Datasheet CLM1117M-5, CLM1117M-3.3, CLM1117M-3, CLM1117M-2.85, CLM1117M-12 Datasheet (Calogic LLC)

...Page 1

800mA Low Dropout Regulator

SCSI-I I Active Terminator

CLM1117

FEATURES

•• Guaran te ed 800mA Ou tp ut

•• Three Terminal Adjustable or Fixed 2.85V, 3V, 3.3V, 5V,

10V & 12V

•• Ver y Low Q ui e s cent Current

•• Low Dropout Voltage of 1.2 Volts at Full Load

•• Extremely Tig h t Load and Line Regul ati on

•• Ver y Low Tempe rat ur e Coeff i cient

•• Fixed 2.8V Device for SCSI- II Acti ve Terminat or

•• Logic-Controlled Electronic Shutdown

•• Internal Overcurrent Limiting & Thermal Overload

Protection

•• Surface Mou nt Packag e SO T-223

APPLICATIONS

•• SCSI-II Active Termin ator

•• Portabl e/ Pal m Top / Notebo ok C om put er s

•• Battery Charger s

•• Disk Driv es

•• Portable Consumer Equipment

•• Portable I nst ru me nt atio n

•• SMPS Post-Regula tor

PRODUCT DESCRIPTION

The Calogic CLM1117 is a low power positive voltage

regulator designed to meet 800mA output current and comply

with SCSI-II specifications with a fixed output voltage of

2.85V. This device is an excellent choi ce for use i n batterypowered applications, as active terminators for the SCSI bus,

and portable computers. The CLM1117 features very low

quiescent current and very low dropout voltage of 1.2V at a

full load and lower as output current decreases. This product

is available as an adjustable or fixed 2.85V, 3V, 3.3V, and 5V

output voltages.

The device is offered in a 3-pin surface mount package

SOT-223. The output capacitor of 10µF or larger is needed

for output stability of CLM1117 as required by most of the

other regulat or circuits.

ORDERING INFORMATION

Part Package Temperature

CLM1117M SOT-223 Industrial

CLM1117M-X SOT-223 Industrial

X = Output Voltage. 5V = Standard.

Contact factory f or 2. 8 5V, 3.0 V, 3.3 V, 10V and 12V .

CORPORATION

PIN CONNECTIONS

SOT-223

TAB IS

GND

CLM1117

ADJ./GND V

OUTVIN

123

1N-12

FRONT VIEW

CALOG IC CORPOR ATION, 237 Whitney Place, Fremont, California 94539, Telephone: 510-656-2900, FAX: 510-651-3025

Page 2

ABSOLUTE MAXIMUM RATINGS

Power Dissipation . . . . . . . . . . . . . . . . . . . . . Internally Limited

Lead Temp. (Solder ing, 5 Seconds) . . . . . . . . . . . . . . . 260

o

C

Storage Temperatur e Ra nge. . . . . . . . . . . . -65

o

C to +150oC

Operating Junct ion Temperatur e Ran ge

CLM1117 . . . . . . . . . . . . . . . . . . . . . . . . . . -40

o

C to +125oC

Input V olt age . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.5V to 6V

Input Supply Vo ltag e . . . . . . . . . . . . . . . . . . . . . . -20V to +20V

ESD Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2KV Min

CLM1117

CALOG IC CORPOR ATION, 237 Whitney Place, Fremont, California 94539, Telephone: 510-656-2900, FAX: 510-651-3025

CORPORATION

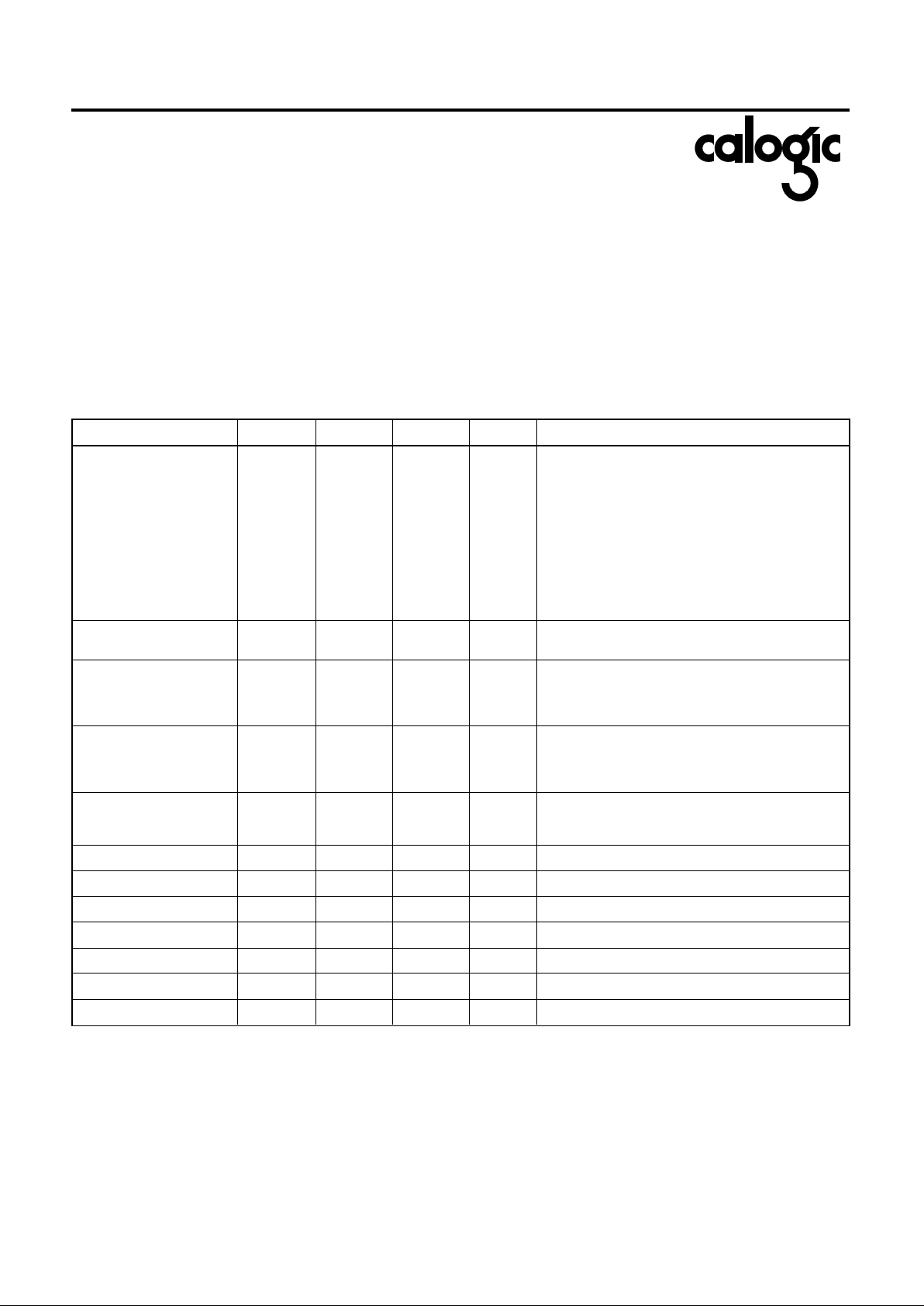

ELECTRICAL CHARACTERISTICS: VIN = V

OUT

+1, TA = 25oC, CL = 3.3µf, unless otherwise noted. Boldface apply over full

operating temperature range.

PARAMETER TYP MIN MAX UNITS CONDITIONS

Output Voltage

2.85

2.85

2.85

3.0

3.0

3.30

3.30

5.0

5.0

2.82

2.79

2.79

2.97

2.94

3.27

3.24

4.95

4.90

2.88

2.91

2.91

3.03

3.06

3.33

3.36

5.05

5.10

V

I

OUT

= 10mA, IIN = 4.8 5V

0 ≤ I

OUT

≤ 800mA, 4.25 ≤ VIN ≤ 10V

0 ≤ I

OUT

≤ 500mA, VIN = 4.05V

I

OUT

= 10mA, VIN = 5.00V

0 ≤ I

OUT

≤ 800mA, 4.50 ≤ VIN ≤ 10V

I

OUT

= 10mA, IIN = 5.3 0V

0 ≤ I

OUT

≤ 800mA, 4.80 ≤ VIN ≤ 10V

I

OUT

= 10mA, IIN = 7.0 0V

0 ≤ I

OUT

≤ 800mA, 6.50 ≤ VIN ≤ 12V

Output Voltage

T emperature Stability

0.05 % (Note 1)

Line Regulation

1.00

1.00

1.00

1.00

6.00

7.00

7.00

10.00

mV

4.25V ≤ V

IN

≤ 10V, V

OUT

= 2.85, I

OUT

= 0

4.50V ≤ V

IN

≤ 12V, V

OUT

= 3.00, I

OUT

= 0

4.80V ≤ V

IN

≤ 12V, V

OUT

= 3.30, I

OUT

= 0

4.50V ≤ V

IN

≤ 15V, V

OUT

= 5.00, I

OUT

= 0

Load Regulation

1.00

1.00

1.00

1.00

10.00

12.00

12.00

15.00

mV

0 ≤ I

OUT

≤ 800mA, VIN = 4.25V, V

OUT

= 2.8 5

0 ≤ I

OUT

≤ 800mA, VIN = 4.50V, V

OUT

= 3.0 0

0 ≤ I

OUT

≤ 800mA, VIN = 4.80V, V

OUT

= 3.3 0

0 ≤ I

OUT

≤ 800mA, VIN = 6.50V, V

OUT

= 5.0 0

Dropout Voltage

(Note 2)

1.00

1.05

1.10

1.10

1.15

1.20

V

I

L

= 100m A

I

L

= 500m A

I

L

= 800m A

Quiescent Voltage 5.00 10.00 mA 4.25V ≤ V

IN

≤ 6.5V

Current Limit 800 950 1200 mA (V

IN

- V

OUT

) = 5V

Thermal Regulation 0.01 0.1 %/W 25

o

C, 30mS Pulse

Ripple Rejection 60 75 dB f

RIPPLE

= 12 0H z, (VIN - V

OUT

) = 3V, V

RIPPLE

= 1V

p-p

Long Term Stability 0.03 % 125oC, 1000Hrs

RMS Output Noiase 0.003 % % of V

OUT

, 10Hz ≤ f ≤ 10kHz

Thermal Resistance 15

o

C/WoJunction to case, at tab

Note 1: Output temperature coeffic ien t is define d as the worst case volta ge change divid ed by the total tempe rature range .

Note 2: Dropout voltage is defined as the input to output differential at which the output voltage drops 100mV below its nominal value measured

at 1V differential at very low values of programmed output voltage, the minimum input supply voltage of 2V (2.3V over temperature) must be

taken input account.

Note 3: Thermal regulation is defined as the change in output voltage at a time T after a change in power dissipation is applied,

excluding load or line regulation effect.

Page 3

APPLICATION NOTES

EXTERNAL CAPACITOR

To ensure the stability of the CLM1117 an output capacitor of

at least 10µF (tantalum) or 50µF (aluminum) is required. The

value may change based on the application requirements on

the output lo ad or te mperature range. The cap acitor equivalent

series resistance (ESR) will effect the CLM1117 stability. The

value of the ESR can vary from the type of capacitor used in

the appli cations. The recommended value for ESR is 0.5Ω.

The output capacitance could increase in size to above the

minimum value. The larger value of output capacitance as

high as 100µF can improve the load tran sient respon se.

SOLDERING METHO D S

The CLM1 117 SOT-223 package is des igned t o be compat ible

with infrar ed refl ow or vapo r-ph ase refl ow sol dering t echniques.

During soldering the non-active or mildly active fluxes may be

used. The CLM1117 die is attached to the heatsink lead

which exits opposite the input , out put , and grou nd pins.

Hand soldering and wave soldering should be avoided since

these methods can cause damage to the device with

excessive thermal gradients on the package. The SOT-223

recommended soldering method are as follows: vapor phase

reflow and infrared reflow with the component preheated to

within 65

o

C of the soldering temper atur e rang e.

THERMAL CHARACTERISTIC S

The thermal resistance of CLM1117 is C

o

/W from junction to

tab and 31 C

o

/W from tab to ambient for a total of 46 Co/W

from junction to ambient. The CLM1117 features the internal

thermal limiting to protect the device during overload

conditions. Special care needs to be taken during continuous

load conditions to insure the maximum junction temperature

does not exceed 125

o

C.

Taking the FR-4 printed circuit board and 1/16 thick with 1

ounce copper foil as an experiment (fig.1 & fig.2), the PCB

material is effective at transmitting heat with the tab attached

to the pad area and a ground plane layer on the backside of

the substrate. Refer to table 1 for the results of the

experiment.

The thermal interaction from other components in the

application can effect the thermal resistance of the CLM1117.

The actual thermal resistance can be determined with

experimentation. CLM1117 power dissipation is calculated as

follows:

P

D

= (VIN - V

OUT

) (I

OUT

)

Maximum Junct ion Temperat ure Ra n ge:

T

J

= T

ambient

(max) + PD (thermal resistance (Junction-to-ambient))

Maximum Ju nction Temperature must not exceed 1 2 5

o

C.

P

O

= (10V - 2.85) (105mA) = (7 .15) (105mA) = 750mW

CLM1117

CORPORATION

FIGURE 1. CIRCUIT LAYOUT, THERMAL EXPERIMENTS

10V

+

10

µ

F

2.85V

27K

Ω

10µF

CLM1117 - 2.85

1N-13

CALOG IC CORPOR ATION, 237 Whitney Place, Fremont, California 94539, Telephone: 510-656-2900, FAX: 510-651-3025

FIGURE 2. SUBSTRATE LA YOUT FOR SOT-223

50 X 50mm

35 X 17mm

16 X 10mm

1N-14

T ABLE 1.

TOTAL PC BOARD AREA TOPSIDE COPPER AREA BACKSIDE COPPER AREA

THERMAL RESISTANCE

JUNCTION TO AMBIENT

2500mm

2500mm

2500mm

2500mm

2500mm

1600mm

2500mm

2500mm

1600mm

900mm

900mm

2500mm

1250mm

950mm

2500mm

1800mm

600mm

1250mm

915mm

600mm

240mm

240mm

2500mm

2500mm

2500mm

0

0

1600mm

0

0

0

900mm

0

46

o

C/W

o

47oC/W

o

49oC/W

o

51oC/W

o

53oC/W

o

55oC/W

o

58oC/W

o

59oC/W

o

67oC/W

o

72oC/W

o

85oC/W

o

Page 4

ACTIVE VS PASSI VE TERM IN ATION

The improvement in noise immunity and low quiescent power

of the terminator of less than 1W is the key advantage of

active termination compared to passive termination. The

CLM1 117 significantly improves the noise level and s ignals o n

the bus by the terminating point due to variations in voltage at

the terminat io n point due to var iat ion in th e V

term

power line.

Another advantage of active ter minat ion is t he im provem ent in

the impedance matching. The low impedance of the device

makes the termination res istance more closely m atched to th e

impedance of the cable. This improvement increases the

data rate by 10 times, from 1mbyte/s to 10mbyte/s. The

CLM1117 increases the protection and the reliability of the

application since it features internal current limiting,

overvoltage pr ot ect ion, and thermal protection.

CLM1117

ACTIVE TERMINATION CONFIGURATION

5V

IN5817

TERMPWR

CLM1117-2.85

10

µ

F

2.85V

110K

Ω

+

6 METERS MAX

10µF

5V

IN5817

CLM1117-2.85

10

µ

F

2.85V

110K

Ω

+

10µF

110K

Ω

6 METERS MAX

110K

Ω

110K

Ω

110K

Ω

UP TO 27 LINES

+ +

1N-15

CORPORATION

Information furni shed by Calogic is believed to be accurate and reliable. Howeve r, no responsibility is assumed for its use: no r for any infring eme nt of patents or other

rights of third parties which may result from its use. No license is granted by implication or otherwise under any patent rights of Calogic.

CALOG IC CORP OR ATION, 237 Whitney Place, Fremont, California 94539, Telephone: 510-656-2900, FAX: 510-651-3025

Loading...

Loading...