Page 1

N

CLC5902

Dual Digital T uner/AGC

0

0

May 1999

CLC5902

Dual Digital Tuner/AGC

General Overview

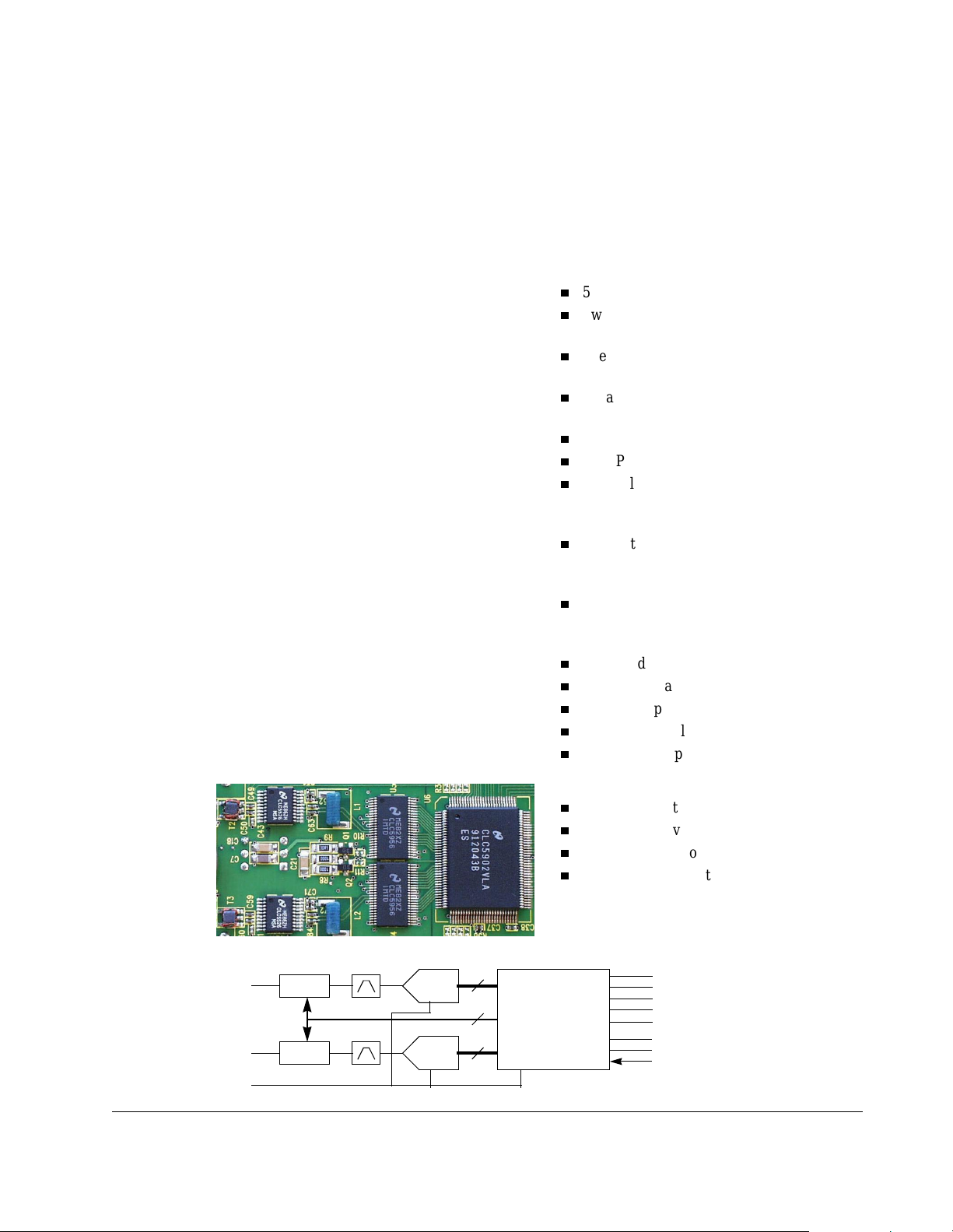

The CLC5902 Dual Digital Tuner/AGC IC is a two channel digital

downconverter (DDC) with integrated automatic gain control

(AGC). The CLC5902 is a key component in the Diversity

Receiver Chipset (DRCS) which includes one CLC5902 Dual

Digital Tuner/AGC, two CLC5956 12-bit analog-to-digital

converters (ADCs), and two CLC5526 digitally controlled variable

gain amplifiers (DVGAs). A block diagram for a Diversity

Receiver Chipset based narrowband communications system is

shown in Figure 1. This system allows direct IF sampling of signals

up to 300MHz for enhanced receive r performance and reduced

system costs.

The CLC5902 offers high dynamic range digital tuning and

filtering based on hard-wired digital signal processing (DSP)

technology. Each channel has independent tuning, phase offset, and

gain settings. Channel filtering is performed by a series of three

filters. The first is a 4-stage Cascaded Integrator Comb (CIC) filter

with a programmable decimation ratio fr om 8 to 2048. Next there

are two symmetric FIR filters, a 21-tap and a 63-tap, both with

programmable coefficients . The first FIR filter de cimates the data

by 2, the second FIR decimates by either 2 or 4. Channel filter

bandwidth at 52MSPS ranges from ±650kHz down to ±1.3kHz.

The CLC5902’s AGC controller monitors the ADC output and

controls the ADC input signal level by adjusting the DVGA setting.

AGC threshold, deadband+hysteresis, and the loop time constant

are user defined. Total dynamic range of greater than 120dB fullscale signal to noise can be achieved with the Diversity Receiver

Chipset.

Features

n

52MSPS Operation

n

Two Independent Channels with

14-bit inputs

n

Greater than 100 dB image rejection

n

Greater than 100 dB spurious free

dynamic range

n

0.02 Hz tuning resolution

n

User Programmable AGC

n

Channel Filters include a Fourth

Order CIC follow ed by 21 -ta p and

63-tap Symmetric FIRs

n

FIR filters process 21-bit Data

with 16-bit Programmable Coefficients

n

Flexible output formats include

12-bit Floating Point or 8, 16, 24,

and 32 bit Fixed Point

n

Serial and Parallel output ports

n

JTAG Boundary Scan

n

8-bit Microprocessor Interface

n

380mW/channel, 52 MHz, 3.3V

n

128 pin PQFP package

Applications

n

Cellular Basestations

n

Satellite Receivers

n

Wireless Local Loop Receivers

n

Digital Communications

CLC5526 CLC5956 CLC5902

LC

IF A

IF B

CLK

Figure 1 Diversity Receiver Chipset Block Diagram

©1999 National Semiconductor Corporation Rev. 3.05 May 27, 1999

DVGA

DVGA

LC

ADC

ADC

12

Dual Digital

4

Tuner/AGC

12

SerialOutA/B

SerialOutB

SCK

SFS

RDY

ParallelOutput[15. .0]

ParallelOutputEnable

ParallelSelect[2..0]

Page 2

RD

WR

CE

A[7:0]

D[7:0]

Microprocessor

Interface

Channel A Controls

GAIN_A

FREQ_A

PHASE_A

AGC_IC_A

AGC_RB_A

DITH_A

AGAIN[2..0]

ASTROBE

AIN

BIN

TEST_REG

Input Source

A_SOURCE

B_SOURCE

CK

MR

AGC_EN

SI

MUX

A

MUX

B

CLK

GEN

Sync

Logic

14

14

Channel A

Tuning,

Channel Filters, and

AGC (see Figure 14)

Channel B

Tuning,

Channel Filters, and

AGC (see Figure 14)

Channel B Controls

GAIN_B

FREQ_B

PHASE_B

Common Channel Controls

DEC

DEC_BY_4

SCALE

EXP_INH

F1_COEFF

F2_COEFF

AGC_FORCE

AGC_RESET_EN

AGC_HOLD_IC

AGC_LOOP_GAIN

AGC_COUNT

AGC_TABLE

Output Formatter

Floating Point:

4-bit Exponent and

8-bit Mantissa

or

Two’s Complement:

32-bit Truncate d or

24-bit Rounded or

16-bit Rounded or

8-bit Truncated

(see Figure 26)

AGC_IC_B

AGC_RB_B

DITH_B

AOUT/BOUT

BOUT

SCK

SFS

RDY

POUT[15..0]

PSEL[2..0]

POUT_EN

BSTROBE

BGAIN[2..0]

Output Controls

RATE

SOUT_EN

SCK_POL

SFS_POL

RDY_POL

MUX_MODE

PACKED

FORMAT

DEBUG_EN

DEBUG_TAP

Figure 2 CLC5902 Dual Digital Tuner/AGC Block Diagram with Control Register Associations

Functional Description.

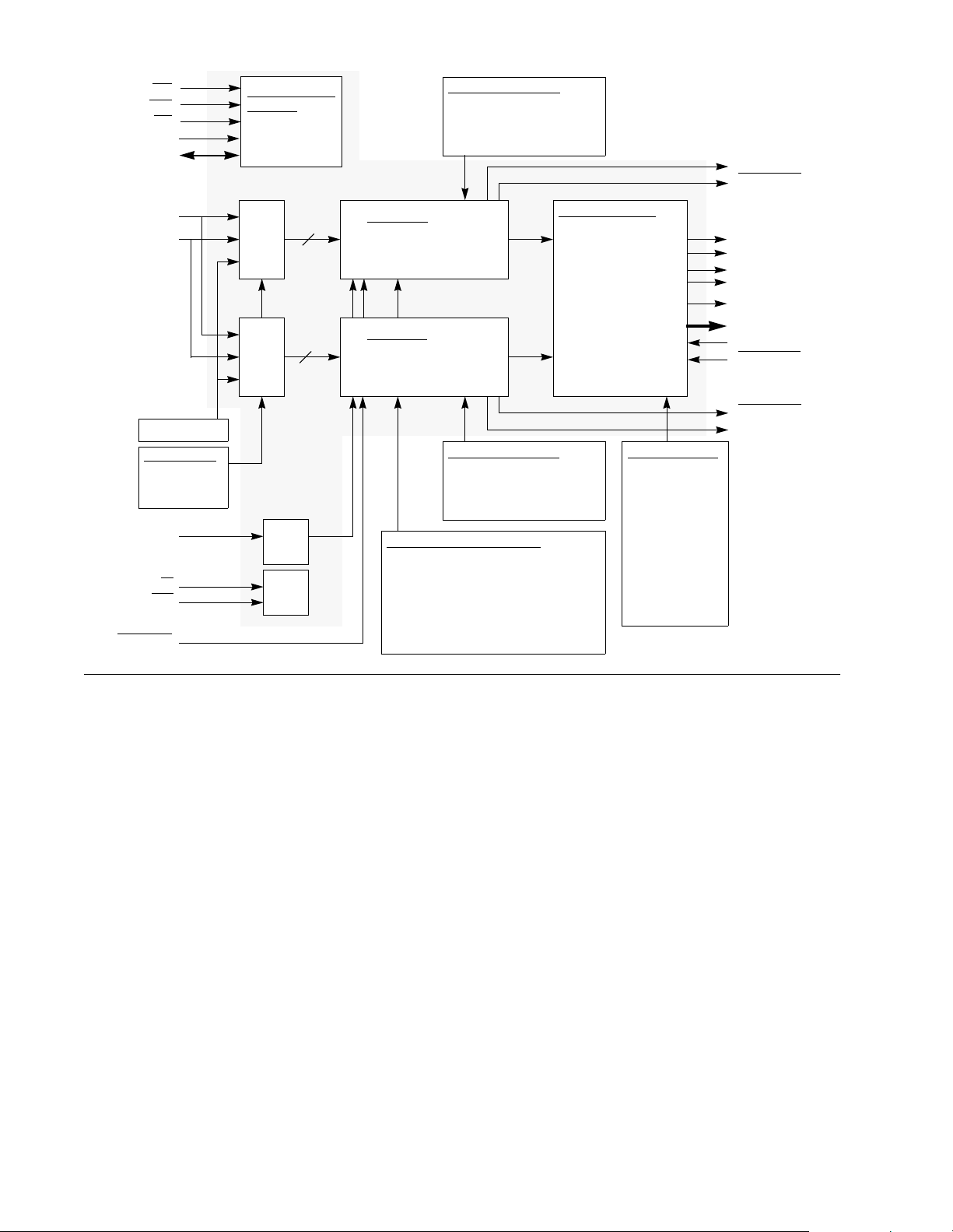

The CLC5902 block diagram is shown in Figure 2. The

CLC5902 contains two identical digital down-conversion

(DDC) circuits. Each DDC accepts a 14-bit sample at up

to 52MSPS, down converts from a selected carrier frequency to baseband, decimates the sign al rate by a programmable factor rang ing from 32 to 16384, provides

channel filteri ng, and outputs qua drature symbols.

A crossbar switch enables either of the two inputs or a test

register to be routed to either DDC ch annel. Flex ible ch annel filtering is provided by the two programma ble decimating FIR filters. The fi nal filter outputs can be

converted to a 12-bit floating point format or standard

two’s complement format. The output data is ava ilable at

both serial and parallel ports.

The CLC5902 maintains over 10 0 dB of spurious free

dynamic range and over 10 0 dB of out-of-band rejection.

This allows considerable latitude in channel filter partitioning between the analog and digital domains.

The frequencies, phase offsets, and phase dither of the two

sine/cosine numerica lly contro lled oscill ators (NCOs ) can

be independently specified. Both channels share the same

decimation ratio, bandwidth, filter coefficients, and input/

output formats.

Each channel has its own AG C circuit for use with narrowband radio channels where most of the cha nnel filtering precedes the ADC. The AGC closes the loop around

the CLC5526 DVGA, compressing the dynamic range of

the signal into the ADC . The AG C can be configure d to

operate continuously or in a gated mode. The two AGC

circuits operate independently but share the same programmed parameters and control sign als.

The chip receives configuration and control information

over a microprocessor-compatible bus consisting of an 8bit data I/O port, an 8-bit address port, a chip enable

strobe, a read strobe, and a write strobe. The chip’s control

registers (8 bits each) are memory mapped into the 8-bit

address space of the control port.

JTAG boundary scan and on-chip diagnostic circuits are

provided to simplify system debug and test.

The CLC5902 supports 3.3V I/O. The CLC5956 ADC

outputs are compatible with the CLC5902 inputs. The

CLC5902 outputs swing to the 3.3V rail so they can be

directly connected to 5V TTL inputs if desired.

Rev. 3.05 May 27, 1999 2 ©1999 National Semiconductor Corporation

Page 3

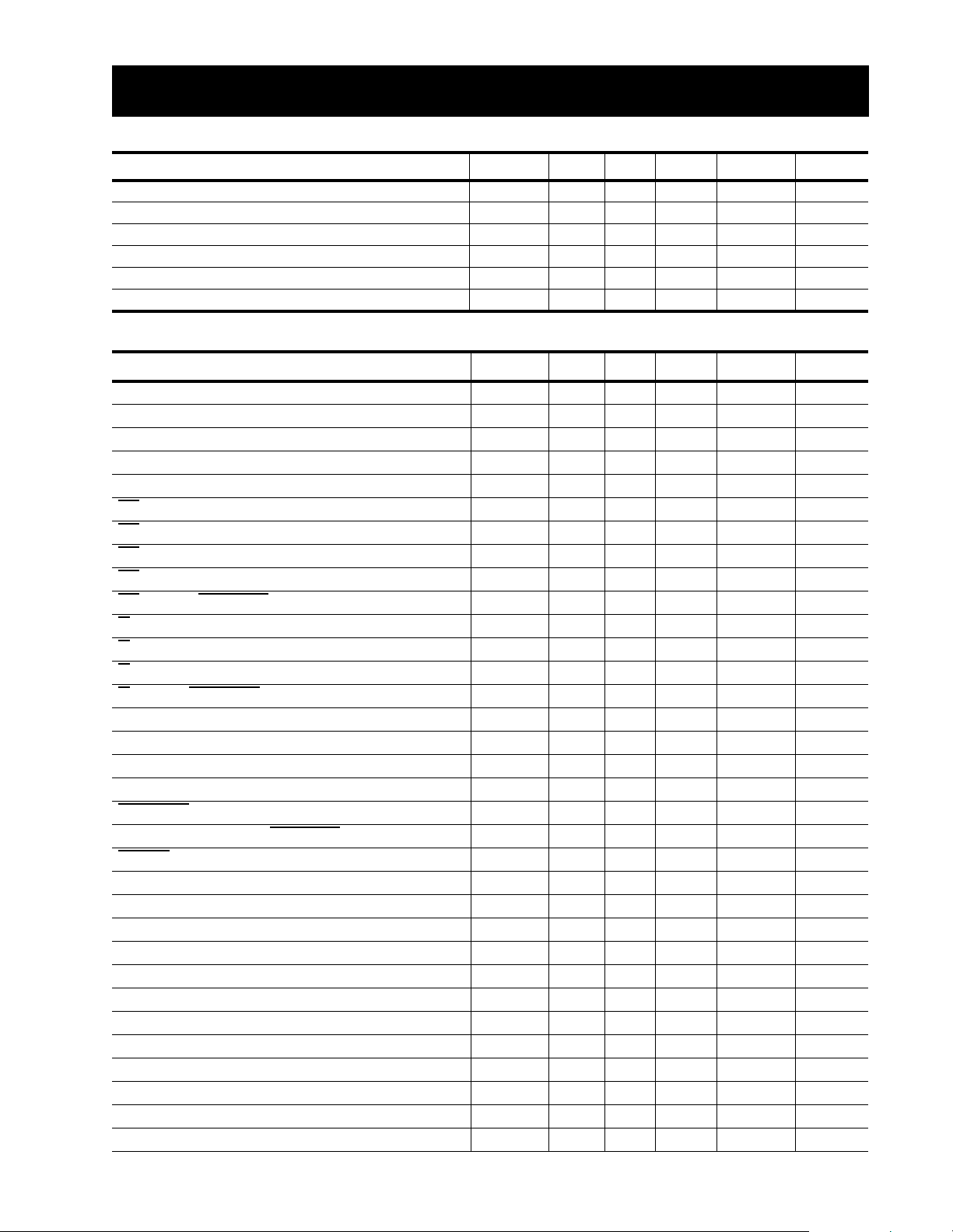

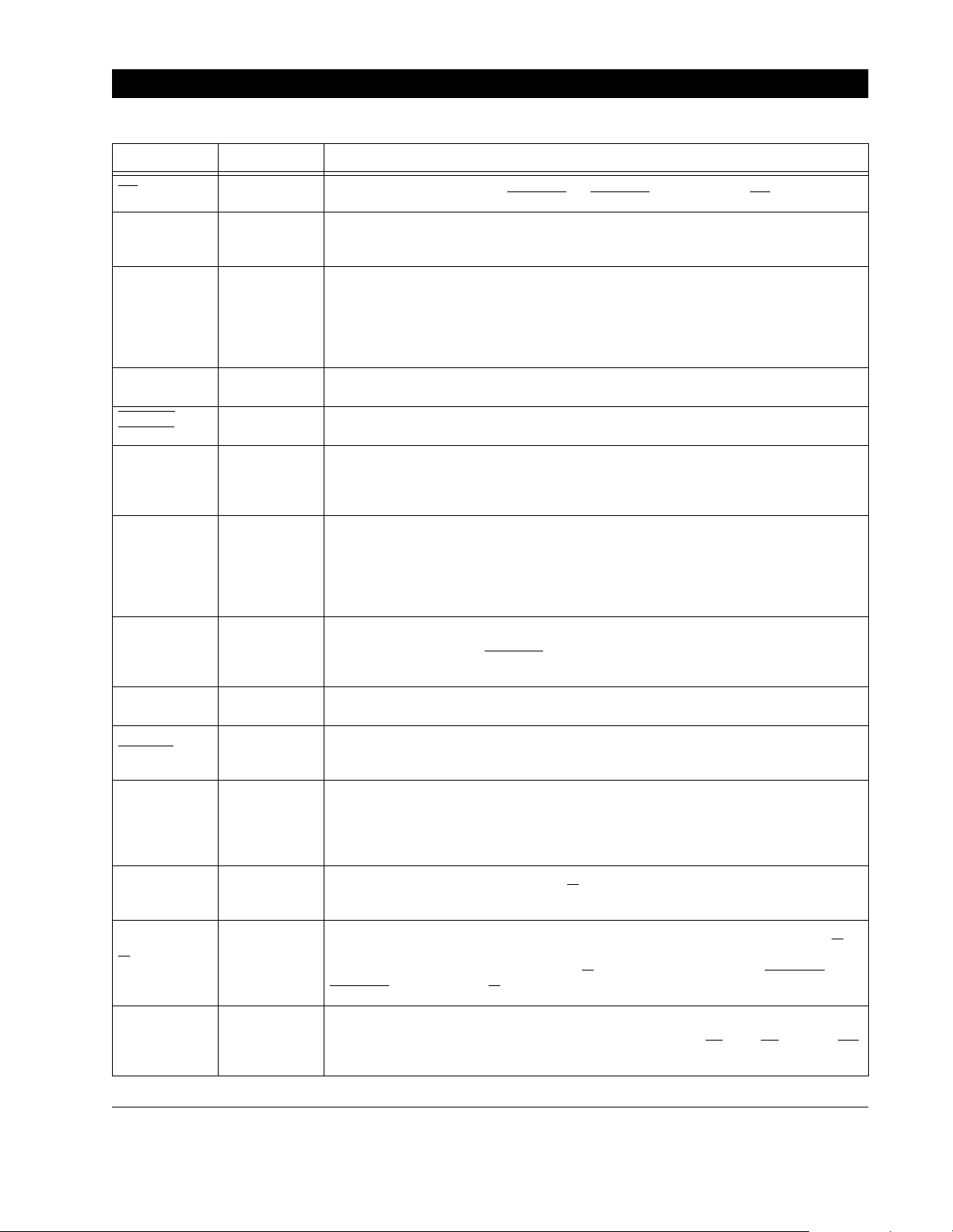

CLC5902 Electrical Characteristics

(VCC=+3.3V, 52MHz, CIC Decimation=48, F2 Decimation=2, T

DC Characteristics

PARAMETER SYMBOL MIN TYP MAX UNITS Notes

Voltage input low V

Voltage input high V

Input current I

Voltage output low (I

Voltage output high (I

Input capacitance C

AC Characteristics

= 4mA/12mA, see pin description) V

OL

= -4mA/-12mA, see pin description) V

OH

PARAMETER (CL=50pF) SYMBOL MIN TYP MAX UNITS Notes

=-40°C, T

min

IL

IH

IN

OL

OH

IN

=+85°C; unless specified)

max

-0.5 0.8 V 1

2.0 VCC+0.5 V 1

10 uA 1

0.4 V 1

2.4 V 1

4.0 pF 3

Clock (CK) Frequency (Figure 7) F

CK

52 MHz 1

Spurious Free Dynamic Range SFDR -100 dBFS

Signal to Noise Ratio SNR -127 dBFS

Tuning Resolution 0.02 Hz

Phase Resoluti on 0.005 °

MR

Active Time (Figure 5) t

MR

Inactive to first Control Port Acc ess (Fi gure 5) t

MR

Setup Time to CK (Fig ure 5) t

MR

Hold Time to CK (Figure 5) t

MR

Inactive to A|BSTROBE Release (Figure 5) t

SI

Setup Time to CK (Figure 6) t

SI

Hold Time from CK (Figure 6) t

SI

Pulse Width (Figure 6) t

SI

Inactive to A|BSTROBE Release (Figure 6) t

CK duty cycle (Figure 7) t

CK rise and fall times (V

to VIH) (Figure 7) t

IL

Input setup before CK goes high (A|BIN) (Figure 7) t

Input hold time after CK goes high (Figure 7) t

A|BSTROBE

A|BGAIN Valid Setup before A|BSTROBE

AGC_EN

Pulse Width (Figure 8) t

(Figure 8) t

Active Width (Figure 8) t

SCK to SFS Valid (Table Note A) (Figure 9) t

SCK to A|BOUT Valid (Table Note B) (Figure 9) t

RDY Pulse Width (Figure 9) t

POUT_EN Active to POUT[15..0] Valid (Figure 10) t

POUT_EN Inactiv e to POUT[15..0] Tri-State (Figure 10) t

PSEL[2..0] to POUT[ 15..0 ] Valid (Figure 11) t

RDY to POUT[15..0] New Value Valid (Table Note C) (Figure 12) t

Propagation Delay TCK to TDO (Figure 13) t

Propagation Delay TCK to Data Out (Figure 13) t

Disable Time TCK to TDO (Figure 13) t

Disable Time TCK to Data Out (Figure 13) t

Enable Time TCK to TDO (Figure 13) t

MRA

MRIC

MRSU

MRH

MRSR

SISU

SIH

SIW

SISR

CKDC

RF

SU

HD

STBPW

GSU

ENW

SFSV

OV

RDYW

OENV

OENT

SELV

RDYV

PLH

PHL

PLZ

PHZ

PZL

4 CK periods 1

10 CK periods 1

9ns1

2ns1

17 ns

9ns1

2ns1

4 CK periods 1

17 ns

40 60 % 1

3ns 1

7ns1

3ns1

1 CK period 2

1 CK period 2

2 CK periods 1

07ns1

07ns1

4 CK periods 1

15 ns 1

15 ns 1

20 ns 1

10 ns 1

30 ns 1

35 ns 1

35 ns 1

35 ns 1

035ns1

©1999 National Semiconductor Corporation 3 Rev. 3.05 May 27, 1999

Page 4

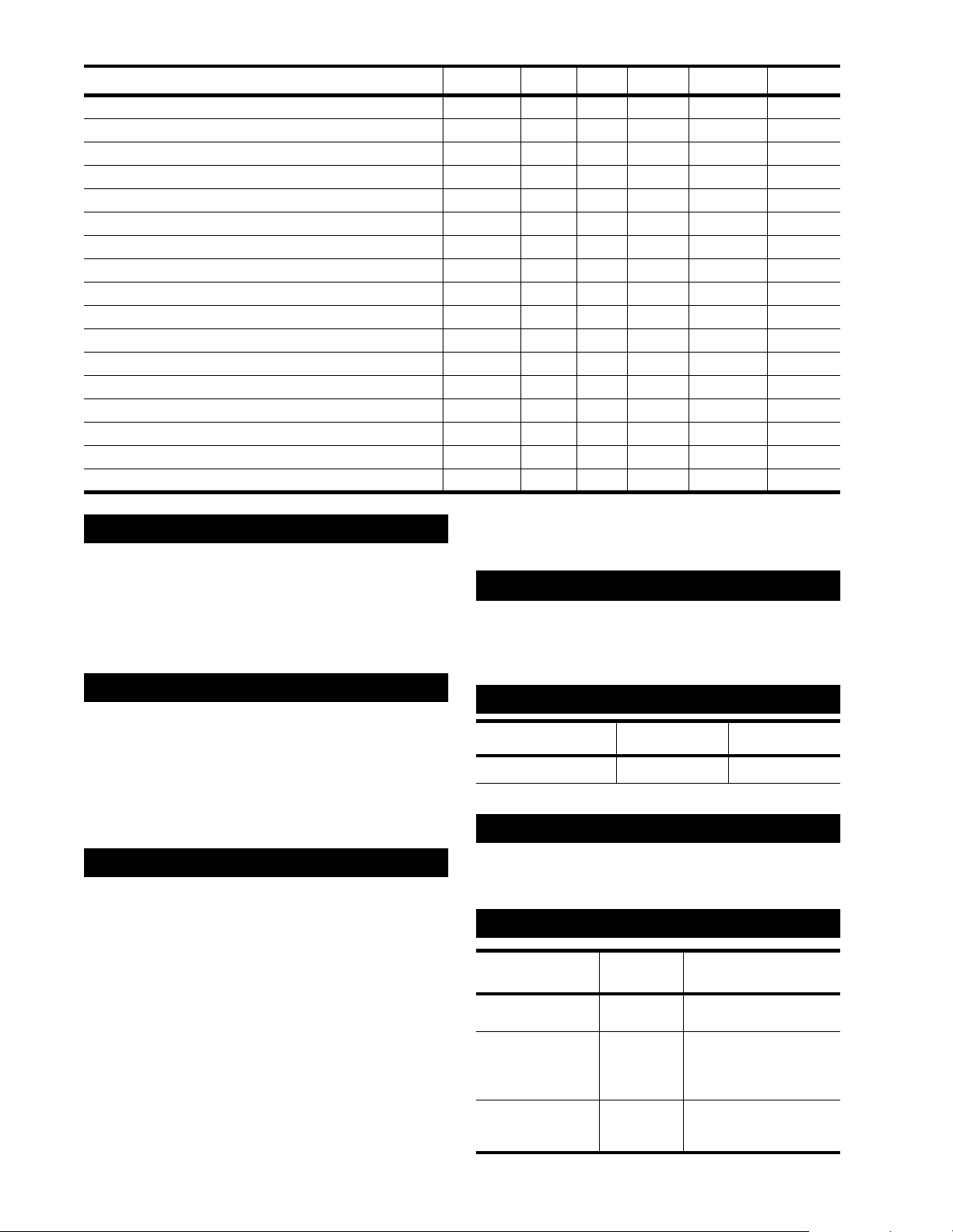

PARAMETER (C

Notes A - C

Notes 1 - 3

Absolute Maximum Ratings

Enable Time TCK to Data Out (Figure 13) t

Setup Time Data to TCK (Figure 13) t

Setup Time TDI to TCK (Figure 13) t

Setup Time TMS to TCK (Figure 13) t

Hold Time Data to TCK (Figure 13) t

Hold Time TCK to TDI (Figure 13) t

Hold Time TCK to TMS (Figure 13) t

TCK Pulse Width High (Figure 13) t

TCK Pulse Width Low (Figure 13) t

TCK Maximum Frequ ency (Figure 13) JTAG

Control Setup before the co ntrolling signal goes low (Figure 14 ) t

Control hold after the controlling signal goes high (Figure 14) t

Controlling strobe pulse wi dth (Write) (Figure 14) t

Control output delay controlling signal low to D (Read) (Figure 14) t

Control tri-state delay after controlling signal goes high (Figure 14) t

Dynamic Supply Current (F

Dynamic Supply Current (F

=52MHz, N=48) I

CK

=52MHz, N=8) I

CK

=50pF) SYMBOL MIN TYP MAX UNITS Notes

L

PZH

S

S

S

H

H

H

WH

WL

CSU

CHD

CSPW

CDLY

CZ

CC

CC

035ns1

10 ns 1

10 ns 1

15 ns 1

55 ns 1

55 ns 1

10 ns 1

55 ns 1

40 ns 1

FMAX

5ns1

5ns1

30 ns 1

230 280 mA 1

260 320 mA 1

essarily implied. Exposure to maximum ratings for extended periods may

affect device reliab i lity.

10 MHz 1

30 ns 1

20 ns 1

A. t

refers to the ri sing edge of SCK when SC K_POL=0 an d the

SFSV

falling edge when SCK_POL=1.

B. t

refers to the rising edge of SCK when SCK_POL=0 and the fall-

OV

ing edge when SCK_POL=1.

C. t

falling edge when RDY_POL=1.

1. These parameters are 100% tested at 25°C.

2. Typical specifications are the mean values of the distributions of deliverable CLC5902s tested to date.

3. Min/max ratings are based on product characterization and simulation.

Individual pa rameters a re tested as noted. Ou tgoing qu ality leve ls are

determined from tested parameters.

refers to the rising edge of RDY when RDY_POL=0 and the

RDYV

Positive Supply Voltage (VCC) -0.3V to 4.2V

Voltage on Any Input or Output Pin -0.3V to VCC+0.5V

Input Current at Any Pin ±25mA

Package Input Curre nt ±50mA

Package Dissipation a t TA=25°C 1W

ESD Susceptibility

Human Body Model

Machine Model

Soldering Temperature, Infrared, 10 seco nds 300°C

Storage Temperature -65°C to 150°C

NOTE: Absolute maximum ratings ar e limiting values, to be applie d

individually, and beyond which the serviceability of the circuit may be

impaired. Functional operability under any of these conditions is not nec-

1500V

100V

Recommended Operating Conditions

Positive Supply Voltage (VCC) 3.3V ±10%

Operating Temperature Range -40°C to +85°C

Package Thermal Resistance

Package

128 pin PQFP 39°C/W TBD°C/W

θja θjc

Reliability Information

Transistor Count 1.2 million

Ordering Information

Order Code

CLC5902VLA

CLC-DRCS-PCASM

CLC-CAPT-PCASM

Temperature

Range

-40°C to

+85°C

Description

128-pin PQFP (industrial

temperature range)

Fully loaded Diversity

Receiver Chipset eval ua tion

board and control panel software.

Data Capture board for the

DRCS with Matlab analysis

routines.

Rev. 3.05 May 27, 1999 4 ©1999 National Semiconductor Corporation

Page 5

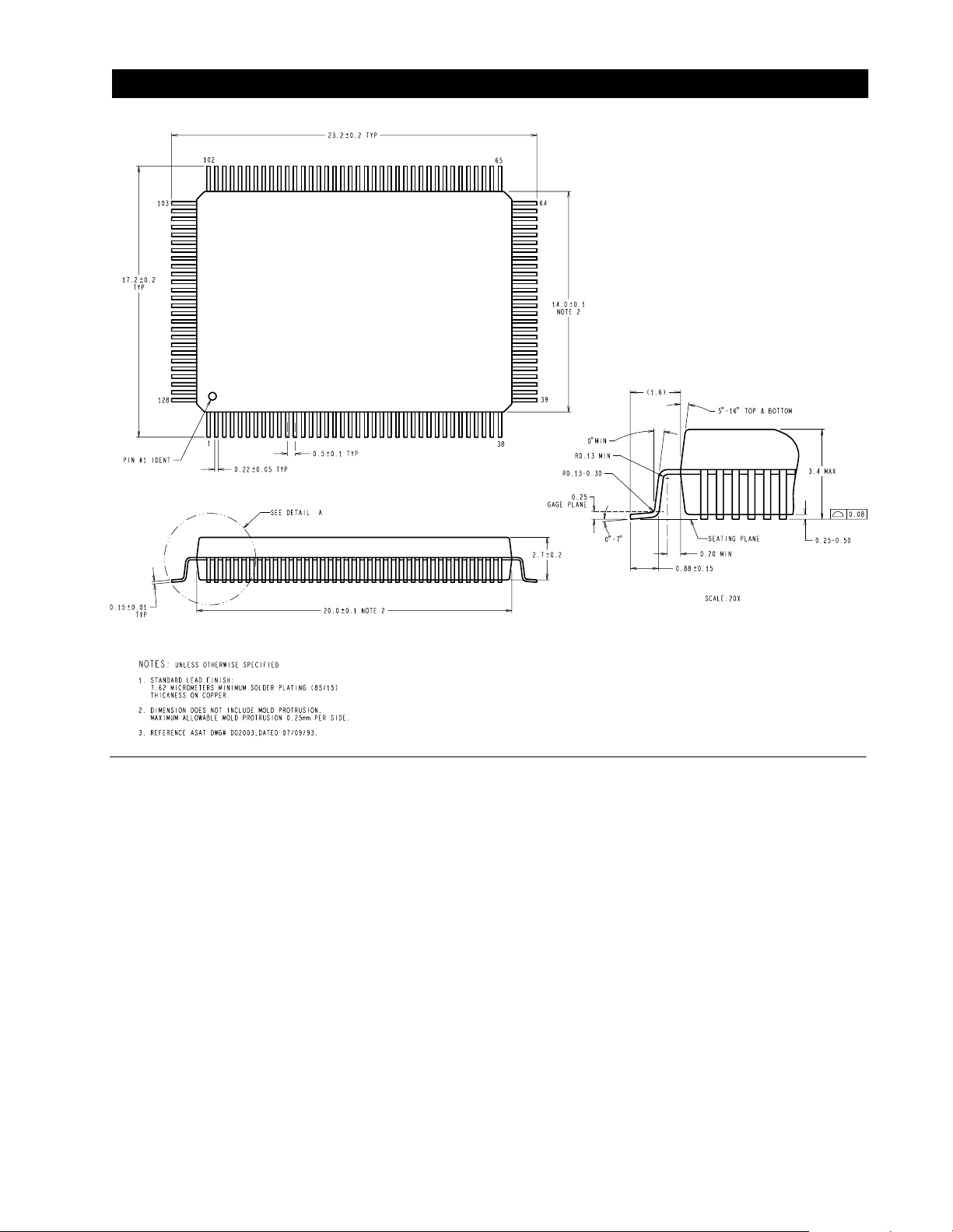

Package Dimensions

Figure 3 CLC5902 Package Dimensions

DETAIL A

Dimension are in millimeters

©1999 National Semiconductor Corporation 5 Rev. 3.05 May 27, 1999

Page 6

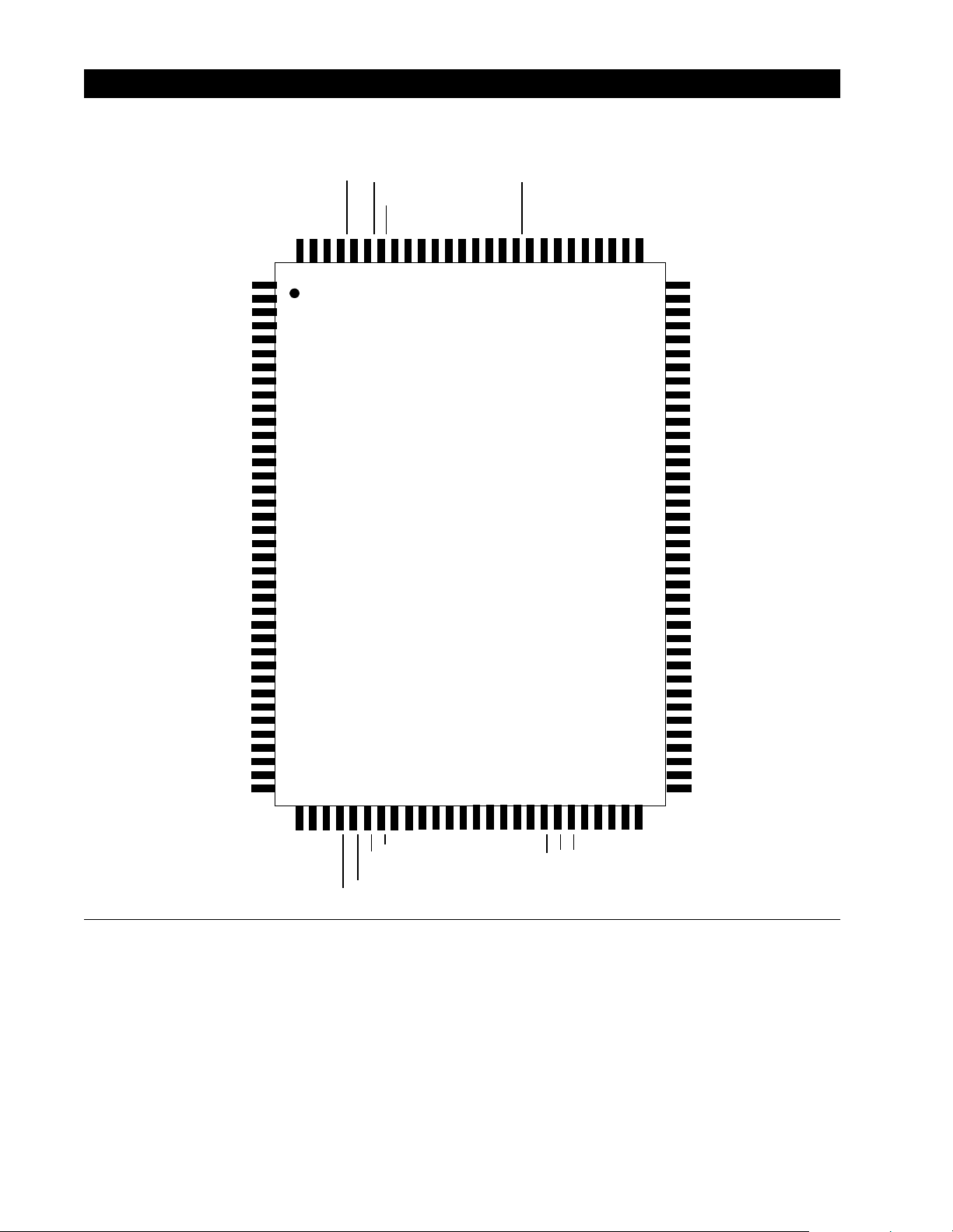

CLC5902 Pinout

AGAIN[0]

VDD

AGAIN[2]

AGAIN[1]

SCAN_EN

TRST

NC

VSS

TMS

TCK

TDI

ASTROBE

TDO

VDD

POUT_SEL[1]

VSS

POUT[1]

VDD

POUT_SEL[0]

POUT_SEL[2]

POUT_EN

POUT[0]

POUT[3]

POUT[2]

POUT[4]

VSS

NC

NC

(MSB) AIN[13]

(MSB) BIN[ 13]

VSS

AIN[12]

AIN[11]

AIN[10]

AIN[9]

AIN[8]

AIN[7]

VDD

AIN[6]

AIN[5]

AIN[4]

AIN[3]

AIN[2]

AIN[1]

AIN[0]

VSS

CK

VDD

BIN[12]

BIN[11]

BIN[10]

BIN[9]

BIN[8]

BIN[7]

VSS

BIN[6]

BIN[5]

BIN[4]

BIN[3]

BIN[2]

BIN[1]

BIN[0]

VSS

NC

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

127

126

128

414344

394042

125

124

123

122

121

120

119

116

118

115

114

117

113

CLC5902

Dual Digital Tuner/AGC

(Top View)

46

45

47

49

485051

535556

52

54

112

110

109

111

57

58

105

107

108

59

60

103

104

106

102

101

100

64

61

62

63

NC

NC

NC

NC

99

VSS

98

POUT[5]

97

POUT[6]

96

95

POUT[7]

POUT[8]

94

93

POUT[9]

92

VDD

POUT[10]

91

POUT[11]

90

VSS

89

88

POUT[12]

87

POUT[13]

86

POUT[14]

85

VDD

84

POUT[15]

VSS

83

AOUT

82

81

SFS

SCK

80

79

VDD

78

BOUT

77

RDY

VSS

76

D[0]

75

VDD

74

D[1]

73

72

D[2]

71

D[3]

70

D[4]

69

D[5]

68

VSS

NC

67

NC

66

NC

65

SI

VDD

BGAIN[1]

BGAIN[2]

MR

AGC_EN

BGAIN[0]

BSTROBE

VSS

A[6]

A[7]

A[5]

VSS

VDD

A[1]

A[3]

A[2]

A[4]

CE

RD

WR

A[0]

D[7]

D[6]

VSS

VDD

Figure 4 CLC5902 Pinout

Rev. 3.05 May 27, 1999 6 ©1999 National Semiconductor Corporation

Page 7

Pin Descriptions

Signal Pin DESCRIPTION

MR

AIN[13:0],

BIN[13:0]

AOUT

BOUT

(12mA drive)

AGAIN[2:0],

BGAIN[2:0]

ASTROBE

BSTROBE

SCK

(12mA drive)

SFS

(12mA drive)

POUT[15:0]

(12mA drive)

POUT_SEL[2:0] 112:114

POUT_EN

RDY

(12mA drive)

CK 20

SI

D[7:0]

(12mA drive)

,

45

4:10,12:18

22:28,30:36

82

78

125:127

40:42

124

43

80

81

84,86:88,90,91,

93:97,104:106,

108,109

111

77

46

62,63,69:73,75

MASTER RESET, Active low

Resets all registers within the chip. ASTROBE

INPUT DATA, Active high

2’s comp le ment input data. AIN[13] and BIN[13] are the MSBs. The data is clocked into the chi p on the

rising edge of the clock (CK) . Th e CLC595X connects direct ly to these input pins with no addit ion al logic.

SERIAL OUTPUT DA TA, Active high

The 2’s complement serial output data is transmitted on these pins, MSB first. The output bits change on

the rising edge of SCK (falling e dge if SCK_POL=1) and should be captu red on the falling edge of SCK

(rising if SCK_POL=1). These pins are tri-stated at power up and are enabled by the SOUT_EN control

register bit. See Figure 9 and Figure 29 timing diagrams. In Debug Mode AOUT=DE BUG[1],

BOUT=DEBUG[0].

OUTPUT DAT A TO DVGA, Active high

3 bit bus that sets the gain of the DVGA determined by the AGC circuit.

DVGA STROBE, Active low

Strobes the data into the DVGA. See Figure 8 and Figure 33 timing diagrams.

SERIAL DATA CLOCK, Active high or low

The serial data is clocke d out of the chi p by this clock. The active edg e of th e clock is user programmable.

This pin is tri-stated at power up and is enabled by the SOUT_EN control register bit. See Figure 9 and Figure 29 timing diagrams . In D ebu g Mode outputs an appropriate clo ck for the debug data.

SERIAL FRAME STROBE, Active high or low

The serial word strobe. This strobe delineates the words within the serial output streams. This strobe is a

pulse at the beginning of each serial word (PACKED=0) or each serial word I/Q pair (PACKED=1). The

polarity of this signal is use r programmable. This pin is tri -stated at power up and is enabl ed by the

SOUT_EN control register bit. See Figure 9 and Figure 29 timing diagrams. In Debug Mode

SFS=DEBUG[2].

PARALLEL OUTPUT DATA, Active high

The output data is transmitted on these pins in parallel format. The POUT_SEL[2..0] pins select one of

eight 16-bit output word s. T he P O U T_ EN

Mode POUT[15..0]=DEBUG[19..4].

PARALLEL OUTPUT DATA SELECT, Active high

The 16-bit output word is sel ecte d wi th these 3 pins according to Table 3. Not used in Debug Mode.

PARALLEL OUTPUT ENABLE. Active low

This pin enables the chip to output the selected output word on the POUT[15:0] pins. Not used in Debu g

Mode.

READY FLAG, Active high or low

The chip asserts this signal to identify the beginning of an output sample period (OSP). The polarity of this

signal is user programmable. This signal is typically used as an interrupt to a DSP chip, but can also be used

as a start pulse to dedicated circuitry. This pin is active regardless of the state of SOUT_EN. In Debug

Mode RDY=DEBUG[3].

INPUT CLOCK. Active high

The clock input to the chip. The AIN, BIN, and SI

of this clock.

SYNC IN. Active low

The sync input to the chip. The decimation counters, dither, and NCO phase can be synchronized by SI

This sync is clocked into the chi p on the rising edge of the input cloc k (CK ). Tie this pin high if external

sync is not required. All sample data is flushed by SI

BSTROBE

DATA BUS. Active high

This is the 8 bit control data I/O bus. Control register data is loade d int o the chip or read from the chip

through these pins. The chip will only drive output data on these pins when CE

is high.

are asserted during SI.

and BSTROBE are asserted during MR.

pin enables these outputs. POUT[15] is t he MSB. In Debug

input signals are clocked into the chip on the rising edge

.

. To properly initialize the DVGA ASTROBE and

is low , RD is low, and WR

Table 1 CLC5902 Pin Descriptions

©1999 National Semiconductor Corporation 7 Rev. 3.05 May 27, 1999

Page 8

Signal Pin DESCRIPTION

ADDRESS BUS. Active high

A[7:0] 48,50,52:57

RD

WR

CE

AGC_EN

TDO 116 TEST DATA OUT. Active high

TDI 117 TEST DATA IN. Active high with pull-up

TMS 118 TEST MODE SELECT. Active high with pull-up

TCK 119 TEST CLOCK. Active high

TRST

SCAN_EN

VSS

VDD

59

58

60

44

121

122

3,19,29,37,47,51,

61,68,76,83,89,

98,103,110,120

11,21,39,49,64,

74,79,85,92,107,

115,128

These pins are used to address the control registers within the chip. Each of the control registers within the

chip are assigned a unique address in a flat address space. A control register can be written to or read from

by setting A[7:0] to the register’s address.

READ ENABLE. Active low

This pin enables the chip to output the contents of the selected register on the D[7:0] pins when CE is also

low.

WRITE ENABLE. Active low

This pin enables the chip to writ e the value on the D[7:0] pins into the selected register when CE is also

low. This pin can also function as RD/WR

CHIP ENABLE. Active low

This control st ro b e enables the read or w r ite operation. Th e co ntents of the regis ter selected by A[7:0] will

be output on D[7:0] when RD

will be loaded w i th the contents of D[7:0] .

AGC ENABLE. Active low

When enabled thi s pin starts the AGC counter. The AGC will operate until the counter decrements to zero

then the AGC holds the last setting.

RESET. Active low with pull-up

Asynchronous reset for TAP controller. Tie low or to MR

SCAN ENABLE. Active low with pull-up

Enables access to interna l sc an re gisters. Tie high. Used for manufacturing test only!

Ground. Quantity 15.

Power. Quantity 12.

is low and CE is low. If WR is low and CE is low, then the selected register

if RD is held low.

if JTAG is not used.

Table 1 CLC5902 Pin Descriptions

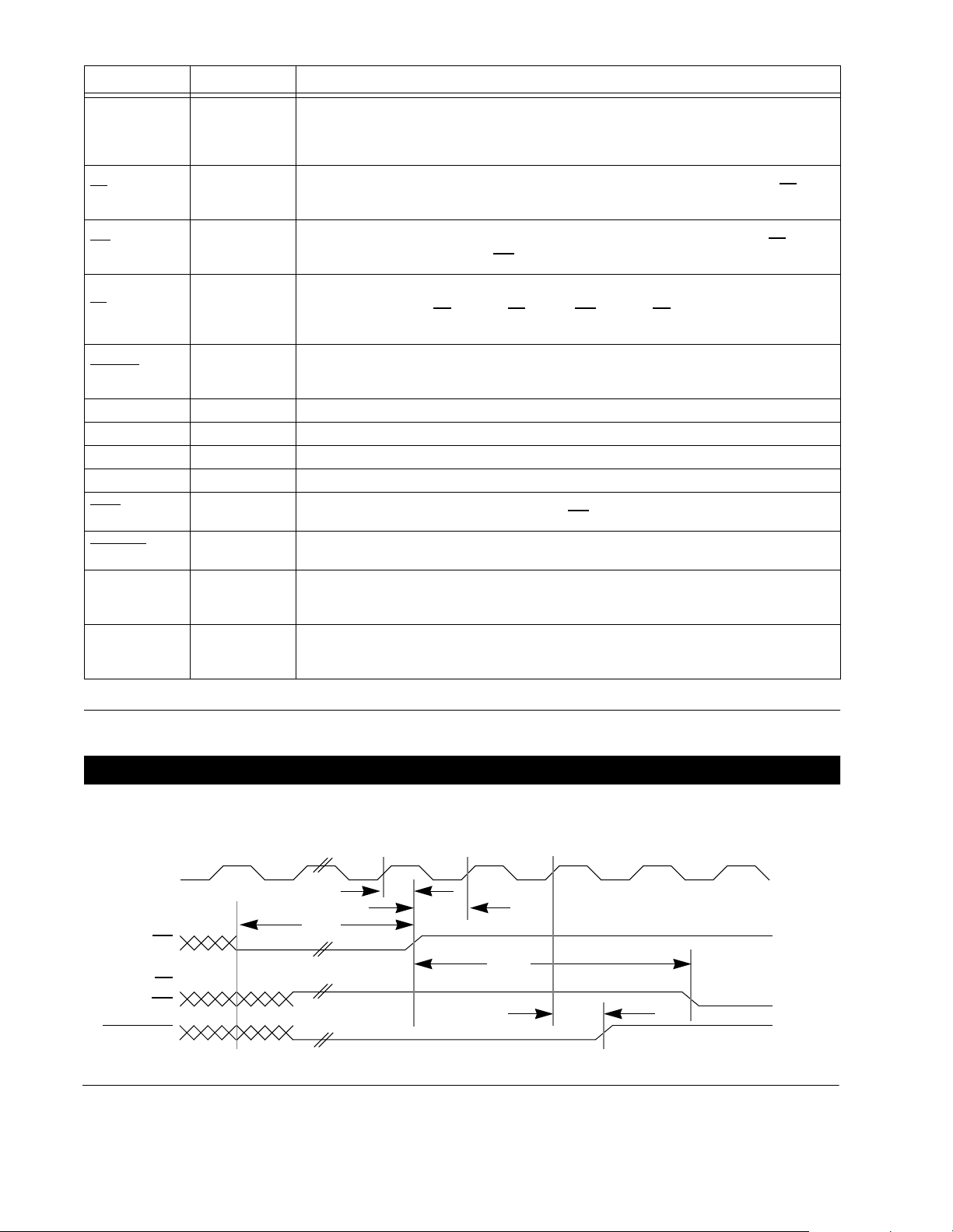

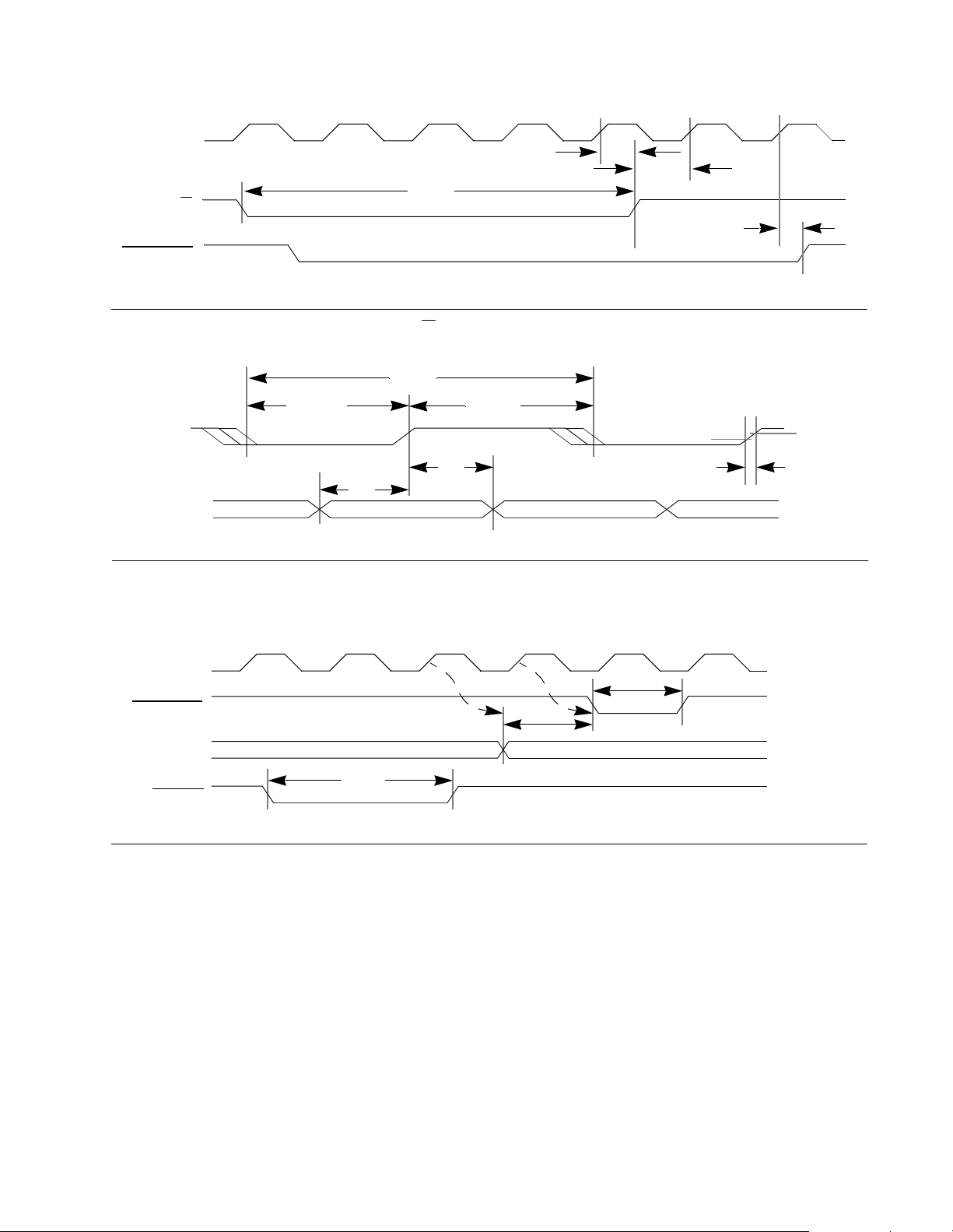

Timing Diagrams

CK

MR

RD

or WR

A|BSTROBE

Figure 5 CLC5902 Master Reset Timing

t

MRH

t

MRA

t

MRSR

t

MRIC

t

MRSU

Rev. 3.05 May 27, 1999 8 ©1999 National Semiconductor Corporation

Page 9

CK

t

SIW

SI

A|BSTROBE

Figure 6 CLC5902 Synchronization Input (SI) Timing

1/F

CK

t

CKDC

t

CK

t

HD

t

SU

A|BIN

Figure 7 CLC5902 ADC Input and Clock Timing

CKDC

t

SIH

t

SISU

t

SISR

V

V

IL

t

RF

IH

CK

A|BSTROBE

A|BGAIN[2..0]

t

ENW

AGC_EN

Figure 8 CLC5902 DVGA Interface Timing

(n-1)

t

GSU

valid (n)

t

STBPW

©1999 National Semiconductor Corporation 9 Rev. 3.05 May 27, 1999

Page 10

SCK

SCK_POL=0

SCK

SCK_POL=1

t

SFSV

SFS

SFS_POL=0

SFS

SFS_POL=1

t

OV

A|BOUT

RDY

RDY_POL=0

RDY

t

RDYW

RDY_POL=1

Figure 9 CLC5902 Serial Port Timing

POUT_EN

t

OENV

POUT[15..0]

SCK=CK/2

t

SFSV

msb msb-1 msb-2 msb-3lsb or undef

t

OV

I Output WordPrevious Q Output Word

t

OENT

Figure 10 CLC5902 Parallel Output Enable Timing

POUT_SEL[2..0]

POUT[15..0]

t

SELV

n

output (n)

n+1

output (n+1)

Figure 11 CLC5902 Parallel Output Select Timing

RDY

RDY_POL=0

RDY

RDY_POL=1

POUT[15..0]

t

RDYV

old output

new output

Figure 12 CLC5902 Parallel Output Data Ready Timing

t

SELV

n+2

output (n+2)

Rev. 3.05 May 27, 1999 10 ©1999 National Semiconductor Corpor at ion

Page 11

TCK

t

PLH,tPHL

TDO, D

TCK

t

PZH

D

TCK

t

PZL

TDO

TCK

TMS, TDI, D

Figure 13 CLC5902 JTAG Port Timing

t

PHZ

t

PLZ

t

t

WL

t

S

1/JTAG

fmax

t

H

WH

CE

WR

RD

A[7:0]

D[7:0]

CE

WR

RD

A[7:0]

D[7:0]

CE

WR

A[7:0]

D[7:0]

CE

WR

A[7:0]

D[7:0]

t

t

t

t

CSU

CSU

CSU

CSU

t

CDLY

READ CYCLE; NORMAL MODE

t

CSPW

WRITE CYCLE; NORMAL MODE

t

CDLY

READ CYCLE; RD HELD LOW

t

CSPW

WRITE CYCLE; RD HELD LOW

t

CHD

t

CHD

t

CHD

t

CHD

t

CZ

t

CZ

Figure 14 CLC5902 Control I/O Timing

©1999 National Semiconductor Corporation 11 Rev. 3.05 May 27, 1999

Page 12

Detailed Description

()

Control Interface

The CLC5902 is configured by writing control information into 148 control registers within the chip. The contents of these control registers and how to use them are

described in Table 5. The registers are written to or read

from using the D[7:0], A[7:0], CE

, RD and WR pins (see

Table 1 for pin descriptions). This interface is designed to

allow the CLC5902 to appear to an external processor as a

memory mapped peripheral. See Figure 14 for details.

The control interface is asynchronous with respect to the

system clock, CK

. This allows the registers to be written

or read at any time. In some cases this might cause an

invalid operation since the interface is not internally synchronized. In order to assure correct operation, SI

must be

asserted after the control registers are written.

The D[7:0] , A[7:0], WR

, RD and CE pins should not be

driven above the positive supply voltage.

Master Reset

A master reset pin, MR, is provided to initialize the

CLC5902 to a known c ondition and should b e strobed

after power up. This signal will clear all sample data and

all user programmed data (filter coefficients and AGC settings). All outputs will be disabled (tri-stated). ASTROBE

and BSTROBE will be asserted to initialize the DVGA

values. Table 5 describes the control reg ister default va lues.

Synchronizing Multiple CLC5902 Chips

A system containing two or more CLC5902 chips will

need to be synchronized if coherent operation is desired.

To synchronize multiple CLC5902 chips, connect all of

the sync input pins together so they can be driven by a

common sync strobe. Synchronization occurs on the rising

edge of CK when SI

all sample data will be flus hed immediatel y, the numerically controlled oscillator (NCO) phase offset will be ini-

goes back high. When SI is asserted

tialized, the NCO dither generators will be reset, and the

CIC decimation ratio will be init ialized. O nly the con fig uration data loaded into the microprocessor interface

remains unaffected.

SI

may be held low as long as desired after a minimum of

4 CK periods.

Input Source

The input crossbar switch allows either AIN, BIN, or a

test register to be routed to the channel A or channel B

AGC/DDC. The AGC outputs, AGAIN and BGAIN, are

not switched. If AIN and BIN are exchanged the AGC

loop will be open and the AGCs will not function properly .

AIN and BIN should meet the timing requirements shown

in Figure 7.

Selecting the test register as the input source allows the

AGC or DDC operation to be verified with a known input.

See the test and diagnostics section for further discussion.

Down Converters

A detailed block diagram of each DDC chann el is shown

in Figure 15. Each down converter uses a complex NCO

and mixer to quadrature downconvert a signal to base-

band. The “FLOAT TO FIXED CONVERTER” treats the

15-bit mixer output as a mantissa and the AGC output,

EXP, as a 3-bit exponent. It performs a bit shift on the data

based on the value of EXP. This bit shifting is used to

expand the compressed dynam ic range re sulting from the

DVGA operation. The DVGA gain is adjusted in 6dB

steps which are equivalent to each digital bit shift.

The exponent (EXP) can be forced to its maximum value

by setting the EXP_INH bit. If is the DDC input,

the signal after the “FLOAT TO FIXED CONVERTER” is

x3n() xinn() ωn()cos• 2

for the I component. Changing the ‘cos’ to ‘sin’ in this

equation will provide the Q component.

xinn

•=

EXP

EQ. 1

(from AGC)

x

in

MUXA

Data @ F

= FS (F

FREQ_A

PHASE_A

EXP

n()

14

CK

SAMPLE

)

17 17

COS

SIN

NCO

EXP_INH

GAIN_A

8 TO 2K

SHIFT UP

SAT & ROUND

Data @ FCK/N Data @ FCK/N*2

N = DEC + 1

F1_COEF

21

F1 FILTER

21

DECIMATE BY 2

21

21

SAT & ROUND

DEC_BY_4

F2_COEF

I

SAT

2 OR 4

F2 FILTER

DECIMATE BY

Data @ FCK/N*2*F2_DEC

= OFS (Output F

Q

SAMPLE

TO

OUTPUT

CIRCUIT

)

CIC FILTER

DEC

DECIMATE BY

SCALE

3

EXP

EXPONENT

15

ROUND

15

22

FLOAT

TO FIXED

CONVERTER

SHIFT UP

22

x3n()

Figure 15 CLC5902 Down Converter, Channel A (Channel B is identical)

Rev. 3.05 May 27, 1999 12 ©1999 National Semiconductor Corpor at ion

Page 13

The “FLOAT TO FIXED CONVERTER” circuit expands

the dynamic range compression performed by the DVGA.

Signals from this point onward extend across the full

dynamic range of the signals applied to the DVGA input.

This allows the AGC to operate continuously through a

burst without producin g artifacts in the s ignal due to th e

settling response of the decim ation filters after a 6dB

DVGA gain adjustment. For example, if the DVGA input

signal were to increase causing the ADC output level to

cross the AGC threshold level, the gain of the DVGA

would change by -6dB. The 6dB step is allowed to propagate through the ADC and mixers and is compensated out

just before the filtering. The accuracy of the compensation

is dependent on the accuracy of the DVGA gain step. This

operating mode requ ires 21 bits (14- bit ADC output + 7bit shift) to represent the full linear dynamic range of the

signal. The output word must be set to either 24-bit or 32bit to take advantage of the entire dynamic range available. The CLC5902 can also be configured to output a

floating point format with up to 138dB of numerical resolution using only 12 output bits.

The “SHIFT UP” circuit will be discussed in the Four

Stage CIC filter section on page 14.

A 4-stage cascaded-integrator-comb (CIC) filter and a

two-stage decimate by 4 or 8 fi nite i mpulse res ponse (FIR)

filter are used to lowpass filter and isolate the desired signal. The CIC filter reduces the sample rate by a programmable factor ranging from 8 to 2048 (decimation ratio).

The CIC outputs are followed by a gain stage and then followed by a two-stage decimate by 4 or 8 filter. The gain

circuit allows the user to boost the gain of weak signals by

up to 42 dB in 6 dB steps. It also rounds the signal to 21

bits and saturates at plus or minus full scale.

The first stage of the two stage filter is a 21-tap, symmetric

decimate by 2 FIR filter (F1) with progra mmable 16 bit

tap weights. The coefficients of the first 11 taps are downloaded to the chip as 16 bit words. Since the filter is a symmetric configuration only the first 11 coefficients must be

loaded. The F1 section on page 15 provides a ge neric set

of coefficients that compensate for the rolloff of the CIC

filter and provide a passband flat to 0.01dB with 70 dB of

out of band rejection. A second coefficient set is provided

that has a narrower output passband and greater out-ofband rejection. The second set of coefficients is ideal for

systems such as GSM where far-image rejection is more

important than adjacent channel rejection.

The second stage is a 63 tap decimate by 2 or 4 program mable FIR filter (F2) also with 16 bit tap weights. Filter

coefficients for a flat response from -0.4F

to +0.4FS of

S

the output sample rate with 80dB of out of band rejection

are provided in the F2 sec tion. A second set of F2 co efficients is also provided to enhance performance for GSM

systems. The user can also design and download their own

final filter to customize the channel’s spectral response.

Typical uses of programmable filter F2 include matched

(root-raised cosine) filt ering, o r filtering to generate oversampled outputs with greater out of band rejection. The 63

tap symmetrical filter is downloaded into the chip as 32

words, 16 bits each. Saturation to plus or minus full scale

is performed at the output of F1 and F2 to clip the signal

rather than allow it to roll over.

The Numerically Controlled Oscillator

The tuning frequency of each down converter is specified

as a 32 bit word (.02Hz resolution at CK=52MHz) and the

phase offset is specified as a 16 bit word (. 005°). These

two parameters are applied to the Numerically Controlled

Complex NCO Output

0

-20

-40

-60

-80

Magnitude (dB)

-100

-120

-140

-160

-0.5 -0.4 -0.3 -0.2 -0.1 0 0.1 0.2 0.3 0.4 0.5

Frequency Normalized to F

S

(a) Befo re Phase Dithering

0

-20

-40

-60

-80

Magnitude (dB)

-100

-120

-140

-160

-0.5 -0.4 -0.3 -0.2 -0.1 0 0.1 0.2 0.3 0.4 0.5

Complex NCO Output

Frequency Normalized to F

(b) After Phase Dithering

S

Figure 16 Example of NCO spurs due to phase truncation

©1999 National Semiconductor Corporation 13 Rev. 3.05 May 27, 1999

Page 14

Oscillator (NCO) circuit to generate sine and cosine signals used by the digital mixer. The NCOs can be synchronized with NCOs on other chips via the sync pin SI

. This

allows multiple down converter outputs to be coherently

combined, each with a unique phase and amplitude.

The tuning frequency is set by loadin g the FREQ re gister

according to the formu la FREQ = 2

the desired tuning frequency and F

32

F/FCK, where F is

is the chip’s clock

CK

rate. FREQ is a 2’s complement word. The range for F is

from -F

/2 to +FCK(1-2

CK

-31

)/2.

In some cases the sampling process causes the order of the

I and Q components to be reversed. Shoul d th is occur simply invert the polarity of the tuning frequency F.

The 2’s complement format represents full-scale negative

as 10000000 and full-scale positive as 01111111 fo r an 8bit example.

The 16 bit phase offset is set by loading the PHASE register according to the formula PHASE = 2

is the desired phase in radians ranging between 0 and 2

16

P/2π, where P

π.

PHASE is an unsigned 16-bit number. P ranges from 0 to

-16

2

π(1-2

).

Phase dithering can be enabled to reduce the spurious signals created by the NCO due to p hase truncat ion. This

truncation is unavoidable sin ce the frequ ency reso lution is

much finer than the phase resolution. With dither enabled,

spurs due to phase truncation are below -100 dBc for all

frequencies and phase offsets. Each NCO has its own

dither source and the initial state of one is maximally offset with respect to the other so that they are effectively

uncorrelated. The phase dither sources are on by default.

They are independently controlled by the DITH_A and

DITH_B bits. The amplitude resolution of the ROM creates a worst-case spur amplitude of -101dBc rendering

amplitude dither unnecessary.

Complex NCO Output

Phase Dither Disabled

0

NCO frequency swept through FS/8

-20

-40

-60

-80

Magnitude (dB)

-100

-120

-140

-160

-0.5 -0.4 -0.3 -0.2 -0.1 0 0.1 0.2 0.3 0.4 0.5

Frequency Normalized to F

S

Figure 17 NCO Spurs due to Phase Quantization

Complex NCO Output

Phase Dither Enabled

0

-20

-40

-60

-80

Magnitude (dB)

-100

-120

-140

The spectrum plots in Figure 16 show the effectiveness of

phase dither in reduc ing NCO sp urs due to phas e truncation for a worst-case example (just below F

/8). With

S

-160

-0.5 -0.4 -0.3 -0.2 -0.1 0 0.1 0.2 0.3 0.4 0.5

Frequency Normalized to F

S

dither off, the spur is at -86.4dBFS. With dither on, the

spur is below -125dBFS, disappearing into the noise floor.

Figure 18 Worst Case Amplitude Spur, NCO at FS/8

This spur is spread into the noise floo r which results in an

SNR of -83.6dBFS.

Four Stage CIC Filter

Figure 17 shows the spur levels as the tuning frequency is

scanned over a narrow portion of th e freq uency rang e. The

spurs are again a result of phase quantization but their

locations move about as the frequency scan progresses. As

before, the peak spur level drops when dith ering is

enabled. When dither is enabled and the fundamental frequency is exactly at F

/8, the worst-case spur due to

S

amplitude quantization can be observed at -101dBc in Figure 18.

Rev. 3.05 May 27, 1999 14 ©1999 National Semiconductor Corpor at ion

The mixer outputs are decimated by a factor of N in a four

stage CIC filter. N is programmable to any integer

between 8 and 2048. Decimation is programmed in the

DEC register where DEC = N - 1. The programmable dec-

imation allows the chip’s usable output bandwidth to range

from about 2.6kHz to 1.3MHz when the input data rate

(which is equal to the chip’s clock rate, F

) is 52 MHz. A

CK

block diagram of the CIC filter is shown in Figure 19.

Page 15

SCALE

GAIN 2

GAIN_A

=

h1n() n, 0 … 20,,=

DATA

IN

Data @ F

= FS (F

22

CK

SAMPLE

66

SHIFT UP

)

22-bit input to SHIFT_UP is aligned

at the bottom of the 66-bit path when SCALE=0.

Figure 19 Four-stage decimate by N CIC filter

The CIC filter has a gain equal to N4 (filter decimation^4)

which must be compensated for in the “SHIFT UP” circuit

shown in Figure 19 as well as Figure 15. This circuit has a

gain equal to 2

40. This circuit divides the input signal by 2

(SCALE-44)

, where SCALE ranges from 0 to

44

providing

maximum headroom through the CIC filter. For optimal

noise performance the SCALE value is set to increase this

level until the CIC filter is just below the point of distortion. A value is normally calculated and loaded for

SCALE such that . The

GAIN

SHIFTUP

GAIN

⋅ 1≤

CIC

actual gain of the CIC filter will only be unity for powe rof-two decimation values. In other cases the gain will be

somewhat less than unity.

Channel Gain

The gain of each channel can be boosted up to 42 dB by

shifting the output of the CIC filter up by 0 to 7 bits prior

to rounding it to 21 bits. For channel A, the gain of this

stage is: , where GAIN_A ranges from 0

to 7. Overflow due to the GAIN circuit is saturated

(clipped) at plus or minus full scale. Each channel c an be

given its own GAIN setting.

First Programmable FIR Filter (F1)

The CIC/GAIN outputs are followed by two stages of filtering. The first stage is a 21 tap decimate-by-2 symm etric

FIR filter with programmable coefficients. Typically, this

filter compensates for a slight droop induced b y the CIC

filter. In addition, it often provides stopband assistance to

F2 when deep stop bands are required. The filter coefficients are 16-bit 2’s complement numbers. Unity gain will

be achieved through the filter if the sum of the 21 coeffi-

cients is equal to 2

introduce a gain equal to (sum of coefficients)/2

coefficients are identified as coefficients

The coefficients are symmetric, so only the first 11 are

loaded into the chip.

Two example sets of coefficients are provided here. The

first set of coefficients, referred to as the standard set

(STD), compensates for the droop of the CIC filter providing a passband which is flat (0.01 dB ripple) over 95% of

the final output bandwid th with 7 0dB of out- of-band rej ection (see Figure 20). Th e filter ha s a gain of 0.999 an d is

16

. If the sum is not 216, then F1 will

16

. The 21

where is the center tap.

h110()

DATA

OF N

DECIMATE

BY FACTOR

N = DEC + 1

Data @ FCK/N

OUT

symmetric with the following 11 unique taps (1|21, 2|20,

..., 10|12, 11):

29, -85, -308, -56, 1068, 1405 , -2056, -6009,

1303, 21121, 32703

Frequency Response of F1 Using STD Set

0

−10

−20

−30

−40

−50

Magnitude (dB)

−60

−70

−80

−90

−100

0 0.1 0.2 0.3 0.4 0.5

Frequency Normalized To Filter Input Sample Rate

Figure 20 F1 STD frequency response

The second set of coefficients (GSM set) are intended for

applications that need deeper stop bands or need oversampled outputs. These requirements are common in cellular

systems where out of band rejection requirements can

exceed 100dB (see Figure 21). They are useful for wideband radio architectures where the channelization is done

after the ADC. These filter coefficients introduce a gain of

0.984 and are:

-49, -340, -1008, -1617, -1269, 425, 3027, 6030,

9115, 11620, 12606

Second Programmable FIR Filter (F2)

The second stage decimate by two o r four filter also uses

externally downloaded filter coefficients. The filter coefficients are 16-bit 2’s complement numbers. Unity gain will

be achieved through the filter if the sum of the 63 coeffi-

cients is equal to 2

introduce a gain equal to (sum of coefficients)/2

The 63 coefficients are identified as

where is the center tap. The coefficients are sym-

h

31()

2

metric, so only the first 32 are loaded into the chip.

16

. If the sum is not 216, then the F2 will

16

.

h2n() n 0 … 62,,=,

©1999 National Semiconductor Corporation 15 Rev. 3.05 May 27, 1999

Page 16

Figure 21 F1 GSM frequency response

0 0.1 0.2 0.3 0.4 0.5

−120

−100

−80

−60

−40

−20

0

Frequency Response of F1 Using GSM Set

Magnitude (dB)

Frequency Normalized To Filter Input Sample Rate

Figure 22 F2 STD frequency response

0 0.1 0.2 0.3 0.4 0.5

−100

−90

−80

−70

−60

−50

−40

−30

−20

−10

0

Frequency Response of F2 Using STD Set

Magnitude (dB)

Frequency Normalized To Filter Input Sample Rate

5

0

−5

−10

−15

−20

−25

Magnitude (dB)

−30

−35

−40

−45

−50

0 0.1 0.2 0.3 0.4 0.5

Frequency Response of F2 Using GSM Set

Frequency Normalized To Filter Input Sample Rate

Figure 23 F2 GSM frequency response

An example filter (STD F2 coefficients, see Figure 22)

with 80dB out-of-band rej ection, gai n of 1.0 0, and 0.03 dB

peak to peak passband ripple is created by this set of 32

unique coefficients:

-14, -20, 19, 73, 43, -70, -82, 84, 171, -49, -269, 34, 374, 192, - 449,

-430, 460,751, -357, -1144, 81, 1581, 443, -2026,

-1337, 2437, 2886,

-2770, -6127, 2987, 20544, 29647

The filter coefficients of both filters can be used to tailor

the spectral response to the user’s needs. For example, the

first can be loaded with the standard set to provide a flat

response through to the second filter. The latter can then

be programmed as a Nyquist (typically a root-raisedcosine) filter for matched filtering of digital data.

Combined Frequency Response of CIC/F1/F2 Using STD Set

0

FCK = 52MHz

Decimation = 192

OFS = 270.83kHz

−50

Magnitude (dB)

−100

−150

0 500 1000 1500 2000 2500 3000

Frequency (KHz)

Figure 24 CIC, F1, & F2 STD frequency response

A second set of F2 co efficients (G SM set , see Figure 23)

suitable for meeting the stringent wideband GSM requirements with a gain of 0.999 are:

-536, -986, 42, 962, 869, 225, 141, 93, -280, -708,

-774, -579, -384,

-79, 536, 1056, 1152, 1067, 789, 32, -935, -1668,

-2104, -2137, -1444,

71, 2130, 4450, 6884, 9053, 10413, 10832

Rev. 3.05 May 27, 1999 16 ©1999 National Semiconductor Corpor at ion

The complete channel filter response for standard coefficients is shown in Figure 24. Pass band fl atness is sh own in

Figure 25.

The complete filter response for GSM coefficients is

shown in Figure 26.

GSM Passband flatness is shown in Figure 27.

The mask shown in Figure 26 is derived from the ET SI

GSM 5.05 specifications for a normal Basestation Transceiver (BTS). For interferers, 9dB was added to the carrier

to interference (C/I) ratios. For blockers , 9dB was added to

the difference between the blocker level an d 3dB above

the reference sensitivity level.

Page 17

Combined Frequency Response of CIC/F1/F2 Using STD Set

0.1

0.08

0.06

0.04

0.02

0

−0.02

Magnitude (dB)

−0.04

−0.06

−0.08

−0.1

0 50 100 150 200 250

Frequency (KHz)

Overall Channel Gain

The overall gain of the chip is a function of the amount of

decimation (N), the settings of the “SHIFT UP” circuit

(SCALE), the GAIN setti ng, the sum o f the F 1 coefficients, and the sum of the F2 coefficients. The overall gain

is shown below in Equation 2.

G

DDC

1

-- -

DEC 1+()

=

2

SCALE 44– AGAIN 1 EXP_INH–()⋅–[]

2

⋅

GAIN

2

⋅

GF1G

⋅⋅

F2

4

EQ. 2

Figure 25 CIC, F1, & F2 STD Passband Flatness

Combined Frequency Response of CIC/F1/F2 Using GSM Set

0

FCK = 52MHz

−20

−40

−60

Magnitude (dB)

−80

−100

0 500 1000 1500 2000 2500 3000

Frequency (KHz)

Decimation = 192

OFS = 270.83kHz

Figure 26 CIC, F1, & F2 GSM frequency response

Combined Frequency Response of CIC/F1/F2 Using GSM Set

1

0.5

0

−0.5

Magnitude (dB)

−1

Where:

21

h1i()

∑

i 1=

----------------------=

G

F1

16

2

EQ. 3

and:

63

h2i()

∑

i 1=

----------------------=

G

F2

16

2

EQ. 4

It is assumed that the DDC output words are treated as

fractional 2’s complement words. The numerators of

and equal the sums of the impulse response coeffi-

G

F2

G

F1

cients of F1 and F2, respectively. For the STD and GSM

sets, and are nearly equal to unity. Observe that

G

F1

the term in EQ. 2 is cancelled by the DVGA oper-

AGAIN

G

F2

ation so that the entire gain of the DRCS is independent of

1

the DVGA setting when EXP_INH=0. The appearing in

-- 2

EQ. 2 is the result of the 6dB conversion loss in the mixer.

1

For full-scale square wave inputs the should be set to 1

-- 2

to prevent signal distortion.

Data Latency and Group Delay

−1.5

The latency from a sync event to data output is approximately 8N CK periods for F2 decimation by 2 and 2 4N

−2

0 20 40 60 80 100

Frequency (KHz)

CK periods for F2 decimation by 4. Actual non-zero data

output can be further delayed depending on the F1 and F2

filter coefficients.

Figure 27 CIC, F1, & F2 GSM Passband Flatness

Group Delay is approximately 90N CK periods for F2

decimation by 2 or 4.

©1999 National Semiconductor Corporation 17 Rev. 3.05 May 27, 1999

Page 18

Output Modes

Note

Note

DIVIDE

BY

BOUT

AOUT

16

RATE

POUT_SEL[2..0]

POUT[15..0]

CH BCH A

SERIALIZER AND

POUT_EN

CK

SCK

3

RDY

MUX

NUMBER FORMAT

CONTROL

FORMAT

TDM FORMATTER

POLARITY INVERT

MUX_MODE

PACKED

RDY_POL, SCK_POL, SFS_POL

Figure 28 CLC5902 output circuit

SFS

SCK

After processing by the DDC, the data is then formatted

for output.

All output data is two’s complement.

Output formats include truncation to 8 or 32 bits, rounding

to 16 or 24 bits, and a 12-bit floating point format (4-bit

exponent, 8-bit mant issa, 138dB numeri c range). This

function is performed in the OUTPUT CIRCUIT shown in

Figure 28.

Serial Outputs

The CLC5902 provides a serial clock (SCK), a frame

strobe (SFS) and two data lines (AOU T and BOUT) to

output serial data. The MUX_MOD E control register

specifies whether the two c hannel o utputs are transmi tted

on two separate serial pins, or multiplex ed on to o ne pin in

a time division multiplexed (TDM) format. Separate output pins are not provided for the I and Q halves of complex data. The I and Q outputs are a lways multiplexed

onto the same serial pin. The I-compon ent is output first,

followed by the Q-component. By setting the PACKED

mode bit to ‘1’ a complex pair may be treated as a single

double-wide word. The RDY signal is used to id entify th e

first word of a complex pair of the TDM formatted output.

The TDM modes are summarized in Table 2.

The channel outputs are accessible through serial output

pins and a 16-bit parallel output port. The RDY pin is provided to notify the user that a new output sample period

(OSP) has begun. OSP refers to the interval between output samples at the decimated output rate. For example, if

the input rate (and clock rate) is 52 MHz and the overall

decimation factor is 192 (N=48, F2 decimation=2) the

OSP will be 3.69 microseconds which corresponds to an

output sample rate of 270.83kHz. An OSP starts when a

sample is ready and stops when the next one is ready.

pin.

The serial outputs power up in a tri-state

condition and must be enabled when the chip

is configured. Parallel outputs are enabled by

the POUT_EN

MUX_MODE

0 OUT

1 OUTA, OUT

SERIAL OUTPUTS

AOUT BOUT

A

B

OUT

LOW

B

Table 2 TDM Modes

The serial outputs use the format shown in Figure 29. Figure 29(a) shows the standar d output mode (the PACKED

mode bit is low). The chip clocks the frame and data out of

the chip on the rising edg e of SCK (or falling edge if the

SCK_POL bit in the input control register is set high).

Data should be captured on the falling edge of SCK (rising if SCK_POL=1). The chip sends the I data first by setting SFS high (or low if SFS_POL in the input control

register is set high) for one clock cycle, and then transmitting the data, MSB first, on as many SCK cycles as are

necessary. Without a pause, the Q data is transferred next

as shown in Figure 29(a). If the PACKED control bit is

high, then the I and Q components are sent as a double

length word with only one SFS strobe as shown in Figure

29(b). If both channels are multiplexed out the same serial

pin, then the subsequent I/Q channel words will be transmitted immediately following the first I/Q pair as shown

in Figure 29(c). Figure 29(c) also shows how the RDY

signal can be used to identify the I and Q channels in the

TDM serial transmission.The se rial output rate is programmable using the RATE register as a integer division

of the input clock , t h e di v isi on rat io ranging from 1 to 25 6.

The serial interface will not work properly if the programmed rate of SCK is insufficie nt to clo ck out al l the

bits in one OSP.

Serial Port Output Number Formats

Several numeric formats are selectable using the FORMAT control re gister. The I/Q samples can be rounded to

16 or 24 bits, or truncated to 8 bits. Th e packed mode

works as described above for these fixed point formats. A

floating point format with 138dB of dynamic range in 12

bits is also provided. The mantissa (m) is 8 bits and the

exponent (e) is 4 bits. The MSB of each segment is trans-

Rev. 3.05 May 27, 1999 18 ©1999 National Semiconductor Corpor at ion

Page 19

SCK

SFS

clock stops and data is zero after transfers are complete

AOUT

I15 I14

I1 I0 Q15 Q14

Q1 Q0

(a) UNPACKED MODE, FRAME SYNC AT THE START OF EACH WORD

clock stops and data is zero after transfers are complete

SCK

SFS

I15

AOUT

I14 I1 I0 Q15 Q14

Q1 Q0

(b) PACKED MODE, ONE FRAME SYNC AT THE START OF EACH DOUBLE-WORD TRANSFER

RDY

SFS

AOUT

SFS

AOUT

leading edge of RDY aligns with leading edge of SFS

Output Sample Period (OSP)

IA QA

IA QA IB QB IA QA IB QB

MUX_MODE=0

MUX_MODE=1

RDY is 4 CK periods wide

IA QA

(c) ONE OR TWO CHANNEL MUX MODES (PACKED MODE IS ON)

clock stops and data is zero after transfers are complete

SCK

SFS

AOUT

mI7 eI3

mI0

mI6 eI2

eI0

eQ3

(d) FLOATING POINT FORMAT

Figure 29 Serial output formats. Refer to Figure 9 for detailed timing information

mitted first. When this mode is selected, the I/Q samples

are packed regar dless of the s tate of M UX_MODE , and

the data is sent as mI/eI/eQ/mQ which allows the two

exponents to form an 8-bit word. This is shown in Figure

can be formatted as floating point numbers with an 8-bit

mantissa and a 4 bit exponent. F or t he fixed - po in t formats ,

the valid bits are justified into the MSBs of the registers of

Table 3 and all other bits are set to zero. For the floating

29(d). For all formats, once the defined length of the word

is complete, SCK stops toggling .

POUT_SEL

Normal Register

Parallel Outputs

Output data from the channels can also be taken from a

16-bit parallel port. A 3-bit word a pplied to the

POUT_SEL[2:0] pins determines which 16-bit segment is

multiplexed to the parallel port. Table 3 defines this mapping. To allow for bussing of multiple chips, the parallel

port is tri-stated unless POUT_EN

is low. The RDY sig-

nal indicates the start of an OSP and that new data is ready

at the parallel output. The user has one OSP to cycle

through whichever registers are needed. The RAT E register must be set so that each OSP is at least 5 SCK periods.

0 IA upper 16 bits 0000/eIA/mIA

1 IA lower 16 bits 0 x0000

2 QA upper 16 bits 0000/eQA/mQA

3 QA lower 16 bits 0x0000

4 IB upper 16 bits 0000/eIB/mIB

5 IB lower 16 bits 0x0000

6 QB upper 16 bits 0000/eQ B/ mQB

7 QB lower 16 bits 0x0000

Table 3 Register Selection for Parallel Output

Parallel Port Output Numeric Formats

The I/Q samples can be rounded to 16 or 24 bits or the full

32 bit word can be read. By setting the word size to 32 bits

it is possible to read out the top 16 bits and only observe

the top 8 bits if desired. Additionally, the output samples

point format, the valid bits are placed in the upper 16 bits

of the appropriate channel register using the format 0000/

eI/mI for the I samples.

eQ0 mQ0

mQ7

Contents

Register Contents

Floating Point

©1999 National Semiconductor Corporation 19 Rev. 3.05 May 27, 1999

Page 20

AGC

Figure 30 Output Gain Scaling vs. Input Signal

Input Power

ADC Output

ADC Full Scale

AGC Threshold

Deadband+Hysteresis

Output Power

D

D

C

O

u

t

p

u

t

Diversity Receiver

A

G

C

O

perates

O

ver T

h

i

s

R

an

g

e

Chipset Full Scale

Figure 31 AGC Setup.

DVGA Input Power

DVGA Output Power

Deadband

Hysteresis=Deadband-6dB

Reference

6dB

6dB

Setpoint

The CLC5902 AGC proces so r monitors the out put l evel of

the ADC and servos it to the desired setpoint. The ADC

input is controlled by the DVGA to maintain the proper

setpoint level. DVGA operation results in a compression

of the signal through the ADC. The DVGA signal com pression is reversed in the CLC5902 to provide > 120dB

of linear dynamic range. This is illustrated in Figure 30.

6dB steps the deadband should always be g reater than 6d B

to prevent oscillation. An increased deadband value will

reduce the amount of AGC operation. A decreased deadband value will increase the amount of AGC operation but

will hold the ADC output closer to the setpoint. The

threshold should be set so th at transien ts do no t cause sustained overrange at the ADC inputs. The thres hold setting

can also be used to set the ADC input near its optimal performance level.

The AGC may be configured to free run, o perate for a pro grammable period of ti me ( burst mode), or sto p r unn in g.

a burst start pulse is applied to the AGC_EN

pin in burst

mode, the AGC will free run for AGC_HOLD_COUNT

CK periods then freeze. At the beginning of the next burst

either the freeze value is maintained or an initial condition

is set from AGC_IC_A|B based on

AGC_RESET_EN.

Allowing the AGC to free run should be appropriate for

most applications. Table 4 shows the AGC mode control

bits.

AGC Mode AgcHldIC AgcRstEn AgcForce

Free Run 0 0 1

Burst, hold previous value 0 0 0

Burst, use initial conditions 0 1 0

Manual 100

If

In order to use the AGC the DRCS Control Panel software

should be used to calculate the programmable parameters.

To generate these parameters only the desired setpoint,

deadband+hysteresis, and loop time constant need to be

supplied. All subsequent cal cul ati on s ar e perf orm ed by t he

software. Complete details of the AGC operation are provided in an appendix but are not required reading.

AGC setpoint and deadband+hysteresis are illustrated in

Figure 31. The loop time constant is a measure of how fast

the loop will track a changing signal. Values down to

approximately 1.0 microsecond will be stable with the second order LC noise filter. Since the DVGA operates with

Rev. 3.05 May 27, 1999 20 ©1999 National Semiconductor Corpor at ion

Table 4 AGC Operating Modes

Power Management

The CLC5902 can be placed in a low power (static) state

by stopping the input clock. To prevent this from placing

the CLC5902 into une xpected state s, the SI

CLC5902 should be asserted prior to disabling the input

clock and held asserted until the inp ut cloc k has return ed

to a stable condition.

pin of the

Page 21

Test and Diagnostics

The CLC5902 supports IEEE 1149.1 compliant JTAG

Boundary Scan for the I/O’s. The following pins are used:

TRST (test reset)

TMS (test mode select)

TDI (test data in)

TDO (test data out)

TCK (test clock)

The following JTAG instructions are supported:

Instruction Description

BYPASS Connects TDI directly to TDO

EXTEST Drives the ‘extest’ TAP controller output

IDCODE Connects the 32-bit ID register to TDO

SAMPLE/PRELOAD Drives the ‘samp_load’ TAP controller output

HIGHZ Tri-states the outputs

The JTAG Boundary Scan can be used to verify printed

circuit board continuity at the system level.

The user is able to program a value into TEST_REG and

substitute this for the normal channel inputs from the AIN/

BIN pins by selecting it with the crossbar. With the NCO

frequency set to zero this allows the DDCs and the output

interface of the chip to be verified. Also, the AGC loop

can be opened by setting AGC_HOLD_IC high and setting the gain of the DVGA by programming the appropriate value into the AGC_IC_A/B register.

Real-time access to the followin g signals is provided by

configuring the control interface debug register:

• NCO sine and cosine outputs

• data after round following mixers

• data befo r e F1 and F2

• data after the CIC filter within the AGC

The access points are mul tiplexe d to a 20-bi t paralle l output port which is created from signal pins POUT[15:0],

AOUT, BOUT, SFS, and RDY according to the table

below:

Normal Mode Pin

POUT[15:0] DEBUG[19..4]

RDY DEBUG[3]

SFS DEBUG[2]

AOUT DEBUG[1]

BOUT DEBUG[0]

SCK will be set

tap point. POUT_EN

Debug Mode Pin

to the proper strobe rate for each debug

and PSEL[2..0] hav e no effect in

Debug Mode. The outputs are tur ned on w hen the Debug

Mode bit is set. Normal serial outputs are also disabled.

Control Registers

The chip is configured and controlled through the use of 8bit control registers. These registers are accessed

ing or writing using the control bu s pins (CE

A[7:0], and D[7:0]) described in the Control Interface section. The register names and descriptions are listed in

T a ble 5.

for read-

, RD, WR,

Control Registers

Register Name Width Type DefaultaAddr Bit Description

DEC 11b R/W 7 0(LSBs)

DEC_BY_4 1b R/W 0 1 4 Controls the decimation factor in F2. 0=Decimate by 2. 1=Decimate by 4. This affects both

SCALE 6b R/W 0 2 5:0 CIC SCALE parameter. Format is an unsigned integer representing the number of left bit

GAIN_A 3b R/W 0 3 2:0 Value of left bit shift prior to F1 for channel A.

GAIN_B 3b R/W 0 4 2:0 Value of left bit shift prior to F1 for channel B.

RATE 1B R/W 1 5 7:0 Determines rate of serial output clock. The output rate is FCK/(RATE+1). Unsigned integer.

SOUT_EN 1b R/W 0 6 0 Enables the serial output pins AOUT, BOUT, SCK, and SFS. 0=Tristate. 1=Enabled.

SCK_POL 1b R/W 0 6 1 Determines polarity of the SCK output. 0=AOUT, BOUT, and SFS change on the ri sing edge

SFS_POL 1b R/W 0 6 2 Determines polarity of the SFS output. 0=Active High. 1=Active Low.

RDY_POL 1b R/W 0 6 3 Determines polarity of the RDY output. 0=Active High. 1=Active Low.

MUX_MODE 1b R/W 0 6 4 Determines the mode of the serial outputs. 0=Each channel is output on its respective pin,

PACKED 1b R/W 0 6 5 Controls when SFS goes active. 0=SFS pulses prior to the start of the I and the Q words.

FORMAT 2b R/W 0 6 6:7 Determines output number format. 0=Truncate serial output to 8 bits. Parallel output is trun-

1(MSBs)

Table 5 CLC5902 Control Registers

7:0

2:0

CIC decimation control. N=DEC+1. Valid range is from 7 to 2047. Format is an unsigned

integer. This affects both channels.

channels.

shifts to perform on the data prior to the CIC filter. Valid range is from 0 to 40. This affects

both channels.

of SCK (capture on falling edge). 1=They change on the falling edge of SCK.

1=Both channels are multiplexed and output on AOUT. See also Table 2.

1=SFS pulses only once prior to the start of each I/Q samp l e p air ( i.e. the pa ir is tre ated a s a

double-sized word) The I word precedes the Q word. See Figure 29.

cated to 32 bits. 1=Round both serial and parallel to 16 bits. All other bits are set to 0.

2=Round both serial and parallel to 24 bits. A ll other bit s are set to 0. 3=Output fl oating point.

8-bit mantissa, 4-bit exponent. All other bits are set to 0.

©1999 National Semiconductor Corporation 21 Rev. 3.05 May 27, 1999

Page 22

Register Name Width Type DefaultaAddr Bit Description

FREQ_A 4B R/W 0 7-10 7:0 Frequency word for channel A. Format is a 32-bit, 2’s complement number spread across 4

PHASE_A 2B R/W 0 11-12 7:0 Phase word for channel A. Format is a 16-bit, unsigned magnitude number spread across 2

FREQ_B 4B R/W 0 13-16 7:0 Frequency word for channel B. Format is a 32-bit, 2’s complement number spread across 4

PHASE_B 2B R/W 0 17-18 7:0 Phase word for channel B. Format is a 16-bit, unsigned magnitude number spread across 2

A_SOURCE 2 R/W 0 19 1:0 0=Select AIN as channel input source. 1=Select BIN. 2=3=Select TEST_REG as channel

B_SOURCE 2 R/W 1 19 2:3 0=Select AIN as channel input source. 1=Select BIN. 2=3=Select TEST_REG as channel

EXP_INH 1b R/W 0 20 0 0=Allow exponent to pass into FLOAT TO FIXED converter . 1 =For ce expon ent in DDC chan -

AGC_FORCE 1b R/W 1 20 1 0=Enable AGC counter operation. 1=AGC loop operates continuously regardless of

AGC_RESET_EN 1b R/W 0 20 2 0=Initial condition is never used. 1=Integrator is reset each time the AGC transitions from

AGC_HOLD_IC 1b R/W 0 20 3 0=Normal closed-loop operation. 1=Hold integrator at initial condition. This affects both

AGC_LOOP_GAIN 2b R/W 0 20 4:5 Bit shift value for AGC loop. Valid range is from 0 to 3. This affects both channels.

AGC_COUNT 2B R/W 0 21-22 7:0 Counter value for AGC enable counter. Format is a 16-bit, unsigned magnitude number

AGC_IC_A 1B R/W 0 23 7:0 AGC integrator initial condition for channel A. Format is an 8-bit, unsigned magnitude num-

AGC_IC_B 1B R/W 0 24 7:0 AGC integrator initial condition for channel B. Format is an 8-bit, unsigned magnitude num-

AGC_RB_A 1B R 0 25 7:0 AGC integrator readback value for channel A. Format is an 8-bit, unsigned magnitude num-

AGC_RB_B 1B R 0 26 7:0 AGC integrator readback value for channel B. Format is an 8-bit, unsigned magnitude num-

TEST_REG 14b R/W 0 27(LSBs)

Reserved 1B - - 29 7:0 For future use.

Reserved 1B - - 30 7:0 For future use.

DEBUG_EN 1b R/W 0 31 0 0=Normal. 1=Enables access to the internal probe points.

DEBUG_TAP 5b R/W 0 31 1:5 Selects internal node tap for debug.

DITH_A 1b R/W 1 31 6 0=Disable NCO dither source for channel A. 1=Enable.

DITH_B 1b R/W 1 31 7 0=Disable NCO dither source for channel B. 1=Enable.

AGC_TABLE 32B R/W 0 128-159 7:0 RAM space that defines key AGC loop parameters. Format is 32 separate 8-bit, 2’s comple-

F1_COEFF 22B R/W 0 160-181 7:0 Coefficients for F1. Format is 11 separate 16-bit, 2’s complement numbers, ea ch on e sp read

F2_COEFF 64B R/W 0 182-245 7:0 Coefficients for F2. Format is 32 separate 16-bit, 2’ s comple ment number s, each one spread

28(MSBs)

7:0

5:0

registers. The LSBs are in the lower registers. The NCO frequency F is F/FCK=FREQ_A/232.

registers. The LSBs are in the lower registers. The NCO phase PHI is PHI=2*pi*PHASE_A/

2^16.

registers. The LSBs are in the lower registers. The NCO frequency F is F/FCK=FREQ_B/232.

registers. The LSBs are in the lower registers. The NCO phase PHI is PHI=2*pi*PHASE_B/

2^16.

input source.

input source.

nel to a 7 (maximum digital gain). This affects both channels.

AGC_EN pin. This affects both channels.

idle to active. This affects both channels.

channels.

spread across 2 registers. The LS Bs a re in the low e r re gister. The value represents the number of CK cycles over which the loop is active.

ber. This number is written into the magnitude MSBs of the channel A AGC integrator whenever it is reset to the initial condition.

ber. This number is written into the magnitude MSBs of the channel B AGC integrator whenever it is reset to the initial condition.

ber. The user can read the magnitude MSBs of the channel A integrator from this register.

ber. The user can read the magnitude MSBs of the channel B integrator from this register.

Test input source. Instead of processing values from the AIN/BIN pins, the value from this

location is used instead. Format is 14-bit 2s complement number spread across 2 registers.

0 selects F1 output for BI, 20 bits

1 selects F1 output for BQ, 20 bits

2 selects F1 output for AQ, 20 bits

3 selects F1 output for AI, 20 bits

4 selects F1 input for BI, 20 bits

5 selects F1 input for BQ, 20 bits

6 selects F1 input for AI, 20 bits

7 selects F1 input for AQ, 20 bits

8 selects NCO A, cosine output. 17 bits, 3 LSBs are 0.

9 selects NCO A, sine output, 17 bits, 3 LSBs are 0.

10 selects NCO B, cosine output, 17 bits, 3 LSBs are 0.

11 selects NCO B, sine output, 17 bits, 3 LSBs are 0.

12 selects NCO AI, rounded output, 15 bits, 5 LSBs are 0.

13 selects NCO AQ, rounded output, 15 bits, 5 LSBs are 0.

14 selects NCO BI, rounded output, 15 bits, 5 LSBs are 0.

15 selects NCO BQ, rounded output, 15 bits, 5 LSBs are 0.

16-31 selects AGC CIC filter output. 9 MSBs from ch A, next 9 bits from ch B, 2 LSBs are 0.

ment numbers. This is common to both channels.

across 2 registers. The LSBs are in the lower regi sters. For exam pl e, coef ficien t h0[7:0 ] is in

address 160, h0[15:8] is in address 161, h1[7:0] is in address 162, h1[15:8] is in address

163.

across 2 registers. The LSBs are in the lower regi sters. For exam pl e, coef ficien t h0[7:0 ] is in

address 182, h0[15:8] is in address 183, h1[7:0] is in address 184, h1[15:8] is in address

185.

Table 5 CLC5902 Control Registers

a. These are the default values set by a master reset (MR). Sync in (SI) will not affect any of the s e values.

Rev. 3.05 May 27, 1999 22 ©1999 National Semiconductor Corpor at ion

Page 23

Condensed Hexadecimal Address Map

Bit4

Dec4

y

Scale4

Rate4

FA4

FA12

FA20

FA28

PA4

PA12

FB4

FB12

FB20

FB28

PB4

PB12

g

g

g

g

g

g

g

Test4

Test12

g

g

The FIR C oefficients loa d from the low address to the high address in this order

y

Reg Name Addr Bit7 Bit6 Bit5

DEC

DEC_BY_4

SCALE

GAIN1_A

GAIN1_B

RATE

SERIAL_CTRL

FREQ _A

PHASE_A

FREQ _B

PHASE_B

SOURCE

AGC_CTRL

AGC_COUNT

AGC_IC_A

AGC_IC_B

AGC_RB_A

AGC_RB_A

TEST_REG

DEBUG

AGC_TABLE

F1_COEFF

F2_COEFF

[

[

[

[

[

[

[

[

[

[

[$

[%

[&

['

[(

[)

[

[

[

[

[

[

[

[

[

[

[$

[%

[&

[)

[

[)

[$

[%

[%

[)

Dec7 Dec6 Dec5

Scale5

Rate7 Rate6 R ate5

FMT1 FM T0 Packed MuxMode RDY_POL SFS_POL SCK_POL SOUT_EN

FA7 FA6 FA5

FA15 FA14 FA13

FA23 FA22 FA21

FA31 FA30 FA29

PA7 PA6 PA5

PA15 PA14 PA13

FB7 FB6 FB5

FB15 FB14 FB13

FB23 FB22 FB21

FB31 FB30 FB29

PB7 PB6 PB5

PB15 PB14 PB13

cCn t7 AgcCn t6 AgcCnt5 AgcCnt4 AgcCnt3 AgcCnt2 AgcCnt1 AgcCnt0

A

A

cCnt15 AgcCn t1 4 AgcCnt13 AgcCnt12 AgcCnt11 AgcCnt10 AgcCnt9 AgcCnt8

cIcA7 AgcIcA6 AgcIcA5 AgcIcA4 AgcIcA3 AgcIcA2 AgcIcA1 AgcIcA0

A

cIcB7 AgcIcB6 AgcIcB5 AgcIcB4 AgcIcB3 AgcIcB2 AgcIcB1 AgcIcB0

A

cRb A7 AgcRb A6 AgcRbA5 AgcRbA 4 AgcRbA 3 AgcRbA 2 AgcRbA 1 AgcRbA 0

A

cRb B7 AgcRb B6 AgcRbB5 AgcRbB 4 AgcRbB 3 AgcRbB 2 AgcRbB 1 AgcRbB 0

A

Test7 Test6 Test5

DITH_ B D IT H_A T apSel4 TapSe l3 T apSel2 Tap Sel1 TapSel0 D ebu

The A

1st location, 2nd location…

1st location low b

A

Test13

c Table loads from the low address to the high address in this order:

Bit3 Bit2 Bit1 Bit0

Dec3 Dec2 Dec1 Dec0

4 Dec10 Dec9 Dec8

DecB

cLG1 AgcLG0 AgcHldIC AgcRstEn AgcForce ExpInh

te, 1 s t loc a tio n h igh byte, 2nd location…

Scale3 Scale2 Scale1 S cale0

G1A2 G1A1 G1A0

G1B2 G1B1 G1B0

Rate3 Rate2 Rate1 R ate0

FA3 FA2 FA1 FA0

FA11 FA10 FA9 FA8

FA19 FA18 FA17 FA16

FA27 FA26 FA25 FA24

PA3 PA2 PA1 PA0

PA11 PA10 PA9 PA8

FB3 FB2 FB1 FB0

FB11 FB10 FB9 FB8

FB19 FB18 FB17 FB16

FB27 FB26 FB25 FB24

PB3 PB2 PB1 PB0

PB11 PB10 PB9 PB8

BSrc1 BSrc0 ASrc1 ASrc0

Test3 Test2 Test1 Test0

Test11 Test10 Test9 Test8

En

©1999 National Semiconductor Corporation 23 Rev. 3.05 May 27, 1999

Page 24

A block diagram of the AGC is shown in Figure 32. The

AGC Theory of Operation

DVGA interface comprises four pins for each of the channels. The first three pins of this interface are a 3-bit binary

word that controls the

The final pin is ASTROBE

to be

latched into the DVGA’s register. A key feature of

the ASTROBE

only if the data on AGAIN

cycle. Not shown is that ASTROBE

independent. For example, ASTROBE

when AGAIN has changed. BSTROBE

DVGA gain in 6dB steps (AGAIN).

which allows the AGAIN bits

, illustrated Figu re 33, is th at it toggl es

has changed from the previous

and BSTROBE are

should only toggle

should not toggle

because AGAIN has changed. This is done to minimize

unnecessary digital noise on

through the DVGA. ASTROBE

asserted during MR

and SI to properly initialize the

the sensitive analog path

and BSTROBE are

DVGAs.

The absolute value circuit and the 2-stage, decimate-by-8

CIC filter comprise the power detection part of the AGC.

The power detector bandwidth is set by the CIC filter to

F

/8. The absolute value circuit doubles th e effective

CK

input frequency. This has the effect of reducing the power

detector b andwidth fro m F

/8 to FCK/16.

CK

For a full-scale sinusoidal input, the absol ute value circuit

output is a dc value of . Because the absolut e

511 2 π⁄()⋅

value circuit also generates undesired even harmonic

terms, the CIC filter (response shown in Figure 34), is

required to remove these harmonics. The first response

null occurs at F

/8, where FCK is the clock frequency,

CK