Page 1

N

CLC532

High-Speed 2:1 Analog Multiplexer

General Description

The CLC532 is a high-speed 2:1 multiplexer with active input and

output stages. The CLC532 also employs a closed-loop design which

dramatically improves accuracy. This monolithic device is constructed

using an advanced high-performance bipolar process.

The CLC532 has been specifically designed to provide settling times

of 17ns to 0.01%. This, coupled with the adjustable noise-bandwidth,

makes the CLC532 an ideal choice for infrared and CCD imaging

systems. Channel-to-channel isolation is better than 80dB @

10MHz. Low distortion (80dBc) and spurious signal levels make the

CLC532 a very suitable choice for both I/Q processors and receivers.

The CLC532 is offered over both the industrial and military temperature

ranges. The Industrial versions, CLC532AJP\AJE\AID, are specified

from -40°C to +85°C and are packaged in 14-pin plastic DIP's, 14-pin

SOIC's and 14-pin Side-Brazed packages. The extended temperature

versions, CLC532A8B/A8D/A8L-2, are specified from -55°C to +125°C

and are packaged in a 14-pin hermetic DIP and 20-terminal LCC

packages. (Contact factory for LCC and CERDIP availability.)

Ordering Information ...

CLC532AJP -40oC to +85oC 14-pin plastic DIP

CLC532AJE -40

o

C to +85oC 14-pin plastic SOIC

CLC532ALC -40

o

C to +85oC dice

CLC532AMC -55oC to +125oC dice, MIL-STD-833

CLC532A8B -55

o

C to +125oC 14-pin CERDIP;

MIL-STD-883

CLC532A8L-2A -55

o

C to +125oC 20-terminal LCC;

MIL-STD-883

Contact factory for other packages and DESC SMD number.

June 1999

CLC532

High-Speed 2:1 Analog Multiplexer

Features

■ 12-bit settling (0.01%) - 17ns

■ Low noise - 32µVrms

■ High isolation - 80dB @ 10MHz

■ Low distortion - 80dBc @ 5MHz

■ Adjustable bandwidth - 190MHz (max)

Applications

■ Infrared system multiplexing

■ CCD sensor signals

■ Radar I/Q switching

■ High definition video HDTV

■ Test and calibration

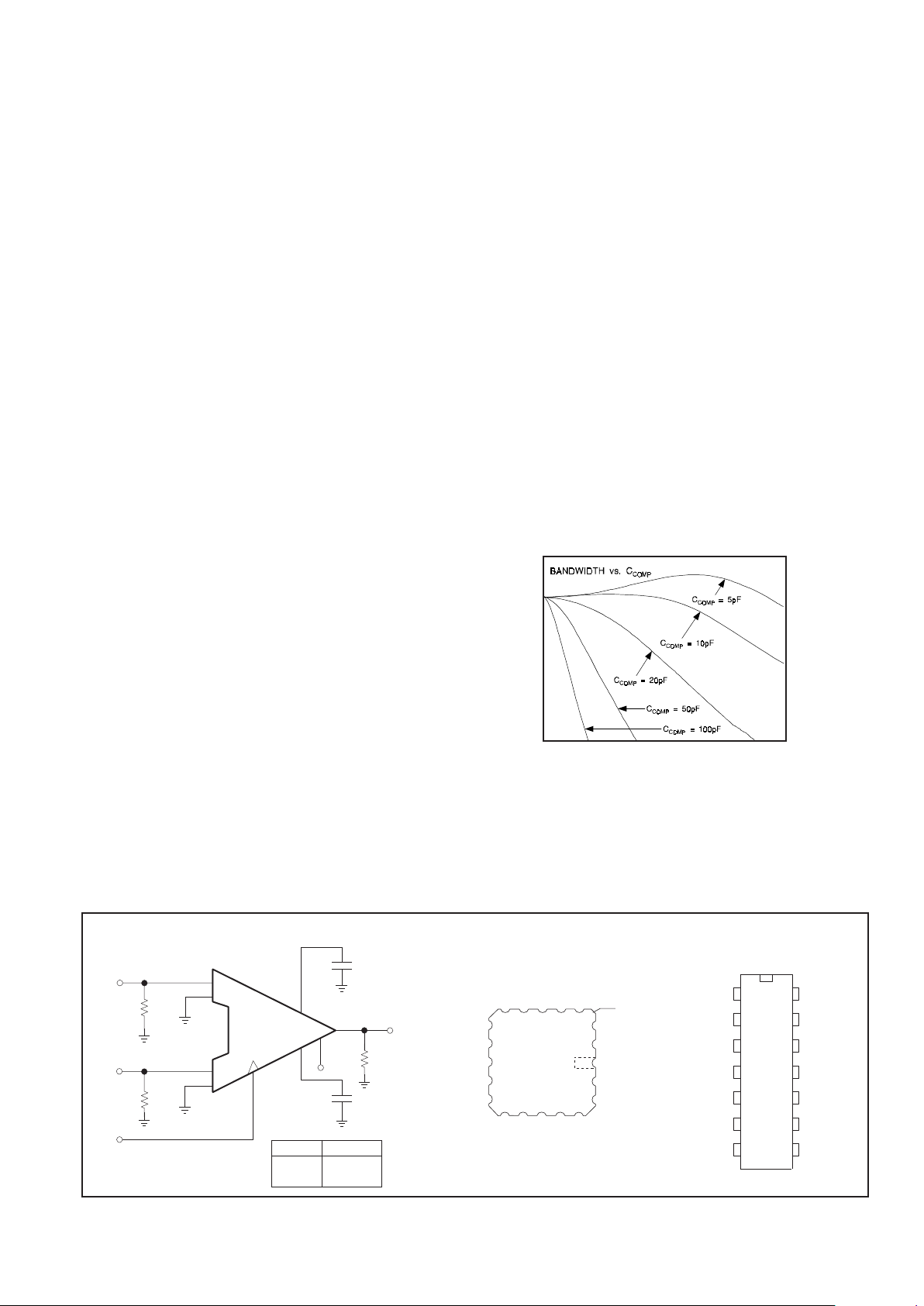

Typical Application Pinout

DIP & SOIC

20-Terminal LCC

R

L

R

IN

R

IN

IN

B

10

6

IN

A

4

3

2

1

7

V

OUT

12

CHANNEL A

CHANNEL B

CHANNEL

SELECT

C

COMP

2

C

COMP

1

CLC532

D

REF

11

SELECT OUTPUT

1 Channel A

0 Channel B

GND

IN

A

GND

IN

B

DGND

D

REF

SELECT

+V

CC

+V

CC

COMP

1

OUTPU

T

COMP

2

V

EE

V

EE

1

2

3

4

5

6

7

14

13

12

11

10

9

8

TOP VIEW

COMP

1

NC

OUTPUT

NC

COMP

2

141

5

1

61718

9

10

11

12

13

87654

3

2

1

20

19

D

REF

SELECT

NC

V

EE

V

EE

DGNDNCINBNC

GND

IN

A

GND

NC

+V

cc

+V

cc

INDEX CORNER

1999 National Semiconductor Corporation http://www.national.com

Printed in the U.S.A.

Page 2

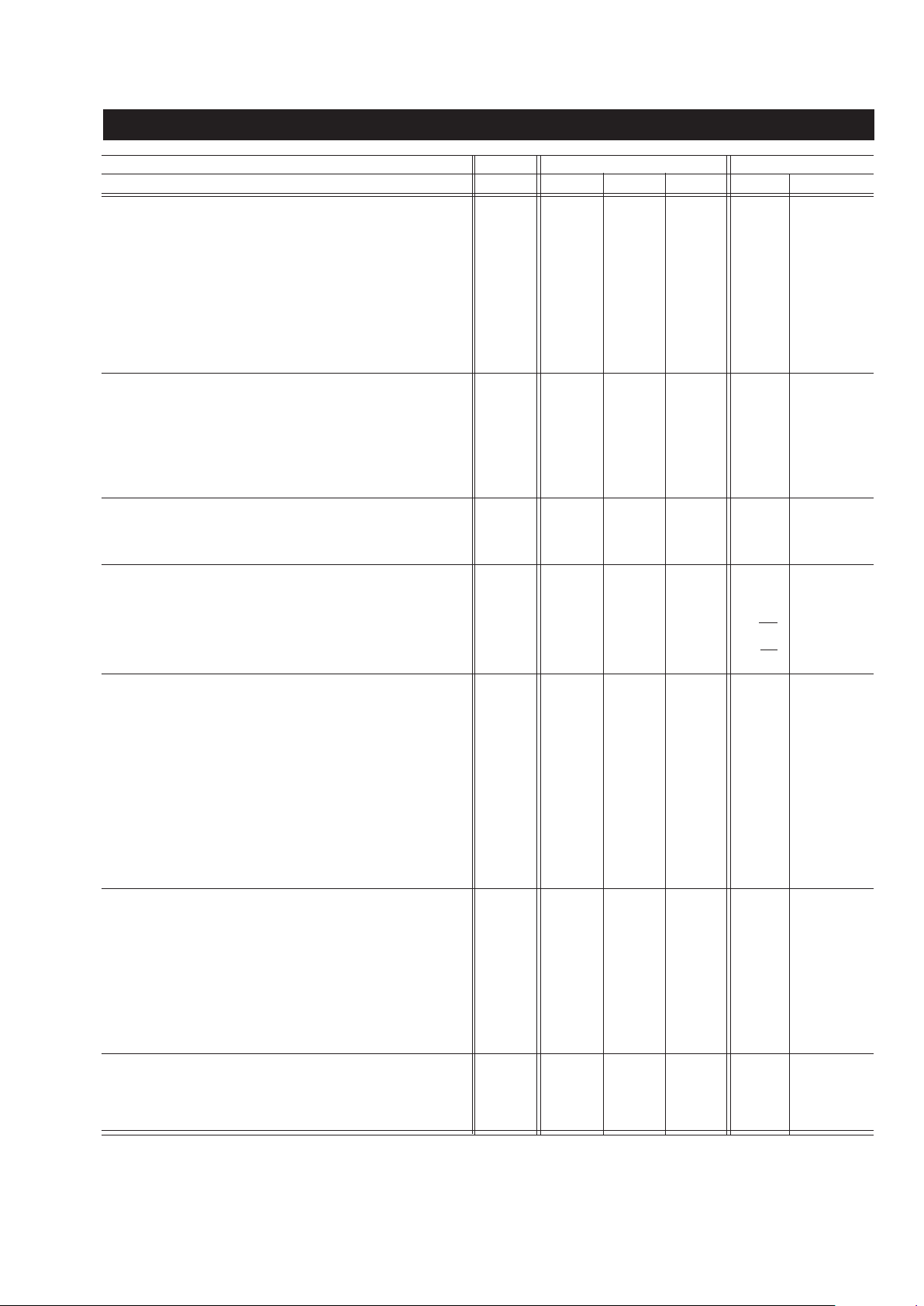

PARAMETER

1

CONDITIONS TYP MAX/MIN RATINGS

2

UNITS SYMBOL

Case Temperature CLC532AJP/AJE/AIB +25°C -40°C +25°C +85°C

FREQUENCY DOMAIN PERFORMANCE

-3dB bandwidth V

OUT

<0.1Vpp 190 140 140 110 MHz SSBW

-3dB bandwidth V

OUT

=2Vpp 45 35 35 30 MHz LSBW

gain flatness V

OUT

<0.1Vpp

peaking 0.1MHz to 200MHz 0. 2 0 .7 0 .7 0 .8 d B G FP

rolloff 0.1MHz to 100MHz 1. 0 1. 8 1. 8 2. 6 d B GFR

linear phase deviation dc to 100MHz 2.0 deg LPD

differential gain C

COMP

= 5pF; RL=150Ω 0.05 % DG

differential phase C

COMP

= 5pF; RL=150Ω 0.01 deg DP

crosstalk rejection 2Vpp, 10MHz 8 0 75 75 74 dB CT10

2Vpp, 20MHz 74 69 69 68 dB CT20

2Vpp, 30MHz 68 63 63 62 dB CT30

TIME DOMAIN PERFORMANCE

rise and fall time 0.5V step 2. 7 3 . 3 3 . 3 3 .8 ns TRS

2V step 10 12.5 12.5 14.5 ns TRL

settling time 2V step; from 50% V

OUT

±0.0025% 35 ns TS14

±0.01% 17 24 2 4 2 7 ns TSP

±0.1% 13 18 18 21 ns TSS

overshoot 2.0V step 2 5 5 6 % OS

slew rate 16 0 1 3 0 1 30 1 1 0 V/µsSR

SWITCH PERFORMANCE

channel to channel switching time 50% SELECT to 10%V

OUT

5 7 7 8 ns SWT10

(2V step at output) 50% SELECT to 90%V

OUT

15 20 20 23 ns SWT90

switching transient 30 mV ST

DISTORTION AND NOISE PERFORMANCE

2nd harmonic distortion 2Vpp, 5MHz 80 6 7 67 67 dBc HD2

3rd harmonic distortion 2Vpp, 5MHz 8 6 6 8 6 8 68 dB c HD3

equivalent input noise

spot noise voltage >1MHz 3.1 nV/√Hz SNF

integrated noise 1MHz to 100MHz 32 4 2 42 46 µVrms INV

spot noise current 3 pA/√Hz SNC

STATIC AND DC PERFORMANCE

* analog output offset voltage 1 6.5 3.5 5.5 mV VOS

temperature coefficient 15 90 20 µV/°C DVIO

analog output offset voltage matching TBD mV VOSM

* analog input bias current 50 250 12 0 1 20 µA IBN

temperature coefficient 0.3 2.0 0.8 µA/°C DIBN

analog input bias current matching TBD µA IBNM

analog input resistance 200 90 120 120 kΩ RIN

analog input capacitance 2 3.0 2.5 2.5 pF CIN

* gain accuracy ±2V 0.998 0.988 0.988 0.988 V/V GA

gain matching ±2V TBD V/V GAM

integral endpoint non-linearity ±1V (full scale) 0.02 0.05 0.03 0.03 %FS ILIN

output voltage no load ±3.4 2.4 2.8 2.8 V VO

output current 45 20 30 30 mA IO

output resistance dc 1.5 4.0 2.5 2.5 Ω RO

DIGITAL INPUT PERFORMANCE

ECL mode (pin 6 floating)

input voltage logic HIGH -1.1 -1.1 -1.1 V VIH1

input voltage logic LOW -1.5 -1.5 -1.5 V VIL1

input current logic HIGH 14 5 0 3 0 30 µA IIH1

input current logic LOW 50 2 70 110 11 0 µA IIL1

TTL mode (pin 6 = +5V)

input voltage logic HIGH 2 .0 2 .0 2. 0 V VIH2

input voltage logic LOW 0. 8 0.8 0. 8 V VIL2

input current logic HIGH 14 5 0 3 0 30 µA IIH2

input current logic LOW 50 2 70 110 11 0 µA IIL2

POWER REQUIREMENTS

* supply current (+VCC = +5.0V) no load 23 3 0 28 25 mA ICC

* supply current (-V

EE

= -5.2V) no load 24 31 30 2 6 mA IE E

nominal power dissipation no load 2 40 mW PD

* power supply rejection ratio 73 6 0 6 4 6 4 d B PSRR

Min/max ratings are based on product characterization and simulation. Individual parameters are tested as noted. Outgoing quality levels are

determined from tested parameters.

Electrical Characteristics (+V

CC

=+5.0V; -VEE=-5.2V; RIN=50

ΩΩ

ΩΩ

Ω; RL=500

ΩΩ

ΩΩ

Ω; C

COMP

=10pF; ECL Mode, pin 6 = NC)

http://www.national.com 2

Page 3

Recommended Operating Conditions

Absolute Maximum Ratings

3

positive supply voltage (+VCC) -0.5V to +7.0V

negative supply voltage (-VEE) +0.5V to -7.0V

differential voltage between any two GND’s 200mV

analog input voltage range -VEE to +V

CC

digital input voltage range -VEE to +V

CC

output short circuit duration (output shorted to GND) Infinite

junction temperature +150°C

operating temperature range

CLC532AJP/AJE/AIB -40°C to +85°C

storage temperature range -65°C to +150°C

lead solder duration (+300°C) 10 sec

ESD rating <500V

transistor count 74

positive supply voltage (+VCC) +5V

negative supply voltage (-VEE) -5.2V or -5.0V

differential voltage between any two GND’s 10mV

analog input voltage range ±2V

SELECT input voltage range (TTL mode) 0.0V to +3.0V

SELECT input voltage range (ECL mode) -2.0V to 0.0V

C

COMP

range

2

0pF to 100pF

thermal data θJC(°C/W) θJA(°C/W)

14-pin plastic 55 100

14-pin Cerdip 35 85

14-pin SOIC 35 10 5

20-terminal LCC 3 5 50

Note 1: Test levels are as follows:

* AJ : 100% tested at +25°C.

Note 2: The CLC532 does not require external C

COMP

capacitors for proper

operation.

Note 3: Absolute maximum ratings are limiting values, to be applied individually,

and beyond which the serviceability of the circuit may be impaired. Functional

operability under any of these conditions is not necessarily implied. Exposure to

maximum ratings for extended periods may affect device reliability.

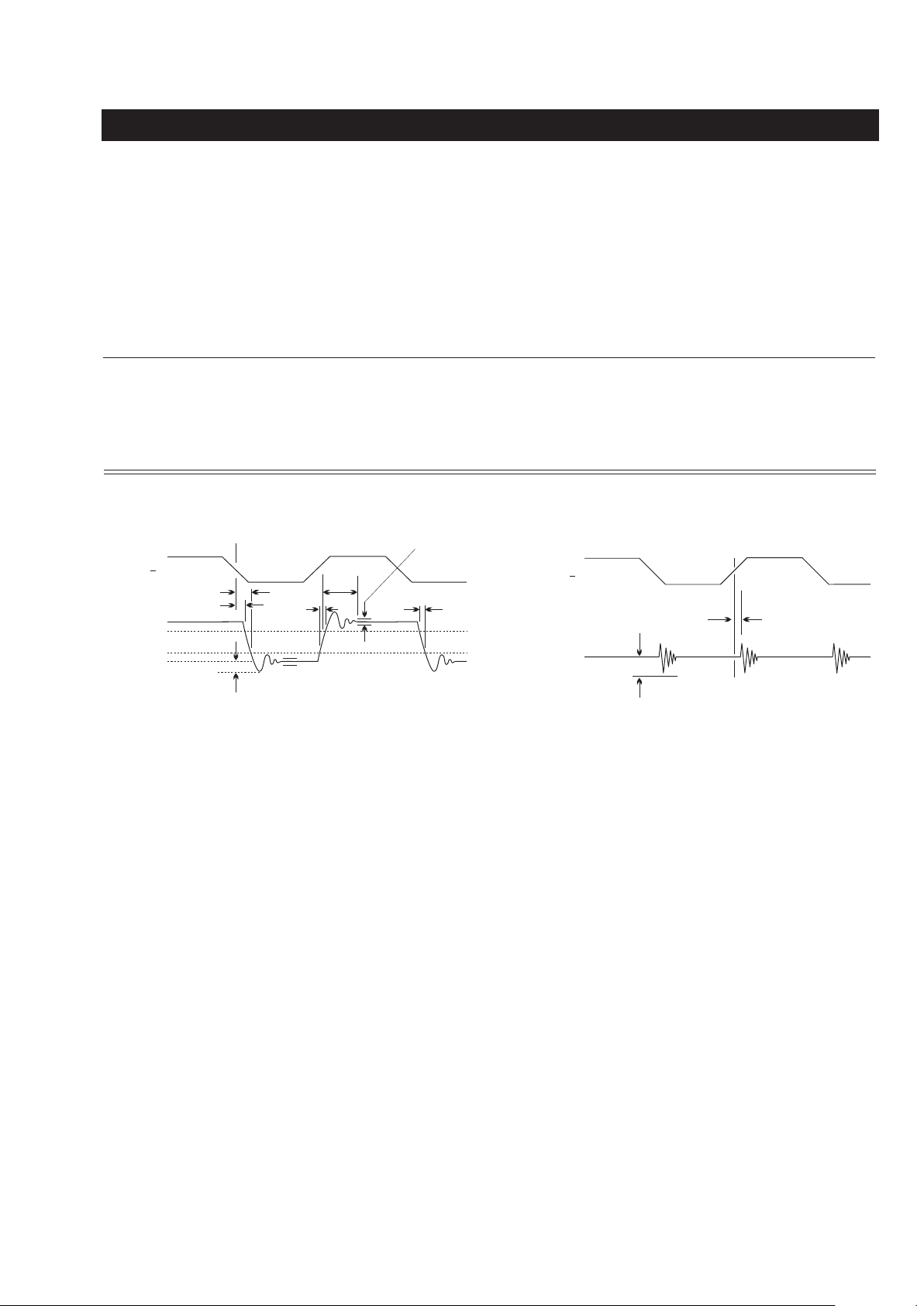

System Timing Diagram Switching Transient Timing Diagram

A

SELECT

B

ST

2ns

~

~

OUTPUT

Channel A = 0V

Channel B = 0V

A

SELECT

B

SWT90

SWT10

90%

10%

TSx

TRx

TRx

SETTLING ERROR

WINDOW

CHANNEL A = +1V

CHANNEL B = -1V

OS

... where TSx is TS14 or TSP or TSS,

and TRx is TRS ro TSL.

OUTPUT

3 http://www.national.com

Page 4

http://www.national.com 4

CLC532 Electrical Characteristics (+25

°

C unless specified)

Page 5

5 http://www.national.com

CLC532 Electrical Characteristics (+25

°

C unless specified)

Page 6

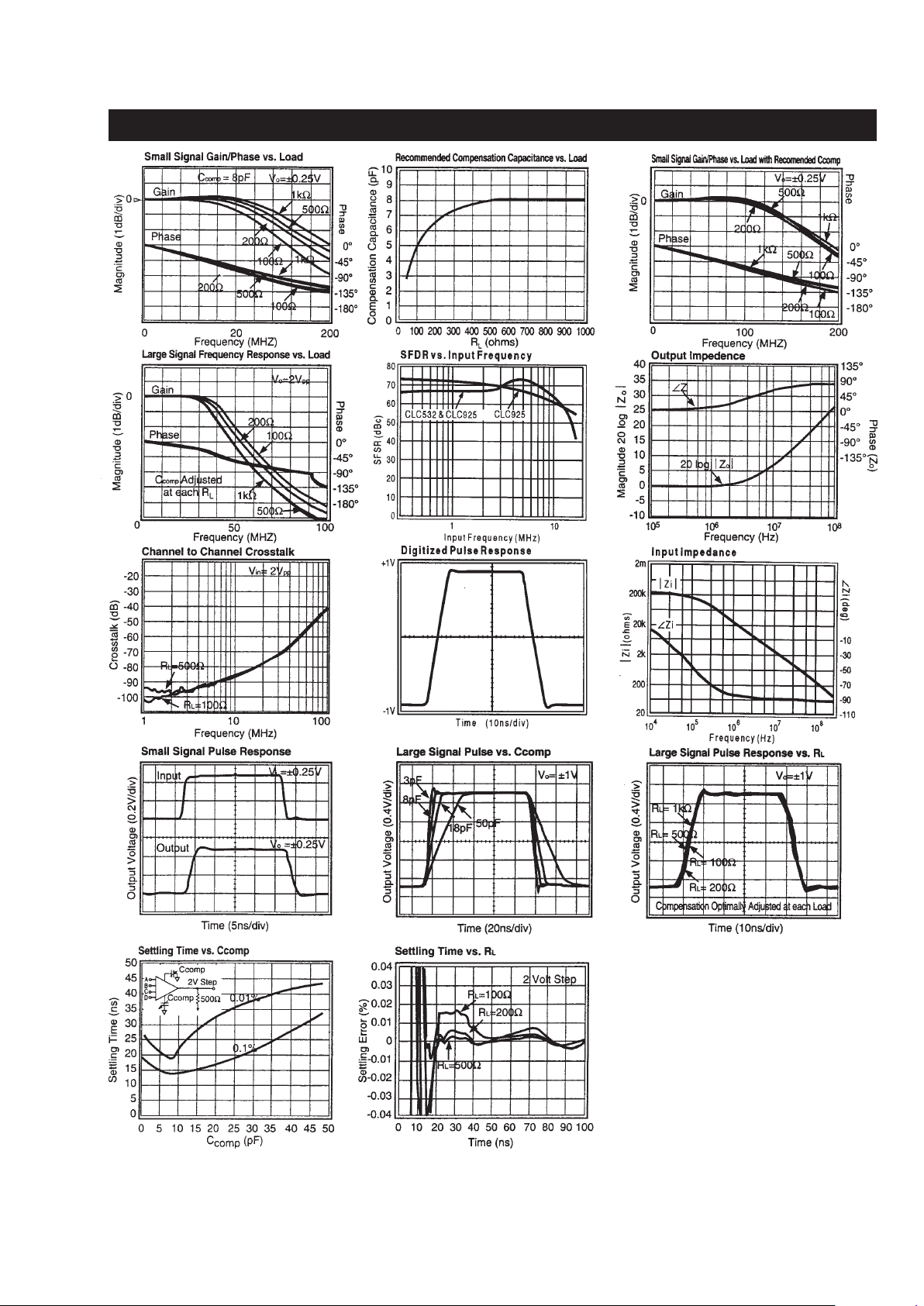

OO

OO

Operation

The CLC532 is a 2:1 analog multiplexer with high-impedance

buffered inputs, and a low-impedance, low-distortion, output

stage. The CLC532 employs a closed-loop design, which

dramatically improves accuracy. The channel SELECT control

(Figure 1) determines which of the two inputs (INA or INB) is

present at the OUTPUT. Beyond the basic multiplexer function,

the CLC532 offers compatibility with either TTL or ECL logic

families, as well as adjustable bandwidth.

R

L

R

IN

R

IN

5

IN

B

8

10

6

9

IN

A

4

3

2

1

7

13

14

V

OUT

12

CHANNEL A

CHANNEL B

CHANNEL

SELECT

DGND

-5.2V

0.1µF

C

COMP

2

C

COMP

1

+5V

CLC532

D

REF

11

0.1

µ

F

+6.8

µ

F

+6.8

µ

F

Figure 1: Standard CLC532 Circuit Configuration

Digital Interface and Channel SELECT

The CLC532 functions with ECL, TTL and CMOS logic families.

D

REF

controls logic compatibility. In normal operation, D

REF

is left

floating, and the channel SELECT responds to ECL level signals,

Figure 2. For TTL or CMOS level SELECT inputs (Figure 3), D

REF

should be tied to +5V (the CLC532 incorporates an internal

2300Ω series isolation resistor for the D

REF

input). For TTL or

CMOS operation, the channel SELECT requires a resistor input

network to prevent saturation of the channel select circuitry.

Without this input network, channel SELECT logic levels above

3V will cause internal junction saturation and slow switching

speeds.

ECL GATE

CHANNEL

SELECT

A

/

B

50Ω

50Ω

-2V

D

REF

7

SELECT

6

(NC)

CLC532

-5.2V

To ECL

Gate

To

SELECT

130

Ω

81Ω

Thevinen Equivalent

Output Termination

R1

R2

Figure 2: ECL Level Channel SELECT Configuration

+5V

CHANNEL

SELECT

A

/

B

7

D

REF

6

+5V

CLC532

TTL CMOS

R3

R2

R1

Ω

Ω

Ω

Ω

Ω

Ω

620

200

510

3.6k

510

680

R2

R3

R1

Figure 3: TTL/CMOS Level Channel SELECT Configuration

Compensation

The CLC532 incorporates compensation nodes that allow both

its bandwidth and its settling time/slew rate to be adjusted.

Bandwidth and settling time/slew adjustments are linked,

meaning that lowering the bandwidth also lowers slew rate

and lengthens settling time. Proper adjustment (compensation)

is necessary to optimize system performance. Time Domain

applications should generally be optimized for lowest RMS

noise at the CLC532 output, while maintaining settling time and

slew rates at adequate levels to meet system needs. Frequency

Domain applications should generally be optimized for maximally

flat frequency response.

Figure 4 below describes the basic relationship between

bandwidth and RS for various values of load capacitance, CL,

where C

COMP

= 10pF.

0.01%

0.05%

Rs

Ts

1kΩ

R

s

C

L

2V Output Step

CL(pF)

Recommended R

s

(Ω)

Settling time, T

s

(ns)

1 100 1000

100

90

80

70

60

50

40

30

20

10

0

100

90

80

70

60

50

40

30

20

10

0

Figure 4: Settling Time and RS vs. C

L

Figure 5 shows the resulting changes in bandwidth and slew rate

for increasing values of C

COMP

. The RMS noise at the CLC532

output can be approximated as:

OUTPUT

NOISE

RMS

= (nV)(√1.57*BW

-3dB

)

where... n

V

= input spot noise voltage;

BW

-3dB

= Bandwidth is from figure 5.

Slew Rate (V/

µ

s)

1 10 100

C

comp

(pF)

200

180

160

140

120

100

80

60

40

20

0

-3dB Bandwidth

Slew Rate

200

180

160

140

120

100

80

60

40

20

Figure 5: C

COMP

for Maximally Flat Frequency Response

Applications Information

http://www.national.com 6

Page 7

Power Supplies and Grounding

Proper power supply bypassing and grounding is essential to

the CLC532’s operation. A 0.1µF to 0.01mF ceramic chip

capacitor should be located as close as possible to the individual

power supply pins. Larger +6.8µF tantalum capacitors should

be used within a few inches of the CLC532. The ground

connections for these larger by-pass capacitors should be very

symmetrically located relative the CLC532 output load ground

connection. Harmonic distortion can be heavily influenced by

non-symmetric decoupling capacitor grounding. The smaller

chip capacitors located directly at the power supply pins are not

particularly susceptible to this effect.

Separation of analog and digital ground planes is not

recommended. In most cases, a single low-impedance ground

plane will provide the best performance. In those special cases

requiring separate ground planes, the following table indicates

the signal and supply ground connections.

Pin Functions Ground Return

1,3 Shield /Supply Returns Supplies and Inputs

5D

REF

Ground D

REF

Currents Only

Input Shielding

The CLC532 has been designed for use in high-speed widedynamic range systems. Guard-ring traces and the use of the

ground pins separating the analog inputs are recommended to

maintain high isolation (Figure 6). Likely sources of noise and

interference that may couple onto the inputs, are the logic signals

and power supplies to the CLC532. Other types of clock and

signal traces should not be overlooked, however.

Channel A

Connector

Channel B

Connector

Chip Resistors

Pin 1

Figure 6: Alternate Layout Using Guard Ring

The general rule in maintaining isolation has two facets, minimize

the primary return ground current path impedances back to the

respective signal sources, while maximizing the impedance

associated with common or secondary ground current return

paths. Success or failure to optimize input signal isolation can

be measured directly as the isolation between the input channels

with the CLC532 removed from circuit. The channel-to-channel

isolation of the CLC532 can never be better than the isolation

level present at its inputs.

Special attention must be paid to input termination resistors.

Minimizing the return current path that is common to both of the input

termination resistors is essential. In the event that a ground return

current from one input termination resistor is able to find a secondary

path back to its signal source (which also happens to be common

with either the primary or secondary return path for the second input

termination resistor), a small voltage can appear across the second

input termination resistor. The small voltage seen across the

second input termination resistor will be highly correlated with the

signal generating the initial return currents. This situation will

severely degrade channel-to-channel isolation at the input of the

CLC532, even if the CLC532 were removed from circuit. Poor

isolation at the input will be transmitted directly to the output.

Use of "small" value input termination resistors will also improve

channel-to-channel isolation. However, extremely low values

(<25Ω) tend to stress the driving source's ability to provide a highquality input signal to the CLC532. Higher values tend to

aggravate any layout dependent crosstalk. 75Ω to 50Ω is a

reasonable target, but the lower the better.

Combining Two Signals in ADC Applications

The CLC532 is applicable in a wide range of circuits and

applications. A classic example of this flexibility is combining two

or more signals for digitization by an analog-to-digital converter

(ADC). A clear understanding of both the multiplexer and the

ADC's operation is needed to optimize this configuration.

To obtain the best performance from the combination, the output

of the CLC532 must be an accurate representation of the

selected input during the ADC conversion cycle. The time at

which the ADC samples the input varies with the type of ADC that

is being used.

Subranging ADCs usually have a Track-and-Hold (T/H) at their

input. For a successful combination of the multiplexer and the

ADC, the multiplexer timing and the T/H timing must be compatible.

When the ADC is given a convert command, the T/H transitions

from Track mode to Hold mode. The delay between the convert

command and this transition is usually specified as Aperture

Delay or as Sampling Time Offset.

To maximize the time that the multiplexer output has to settle, and

that the T/H has to acquire the signal, the multiplexer should

begin its transition from one input to the other immediately after

the T/H transition into HOLD mode. Unfortunately it is during the

initial portion of the HOLD period that a subranging ADC performs

analog processing of the sampled signal. High slew rate

transitions on the input during this time may have a detrimental

effect on the conversion accuracy.

To minimize the effects of high input slew rates, two strategies

that can employed. Strategy one applies when the sample rate

of the system is below the rated speed of the ADC. Here the

CLC532 SELECT timing is delayed until after the multiplexer

transition takes place, and after the A/D has completed one

conversion cycle and is waiting for the next convert command.

As an example, if a CLC935 (15MSPS) ADC is being used at

10MSPS, the conversion takes place in the first 67ns after the

CONVERT command. The next 33ns are spent waiting for the

next CONVERT command, and would be an ideal place to switch

the multiplexer from one channel to the next.

Sample Rate (MSPS)

C

comp

(pF)

10 11 12 13 14 15 16 17 18 19 20

50

45

40

35

30

25

20

15

10

5

Figure 7: Recommended C

COMP

vs. ADC Sample Rate

The second optimization strategy involves lowering the slew rate

at the input of the ADC so that fewer high frequency components

are available to feed through to the hold capacitor during HOLD

7 http://www.national.com

Page 8

mode. The CLC532 output signal can be slew limited by using

its compensation capacitors. This approach also has the

advantage of limiting the excess noise passed through the

CLC532 and on to the ADC. Figure 7 shows the recommended

C

COMP

values as a function of ADC Sample rate. Since the optimal

values will change from one ADC to the next, this graph should

be used as a starting point for C

COMP

selection. Both C

COMP

capacitors should be the same value to maintain output symmetry.

Flash ADCs are similar to subranging ADCs in that the sampling

period is very brief. The primary difference is that the acquisition

time of a flash converter is much shorter than that of a subranging

ADC. With a flash ADC, the transition of the CLC532 output

should be after the sampling instant ("Aperture Delay" after the

CONVERT command). It is only during this period that a flash

converter is susceptible to interference from a rapidly changing

analog input signal.

Gain Selection for an ADC

In many applications, such as RADAR, the dynamic range

requirements may exceed the accuracy requirements. Since

wide dynamic range ADCs are also typically highly accurate

ADCs, this often leads the designer into selecting an ADC which

is a technical overkill and a budget buster. By using the CLC532

as a selectable-gain stage, a less expensive ADC can be used.

As an example, if an application calls for 80dB of dynamic Range

and 0.05% accuracy, rather than using a 14-bit converter, a 12bit converter combined with the circuit in figure 8 will meet the

same objective. The CLC532 is used to select between the

analog input signal and a version of the input signal attenuated

by 12dB. This circuit affords 14-bit dynamic range, 12-bit

accuracy and 12-bit ease of implementation.

CLC532

µ

F

Gain

SELECT

0.1 F

F

µ

R

48.7

5

IN

B

8

10

6

9

IN

A

4

3

2

1

7

13

14

12

DGND

-5.2V

0.1µF

+5V

D

REF

11

µ

+6.8

+6.8

10pF

10pF

50Ω

50Ω

OUT

Ω

50ΩTo

Load

50ΩTo

Source

Ω200

Ω66.6

0ΩTo

Source

Input

R7

R6

R

INB

Figure 8: Selectable Gain Stage Improves

ADC Dynamic Range

Full Wave Rectifier Circuit

The use of a diode rectifier provides significant distortion for

signals that are small compared to the forward bias voltage.

Accordingly, when low distortion performance is needed, standard

diode based circuits do not work well. The CLC532 can be

configured to provide a very low distortion full wave rectifier. The

circuit in figure 9 is used to select between an analog input signal

and an inverted version of the input signal. The resulting output

exhibits very little distortion for small scale signals up to several

hundred kilohertz.

10114

50Ω

50Ω

50Ω

50Ω

-2V

R

L

IN

B

IN

A

V

OUT

CLC532

V

BB

0.1µF

+1

-1

+20

RECTIFIER

INPUT

Zero Crossing

Treshold

Detector

Figure 9: Low Distortion Full Wave Rectifier

Use of the CLC532 as a Mixer.

A double balanced mixer, such as is shown in figure 10, operates

by multiplying the RF input by the LO input. This is done by using

the LO to select one of two paths through a diode bridge

depending upon the LO sign. The result is an output where IF=RF

when LO>0 and IF=-RF if LO<0. This same result can be

obtained with the circuit shown in figure 11. The CLC532 based

circuit uses a digital LO making system design easier in those

cases where the LO is digitally derived. One advantage of the

CLC532 based approach is excellent isolation between all three

ports. Also see the

RF design awards

article by Thomas Hack

in the January 1993 issue of

RF Design

.

RF

INPUT

LO

INPUT

IF

OUTPUT

Figure 10: Typical Double-Balanced Mixer

R

L

IN

B

IN

A

IF OUTPUT

200Ω

MINI-CIRCUITS

T4-1T

CLC532

RF INPUT

DIGITAL

LO INPUT

Figure 11: High-Isolation Mixer Implementation

Evaluation Board

An evaluation board (part number CLC730028) for the CLC532

is available. This board can be used for fast, trouble-free,

evaluation and characterization of the CLC532. Additionally,

this board serves as a template for layout and fabrication

information. The CLC532 evaluation board data sheet is available.

http://www.national.com 8

Page 9

This page intentionally left blank.

9 http://www.national.com

Page 10

This page intentionally left blank.

10 http://www.national.com

Page 11

This page intentionally left blank.

11 http://www.national.com

Page 12

CLC532

High-Speed 2:1 Analog Multiplexer

http://www.national.com

12

Customer Design Applications Support

National Semiconductor is committed to design excellence. For sales, literature and technical support, call the

National Semiconductor Customer Response Group at 1-800-272-9959 or fax 1-800-737-7018.

Life Support Policy

National’s products are not authorized for use as critical components in life support devices or systems without the express written approval

of the president of National Semiconductor Corporation. As used herein:

1. Life support devices or systems are devices or systems which, a) are intended for surgical implant into the body, or b) support or

sustain life, and whose failure to perform, when properly used in accordance with instructions for use provided in the labeling, can

be reasonably expected to result in a significant injury to the user.

2. A critical component is any component of a life support device or system whose failure to perform can be reasonably expected to

cause the failure of the life support device or system, or to affect its safety or effectiveness.

National Semiconductor National Semiconductor National Semiconductor National Semiconductor

Corporation Europe Hong Kong Ltd. Japan Ltd.

1111 West Bardin Road Fax: (+49) 0-180-530 85 86 2501 Miramar Tower Tel: 81-043-299-2309

Arlington, TX 76017 E-mail: europe.support.nsc.com 1-23 Kimberley Road Fax: 81-043-299-2408

Tel: 1(800) 272-9959 Deutsch Tel: (+49) 0-180-530 85 85 Tsimshatsui, Kowloon

Fax: 1(800) 737-7018 English Tel: (+49) 0-180-532 78 32 Hong Kong

Francais Tel: (+49) 0-180-532 93 58 Tel: (852) 2737-1600

Italiano Tel: (+49) 0-180-534 16 80 Fax: (852) 2736-9960

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said

circuitry and specifications.

N

Loading...

Loading...