Page 1

查询COP87L84EGM-XE供应商

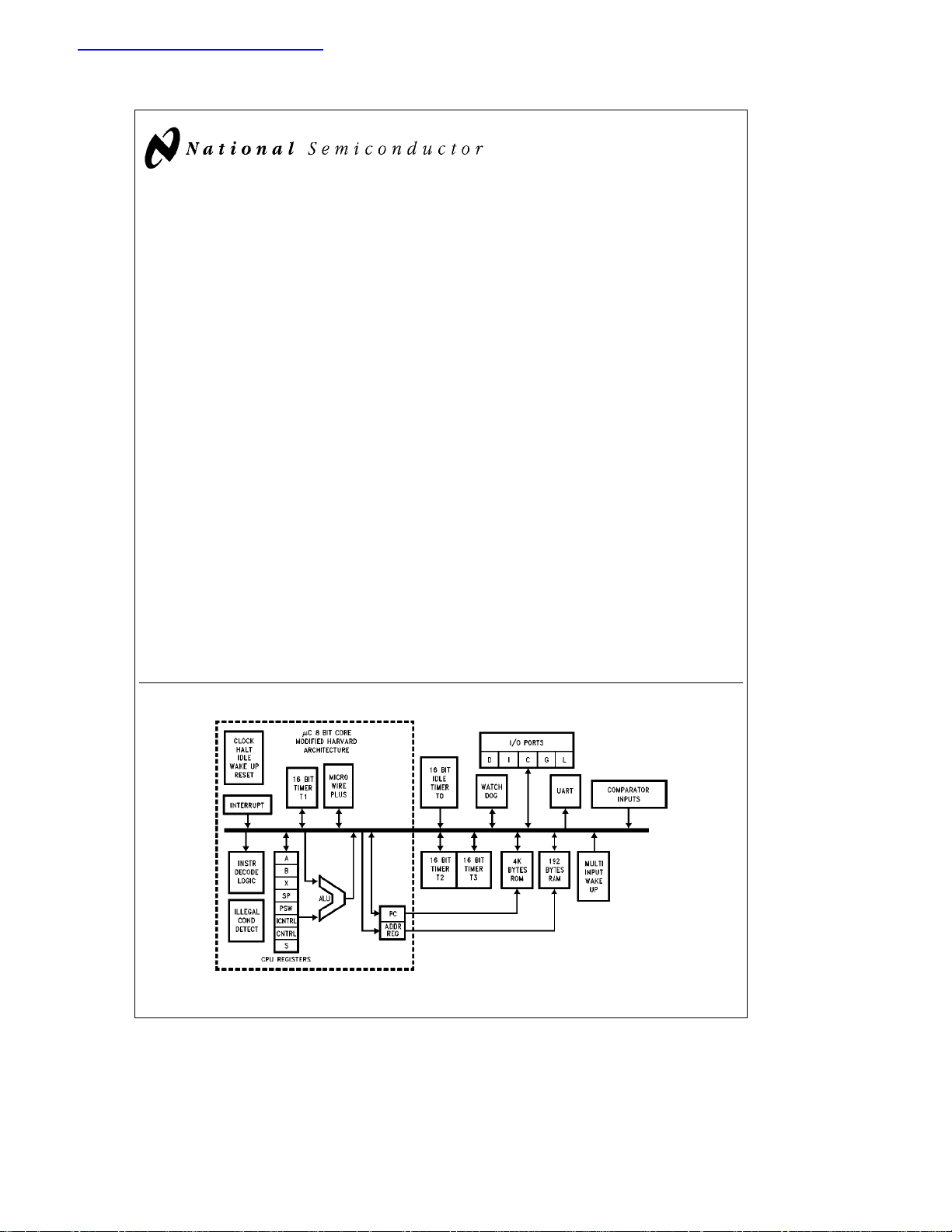

COP884CG/COP888CG 8-Bit Microcontroller

with UART and Three Multi-Function Timers

General Description

The COP888 family of microcontrollers uses an 8-bit single

chip core architecture fabricated with National Semiconduc-

2

tor’s M

CMOSTMprocess technology. The COP888CG is a

member of this expandable 8-bit core processor family of

microcontrollers. (Continued)

Key Features

Y

Full duplex UART

Y

Three 16-bit timers, each with two 16-bit registers supporting:

Ð Processor independent PWM mode

Ð External event counter mode

Ð Input capture mode

Y

Quiet design (low radiated emissions)

Y

4 kbytes of on-chip ROM

Y

192 bytes of on-chip RAM

Additional Peripheral Features

Y

Idle timer

Y

Multi-Input Wake Up (MIWU) with optional interrupts (8)

Y

Two analog comparators

Y

WATCHDOGTMand Clock Monitor logic

Y

MICROWIRE/PLUSTMserial I/O

I/O Features

Y

Memory mapped I/O

Y

Software selectable I/O options (TRI-STATEÉoutput,

push-pull output, weak pull-up input, high impedance input)

Y

High current outputs

August 1996

Y

Schmitt trigger inputs on Port G

Y

Packages:

Ð 44 PLCC with 40 I/O pins

Ð 40 DIP with 36 I/O pins

Ð 28 DIP with 24 I/O pins

Ð 28 SO with 24 I/O pins

CPU/Instruction Set Feature

Y

1 ms instruction cycle time

Y

Fourteen multi-source vectored interrupts servicing

Ð External interrupt with selectable edge

Ð Idle timer T0

Ð Three timers (each with 2 interrupts)

Ð MICROWIRE/PLUS

Ð Multi-Input WAke Up

Ð Software trap

Ð UART (2)

Ð Default VIS (default interrupt)

Y

Versatile and easy to use instruction set

Y

8-bit Stack Pointer (SP)Ðstack in RAM

Y

Two 8-bit register indirect data memory pointers (B, X)

Fully Static CMOS

Y

Low current drain (typicallyk1 mA)

Y

Single supply operation: 2.5V to 6.0V

Y

Temperature range:b40§Ctoa85§C

Development Support

Y

Emulation and OTP devices

Y

Real time emulation and full program debug offered by

MetaLink Development System

COP884CG/COP888CG 8-Bit Microcontroller with UART and Three Multi-Function Timers

Block Diagram

TRI-STATEÉis a registered trademark of National Semiconductor Corporation.

MICROWIRE/PLUS

iceMASTER

C

1996 National Semiconductor Corporation RRD-B30M106/Printed in U. S. A.

TM

,M2CMOSTM, COP8TMmicrocontrollers, MICROWIRETMand WATCHDOGTMare trademarks of National Semiconductor Corporation.

TM

is a trademark of MetaLink Corporation.

TL/DD/9765

FIGURE 1. Block Diagram

TL/DD/9765– 1

http://www.national.com

Page 2

General Description (Continued)

They are fully static parts, fabricated using double-metal silicon gate microCMOS technology. Features include an 8-bit

memory mapped architecture, MICROWIRE/PLUS serial

I/O, three 16-bit timer/counters supporting three modes

(Processor Independent PWM generation, External Event

counter, and Input Capture mode capabilities), full duplex

UART, two comparators, and two power savings modes

(HALT and IDLE), both with a multi-sourced wakeup/interrupt capability. This multi-sourced interrupt capability may

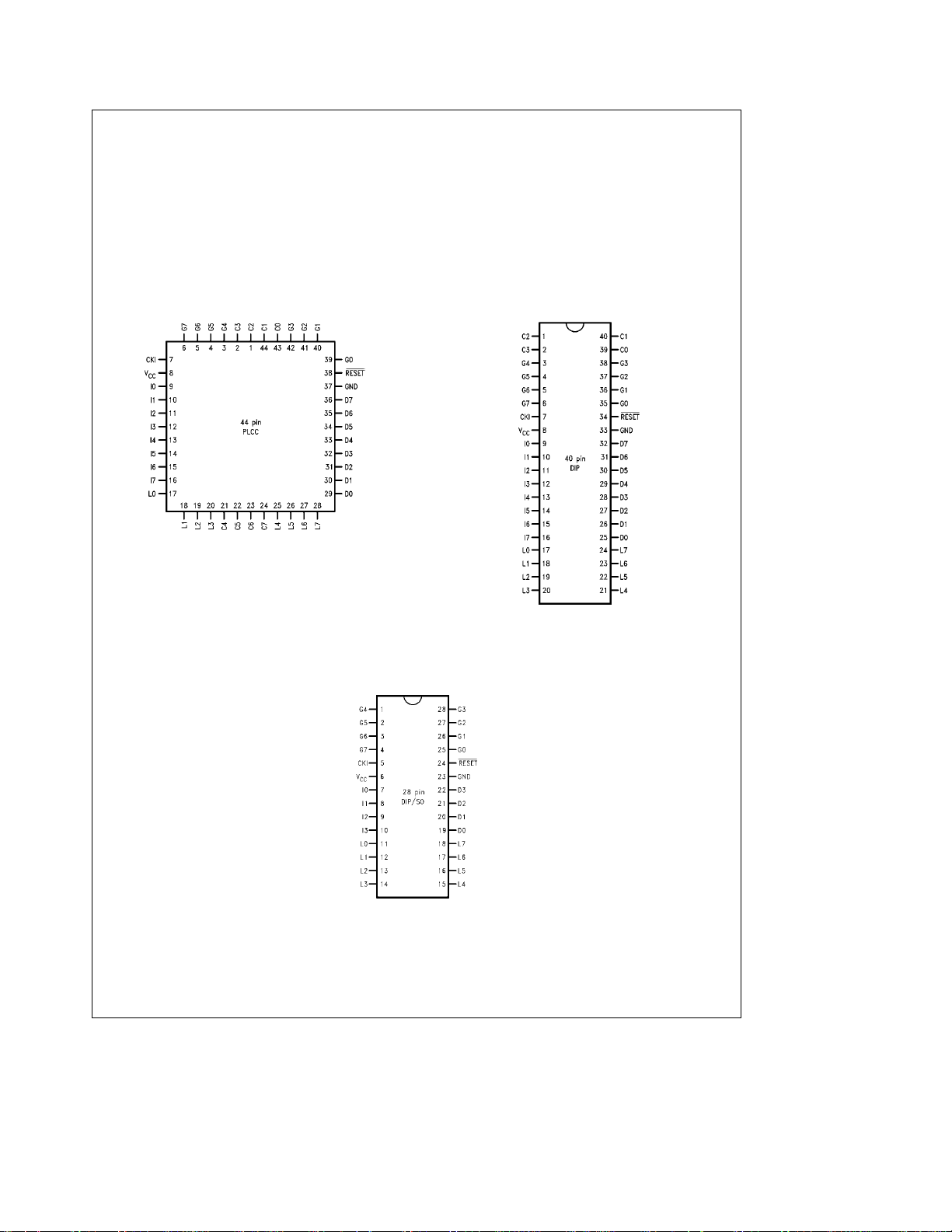

Connection Diagrams

Plastic Chip Carrier

also be used independent of the HALT or IDLE modes.

Each I/O pin has software selectable configurations. The

device operates over a voltage range of 2.5V to 6V. High

throughput is achieved with an efficient, regular instruction

set operating at a maximum of 1 ms per instruction rate.

The device has reduced EMI emissions. Low radiated emissions are achieved by gradual turn-on output drivers and

internal I

filters on the chip logic and crystal oscillator.

CC

Dual-In-Line Package

Top View

TL/DD/9765– 2

Order Number COP888CG-XXX/V

See NS Plastic Chip Package Number V44A

Order Number COP884CG-XXX/N or COP884CG-XXX/WM

See NS Molded Package Number N28A OR M28B

FIGURE 2a. Connection Diagrams

Top View

TL/DD/9765– 4

Order Number COP888CG-XXX/N

See NS Molded Package Number N40A

Dual-In-Line Package

TL/DD/9765– 5

Top View

http://www.national.com 2

Page 3

Connection Diagrams (Continued)

Pinouts for 28-, 40- and 44-Pin Packages

Port Type Alt. Fun Alt. Fun

L0 I/O MIWU 11 17 17

L1 I/O MIWU CKX 12 18 18

L2 I/O MIWU TDX 13 19 19

L3 I/O MIWU RDX 14 20 20

L4 I/O MIWU T2A 15 21 25

L5 I/O MIWU T2B 16 22 26

L6 I/O MIWU T3A 17 23 27

L7 I/O MIWU T3B 18 24 28

G0 I/O INT 25 35 39

G1 WDOUT 26 36 40

G2 I/O T1B 27 37 41

G3 I/O T1A 28 38 42

G4 I/O SO 1 3 3

G5 I/O SK 2 4 4

G6 I SI 3 5 5

G7 I/CKO HALT Restart 4 6 6

D0 O 19 25 29

D1 O 20 26 30

D2 O 21 27 31

D3 O 22 28 32

I0 I 7 9 9

I1 I COMP1IN

I2 I COMP1IN

I3 I COMP1OUT 10 12 12

I4 I COMP2IN

I5 I COMP2IN

I6 I COMP2OUT 15 15

I7 I 16 16

D4 O 29 33

D5 O 30 34

D6 O 31 35

D7 O 32 36

C0 I/O 39 43

C1 I/O 40 44

C2 I/O 1 1

C3 I/O 2 2

C4 I/O 21

C5 I/O 22

C6 I/O 23

C7 I/O 24

V

CC

GND 23 33 37

CKI 5 7 7

RESET

28-Pin 40-Pin 44-Pin

Pack. Pack. Pack.

b

a

b

a

81010

91111

13 13

14 14

688

24 34 38

http://www.national.com3

Page 4

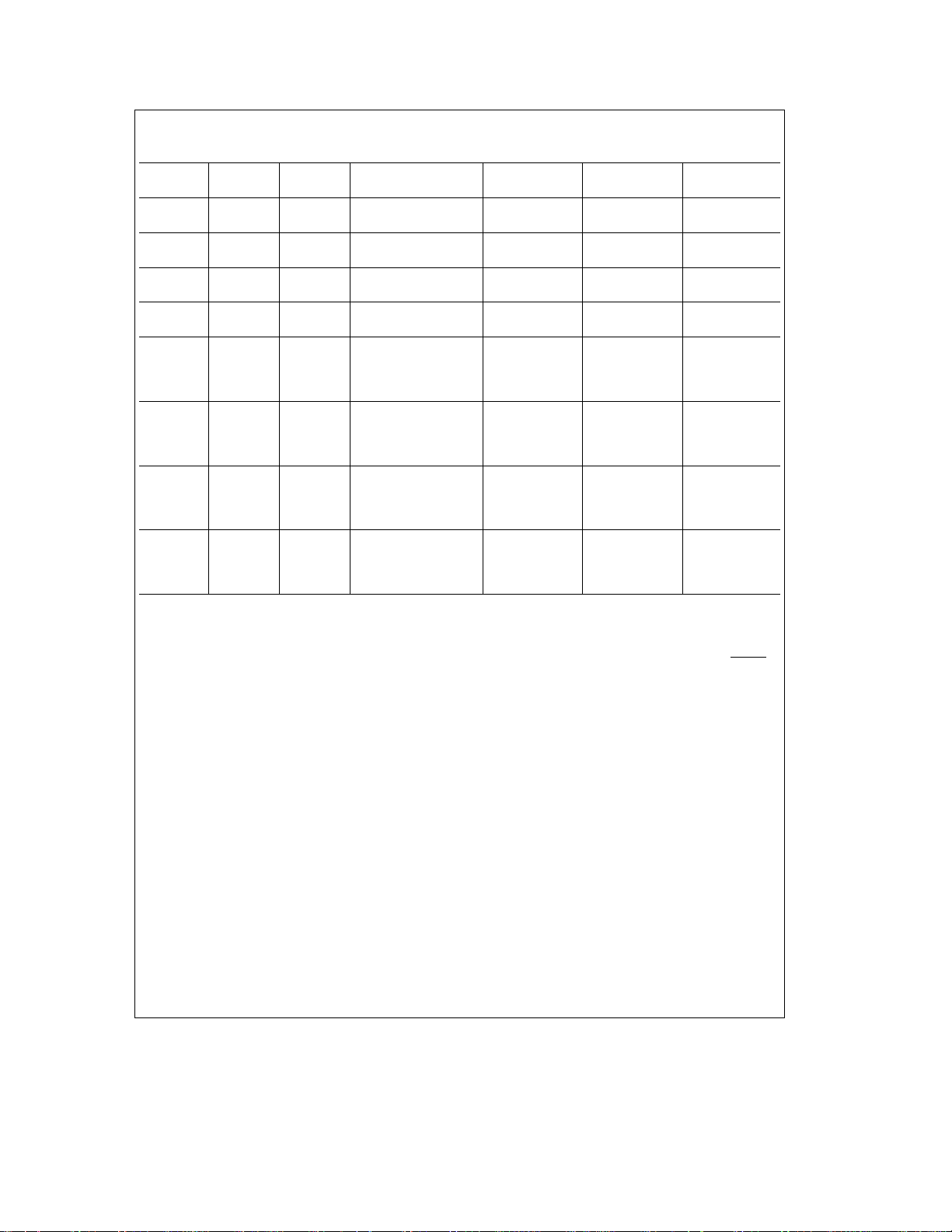

Absolute Maximum Ratings

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales

Office/Distributors for availability and specifications.

Supply Voltage (V

Voltage at Any Pin

Total Current into V

DC Electrical Characteristics

)7V

CC

Pin (Source) 100 mA

CC

b

0.3V to V

a

CC

b

40§CsT

0.3V

Parameter Conditions Min Typ Max Units

Operating Voltage 2.5 6 V

Power Supply Ripple (Note 1) Peak-to-Peak 0.1 V

Supply Current (Note 2)

e

CKI

10 MHz V

e

CKI

4 MHz V

CKIe4 MHz V

e

CKI

1 MHz V

HALT Current (Note 3) V

e

6V, t

CC

e

6V, t

CC

e

4.0V, t

CC

e

4.0V, t

CC

e

6V, CKIe0 MHz

CC

e

V

4.0V, CKIe0 MHz

CC

c

c

IDLE Current

e

CKI

10 MHz V

e

CKI

4 MHz V

CKIe1 MHz V

CC

CC

CC

e

e

e

6V, t

6V, t

4.0V, t

c

c

Input Levels

RESET

Logic High 0.8 V

Logic Low 0.2 V

CKI (External and Crystal Osc. Modes)

Logic High 0.7 V

Logic Low 0.2 V

All Other Inputs

Logic High 0.7 V

Logic Low 0.2 V

Hi-Z Input Leakage V

Input Pullup Current V

CC

CC

e

6V

e

6V, V

G and L Port Input Hysteresis 0.35 V

Output Current Levels

D Outputs

Source V

Sink V

All Others

Source (Weak Pull-Up Mode) V

Source (Push-Pull Mode) V

Sink (Push-Pull Mode) V

TRI-STATE Leakage V

Note 1: Rate of voltage change must be less then 0.5 V/ms.

Note 2: Supply current is measured after running 2000 cycles with a crystal/resonator oscillator, inputs at rails and outputs open.

Note 3: The HALT mode will stop CKI from oscillating in the RC and the Crystal configurations. Test conditions: All inputs tied to V

as outputs and set high. The D port set to zero. The clock monitor and the comparators are disabled.

e

4V, V

CC

e

V

2.5V, V

CC

e

4V, V

CC

e

V

2.5V, V

CC

e

4V, V

CC

e

V

2.5V, V

CC

e

4V, V

CC

e

V

2.5V, V

CC

e

4V, V

CC

e

V

2.5V, V

CC

e

6.0V

CC

Total Current out of GND Pin (Sink) 110 mA

Storage Temperature Range

Note:

Absolute maximum ratings indicate limits beyond

b

65§Ctoa140§C

which damage to the device may occur. DC and AC electrical specifications are not ensured when operating the device at absolute maximum ratings.

s

a

85§C unless otherwise specified

A

CC

e

1 ms 8.0 mA

e

2.5 ms 4.5 mA

e

2.5 ms 2.5 mA

c

e

10 ms 1.4 mA

c

k

110 mA

k

0.5 6 mA

e

1 ms 3.5 mA

e

2.5 ms 2.5 mA

e

10 ms 0.7 mA

c

CC

CC

CC

b

2

e

0V

IN

e

3.3V

OH

e

1.8V

OH

e

1V 10 mA

OL

e

0.4V 2.0 mA

OL

e

2.7V

OH

e

1.8V

OH

e

3.3V

OH

e

1.8V

OH

e

0.4V 1.6 mA

OL

e

0.4V 0.7 mA

OL

b

40

b

0.4 mA

b

0.2 mA

b

10

b

2.5

b

0.4 mA

b

0.2 mA

b

2

CC

CC

CC

a

2 mA

b

250 mA

CC

b

100 mA

b

33 mA

a

2 mA

, L, C, and G0 –G5 configured

CC

V

V

V

V

V

V

V

V

http://www.national.com 4

Page 5

DC Electrical Characteristics

b

40§CsT

s

a

85§C unless otherwise specified (Continued)

A

Parameter Conditions Min Typ Max Units

Allowable Sink/Source

Current per Pin

D Outputs (Sink) 15 mA

All others 3mA

Maximum Input Current T

without Latchup

RAM Retention Voltage, V

r

e

25§C

A

500 ns Rise

and Fall Time (Min)

g

100 mA

2V

Input Capacitance 7pF

Load Capacitance on D2 1000 pF

AC Electrical Characteristics

b

40§CsT

s

a

85§C unless otherwise specified

A

Parameter Conditions Min Typ Max Units

Instruction Cycle Time (tc)

s

4V

2.5V

s

V

6V 1 DC ms

CC

k

s

V

4V 2.5 DC ms

CC

s

s

V

6V 3 DC ms

CC

k

s

V

4V 7.5 DC ms

CC

Crystal, Resonator, 4V

R/C Oscillator 2.5V

Inputs

t

SETUP

t

HOLD

4VsV

2.5V

4VsV

2.5V

Output Propagation Delay (Note 4) R

t

PD1,tPD0

SO, SK 4VsV

2.5V

All Others 4V

2.5V

MICROWIRETMSetup Time (t

MICROWIRE Hold Time (t

MICROWIRE Output Propagation Delay (t

)20ns

UWS

)56ns

UWH

) 220 ns

UPD

s

6V 200 ns

CC

k

s

V

4V 500 ns

CC

s

6V 60 ns

CC

k

s

V

4V 150 ns

CC

e

L

s

s

s

e

2.2k, C

CC

V

V

CC

V

100 pF

L

s

6V 0.7 ms

k

4V 1.75 ms

CC

s

6V 1 ms

k

4V 2.5 ms

CC

Input Pulse Width

Interrupt Input High Time 1 t

Interrupt Input Low Time 1 t

Timer Input High Time 1 t

Timer Input Low Time 1 t

Reset Pulse Width 1 ms

Note 4: The output propagation delay is referenced to the end of the instruction cycle where the output change occurs.

c

c

c

c

http://www.national.com5

Page 6

Comparators AC and DC Characteristics V

CC

e

5V, T

e

25§C

A

Parameter Conditions Min Typ Max Units

Input Offset Voltage 0.4VsV

b

V

CC

1.5V

IN

g

10

s

Input Common Mode Voltage Range 0.4 V

Low Level Output Current V

High Level Output Current V

e

0.4V 1.6 mA

OL

e

4.6V 1.6 mA

OH

DC Supply Current Per Comparator

(When Enabled)

Response Time TBD mV Step, TBD mV

Overdrive, 100 pF Load

1 ms

g

25 mV

b

1.5 V

CC

250 mA

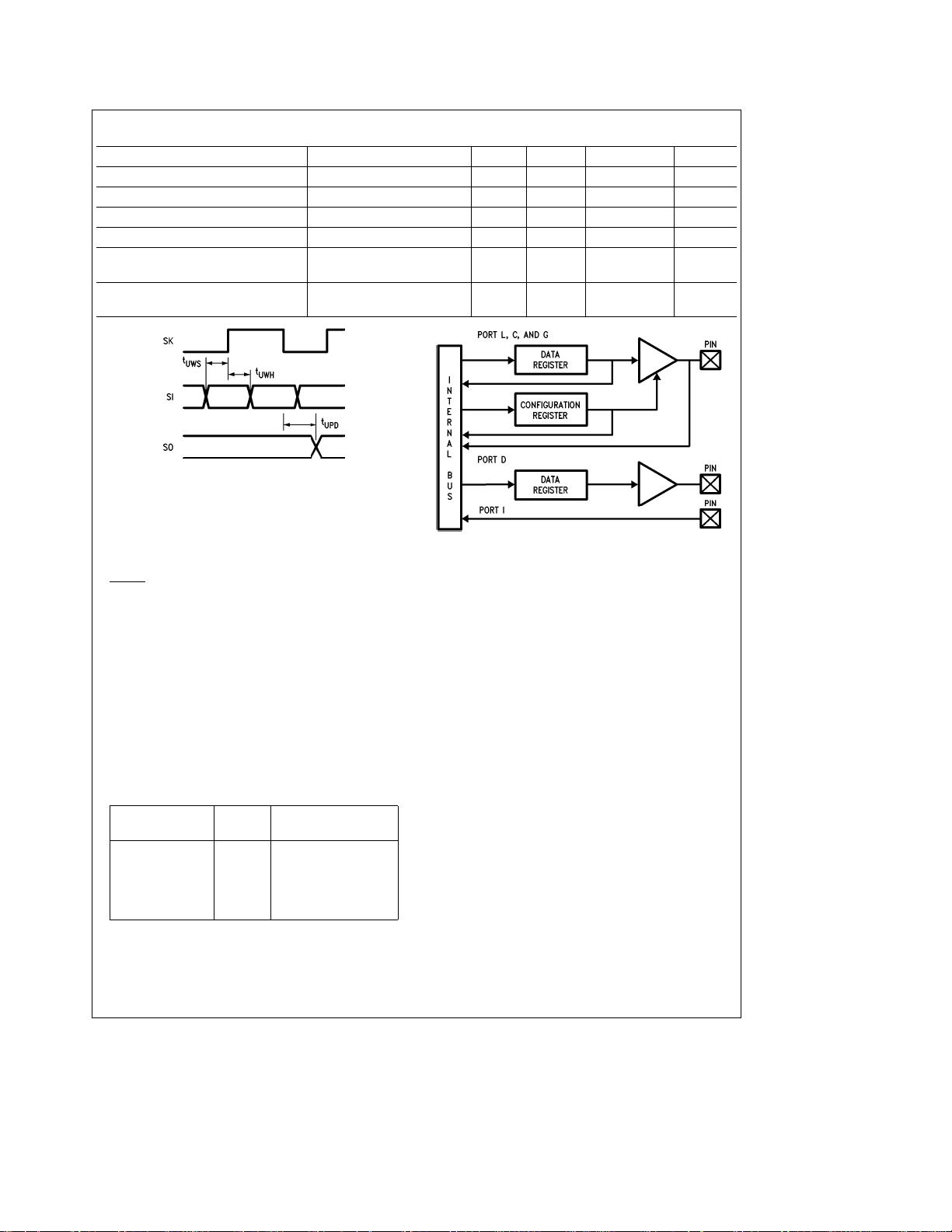

FIGURE 2. MICROWIRE/PLUS Timing

TL/DD/9765– 7

Pin Descriptions

VCCand GND are the power supply pins.

CKI is the clock input. This can come from an R/C generated oscillator, or a crystal oscillator (in conjunction with

CKO). See Oscillator Description section.

RESET

is the master reset input. See Reset Description

section.

The device contains three bidirectional 8-bit I/O ports (C, G

and L), where each individual bit may be independently configured as an input (Schmitt trigger inputs on ports L and G),

output or TRI-STATE under program control. Three data

memory address locations are allocated for each of these

I/O ports. Each I/O port has two associated 8-bit memory

mapped registers, the CONFIGURATION register and the

output DATA register. A memory mapped address is also

reserved for the input pins of each I/O port. (See the memory map for the various addresses associated with the I/O

ports.)

Figure 3

DATA and CONFIGURATION registers allow for each port

bit to be individually configured under software control as

shown below:

CONFIGURATION DATA

Register Register

shows the I/O port configurations. The

Port Set-Up

0 0 Hi-Z Input

(TRI-STATE Output)

0 1 Input with Weak Pull-Up

1 0 Push-Pull Zero Output

1 1 Push-Pull One Output

FIGURE 3. I/O Port Configurations

TL/DD/9765– 8

PORT L is an 8-bit I/O port. All L-pins have Schmitt triggers

on the inputs.

The Port L supports Multi-Input Wake Up on all eight pins.

L1 is used for the UART external clock. L2 and L3 are used

for the UART transmit and receive. L4 and L5 are used for

the timer input functions T2A and T2B. L6 and L7 are used

for the timer input functions T3A and T3B.

The Port L has the following alternate features:

L0 MIWU

L1 MIWU or CKX

L2 MIWU or TDX

L3 MIWU or RDX

L4 MIWU or T2A

L5 MIWU or T2B

L6 MIWU or T3A

L7 MIWU or T3B

Port G is an 8-bit port with 5 I/O pins (G0, G2 –G5), an input

pin (G6), and two dedicated output pins (G1 and G7). Pins

G0 and G2 –G6 all have Schmitt Triggers on their inputs. Pin

G1 serves as the dedicated WDOUT WATCHDOG output,

while pin G7 is either input or output depending on the oscillator mask option selected. With the crystal oscillator option

selected, G7 serves as the dedicated output pin for the CKO

clock output. With the single-pin R/C oscillator mask option

selected, G7 serves as a general purpose input pin but is

also used to bring the device out of HALT mode with a low

to high transition on G7. There are two registers associated

with the G Port, a data register and a configuration register.

Therefore, each of the 5 I/O bits (G0, G2 – G5) can be individually configured under software control.

http://www.national.com 6

Page 7

Pin Descriptions (Continued)

Since G6 is an input only pin and G7 is the dedicated CKO

clock output pin (crystal clock option) or general purpose

input (R/C clock option), the associated bits in the data and

configuration registers for G6 and G7 are used for special

purpose functions as outlined below. Reading the G6 and

G7 data bits will return zeros.

Note that the chip will be placed in the HALT mode by writing a ‘‘1’’ to bit 7 of the Port G Data Register. Similarly the

chip will be placed in the IDLE mode by writing a ‘‘1’’ to bit 6

of the Port G Data Register.

Writing a ‘‘1’’ to bit 6 of the Port G Configuration Register

enables the MICROWIRE/PLUS to operate with the alternate phase of the SK clock. The G7 configuration bit, if set

high, enables the clock start up delay after HALT when the

R/C clock configuration is used.

Config Reg. Data Reg.

G7 CLKDLY HALT

G6 Alternate SK IDLE

Port G has the following alternate features:

G0 INTR (External Interrupt Input)

G2 T1B (Timer T1 Capture Input)

G3 T1A (Timer T1 I/O)

G4 SO (MICROWIRE

G5 SK (MICROWIRE Serial Clock)

G6 SI (MICROWIRE Serial Data Input)

Port G has the following dedicated functions:

G1 WDOUT WATCHDOG and/or Clock Monitor dedicat-

ed output

G7 CKO Oscillator dedicated output or general purpose

input

Port C is an 8-bit I/O port. The 40-pin device does not have

a full complement of Port C pins. The unavailable pins are

not terminated. A read operation for these unterminated

pins will return unpredicatable values.

PORT I is an eight-bit Hi-Z input port. The 28-pin device

does not have a full complement of Port I pins. The unavailable pins are not terminated i.e., they are floating. A read

operation for these unterminated pins will return unpredictable values. The user must ensure that the software takes

this into account by either masking or restricting the accesses to bit operations. The unterminated Port I pins will draw

power only when addressed.

Port I1–I3 are used for Comparator 1. Port I4 –I6 are used

for Comparator 2.

The Port I has the following alternate features.

I1 COMP1

I2 COMP1aIN (Comparator 1 Positive Input)

I3 COMP1OUT (Comparator 1 Output)

I4 COMP2bIN (Comparator 2 Negative Input)

I5 COMP2

I6 COMP2OUT (Comparator 2 Output)

Port D is an 8-bit output port that is preset high when

RESET

goes low. The user can tie two or more D port out-

puts together in order to get a higher drive.

TM

Serial Data Output)

b

IN (Comparator 1 Negative Input)

a

IN (Comparator 2 Positive Input)

Functional Description

The architecture of the device is modified Harvard architecture. With the Harvard architecture, the control store program memory (ROM) is separated from the data store memory (RAM). Both ROM and RAM have their own separate

addressing space with separate address buses. The architecture, though based on Harvard architecture, permits

transfer of data from ROM to RAM.

CPU REGISTERS

The CPU can do an 8-bit addition, subtraction, logical or

shift operation in one instruction (t

There are six CPU registers:

A is the 8-bit Accumulator Register

PC is the 15-bit Program Counter Register

PU is the upper 7 bits of the program counter (PC)

PL is the lower 8 bits of the program counter (PC)

B is an 8-bit RAM address pointer, which can be optionally

post auto incremented or decremented.

X is an 8-bit alternate RAM address pointer, which can be

optionally post auto incremented or decremented.

SP is the 8-bit stack pointer, which points to the subroutine/

interrupt stack (in RAM). The SP is initialized to RAM address 06F with reset.

S is the 8-bit Data Segment Address Register used to extend the lower half of the address range (00 to 7F) into 256

data segments of 128 bytes each.

All the CPU registers are memory mapped with the exception of the Accumulator (A) and the Program Counter (PC).

PROGRAM MEMORY

The program memory consists of 4096 bytes of ROM.

These bytes may hold program instructions or constant data

(data tables for the LAID instruction, jump vectors for the

JID instruction, and interrupt vectors for the VIS instruction).

The program memory is addressed by the 15-bit program

counter (PC). All interrupts in the devices vector to program

memory location 0FF Hex.

DATA MEMORY

The data memory address space includes the on-chip RAM

and data registers, the I/O registers (Configuration, Data

and Pin), the control registers, the MICROWIRE/PLUS SIO

shift register, and the various registers, and counters associated with the timers (with the exception of the IDLE timer).

Data memory is addressed directly by the instruction or indirectly by the B, X, SP pointers and S register.

The device has 192 bytes of RAM. Sixteen bytes of RAM

are mapped as ‘‘registers’’ at addresses 0F0 to 0FF Hex.

These registers can be loaded immediately, and also decremented and tested with the DRSZ (decrement register and

skip if zero) instruction. The memory pointer registers X, SP,

B and S are memory mapped into this space at address

locations 0FC to 0FF Hex respectively, with the other registers being available for general usage.

The instruction set permits any bit in memory to be set,

reset or tested. All I/O and registers (except A and PC) are

memory mapped; therefore, I/O bits and register bits can be

directly and individually set, reset and tested. The accumulator (A) bits can also be directly and individually tested.

Note: RAM contents are undefined upon power-up.

) cycle time.

c

http://www.national.com7

Page 8

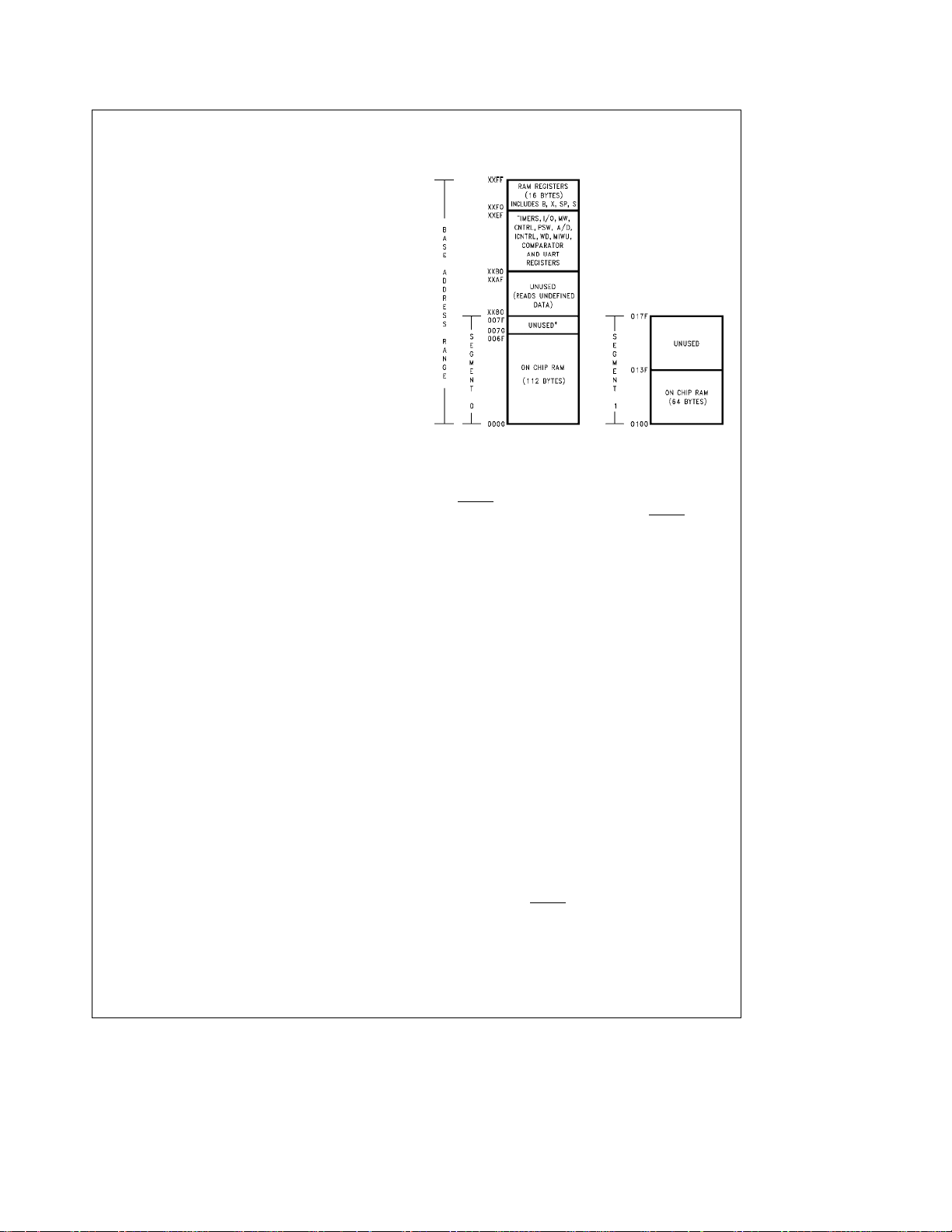

Data Memory Segment RAM Extension

Data memory address 0FF is used as a memory mapped

location for the Data Segment Address Register (S).

The data store memory is either addressed directly by a

single byte address within the instruction, or indirectly relative to the reference of the B, X, or SP pointers (each contains a single-byte address). This single-byte address allows

an addressing range of 256 locations from 00 to FF hex.

The upper bit of this single-byte address divides the data

store memory into two separate sections as outlined previously. With the exception of the RAM register memory from

address locations 00F0 to 00FF, all RAM memory is memory mapped with the upper bit of the single-byte address being equal to zero. This allows the upper bit of the single-byte

address to determine whether or not the base address

range (from 0000 to 00FF) is extended. If this upper bit

equals one (representing address range 0080 to 00FF),

then address extension does not take place. Alternatively, if

this upper bit equals zero, then the data segment extension

register S is used to extend the base address range (from

0000 to 007F) from XX00 to XX7F, where XX represents the

8 bits from the S register. Thus the 128-byte data segment

extensions are located from addresses 0100 to 017F for

data segment 1, 0200 to 027F for data segment 2, etc., up

to FF00 to FF7F for data segment 255. The base address

range from 0000 to 007F represents data segment 0.

Figure 4

illustrates how the S register data memory extension is used in extending the lower half of the base address

range (00 to 7F hex) into 256 data segments of 128 bytes

each, with a total addressing range of 32 kbytes from XX00

to XX7F. This organization allows a total of 256 data segments of 128 bytes each with an additional upper base segment of 128 bytes. Furthermore, all addressing modes are

available for all data segments. The S register must be

changed under program control to move from one data segment (128 bytes) to another. However, the upper base segment (containing the 16 memory registers, I/O registers,

control registers, etc.) is always available regardless of the

contents of the S register, since the upper base segment

(address range 0080 to 00FF) is independent of data segment extension.

The instructions that utilize the stack pointer (SP) always

reference the stack as part of the base segment (Segment

0), regardless of the contents of the S register. The S register is not changed by these instructions. Consequently, the

stack (used with subroutine linkage and interrupts) is always

located in the base segment. The stack pointer will be intitialized to point at data memory location 006F as a result of

reset.

The 128 bytes of RAM contained in the base segment are

split between the lower and upper base segments. The first

116 bytes of RAM are resident from address 0000 to 006F

in the lower base segment, while the remaining 16 bytes of

RAM represent the 16 data memory registers located at addresses 00F0 to 00FF of the upper base segment. No RAM

is located at the upper sixteen addresses (0070 to 007F) of

the lower base segment.

Additional RAM beyond these initial 128 bytes, however, will

always be memory mapped in groups of 128 bytes (or less)

at the data segment address extensions (XX00 to XX7F) of

the lower base segment. The additional 64 bytes of RAM

(beyond the initial 128 bytes) are memory mapped at address locations 0100 to 013F hex.

*Reads as all ones.

FIGURE 4. RAM Organization

TL/DD/9765– 9

Reset

The RESET input when pulled low initializes the microcontroller. Initialization will occur whenever the RESET

pulled low. Upon initialization, the data and configuration

registers for ports L, G and C are cleared, resulting in these

Ports being initialized to the TRI-STATE mode. Pin G1 of the

G Port is an exception (as noted below) since pin G1 is

dedicated as the WATCHDOG and/or Clock Monitor error

output pin. Port D is set high. The PC, PSW, ICNTRL,

CNTRL, T2CNTRL and T3CNTRL control registers are

cleared. The UART registers PSR, ENU (except that TBMT

bit is set), ENUR and ENUI are cleared. The Comparator

Select Register is cleared. The S register is initialized to

zero. The Multi-Input Wakeup registers WKEN, WKEDG and

WKPND are cleared. The stack pointer, SP, is initialized to

6F Hex.

The device comes out of reset with both the WATCHDOG

logic and the Clock Monitor detector armed, with the

WATCHDOG service window bits set and the Clock Monitor

bit set. The WATCHDOG and Clock Monitor circuits are inhibited during reset. The WATCHDOG service window bits

being initialized high default to the maximum WATCHDOG

service window of 64k t

being initialized high will cause a Clock Monitor error following reset if the clock has not reached the minimum specified

frequency at the termination of reset. A Clock Monitor error

will cause an active low error output on pin G1. This error

output will continue until 16 t

the clock frequency reaching the minimum specified value,

at which time the G1 output will enter the TRI-STATE mode.

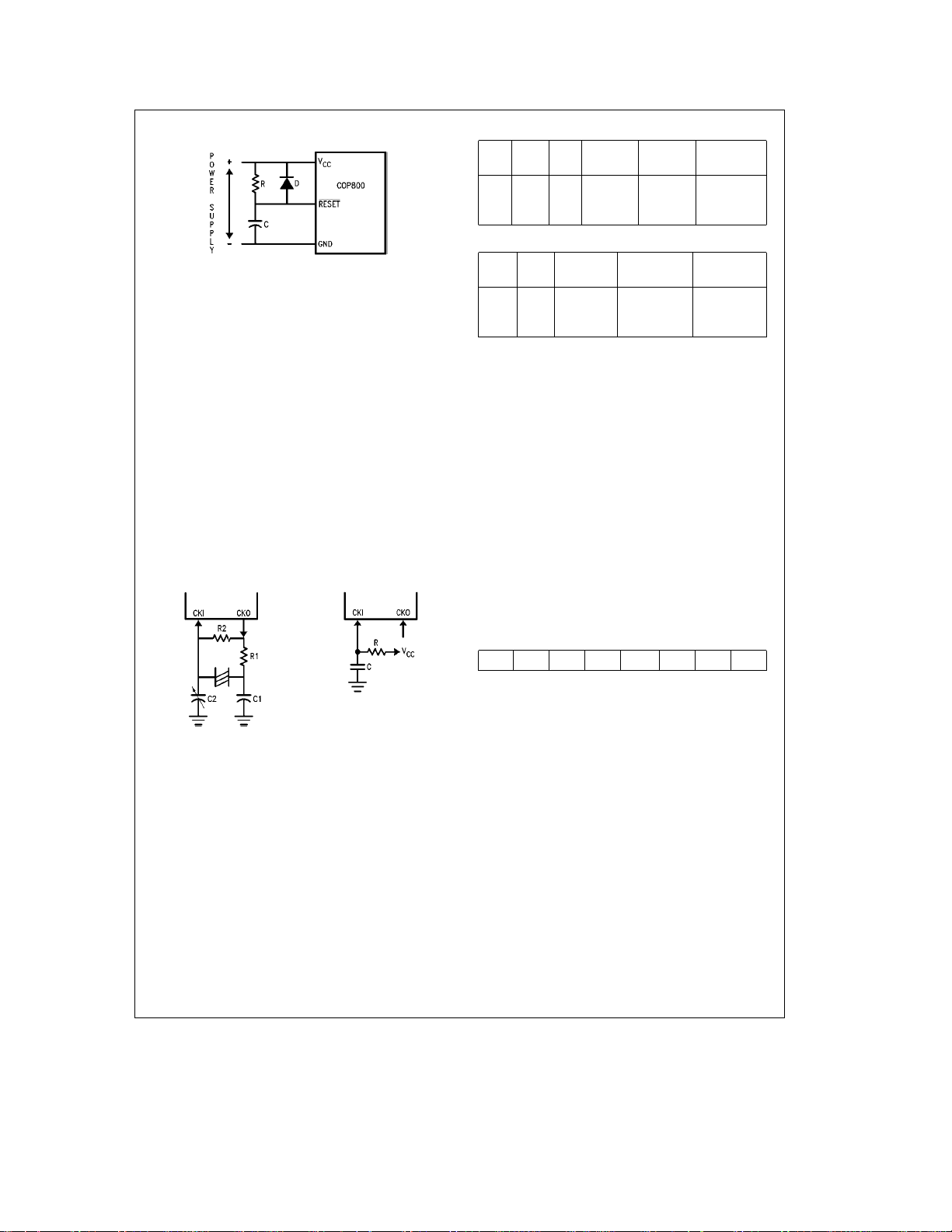

The external RC network shown in

to ensure that the RESET

supply to the chip stabilizes.

clock cycles. The Clock Monitor bit

C

–32 tCclock cycles following

C

Figure 5

pin is held low until the power

input is

should be used

http://www.national.com 8

Page 9

Reset (Continued)

RCl5cPower Supply Rise Time

FIGURE 5. Recommended Reset Circuit

TL/DD/9765– 10

Oscillator Circuits

The chip can be driven by a clock input on the CKI input pin

which can be between DC and 10 MHz. The CKO output

clock is on pin G7 (crystal configuration). The CKI input frequency is divided down by 10 to produce the instruction

cycle clock (1/t

Figure 6

CRYSTAL OSCILLATOR

CKI and CKO can be connected to make a closed loop

crystal (or resonator) controlled oscillator.

Table A shows the component values required for various

standard crystal values.

R/C OSCILLATOR

By selecting CKI as a single pin oscillator input, a single pin

R/C oscillator circuit can be connected to it. CKO is available as a general purpose input, and/or HALT restart input.

Table B shows the variation in the oscillator frequencies as

functions of the component (R and C) values.

).

c

shows the Crystal and R/C diagrams.

TL/DD/9765– 12

TABLE A. Crystal Oscillator Configuration, T

R1 R2 C1 C2 CKI Freq

(kX)(MX) (pF) (pF) (MHz)

0 1 30 30 –36 10 V

0 1 30 30 –36 4 V

0 1 200 100–150 0.455 V

TABLE B. RC Oscillator Configuration, T

R C CKI Freq Instr. Cycle

(kX) (pF) (MHz) (ms)

3.3 82 2.2 to 2.7 3.7 to 4.6 V

5.6 100 1.1 to 1.3 7.4 to 9.0 V

6.8 100 0.9 to 1.1 8.8 to 10.8 V

Note: 3ksRs200k

50 pF

sCs

200 pF

e

25§C

A

Conditions

e

5V

CC

e

5.0V

CC

e

5V

CC

e

25§C

A

Conditions

e

5V

CC

e

5V

CC

e

5V

CC

Control Registers

CNTRL Register (Address XÊ00EE)

The Timer1 (T1) and MICROWIRE/PLUS control register

contains the following bits:

SL1 & SL0 Select the MICROWIRE/PLUS clock divide

IEDG External interrupt edge polarity select

MSEL Selects G5 and G4 as MICROWIRE/PLUS

T1C0 Timer T1 Start/Stop control in timer

T1C1 Timer T1 mode control bit

T1C2 Timer T1 mode control bit

T1C3 Timer T1 mode control bit

T1C3 T1C2 T1C1 T1C0 MSEL IEDG SL1 SL0

Bit 7 Bit 0

e

by (00

(0

2, 01e4, 1xe8)

e

Rising edge, 1eFalling edge)

signals SK and SO respectively

modes 1 and 2

Timer T1 Underflow Interrupt Pending Flag in

timer mode 3

FIGURE 6. Crystal and R/C Oscillator Diagrams

TL/DD/9765– 11

http://www.national.com9

Page 10

Control Registers (Continued)

PSW Register (Address X

The PSW register contains the following select bits:

GIE Global interrupt enable (enables interrupts)

EXEN Enable external interrupt

BUSY MICROWIRE/PLUS busy shifting flag

EXPND External interrupt pending

T1ENA Timer T1 Interrupt Enable for Timer Underflow

or T1A Input capture edge

T1PNDA Timer T1 Interrupt Pending Flag (Autoreload RA

in mode 1, T1 Underflow in Mode 2, T1A capture edge in mode 3)

C Carry Flag

HC Half Carry Flag

HC C T1PNDA T1ENA EXPND BUSY EXEN GIE

Bit 7 Bit 0

The Half-Carry bit is also affected by all the instructions that

affect the Carry flag. The SC (Set Carry) and RC (Reset

Carry) instructions will respectively set or clear both the carry flags. In addition to the SC and RC instructions, ADC,

SUBC, RRC and RLC instructions affect the carry and Half

Carry flags.

ICNTRL Register (Address X

The ICNTRL register contains the following bits:

T1ENB Timer T1 Interrupt Enable for T1B Input capture

edge

T1PNDB Timer T1 Interrupt Pending Flag for T1B cap-

ture edge

mWEN Enable MICROWIRE/PLUS interrupt

mWPND MICROWIRE/PLUS interrupt pending

T0EN Timer T0 Interrupt Enable (Bit 12 toggle)

T0PND Timer T0 Interrupt pending

LPEN L Port Interrupt Enable (Multi-Input Wakeup/In-

terrupt)

Bit 7 could be used as a flag

Unused LPEN T0PND T0EN mWPND mWEN T1PNDB T1ENB

Bit 7 Bit 0

T2CNTRL Register (Address XÊ00C6)

The T2CNTRL register contains the following bits:

T2ENB Timer T2 Interrupt Enable for T2B Input capture

edge

T2PNDB Timer T2 Interrupt Pending Flag for T2B cap-

ture edge

T2ENA Timer T2 Interrupt Enable for Timer Underflow

or T2A Input capture edge

T2PNDA Timer T2 Interrupt Pending Flag (Autoreload RA

in mode 1, T2 Underflow in mode 2, T2A capture edge in mode 3)

T2C0 Timer T2 Start/Stop control in timer modes 1

and 2 Timer T2 Underflow Interrupt Pending

Flag in timer mode 3

00EF)

Ê

00E8)

Ê

T2C1 Timer T2 mode control bit

T2C2 Timer T2 mode control bit

T2C3 Timer T2 mode control bit

T2C3 T2C2 T2C1 T2C0 T2PNDA T2ENA T2PNDB T2ENB

Bit 7 Bit 0

T3CNTRL Register (Address XÊ00B6)

The T3CNTRL register contains the following bits:

T3ENB Timer T3 Interrupt Enable for T3B

T3PNDB Timer T3 Interrupt Pending Flag for T3B pin

T3ENA Timer T3 Interrupt Enable for Timer Underflow

T3PNDA Timer T3 Interrupt Pending Flag (Autoload RA

T3C0 Timer T3 Start/Stop control in timer modes 1

T3C1 Timer T3 mode control bit

T3C2 Timer T3 mode control bit

T3C3 Timer T3 mode control bit

T3C3 T3C2 T3C1 T3C0 T3PNDA T3ENA T3PNDB T3ENB

Bit 7 Bit 0

(T3B capture edge)

or T3A pin

in mode 1, T3 Underflow in mode 2, T3a capture edge in mode 3)

and 2

Timer T3 Underflow Interrupt Pending Flag in

timer mode 3

Timers

The device contains a very versatile set of timers (T0, T1,

T2, T3). All timers and associated autoreload/capture registers power up containing random data.

TIMER T0 (IDLE TIMER)

The device supports applications that require maintaining

real time and low power with the IDLE mode. This IDLE

mode support is furnished by the IDLE timer T0, which is a

16-bit timer. The Timer T0 runs continuously at the fixed

rate of the instruction cycle clock, t

or write to the IDLE Timer T0, which is a count down timer.

The Timer T0 supports the following functions:

Exit out of the Idle Mode (See Idle Mode description)

WATCHDOG logic (See WATCHDOG description)

Start up delay out of the HALT mode

The IDLE Timer T0 can generate an interrupt when the thirteenth bit toggles. This toggle is latched into the T0PND

pending flag, and will occur every 4 ms at the maximum

clock frequency (t

interrupt from the thirteenth bit of Timer T0 to be enabled or

disabled. Setting T0EN will enable the interrupt, while resetting it will disable the interrupt.

e

1 ms). A control flag T0EN allows the

c

. The user cannot read

c

http://www.national.com 10

Page 11

Timers (Continued)

TIMER T1, TIMER T2 AND TIMER T3

The device has a set of three powerful timer/counter

blocks, T1, T2 and T3. The associated features and functioning of a timer block are described by referring to the

timer block Tx. Since the three timer blocks, T1, T2 and T3

are identical, all comments are equally applicable to any of

the three timer blocks.

Each timer block consists of a 16-bit timer, Tx, and two

supporting 16-bit autoreload/capture registers, RxA and

RxB. Each timer block has two pins associated with it, TxA

and TxB. The pin TxA supports I/O required by the timer

block, while the pin TxB is an input to the timer block. The

powerful and flexible timer block allows the device to easily

perform all timer functions with minimal software overhead.

The timer block has three operating modes: Processor Independent PWM mode, External Event Counter mode, and

Input Capture mode.

The control bits TxC3, TxC2, and TxC1 allow selection of

the different modes of operation.

Mode 1. Processor Independent PWM Mode

As the name suggests, this mode allows the device to generate a PWM signal with very minimal user intervention. The

user only has to define the parameters of the PWM signal

(ON time and OFF time). Once begun, the timer block will

continuously generate the PWM signal completely independent of the microcontroller. The user software services the

timer block only when the PWM parameters require updating.

In this mode the timer Tx counts down at a fixed rate of t

Upon every underflow the timer is alternately reloaded with

the contents of supporting registers, RxA and RxB. The very

first underflow of the timer causes the timer to reload from

the register RxA. Subsequent underflows cause the timer to

be reloaded from the registers alternately beginning with the

register RxB.

The Tx Timer control bits, TxC3, TxC2 and TxC1 set up the

timer for PWM mode operation.

Figure 7

shows a block diagram of the timer in PWM mode.

The underflows can be programmed to toggle the TxA output pin. The underflows can also be programmed to generate interrupts.

Underflows from the timer are alternately latched into two

pending flags, TxPNDA and TxPNDB. The user must reset

these pending flags under software control. Two control enable flags, TxENA and TxENB, allow the interrupts from the

timer underflow to be enabled or disabled. Setting the timer

enable flag TxENA will cause an interrupt when a timer underflow causes the RxA register to be reloaded into the timer. Setting the timer enable flag TxENB will cause an interrupt when a timer underflow causes the RxB register to be

reloaded into the timer. Resetting the timer enable flags will

disable the associated interrupts.

Either or both of the timer underflow interrupts may be enabled. This gives the user the flexibility of interrupting once

per PWM period on either the rising or falling edge of the

PWM output. Alternatively, the user may choose to interrupt

on both edges of the PWM output.

FIGURE 7. Timer in PWM Mode

Mode 2. External Event Counter Mode

This mode is quite similar to the processor independent

PWM mode described above. The main difference is that

the timer, Tx, is clocked by the input signal from the TxA pin.

The Tx timer control bits, TxC3, TxC2 and TxC1 allow the

timer to be clocked either on a positive or negative edge

from the TxA pin. Underflows from the timer are latched into

the TxPNDA pending flag. Setting the TxENA control flag

will cause an interrupt when the timer underflows.

In this mode the input pin TxB can be used as an independent positive edge sensitive interrupt input if the TxENB

control flag is set. The occurrence of a positive edge on the

TxB input pin is latched into the TxPNDB flag.

.

c

Figure 8

shows a block diagram of the timer in External

Event Counter mode.

Note: The PWM output is not available in this mode since the TxA pin is

being used as the counter input clock.

FIGURE 8. Timer in External Event Counter Mode

Mode 3. Input Capture Mode

The device can precisely measure external frequencies or

time external events by placing the timer block, Tx, in the

input capture mode.

In this mode, the timer Tx is constantly running at the fixed

t

rate. The two registers, RxA and RxB, act as capture

c

registers. Each register acts in conjunction with a pin. The

register RxA acts in conjunction with the TxA pin and the

register RxB acts in conjunction with the TxB pin.

TL/DD/9765– 14

TL/DD/9765– 15

http://www.national.com11

Page 12

Timers (Continued)

The timer value gets copied over into the register when a

trigger event occurs on its corresponding pin. Control bits,

TxC3, TxC2 and TxC1, allow the trigger events to be specified either as a positive or a negative edge. The trigger condition for each input pin can be specified independently.

The trigger conditions can also be programmed to generate

interrupts. The occurrence of the specified trigger condition

on the TxA and TxB pins will be respectively latched into the

pending flags, TxPNDA and TxPNDB. The control flag

TxENA allows the interrupt on TxA to be either enabled or

disabled. Setting the TxENA flag enables interrupts to be

generated when the selected trigger condition occurs on the

TxA pin. Similarly, the flag TxENB controls the interrupts

from the TxB pin.

Underflows from the timer can also be programmed to generate interrupts. Underflows are latched into the timer TxC0

pending flag (the TxC0 control bit serves as the timer underflow interrupt pending flag in the Input Capture mode). Consequently, the TxC0 control bit should be reset when entering the Input Capture mode. The timer underflow interrupt is

enabled with the TxENA control flag. When a TxA interrupt

occurs in the Input Capture mode, the user must check both

the TxPNDA and TxC0 pending flags in order to determine

whether a TxA input capture or a timer underflow (or both)

caused the interrupt.

Figure 9

shows a block diagram of the timer in Input Capture

mode.

FIGURE 9. Timer in Input Capture Mode

TL/DD/9765– 16

TIMER CONTROL FLAGS

The timers T1, T2 and T3 have indentical control structures.

The control bits and their functions are summarized below.

TxC0 Timer Start/Stop control in Modes 1 and 2

(Processor Independent PWM and External

Event Counter), where 1

e

Start, 0eStop

Timer Underflow Interrupt Pending Flag in

Mode 3 (Input Capture)

TxPNDA Timer Interrupt Pending Flag

TxPNDB Timer Interrupt Pending Flag

TxENA Timer Interrupt Enable Flag

TxENB Timer Interrupt Enable Flag

e

1

Timer Interrupt Enabled

e

0

Timer Interrupt Disabled

TxC3 Timer mode control

TxC2 Timer mode control

TxC1 Timer mode control

http://www.national.com 12

Page 13

Timers (Continued)

The timer mode control bits (TxC3, TxC2 and TxC1) are detailed below:

TxC3 TxC2 TxC1 Timer Mode

0 0 0 MODE 2 (External Timer Pos. TxB TxA

Event Counter) Underflow Edge Pos. Edge

0 0 1 MODE 2 (External Timer Pos. TxB TxA

Event Counter) Underflow Edge Neg. Edge

1 0 1 MODE 1 (PWM) Autoreload Autoreload

TxA Toggle RA RB

1 0 0 MODE 1 (PWM) Autoreload Autoreload

No TxA Toggle RA RB

0 1 0 MODE 3 (Capture) Pos. TxA Pos. TxB t

Captures: Edge or Edge

TxA Pos. Edge Timer

TxB Pos. Edge Underflow

1 1 0 MODE 3 (Capture) Pos. TxA Neg. TxB t

Captures: Edge or Edge

TxA Pos. Edge Timer

TxB Neg. Edge Underflow

0 1 1 MODE 3 (Capture) Neg. TxB Pos. TxB t

Captures: Edge or Edge

TxA Neg. Edge Timer

TxB Pos. Edge Underflow

1 1 1 MODE 3 (Capture) Neg. TxA Neg. TxB t

Captures: Edge or Edge

TxA Neg. Edge Timer

TxB Neg. Edge Underflow

Interrupt A Interrupt B Timer

Source Source Counts On

t

c

t

c

c

c

c

c

Power Save Modes

The device offers the user two power save modes of operation: HALT and IDLE. In the HALT mode, all microcontroller

activities are stopped. In the IDLE mode, the on-board oscillator circuitry the WATCHDOG logic, the Clock Monitor and

timer T0 are active but all other microcontroller activities are

stopped. In either mode, all on-board RAM, registers, I/O

states, and timers (with the exception of T0) are unaltered.

HALT MODE

The device can be placed in the HALT mode by writing a

‘‘1’’ to the HALT flag (G7 data bit). All microcontroller activities, including the clock and timers, are stopped. The

WATCHDOG logic is disabled during the HALT mode. However, the clock monitor circuitry if enabled remains active

and will cause the WATCHDOG output pin (WDOUT) to go

low. If the HALT mode is used and the user does not want

to activate the WDOUT pin, the Clock Monitor should be

disabled after the device comes out of reset (resetting the

Clock Monitor control bit with the first write to the WDSVR

register). In the HALT mode, the power requirements of the

device are minimal and the applied voltage (V

decreased to V

machine.

e

2.0V) without altering the state of the

r(Vr

The device supports three different ways of exiting the

HALT mode. The first method of exiting the HALT mode is

with the Multi-Input Wakeup feature on the L port. The second method is with a low to high transition on the CKO (G7)

pin. This method precludes the use of the crystal clock con-

) may be

CC

figuration (since CKO becomes a dedicated output), and so

may be used with an RC clock configuration. The third

method of exiting the HALT mode is by pulling the RESET

pin low.

Since a crystal or ceramic resonator may be selected as the

oscillator, the Wakeup signal is not allowed to start the chip

running immediately since crystal oscillators and ceramic

resonators have a delayed start up time to reach full amplitude and frequency stability. The IDLE timer is used to generate a fixed delay to ensure that the oscillator has indeed

stabilized before allowing instruction execution. In this case,

upon detecting a valid Wakeup signal, only the oscillator

circuitry is enabled. The IDLE timer is loaded with a value of

256 and is clocked with the t

clock is derived by dividing the oscillator clock down by a

instruction cycle clock. The t

c

factor of 10. The Schmitt trigger following the CKI inverter

on the chip ensures that the IDLE timer is clocked only

when the oscillator has a sufficiently large amplitude to

meet the Schmitt trigger specifications. This Schmitt trigger

is not part of the oscillator closed loop. The startup timeout

from the IDLE timer enables the clock signals to be routed

to the rest of the chip.

If an RC clock option is being used, the fixed delay is introduced optionally. A control bit, CLKDLY, mapped as configuration bit G7, controls whether the delay is to be introduced or not. The delay is included if CLKDLY is set, and

excluded if CLKDLY is reset. The CLKDLY bit is cleared on

reset.

http://www.national.com13

c

Page 14

Power Save Modes (Continued)

The device has two mask options associated with the HALT

mode. The first mask option enables the HALT mode feature, while the second mask option disables the HALT

mode. With the HALT mode enable mask option, the device

will enter and exit the HALT mode as described above. With

the HALT disable mask option, the device cannot be placed

in the HALT mode (writing a ‘‘1’’ to the HALT flag will have

no effect).

The WATCHDOG detector circuit is inhibited during the

HALT mode. However, the clock monitor circuit if enabled

remains active during HALT mode in order to ensure a clock

monitor error if the device inadvertently enters the HALT

mode as a result of a runaway program or power glitch.

IDLE MODE

The device is placed in the IDLE mode by writing a ‘‘1’’ to

the IDLE flag (G6 data bit). In this mode, all activities, except

the associated on-board oscillator circuitry, the WATCHDOG logic, the clock monitor and the IDLE Timer T0, are

stopped.

As with the HALT mode, the device can be returned to normal operation with a reset, or with a Multi-Input Wakeup

from the L Port. Alternately, the microcontroller resumes

normal operation from the IDLE mode when the thirteenth

bit (representing 4.096 ms at internal clock frequency of

1 MHz, t

e

1 ms) of the IDLE Timer toggles.

c

This toggle condition of the thirteenth bit of the IDLE Timer

T0 is latched into the T0PND pending flag.

The user has the option of being interrupted with a transition

on the thirteenth bit of the IDLE Timer T0. The interrupt can

be enabled or disabled via the T0EN control bit. Setting the

T0EN flag enables the interrupt and vice versa.

The user can enter the IDLE mode with the Timer T0 interrupt enabled. In this case, when the T0PND bit gets set, the

device will first execute the Timer T0 interrupt service routine and then return to the instruction following the ‘‘Enter

Idle Mode’’ instruction.

Alternatively, the user can enter the IDLE mode with the

IDLE Timer T0 interrupt disabled. In this case, the device

will resume normal operation with the instruction immediately following the ‘‘Enter IDLE Mode’’ instruction.

Note: It is necessary to program two NOP instructions following both the set

HALT mode and set IDLE mode instructions. These NOP instructions

are necessary to allow clock resynchronization following the HALT or

IDLE modes.

Multi-Input Wakeup

The Multi-Input Wakeup feature is ued to return (wakeup)

the device from either the HALT or IDLE modes. Alternately

Multi-Input Wakeup/Interrupt feature may also be used to

generate up to 8 edge selectable external interrupts.

Figure 10

shows the Multi-Input Wakeup logic.

FIGURE 10. Multi-Input Wake Up Logic

http://www.national.com 14

TL/DD/9765– 17

Page 15

Multi-Input Wakeup (Continued)

The Multi-Input Wakeup feature utilizes the L Port. The user

selects which particular L port bit (or combination of L Port

bits) will cause the device to exit the HALT or IDLE modes.

The selection is done through the Reg: WKEN. The Reg:

WKEN is an 8-bit read/write register, which contains a control bit for every L port bit. Setting a particular WKEN bit

enables a Wakeup from the associated L port pin.

The user can select whether the trigger condition on the

selected L Port pin is going to be either a positive edge (low

to high transition) or a negative edge (high to low transition).

This selection is made via the Reg: WKEDG, which is an 8bit control register with a bit assigned to each L Port pin.

Setting the control bit will select the trigger condition to be a

negative edge on that particular L Port pin. Resetting the bit

selects the trigger condition to be a positive edge. Changing

an edge select entails several steps in order to avoid a

pseudo Wakeup condition as a result of the edge change.

First, the associated WKEN bit should be reset, followed by

the edge select change in WKEDG. Next, the associated

WKPND bit should be cleared, followed by the associated

WKEN bit being re-enabled.

An example may serve to clarify this procedure. Suppose

we wish to change the edge select from positive (low going

high) to negative (high going low) for L Port bit 5, where bit 5

has previously been enabled for an input interrupt. The program would be as follows:

RBIT 5, WKEN

SBIT 5, WKEDG

RBIT 5, WKPND

SBIT 5, WKEN

If the L port bits have been used as outputs and then

changed to inputs with Multi-Input Wakeup/Interrupt, a safety procedure should also be followed to avoid inherited

pseudo wakeup conditions. After the selected L port bits

have been changed from output to input but before the associated WKEN bits are enabled, the associated edge select bits in WKEDG should be set or reset for the desired

edge selects, followed by the associated WKPND bits being

cleared.

This same procedure should be used following reset, since

the L port inputs are left floating as a result of reset.

The occurrence of the selected trigger condition for Multi-Input Wakeup is latched into a pending register called

WKPND. The respective bits of the WKPND register will be

set on the occurrence of the selected trigger edge on the

corresponding Port L pin. The user has the responsibility of

clearing these pending flags. Since WKPND is a pending

register for the occurrence of selected wakeup conditions,

the device will not enter the HALT mode if any Wakeup bit is

both enabled and pending. Consequently, the user has the

responsibility of clearing the pending flags before attempting to enter the HALT mode.

WKEN, WKPND and WKEDG are all read/write registers,

and are cleared at reset.

PORT L INTERRUPTS

Port L provides the user with an additional eight fully selectable, edge sensitive interrupts which are all vectored into

the same service subroutine.

The interrupt from Port L shares logic with the wake up circuitry. The register WKEN allows interrupts from Port L to

be individually enabled or disabled. The register WKEDG

specifies the trigger condition to be either a positive or a

negative edge. Finally, the register WKPND latches in the

pending trigger conditions.

The GIE (Global Interrupt Enable) bit enables the interrupt

function.

A control flag, LPEN, functions as a global interrupt enable

for Port L interrupts. Setting the LPEN flag will enable interrupts and vice versa. A separate global pending flag is not

needed since the register WKPND is adequate.

Since Port L is also used for waking the device out of the

HALT or IDLE modes, the user can elect to exit the HALT or

IDLE modes either with or without the interrupt enabled. If

he elects to disable the interrupt, then the device will restart

execution from the instruction immediately following the instruction that placed the microcontroller in the HALT or

IDLE modes. In the other case, the device will first execute

the interrupt service routine and then revert to normal operation.

The Wakeup signal will not start the chip running immediately since crystal oscillators or ceramic resonators have a finite start up time. The IDLE Timer (T0) generates a fixed

delay to ensure that the oscillator has indeed stabilized before allowing the device to execute instructions. In this case,

upon detecting a valid Wakeup signal, only the oscillator

circuitry and the IDLE Timer T0 are enabled. The IDLE Timer is loaded with a value of 256 and is clocked from the t

instruction cycle clock. The tcclock is derived by dividing

down the oscillator clock by a factor of 10. A Schmitt trigger

following the CKI on-chip inverter ensures that the IDLE timer is clocked only when the oscillator has a sufficiently large

amplitude to meet the Schmitt trigger specifications. This

Schmitt trigger is not part of the oscillator closed loop. The

startup timeout from the IDLE timer enables the clock signals to be routed to the rest of the chip.

If the RC clock option is used, the fixed delay is under software control. A control flag, CLKDLY, in the G7 configuration bit allows the clock start up delay to be optionally inserted. Setting CLKDLY flag high will cause clock start up delay

to be inserted and resetting it will exclude the clock start up

delay. The CLKDLY flag is cleared during reset, so the clock

start up delay is not present following reset with the RC

clock options.

c

http://www.national.com15

Page 16

UART

The COP888CG contains a full-duplex software programmable UART. The UART

shift register, a receiver shift register and seven addressable registers, as follows: a transmit buffer register (TBUF),

a receiver buffer register (RBUF), a UART control and

status register (ENU), a UART receive control and status

register (ENUR), a UART interrupt and clock source register

(ENUI), a prescaler select register (PSR) and baud (BAUD)

register. The ENU register contains flags for transmit and

receive functions; this register also determines the length of

the data frame (7, 8 or 9 bits), the value of the ninth bit in

transmission, and parity selection bits. The ENUR register

flags framming, data overrun and parity errors while the

UART is receiving.

(Figure 11)

consists of a transmit

Other functions of the ENUR register include saving the

ninth bit received in the data frame, enabling or disabling the

UART’s attention mode of operation and providing additional receiver/transmitter status information via RCVG and

XMTG bits. The determination of an internal or external

clock source is done by the ENUI register, as well as selecting the number of stop bits and enabling or disabling transmit and receive interrupts. A control flag in this register can

also select the UART mode of operation: asynchronous or

synchronous.

FIGURE 11. UART Block Diagram

http://www.national.com 16

TL/DD/9765– 18

Page 17

UART (Continued)

UART CONTROL AND STATUS REGISTERS

The operation of the UART is programmed through three

registers: ENU, ENUR and ENUI. The function of the individual bits in these registers is as follows:

ENU-UART Control and Status Register (Address at 0BA)

PEN PSEL1 XBIT9/ CHL1 CHL0 ERR RBFL TBMT

0RW 0RW 0RW 0RW 0RW 0R 0R 1R

Bit 7 Bit 0

ENUR-UART Receive Control and Status Register

(Address at 0BB)

DOE FE PE SPARE RBIT9 ATTN XMTG RCVG

0RD 0RD 0RD 0RW* 0R 0RW 0R 0R

Bit7 Bit0

ENUI-UART Interrupt and Clock Source Register

(Address at 0BC)

STP2 STP78 ETDX SSEL XRCLK XTCLK ERI ETI

0RW 0RW 0RW 0RW 0RW 0RW 0RW 0RW

Bit7 Bit0

*Bit is not used.

0 Bit is cleared on reset.

1 Bit is set to one on reset.

R Bit is read-only; it cannot be written by software.

RW Bit is read/write.

D Bit is cleared on read; when read by software as a one, it is cleared

automatically. Writing to the bit does not affect its state.

DESCRIPTION OF UART REGISTER BITS

ENUÐUART CONTROL AND STATUS REGISTER

TBMT: This bit is set when the UART transfers a byte of

data from the TBUF register into the TSFT register for transmission. It is automatically reset when software writes into

the TBUF register.

RBFL: This bit is set when the UART has received a complete character and has copied it into the RBUF register. It

is automatically reset when software reads the character

from RBUF.

ERR: This bit is a global UART error flag which gets set if

any or a combination of the errors (DOE, FE, PE) occur.

CHL1, CHL0: These bits select the character frame format.

Parity is not included and is generated/verified by hardware.

CHL1

CHL1

CHL1

CHL1

XBIT9/PSEL0: Programs the ninth bit for transmission

when the UART is operating with nine data bits per frame.

For seven or eight data bits per frame, this bit in conjunction

with PSEL1 selects parity.

PSEL1, PSEL0: Parity select bits.

PSEL1

PSEL1

PSEL0

e

0, CHL0e0 The frame contains eight data bits.

e

0, CHL0e1 The frame contains seven data

e

1, CHL0e0 The frame contains nine data bits.

e

1, CHL0e1 Loopback Mode selected. Trans-

bits.

mitter output internally looped

back to receiver input. Nine bit

framing format is used.

e

0, PSEL0e0 Odd Parity (if Parity enabled)

e

0, PSEL0e1 Even Parity (if Parity enabled)

e

PSEL1

PSEL1

1, PSEL0e0 Mark(1) (if Parity enabled)

e

1, PSEL0e1 Space(0) (if Parity enabled)

PEN: This bit enables/disables Parity (7- and 8-bit modes

only).

e

PEN

0 Parity disabled.

e

PEN

1 Parity enabled.

ENURÐUART RECEIVE CONTROL AND

STATUS REGISTER

RCVG: This bit is set high whenever a framing error occurs

and goes low when RDX goes high.

XMTG: This bit is set to indicate that the UART is transmitting. It gets reset at the end of the last frame (end of last

Stop bit).

ATTN: ATTENTION Mode is enabled while this bit is set.

This bit is cleared automatically on receiving a character

with data bit nine set.

RBIT9: Contains the ninth data bit received when the UART

is operating with nine data bits per frame.

SPARE: Reserved for future use.

PE: Flags a Parity Error.

e

PE

0 Indicates no Parity Error has been detected since

the last time the ENUR register was read.

e

PE

1 Indicates the occurrence of a Parity Error.

FE: Flags a Framing Error.

e

FE

0 Indicates no Framing Error has been detected

since the last time the ENUR register was read.

e

FE

1 Indicates the occurrence of a Framing Error.

DOE: Flags a Data Overrun Error.

e

DOE

0 Indicates no Data Overrun Error has been de-

tected since the last time the ENUR register

was read.

e

DOE

1 Indicates the occurrence of a Data Overrun Er-

ror.

ENUIÐUART INTERRUPT AND

CLOCK SOURCE REGISTER

ETI: This bit enables/disables interrupt from the transmitter

section.

e

ETI

0 Interrupt from the transmitter is disabled.

e

ETI

1 Interrupt from the transmitter is enabled.

ERI: This bit enables/disables interrupt from the receiver

section.

e

ERI

0 Interrupt from the receiver is disabled.

e

ERI

1 Interrupt from the receiver is enabled.

XTCLK: This bit selects the clock source for the transmittersection.

e

XTCLK

XTCLK

0 The clock source is selected through the

PSR and BAUD registers.

e

1 Signal on CKX (L1) pin is used as the clock.

XRCLK: This bit selects the clock source for the receiver

section.

e

XRCLK

XRCLK

SSEL: UART mode select.

SSEL

SSEL

0 The clock source is selected through the

PSR and BAUD registers.

e

1 Signal on CKX (L1) pin is used as the clock.

e

0 Asynchronous Mode.

e

1 Synchronous Mode.

http://www.national.com17

Page 18

UART (Continued)

ETDX: TDX (UART Transmit Pin) is the alternate function

assigned to Port L pin L2; it is selected by setting ETDX bit.

To simulate line break generation, software should reset

ETDX bit and output logic zero to TDX pin through Port L

data and configuration registers.

STP78: This bit is set to program the last Stop bit to be

7/8th of a bit in length.

STP2: This bit programs the number of Stop bits to be transmitted.

e

STP2

0 One Stop bit transmitted.

e

STP2

1 Two Stop bits transmitted.

Associated I/O Pins

Data is transmitted on the TDX pin and received on the RDX

pin. TDX is the alternate function assigned to Port L pin L2;

it is selected by setting ETDX (in the ENUI register) to one.

RDX is an inherent function of Port L pin L3, requiring no

setup.

The baud rate clock for the UART can be generated onchip, or can be taken from an external source. Port L pin L1

(CKX) is the external clock I/O pin. The CKX pin can be

either an input or an output, as determined by Port L Configuration and Data registers (Bit 1). As an input, it accepts a

clock signal which may be selected to drive the transmitter

and/or receiver. As an output, it presents the internal Baud

Rate Generator output.

UART Operation

The UART has two modes of operation: asynchronous

mode and synchronous mode.

ASYNCHRONOUS MODE

This mode is selected by resetting the SSEL (in the ENUI

register) bit to zero. The input frequency to the UART is 16

times the baud rate.

The TSFT and TBUF registers double-buffer data for transmission. While TSFT is shifting out the current character on

the TDX pin, the TBUF register may be loaded by software

with the next byte to be transmitted. When TSFT finishes

transmitting the current character the contents of TBUF are

transferred to the TSFT register and the Transmit Buffer

Empty Flag (TBMT in the ENU register) is set. The TBMT

flag is automatically reset by the UART when software loads

a new character into the TBUF register. There is also the

XMTG bit which is set to indicate that the UART is transmitting. This bit gets reset at the end of the last frame (end of

last Stop bit). TBUF is a read/write register.

The RSFT and RBUF registers double-buffer data being received. The UART receiver continually monitors the signal

on the RDX pin for a low level to detect the beginning of a

Start bit. Upon sensing this low level, it waits for half a bit

time and samples again. If the RDX pin is still low, the receiver considers this to be a valid Start bit, and the remaining bits in the character frame are each sampled a single

time, at the mid-bit position. Serial data input on the RDX pin

is shifted into the RSFT register. Upon receiving the complete character, the contents of the RSFT register are copied into the RBUF register and the Received Buffer Full Flag

(RBFL) is set. RBFL is automatically reset when software

reads the character from the RBUF register. RBUF is a read

only register. There is also the RCVG bit which is set high

when a framing error occurs and goes low once RDX goes

high. TBMT, XMTG, RBFL and RCVG are read only bits.

SYNCHRONOUS MODE

In this mode data is transferred synchronously with the

clock. Data is transmitted on the rising edge and received

on the falling edge of the synchronous clock.

This mode is selected by setting SSEL bit in the ENUI register. The input frequency to the UART is the same as the

baud rate.

When an external clock input is selected at the CKX pin,

data transmit and receive are performed synchronously with

this clock through TDX/RDX pins.

If data transmit and receive are selected with the CKX pin

as clock output, the device generates the synchronous

clock output at the CKX pin. The internal baud rate generator is used to produce the synchronous clock. Data transmit

and receive are performed synchronously with this clock.

FRAMING FORMATS

The UART supports several serial framing formats

12).

The format is selected using control bits in the ENU,

ENUR and ENUI registers.

The first format (1, 1a, 1b, 1c) for data transmission (CHL0

e

1, CHL1e0) consists of Start bit, seven Data bits (excluding parity) and 7/8, one or two Stop bits. In applications

using parity, the parity bit is generated and verified by hardware.

The second format (CHL0

Start bit, eight Data bits (excluding parity) and 7/8, one or

two Stop bits. Parity bit is generated and verified by hardware.

The third format for transmission (CHL0

consists of one Start bit, nine Data bits and 7/8, one or two

Stop bits. This format also supports the UART ‘‘ATTENTION’’ feature. When operating in this format, all eight bits

of TBUF and RBUF are used for data. The ninth data bit is

transmitted and received using two bits in the ENU and

ENUR registers, called XBIT9 and RBIT9. RBIT9 is a read

only bit. Parity is not generated or verified in this mode.

For any of the above framing formats, the last Stop bit can

be programmed to be 7/8th of a bit in length. If two Stop

bits are selected and the 7/8th bit is set (selected), the

second Stop bit will be 7/8th of a bit in length.

The parity is enabled/disabled by PEN bit located in the

ENU register. Parity is selected for 7- and 8-bit modes only.

If parity is enabled (PEN

performed by PSEL0 and PSEL1 bits located in the ENU

register.

Note that the XBIT9/PSEL0 bit located in the ENU register

serves two mutually exclusive functions. This bit programs

the ninth bit for transmission when the UART is operating

with nine data bits per frame. There is no parity selection in

this framing format. For other framing formats XBIT9 is not

needed and the bit is PSEL0 used in conjunction with

PSEL1 to select parity.

The frame formats for the receiver differ from the transmitter in the number of Stop bits required. The receiver only

requires one Stop bit in a frame, regardless of the setting of

the Stop bit selection bits in the control register. Note that

an implicit assumption is made for full duplex UART operation that the framing formats are the same for the transmitter and receiver.

e

0, CHL1e0) consists of one

e

e

1), the parity selection is then

(Figure

0, CHL1e1)

http://www.national.com 18

Page 19

UART Operation (Continued)

FIGURE 12. Framing Formats

UART INTERRUPTS

The UART is capable of generating interrupts. Interrupts are

generated on Receive Buffer Full and Transmit Buffer Empty. Both interrupts have individual interrupt vectors. Two

bytes of program memory space are reserved for each interrupt vector. The two vectors are located at addresses 0xEC

to 0xEF Hex in the program memory space. The interrupts

can be individually enabled or disabled using Enable Transmit Interrupt (ETI) and Enable Receive Interrupt (ERI) bits in

the ENUI register.

The interrupt from the Transmitter is set pending, and remains pending, as long as both the TBMT and ETI bits are

set. To remove this interrupt, software must either clear the

ETI bit or write to the TBUF register (thus clearing the TBMT

bit).

The interrupt from the receiver is set pending, and remains

pending, as long as both the RBFL and ERI bits are set. To

remove this interrupt, software must either clear the ERI bit

or read from the RBUF register (thus clearing the RBFL bit).

Baud Clock Generation

The clock inputs to the transmitter and receiver sections of

the UART can be individually selected to come either from

an external source at the CKX pin (port L, pin L1) or from a

TL/DD/9765– 19

source selected in the PSR and BAUD registers. Internally,

the basic baud clock is created from the oscillator frequency

through a two-stage divider chain consisting of a 1–16 (increments of 0.5) prescaler and an 11-bit binary counter.

(Figure 13)

read/write registers shown in

Baud Rate Divisor spills over into the Prescaler Select Register (PSR). PSR is cleared upon reset.

As shown in Table I, a Prescaler Factor of 0 corresponds to

NO CLOCK. NO CLOCK condition is the UART power down

mode where the UART clock is turned off for power saving

purpose. The user must also turn the UART clock off when

a different baud rate is chosen.

The correspondences between the 5-bit Prescaler Select

and Prescaler factors are shown in Table I. Therer are many

ways to calculate the two divisor factors, but one particularly

effective method would be to achieve a 1.8432 MHz frequency coming out of the first stage. The 1.8432 MHz prescaler output is then used to drive the software programmable baud rate counter to create a x16 clock for the following

baud rates: 110, 134.5, 150, 300, 600, 1200, 1800, 2400,

3600, 4800, 7200, 9600, 19200 and 38400 (Table II). Other

baud rates may be created by using appropriate divisors.

The x16 clock is then divided by 16 to provide the rate for

the serial shift registers of the transmitter and receiver.

The divide factors are specified through two

Figure 14

. Note that the 11-bit

http://www.national.com19

Page 20

Baud Clock Generation (Continued)

FIGURE 13. UART BAUD Clock Generation

FIGURE 14. UART BAUD Clock Divisor Registers

TABLE I. Prescaler Factors

Prescaler Prescaler

Select Factor

00000 NO CLOCK

00001 1

00010 1.5

00011 2

00100 2.5

00101 3

00110 3.5

00111 4

01000 4.5

01001 5

01010 5.5

01011 6

01100 6.5

01101 7

01110 7.5

01111 8

10000 8.5

10001 9

10010 9.5

10011 10

10100 10.5

10101 11

10110 11.5

10111 12

11000 12.5

11001 13

11010 13.5

11011 14

11100 14.5

11101 15

11110 15.5

11111 16

TL/DD/9765– 20

TL/DD/9765– 21

TABLE II. Baud Rate Divisors

(1.8432 MHz Prescaler Output)

Baud Baud Rate

Rate Divisor

b

1 (N-1)

110 (110.03) 1046

134.5 (134.58) 855

150 767

300 383

600 191

1200 95

1800 63

2400 47

3600 31

4800 23

7200 15

9600 11

19200 5

38400 2

The entries in Table II assume a prescaler output

of 1.8432 MHz. In the asynchronous mode the

baud rate could be as high as 625k.

As an example, considering the Asynchronous Mode and a

CKI clock of 4.608 MHz, the prescaler factor selected is:

4.608/1.8432

e

2.5

The 2.5 entry is available in Table I. The 1.8432 MHz prescaler output is then used with proper Baud Rate Divisor

(Table II) to obtain different baud rates. For a baud rate of

19200 e.g., the entry in Table II is 5.

b1e

N

5(Nb1 is the value from Table II)

Ne6 (N is the Baud Rate Divisor)

Baud Ratee1.8432 MHz/(16c6)e19200

The divide by 16 is performed because in the asynchronous

mode, the input frequency to the UART is 16 times the baud

rate. The equation to calculate baud rates is given below.

The actual Baud Rate may be found from:

e

BR

Fc/(16cNcP)

http://www.national.com 20

Page 21

Baud Clock Generation (Continued)

Where:

BR is the Baud Rate

Fc is the CKI frequency

N is the Baud Rate Divisor (Table II).

P is the Prescaler Divide Factor selected by the value in the

Prescaler Select Register (Table I)

Note: In the Synchronous Mode, the divisor 16 is replaced by two.

Example:

Asynchronous Mode:

Crystal Frequencye5 MHz

Desired baud rate

Using the above equation NcP can be calculated first.

NcPe(5c106)/(16c9600)e32.552

Now 32.552 is divided by each Prescaler Factor (Table II) to

obtain a value closest to an integer. This factor happens to

be 6.5 (P

The programmed value (from Table II) should be 4 (Nb1).

Using the above values calculated for N and P:

e

6.5).

Ne32.552/6.5e5.008 (Ne5)

e

(5c106)/(16c5c6.5)e9615.384

BR

% errore(9615.385b9600)/9600e0.16

e

9600

Effect of HALT/IDLE

The UART logic is reinitialized when either the HALT or

IDLE modes are entered. This reinitialization sets the TBMT

flag and resets all read only bits in the UART control and

status registers. Read/Write bits remain unchanged. The

Transmit Buffer (TBUF) is not affected, but the Transmit

Shift register (TSFT) bits are set to one. The receiver registers RBUF and RSFT are not affected.

The device will exit from the HALT/IDLE modes when the

Start bit of a character is detected at the RDX (L3) pin. This

feature is obtained by using the Multi-Input Wakeup scheme

provided on the device.

Before entering the HALT or IDLE modes the user program

must select the Wakeup source to be on the RDX pin. This

selection is done by setting bit 3 of WKEN (Wakeup Enable)

register. The Wakeup trigger condition is then selected to

be high to low transition. This is done via the WKEDG register (Bit 3 is one.)

If the device is halted and crystal oscillator is used, the

Wakeup signal will not start the chip running immediately

because of the finite start up time requirement of the crystal

oscillator. The idle timer (T0) generates a fixed (256 t

lay to ensure that the oscillator has indeed stabilized before

allowing the device to execute code. The user has to consider this delay when data transfer is expected immediately

after exiting the HALT mode.

) de-

c

Diagnostic

Bits CHARL0 and CHARL1 in the ENU register provide a

loopback feature for diagnostic testing of the UART. When

these bits are set to one, the following occur: The receiver

input pin (RDX) is internally connected to the transmitter

output pin (TDX); the output of the Transmitter Shift Register is ‘‘looped back’’ into the Receive Shift Register input. In

this mode, data that is transmitted is immediately received.

This feature allows the processor to verify the transmit and

receive data paths of the UART.

Note that the framing format for this mode is the nine bit

format; one Start bit, nine data bits, and 7/8, one or two

Stop bits. Parity is not generated or verified in this mode.

Attention Mode

The UART Receiver section supports an alternate mode of

operation, referred to as ATTENTION Mode. This mode of

operation is selected by the ATTN bit in the ENUR register.

The data format for transmission must also be selected as

having nine Data bits and either 7/8, one or two Stop bits.

The ATTENTION mode of operation is intended for use in

networking the device with other processors. Typically in

such environments the messages consists of device addresses, indicating which of several destinations should receive them, and the actual data. This Mode supports a

scheme in which addresses are flagged by having the ninth

bit of the data field set to a 1. If the ninth bit is reset to a

zero the byte is a Data byte.

While in ATTENTION mode, the UART monitors the communication flow, but ignores all characters until an address

character is received. Upon receiving an address character,

the UART signals that the character is ready by setting the