Page 1

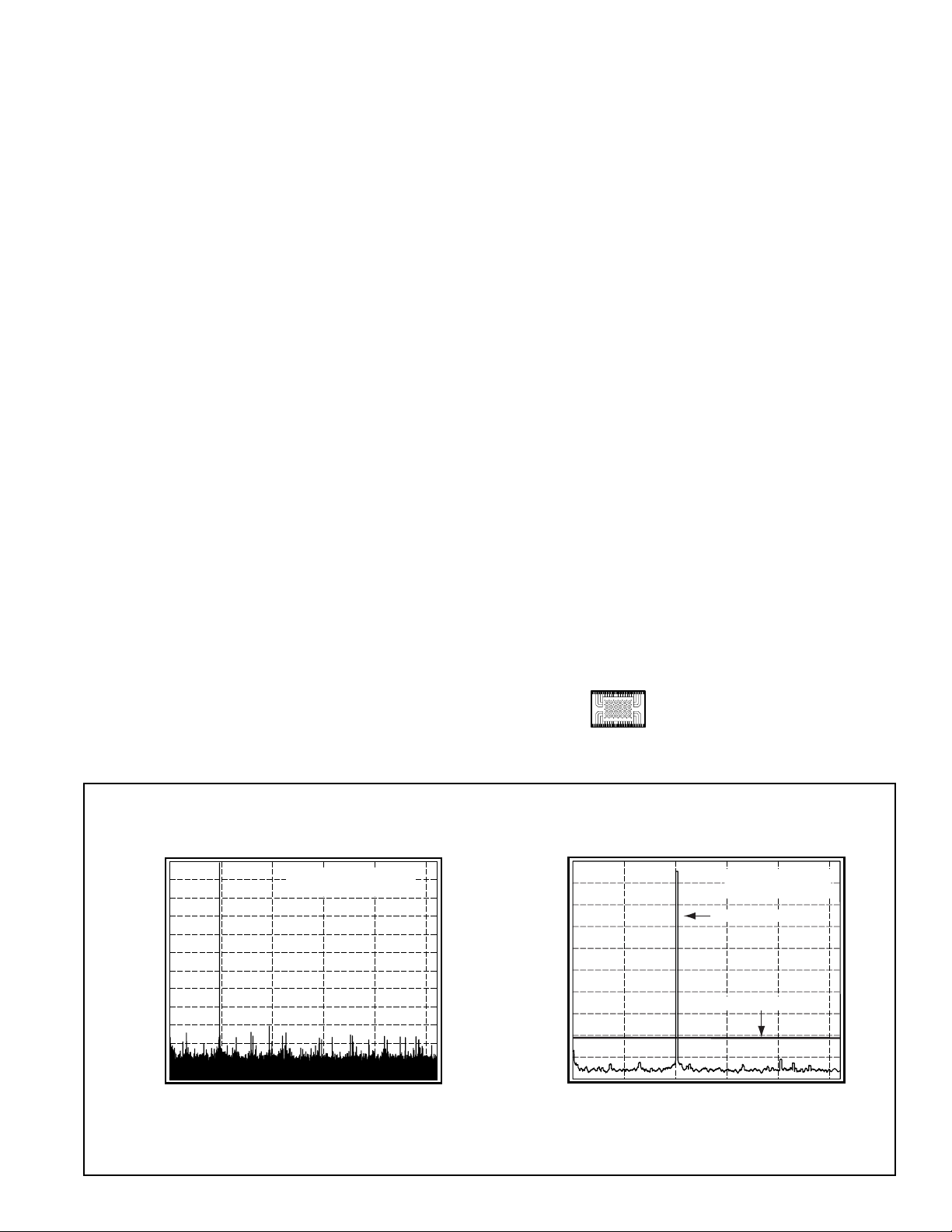

Output Response with GSM 1800 Blocker

Power at the Antenna (dBm)

Frequency (MHz)

-20

-40

-60

-80

-100

-120

0

5

25

10

15

20

Full Scale = -24dBM

Res. BW = 200KHz

-25dBm blocker

-101dBm reference

N

CLC5958

14-bit, 52MSPS A/D Converter

September 1999

CLC5958

14-bit, 52MSPS A/D Converter

General Description

The CLC5958 is a monolithic 14-bit, 52MSPS analog-to-digital

converter. The ultra-wide dynamic range and high sample rate of

the device make it an excellent choice for wideband receivers

found in multi-channel basestations. The CLC5958 integrates a

low distortion track-and-hold amplifier and a 14-bit multi-stage

quantizer on a single die. Other features include differential

analog inputs, low jitter differential clock inputs, an internal

bandgap voltage reference, and CMOS/TTL compatible outputs.

The CLC5958 is fabricated on the National ABIC-V 0.8 micron

BiCMOS process.

The CLC5958 features a 90dB spurious free dynamic range

(SFDR) and a 70dB signal to noise ratio (SNR). The balanced

differential analog inputs ensure low even-order distortion, while

the differential clock inputs permit the use of balanced clock signals

to minimize clock jitter. The 48-pin CSP package provides an

extremely small footprint for applications where space is a critical

consideration. The package also provides a very low thermal

resistance to ambient. The CLC5958 may be operated with a

single +5V power supply. Alternatively, an additional supply may

be used to program the digital output levels over the range of

+3.3V to +5V. Operation over the industrial temperature range of

-40°C to +85°C is guaranteed. National Semiconductor tests

each part to verify compliance with the guaranteed specifications.

Features

• 14-bit

• 52MSPS

• Ultra-wide dynamic range

Noise floor: -72dBFS

SFDR: 90dB

• Excellent performance to Nyquist

• IF sampling capability

• Very small package: 48-pin CSP

• Programmable output levels:

3.3V to 5V

Applications

• Multi-channel basestations

• Multi-standard basestations:

GSM, WCDMA, DAMPS, etc.

• Smart antenna systems

• Wireless local loop

• Wideband digital communications

Actual Size

(Bottom View)

Single-Tone Output Spectrum

0

-20

© 1999 National Semiconductor Corporation http://www.national.com

Printed in the U.S.A.

-40

-60

-80

Power (dBFS)

-100

-120

0

5

Frequency (MHz)

Sample Rate = 52MSPS

Input Frequency = 5MHz

10

15

20

25

Page 2

Ω

µ

µ

CLC5958 Electrical Characteristics

(V

= +5V, DV

cc

= +3.3V, 52MSPS; unless specified, T

cc

= -40°C, T

min

= +85°C)

max

PARAMETERS CONDITIONS TEMP RATINGS UNITS NOTES

MIN TYP MAX

RESOLUTION

DIFF. INPUT VOLTAGE RANGE

MAXIMUM CONVERSION RATE

SNR

SFDR

SFDR EXCLUDING 2nd & 3rd HARM. f

NO MISSING CODES

f

= 10MHZ, A

in

f

= 10MHZ, A

in

= 10MHZ, A

in

f

= 10MHZ, A

in

= -0.6dBFS +25°C 69 71 dBFS 1

in

= -0.6dBFS +25°C 80 90 dB 1

in

= -0.6dBFS +25°C 85 92 dB 1

in

= -0.6dBFS +25°C Guaranteed 1

in

Full 14 Bits 1

Full 2.048 V

Full 52 65 MSPS 1

NOISE AND DISTORTION

noise floor 2

f

= 5MHz A

in

f

= 5MHz A

in

= -1dBFS +25°C -71.0 dBFS

in

= -20dBFS +25°C -72.0 dBFS

in

2nd & 3rd harmonic distortion (w/o dither)

= 5MHz A

f

in

f

= 20MHz A

in

f

= 70MHz A

in

= -1dBFS +25°C -90 dBFS

in

= -1dBFS +25°C -87 dBFS

in

= -3dBFS +25°C -78 dBFS

in

next worst harmonic distortion (w/o dither) 3

= 5MHz A

f

in

f

= 20MHz A

in

f

= 70MHz A

in

= -1dBFS +25°C -92 dBFS

in

= -1dBFS +25°C -90 dBFS

in

= -3dBFS +25°C -90 dBFS

in

worst harmonic distortion (with dither) 4

= 5MHz A

f

in

f

= 20MHz A

in

f

= 70MHz A

in

f

= 70MHz (2nd & 3rd excluded) A

in

= -6dBFS +25°C -95 dBFS

in

= -6dBFS +25°C -95 dBFS

in

= -6dBFS +25°C -82 dBFS

in

= -6dBFS +25°C -95 dBFS

in

2-Tone IM distortion (w/o dither)

f

=12MHz, f

in1

= 15MHz A

in2

in1

= A

= -7dBFS +25°C -100 dBFS

in2

SINAD (w/o dither)

= 5MHz A

f

in

= -1dBFS +25°C 69 dB

in

CLOCK RELATED SPURIOUS TONES

fs/8, fs/4 +25°C -95 dBFS

next worst clock spur +25°C -100 dBFS 5

calibration sideband coefficient +25°C 100e-6 6

DC ACCURACY AND PERFORMANCE

differential non-linearity +25°C ±0.3 LSB

integral non-linearity +25°C ±1.5 LSB

offset error +25°C ±2.0 mV

gain error +25°C 2 % of FS

DYNAMIC PERFORMANCE

large-signal bandwidth +25°C 210 MHz

aperture jitter +25°C 0.5 ps(rms)

TIMING

effective aperture delay (t

pipeline delay (t

) Full 3 clk cycle

P

output buffer delay (t

data valid buffer delay (t

) +25°C -0.2 ns

A

) +25°C 6.6 ns

o

) +25°C 6.6 ns

DAV

ANALOG INPUT CHARACTERISTICS

single-ended input resistance +25°C 500

single-ended capacitance +25°C 3.6 pF

ENCODE INPUT CHARACTERISTICS

VIH Full 3.9 4.5 V 7

VIL Full 3.0 3.8 V 7

differential input swing Full 0.2 V

IIL Full 2

IIH Full 25

A

A

Min/max ratings are based on product characterization and simulation. Individual parameters are tested as noted. Outgoing quality levels are

determined from tested parameters.

http://www.national.com

2

Page 3

CLC5958 Electrical Characteristics

(V

= +5V, DV

cc

= +3.3V, 52MSPS; unless specified, T

cc

= -40°C, T

min

= +85°C)

max

PARAMETERS CONDITIONS TEMP RATINGS UNITS NOTES

MIN TYP MAX

DIGITAL OUTPUT CHARACTERISTICS

VOH IOH = 50 µ A Full 3.2 V

VOL IOL = 50 µ A Full 0.1 V

SUPPLY CHARACTERISTICS

+5V supply current (V

+3.3V supply current (DV

) +25°C 260 300 mA 1

CC

) +25°C 32 40 mA 1

CC

power dissipation +25°C 1.4 W

power supply rejection ratio +25°C 0.75 mV/V

V

CC

Min/max ratings are based on product characterization and simulation. Individual parameters are tested as noted. Outgoing quality levels are

determined from tested parameters.

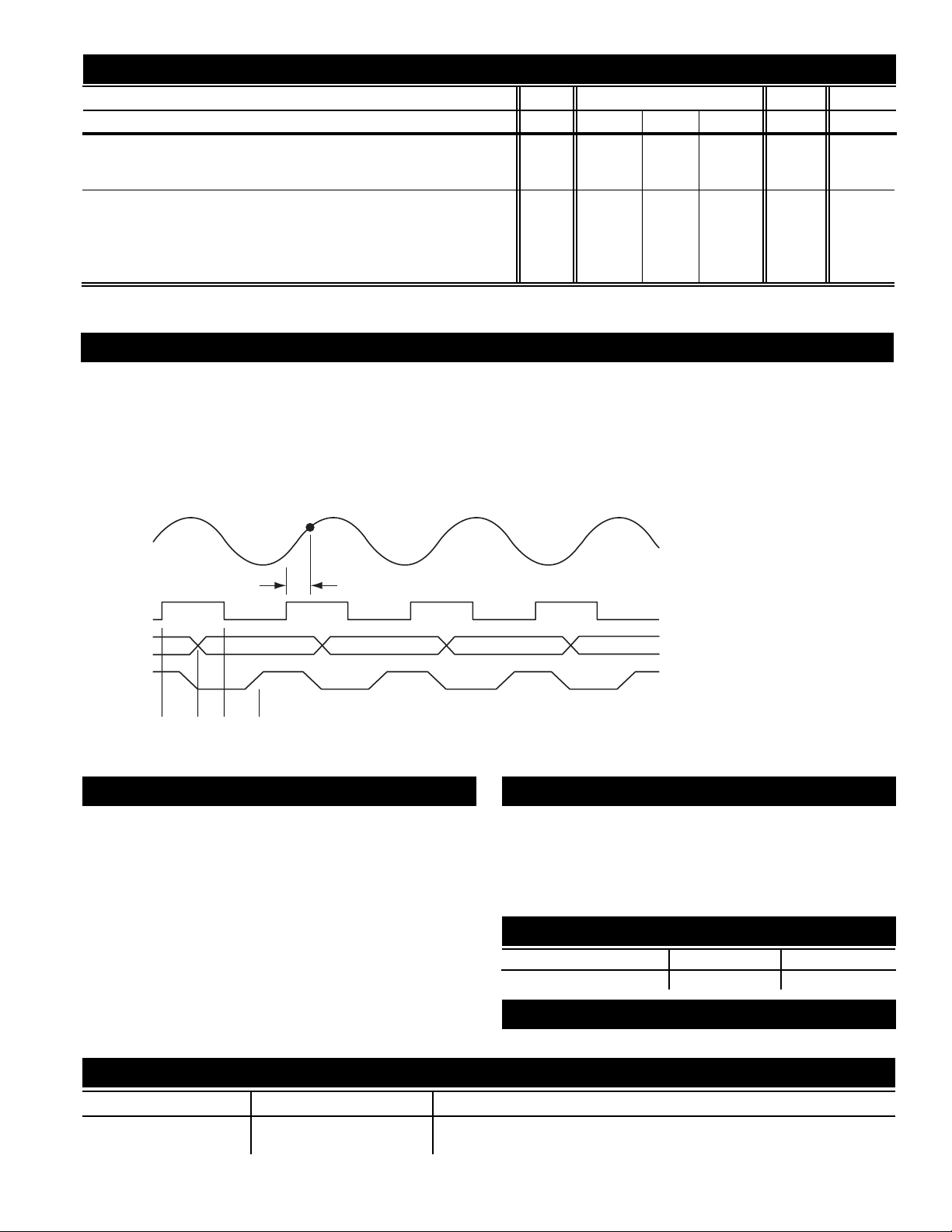

CLC5958 Timing Diagram

1) These parameters are 100% tested at 25°C.

2) Harmonics and clock spurious are removed in noise

measurements.

3) 4th or higher harmonic.

4) Low frequency dither injected in the DC to 500KHz band.

5) Next worst clock spur is a subharmonic of fs, but not fs/8 or fs/4.

See text on spurious.

N + 1

Notes

6) See text on calibration sidebands in the application

information section.

7) Encode levels are referenced to V

1.1V below V

, and the maximum VIH value is 0.5V below V

CC

, i.e. the minimum VIH value is

CC

CC

.

Analog

Input

t

A

ENCODE

Data

DAV

N

N-3

t

O

t

DAV

N+1

N-2

N+2

CLC5958 Timing Diagram

Absolute Maximum Ratings

positive supply voltage (V

differential voltage between any two grounds <200mV

analog input voltage range GND to V

digital input voltage range -0.5V to +V

output short circuit duration (one-pin to ground) infinite

junction temperature 175°C

storage temperature range -65°C to 150°C

lead solder duration (+240°C) 5sec

Note: Absolute maximum ratings are limiting values , to be applied individually, and

beyond which the serviceability of the circuit may be impaired. Functional

operability under any of these conditions is not necessarily implied. Exposure to

maximum ratings for extended periods may affect device reliability.

) -0.5V to +6V

CC

CC

CC

tO: Delay from rising edge of

ENCODE to output data

transition – nominally 6.6ns

: Delay from falling edge of

t

DAV

ENCODE to rising edge of DAV

– nominally 6.6ns

: Effective aperture delay

t

A

– nominally -0.2ns

N-1

N+3

N

Recommended Operating Conditions

positive supply voltage (V

analog input voltage range 2.048V

input coupling AC

operating temperature range -40°C to +85°C

digital output supply voltage (DV

analog input common mode voltage V

) +5V ±5%

CC

) +3.3V ±5%

CC

±0.025V

cm

diff.

pp

Pac kage Thermal Resistance

Package

48-pin CSP 39°C/W 5°C/W

θ

JA

θ

JC

Pac kage Transistor Count

Transistor count 10,000

Ordering Information

Model Temperature Range Description

CLC5958SLB -40°C to +85°C 48-pin CSP (industrial temperature range)

CLC5958PCASM Fully loaded evaluation board with CLC5958 … ready for test.

3

http://www.national.com

Page 4

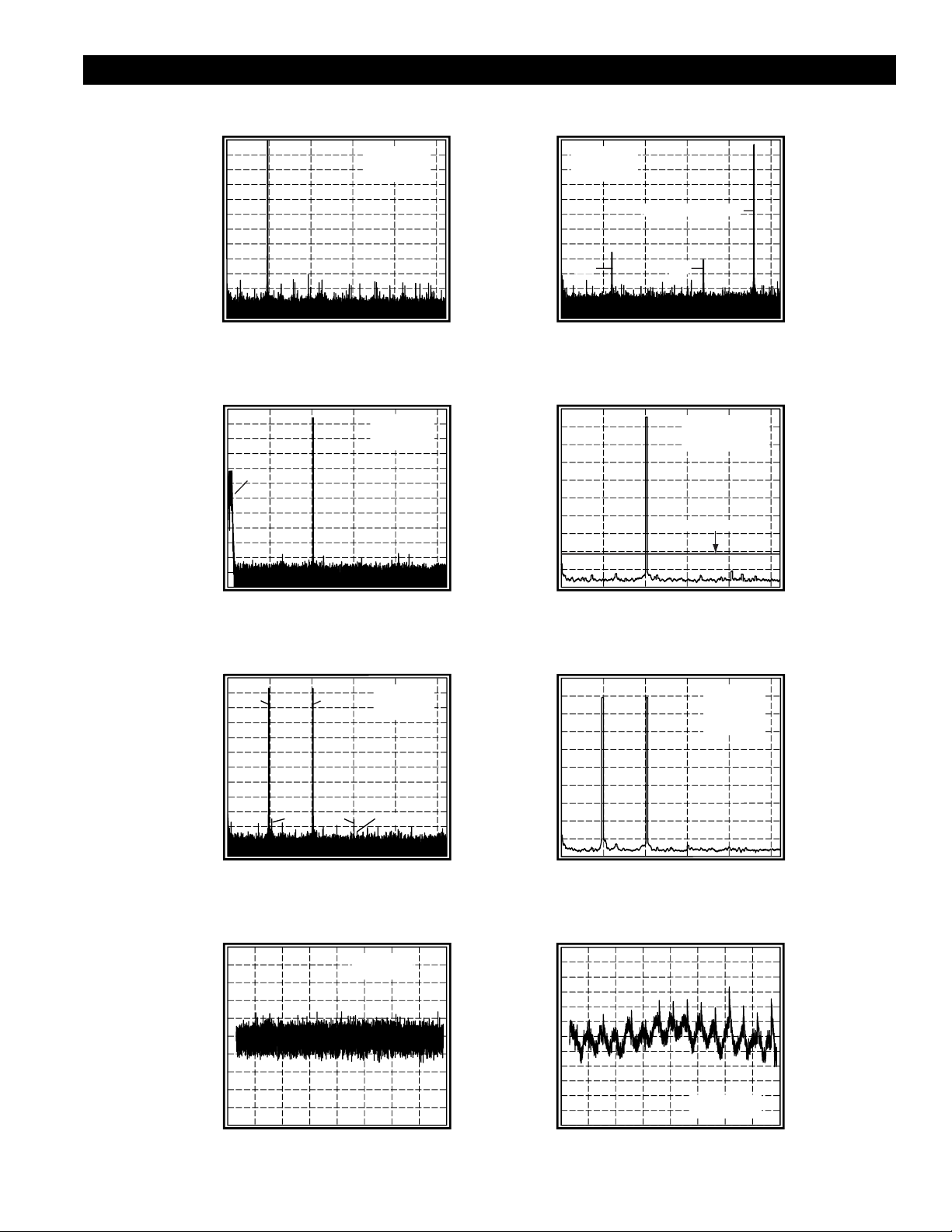

CLC5958 Typical Performance Characteristics

(V

= +5V, 52MSPS; unless specified)

cc

Single-Tone Output Spectrum

0

-20

-40

-60

-80

Power (dBFS)

-100

-120

0

10

5

Fs = 52MSPS

F

in

A

in

15

= 5MHz

= -0.6dBFS

20

-20

-40

-60

-80

Power (dBFS)

-100

-120

25

Frequency (MHz)

Single-Tone Output Spectrum (w/Dither)

0

-20

-40

Dither

-60

-80

Power (dBFS)

-100

Fs = 52MSPS

F

= 10MHz

in

A

= -6dBFS

in

-20

-40

-60

-80

-100

Power at the Antenna (dBm)

-120

10

15

0

5

20

25

-120

Frequency (MHz)

Single-Tone Output Spectrum

0

Fs = 52MSPS

F

= 75MHz

in

A

= -3.2dBFS

in

Fundamental = 75MHz

2nd

0

5

3rd

10

15

Frequency (MHz)

Single-Tone Output Spectrum

w/200KHz Res. BW

Full Scale = -24dBm

F

= 10MHz

in

A

= -25dBm

in

-101dBm reference

10

0

5

15

Frequency (MHz)

20

25

20

25

Two-Tone Output Spectrum

0

-20

f1

-40

-60

-80

Power (dBFS)

-100

f2-f1

-120

0

5

Frequency (MHz)

Differential Non-Linearity

1.0

0.6

0.2

LSBs

-0.2

-0.6

-1.0

0

4000

10

f2

f1+f2

8000

Code

Fs = 52MSPS

f

= 5MHz

1

f

= 10MHz

2

2f2-f1

15

Fs = 52MSPS

F

= 4.9791

in

12000 16000

Two-Tone Output Spec. w/200KHz Res. BW

-20

-40

-60

-80

-100

F

= 5MHz

in1

F

= 10MHz

in2

A

= -31dBm

in1

A

= -31dBm

in2

Power at the Antenna (dBm)

20

25

0

-120

10

15

5

20

25

Frequency (MHz)

Integral Non-Linearity

3.0

2.0

1.0

0

LSBs

-1.0

-2.0

-3.0

0

4000

8000

Fs = 52MSPS

F

= 4.9791MHz

in

12000 16000

Code

http://www.national.com

4

Page 5

CLC5958 Typical Performance Characteristics

(V

= +5V, 52MSPS; unless specified)

cc

Noise and Spurious

vs. Amplitude at F

120

110

Other Spurious

100

90

-dBFS

80

Noise Floor

70

60

-60 -50

-70

Noise and Spurious

vs. Amplitude at F

120

110

100

90

-dBFS

Other Spurious

80

Noise Floor

70

60

-60 -50 -40

-70

= 10MHz

in

Fs/8 or Fs/4

2nd or 3rd Harmonic

-30

-40

Amplitude (dBFS)

= 75MHz

in

2nd or 3rd Harmonic

-30

Amplitude (dBFS)

Fs = 52MSPS

-10

-20

Fs = 52MSPS

Fs/8 or Fs/4

-20 -10

Spurious vs. Amplitude

with Dither at F

120

110

= 10MHz

in

2nd or 3rd Harmonic

100

90

-dBFS

Other Spurious

Fs/8 or Fs/4

80

70

Fs = 52MSPS

60

-20 -10

-60 -50 -40

0

-70

-30

0

Amplitude (dBFS)

Spurious vs. Amplitude

with Dither at F

120

110

= 75MHz

in

2nd or 3rd Harmonic

100

90

-dBFS

Other Spurious

Fs/8 or Fs/4

80

70

Fs = 52MSPS

60

-10

-20

-60 -50 -40

0

-70

-30

0

Amplitude (dBFS)

Noise and Distortion vs. Sample Rate

120

110

100

2nd or 3rd Harmonic

90

dBFS

80

70

Noise Floor

Other Spurious

60

50

40

10 20

30

Sample Rate (MSPS)

Noise and Spurious vs. Input Frequency

120

110

100

Fs/8 or Fs/4

90

-dBFS

80

70

2nd or 3rd Harmonic

Other Spurious

Noise Floor

60

15

10

5

0

Input Frequency (MHz)

Fin = 10MHz

A

= -0.6dBFS

in

60

Fs = 52MSPS

A

= -0.6dBFS

in

20

Clock Spurious vs. Sample Rate

120

110

fs/8

"next clock spurs"

100

-dBFS

90

fs/4

80

70

40

70

10 20

30

Fin = 10MHz

A

= -0.6dBFS

in

50

60

70

Sample Rate (MSPS)

Noise and Spurious vs. Input Frequency

120

110

100

90

Other Spurious

Fs = 52MSPS

A

= -3.2dBFS

in

Fs/8 or Fs/4

-dBFS

80

70

Noise Floor

60

25

010

2nd or 3rd Harmonic

20

30

40

70

60

50

Input Frequency (MHz)

5 http://www.national.com

Page 6

CLC5958 Pin Definitions

1 GND

2 GND

3 GND

4 GND

5V

CC

6V

CC

7V

CC

8 GND

9 ENCODE

10 ENCODE

11 GND

12 GND

13 A

IN

14 A

IN

15 GND

16 V

CC

17 V

CC

18 V

CC

19 GND

20 GND

21 V

CM

22 V

CC

23 GND

24 GND

CLC5958

vias

GND

GND

V

CC

(MSB) D13

D12

D11

D10

D9

D8

D7

DV

CC

DV

CC

GND

GND

D6

D5

D4

D3

D2

D1

(LSB) DO

DAV

GND

GND

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

A

IN, AIN

(Pins 13, 14) Differential inputs. Self biased at a common

mode voltage of +3.25V. The ADC full scale input is

2.048Vpp differential.

ENCODE, (Pins 9, 10) Differential clock inputs. ENCODE initiates a

ENCODE new data conversion cycle on each rising edge. Clock

signals may be sinusoidal or square waves with PECL

encode levels. The falling edge of ENCODE clocks

internal pipeline stages.

D0-D13 (Pins 28 - 34, 39 - 45) Digital data outputs. CMOS

and TTL compatib le. D0 is the LSB and D13 is the inverted

MSB. Output coding is two’s complement.

DAV (Pin 27) Data valid. The rising edge of this signal occurs

when output data is valid and may be used to latch data

into following circuitry.

V

CM

(Pin 21) Internal analog input common mode voltage

reference. Nominally +3.25V. Can be used to establish the

analog input common mode voltage for DC coupled

applications (DC coupling not recommended, see

applications section).

GND (Pins 1 - 4, 8, 11, 12, 15, 19, 20, 23 - 26, 35, 36, 47, 48,

and vias) circuit ground.

V

CC

(Pins 5 - 7, 16 - 18, 22, 46) +5V power supply. Bypass

each group of supply pins to ground with a 0.01µF

capacitor.

AIN

ENCODE

T&H

DV

CC

(Pins 37, 38) +3.3V to +5V power supply for the digital

outputs. Establishes the high output level for the digital

outputs. Bypass to ground with a 0.1µF capacitor.

CLC5958 Block Diagram

Summing

Network

4-bit

Flash

Over-range Correction Logic & Output Buffers

4-bit

DAC

Residue

Amp

10-bit

Fine

ADC

http://www.national.com 6

Page 7

CLC5958 Package Dimensions

7 http://www.national.com

Page 8

CLC5958 Application Information

Driving the Analog Inputs

The differential analog inputs, AIN and AIN, are biased

from an internal 3.25V reference (a 2.4V bandgap

reference plus a diode) through an on-chip resistance of

500Ω. This bias voltage is set for optimum performance,

and varies with temperature. Since DC coupling the

inputs overrides the internal common mode voltage, it is

recommended that the inputs to the CLC5958 be AC

coupled whenever possible. The time constant of the

input coupling network must be greater than 1µsec to

minimize distortion due to nonlinear input bias currents.

Additionally, the common mode source impedance

should be less than 100Ω at the sample rate.

If DC coupling is required, then the V

output may be

CM

used to establish the input common mode voltage. The

CLC5958 samples the common mode voltage at the

internal track-and-hold output and servos the VCM output

to establish the optimum common mode potential at the

track-and-hold. It is possible to use the VCM output to

construct an external servo loop.

Figure 1 below illustrates one input coupling method. The

transformer provides noiseless single-ended to

differential conversion. The two 50Ω resistors in the

secondary define the input impedance and provide a low

common mode source impedance through the bypass

capacitors.

VIN

0.1

1:1.4

0.1

50

0.01

50

AIN

CLC5958

0.1

100

VIN

VIN

100

0.1

AIN

39pf

CLC5958

39pf

AIN

0.1

Figure 2: Differential Amplifier

Driving the ENCODE Inputs

The ENCODE and ENCODE inputs are differential clock

inputs that are referenced to VCC. They may be driven

with PECL input levels. Alternatively they may be driven

with a differential input (e.g. a sine input) that is centered

at 1.2 Volts below VCC and which meets the min and max

ratings for VIL and VIH. Low noise differential clock signals

provide the best SNR performance for the converter.

The ENCODE inputs are not self biasing, so a DC bias

current path must be provided to each of the inputs.

Figure 3 shows one method of driving the encode inputs.

25

MC10EL16

Q

D

Q

0.1

25

D

V

BB

ENCODE

CLC5958

ENCODE

332332

Clock

0.1

1:1

Figure 3: ENCODE Inputs

0.1

AIN

Figure 1: Input Coupling

Alternatively, the inputs can be driven using a differential

amplifier as shown in Figure 2.

The network of Figure 2 uses a simple RC low-pass filter

to roll off the noise of the differential amplifier. The network has a cutoff frequency of 40MHz. Different noise

filter designs are required for different applications. For

example, an IF application would require a band-pass

noise filter.

The analog input lines should be routed close together so

that any coupling from other sources is common mode.

http://www.national.com 8

The transformer converts the single-ended clock signal to

a differential signal. The center-tap of the secondary is

biased by the VBB potential of the ECL buffer. The diodes

in the secondary limit the input swing to the buffer.

Since the encode inputs are close to the analog inputs, it

is recommended that the analog inputs be routed on the

top of the board directly over a ground plane and that the

encode lines be routed on the back of the board and then

connected through via to the encode inputs.

Latching the Output Data

The rising edge of DAV is approximately centered in the

data transition window, and may be used to latch the

output data. The DAV output has twice the load driving

capability of the data outputs so that two latch clock

inputs may be driven by this output.

Page 9

Routing Output Data Lines

It is recommended that the ground plane be removed

under the data output lines to minimize the capacitive

loading of these lines. In some systems this may not be

permissible because of EMI considerations.

Harmonics and Clock Spurious

Harmonics are created by non-linearity in the track-andhold and the quantizer. Harmonics that arise from

repetitive non-linearities in the quantizer may be reduced

by the application of a dither signal.

Transformers and baluns can contribute harmonic

distortion, particularly at low frequencies where transformer operation relies on magnetic flux in the core. If a

transformer is used to perform single-ended to differential

conversion at the input, care should be taken in the

selection of the transformer.

The clock is internally divided by the CLC5958 in order to

generate internal control signals. These divided clocks

can contribute spurious energy , principally at fs/4 and fs/8.

The clock spurious is typically less than -90dBFS.

6

3 52e

32

6

3

=

6

7.9KHz

32 4.8671e

n round

=

f 4.8671e

=−∗=

∆

∗

52e

6

If the input is a full scale input, then the magnitude of the

sidebands is derived as:

x 1024 7.9e /52e 0.489

==

a 100e

=∗

∆

36

π

sin .489

-6 -6

()

.489

==−

96e 80dBc

The sidebands roll off rapidly with increasing sideband

offset. For example, if the sideband is offset 200KHz from

the carrier (in an adjacent GSM channel) as opposed to

the 7.9KHz offset from the previous example, the sideband magnitude is reduced to -116dBc.

Figure 4 shows how the sideband offset frequency

varies with input frequency at a sample rate of 52MSPS.

Calibration Sidebands

The CLC5958 incorporates on-board calibration. The

calibration process creates low level sideband spurious

close to the carrier and near DC for some input

frequencies. In most applications these sidebands will

not be an issue. The sidebands add negligible power to

the carrier and therefore do not reduce sensitivity in

receiver applications. Also, the sidebands never fall in

adjacent channels with any appreciable power. They may

be visible in some very narrow-band applications, and so

are documented here for completeness.

The offset of the sidebands relative to the carrier and relative to DC is derived using the equations:

n round

=

32f

in

f

s

ff

=−

∆

nf

s

in

32

where f∆ is the sideband offset, fin is the input

frequency, fs is the sample rate, and round(•) denotes

integer rounding. The magnitude of the sideband relative

to the carrier for a full scale input tone is approximated by

the equations:

sin x

x 1024 f / f a

==

πα

s

∆∆

()

x

where a∆ is the sideband magnitude relative to the input,

and α is the calibration sideband coefficient. The value of

α rolls off 2dB per dB as the input amplitude is reduced.

For example, assume the input frequency is 4.8671MHz

and the sample rate is 52MSPS. Then the sideband

offset is derived as follows:

800

700

600

500

400

(KHz)

∆

f

300

200

100

0

0

10

5

Input Frequency (MHz)

15

20

25

Figure 4: Sideband Offset vs. Input Frequency

The sideband magnitude is a function of the sideband

offset, as illustrated in Figure 5.

-80

-85

-90

-95

-100

-105

-110

-115

Sideband Magnitude (dBc)

-120

0 100 200 300 400 500 600

f∆ (KHz)

700

800

Figure 5: Sideband Magnitude vs. Sideband Offset

9 http://www.national.com

Page 10

Power Supplies

The VCC pins supply power to all of the CLC5958

circuitry with the exception of the digital output buffers.

The D VCC pins provide power to the digital output buffers.

Each supply pin should be connected to a supply (i.e. do

not leave any supply pins floating).

Local groups of supply pins should be bypassed

with.01uF capacitors. These capacitors should be placed

as close to the part as possible. Avoid using via to the

ground plane. If vias to the ground plane cannot be

avoided, then use multiple vias in close proximity to the

bypass capacitor.

The supplies should be bypassed in a manner to prevent

supply return currents from flowing near the analog

inputs. The evaluation board layout is an example of how

to accomplish this.

The digital output buffer supplies (DVCC) provide a

means for programming the output buffer high level.

Supply values ranging from 3.3V to 5.0V may be applied

to these pins. In general, best performance is achieved

with DVCC set to 3.3V.

Layout Recommendations for the CSP

The 48 lead chip scale package not only provides a small

footprint, but also provides an excellent connection to

ground. The thermal vias on the bottom of the package

also serve as additional ground pads. The solder pad

dimensions on the pc board should match the package

pads 1:1.

Soldering Recommendations for the CSP

A 4 mil thick stencil for the solder screen printing is

recommended. The suggested IR reflow profile is:

Ramp Up: 2°C/sec

Dwell Time > 183°C: 75 sec

Solder Temperature: 215°C

(max solder temperature): 235°C

Dwell Time @ Max Temp: 5 sec

Ramp Down: 2°C/sec

CLC5958 Evaluation Board

Description

The CLC5958 evaluation printed circuit board provides a

convenient test bed for rapid evaluation of the CLC5958.

It illustrates the proper approach to layout in order to

achieve best performance, and provides a performance

benchmark.

Analog Input

The CLC5958 evaluation board is configured to be driven

by a single-ended signal at the AIN SMA connector (the

AIN

connector is disconnected). The AIN SMA

connector should be driven from a 50Ω source

impedance. A full scale input is approximately 1.4V

(7dBm). The single-ended input is converted to a

differential input by an on-board transformer.

When performing sine wave testing, it is critical that the

input sine wave be filtered to remove harmonics and

source noise.

Encode Input

The CLK SMA connector is the encode input and should

also be driven from a 50Ω source. A low jitter 16dBm sine

wave should be applied at this input. In some cases it

may be necessary to band-pass filter the sine wave in

order to achieve low jitter.

pp

The single-ended clock input is converted to a differential

signal by an on-board transformer and buffered by an

ECL buffer.

Digital Outputs

The digital outputs are available at the Eurocard

connector (J1). Data bits D0 through D13

J1 pins 18B through 5B. The data ready signal (labeled

DR in the schematic) is available at J1 pin 20B. These

outputs are also available at the HP 01650-63203

termination adapter for direct connection to an HP logic

analyzer (see evaluation board schematic). The outputs

are buffered by 3.3V digital latches. The falling edge of

the data ready signal may be used to latch the output data.

Supply V oltages

Power is sourced to the board through the Eurocard connector. A 5V supply should be connected at J1 pins 32A

and 32B. A 3.3V supply should be connected at J1 pins

31A and 31 B. The ground return for these supplies is at

J1 pins 27A, 27B, 28A, and 28B. It is recommended that

low noise linear supplies be used.

are available at

http://www.national.com 10

Page 11

CLC5958 Evaluation Board Layout

CLC5958PCASM Layer 1 CLC5958PCASM Layer 2

CLC5958PCASM Layer 3 CLC5958PCASM Layer 4

11 http://www.national.com

Page 12

CLC5958 Evaluation Board Schematic

http://www.national.com 12

Page 13

CLC5958

14-bit, 52MSPS A/D Converter

Customer Design Applications Support

National Semiconductor is committed to design excellence. For sales, literature and technical support, call the

National Semiconductor Customer Response Group at 1-800-272-9959 or fax 1-800-737-7018.

Life Support Policy

National’s products are not authorized for use as critical components in lif e support devices or systems without the e xpress written approv al

of the president of National Semiconductor Corporation. As used herein:

1. Life support devices or systems are devices or systems which, a) are intended for surgical implant into the body, or b) suppor t or

sustain life, and whose failure to perform, when properly used in accordance with instructions for use provided in the labeling, can

be reasonably expected to result in a significant injury to the user.

2. A critical component is any component of a life support device or system whose failure to perform can be reasonably expected to

cause the failure of the life support device or system, or to affect its safety or effectiveness.

National Semiconductor National Semiconductor National Semiconductor National Semiconductor

Corporation Europe Hong Kong Ltd. Japan Ltd.

1111 West Bardin Road Fax: (+49) 0-180-530 85 86 13th Floor, Straight Block Tel: 81-043-299-2309

N

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said

circuitry and specifications.

http://www.national.com 13

Arlington, TX 76017 E-mail: europe.support.nsc.com Ocean Centre, 5 Canton Road Fax: 81-043-299-2408

Tel: 1(800) 272-9959 Deutsch Tel: (+49) 0-180-530 85 85 Tsimshatsui, Kowloon

Fax: 1(800) 737-7018 English Tel: (+49) 0-180-532 78 32 Hong Kong

Francais Tel: (+49) 0-180-532 93 58 Tel: (852) 2737-1600

Italiano Tel: (+49) 0-180-534 16 80 Fax: (852) 2736-9960

Loading...

Loading...