Datasheet CLM2815AT-3.3, CLM2815AT-2.5, CLM2815AT-1.5, CLM2815AT, CLM2815AAU-5 Datasheet (Calogic LLC)

...Page 1

1.5A Low Dropout Voltage Regulator

Adjustable & Fixed Output

Fast Response

CLM2815

FEATURES

•• Adjustable Output . . . . . . . . . . . . . . . . . . . Down To 1.2V

•• Fixed Output Voltages. . . . . . . . . . . . . . 1.5, 2.5, 3.3, 5.0V

•• Output Current. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5A

•• Low Dropout Voltage. . . . . . . . . . . . . . . . . . . . . 1.1V Ty p.

•• Extremely T ig ht Load And Line Regulation

•• Current & Thermal Limiting

•• Standard 3-Te rm i nal Low Cost T O -2 20, TO - 2 6 3 &

TO-252

•• Similar To Industr y Sta ndard LT10 86/ LT15 86

APPLICATIONS

•• Powering VGA & Soun d Card

•• Power PC Supplies

•• SMPS Post-Regula tor

•• High Effic ie ncy "Gr een " Co m put er System s

•• High Efficie ncy Line ar Powe r Supp lies

•• Portable I nst ru me nt atio n

•• Constant Curr ent Regulators

•• Adjusta ble Power Supplies

•• Battery charger

PRODUCT DESCRIPTION

Calogic’s CLM2815 is a low power 1.5A adjustable and fixed

voltage regulator. The device requires 2 external resistors to

set the output for the adjustable version. The CLM2815 has

been designed for low voltage applications that require lower

dropout and faster transient responses. The device is well

suited to power a low voltage microprocessor that requires a

low dropout and a fast transient response to regulate from

+2.85V to 3.8V. The device is adjustable t o 1.2 volts.

The product family offers full protection against over-current

faults, reversed input polarity, reversed load insertion, and

positive and negative transient voltage. On-chip trimming

adjusts the reference voltage to 1% while delivering 1.5A

output current.

Encapsulated in a 3-pin TO-22 0, TO-26 3 & T O-252 pa ckag es.

ORDERING INFORMATION

Part Package Temperature Range

CLM2815AU TO-220 -45 to +125

o

C

CLM2815AAU TO-220 -45 to +125

o

C

CLM2815AU-X TO-220 -45 to +125

o

C

CLM2815AAU-X TO-220 -45 to +125

o

C

CLM2815AT TO-263 (DD) -45 to +125

o

C

CLM2815AAT TO-263 (DD) -45 to +125

o

C

CLM2815AT - X TO-263 (DD) -45 to +125

o

C

CLM2815AAT -X TO-263 (DD) -45 to +125

o

C

CORPORATION

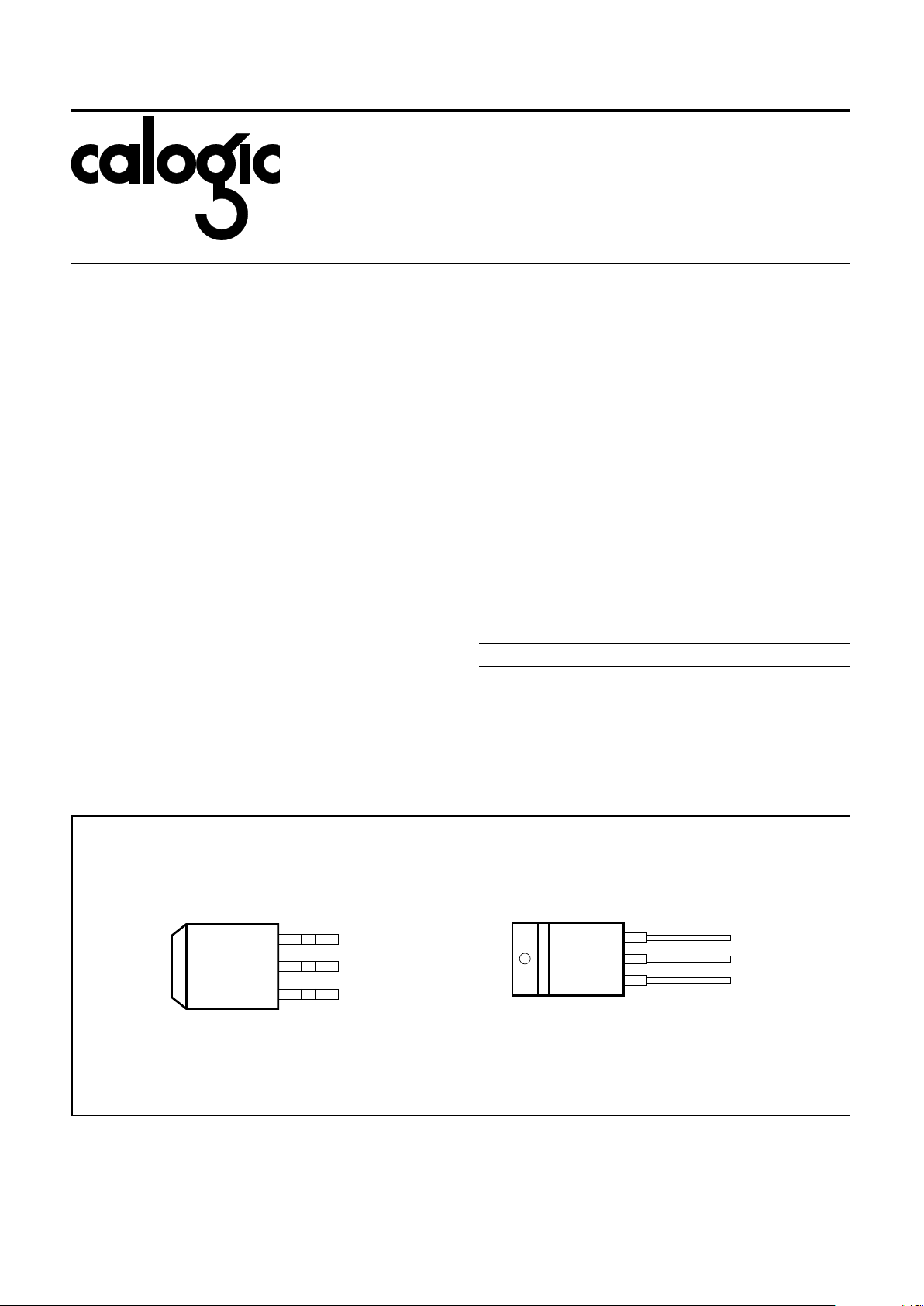

PIN CONNECTIONS

1E-30A

FRONT VIEW

V

IN

V

OUT

CLM2815

PLASTI C T O - 220 P A CK AG E

V

ADJ/GND

1E-29A

PLASTI C T O - 263 P A CK AGE

FRONT VIEW

CLM2815

3

2

1V

ADJ/GND

V

OUT

V

IN

CALOGIC CORPORATION, 237 Whitney Place, Fremont, California 94539, Telephone: 510 -656-290 0, FAX: 510-651-3025

Page 2

ABSOLUTE MAXIMUM RATINGS

Lead Temp. (Solder ing, 10 Se cond s) . . . . . . . . . . . . . . 300

o

C

Storage Te m per atur e Range . . . . . . . . . . . . -65

o

C to +150oC

Operating Junct ion Temperat ure Ran ge

CLM2815 Control Sectio n . . . . . . . . . . . . . . -45

o

C +125oC

CLM2815 Power Tr ans isto r . . . . . . . . . . . . . . -45

o

C +150oC

Input Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10V

Input to Output Voltage Differentia l . . . . . . . . . . . . . . . . . . 10V

Maximum Out pu t Current . . . . . . . . . . . . . . . . . . . . . . . . . . 2A

CALOGIC CORPORATION, 237 Whitney Place, Fremont, California 94539, Telephone: 510 -656-290 0, FAX: 510-651-3025

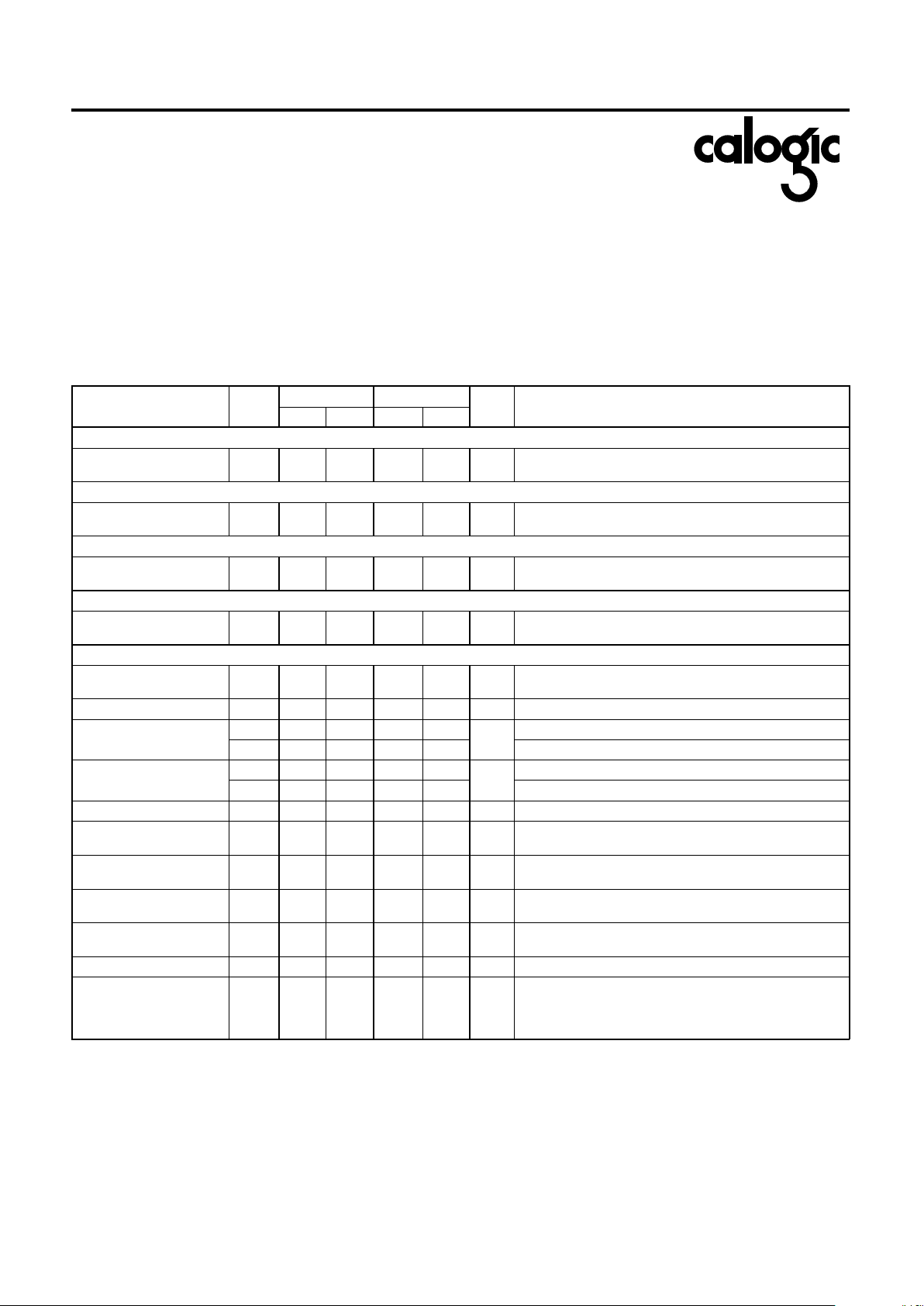

ELECTRICAL CHARACTERISTIC S (Note 1) at I

OUT

= 10mA, TA = 25oC, unless otherwise specified .

PARAMETER TYP

CLM2815A CLM2815

UNITS CONDITIONS

MIN MAX MIN MAX

1.5V VERSION

Output Voltage (Note 2)

1.5

1.5

1.485

1.470

1.515

1.530

1.470

1.455

1.530

1.545

V CLM2815-1.5V , 0 ≤ I

OUT

≤ 1.5A, 2.75V ≤ VIN ≤ 7V

2.5V VERSION

Output Voltage (Note 2)

2.5

2.5

2.475

2.450

2.525

2.550

2.450

2.425

2.550

2.575

V CLM2815-2.5V , 0 ≤ I

OUT

≤ 1.5A, 3.5V ≤ VIN ≤ 7V

3.3V VERSION

Output Voltage (Note 2)

3.3

3.3

3.270

3.240

3.330

3.360

3.230

3.201

3.370

3.399

V CLM2815-3.3V , 0 ≤ I

OUT

≤ 1.5A, 4.75V ≤ VIN ≤ 7V

5.0V VERSION

Output Voltage (Note 2)

5.0

5.0

4.95

4.90

5.05

5.10

4.900

4.850

5.100

5.150

V CLM2815-5.0V , 0 ≤ I

OUT

≤ 1.5A, 5.5V ≤ VIN ≤ 7V

ALL VOLTAGE OPTIONS

Reference Voltage

(V

REF

)

1.250 1.225 1.270 1.225 1.270 V

V

IN

≤ 7V, P ≤ P

MAX

1.5V ≤ (VIN - V

OUT

) ≤ 5.75V, 10mA ≤ I

OUT

≤ I

OUT

≤ 5.75

Min. Load Current (Note 3) 51010mA 1.5V ≤ (V

IN

- V

OUT

) ≤ 5.75V

Line Regulation

(∆V

REF

(IIN))

0.005 0.2 0.2

%

2.75V ≤ V

IN

≤ 7V, I

OUT

= 10mA, TJ = 125oC (Note 3)

0.005 0.2 0.2 V

IN

≤ 7V, I

OUT

= 0mA, TJ = 125oC (Note 2)

Load Regulation

(∆V

REF

(I

OUT

))

0.05 0.3 0.3

%

10mA ≤ I

OUT

≤ 1.5A, (VIN - V

OUT

) = 3V, TJ = 25oC

0.05 0.3 0.3 0 ≤ I

OUT

≤ 1.5A, VIN = 7V, TJ = 125oC (Note 2)

Dropout Voltage 1.1 1.2 1.2 V ∆V

REF

= 1%, I

OUT

= 1.5A (Note 3), I

OUT

≤ 1.5A (Note 2)

Current Limit

(I

OUT(MAX)

)

2.5 1.7 1.7 A

V

IN

= 7V ≤ 1.5A

1.4V ≤ (V

IN

- V

OUT

) (Note 3)

Long Term Stability

0.3

(Note 2)

11%T

A

= 125oC, 1000 Hrs.

Thermal Regulation

(∆V

OUT

(PWR))

0.01 0.020 0.020 %/W T

A

= 25oC, 20ms pulse

T emperature Stability

(∆V

OUT

(T))

0.25 %

Output Noise, RMS 0.003 %V

O

10Hz to 10kHz, TA = 25oC

Thermal Resistance

3.0

60

3.0

60

3.0

60

3.0

60

3.0

60

3.0

60

o

C/W

TO-220 Junction to Tab

Junction to Ambient

DD Package Junction to Tab

Junction to Ambient

The Bold specifications apply to the over full opera ting tem p era ture rang e.

Note 1: Changes in output voltage due to heating effects are covered under the specification for thermal regulation.

Note 2: Fixed version only.

Note 3: Adustable version only.

CLM2815

CORPORATION

Page 3

APPLICATION HINTS

The Calogic Semiconductor CLM2815 incorporates protect ion

against over-current faults, reversed load insertion, over

temperature operation, and positive and negative transient

voltage. However, the use of an output capacitor i s required

in order to insure the stability and the performances.

Stabilit y

The output capacitor is part of the regulator’s frequency

compensation system. Either a 220µF aluminum electrolytic

capacitor or a 47µF solid tantalum capacitor between the

output terminal and ground guarantees sta ble operat ion f or all

operating conditions.

However, in order to minimize overshoot and undershoot, and

therefore optimize the design, please refer to the section

’Ripple Rejection’.

Ripple Reject i on

Ripple rejection can be improved by adding a capacitor

between the ADJ pin and ground. When ADJ pin bypas sing is

used, the value of the output capacitor required increases to

its maximum (220µF for an aluminum electrolytic capacitor, or

47µF for a soli d tantalum capacitor). If the ADJ pin is not

bypass, the value of the output capacitor can be lowered to

100µF for an electrolytic aluminum capacitor or 15µF for a

solid tantalum capacit or.

However the value of the ADJ-bypass capacitor should be

chosen with respec t to the f ollo wing equa tion :

C = 1 / ( 6.28

•

FR • R1 )

Where C = value of the capacitor in Fara d s (select an equal or

larger standa rd value) ,

F

R

= ripple frequency in Hz,

R

1

= value of resistor R1 in Ohms.

If an ADJ-bypass capacitor is used, the amplitude of the

output ripple will be independent of the output voltage. If an

ADJ-bypass capacitor is not used, the output ripple will be

proportional to the ratio of the output voltage to the reference

voltage:

M = V

OUT

/ V

REF

Where M = multiplier for the ripple seen when the ADJ pin is

optimally bypassed .

V

REF

= Reference Voltage

Reducing parasit ic resis tance an d induct an ce

One solution to minimize parasitic resistance and inductance

is to connect in parallel capacitors. This arrangement will

improve the transient response of the power supply if your

system require s rapidly chan ging curr ent load condit io n.

Thermal Consideratio n

Although the CLM2815 offers some limiting circuitry for

overload conditions, it is necessary not to exceed the

maximum junction temperature, and therefore to be careful

about thermal resistance. The heat flow will follow the lowest

resistance path, which is the Junction-to-case thermal

resistance. In order to insure the best thermal flow of the

component, a proper mo unting is required. Note that the case

of the device is electrically connected to the output. In case

the case has to be electrically isolated, a thermally condu ct ive

spacer can be used. However do not forget to consider its

contribution to ther m al resist ance .

Assuming:

V

IN

= 10V, V

OUT

= 5V, I

OUT

= 1.5A, TA = 90oC, Θ

CASE

= 1oC/W

(no external heat sink, no wind)

Power dissipation under t hese conditions

P

D

= (VIN - V

OUT

) • I

OUT

= 7.5W

Junct io n Tem perature

T

J

= TA + PD • (Θ

CASE

+ ΘJC)

For the Control Sect i on

T

J

= 90oC + 7.5W • (1oC/W + 0.6oC/W) = 10 2oC

114

o

C T

JUNCTION MAX

for the contr ol s ect ion.

For the Power Section

T

J

= 90oC + 7.5W • (1oC/W + 1.6oC/W) = 104. 5oC

109.5

o

C T

JUNCTION MAX

for the power t ra nsist or.

In both cases reliable operation is insured by adequate

junction tempe ratu re .

CALOGIC CORPORATION, 237 Whitney Place, Fremont, California 94539, Telephone: 510 -656-290 0, FAX: 510-651-3025

CLM2815

CORPORATION

Page 4

Output Voltage

Consider Figure 2. The resistance R

1

generates a constant

current flow, normally the specified load current of 10mA.

This current will go through the resista nce R

2

to set the overall

output voltage. The current I

ADJ

is very small and constant.

Therefore its contribution to the overall output voltage is very

small and can generally be ignor ed.

Load Regulation

Parasitic line resistance can degrade load r egulat ion. In order

not to affect the behavior of the regulator, it is best to connect

directly the R

1

resistance from the resistor divider to the case,

and not to the load. For the same reason, it is best to connect

the resistor R

2

to the Negative side of the lo ad.

CORPORATION

CLM2815

CORPORATION

CALOGIC CORPORATION, 237 Whitney Place, Fremont, California 94539, Telephone: 510 -656-290 0, FAX: 510-651-3025

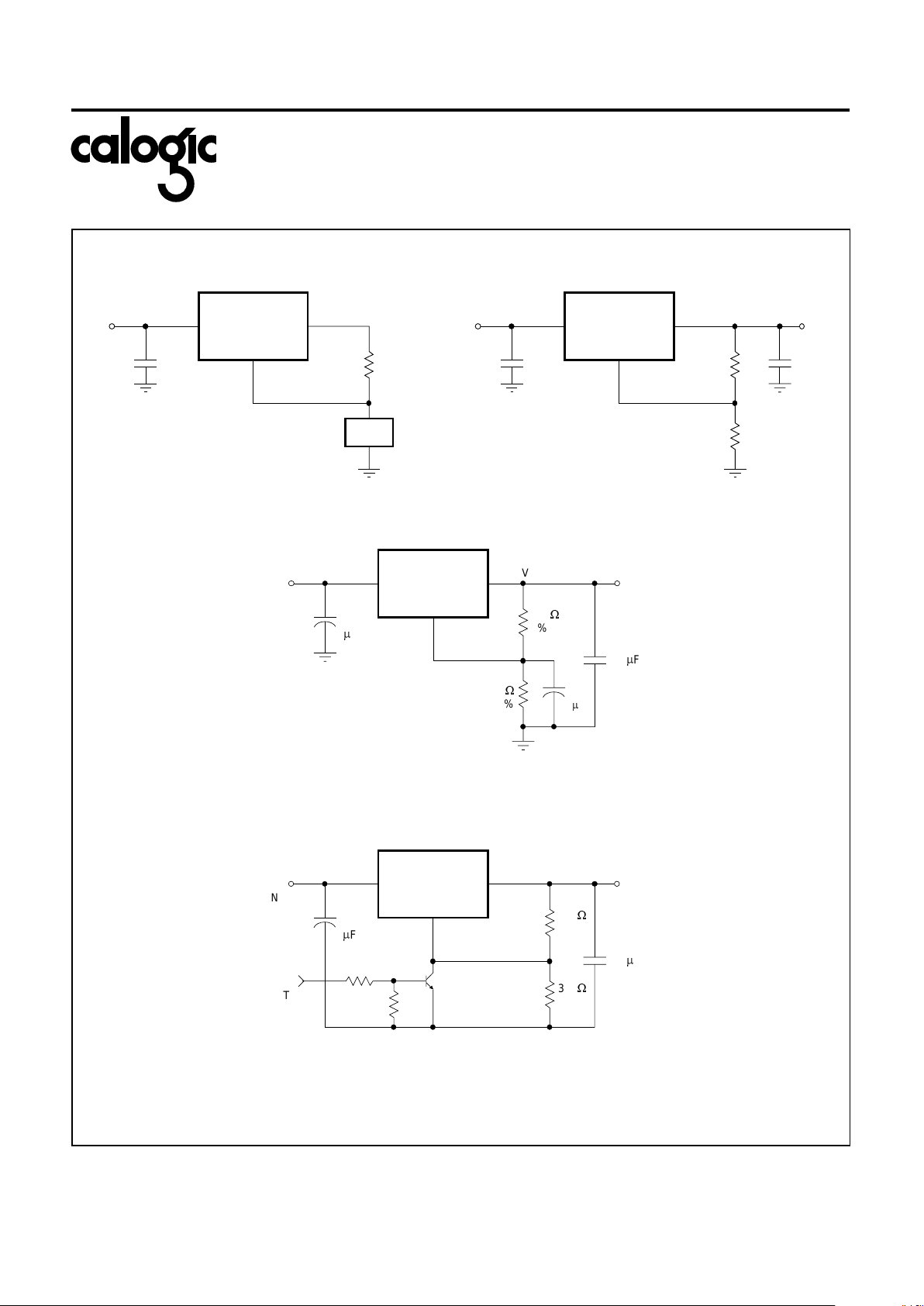

FIGURE 3. BASIC ADJUSTABLE REGULAT OR

1U-24

CLM2815

R

1

R

2

V

OUT

R PARASITIC LINE

RESISTANCE

P

CONNECT R

TO CASE OF

REGULATOR

CONNECT

R TO

LOAD

1

2

R

L

FIGURE 2. BASIC ADJUSTABLE REGULAT OR

1U-23

CLM2815

R

1

R

2

V

OUT

V

OUT

V

REF

I

ADJ

50mA

) + I

ADJ

(1 + R1/R

2

= V

REF

V

OUT

R

2

Page 5

CLM2815

CORPORATION

CALOGIC CORPORATION, 237 Whitney Place, Fremont, California 94539, Telephone: 510 -656-290 0, FAX: 510-651-3025

TYPICAL APPLICA TION S

1E-37

CLM2815

OUT

ADJ

1.5A CURRENT OUTPUT REGULATOR

V

IN

R

1

C

1

IN

LOAD

1E-38

CLM2815

OUT

ADJ

TYPICAL ADJUSTABLE REGULATOR

OUT

) + I

ADJ

(1 + R1/R

2

= V

REF

V

OUT

V

IN

R

2

R

1

C

2

V

C

1

IN

R

2

1U-26

CLM2815

OUT

ADJ

5V REGULATOR WITH SHUTDOWN

OUT

V

IN

5V

IN

+

+

10mF

100mF

TTL

OUTPUT

1k

1k

121

W

1%

365

W

1%

(NOTE A)

V

IN (MIN)

= (INTENDED V ) + (V

DROPOUT (MAX)

)NOTE A:

2N3904

1U-25

CLM2815

OUT

ADJ

IMPROVING RIPPLE REJECTION

OUT

V

IN

IN

+

10mF

150mF

121

W

1%

365

W

1%

(NOTE A)

V

IN (MIN)

= (INTENDED V ) + (V

DROPOUT (MAX)

)

NOTE A:

R

1

R

2

+

10mF

C

1

V

OUT

5V

*C IMPROVES RIPPLE REJECTION.

X SHOULD BE - R AT RIPPLE

FREQUENCY.

1

1C

Page 6

OUTPUT CURRENT (A)

1U-27

DROPOUT VOLTAGE

0

4

1 2 3

2

0

1

MINIMUM INPUT/OUTPUT DIFFERENTIAL (V)

0˚C T

J

120˚C

TJ= 25˚C

T

J

= –55˚C

T

J

= 150˚C

–40˚C T

J

150˚C

5

6

7

8

9

10

INDICATES GUARANTEED TEST POINT

TEMPERATURE (˚C)

0.10

–0.20

–50 150

1E-31A

LOAD REGULATION

OUTPUT VOLTAGE DEVIATION (%)

0.05

0

–0.05

–0.10

–0.15

–25

0 25 50 75 100 125

TYPICAL PERFORMANCE CHARACTERI STIC S

INPUT/OUTPUT DIFFERENTIAL (V)

12

0

035

1E-32A

SHORT CIRCUIT CURRENT

SHORT CIRCUIT CURRENT (A)

10

8

6

4

2

5 1015202530

25˚C

150˚C

–55˚C

I

FULL LOAD

INPUT/OUTPUT DIFFERENTIAL (V)

10

0

035

1U-28

MINIMUM

OPERATING CURRENT

MINIMUM OPERATING CURRENT (mA)

1

2

3

4

5

6

7

8

9

5 1015202530

TJ= –55˚C

TJ= 25˚C

TJ= 150˚C

TEMPERATURE (˚C)

1E-33

ADJUSTMENT PIN CURRENT

–50 150–25 0 25 50 75 100 125

100

0

10

20

30

40

50

60

70

80

90

ADJUSTMENT PIN CURRENT (µA)

TEMPERATURE (˚C)

1.270

1.230

–50 150

1U-29

TEMPERATURE STABILITY

OUTPUT VOLTAGE CHANGE (%)

–25 0 25 50 75 100 125

1.240

1.260

1.250

CLM2815

CORPORATION

Information furnished by Calogi c is believed to be accurate and reliable. Howeve r, no responsibility is assumed for its use: no r for any infring eme nt of pate nts or other

rights of third parties which may result from its use. No license is granted by implication or otherwise under any patent rights of Calogic.

CALOGIC CORPORATION, 237 Whitney Place, Fremont, California 94539, Telephone: 510-656-2900, FAX: 510-651-3025

Loading...

Loading...