a

range of COP8 software and hardware development tools.

Voltage

I/O

Pins

37,39,49,

59

37,39,49,

59

37,39,49,

59

Packages Temperature

44 LLP,

44/68 PLCC,

48/56 TSSOP

44 LLP,

44/68 PLCC,

48/56 TSSOP

44 LLP,

44/68 PLCC,

48/56 TSSOP

−40˚C to +85˚C

−40˚C to +85˚C

−40˚C to +125˚C

−40˚C to +85˚C

−40˚C to +125˚C

August 2003

COP8SBR9/COP8SCR9/COP8SDR9 8-Bit CMOS Flash Based Microcontroller with 32k Memory,

Virtual EEPROM and Brownout

2.0 Features

KEY FEATURES

n 32 kbytes Flash Program Memory with Security Feature

n Virtual EEPROM using Flash Program Memory

n 1 kbyte volatile RAM

n USART with on chip baud generator

n 2.7V–5.5V In-System Programmability of Flash

n High endurance - 100k Read/Write Cycles

n Superior data retention - 100 years

n Dual Clock Operation with HALT/IDLE Power Save

Modes

n Three 16-bit timers:

— Timers T2 and T3 can operate at high speed (50 ns

resolution)

— Processor Independent PWM mode

— External Event counter mode

— Input Capture mode

n Brown-out Reset (COP8SBR9/SCR9)

OTHER FEATURES

n Single supply operation: 2.7V– 5.5V

n Quiet Design (low radiated emissions)

n Multi-Input Wake-up with optional interrupts

n MICROWIRE/PLUS (Serial Peripheral Interface

Compatible)

n Clock Doubler for 20 MHz operation from 10 MHz

Oscillator, with 0.5 µs Instruction Cycle

n Thirteen multi-source vectored interrupts servicing:

— External Interrupt

— USART (2)

— Idle Timer T0

— Three Timers (each with 2 interrupts)

— MICROWIRE/PLUS Serial peripheral interface

— Multi-Input Wake-Up

— Software Trap

n Idle Timer with programmable interrupt interval

n 8-bit Stack Pointer SP (stack in RAM)

n Two 8-bit Register Indirect Data Memory Pointers

n True bit manipulation

n WATCHDOG and Clock Monitor logic

n Software selectable I/O options

— TRI-STATE

— Push-Pull Output

— Weak Pull Up Input

n Schmitt trigger inputs on I/O ports

n High Current I/Os

n Temperature range: –40˚C to +85˚C and –40˚C to

+125˚C (COP8SCR9/SDR9)

n Packaging: 44 and 68 PLCC, 44 LLP, 48 and 56 TSSOP

n True In-System, Real time emulation and debug offered

by MetaLink’s Development Systemstools available

®

Output/High Impedance Input

COP8™is a trademark of National Semiconductor Corporation.

© 2003 National Semiconductor Corporation DS101389 www.national.com

Page 2

3.0 Block Diagram

COP8SBR9/COP8SCR9/COP8SDR9

4.0 Ordering Information

COP8 SB R 9 H VA 8

Family and

Feature Set

Indicator

SB = Low Brownout Voltage

SC = High Brownout Voltage

SD = No Brownout

Part Numbering Scheme

Program

Memory

Size

R = 32k 9 = Flash H = 44 Pin

Program

Memory

Type

No. Of Pins

I=48Pin

k=56Pin

L = 68 Pin

Package

Type

LQ = LLP

MT = TSSOP

VA = PLCC

10138901

Temperature

7 = -40 to +125˚C

8 = -40 to +85˚C

www.national.com 2

Page 3

Table of Contents

1.0 General Description ..................................................................................................................................... 1

2.0 Features ....................................................................................................................................................... 1

3.0 Block Diagram .............................................................................................................................................. 2

4.0 Ordering Information .................................................................................................................................... 2

5.0 Connection Diagrams ................................................................................................................................... 6

6.0 Architectural Overview ............................................................................................................................... 10

6.1 EMI REDUCTION .................................................................................................................................... 10

6.2 IN-SYSTEM PROGRAMMING AND VIRTUAL EEPROM ...................................................................... 10

6.3 DUAL CLOCK AND CLOCK DOUBLER ................................................................................................. 10

6.4 TRUE IN-SYSTEM EMULATION ............................................................................................................ 10

6.5 ARCHITECTURE ................................................................................................................................... 10

6.6 INSTRUCTION SET ............................................................................................................................... 10

6.6.1 Key Instruction Set Features ............................................................................................................. 10

6.6.2 Single Byte/Single Cycle Code Execution ....................................................................................... 10

6.6.3 Many Single-Byte, Multi-Function Instructions .................................................................................. 10

6.6.4 Bit-Level Control ................................................................................................................................ 11

6.6.5 Register Set ....................................................................................................................................... 11

6.7 PACKAGING/PIN EFFICIENCY .............................................................................................................. 11

7.0 Absolute Maximum Ratings ....................................................................................................................... 12

8.0 Electrical Characteristics ............................................................................................................................ 12

9.0 Pin Descriptions ......................................................................................................................................... 17

9.1 EMULATION CONNECTION ................................................................................................................... 18

10.0 Functional Description .............................................................................................................................. 19

10.1 CPU REGISTERS ................................................................................................................................. 19

10.2 PROGRAM MEMORY ........................................................................................................................... 19

10.3 DATA MEMORY .................................................................................................................................... 19

10.4 DATA MEMORY SEGMENT RAM EXTENSION .................................................................................. 19

10.4.1 Virtual EEPROM .............................................................................................................................. 20

10.5 OPTION REGISTER ............................................................................................................................. 20

10.6 SECURITY ............................................................................................................................................ 21

10.7 RESET ................................................................................................................................................... 21

10.7.1 External Reset ................................................................................................................................. 22

10.7.2 On-Chip Brownout Reset ................................................................................................................. 22

10.8 OSCILLATOR CIRCUITS ...................................................................................................................... 24

10.8.1 Oscillator .......................................................................................................................................... 24

10.8.2 Clock Doubler .................................................................................................................................. 24

................................................................................................................................................................... 0

10.9 CONTROL REGISTERS ....................................................................................................................... 25

10.9.1 CNTRL Register (Address X'00EE) ................................................................................................. 25

10.9.2 PSW Register (Address X'00EF) ..................................................................................................... 25

10.9.3 ICNTRL Register (Address X'00E8) ................................................................................................ 25

10.9.4 T2CNTRL Register (Address X'00C6) ............................................................................................. 25

10.9.5 T3CNTRL Register (Address X'00B6) ............................................................................................. 26

10.9.6 HSTCR Register (Address X'00AF) ................................................................................................ 26

10.9.7 ITMR Register (Address X'00CF) .................................................................................................... 26

11.0 In-System Programming ........................................................................................................................... 27

11.1 INTRODUCTION ................................................................................................................................... 27

11.2 FUNCTIONAL DESCRIPTION .............................................................................................................. 27

11.3 REGISTERS .......................................................................................................................................... 27

11.3.1 ISP Address Registers ..................................................................................................................... 27

11.3.2 ISP Read Data Register .................................................................................................................. 28

11.3.3 ISP Write Data Register ................................................................................................................... 28

11.3.4 ISP Write Timing Register ................................................................................................................ 28

11.4 MANEUVERING BACK AND FORTH BETWEEN FLASH MEMORY AND BOOT ROM ..................... 29

11.5 FORCED EXECUTION FROM BOOT ROM ......................................................................................... 29

11.6 RETURN TO FLASH MEMORY WITHOUT HARDWARE RESET ....................................................... 30

11.7 MICROWIRE/PLUS ISP ........................................................................................................................ 30

11.8 USER ISP AND VIRTUAL E

11.9 RESTRICTIONS ON SOFTWARE WHEN CALLING ISP ROUTINES IN BOOT ROM ....................... 32

11.10 FLASH MEMORY DURABILITY CONSIDERATIONS ........................................................................ 32

12.0 Timers ....................................................................................................................................................... 34

12.1 TIMER T0 (IDLE TIMER) ...................................................................................................................... 34

2

................................................................................................................ 30

COP8SBR9/COP8SCR9/COP8SDR9

www.national.com3

Page 4

Table of Contents (Continued)

12.1.1 ITMR Register .................................................................................................................................. 34

12.2 TIMER T1, TIMER T2, AND TIMER T3 ................................................................................................ 35

12.2.1 Timer Operating Speeds .................................................................................................................. 35

12.2.2 Mode 1. Processor Independent PWM Mode ................................................................................. 35

12.2.3 Mode 2. External Event Counter Mode ........................................................................................... 36

12.2.4 Mode 3. Input Capture Mode .......................................................................................................... 36

12.3 TIMER CONTROL FLAGS .................................................................................................................... 36

13.0 Power Saving Features ............................................................................................................................ 37

13.1 POWER SAVE MODE CONTROL REGISTER .................................................................................... 38

13.2 OSCILLATOR STABILIZATION ............................................................................................................. 39

13.3 HIGH SPEED MODE OPERATION ......................................................................................................39

COP8SBR9/COP8SCR9/COP8SDR9

13.3.1 High Speed Halt Mode .................................................................................................................... 39

13.3.1.1 Entering The High Speed Halt Mode ......................................................................................... 39

13.3.1.2 Exiting The High Speed Halt Mode ........................................................................................... 39

13.3.1.3 HALT Exit Using Reset .............................................................................................................. 39

13.3.1.4 HALT Exit Using Multi-Input Wake-up ....................................................................................... 39

13.3.1.5 Options ....................................................................................................................................... 39

13.3.2 High Speed Idle Mode ..................................................................................................................... 40

13.4 DUAL CLOCK MODE OPERATION ......................................................................................................40

13.4.1 Dual Clock HALT Mode ................................................................................................................... 41

13.4.1.1 Entering The Dual Clock Halt Mode .......................................................................................... 41

13.4.1.2 Exiting The Dual Clock Halt Mode .............................................................................................41

13.4.1.3 HALT Exit Using Reset .............................................................................................................. 41

13.4.1.4 HALT Exit Using Multi-Input Wake-up ....................................................................................... 41

13.4.1.5 Options ....................................................................................................................................... 41

13.4.2 Dual Clock Idle Mode ...................................................................................................................... 41

13.5 LOW SPEED MODE OPERATION .......................................................................................................42

13.5.1 Low Speed HALT Mode ................................................................................................................... 42

13.5.1.1 Entering The Low Speed Halt Mode ......................................................................................... 42

13.5.1.2 Exiting The Low Speed Halt Mode ............................................................................................ 42

13.5.1.3 HALT Exit Using Reset .............................................................................................................. 42

13.5.1.4 HALT Exit Using Multi-Input Wake-up ....................................................................................... 42

13.5.1.5 Options ....................................................................................................................................... 42

13.5.2 Low Speed Idle Mode ...................................................................................................................... 42

13.6 MULTI-INPUT WAKE-UP ...................................................................................................................... 43

14.0 USART ..................................................................................................................................................... 44

14.1 USART CONTROL AND STATUS REGISTERS ................................................................................... 45

14.2 DESCRIPTION OF USART REGISTER BITS ...................................................................................... 45

14.3 ASSOCIATED I/O PINS ........................................................................................................................ 46

14.4 USART OPERATION ............................................................................................................................ 46

14.4.1 Asynchronous Mode ........................................................................................................................ 47

14.4.2 Synchronous Mode .......................................................................................................................... 47

14.5 FRAMING FORMATS ............................................................................................................................ 47

14.6 USART INTERRUPTS .......................................................................................................................... 48

14.7 BAUD CLOCK GENERATION .............................................................................................................. 48

14.8 EFFECT OF HALT/IDLE ....................................................................................................................... 50

14.9 DIAGNOSTIC ........................................................................................................................................ 50

14.10 ATTENTION MODE ............................................................................................................................. 50

14.11 BREAK GENERATION ........................................................................................................................ 50

15.0 Interrupts .................................................................................................................................................. 51

15.1 INTRODUCTION ................................................................................................................................... 51

15.2 MASKABLE INTERRUPTS ................................................................................................................... 51

15.3 VIS INSTRUCTION ............................................................................................................................... 52

15.3.1 VIS Execution .................................................................................................................................. 53

15.4 NON-MASKABLE INTERRUPT ............................................................................................................ 54

15.4.1 Pending Flag .................................................................................................................................... 54

15.4.2 Software Trap .................................................................................................................................. 54

15.4.2.1 Programming Example: External Interrupt ................................................................................. 56

15.5 PORT L INTERRUPTS .......................................................................................................................... 56

15.6 INTERRUPT SUMMARY ....................................................................................................................... 56

16.0 WATCHDOG/Clock Monitor ..................................................................................................................... 57

www.national.com 4

Page 5

Table of Contents (Continued)

16.1 CLOCK MONITOR ................................................................................................................................ 57

16.2 WATCHDOG/CLOCK MONITOR OPERATION .................................................................................... 57

16.3 WATCHDOG AND CLOCK MONITOR SUMMARY .............................................................................. 58

16.4 DETECTION OF ILLEGAL CONDITIONS ............................................................................................ 58

17.0 MICROWIRE/PLUS .................................................................................................................................. 59

17.1 MICROWIRE/PLUS OPERATION ......................................................................................................... 59

17.1.1 MICROWIRE/PLUS Master Mode Operation .................................................................................. 59

17.1.2 MICROWIRE/PLUS Slave Mode Operation .................................................................................... 59

17.1.2.1 Alternate SK Phase Operation and SK Idle Polarity ................................................................. 60

18.0 Memory Map ............................................................................................................................................ 62

19.0 Instruction Set .......................................................................................................................................... 64

19.1 INTRODUCTION ................................................................................................................................... 64

19.2 INSTRUCTION FEATURES .................................................................................................................. 64

19.3 ADDRESSING MODES ......................................................................................................................... 64

19.3.1 Operand Addressing Modes ............................................................................................................ 64

19.3.2 Tranfer-of-Control Addressing Modes .............................................................................................. 65

19.4 INSTRUCTION TYPES ......................................................................................................................... 66

19.4.1 Arithmetic Instructions ...................................................................................................................... 66

19.4.2 Transfer-of-Control Instructions ....................................................................................................... 66

19.4.3 Load and Exchange Instructions ..................................................................................................... 66

19.4.4 Logical Instructions .......................................................................................................................... 66

19.4.5 Accumulator Bit Manipulation Instructions ....................................................................................... 66

19.4.6 Stack Control Instructions ................................................................................................................ 66

19.4.7 Memory Bit Manipulation Instructions ............................................................................................. 66

19.4.8 Conditional Instructions ................................................................................................................... 66

19.4.9 No-Operation Instruction .................................................................................................................. 66

19.5 REGISTER AND SYMBOL DEFINITION .............................................................................................. 67

19.6 INSTRUCTION SET SUMMARY .......................................................................................................... 67

19.7 INSTRUCTION EXECUTION TIME ...................................................................................................... 69

20.0 Development Support .............................................................................................................................. 71

20.1 TOOLS ORDERING NUMBERS FOR THE COP8 FLASH FAMILY DEVICES ................................... 71

20.2 COP8 TOOLS OVERVIEW ................................................................................................................... 73

20.3 WHERE TO GET TOOLS ..................................................................................................................... 74

21.0 Revision History ....................................................................................................................................... 76

22.0 Physical Dimensions ................................................................................................................................ 79

COP8SBR9/COP8SCR9/COP8SDR9

www.national.com5

Page 6

5.0 Connection Diagrams

COP8SBR9/COP8SCR9/COP8SDR9

Top View

Plastic Chip Package

See NS Package Number V68A

10138902

Top View

10138903

Plastic Chip Package

See NS Package Number V44A

Top View

10138940

LLP Package

See NS Package Number LQA44A

www.national.com 6

Top View

10138941

TSSOP Package

See NS Package Number MTD48

Page 7

5.0 Connection Diagrams (Continued)

COP8SBR9/COP8SCR9/COP8SDR9

Top View

10138942

TSSOP Package

See NS Package Number MTD56

TABLE 1. Pinouts for All Packages

Port Type Alt. Fun

In System

Emulation

Mode

44-Pin LLP

44-Pin

PLCC

48-Pin

TSSOP

56-Pin

TSSOP

68-Pin

PLCC

L0 I/O MIWU or Low Speed OSC In 16 11 11 15 22

L1 I/O MIWU or CKX or Low Speed

17 12 12 16 23

OSC Out

L2 I/O MIWU or TDX 18 13 13 17 24

L3 I/O MIWU or RDX 19 14 14 18 25

L4 I/O MIWU or T2A 20 15 15 19 26

L5 I/O MIWU or T2B 21 16 16 20 27

L6 I/O MIWU or T3A 22 17 17 21 28

L7 I/O MIWU or T3B 23 18 18 22 29

G0 I/O INT Input 7 2223

G1 I/O WDOUT

a

POUT 8 3334

G2 I/O T1B Output 9 4445

G3 I/O T1A Clock 10 5556

G4 I/O SO 11 6 6 6 11

G5 I/O SK 12 7 7 7 12

G6 I SI 13 8 8 8 13

www.national.com7

Page 8

5.0 Connection Diagrams (Continued)

TABLE 1. Pinouts for All Packages (Continued)

In System

Port Type Alt. Fun

Emulation

44-Pin LLP

Mode

G7 I CKO 14 9 9 9 14

D0O 42 37414958

D1O 43 38425059

D2O 44 39435160

D3 O 1 40 44 52 61

D4 O 2 41 45 53 62

D5 O 3 42 46 54 63

COP8SBR9/COP8SCR9/COP8SDR9

D6 O 4 43 47 55 64

D7 O 5 44 48 56 65

E0 I/O 47 54

E1 I/O 48 55

E2 I/O 56

E3 I/O 57

E4 I/O 67

E5 I/O 68

E6 I/O 1

E7 I/O 2

C0 I/O 11 18

C1 I/O 12 19

C2 I/O 13 20

C3 I/O 14 21

C4 I/O 23 30

C5 I/O 24 31

C6 I/O 25 32

C7 I/O 26 33

A0 I/O 33 39 46

A1 I/O 34 40 47

A2 I/O 36 31 35 41 48

A3 I/O 37 32 36 42 49

A4 I/O 38 33 37 43 50

A5 I/O 39 34 38 44 51

A6 I/O 40 35 39 45 52

A7 I/O 41 36 40 46 53

B0 I/O 24 19 19 27 34

B1 I/O 25 20 20 28 35

B2 I/O 26 21 21 29 36

B3 I/O 27 22 22 30 37

B4 I/O 28 23 23 31 38

B5 I/O 29 24 24 32 39

B6 I/O 30 25 25 33 40

B7 I/O 31 26 26 34 41

F0 I/O 7

F1 I/O 8

F2 I/O 9

F3 I/O 10

DV

CC

V

CC

35 30 32 38 17, 45

44-Pin

PLCC

48-Pin

TSSOP

56-Pin

TSSOP

68-Pin

PLCC

www.national.com 8

Page 9

5.0 Connection Diagrams (Continued)

TABLE 1. Pinouts for All Packages (Continued)

In System

Port Type Alt. Fun

DGND GND 32 27 27 35 16, 42

CKII 15 10101015

RESET

a. G1 operation as WDOUT is controlled by Option Register bit 2.

I RESET 6 11166

Emulation

Mode

44-Pin LLP

44-Pin

PLCC

48-Pin

TSSOP

56-Pin

TSSOP

68-Pin

PLCC

COP8SBR9/COP8SCR9/COP8SDR9

www.national.com9

Page 10

6.0 Architectural Overview

6.1 EMI REDUCTION

The COP8SBR9/SCR9/SDR9 devices incorporate circuitry

that guards against electromagnetic interference - an increasing problem in today’s microcontroller board designs.

National’s patented EMI reduction technology offers low EMI

clock circuitry, gradual turn-on output drivers (GTOs) and

internal Icc smoothing filters, to help circumvent many of the

EMI issues influencing embedded control designs. National

has achieved 15 dB–20 dB reduction in EMI transmissions

when designs have incorporated its patented EMI reducing

circuitry.

6.2 IN-SYSTEM PROGRAMMING AND VIRTUAL

COP8SBR9/COP8SCR9/COP8SDR9

EEPROM

The device includes a program in a boot ROM that provides

the capability, through the MICROWIRE/PLUS serial interface, to erase, program and read the contents of the Flash

memory.

Additional routines are included in the boot ROM, which can

be called by the user program, to enable the user to customize in system software update capability if MICROWIRE/

PLUS is not desired.

Additional functions will copy blocks of data between the

RAM and the Flash Memory. These functions provide a

virtual EEPROM capability by allowing the user to emulate a

variable amount of EEPROM by initializing nonvolatile variables from the Flash Memory and occasionally restoring

these variables to the Flash Memory.

The contents of the boot ROM have been defined by National. Execution of code from the boot ROM is dependent

on the state of the FLEX bit in the Option Register on exit

from RESET. If the FLEX bit is a zero, the Flash Memory is

assumed to be empty and execution from the boot ROM

begins. For further information on the FLEX bit, refer to

Section 4.5, Option Register.

6.3 DUAL CLOCK AND CLOCK DOUBLER

The device includes a versatile clocking system and two

oscillator circuits designed to drive a crystal or ceramic

resonator. The primary oscillator operates at high speed up

to 10 MHz. The secondary oscillator is optimized for operation at 32.768 kHz.

The user can, through specified transition sequences

(please refer to 13.0 Power Saving Features), switch execution between the high speed and low speed oscillators. The

unused oscillator can then be turned off to minimize power

dissipation. If the low speed oscillator is not used, the pins

are available as general purpose bidirectional ports.

The operation of the CPU will use a clock at twice the

frequency of the selected oscillator (up to 20 MHz for high

speed operation and 65.536 kHz for low speed operation).

This doubled clock will be referred to in this document as

‘MCLK’. The frequency of the selected oscillator will be

referred to as CKI. Instruction execution occurs at one tenth

the selected MCLK rate.

6.4 TRUE IN-SYSTEM EMULATION

On-chip emulation capability has been added which allows

the user to perform true in-system emulation using final

production boards and devices. This simplifies testing and

evaluation of software in real environmental conditions. The

user, merely by providing for a standard connector which can

be bypassed by jumpers on the final application board, can

provide for software and hardware debugging using actual

production units.

6.5 ARCHITECTURE

The COP8 family is based on a modified Harvard architecture, which allows data tables to be accessed directly from

program memory. This is very important with modern

microcontroller-based applications, since program memory

is usually ROM or EPROM, while data memory is usually

RAM. Consequently constant data tables need to be contained in non-volatile memory, so they are not lost when the

microcontroller is powered down. In a modified Harvard architecture, instruction fetch and memory data transfers can

be overlapped with a two stage pipeline, which allows the

next instruction to be fetched from program memory while

the current instruction is being executed using data memory.

This is not possible with a Von Neumann single-address bus

architecture.

The COP8 family supports a software stack scheme that

allows the user to incorporate many subroutine calls. This

capability is important when using High Level Languages.

With a hardware stack, the user is limited to a small fixed

number of stack levels.

6.6 INSTRUCTION SET

In today’s 8-bit microcontroller application arena cost/

performance, flexibility and time to market are several of the

key issues that system designers face in attempting to build

well-engineered products that compete in the marketplace.

Many of these issues can be addressed through the manner

in which a microcontroller’s instruction set handles processing tasks. And that’s why the COP8 family offers a unique

and code-efficient instruction set - one that provides the

flexibility, functionality, reduced costs and faster time to market that today’s microcontroller based products require.

Code efficiency is important because it enables designers to

pack more on-chip functionality into less program memory

space (ROM, OTP or Flash). Selecting a microcontroller with

less program memory size translates into lower system

costs, and the added security of knowing that more code can

be packed into the available program memory space.

6.6.1 Key Instruction Set Features

The COP8 family incorporates a unique combination of instruction set features, which provide designers with optimum

code efficiency and program memory utilization.

6.6.2 Single Byte/Single Cycle Code Execution

The efficiency is due to the fact that the majority of instructions are of the single byte variety, resulting in minimum

program space. Because compact code does not occupy a

substantial amount of program memory space, designers

can integrate additional features and functionality into the

microcontroller program memory space. Also, the majority

instructions executed by the device are single cycle, resulting in minimum program execution time. In fact, 77% of the

instructions are single byte single cycle, providing greater

code and I/O efficiency, and faster code execution.

6.6.3 Many Single-Byte, Multi-Function Instructions

The COP8 instruction set utilizes many single-byte, multifunction instructions. This enables a single instruction to

accomplish multiple functions, such as DRSZ, DCOR, JID,

LD (Load) and X (Exchange) instructions with postincrementing and post-decrementing, to name just a few

www.national.com 10

Page 11

6.0 Architectural Overview (Continued)

examples. In many cases, the instruction set can simultaneously execute as many as three functions with the same

single-byte instruction.

JID: (Jump Indirect); Single byte instruction decodes external events and jumps to corresponding service routines

(analogous to “DO CASE” statements in higher level languages).

LAID: (Load Accumulator-Indirect); Single byte look up table

instruction provides efficient data path from the program

memory to the CPU. This instruction can be used for table

lookup and to read the entire program memory for checksum

calculations.

RETSK: (Return Skip); Single byte instruction allows return

from subroutine and skips next instruction. Decision to

branch can be made in the subroutine itself, saving code.

AUTOINC/DEC: (Auto-Increment/Auto-Decrement); These

instructions use the two memory pointers B and X to efficiently process a block of data (simplifying “FOR NEXT” or

other loop structures in higher level languages).

6.6.4 Bit-Level Control

Bit-level control over many of the microcontroller’s I/O ports

provides a flexible means to ease layout concerns and save

board space. All members of the COP8 family provide the

COP8SBR9/COP8SCR9/COP8SDR9

ability to set, reset and test any individual bit in the data

memory address space, including memory-mapped I/O ports

and associated registers.

6.6.5 Register Set

Three memory-mapped pointers handle register indirect addressing and software stack pointer functions. The memory

data pointers allow the option of post-incrementing or postdecrementing with the data movement instructions (LOAD/

EXCHANGE). And 15 memory-mapped registers allow designers to optimize the precise implementation of certain

specific instructions.

6.7 PACKAGING/PIN EFFICIENCY

Real estate and board configuration considerations demand

maximum space and pin efficiency, particularly given today’s

high integration and small product form factors. Microcontroller users try to avoid using large packages to get the I/O

needed. Large packages take valuable board space and

increase device cost, two trade-offs that microcontroller designs can ill afford.

The COP8 family offers a wide range of packages and does

not waste pins.

www.national.com11

Page 12

7.0 Absolute Maximum Ratings

(Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Supply Voltage (V

Voltage at Any Pin −0.3V to V

Total Current into V

)7V

CC

+0.3V

CC

Pin (Source) 200 mA

CC

8.0 Electrical Characteristics

Total Current out of GND Pin (Sink) 200 mA

Storage Temperature Range −65˚C to +140˚C

ESD Protection Level 2 kV (Human Body

Model)

Note 1: Absolute maximum ratings indicate limits beyond which damage to

the device may occur. DC and AC electrical specifications are not ensured

when operating the device at absolute maximum ratings.

DC Electrical Characteristics (−40˚C ≤ T

Datasheet min/max specification limits are guaranteed by design, test, or statistical analysis.

COP8SBR9/COP8SCR9/COP8SDR9

≤ +85˚C)

A

Parameter Conditions Min Typ Max Units

Operating Voltage 2.7 5.5 V

Power Supply Rise Time 10 50 x 10

Power Supply Ripple (Note 2) Peak-to-Peak 0.1 V

CC

Supply Current (Note 3)

High Speed Mode

CKI = 10 MHz V

CKI = 3.33 MHz V

= 5.5V, tC= 0.5 µs 14.7 mA

CC

= 4.5V, tC= 1.5 µs 7 mA

CC

Dual Clock Mode

CKI = 10 MHz, Low Speed OSC = 32 kHz V

CKI = 3.33 MHz, Low Speed OSC = 32 kHz V

= 5.5V, tC= 0.5 µs 14.7 mA

CC

= 4.5V, tC= 1.5 µs 7 mA

CC

Low Speed Mode

Low Speed OSC = 32 kHz V

= 5.5V 60 103 µA

CC

HALT Current with BOR Disabled (Note 4)

High Speed Mode V

Dual Clock Mode V

Low Speed Mode V

= 5.5V, CKI=0MHz

CC

= 5.5V, CKI = 0 MHz, Low

CC

Speed OSC = 32 kHz

= 5.5V, CKI = 0 MHz, Low

CC

Speed OSC = 32 kHz

<

210µA

<

517µA

<

517µA

Idle Current (Note 3)

High Speed Mode

CKI = 10 MHz V

CKI = 3.33 MHz V

= 5.5V, tC= 0.5 µs 2.5 mA

CC

= 4.5V, tC= 1.5 µs 1.2 mA

CC

Dual Clock Mode

CKI = 10 MHz, Low Speed OSC = 32 kHz V

CKI = 3.33 MHz, Low Speed OSC = 32 kHz V

= 5.5V, tC= 0.5 µs 2.5 mA

CC

= 4.5V, tC= 1.5 µs 1.2 mA

CC

Low Speed Mode

Low Speed OSC = 32 kHz V

Supply Current for BOR Feature V

= 5.5V 15 30 µA

CC

= 5.5V 45 µA

CC

High Brownout Trip Level (BOR Enabled) 4.17 4.28 4.5 V

Low Brownout Trip Level (BOR Enabled) 2.7 2.78 2.9 V

Input Levels (V

Logic High 0.8 V

Logic Low 0.16 V

Internal Bias Resistor for the CKI

Crystal/Resonator Oscillator

Hi-Z Input Leakage V

Input Pullup Current V

Port Input Hysteresis 0.25 V

IH,VIL

)

CC

CC

0.3 1.0 2.5 MΩ

= 5.5V −0.5 +0.5 µA

CC

= 5.5V, VIN= 0V −50 −210 µA

CC

CC

6

ns

V

V

V

V

www.national.com 12

Page 13

COP8SBR9/COP8SCR9/COP8SDR9

8.0 Electrical Characteristics (Continued)

DC Electrical Characteristics (−40˚C ≤ TA≤ +85˚C) (Continued)

Datasheet min/max specification limits are guaranteed by design, test, or statistical analysis.

Parameter Conditions Min Typ Max Units

Output Current Levels

D Outputs

Source V

Sink (Note 7) V

All Others

Source (Weak Pull-Up Mode) V

Source (Push-Pull Mode) V

Sink (Push-Pull Mode) (Note 7) V

TRI-STATE Leakage V

Allowable Sink Current per Pin 15 mA

Maximum Input Current without Latchup (Note

5)

RAM Retention Voltage, V

(in HALT Mode) 2.0 V

R

Input Capacitance 7pF

Load Capacitance on D2 1000 pF

Voltage on G6 to Force Execution from Boot

ROM (Note 8)

G6 Rise Time to Force Execution from Boot

ROM

Input Current on G6 when Input

>

V

CC

Flash Memory Data Retention 25˚C 100 yrs

Flash Memory Number of Erase/Write Cycles See Table 13, Typical Flash

= 4.5V, VOH= 3.8V −7 mA

CC

V

= 2.7V, VOH= 1.8V −4 mA

CC

= 4.5V, VOL= 1.0V 10 mA

CC

V

= 2.7V, VOL= 0.4V 3.5 mA

CC

= 4.5V, VOH= 3.8V −10 µA

CC

V

= 2.7V, VOH= 1.8V −5 µA

CC

= 4.5V, VOH= 3.8V −7 mA

CC

V

= 2.7V, VOH= 1.8V −4 mA

CC

= 4.5V, VOL= 1.0V 10 mA

CC

V

= 2.7V, VOL= 0.4V 3.5 mA

CC

= 5.5V −0.5 +0.5 µA

CC

±

200 mA

G6 rise time must be slower

than 100 nS

2xV

CC

VCC+7 V

100 nS

VIN= 11V, VCC= 5.5V 500 µA

5

Memory Endurance

10

cycles

AC Electrical Characteristics (−40˚C ≤ TA≤ +85˚C)

Datasheet min/max specification limits are guaranteed by design, test, or statistical analysis.

Parameter Conditions Min Typ Max Units

Instruction Cycle Time (t

Crystal/Resonator 4.5V ≤ V

Flash Memory Page Erase Time See Table 13, Typical

Flash Memory Mass Erase Time 8 ms

Frequency of MICROWIRE/PLUS in

Slave Mode

MICROWIRE/PLUS Setup Time (t

MICROWIRE/PLUS Hold Time (t

MICROWIRE/PLUS Output Propagation

UPD

)

Delay (t

Input Pulse Width

Interrupt Input High Time 1 t

Interrupt Input Low Time 1 t

)

C

≤ 5.5V 0.5 DC µs

CC

2.7V ≤ V

Flash Memory

<

4.5V 1.5 DC µs

CC

1ms

Endurance

2 MHz

)20ns

UWS

)20ns

UWH

150 ns

www.national.com13

C

C

Page 14

8.0 Electrical Characteristics (Continued)

AC Electrical Characteristics (−40˚C ≤ TA≤ +85˚C) (Continued)

Datasheet min/max specification limits are guaranteed by design, test, or statistical analysis.

Parameter Conditions Min Typ Max Units

Timer 1 Input High Time 1 t

Timer 1 Input Low Time 1 t

Timer 2, 3 Input High Time (Note 6) 1 MCLK or t

Timer 2, 3 Input Low Time (Note 6) 1 MCLK or t

Output Pulse Width

Timer 2, 3 Output High Time 150 ns

Timer 2, 3 Output Low Time 150 ns

COP8SBR9/COP8SCR9/COP8SDR9

USART Bit Time when using External

CKX

USART CKX Frequency when being

Driven by Internal Baud Rate Generator

Reset Pulse Width 1 t

tC= instruction cycle time.

<

Note 2: Maximum rate of voltage change must be

Note 3: Supply and IDLE currents are measured with CKI driven with a square wave Oscillator, CKO driven 180˚ out of phase with CKI, inputs connected to V

and outputs driven low but not connected to a load.

Note 4: The HALT mode will stop CKI from oscillating. Measurement of I

and G2–G5 programmed as low outputs and not driving a load; all D outputs programmed low and not driving a load; all inputs tied to V

monitor and BOR disabled. Parameter refers to HALT mode entered via setting bit 7 of the G Port data register.

Note 5: Pins G6 and RESET are designed with a high voltage input network. These pins allow input voltages

biased at voltages>VCC(the pins do not have source current when biased at a voltage below VCC). These two pins will not latch up. The voltage at the pins must

be limited to

Note 6: If timer is in high speed mode, the minimum time is 1 MCLK. If timer is not in high speed mode, the minimum time is 1 t

Note 7: Absolute Maximum Ratings should not be exceeded.

Note 8: V

<

14V. WARNING: Voltages in excess of 14V will cause damage to the pins. This warning excludes ESD transients.

must be valid and stable before G6 is raised to a high voltage.

CC

0.5 V/ms.

HALT is done with device neither sourcing nor sinking current; with L. A. B, C, E, F, G0,

DD

6 CKI

periods

2 MHz

; A/D converter and clock

CC

>

VCCand the pins will have sink current to VCCwhen

.

C

C

C

C

C

µs

C

CC

DC Electrical Characteristics (−40˚C ≤ TA≤ +125˚C)

Datasheet min/max specification limits are guaranteed by design, test, or statistical analysis.

Parameter Conditions Min Typ Max Units

Operating Voltage 4.5 5.5 V

Power Supply Rise Time 10 50 x 10

Power Supply Ripple (Note 2) Peak-to-Peak 0.1 V

Supply Current (Note 3)

High Speed Mode

CKI = 10 MHz V

CKI = 3.33 MHz V

= 5.5V, tC= 0.5 µs 14.5 mA

CC

= 4.5V, tC= 1.5 µs 7 mA

CC

Dual Clock Mode

CKI = 10 MHz, Low Speed OSC = 32 kHz V

CKI = 3.33 MHz, Low Speed OSC = 32 kHz V

= 5.5V, tC= 0.5 µs 14.5 mA

CC

= 4.5V, tC= 1.5 µs 7 mA

CC

Low Speed Mode

Low Speed OSC = 32 kHz V

= 5.5V 65 110 µA

CC

HALT Current with BOR Disabled (Note 4)

High Speed Mode V

Dual Clock Mode V

Low Speed Mode V

= 5.5V, CKI=0MHz

CC

= 5.5V, CKI = 0 MHz, Low

CC

Speed OSC = 32 kHz

= 5.5V, CKI = 0 MHz, Low

CC

Speed OSC = 32 kHz

<

440 µA

<

950 µA

<

950 µA

Idle Current (Note 3)

High Speed Mode

CKI = 10 MHz V

= 5.5V, tC= 0.5 µs 2.7 mA

CC

6

CC

ns

V

www.national.com 14

Page 15

COP8SBR9/COP8SCR9/COP8SDR9

8.0 Electrical Characteristics (Continued)

DC Electrical Characteristics (−40˚C ≤ TA≤ +125˚C) (Continued)

Datasheet min/max specification limits are guaranteed by design, test, or statistical analysis.

Parameter Conditions Min Typ Max Units

Dual Clock Mode

CKI = 10 MHz, Low Speed OSC = 32 kHz V

Low Speed Mode

Low Speed OSC = 32 kHz V

Supply Current for BOR Feature V

High Brownout Trip Level (BOR Enabled) 4.17 4.28 4.5 V

Input Levels (V

IH,VIL

)

Logic High 0.8 V

Logic Low 0.16 V

Internal Bias Resistor for the CKI

Crystal/Resonator Oscillator

Hi-Z Input Leakage V

Input Pullup Current V

Port Input Hysteresis 0.25 V

Output Current Levels

D Outputs

Source V

Sink (Note 7) V

All Others

Source (Weak Pull-Up Mode) V

Source (Push-Pull Mode) V

Sink (Push-Pull Mode) (Note 7) V

TRI-STATE Leakage V

Allowable Sink Current per Pin 1mA

Maximum Input Current without Latchup (Note 5)

RAM Retention Voltage, V

(in HALT Mode) 2.0 V

R

Input Capacitance 7pF

Load Capacitance on D2 1000 pF

Voltage on G6 to Force Execution from Boot

ROM(Note *NO TARGET FOR FNXref NS20196*)

G6 Rise Time to Force Execution from Boot ROM 100 nS

Input Current on G6 when Input

>

V

CC

= 5.5V, tC= 0.5 µs 2.7 mA

CC

= 5.5V 30 70 µA

CC

= 5.5V 45 µA

CC

CC

CC

V

V

0.3 1.0 2.5 MΩ

= 5.5V −3 +3 µA

CC

= 5.5V, VIN= 0V −40 −250 µA

CC

CC

= 4.5V, VOH= 3.8V −6.3 mA

CC

= 4.5V, VOL= 1.0V 9 mA

CC

= 4.5V, VOH= 3.8V −9 µA

CC

= 4.5V, VOH= 3.8V −6.3 mA

CC

= 4.5V, VOL= 1.0V 9 mA

CC

= 5.5V −3 +3 µA

CC

±

200 mA

G6 rise time must be slower than

100 ns

2xV

CC

VCC+7 V

V

VIN= 11V, VCC= 5.5V 500 µA

AC Electrical Characteristics (−40˚C ≤ TA≤ +125˚C)

Datasheet min/max specification limits are guaranteed by design, test, or statistical analysis.

Parameter Conditions Min Typ Max Units

Instruction Cycle Time (t

Crystal/Resonator 4.5V ≤ V

Output Propagation Delay R

Frequency of MICROWIRE/PLUS in

Slave Mode

MICROWIRE/PLUS Setup Time (t

MICROWIRE/PLUS Hold Time (t

MICROWIRE/PLUS Output Propagation

Delay (t

UPD

)

Input Pulse Width

Interrupt Input High Time 1 t

)

C

≤ 5.5V 0.5 DC µs

CC

=2.2k, CL= 100 pF

L

2 MHz

)20ns

UWS

)20ns

UWH

150 ns

C

www.national.com15

Page 16

8.0 Electrical Characteristics (Continued)

AC Electrical Characteristics (−40˚C ≤ TA≤ +125˚C) (Continued)

Datasheet min/max specification limits are guaranteed by design, test, or statistical analysis.

Parameter Conditions Min Typ Max Units

Interrupt Input Low Time 1 t

Timer 1 Input High Time 1 t

Timer 1 Input Low Time 1 t

Timer 2, 3 Input High Time (Note 6) 1 MCLK or t

Timer 2, 3 Input Low Time (Note 6) 1 MCLK or t

Output Pulse Width

Timer 2, 3 Output High Time 150 ns

COP8SBR9/COP8SCR9/COP8SDR9

Timer 2, 3 Output Low Time 150 ns

USART Bit Time when using External

CKX

USART CKX Frequency when being

Driven by Internal Baud Rate Generator

6 CKI

periods

2 MHz

Reset Pulse Width 0.5 t

tC= instruction cycle time.

<

Note 9: Maximum rate of voltage change must be

Note 10: Supply and IDLE currents are measured with CKI driven with a square wave Oscillator, CKO driven 180˚ out of phase with CKI, inputs connected to V

and outputs driven low but not connected to a load.

Note 11: The HALT mode will stop CKI from oscillating. Measurement of I

G0, and G2–G5 programmed as low outputs and not driving a load; all D outputs programmed low and not driving a load; all inputs tied to V

clock monitor and BOR disabled. Parameter refers to HALT mode entered via setting bit 7 of the G Port data register.

Note 12: Pins G6 and RESET are designed with a high voltage input network. These pins allow input voltages

when biased at voltages>VCC(the pins do not have source current when biased at a voltage below VCC). These two pins will not latch up. The voltage at the pins

must be limited to

Note 13: If timer is in high speed mode, the minimum time is 1 MCLK. If timer is not in high speed mode, the minimum time is 1 t

Note 14: Absolute Maximum Ratings should not be exceeded.

Note 15: V

<

(VCC+7V.WARNING: Voltages in excess of 14V will cause damage to the pins. This warning excludes ESD transients.

must be valid and stable before G6 is raised to a high voltage.

cc

0.5 V/ms.

HALT is done with device neither sourcing nor sinking current; with L. A. B, C, E, F,

DD

>

VCCand the pins will have sink current to V

C

.

; A/D converter and

CC

C

C

C

C

C

C

CC

CC

FIGURE 1. MICROWIRE/PLUS Timing

www.national.com 16

10138905

Page 17

9.0 Pin Descriptions

The COP8SBR9/SCR9/SDR9 I/O structure enables designers to reconfigure the microcontroller’s I/O functions with a

single instruction. Each individual I/O pin can be independently configured as output pin low, output high, input with

high impedance or input with weak pull-up device. A typical

example is the use of I/O pins as the keyboard matrix input

lines. The input lines can be programmed with internal weak

pull-ups so that the input lines read logic high when the keys

are all open. With a key closure, the corresponding input line

will read a logic zero since the weak pull-up can easily be

overdriven. When the key is released, the internal weak

pull-up will pull the input line back to logic high. This eliminates the need for external pull-up resistors. The high current options are available for driving LEDs, motors and

speakers. This flexibility helps to ensure a cleaner design,

with less external components and lower costs. Below is the

general description of all available pins.

and GND are the power supply pins. All VCCand GND

V

CC

pins must be connected.

Users of the LLP package are cautioned to be aware that the

central metal area and the pin 1 index mark on the bottom of

the package may be connected to GND. See figure below:

10138970

FIGURE 2. LLP Package Bottom View

CKI is the clock input. This can be connected (in conjunction

with CKO) to an external crystal circuit to form a crystal

oscillator. See Oscillator Description section.

RESET is the master reset input. See Reset description

section.

is the Analog Supply for A/D converter. It should be

AV

CC

connected to V

resistor ladder D/A converter used within the A/D converter.

AGND is the ground pin for the A/D converter. It should be

connected to GND externally. This is also the bottom of the

resistor ladder D/A converter used within the A/D converter.

The device contains up to six bidirectional 8-bit I/O ports (A,

B, C, E, G and L) and one 4-bit I/O port (F), where each

individual bit may be independently configured as an input

(Schmitt trigger inputs on ports L and G), output or TRISTATE under program control. Three data memory address

locations are allocated for each of these I/O ports. Each I/O

port has three associated 8-bit memory mapped registers,

the CONFIGURATION register, the output DATAregister and

the Pin input register. (See the memory map for the various

addresses associated with the I/O ports.) Figure 3 shows the

I/O port configurations. The DATA and CONFIGURATION

registers allow for each port bit to be individually configured

externally. This is also the top of the

CC

under software control as shown below:

CONFIGURATION

Register

0 0 Hi-Z Input

0 1 Input with Weak Pull-Up

1 0 Push-Pull Zero Output

1 1 Push-Pull One Output

DATA

Register

Port Set-Up

(TRI-STATE Output)

Port A is an 8-bit I/O port. All A pins have Schmitt triggers on

the inputs. The 44-pin package does not have a full 8-bit port

and contains some unbonded, floating pads internally on the

chip. The binary value read from these bits is undetermined.

The application software should mask out these unknown

bits when reading the Port A register, or use only bit-access

program instructions when accessing Port A. These unconnected bits draw power only when they are addressed (i.e.,

in brief spikes).

Port B is an 8-bit I/O port. All B pins have Schmitt triggers on

the inputs.

Port C is an 8-bit I/O port. The 44-pin device does not offer

Port C. The unavailable pins are not terminated. A read

operation on these unterminated pins will return unpredictable values. On this device, the associated Port C Data and

Configuration registers should not be used. All C pins have

Schmitt triggers on the inputs. Port C draws no power when

unbonded.

Port E is an 8-bit I/O Port. The 44-pin device does not offer

Port E. The unavailable pins are not terminated. A read

operation on these unterminated pins will return unpredictable values. On this device, the associated Port E Data and

Configuration registers should not be used. All E pins have

Schmitt triggers on the inputs. Port E draws no power when

unbonded.

Port F is a 4-bit I/O Port. All F pins have Schmitt triggers on

the inputs.

The 68-pin package has fewer than eight Port F pins, and

contains unbonded, floating pads internally on the chip. The

binary values read from these bits are undetermined. The

application software should mask out these unknown bits

when reading the Port F register, or use only bit-access

program instructions when accessing Port F. The unconnected bits draw power only when they are addressed (i.e.,

in brief spikes).

Port G is an 8-bit port. Pin G0, G2–G5 are bi-directional I/O

ports. Pin G6 is always a general purpose Hi-Z input. All pins

have Schmitt Triggers on their inputs. Pin G1 serves as the

dedicated WATCHDOG output with weak pull-up if the

WATCHDOG feature is selected by the Option register.

The pin is a general purpose I/O if WATCHDOG feature is

not selected. If WATCHDOG feature is selected, bit 1 of the

Port G configuration and data register does not have any

effect on Pin G1 setup. G7 serves as the dedicated output

pin for the CKO clock output.

Since G6 is an input only pin and G7 is the dedicated CKO

clock output pin, the associated bits in the data and configuration registers for G6 and G7 are used for special purpose

functions as outlined below. Reading the G6 and G7 data

bits will return zeros.

The device will be placed in the HALT mode by writing a “1”

to bit 7 of the Port G Data Register. Similarly the device will

be placed in the IDLE mode by writing a “1” to bit 6 of the

Port G Data Register.

COP8SBR9/COP8SCR9/COP8SDR9

www.national.com17

Page 18

9.0 Pin Descriptions (Continued)

Writing a “1” to bit 6 of the Port G Configuration Register

enables the MICROWIRE/PLUS to operate with the alternate phase of the SK clock. The G7 configuration bit, if set

high, enables the clock start up delay after HALT when the

R/C clock configuration is used.

Config. Reg. Data Reg.

G7 CLKDLY HALT

G6 Alternate SK IDLE

Port G has the following alternate features:

G7 CKO Oscillator dedicated output

G6 SI (MICROWIRE/PLUS Serial Data Input)

COP8SBR9/COP8SCR9/COP8SDR9

G5 SK (MICROWIRE/PLUS Serial Clock)

G4 SO (MICROWIRE/PLUS Serial Data Output)

G3 T1A (Timer T1 I/O)

G2 T1B (Timer T1 Capture Input)

G1 WDOUT WATCHDOG and/or Clock Monitor if WATCH-

DOG enabled, otherwise it is a general purpose I/O

G0 INTR (External Interrupt Input)

G0 through G3 are also used for In-System Emulation.

Port L is an 8-bit I/O port. All L-pins have Schmitt triggers on

the inputs.

Port L supports the Multi-Input Wake-Up feature on all eight

pins. Port L has the following alternate pin functions:

L7 Multi-Input Wake-up or T3B (Timer T3B Input)

L6 Multi-Input Wake-up or T3A (Timer T3A Input/Output)

L5 Multi-Input Wake-up or T2B (Timer T2B Input)

L4 Multi-Input Wake-up or T2A (Timer T2A Input/Output)

L3 Multi-Input Wake-up and/or RDX (USART Receive)

L2 Multi-Input Wake-up or TDX (USART Transmit)

L1 Multi-Input Wake-up and/or CKX (USART Clock) (Low

Speed Oscillator Output)

L0 Multi-Input Wake-up (Low Speed Oscillator Input)

Port D is an 8-bit output port that is preset high when RESET

goes low. The user can tie two or more D port outputs

(except D2) together in order to get a higher drive.

Note: Care must be exercised with the D2 pin operation. At

RESET, the external loads on this pin must ensure that the

output voltages stay above 0.7 V

entering special modes. Also keep the external loading on

D2 to less than 1000 pF.

to prevent the chip from

CC

10138907

FIGURE 4. I/O Port Configurations —Output Mode

10138908

FIGURE 5. I/O Port Configurations —Input Mode

9.1 EMULATION CONNECTION

Connection to the emulation system is made viaa2x7

connector which interrupts the continuity of the RESET, G0,

G1, G2 and G3 signals between the COP8 device and the

rest of the target system (as shown in Figure 6). This connector can be designed into the production pc board and can

be replaced by jumpers or signal traces when emulation is

no longer necessary. The emulator will replicate all functions

of G0 - G3 and RESET. For proper operation, no connection

should be made on the device side of the emulator connector.

10138906

FIGURE 3. I/O Port Configurations

www.national.com 18

Page 19

9.0 Pin Descriptions (Continued)

10138909

FIGURE 6. Emulation Connection

10.0 Functional Description

The architecture of the device is a modified Harvard architecture. With the Harvard architecture, the program memory

(Flash) is separate from the data store memory (RAM). Both

Program Memory and Data Memory have their own separate

addressing space with separate address buses. The architecture, though based on the Harvard architecture, permits

transfer of data from Flash Memory to RAM.

10.1 CPU REGISTERS

The CPU can do an 8-bit addition, subtraction, logical or shift

operation in one instruction (t

There are six CPU registers:

A is the 8-bit Accumulator Register

PC is the 15-bit Program Counter Register

PU is the upper 7 bits of the program counter (PC)

PL is the lower 8 bits of the program counter (PC)

B is an 8-bit RAM address pointer, which can be optionally

post auto incremented or decremented.

X is an 8-bit alternate RAM address pointer, which can be

optionally post auto incremented or decremented.

S is the 8-bit Data Segment Address Register used to extend

the lower half of the address range (00 to 7F) into 256 data

segments of 128 bytes each.

SP is the 8-bit stack pointer, which points to the subroutine/

interrupt stack (in RAM). With reset the SP is initialized to

RAM address 06F Hex. The SP is decremented as items are

pushed onto the stack. SP points to the next available location on the stack.

All the CPU registers are memory mapped with the exception of the Accumulator (A) and the Program Counter (PC).

10.2 PROGRAM MEMORY

The program memory consists of 32,768 bytes of Flash

Memory. These bytes may hold program instructions or constant data (data tables for the LAID instruction, jump vectors

) cycle time.

C

COP8SBR9/COP8SCR9/COP8SDR9

for the JID instruction, and interrupt vectors for the VIS

instruction). The program memory is addressed by the 15-bit

program counter (PC). All interrupts in the device vector to

program memory location 00FF Hex. The program memory

reads 00 Hex in the erased state. Program execution starts

at location 0 after RESET.

If a Return instruction is executed when the SP contains 6F

(hex), instruction execution will continue from Program

Memory location 7FFF (hex). If location 7FFF is accessed by

an instruction fetch, the Flash Memory will return a value of

00. This is the opcode for the INTR instruction and will cause

a Software Trap.

For the purpose of erasing and rewriting the Flash Memory,

it is organized in pages of 128 bytes.

10.3 DATA MEMORY

The data memory address space includes the on-chip RAM

and data registers, the I/O registers (Configuration, Data and

Pin), the control registers, the MICROWIRE/PLUS SIO shift

register, and the various registers, and counters associated

with the timers and the USART (with the exception of the

IDLE timer). Data memory is addressed directly by the instruction or indirectly by the B, X and SP pointers.

The data memory consists of 1024 bytes of RAM. Sixteen

bytes of RAM are mapped as “registers” at addresses 0F0 to

0FF Hex. These registers can be loaded immediately, and

also decremented and tested with the DRSZ (decrement

register and skip if zero) instruction. The memory pointer

registers X, SP, B and S are memory mapped into this space

at address locations 0FC to 0FF Hex respectively, with the

other registers being available for general usage.

The instruction set permits any bit in memory to be set, reset

or tested. All I/O and registers (except A and PC) are

memory mapped; therefore, I/O bits and register bits can be

directly and individually set, reset and tested. The accumulator (A) bits can also be directly and individually tested.

Note: RAM contents are undefined upon power-up.

10.4 DATA MEMORY SEGMENT RAM EXTENSION

Data memory address 0FF is used as a memory mapped

location for the Data Segment Address Register (S).

The data store memory is either addressed directly by a

single byte address within the instruction, or indirectly relative to the reference of the B, X, or SP pointers (each

contains a single-byte address). This single-byte address

allows an addressing range of 256 locations from 00 to FF

hex. The upper bit of this single-byte address divides the

data store memory into two separate sections as outlined

previously. With the exception of the RAM register memory

from address locations 00F0 to 00FF, all RAM memory is

memory mapped with the upper bit of the single-byte address being equal to zero. This allows the upper bit of the

single-byte address to determine whether or not the base

address range (from 0000 to 00FF) is extended. If this upper

bit equals one (representing address range 0080 to 00FF),

then address extension does not take place. Alternatively, if

this upper bit equals zero, then the data segment extension

register S is used to extend the base address range (from

0000 to 007F) from XX00 to XX7F, where XX represents the

8 bits from the S register. Thus the 128-byte data segment

extensions are located from addresses 0100 to 017F for

data segment 1, 0200 to 027F for data segment 2, etc., up to

FF00 to FF7F for data segment 255. The base address

range from 0000 to 007F represents data segment 0.

www.national.com19

Page 20

10.0 Functional Description

(Continued)

Figure 7 illustrates how the S register data memory extension is used in extending the lower half of the base address

range (00 to 7F hex) into 256 data segments of 128 bytes

each, with a total addressing range of 32 kbytes from XX00

to XX7F. This organization allows a total of 256 data segments of 128 bytes each with an additional upper base

segment of 128 bytes. Furthermore, all addressing modes

are available for all data segments. The S register must be

changed under program control to move from one data

segment (128 bytes) to another. However, the upper base

segment (containing the 16 memory registers, I/O registers,

COP8SBR9/COP8SCR9/COP8SDR9

control registers, etc.) is always available regardless of the

contents of the S register, since the upper base segment

(address range 0080 to 00FF) is independent of data segment extension.

The instructions that utilize the stack pointer (SP) always

reference the stack as part of the base segment (Segment

0), regardless of the contents of the S register. The S register

is not changed by these instructions. Consequently, the

stack (used with subroutine linkage and interrupts) is always

located in the base segment. The stack pointer will be initialized to point at data memory location 006F as a result of

reset.

FIGURE 7. RAM Organization

The 128 bytes of RAM contained in the base segment are

split between the lower and upper base segments. The first

112 bytes of RAM are resident from address 0000 to 006F in

the lower base segment, while the remaining 16 bytes of

RAM represent the 16 data memory registers located at

addresses 00F0 to 00FF of the upper base segment. No

RAM is located at the upper sixteen addresses (0070 to

007F) of the lower base segment.

Additional RAM beyond these initial 128 bytes, however, will

always be memory mapped in groups of 128 bytes (or less)

at the data segment address extensions (XX00 to XX7F) of

the lower base segment. The additional 892 bytes of RAM in

this device are memory mapped at address locations 0100

to 017F through 0700 to 077F hex.

10.4.1 Virtual EEPROM

The Flash memory and the User ISP functions (see Section

5.7), provide the user with the capability to use the flash

program memory to back up user defined sections of RAM.

This effectively provides the user with the same nonvolatile

data storage as EEPROM. Management, and even the

www.national.com 20

10138910

amount of memory used, are the responsibility of the user,

however the flash memory read and write functions have

been provided in the boot ROM.

One typical method of using the Virtual EEPROM feature

would be for the user to copy the data to RAM during system

initialization, periodically, and if necessary, erase the page of

Flash and copy the contents of the RAM back to the Flash.

10.5 OPTION REGISTER

The Option register, located at address 0x7FFF in the Flash

Program Memory, is used to configure the user selectable

security, WATCHDOG, and HALT options. The register can

be programmed only in external Flash Memory programming

or ISP Programming modes. Therefore, the register must be

programmed at the same time as the program memory. The

contents of the Option register shipped from the factory read

00 Hex.

Page 21

10.0 Functional Description

(Continued)

The format of the Option register is as follows:

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Reserved SECURITY Reserved

Bits 7, 6 These bits are reserved and must be 0.

Bit 5

= 1 Security enabled. Flash Memory read and write

are not allowed except in User ISP/Virtual E

mands. Mass Erase is allowed.

= 0 Security disabled. Flash Memory read and write

are allowed.

Bits 4, 3 These bits are reserved and must be 0.

Bit 2

= 1 WATCHDOG feature disabled. G1 is a general

purpose I/O.

= 0 WATCHDOG feature enabled. G1 pin is

WATCHDOG output with weak pullup.

Bit 1

= 1 HALT mode disabled.

= 0 HALT mode enabled.

Bit 0

= 1 Execution following RESET will be from Flash

Memory.

= 0 Flash Memory is erased. Execution following RE-

SET will be from Boot ROM with the MICROWIRE/

PLUS ISP routines.

The COP8 assembler defines a special ROM section type,

CONF, into which the Option Register data may be coded.

The Option Register is programmed automatically by programmers that are certified by National.

The user needs to ensure that the FLEX bit will be set when

the device is programmed.

The following examples illustrate the declaration of the Option Register.

Syntax:

[label:].sect config, conf

.db value ;1 byte,

.endsect

Example: The following sets a value in the Option Register

and User Identification for a COP8SBR9VHA7. The Option

Register bit values shown select options: Security disabled,

WATCHDOG enabled HALT mode enabled and execution

will commence from Flash Memory.

.chip 8SBR

.sect option, conf

.db 0x01 ;wd, halt, flex

.endsect

...

.end start

Note: All programmers certified for programming this family

of parts will support programming of the Option Register.

Please contact National or your device programmer supplier

for more information.

WATCH

DOG

HALT FLEX

;configures

;options

2

com-

COP8SBR9/COP8SCR9/COP8SDR9

10.6 SECURITY

The device has a security feature which, when enabled,

prevents external reading of the Flash program memory. The

security bit in the Option Register determines, whether security is enabled or disabled. If the security feature is disabled, the contents of the internal Flash Memory may be

read by external programmers or by the built in

MICROWIRE/PLUS serial interface ISP. Security must be

enforced by the user when the contents of the Flash

Memory are accessed via the user ISP or Virtual EEPROM capability.

If the security feature is enabled, then any attempt to externally read the contents of the Flash Memory will result in the

value FF (hex) being read from all program locations (except

the Option Register). In addition, with the security feature

enabled, the write operation to the Flash program memory

and Option Register is inhibited. Page Erases are also inhibited when the security feature is enabled. The Option Register is readable regardless of the state of the security bit by

accessing location FFFF (hex). Mass Erase Operations are

possible regardless of the state of the security bit.

The security bit can be erased only by a Mass Erase of the

entire contents of the Flash unless Flash operation is under

the control of User ISP functions.

Note: The actual memory address of the Option Register is

7FFF (hex), however the MICROWIRE/PLUS ISP routines

require the address FFFF (hex) to be used to read the

Option Register when the Flash Memory is secured.

The entire Option Register must be programmed at one time

and cannot be rewritten without first erasing the entire last

page of Flash Memory.

10.7 RESET

The device is initialized when the RESET pin is pulled low or

the On-chip Brownout Reset is activated. The Brownout

Reset feature is not available on the COP8SDR9.

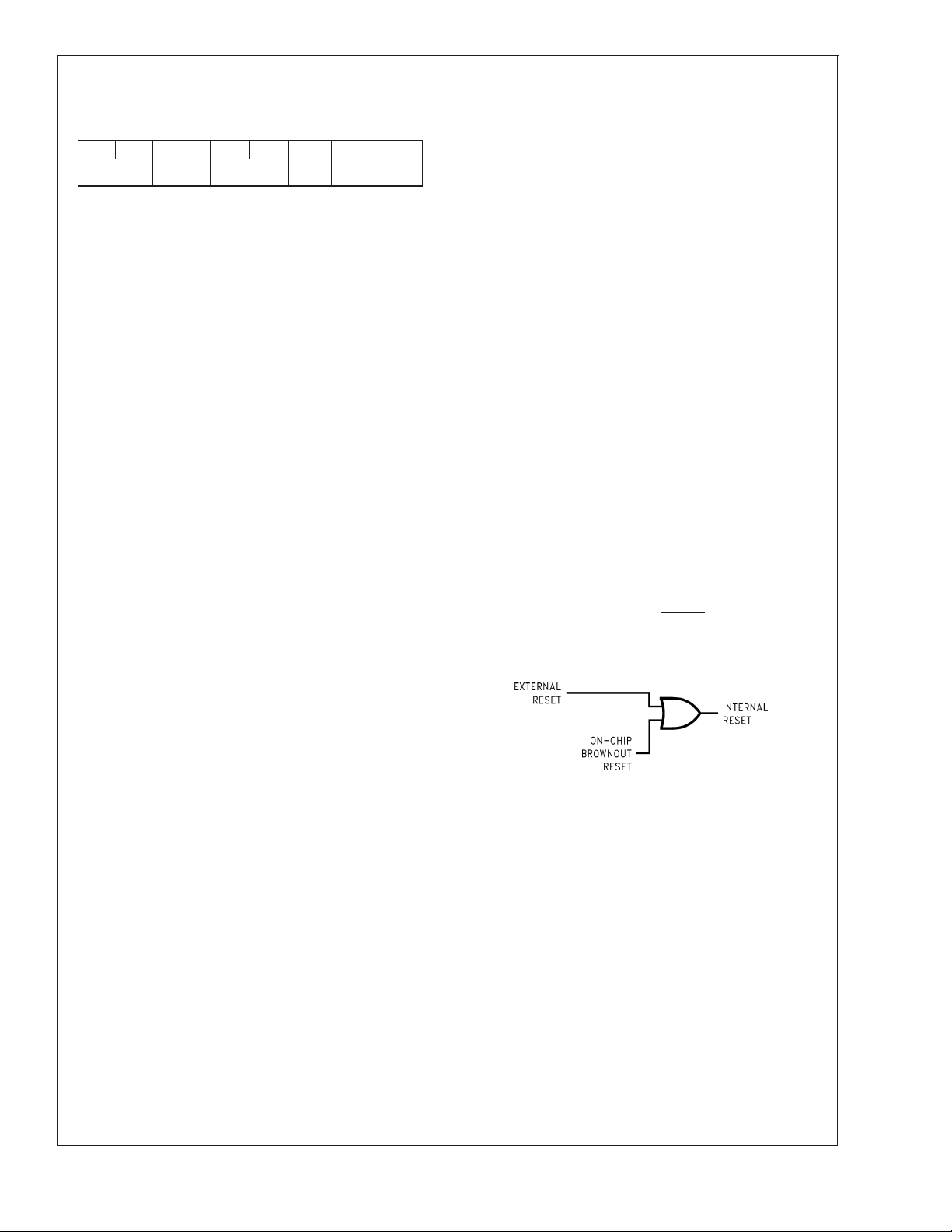

10138911

FIGURE 8. Reset Logic

The following occurs upon initialization:

Port A: TRI-STATE (High Impedance Input)

Port B: TRI-STATE (High Impedance Input)

Port C: TRI-STATE (High Impedance Input)