Page 1

CLC5509

Ultra-Low Noise Preamplifier

General Description

The CLC5509 is a high performance, ultra-low noise preamplifier designed for applications requiring unconditional stability for wide ranges of complex input loads. Both input impedance and gain are externally adjustable, which make it

simple to interface to peizoelectric ultrasound transducers.

The CLC5509 preamplifier’s low 0.58nV

total input

noise makes it ideal for noise sensitive front ends. The high

repeatability in group delay over voltage and temperature

translates intoprecisionedge measurements for Doppler applications.

The IC consists of an emitter input, common base amplifier

stage followed by a low distortion, closed loop buffer. External negative feedback creates a well controlled input impedance to allow a near noiseless active input transmission line

termination. The preamp is stable against changes in source

impedance of 50 to 200Ω over temperature and supply

variations, with gains from 14dB to 26dB. The CLC5509

preamp architecture is also well suited for use with

magneto-resistive tape or disk drive heads. In these applications the head bias current can be reused to bias the

preamp. The part is packaged in an 8-pin plastic SOIC, and

runs off

±

5V supplies. External biasing is required for the in-

put signal path.

The CLC5509 is constructed using an advanced comple-

mentary bipolar process and National Semiconductor’s

proven high performance architectures.

Features

n 0.58nV total input noise@12MHz

n

<

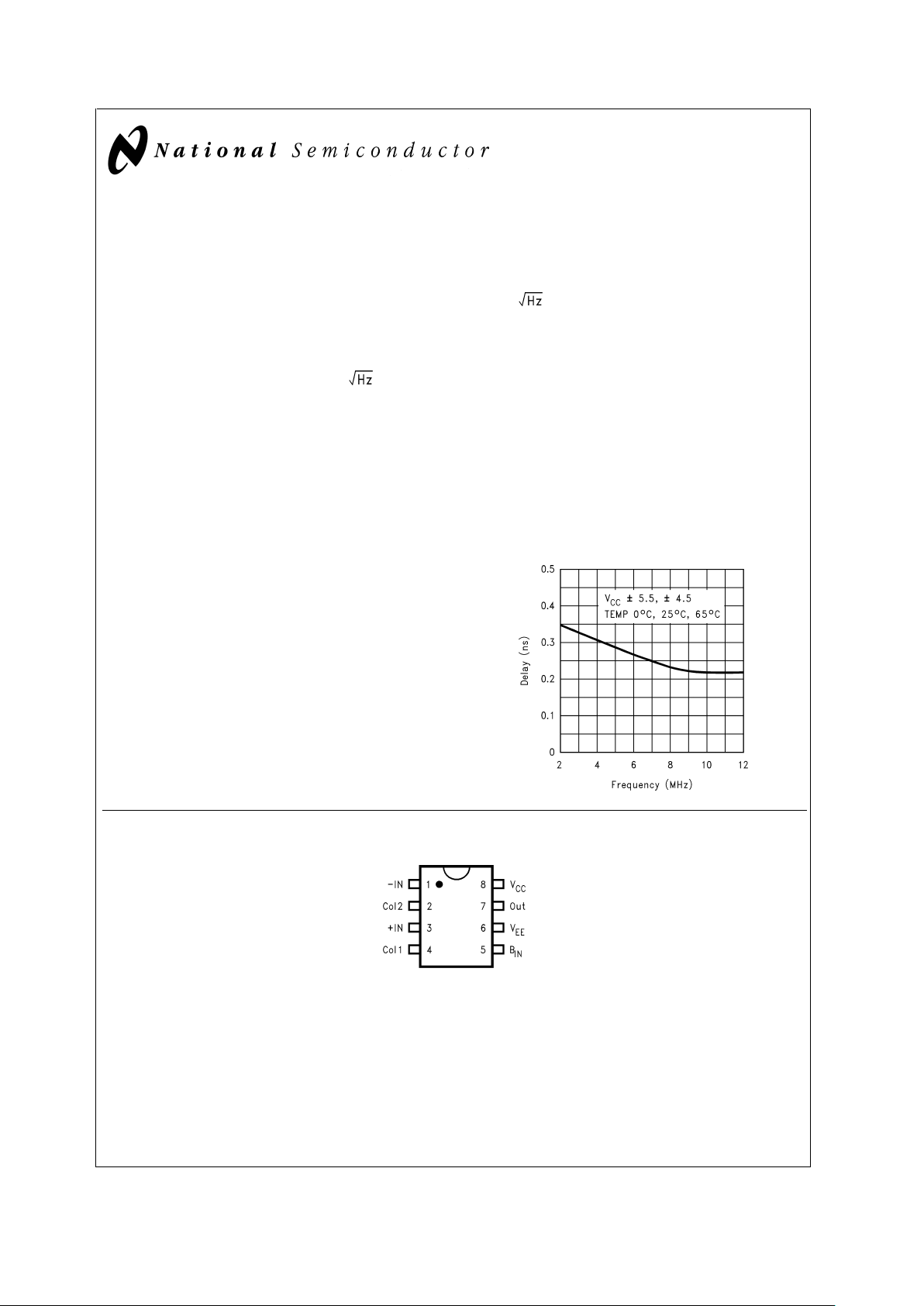

.5ns group delay repeatability

n High cutoff −3dB

@

33MHz

n Low cutoff −3dB

@

0.5MHz

n 2.0dB noise figure

@

50Ω

n −60dBc intermod for 2V

PP

@

5MHz

n Supply current: 11mA

n Available in 8-pin SOIC

Applications

n Ultrasound preamp

n Tape drive preamp

n Disk drive preamp

Connection Diagram

Group Delay Repeatability

DS101304-1

DS101304-3

Pinout

SOIC

January 2000

CLC5509 Ultra-Low Noise Preamplifier

© 2000 National Semiconductor Corporation DS101304 www.national.com

Page 2

Typical Application

Ordering Information

Package Temperature Range

Industrial

0˚C to 70˚C

Packaging

Marking

Transport Media NSC

Drawing

8-pin SOIC CLC5509CM CLC5509CM Rails M08A

DS101304-2

Ultrasound PreAmp

CLC5509

www.national.com 2

Page 3

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Supply Voltage

±

5.5V

Output Current 70mA

Common-Mode Input Voltage

±

V

CC

Maximum Junction Temperature +150˚C

Storage Temperature Range −65˚C to +150˚C

Lead Temperature (soldering 10 sec) +300˚C

ESD Rating (human body model) 4000V

Electrical Characteristics (Note 3)

(VCC,V

EE

=

±

5V, R

S

=

50Ω,A

V

=

10V/V, R

g

=

1kΩ,R

L

=

100Ω; unless specified)

Symbol Parameter Conditions Typ Min/Max

Ratings

(Note 2)

Units

Ambient Temperature CLC5509 +25˚C +25˚C

Frequency Domain Response

-3dB Bandwidth V

O

<

2.0V

PP

High Cutoff −3dB 33 28

45

MHz

Low Cutoff −3dB 0.5 0.4

0.7

MHz

Gain Flatness Inband 2

<

12.5MHz, V

O

<

1.0V

PP

−1.5

+.1

dB

Gain Accuracy

@

5MHz

±

0.3 dB

Phase Variation 3

<

9MHz, V

O

<

.1V

PP

1 Deg

Gain Variation 3

<

9MHz, V

O

<

.1V

PP

.3 dB

Time Domain Response

Rise and Fall Time 2V step 10 10

15

ns

Settling Time to 0.2

%

2V step 1 µs

Overshoot 2V step 0 5

%

Group Delay 2.5MHz

<

10MHz, V

IN

=

10mV

PP

5.5 3

7.5

ns

Group Delay Repeatability .5 ns

Distortion And Noise Response

2nd Harmonic Distortion

<

12.5MHz, V

IN

=

100mV

PP

−51 dBc

3rd Harmonic Distortion −56 dBc

Intermodulation Distortion

@

5MHz −65 dBc

Equivalent Input Noise Voltage (e

ni

)

>

1MHz, R

S

=

50Ω 0.7 0.78 nV

Noise Figure

@

50Ω 2 2.4 dB

Optimum R

S

85 80

110

Ω

Static, DC Performance

PSRR (preamp only)

<

1MHz 40 dB

Supply Current (preamp only) R

L

=

∞

911mA

Miscellaneous Performance

Output Impedance DC

<

12MHz 0.2 0.2

1

Ω

Output Voltage Range R

L

=

100Ω

±

2

±

1.7 V

Output Current

±

45

±

35 mA

CLC5509

www.national.com3

Page 4

Electrical Characteristics (Note 3) (Continued)

Note 1: “Absolute Maximum Ratings” are those values beyond which the safety of the device cannot be guaranteed. They are not meant to imply that the devices

should be operated at these limits. The table of “Electrical Characteristics” specifies conditions of device operation.

Note 2: Min/max ratings are based on product characterization and simulation. Individual parameters are tested as noted. Outgoing quality levels are determined

from tested parameters.

Note 3: All data taken in circuit shown as typical application.

Typical Performance Characteristics

Frequency Response

DS101304-4

Frequency Response

DS101304-5

Frequency Response

DS101304-6

Group Delay

DS101304-7

Group Delay

DS101304-8

3rd Harmonic Distortion

DS101304-9

CLC5509

www.national.com 4

Page 5

Typical Performance Characteristics (Continued)

3rd Harmonic Distortion

DS101304-10

2rd Harmonic Distortion

DS101304-11

2rd Harmonic Distortion

DS101304-12

Intermodulation Distortion

DS101304-13

Intermodulation Distortion

DS101304-14

Total Input Referred Noise (R

S

=

50Ω)

DS101304-15

CLC5509

www.national.com5

Page 6

Typical Performance Characteristics (Continued)

Total Input Referred Noise (R

S

=

50Ω)

DS101304-16

Total Input Referred Noise (R

S

=

100Ω)

DS101304-17

Total Input Referred Noise (R

S

=

100Ω)

DS101304-18

Total Input Referred Noise (R

S

=

200Ω)

DS101304-19

Total Input Referred Noise (R

S

=

200Ω)

DS101304-20

Z

in

DS101304-21

CLC5509

www.national.com 6

Page 7

Typical Performance Characteristics (Continued)

Z

in

DS101304-22

Z

O

DS101304-23

Z

O

DS101304-24

Positive PSRR (VCC)

DS101304-25

Positive PSRR (VCC)

DS101304-26

Negative PSRR (VEE)

DS101304-27

CLC5509

www.national.com7

Page 8

Typical Performance Characteristics (Continued)

Application Information

Introduction

The CLC5509 is a two stage ultra-low noise preamplifier,

with low distortion, and externally variable input impedance.

The unusual emitter driven input stage remains stable for a

wide range of transducer source loads. The input termination

can be matched (for 50-200Ω source matching) to a wide

range of complex loads (C

S

up to 5000pF and CPup to

10000pF, L

S

up to 1µH). The IC was designed for low cost

multiple channel ultrasound applications requiring flexible

configurations for a variety of transmit/receive topologies. In

a typical application, the CLC5509 is connected to a single

element of an ultrasound transducer through a

transmit/receive switch.

Theory of Operation

The CLC5509 simplified circuit is shown in

Figure 1

. For

analysis, the transmit/receive switch diode is modeled in the

circuit as a series resistance R

TR

with a voltage drop of VRT.

Apiezo transducer generated, single-ended voltage signal is

applied to the emitter input of the 1st stage. The voltage signal is converted to a current (i) that is passed through a high

pass filter then restored back to a voltage signal at R

g

.A high

speed, low distortion, unity gain buffer, applies the signal to

the load and feedback resistor. Negative feedback from the

buffer output to the inverting input completes the signal path.

The input and output voltage can be expressed as shown:

V

in

=

(R

TR+re

)i+VO(R1/(R1+R2))

V

O

=

−(ixR

g

) for α=1

The input resistance is calculated

The current I

BIAS1

is the input stage emitter current that

sets r

e

.

I

BIAS1

=

(V

EE-VTR

)/R

BIAS1

for V

EE

=

V

TR

=

.65V

r

e

=

26mV/I

BIAS1

Combining terms, then solving for close loop gain

V

O/Vin

results in

Negative PSRR (VEE)

DS101304-28

DS101304-29

FIGURE 1. Simplified Circuit

CLC5509

www.national.com 8

Page 9

Application Information (Continued)

Choosing External Component Values

There are three key parameters to consider in the design:

Noise, signal bandwidth, and gain. Refer to

Figure 2

.

The best noise performance for a given transmit/receive

switch R

TR

is obtained by: choosing RSbetween 50Ω and

200Ω; selecting the matching terminationresistance R

in

; and

by reducing I

BIAS1

(by increasing R

BIAS1

) to increase r

e

which optimizes the Noise Figure (NF). For this circuit, with

R

TR

=

6Ω, the optimum NF isachieved at R

s

∼ 95Ω when R

in

is set to 50Ω and Rs∼ 145Ω when Rinis set to 200Ω.

The signal bandwidth is determined by the selection of L

1

,

L

2,RBIAS1

and R

BIAS2

which set the open loop gain roll-off of

the first stage. R

g

and C2form a desirable signal path filter

that introduces an additional highpass pole. The filter values

can be chosen to create a sharper high frequency roll off of

the closed loop gain. For R

g

=

1k, C2 ∼ 470pF the small sig-

nal (V

in

<

25mW), wide bandwidth performance can be ob-

served. By increasing C

2

(to>1500pF) and increasing output series resistance with a small resistor, the stability and

harmonic distortion performance can be improved for large

signals. This filter can also be designed as a multi-pole Butterworth filter but care must be taken to ensure stability with

the desired load over the operating temperature range.

The passband gain is customer selected by setting R

g

and

R

in

. Note that using R1to reduce or increase the gain allows

for minimal interaction with other parameters.

Capacitor C

C

and resistor RCare used for local compensa-

tion of the gm input stage with values of C

C

=

0.1µF and R

C

=

1k for the applications described below.

Calculating and Measuring the Noise

The circuit input referred noise is best calculated using a

SPICE model where the external components can be optimized for the transducer source impedance and

transmit/receive switch impedance. The SPICE model for

the CLC5509 is available on the NSC web site. Refer to the

figures for total noise performance over temperature and

supply at 3mA. Once the noise is modeled and circuit parameters chosen the evaluation board can be used to measure

actual noise performance.

To measure the CLC5509 input referred noise vs. other

noise sources, several key steps should be followed. The

bench setup is fairly simple using the evaluation board and a

spectrum analyzer. (If a noise figure meter is available that is

even easier yet.) The procedure requires calibrating out the

spectrum analyzer background noise, and other noise

sources from the CLC5509 noise. Since the thermal noise of

a resistor is well known, add a series resistor R

4

between the

signal source V

in

and the L1,R

BIAS1

bias network for these

noise measurements. Several R

4

resistor values are used as

’’reference’’ noise sources. The values chosen depend on

the R

s

of the system. For R

s

=

50Ω, resistor (R

4

) with values

of 0, 12.5, 25, 50Ω should be used. If R

s

=

200Ω, resistors

(R

4

) with values of 0, 25, 50, 100, 200Ω should be used.

Start by connecting the analyzer input to the evaluation

board output. Remove R

4

from the signal source and con-

nect R

4

to GND. Now take at least 10 measurements and av-

erage them for each R

4

reference value. Be sure to divide

the result by the analyzer and circuit gain to make the noise

input referred. Subtract the R

4

=

0Ω results from the data for

each value. Compare the result to the theoretical noise values. They should agree closely over the R

s

=

0toR

in

range.

This verifies the test method.The CLC5509 noise is the R

s

=

0Ω data point. A similar procedure can be used to remove

the T/R switch noise by varying the T/R bias current I

BIAS1

.

The total circuit noise performance can now be optimized for

R

in

as described above.

Evaluation Board

Evaluation boards are available for customer product evaluation for the 8-pin SOIC. Evaluation kits that contain an

evaluation board and CLC5509 samples can be obtained by

calling National Semiconductor’s Customer Service Cen-

ter. The evaluation kit number is CLC730101. The evaluation board utilizes surface mount components. The corner

frequencies are set to ∼ 0.9MHz to 12.5MHz with a passband gain set at 20dB. The highpass filter is set at R

g

=

1k,

C

2

=

470pF to view small signal (V

in

<

25mV) performance.

Increasing C

4

(to>1500pF) reduces the bandwidth and im-

proves distortion for large signals. R

9

, is a back match resistor that terminates the output and isolates cable capacitance, for minimum distortion, over the frequency band of

interest. An R

in

∼ 50.2Ω was chosen for R

s

=

50Ω (this

source resistor R

s

is open ) and R

TR

=

0, with I

BIAS1

set to

3mA. The expected input referred noise based on bench

measurements on similar boards is ∼ 0.6nV

oraNFof

2dB. The noise can be optimized with slight variations in R

2

,

R

g

and R

BIAS1

. If transmit/receive switches are added to the

evaluation board both the voltage drop and R

TR

should be

compensated for. The R

in

, gain and noise will be affected by

the addition of the T/R switch. The V

TR

drop can be removed, to a first order, by adding a second switch in series

with the feedback gain setting resistor R

1

to ground. This will

restore the input DC level to ∼ 0V. This T/R switch diode

should be biased with a resistor (∼ R

BIAS2

)toVCCand bypassed with a 0.1µF cap to maintain the same AC performance as the evaluation board without the switches.

CLC5509 Applications

The signal path for a typical ultrasound transceiver is shown

in

Figure 3

.

DS101304-32

FIGURE 2. Complete Circuit

DS101304-33

FIGURE 3.

CLC5509

www.national.com9

Page 10

Application Information (Continued)

The CLC5509 system dynamic range performance is enhanced by using the CLC5523 variable gain amplifier as a post amplifier.

See

Figure 4

below.

The signal gain range is divided between the CLC5509 preamplifier and the post amplifier to allow wider dynamic range and better performance for high crest factor signals. There are two common ways the CLC5523 variable gain could be controlled. The

first,

Figure 5

, uses a DAC to digitally increase the gain in discrete steps. The second

Figure 6

uses anAGC loop to maintain the

maximum system input signal-to-noise. Refer to the CLC5523 data sheet applications for the implementation details.

DS101304-36

FIGURE 4. Low Noise Pre Amp with Variable Gain Amplifier Circuit

DS101304-34

FIGURE 5. VGControlled by DAC in Discrete Steps

DS101304-35

FIGURE 6. VGControlled by AGC Loop

CLC5509

www.national.com 10

Page 11

Physical Dimensions inches (millimeters) unless otherwise noted

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

labeling, can be reasonably expected to result in a

significant injury to the user.

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

National Semiconductor

Corporation

Americas

Tel: 1-800-272-9959

Fax: 1-800-737-7018

Email: support@nsc.com

National Semiconductor

Europe

Fax: +49 (0) 1 80-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 1 80-530 85 85

English Tel: +49 (0) 1 80-532 78 32

Français Tel: +49 (0) 1 80-532 93 58

Italiano Tel: +49 (0) 1 80-534 16 80

National Semiconductor

Asia Pacific Customer

Response Group

Tel: 65-2544466

Fax: 65-2504466

Email: sea.support@nsc.com

National Semiconductor

Japan Ltd.

Tel: 81-3-5639-7560

Fax: 81-3-5639-7507

www.national.com

8-pin SOIC

Order Number CLC5509CM

NS Product Number M08A

CLC5509 Ultra-Low Noise Preamplifier

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

Loading...

Loading...