Page 1

CN-0221

Rev. 0

Circuits from the Lab™ circuits from Analog Devices have been designed and built by Analog Devices

each circuit, and their function and performance have been tested and verified in a lab environment at

room temperature. However, you are solely responsible for testing the circuit and determining its

r your use and application. Accordingly, in no event shall Analog Devices

be liable for direct, indirect, special, incidental, consequential or punitive damages due to any cause

whatsoever connected to the use of any Circuits from the Lab circuits. (Continued on last page)

Fax: 781.461.3113 ©2012 Analog Devices, Inc. All rights reserved.

ADuCM360

AIN5/IEXC

AVDD IOVDD

AIN0

RxD

RxD

TxD

TxD

RESET

P2.2/BM

RESET

SD

V

REF

+

R

REF

V

REF

–

AIN1

5.6k

Ω

0.1%

100

Ω

PtRTD

AIN2

THERMOCOUPLE

JUNCTION

AIN3

J1

AIN7/VBIAS

AGND

09985-001

BEAD

3.3V

BEAD

USB HEADER

10Ω

10Ω

10Ω

0.01µF

0.01µF

0.1µF

4.7µF

4.7µF

0.1µF

10µF

IN

5V

D–

D+

GND

OUT

GND

ADP1720-3.3

FT232R

BEAD

FERRITE BE ADS :

1kΩ @ 100MHz

TAIYO Y UDE N

BK2125HS102-T

0.1µF

SHIELD

P0.2/SOUT

P0.1/SIN

Circuits from the Lab™ reference circuits are engineered and

tested for quick and easy system integration to help solve today’s

analog, mixed-signal, and RF design challenges. For more

information and/or support, visit www.analog.com/CN0221.

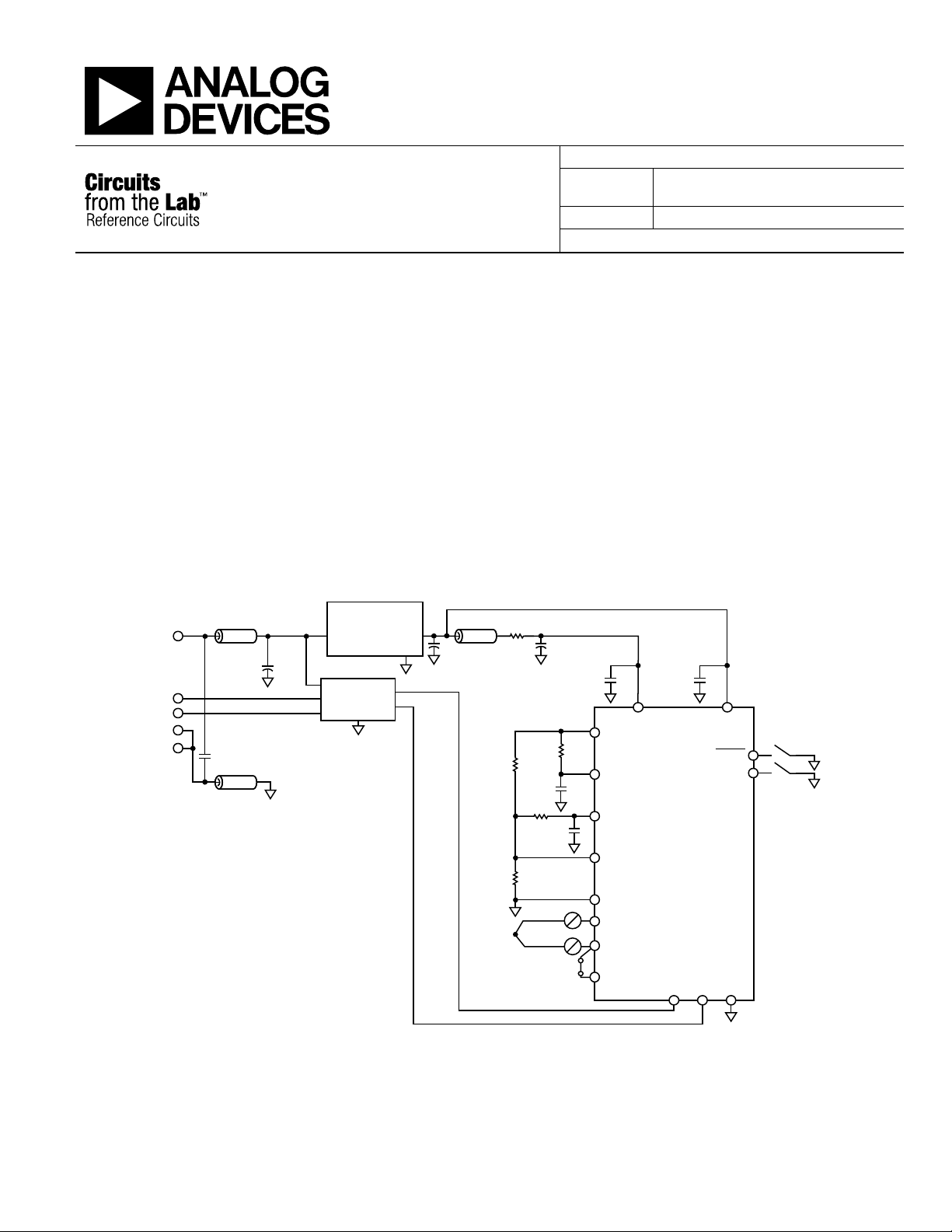

USB-Based Temperature Monitor Using the ADuCM360 Precision Analog

Microcontroller and an External Thermocouple

EVALUATION AND DESIGN SUPPORT

Circuit Evaluation Board

CN-0221 Evaluation Board (EVAL-ADuCM360TCZ)

Design and Integration Files

Schematics, Layout Files, Bill of Materials, source code for

ADuCM360

CIRCUIT FUNCTION AND BENEFITS

This circuit uses the ADuCM360/ADuCM361 precision analog

microcontroller in an accurate thermocouple temperature

monitoring application. The ADuCM360/ADuCM361 integrates

dual 24-bit sigma-delta (Σ-Δ) analog-to-digital converters (ADCs),

dual programmable current sources, a 12-bit digital-to-analog

Circuit Note

Devices Connected/Referenced

ADuCM360/

ADuCM361

ADP1720-3.3 Low Dropout Linear Regulator

converter (DAC), and a 1.2 V internal reference, as well as an ARM

Cortex-M3 core, 126 kB flash, 8 kB SRAM, and various digital

peripherals such as UART, timers, SPIs, and I

In the circuit, the ADuCM360/ADuCM361 is connected to a

thermocouple and a 100 Ω platinum resistance temperature

detector (RTD). The RTD is used for cold junction compensation.

In the source code, an ADC sampling rate of 4 Hz is chosen. When

the ADC input programmable gain amplifier (PGA) is configured

for a gain of 32, the noise-free code resolution of the ADuCM360/

ADuCM361 is greater than 18 bits.

Cortex-M3 Based Microcontroller with

Dual 24-Bit Σ-Δ ADCs

2

C interfaces.

Figure 1. ADuCM360/ADuCM361 as a Temperature Monitor Controller with a Thermocouple Interface (Simplified Schematic, All Connections Not Shown)

engineers. Standard engineering practices have been employed in the design and construction of

suitability and applicability fo

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700

www.analog.com

Page 2

CN-0221 Circuit Note

09985-002

CIRCUIT DESCRIPTION

The following features of the ADuCM360/ADuCM361 are used

in this application:

• A 24-bit Σ-Δ ADC with a PGA set for a gain of 32 in the

software for the thermocouple and RTD. The ADC1 was

switched continuously between sampling the thermocouple

and the RTD voltages.

• Programmable excitation current sources for forcing a

controlled current through the RTD. The dual current

sources are configurable in from 0 µA to 2 mA. For this

example, a 200 µA setting was used to minimize the error

introduced by the RTD self-heating.

• An internal 1.2 V reference for the ADC in the ADuCM360/

ADuCM361. It measures the thermocouple voltage; the

internal voltage reference was used due to its precision.

• An external voltage reference for the ADC in the

ADuCM360/ADuCM361. It measures the RTD resistance;

a ratiometric setup was used where an external reference

resistor (R

and VREF− pins.

• A bias voltage generator (VBIAS). The VBIAS function was

used to set the thermocouple common-mode voltage to

AVDD/2.

• The ARM Cortex-M3 core. The powerful 32-bit ARM core

with integrated 126 kB flash and 8 kB SRAM memory runs

the user code that configures and controls the ADC, processes

the ADC conversions from the RTD, and controls the

communications over the UART/USB interface.

• The UART was used as the communication interface to the

host PC.

• Two external switches are used to force the part into its

flash boot mode. By holding SD low and toggling the RESET

button, the ADuCM360/ADuCM361 enters boot mode

instead of normal user mode. In boot mode, the internal

flash can be reprogrammed through the UART interface.

Both the thermocouple and the RTD generate very small signals;

therefore, a PGA is required to amplify those signals.

The thermocouple used in this application is a Type T (copperconstantan) that has a temperature range of −200°C to +350°C.

Its sensitivity is approximately 40 µV/°C, which means that the

ADC in bipolar mode, with a PGA gain of 32, can cover the

entire temperature range of the thermocouple.

The RTD was used for cold junction compensation. The

particular one used in this circuit was a platinum 100 Ω RTD,

Enercorp PCS 1.1503.1. It is available in a 0805, surface-mount

package. This RTD has a temperature variation of 0.385 Ω/°C.

) was connected across the external VREF+

REF

Note that the reference resistor, R

5.6 kΩ (±0.1%).

The USB interface to the ADuCM360/ADuCM361 is implemented

with an FT232R UART to USB transceiver, which converts USB

signals directly to the UART.

In addition to the decoupling shown Figure 1, the USB cable itself

must have a ferrite bead for added EMI/RFI protection. The ferrite

beads used in the circuit were Taiyo Yuden, #BK2125HS102-T,

which have an impedance of 1000 Ω at 100 MHz.

Construct the circuit on a multilayer printed circuit board (PCB)

with a large area ground plane. Use proper layout, grounding,

and decoupling techniques to achieve optimum performance (see

Tutorial MT-031, Grounding Data Converters and Solving the

Mystery of "AGND" and "DGND," Tut o r ia l MT-101, Decoupling

Techni q u e s , and the ADuCM360TCZ Evaluation Board layout).

The PCB used for evaluating this circuit is shown in Figure 2.

Figure 2. EVAL-ADuCM360TCZ Board Used for this Circuit

, should be a precision

REF

Rev. 0 | Page 2 of 5

Page 3

Circuit Note CN-0221

09985-003

20

0

–20

–40

–60

–80

–100

–210 –140 –70 0 70 140 210 280 350

ERROR (°C)

TEMPERATURE (°C)

09985-004

0.30

0.25

0.20

0

0.05

0.10

0.15

–0.05

–210 –140 –70 0 70 140 210 280 350

ERROR (°C)

TEMPERATURE (°C)

09985-005

Code Description

The source code used to test the circuit can be downloaded as a zip

file from the ADuCM360 product page.

The UART is configured for a baud rate of 9600, 8 data bits, no

pari t y, and no flow control. If the circuit is connected directly to

a PC, a communication port viewing application, such as a

HyperTerminal, can be used to view the results sent by the

program to the UART, as shown in Figure 3.

Figure 4. Error When Using Simple Linear Approximation

Initially, this was done using a simple linear assumption that the

voltage on the thermocouple was 40 µV/°C. It can be seen from

Figure 4 that this gives an acceptable error only for a small range,

around 0°C. A better way of calculating the thermocouple

temperatures is to use a six-order polynomial for the positive

temperatures and a seventh-order polynomial for the negative

temperatures. This requires mathematical operations that add

to computational time and code size. A suitable compromise is to

calculate the respective temperatures for a fixed number of

voltages. These temperatures are stored in an array, and values in

between are calculated using a linear interpolation between the

adjacent points. It can be seen from Figure 5 that the error is

drastically reduced using this method. Figure 5 gives the algorithm

error using ideal thermocouple voltages.

Figure 3. Output of HyperTerminal Communication Port Viewing Application

To get a temperature reading, measure the temperature of the

thermocouple and the RTD. The RTD temperature is converted

to its equivalent thermocouple voltage via a look-up table (see the

ISE, Inc., ITS-90 Table for Type T Thermocouple). These two

voltages are added together to give the absolute value at the

thermocouple.

First, the voltage measured between the two wires of the

thermocouple (V1). The RTD voltage is measured, converted to

a temperature via a look-up table, and then, this temperature is

converted to its equivalent thermocouple voltage (V2). V1 and

V2 are then added to give the overall thermocouple voltage, and

this is then converted to the final temperature measurement.

Figure 5. Error When Using Piecewise Linear Approximation Using

Rev. 0 | Page 3 of 5

52 Calibration Points and Ideal Measurements

Page 4

CN-0221 Circuit Note

–0.5

–0.4

–0.3

–0.2

–0.1

0

0.1

0.2

0.3

0.4

0.5

–210 –140 –70 0 70 140 210 280 350

ERROR (°C)

TEMPERATURE (°C)

09985-006

EVAL-ADuCM360TCZ

WAVETEK 4808

MULTIFUNCTION

CALIBRATOR

PC

J5

J1

AIN7/VBIAS

THERMOCOUPLE

JUNCTION

SEE TEXT

USB

CABLE

09985-007

Figure 6 shows the error obtained when using ADC1 on the

ADuCM360 to measure 52 thermocouple voltages over the full

thermocouple operating range. The overall worst-case error

is <1°C.

Figure 6. Error When Using Piecewis e Linear Approximation Using

52 Calibration Points Measured by ADuCM360/ADuCM361

The RTD temperature is calculated using lookup tables and is

implemented for the RTD the same way as for the thermocouple.

Note that the RTD has a different polynomial describing its

temperatures as a function of resistance.

For details on linearization and maximizing the performance of

the RTD, refer to Application Note AN-0970, RTD Interfacing

and Linearization Using an ADuC706x Microcontroller.

COMMON VARIATIONS

The ADP1720 regulator can be replaced with the ADP120, which

has the same operating temperature range (−40°C to +125°C)

and consumes less power (typically 35 µA vs. 70 µA) but has a

lower maximum input voltage. Note that the ADuCM360/

ADuCM361 can be programmed or debugged via a standard

serial wire interface.

For a standard UART to RS-232 interface, the FT232R transceiver

can be replaced with a device such as the ADM3202, which

requires a 3 V power supply. For a wider temperature range, a

different thermocouple can be used, such as a Type J. To minimize

the cold junction compensation error, a thermistor can be placed in

contact with the actual cold junction instead of on the PCB.

Instead of using the RTD and external reference resistor for

measuring the cold junction temperature, an external digital

temperature sensor can be used. For example, the ADT7410 can

connect to the ADuCM360/ADuCM361 via the I

For more details on cold junction compensation, refer to Sensor

Signal Conditioning, Analog Devices, Chapter 7, “Temperature

Sensors.”

If isolation between the USB connector and this circuit is required,

the ADuM3160/ADuM4160 isolation devices must be added.

2

C interface.

CIRCUIT EVALUATION AND TEST

To test and evaluate the circuit, the thermocouple measurements

and the RTD measurements were evaluated separately.

Thermocouple Measurement Test

The basic test setup is shown in Figure 7. The thermocouple is

connected to J5, and Jumper J1 must be installed to allow the

AIN7/VBIAS pin to set the thermocouple common-mode

voltage. The circuit board receives its power from the USB

connection to the PC.

Two methods were used to evaluate the performance of the

circuit. Initially, the circuit was tested with the thermocouple

attached to the board and it was used to measure the temperature

of an ice bucket. Then, it was used to measure the temperature

of boiling water.

A Wavetek 4808 Multifunction Calibrator was used to fully

evaluate the error, as shown in Figure 4 and Figure 6. In this

Rev. 0 | Page 4 of 5

mode, the thermocouple was replaced with the calibrator as the

voltage source, as shown in Figure 7. To evaluate the entire range

of a Type T thermocouple, the calibrator was used to set the

equivalent thermocouple voltage at 52 points between −200°C

to +350°C for the negative and positive ranges of the T-type

thermocouple (see the ISE, Inc., ITS-90 Table for Type T

Thermocouple).

To evaluate the accuracy of the lookup algorithm, 551 voltage

r

+350°C spaced at +1°C, were passed onto the temperature

calculation functions. Errors were calculated for the linear

method and the piecewise linear approximation method as is

shown in Figure 4

eadings, equivalent to temperatures in the range of −200°C to

and Figure 5.

Figure 7. Test Setup Used to Calibrate and Test the Circuit Over Full

Thermocouple Output Voltage Range

Page 5

Circuit Note CN-0221

1433-Z

DECADE

RESISTOR

ADuCM360

0.1µF

0.01µF

0.01µF

R

REF

5.6kΩ

0.1%

10Ω

10Ω

AVDD

V

REF

+

V

REF

–

IOVDD

AVDD IOVDD

0.1µF

09985-008

AIN5/IEXC

AIN0

AIN1

0

–0.01

–25 –5

ERROR (°C)

TEMPERATURE (°C)

–0.02

–0.03

–0.04

–0.05

–0.06

–0.07

–0.08

–0.09

–0.10

15 35 55 75 95 115

09985-009

(Continued from f irst page) Circuits from the Lab circuits are intended only for use with Analog Devices products and are the intellectual property of Analog Devices or its licensors. While you

reserves the right to change any Circuits from the Lab circuits at any time without notic e but is under no obligation to do so.

registered trademarks are the property of their respective owners.

RTD Measurement Test

To evaluate the RTD circuit and linearization source code, the

RTD on the board was replacement with an accurate, adjustable

resistance source. The instrument used was the 1433-Z Decade

Resistor. The RTD values are from 90 Ω to 140 Ω, which represents

an RTD temperature range of −25°C to +114°C.

The test setup circuit is shown in Figure 8, and the error results

for the RTD tests are shown in Figure 9.

LEARN MORE

CN0221 Design Support Package:

http://www.analog.com/CN0221-DesignSupport

ADIsimPower Design Tool.

Kester, Walt. 1999. Sensor Signal Conditioning. Analog Devices.

Chapter 7, "Temperature Sensors."

Kester, Wa lt. 1999. Sensor Signal Conditioning. Analog Devices.

Chapter 8, "ADCs for Signal Conditioning."

Looney, Mike. RTD Interfacing and Linearization Using an

ADuC706x Microcontroller. AN-0970 Application Note.

Analog Devices.

MT-022 Tutorial, ADC Architectures III: Sigma-Delta ADC

Basics. Analog Devices.

MT-023 Tutorial, ADC Architectures IV: Sigma-Delta ADC

Advanced Concepts and Applications. Analog Devices.

MT-031 Tutorial, Grounding Data Converters and Solving the

Mystery of "AGND" and "DGND." Analog Devices.

MT-101 Tutorial, Decoupling Techniques. Analog Devices.

ITS-90 Table for Type T Thermocouple.

Figure 8. Test Setup for Measuring RTD Error

Data Sheets and Evaluation Boards

ADuCM360/ADuCM361 Data Sheet

ADuCM360/ADuCM361 Evaluation Kit

ADM3202 UART to RS232 Transceiver Data Sheet

ADP120 Data Sheet

ADP1720 Data Sheet

REVISION HISTORY

5/12—Revision 0: Initial Version

Figure 9. Error in °C of RTD Measurement Using Piecewise Linearization Code

and ADC0 Measurements

may use the Circuits from the Lab circuits in the design of your product, no other license is granted by implication or otherwise under any patents or other intellectual property by

application or use of the Circuits from the Lab circuits. Information furnished by Analog Devices is believed to be accurate and reliable. However, Circuits from the Lab circuits are supplied

"as is" and without warranties of any kind, express, implied, or statutory including, but not limited to, any implied warranty of merchantability, noninfringement or fitness for a particular

purpose and no responsibility is assumed by Analog Devices for their use, nor for any infringements of patents or other rights of third parties that may result from their use. Analog Devices

©2012 Analog Devices, Inc. All rights reserved. Trademarks and

CN09985-0-5/12(0)

Rev. 0 | Page 5 of 5

Loading...

Loading...