Page 1

CLP200M

ApplicationSpecific Discretes

A.S.D.

OVERVOLTAGE AND OVERCURRENT

PROTECTION FOR TELECOM LINE

MAINAPPLICATIONS

Any telecom equipment submitted to transient

overvoltagesandlightningstrikes suchas:

Analogand ISDNline cards

PABX

MainDistribution Frames

Primaryprotection modules

DESCRIPTION

TheCLP200Mis designedtoprotecttelecommunicationequipment.It providesbothatransientovervoltageprotectionand an overcurrentprotection.

It is housedin a PowerSO-10

TM

package.

FEATURES

DUALBIDIRECTIONALPROTECTIONDEVICE.

HIGHPEAKPULSE CURRENT:

Ipp = 100A(10/1000µs SURGE)

MAX.VOLTAGEAT SWITCHING-ON: 290V

MIN.CURRENT AT SWITCHING-OFF : 150mA

FAILURESTATUSOUTPUTPIN

BENEFITS

Both primary and secondaryprotectionlevelsin

onedevice.

Voltageand current controlledsuppression.

SurfaceMountingwithPowerSO-10

TM

package.

Line card cost reduction thanks to the very low

power rating of external components required :

balanced resistors, ring relay, low voltage SLIC

protection.

PowerSO-10

SCHEMATICDIAGRAM

1

TIP

S

TIP

L

TIP

L

TIP

L

TABis connected to GND

TM

NCFS

RING

RING

RING

RING

S

L

L

L

COMPLIESWITH THEFOLLOWINGSTANDARDS :

CCITTK20: 10/ 700µs 4kV

5 / 310µs 100A

BELLCORETR-NWT-000974

10/ 1000µs 1kV

10/ 1000µs 100A

February 1998 Ed : 3

1/21

Page 2

CLP200M

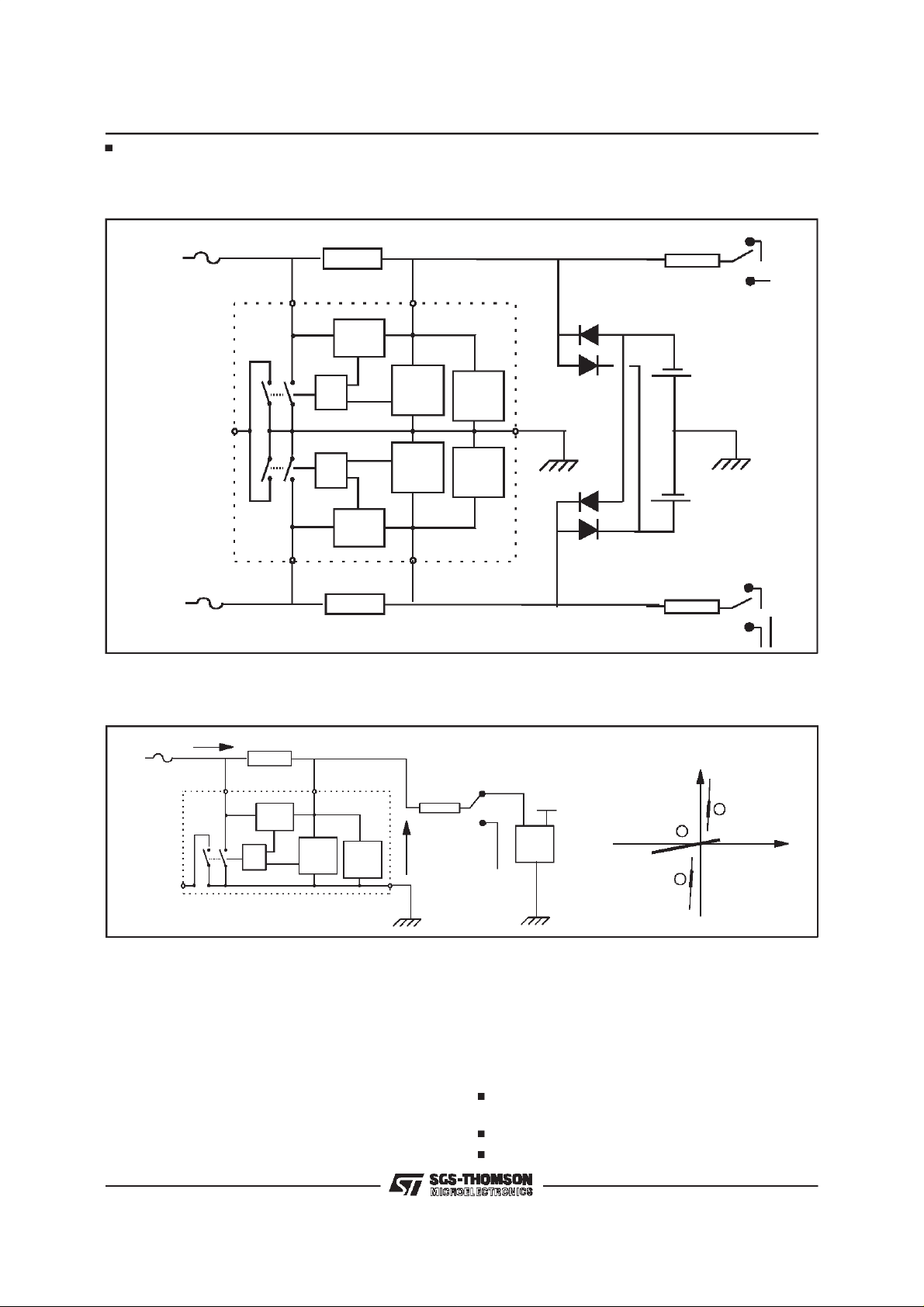

BLOCKDIAGRAM

TIPL TIPS

Overcurrent

detector

OR

SW3 SW1

FS GND

SW4 SW2

OR

Overcurrent

detector

RINGL RINGS

Overvoltage

detector

Overvoltage

detector

Overvoltage

reference

(+/- 215 V)

Overvoltage

reference

(+/- 215 V)

Pin Symbol Description

1 FS FailureStatus

2 TIPS TIP(SLICside)

3 / 4 / 5 TIPL

TIP(Lineside)

6 / 7 / 8 RINGL RING(Lineside)

2/21

9 RINGS RING(SLICside)

10 NC Not connected

TAB GND Ground

Page 3

APPLICATION NOTE

1. INTRODUCTION

The aim of this section is to show the behaviorof

ournewtelecomlineprotectiondevice.Thisdevice

includes a primary protection level and is suitable

for main distribution frames and line cards. This

protection concept is explained and, in addition,

the CLP200M performances are analysed when

facing different surgesas described in the CCITT

recommendations.

Fig.1 :

Subscriberline protectiontopology

telecommunication

line

”PRIMARYPROTECTION” ”SECONDARYPROTECTION”

MDF LINECARD

EXCHANGE

SLICCLP200M

CLP200M

2. SGS-THOMSONCLP200M CONCEPT

2.1Evolution of the SLIC protection

Over the years, the silicon protection performances have considerably changed .

The first generation of products like SMTHBTxx

and SMTHDTxx offered fixed overvoltage protection against surges on either TIP or RING line in

fourpackages.

The following generation like THBTxx and

THDTxx still offered fixed overvoltageprotection

againstsurgeson both TIP andRINGlines in two

packages.

The next step was the introduction of the

LCP1511D which brought the advantage of full

programmablevoltage.

Today, the CLP200M combines the features of all

the previous generations.In addition to that, it offers an overcurrent detection when operating in

speechmode and also a FailureStatusoutputsignal.

telecommunication

line

MDF LINECARD

”SECONDARYPROTECTION”

THDTxx or

EXCHANGE

LPC1511D

or LB200B

CLP200M SLIC

Figure 1 is a simplified block diagram of a subscriberline protectionthat ismainlyused sofar.

Thisshows two differentthings:

A ”primaryprotection”locatedon theMain DistributionFrame(MDF)eliminatescoarselythehigh

energy environmental disturbances (lightning

transientsand AC powermainsdisturbances)

A ”secondaryprotection”locatedon the line card

includesa primaryprotectionlevel(firststage)and

a residualprotection(secondstage)which eliminatesfinelytheremainingtransientsthathavenot

beentotallysuppressedby thefirststage.

The CLP200M can be used both in MDFs and in

line cards. In that case, any line card may be

swappedfrom one MDFtoanotherone withoutreducing the efficiency of the whole system protection.

The CCITT requirements are different for these

two protection locations (MDFs and line cards).

Concerningthe”primaryprotection”,theCCITTrequires a 4kV, 10/700µs surge test whereas the

”secondary protection” has to withstand a 1kV,

10/700µs surge test.

The explanations which follow are basically

coveringthelinecardapplication.

Fig. 2 :

Programmablethanks to

any external voltagereference

Linecard protection

I

+I

SWON

-I

Programmablethanks to

an external resistor

SWON

V

Line card operating conditions

The figure 2 summarizes the performance of the

CLP200MwhichbasicallyholdstheSLICinside its

correctvoltageandcurrentvalues.

3/21

Page 4

CLP200M

APPLICATION CIRCUIT : CLP200Min linecard

Fig.3 : CLP200Min line card

Fuse

TIP

RING

SW3 SW1

FS GND

SW4 SW2

Fuse

R sense

TIPL TIPS

Overcurrent

detector

Overvoltage

detector

Overvoltage

detector

RINGS

RINGL

OR

OR

Overcurrent

R sense

detector

Overvoltage

reference

(+/- 215 V)

Overvoltage

reference

(+/- 215 V)

I

1

Rp

2

1

Rp

2

Ring

Generator

External

voltage

reference

-Vbat

TIP

-Vbat

(*)

SLIC

RING

(*) LCP1511D orTHDT series

Figure 3 above showsthe topology of a protected

analog subscriber line at the exchange side. The

CLP200M is connected to the ring relay via two

balancedRp resistors, and to the SubscriberLine

Interface Circuit. A second device is located near

theSLIC : it canbe either a LCP1511Dor a THDT

series.

These two devices are complementary and their

functionsare explainedbelow:

The first stage based on CLP200M manages

the high power issued from the external

surges. When used in ringing mode, the

CLP200M operates in voltage mode and provides a symmetrical and bidirectional

overvoltage protection at +/-215 V on both TIP

and RING lines. When used in speech mode,

the CLP200M operates in current mode and

the activation current of the CLP200M is adjusted by R

SENSE

.

The second stage is the external voltage reference device which defines the firing threshold

voltage during the speech mode and also assumes a residual power overvoltage

suppression.This protectionstagecan be either

a fixed or programmable breakover device. The

THDTxxfamilyacts as a fixed breakover device

whilethe LCP1511Doperatesas a programmableprotection.

Thanks to this topology, thesurge current in the

line is reduced after the CLP200M. Because the

remainingsurgeenergyis low,thepowerratingsof

Rp,the ringrelaycontactsand theexternalvoltage

referencecircuit maybe downsized.This resultsin

a significantcostreduction.

4/21

Page 5

2.3 Ringingmode

Fig.4 : Switchingbyvoltage duringringingmode.

ILG

Fuse

TIP

FS

Rsense

TIPL TIPS

Overcurrent

detector

OR

SW3 SW1

Overvoltage

detector

1/2 CLP200M

Overvoltage

reference

(+/- 215 V)

VLG

GND

CLP200M

ILG

1

Rp

2

-215

3

A1

2

1

VLG

+215

In ringing mode (Ring relay in position 2), the only

protectiondeviceinvolvedis theCLP200M.

Innormalconditions,theCLP200Moperatesin region1 of A1 curve,andisidle.

If an overvoltageoccuringbetween TIP(or RING)

and GND reaches the internal overvoltage reference(+/- 215V),theCLP200Mactsand thelineis

short-circuited to GND. At this time the operating

pointmovestoregion2 for positive surges(region

3 for negativesurges).Oncethe surgecurrentdisappears, the device returns to its initial state (region1).

Fig.5a : Methodto adjustthereferencevoltage.

Fuse

TIP

SW3 SW1

R sense

TIPL TIPS

Overcurrent

detector

Overvoltage

OR

detector

For surges occuring between TIP and RING, the

CLP200M acts in the same way. This means that

theCLP200M ensuresa tripolarprotection.

Whenused alone, theCLP200M acts at the internalovervoltagereferencelevel(+/-215V).Furthermore,it is possible to adjust this thresholdlevel to

a lowervoltageby using :

.up to 4 fixed external voltage reference (V

V

) (seefig.5a).

Z4

1

Rp

2

VZ1

Overvoltage

reference

(+/- 215 V)

VZ2

Z1

to

RING

FS GND

Fuse

SW4 SW2

RINGL

OR

Overcurrent

detector

R sense

Overvoltage

detector

RINGS

Overvoltage

reference

(+/- 215 V)

VZ3

VZ4

1

Rp

2

5/21

Page 6

CLP200M

externalreferencesupplies,Vb1andVb2(seefig.5b)..

Fig. 5b: Methodto adjustthe referencevoltage.

TIP

RING

Fuse

R sense

TIPL TIPS

Overcurrent

detector

Overvoltage

OR

SW3 SW1

FS GND

Fuse

SW4 SW2

RINGL

OR

Overcurrent

R sense

detector

detector

Overvoltage

detector

RINGS

Overvoltage

reference

(+/- 215 V)

Overvoltage

reference

(+/- 215 V)

1

Rp

2

VB1

VB2

1

Rp

2

2.4 Speechmode

Fig.6 : Switchingby currentduring speechmode.

ILG

Fuse

TIP

FS

R sense

TIPL TIPS

Overcurrent

detector

OR

SW3 SW1

Overvoltage

detector

Overvoltage

reference

(+/- 215V)

VLG

GND

In speech mode(Ringrelayin position1),the protection is provided by the combination of both

CLP200M and the external voltage reference device.

In normal conditions, the working point of this circuit is located in region 4 of A2 curve : the

CLP200Mis idle.

Whena surgeoccurs on the line,theexternal voltage reference device clamps at GND or -V

bat

respectivelyforpositiveand negativesurges.

This generates a current which is detected by

R

andcausestheprotectiontoact: theline is

SENSE

short-circuitedto GND.

6/21

ILG

1

External

voltage

reference

-Vbat

-VREF2

5

4

VREF1

6

Rp

2

The operatingpoint moves to region 5 for positive

surgesor region6 fornegative surges.

Once the surge current falls below the switchingoff current I

, the CLP200M returns to its in-

SWOFF

itialstate (region 4).

Furthermore, the CLP200M switches when an

overvoltage, either positive or negative, occurs

either:

simultaneouslyon bothTIP and RING lines versusGND.

betweenTIP andRING.

onTIP (orRING)versus GND.

A2

V

LG

Page 7

CLP200M

Fig. 7a and 7b : Switching-on current versus

R

.

SENSE

ISWON (mA)

500

300

200

100

3 5 7 9 11 13

Iswon@ 25°C (mA)

500

300

200

100

357911

-20°C25°C75°C

Rsense ( )Ω

Iswonmin Iswon max Iswonmin Iswonmin

negative negative positive positive

Rsense ( )Ω

The choice of the switching-on current is function

oftheR

SENSE

resistors.

In normal operating condition, only the negative

currentofthesignalisof interest.Thiscurrent(typically below -150 mA) should not activate the protection device CLP200M. Therefore the level of

activationis to be chosenjustabove thislimit (typically -200 mA). This level is adjusted through

SENSE

.

R

Figures7a and 7b enablethe designersto choose

theright R

SENSE

value.

2.5. FailureStatus

The CLP200M has an internal feature that allows

the user to get a Failure Status (FS) indication.

When the CLP200M is short-circuiting the line to

GND,a signalcanbemanagedthrough pin 1.This

signalcan beusedto turna LEDon inordertoprovide a surge indication. It mayalsobe used with a

logic circuitryto count the number of disturbances

appearingon the lines.

Fig. 8 : FailureStatus circuit anddiagnostic.

Rsense

1

FAILURE

STATUS

1k

+12V

CLP200M

Rsense

If a surge exceeding the maximum ratings of the

CLP200Moccurson the line, the devicewill fail in

a short-circuit state.

Fig.9 :

Operationlimitsanddestructionzoneof the

CLP200M.

Ipp (A)

1000

100

10

0.01 0.1 1 10

t (ms)

EXAMPLE :

The choice of R

=4Ωensures a negative

SENSE

triggeringof -220mAmin and-320mAmax.In this

case,thepositivetriggeringwillbe 180mAminand

280mAmax.

Thefigure 9 showstwo differentcurves:

Theloweroneindicatesthe maximumguaranted

workinglimits of the CLP200M.

Theupper curveshowsthelimit abovewhichthe

CLP200Miscompletelydestructed. Inthiscase,

theFail Diagnosticpin is on.

7/21

Page 8

CLP200M

3. CLP200MTESTSRESULTSACCORDINGTO

CCITTK20RECOMMENDATIONS

3.1CCITT K20 Recommendations

In respect with the CCITT recommendations, the

CLP200M has to withstand three kinds of disturbances.

3.1.1. Lightning simulation

(Test2, table2/K20)

Thistest shallbe donein transversaland longitudinalmodesas shown in figure10.

Fig.10 : Transversaland longitudinaltest

topologies.

AorB

ITEM

UNDER

BorA

TEST

E

A

25

25

ITEM

UNDER

B

TEST

E

4kv

4kv

15 25

0.2µF5020µF

TRANSVERSAL TEST

15

0.2µF5020µF

Fig. 11 :

Powerinduction testcircuit.

1µF

S2

1µF

100

S1

R1

R2

A

ITEM

UNDER

TEST

B

E

3.1.3.Powercontact(Test 3, table1/K20)

Thistest shall be donewith the testcircuitof figure

12.

Vac(max)= 220V

, with switchS in each posi-

RMS

tionand duration 15 min.

Fig. 12 : Powercontact testcircuit.

<10

600

<10

600

A

UNDER

B

ITEM

TEST

E

LONGITUDINAL TEST

The test generator is the 10/700µs with 4kV of

peakvoltage.

3.1.2. Powerinduction

(Test3a and3b, table2/K20)

Twokinds of testsusing thesame circuittopology

(seefig.11) are definedin the CCITTK20.

Test3a :

Vac(max)= 300V

, R1= R2= 600

RMS

Ω

S2operatingand test duration= 200ms.

Test3b :

Vac(max)= 300V

(*),R1 = R2 = 200Ω

RMS

S2operatingand test durationnot defined.

(*)Recommended value.

8/21

3.1.4.Acceptance criteriaand numberof tests

Forthetestsdescribedin chapter3.1.1.,3.1.2.and

3.1.3.two criteria aredefined:

A:Equipmentshallwithstandthetestwithoutdam-

ageand shalloperateproperly withinthespecified

limits.

B:A fire hazard shouldnot occur in the equipment

asa resultof thetests.

The criteria are affected to the different tests as

mentionedin the table 1.

Page 9

CLP200M

Table1 : Acceptancecriteriaand numberof tests.

TEST ACCEPTANCE

NUMBERTO TESTS

CRITERIA

2 A 10 forlongitudinalA

10 forlongitudinalB

and 10 fortransversal

3a A 5

3b B 1

3 B 1 foreach positionof s

3.2.Ringingmode

3.2.1. Lightningsimulationtest

Lightningphenomenaare themostcommon surge

causes.The purpose of thistest isto checkthe robustnessof the CLP200M against these lightning

strikes.

Fig.13 : Lightningsimulationtest.

10/700µs

I

GENERATOR

+/- 4kV

Rsense

TIPL

1/2 CLP200M

GND

4Ω

TIPS

Rp

V

Fig.15 :

CLP200Mresponseto a negativesurge.

Figures 14 and 15 show that the remaining overvoltagedoesnot exceed+/- 260V. The CLP200M

switcheson within0.7µsandwithstandsthe 100A

givenby theCCITTK20 generator.

Consequently,the CLP200Mtotally fulfillsthistest.

3.2.2Power induction

(Test3a and 3b table2/K20)

Surgesof longdurationwithmediumvoltagevalue

are mainly produced by the proximity of a subscriber line with an AC mains line or equipment.

Thepurpose of this testisto checkthe robustness

ofthe CLP200Magainst these capacitivecoupling

disturbances.

Fig. 16 : Powerinductancetest.

Fig.14 :

CLP200Mresponseto a positivesurge.

TEST V

(RMS)

R(Ω) Duration

3a 300 600 0.2s

3b 300 200 ?

9/21

Page 10

CLP200M

Fig. 17 : CLP200Mresponseto the induction test

(Test3a).

Fig. 18 : CLP200M reponse to the induction test

(Test3b).

The test 3 of CCITT K20 requiresa serial PTC (or

fuse)which is insertedin the test circuit to limit the

currentrate. ThisPTCactslikean open-circuitin a

non-instantaneous way when a surge occurs on

the line. Meanwhile, the CLP200M has to withstandthe surge.

Fig.19 : Powercontact test.

600 < 10ΩΩ

or

15min

V(RMS)

50Hz

I

PTC

4

Rsense Rp

TIPL TIPS

1/2 CLP200M

GND

V

Fig. 20 : Powercontacttest 3 (With10Ωseries).

Figures17 and18 showthat theremainingvoltage

doesnotexceed 270 V.

Consequently,the CLP200Mtotally fulfillsthistest.

The test duration is not specified in test 3b. If the

duration exceeds 5s we do suggest to follow the

soldering and mounting recommendations given

onpage17ofthis document.

3.2.3Power contact(Test3 table1/K20)

This long duration surge is produced when connecting a subscriber line to an AC mains line or

equipment.Thepurposeof thistestis tocheckthe

robustnessof the CLP200M against these disturbances.

10/21

Figure 20 shows that the remaining overvoltage

does not exceed 250 V and shows that the PTC

actslike anopen-circuit after60 ms.

Consequently,the CLP200Mtotally fulfillsthistest.

3.3.Speechmode

3.3.1.Lightningsimulation test

(Test2, table2/K20)

Fig.21: Lightningtest in speechmode.

10/700µs

GENERATOR

+/- 4kV

I

1

4

Rsense

TIPL TIPS

1/2 CLP200M

GND

V1

I2

50

Rp

-48V

LCP1511D

SLIC

V2

Page 11

CLP200M

Fig.22 : CLP200Mresponseto a positivesurge.

Fig. 23 : CLP200Mresponseto a negativesurge.

3.3.2Power inductiontest

(Test3a and 3b, table 2/K20)

Fig.24 : Powerinductiontest.

I

1

V(RMS)

50 Hz

TEST V

TIPL

1/2 CLP200M

(RMS)

4Ω

Rsense

TIPS

GND

V1

R(Ω) Duration

I2

50

Rp

-48V

LCP1511D

SLIC

V2

3a 300 600 0.2s

3b 300 200 ?

Figures25 and26 showthat themaximumremaining voltage does not exceed +2V for positive

surgesand -55V for negativesurges.

Consequently,the CLP200Mtotally fulfillsthistest.

The test duration is not specified in test 3b. If the

duration exceeds 5s we do suggest to follow the

soldering and mounting recommendations given

onpage17of this document.

Figures22 and23 givethe voltageandcurrentbehaviorduringpositiveandnegative4kV,10/700µs,

surge tests using a LCP1511D as second stage

protection device. The firing threshold values are

now adjusted to GND and to -Vbat (-48V) by the

actionof thesecondstageprotectionwhichactsas

anexternalvoltage reference.

As shown on these figures, the maximumremaining voltage does not exceed +2.5V for positive

surgesand -60V for negativesurges.

Consequently,the CLP200Mtotally fulfillsthistest.

Fig.25 :

Inductiontest behavior(Test3a).

11/21

Page 12

CLP200M

Fig.26 : Inductiontest behavior(Test3b).

3.3.3- Powercontact test (Test3 table1/K20)

The test 3 of CCITT K20 requires a serial PTC (or

fuse)which isinsertedinthe test circuitto limit the

currentrate. This PTC acts like an open-circuitafter 60 mswhen a surge occurs on the line. Meanwhile,theCLP200Mhasto withstandthe surge.

The protection device CLP200M totally fulfills this

test.

Fig.28 :Powercontacttest3 (withR≤10Ωseries).

Fig. 27 : Power contacttest.

600 or < 10

12/21

V(RMS)

50Hz

I

PTC

15min

4Ω

Rsense Rp

TIPL TIPS

1/2 CLP200M

GND

I2

SLIC

-48V

V

LCP1511D

V2

Page 13

CLP200M

ABSOLUTEMAXIMUMRATINGS (R

SENSE

=4Ω, and T

Symbol Parameter Test Conditions Value Unit

I

PP

Line to GNDpeak surge

current

10/1000µs (open circuitvoltage

wave shape10/1000µs)

5/310µs(opencircuit voltage

wave shape10/700µs)

I

TSM

Mainspowerinduction

current

Mainspowercontact current V

V

=300V,R= 600Ω

RMS

t =200ms

=220V,R= 10Ω

RMS

(failurestatus threshold)

t =200 ms

= 220V,R =600

V

RMS

t =15 mn

T

stg

T

j

T

L

Storagetemperature range

Maximumjunctiontemperature

Maximumleadtemperatureforsolderingduring10 s

amb

=25°C)

Ω

100 A

130 A

0.5 A

22 A

0.30 A

- 40 to + 150

150

260 °C

°C

ELECTRICAL CHARACTERISTICS

(R

SENSE

=4Ω, andT

amb

=25°C)

Symbol Parameter Test Conditions

I

LGL

Line to GNDleakage

current

. VLG= 200V

.

MeasuredbetweenTIP

(orRING)and GND

V

ref

Overvoltageinternal

reference

.

=1mA

I

LG

.MeasuredbetweenTIP

(orRING)and GND

V

SWON

I

SWOFF

Line to GNDvoltage at SW1

or SW2switching-on

Line to GNDcurrent at SW1

. Measuredat50 Hzbetween

TIPL(or RINGL)and GND

.

Refertotest circuit page 14 150 mA

or SW2switching-off

I

SWON

Line currentat SW1or SW2

switching-on

C LinetoGNDcapacitance

.

Positivepulse

. Negativepulse

.

=-1V+1V

V

LG

RMS

. F = 1 MHz

Value

Min. Max.

Unit

10

215 V

290 V

180

220

280

320

200 pF

A

µ

mA

13/21

Page 14

CLP200M

TEST CIRCUITFORI

PARAMETER: GO-NOGO TEST

SWOFF

R

D.U.T.

V

BAT

This is a GO-NOGOtest whichallows to confirmthe switch-off(I

TESTPROCEDURE:

- Adjust the currentlevel at the I

- Firethe D.U.T.witha surgecurrent : I

- The D.U.T.will comebacktotheOFF-statewithin a durationof 50msmax.

Fig. 29 : Typical variation of switching-on current

(positive or negative) versus R

junctiontemperature(seetestconditionFig31).

ISWON (mA)

500

=

-48V

-20°C25°C75°C

SWOFF

SENSE

SWOFF

valueby shortcircuitingthe D.U.T.

=10A, 10/1000µs.

PP

Fig. 30 : Variation of switching-oncurrent versus

resistor and

R

at25°C.

SENSE

Iswon@ 25°C (mA)

500

) levelina functionaltest circuit.

-V

Surge

generator

Iswonmin Iswon max Iswonmin Iswonmin

negative negative positive positive

P

300

200

100

3 5 7 9 11 13

Rsense ( )Ω

Fig. 31 : I

MEASUREMENT

SWON

- Iswon = I1 when the CLP200M switches on (I1 is

progressivelyincreasedusing R)

- Both TIP and RING sides of the CLP200M are

checked

.

=10

-R

Ω

L

RL

±

48 V

R sense

TIPL TIPS

DUT

RINGL RINGS

I1

GND

300

200

100

357911

Rsense ( )Ω

Fig. 32 : Relativevariationof switching-offcurrent

versusjunctiontemperatureforR

SENSE

and 10Ω.

ISWOFF [Tj°C] / ISWOFF [25°C]

2.0

1.8

1.6

1.4

1.2

1.0

R

0.8

0.6

0.4

-40 -20 0 20 40 60 80

Tj (°C)

between3

14/21

Page 15

CLP200M

Fig. 33 : Relativevariationof switching-offcurrent

versusR

(between3 and10Ω).

SENSE

ISWOFF[Rsense] / ISWOFF[4 Ω]

1.6

1.4

1.2

1.0

0.8

0.6

0.4

46810

Rsense ( )Ω

Fig.34 : Residualcurrent l1 after theCLP200M.

The residualcurrentl1 is defined by its peakvalue

(I

) and its duration(τ)@IP/2 .

P

Currentsurge input

waveform(µs)

I

(A)

PP

5/310

130A

SURGE

GENERATOR

positivesurge

negativesurge

TIPL TIPS

DUT

RINGL RINGS

R sense

Residual current

after theCLP200M

Peak

waveform

current

I

(A)

P

4.2

1.1

R = 50 Ohms

I1

GND

t(µs)

1

0.5

-48V

Fig.35 : Relativevariation of switching-onvoltage

versusdV/dt with an externalresistor of 4 Ω.

SWON / REFV

V

1.12

1.10

1.08

1.06

1.04

1.02

1.00

0.98

0.1 0.3 1 3 10 30 100 300 1000

dV/dt (V/µs)

Fig. 36 : Relative variation of internal reference

voltageversusjunctiontemperature (I

REF [Tj°C] /V [25°C]REF

V

1.10

1.05

1.00

0.95

0.90

0.85

-40 -20 0 20 40 60

Tj (°C)

=1mA).

LG

15/21

Page 16

CLP200M

Fig.37 : Junctioncapacitance(TIPL/GND)versus

appliedvoltage

C (pF)

220

200

180

160

140

120

100

80

60

40

0 102030405060

(V)

V

R

Fig. 39 : Maximum non repetitive surge RMS on

state current versus overload duration (with 50Hz

sinusoidal wave and initial junction temperature

equal to 25°C)

ITSM (A)

100

10

Fig. 38 : Typical and maximal capacitance

between TIPL, RINGL and GND.

V TIPL= - 48V

V RINGL# 0V

V GND= 0 V

Capacitance

between

RINGLand

GND

Capacitance

between

TIPL and

GND

Capacitance

between

TIPLand

RINGL

Typ. 195 62 57

Max. 200

Fig. 40 : Maximum peak pulse current versus

surgeduration

Ipp (A)

300

200

100

1

t (s)

0.1

0.1 1 10 100 1000

16/21

50

30

20

0.01 0.02 0.05 0.1 0.2 0.5 1 2 5 10

t (ms)

Page 17

CLP200M

SOLDERINGRECOMMENDATION

The soldering process causes considerable thermal stress to a semiconductor component. This

has to be minimized to assure a reliable and extended lifetime of the device. The PowerSO-10

TM

packagecan be exposed to a maximum temperature of 260°C for 10 seconds. However a proper

soldering of the packagecould be done at 215°C

for 3 seconds. Any solder temperature profile

shouldbe within these limits. As reflowtechniques

are most common in surface mounting, typical

heating profiles are given in Figure 1,either for

mountingon FR4 or on metal-backedboards. For

each particular board, the appropriateheat profile

has to be adjusted experimentally. The present

proposalisjustastartingpoint.Inanycase,the followingprecautionshaveto be considered:

- alwayspreheat the device

- peaktemperatureshouldbeat least30 °C

higherthan the meltingpointof the solder

alloychosen

- thermalcapacityof the basesubstrate

Voids pose a difficult reliability problem for large

Fig1 : Typical reflowsoldering heat profile

Temperature ( C)

250

o

o

245 C

surfacemountdevices.Suchvoidsunderthe package result in poor thermal contact and the high

thermal resistance leads to component failures.

The PowerSO-10 is designed from scratch to be

solely a surfacemount package,hencesymmetry

in the x- and y-axis gives the package excellent

weightbalance.Moreover, the PowerSO-10offers

the unique possibility to control easily the flatness

and quality of the soldering process. Both the top

and the bottomsolderededges of the packageare

accessible for visual inspection (soldering meniscus).

Coplanarity between the substrate and the packagecanbeeasilyverified.The quality of the solder

joints is very important for two reasons : (I) poor

qualitysolder jointsresultdirectlyin poor reliability

and (II) solder thickness affects the thermal resistance significantly. Thus a tight control of this parameter results in thermally efficient and reliable

solderjoints.

o

215 C

200

Soldering

Cooli ng

150

Epoxy FR4

board

Preheating

100

Metal-backed

50

board

0

0 40 80 120 1 60 200 240 280 320 360

Time (s )

17/21

Page 18

CLP200M

SUBSTRATES ANDMOUNTINGINFORMATION

The use of epoxy FR4 boardsis quite commonfor

surface mounting techniques, however, their poor

thermalconductioncompromises the otherwise

outstandingthermalperformanceof the PowerSO-

10. Some methods to overcomethis limitation are

discussedbelow.

One possibility to improvethe thermal conduction

is the use of large heat spreaderareasat thecopperlayerof the PCboard.Thisleadsto a reduction

of thermal resistance to 35 °C for 6 cm

2

of the

boardheatsink(seefig. 2).

Use ofcopper-filledthroughholesonconventional

FR4 techniqueswill increase the metallizationand

Fig2 :

Mountingon epoxyFR4 headdissipationbyextendingthe areaof the copperlayer

Copper foil

decrease thermal resistance accordingly. Using

a configurationwith 16holesunderthe spreaderof

thepackage with a pitchof1.8mmanda diameter

of 0.7 mm, the thermal resistance (junction heatsink) can be reduced to 12°C/W (see fig. 3).

Besidethe thermaladvantage,thissolutionallows

multi-layer boards to be used. However, a drawback of this traditional material prevent its use in

veryhighpower, highcurrentcircuits.For instance,

it is not advisable to surface mount devices with

currents greater than 10 A on FR4 boards. A

PowerMosfetor Schottkydiodeinasurfacemount

power package can handle up to around 50 A if

bettersubstratesareused.

FR4 board

Fig3 :

18/21

Mountingon epoxy FR4 by usingcopper-filledthroughholes for heat transfer

Copperfoil

heattransferheatsink

FR4board

Page 19

CLP200M

A newtechnologyavailabletodayis IMS - anInsulated Metallic Substrate. This offers greatly enhanced thermal characteristics for surface

mount components.IMS is a substrate consisting

of threedifferentlayers,(I)thebasematerialwhich

is availableas an aluminiumor a copper plate, (II)

a thermal conductive dielectrical layer and (III) a

copper foil, which can be etched as a circuitlayer.

Using this material a thermal resistance of 8°C/W

with 40 cm

2

of board floating in air is achievable

(seefig.4). If evenhigherpoweristobe dissipated

Fig 4 : Mounting onmetalbacked board

Copper foil

Aluminium

Insulation

an externalheatsink could be appliedwhich leads

to an R

that R

(j-a) of 3.5°C/W (see Fig. 5), assuming

th

(heatsink-air) is equal to Rth(junction-

th

heatsink). This is commonly applied in practice,

leading to reasonable heatsink dimensions. Often

power devices are defined by considering the

maximum junction temperature of the device. In

practice, however,this is farfrombeingexploited.

A summary of various power management capabilities is made in table 1 based on a reasonable

delta T of 70°Cjunctionto air.

Fig 5 :

Mounting on metal backed board with an

externalheatsinkapplied

Copperfoil

Aluminium

heatsink

FR4boar d

The PowerSO-10 concept also represents an attractive alternative to C.O.B. techniques. PowerSO-10offers devices fully testedat lowand high

temperature. Mounting is simple - only conventionalSMTisrequired- enablingtheuserstoget rid

thehigh temperaturesoft solderingaswell.Anoptimized thermal management is guaranteed

through PowerSO-10 as the power chips must in

any case be mounted on heat spreaders before

beingmounted onto the substrate.

of bond wire problems and the problem to control

TABLE1 : THERMALIMPEDANCEVERSUS SUBSTRATE

PowerSo-10packagemountedon Rth(j-a) PDiss (*)

1.FR4usingtherecommendedpad-layout 50°C/W 1.5 W

2

2.FR4withheatsink on board (6cm

3.FR4withcopper-filledthroughholes and externalheatsink applied

2

4. IMSfloatinginair (40cm

)8°C/W 8.8W

)35°C/W 2.0 W

12°C/W 5.8 W

5. IMSwithexternalheatsinkapplied 3.5 °C/W 20 W

(*)Basedon a delta Tof70 °Cjunction train.

19/21

Page 20

CLP200M

PACKAGEMECHANICALDATA

10

B

0.10 A B

6

H

A1

Q

E3 E1

SEATING

PLANE

A

C

a

SEATING

PLANE

A1

L

E2E

1

eB

0.25 M

h

A

F

E4

5

DETAIL”A”

D

D1

DETAIL”A”

DIMENSIONS

REF.

Millimeters Inches

Min. Typ. Max. Min. Typ. Max.

A 3.35 3.65 0.131 0.143

A1 0.00 0.10 0.00 0.0039

B 0.40 0.60 0.0157 0.0236

C 0.35 0.55 0.0137 0.0217

D 9.40 9.60 0.370 0.378

D1 7.40 7.60 0.291 0.299

E 9.30 9.50 0.366 0.374

E1 7.20 7.40 0.283 0.291

E2 7.20 7.60 0.283 0.299

MARKING

Package Type Marking

Power SO-10

20/21

TM

CLP200M CLP200M

DIMENSIONS

REF.

Millimeters Inches

Min. Typ. Max. Min. Typ. Max.

E3 6.10 6.35 0.240 0.250

E4 5.90 6.10 0.232 0.240

e 1.27 0.05

F 1.25 1.35 0.0492 0.0531

H 13.80 14.40 0.543 0.567

h 0.50 0.019

L 1.20 1.80 0.0472 0.0708

Q 1.70 0.067

a0° 8°0° 8°

Page 21

ORDERCODE

CurrentLimiting Protection

FOOTPRINT

MOUNTINGPAD LAYOUT

RECOMMENDED

CLP200M

CLP 200 M - TR

TR = tapeand reel

= tube

Package: PowerSO-10

Minimumoperation voltage

HEADERSHAPE

Dimensionsin millimeters Dimensionsinmillimeters

SHIPPINGTUBE

C

DIMENSIONS(mm)

TYP

B

A

Information furnished is believed to be accurate and reliable. However, SGS-THOMSON Microelectronicsassumes no responsibility for the

consequences of use of such information nor forany infringement of patents or other rights of thirdparties which may result from its use. No

license is granted by implication orotherwise under any patentor patentrights ofSGS-THOMSON Microelectronics.Specifications mentioned

in this publication are subject tochange withoutnotice.This publication supersedesand replaces all information previouslysupplied.

SGS-THOMSONMicroelectronics products are notauthorized for useas criticalcomponentsin lifesupportdevices orsystemswithoutexpress

writtenapproval of SGS-THOMSON Microelectronics.

1998SGS-THOMSON Microelectronics - Printedin Italy -All rights reserved.

SGS-THOMSON Microelectronics GROUP OF COMPANIES

Australia- Brazil- Canada -China - France -Germany - Italy- Japan - Korea -Malaysia - Malta - Morocco

The Netherlands - Singapore - Spain- Sweden - Switzerland - Taiwan- Thailand - UnitedKingdom - U.S.A.

A

B

C

Lengthtube

18

12

0,8

532

Quantityper tube 50

21/21

Loading...

Loading...