Page 1

CLC020

SMPTE 259M Digital Video Serializer with Integrated

Cable Driver

General Description

The CLC020 SMPTE 259M Digital Video Serializer with Integrated Cable Driver is a monolithic integrated circuit that encodes, serializes and transmits bit-parallel digital data conforming to SMPTE 125M and SMPTE 267M component

video and SMPTE 244M composite video standards. The

CLC020 can also serialize other 8 or 10-bitparalleldata.The

CLC020 operates at data rates from below 100 Mbps to over

400 Mbps. The serial data clock frequency is internally generated and requires no external frequency setting components, trimming or filtering

*

. Functions performed by the

CLC020 include: parallel-to-serial data conversion, data encoding using the polynomial (X

9+X4

+1), data format conversion from NRZ to NRZI, parallel data clock frequency multiplication and encoding with the serial data, and coaxial cable

driving. Input for sync (TRS) detection disabling and a PLL

lock detect output are provided. The CLC020 has an exclusive built-in self-test (BIST) and video test pattern generator

(TPG) with 4 component video test patterns, reference

black, PLLandEQpathologicals and modified colour bars, in

4:3 and 16:9 raster and both NTSC and PALformats

*

. Separate power pins for the output driver, VCO and the digital

logic improve power supply rejection, output jitter and noise

performance.

The CLC020 is the ideal complement to the CLC011B

SMPTE 259M Serial Digital Video Decoder, CLC014 Active

Cable Equalizer, CLC016 Data Retiming PLL (clock-data

separator), CLC018 8X8 Digital Crosspoint Switch and

CLC006 or CLC007 Cable Drivers, for a complete

parallel-serial-parallel, high-speed data processing and

transmission system.

The CLC020 is powered from a single 5V supply. Power dissipation is typically 235 mW including two 75Ω

back-matched output loads. The device is packaged in a

JEDEC 28-lead PLCC.

Features

n SMPTE 259M serial digital video standard compliant

n No external serial data rate setting or VCO filtering

components required

*

n Built-in self-test (BIST) and video test pattern generator

(TPG) with 16 internal patterns

*

n Supports all NTSC and PAL standard component and

composite serial video data rates

n HCMOS/TTL-compatible data and control inputs and

outputs

n 75Ω ECL-compatible, differential, serial cable-driver

outputs

n Fast VCO lock time:

<

75 µs

n Single +5V TTL or −5V ECL supply operation

n Low power: 235 mW typical

n 28-lead PLCC package

n Commercial temperature range 0˚C to +70˚C

Applications

n SMPTE 259M parallel-to-serial digital video interfaces

for:

— Video cameras

— VTRs

— Telecines

— Video test pattern generators and digital video test

equipment

n Non-SMPTE video applications

n Other high data rate parallel/serial video and data

systems

*

Patents applications made or pending.

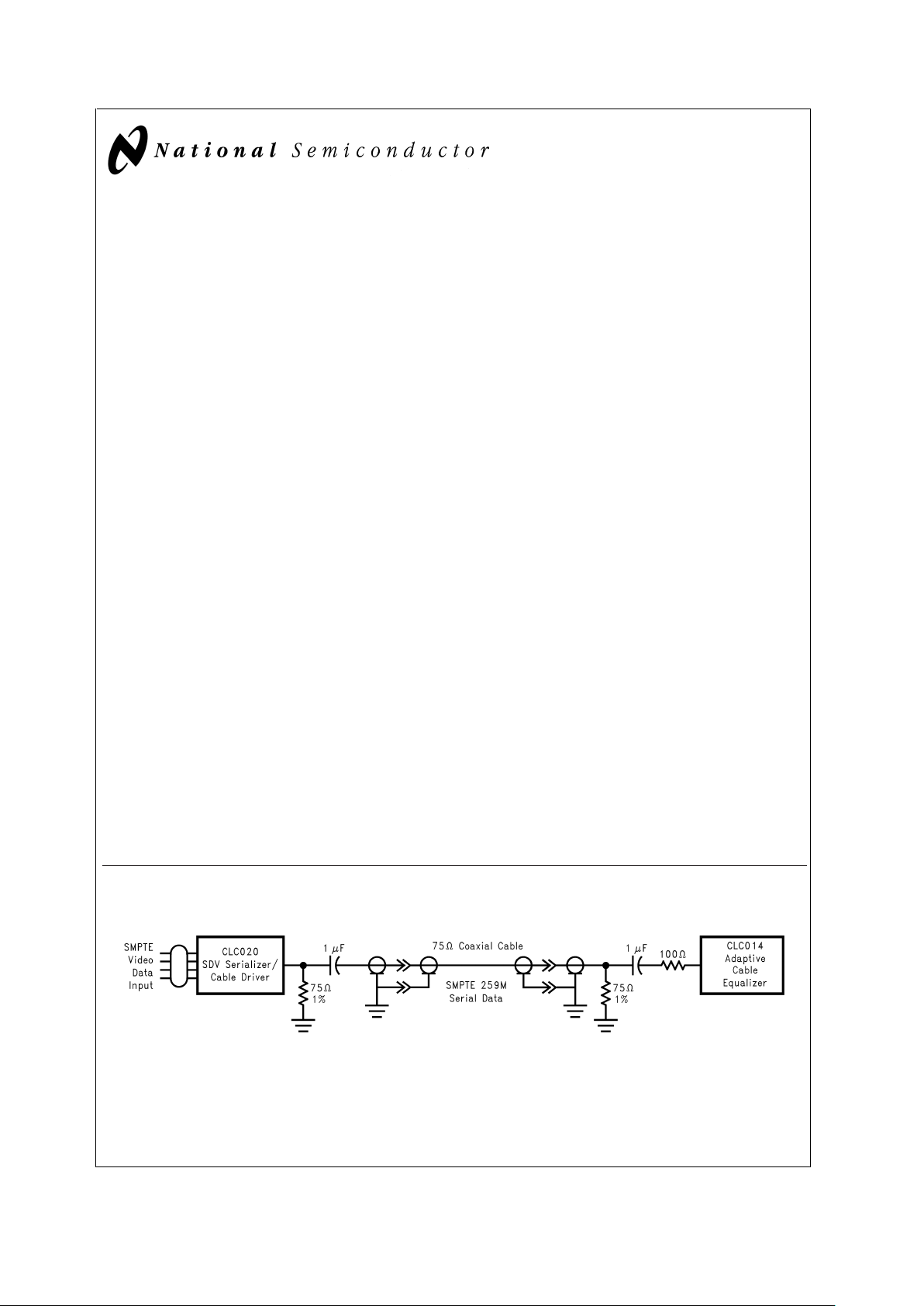

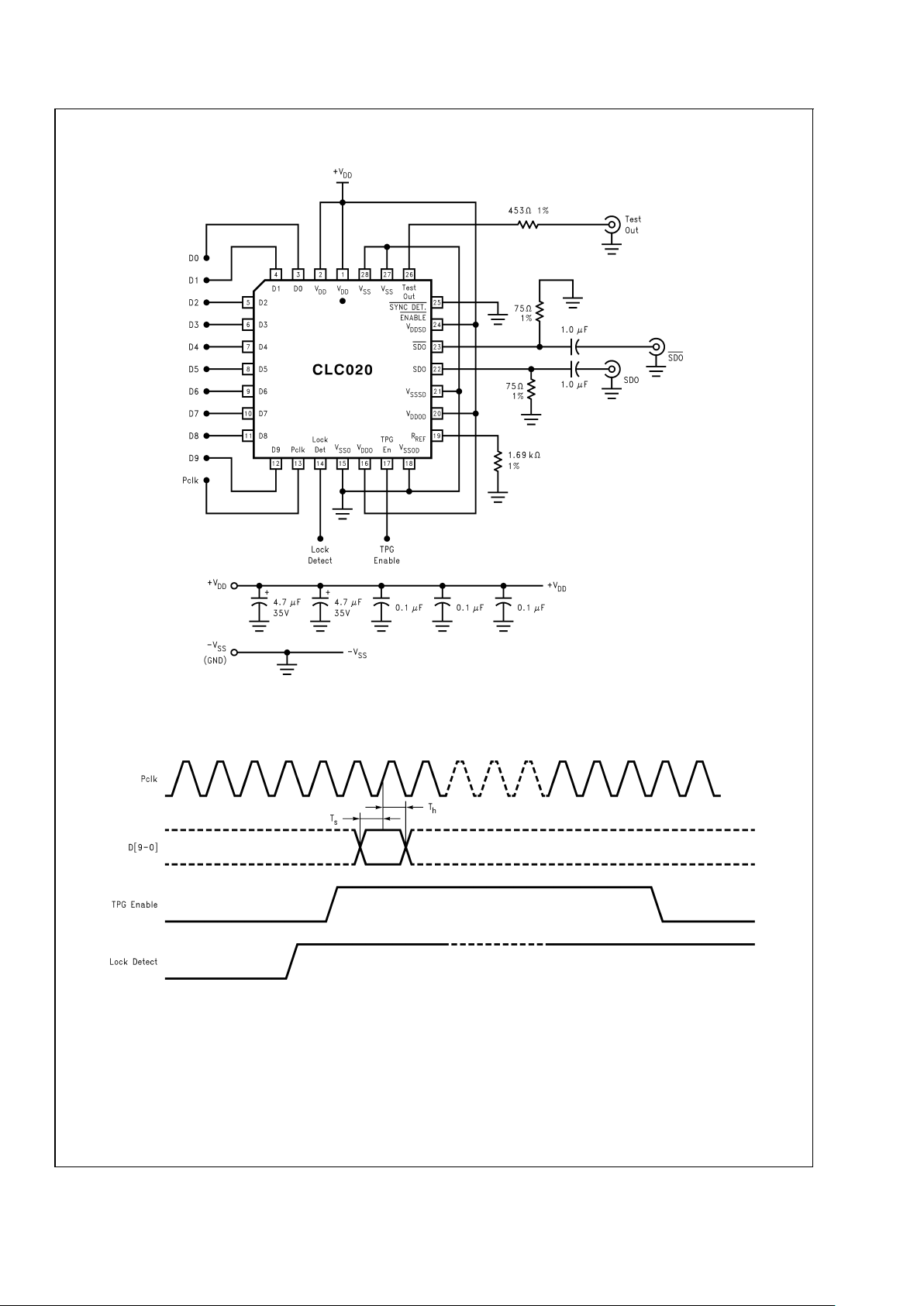

Typical Application

DS100917-12

February 2000

CLC020 SMPTE 259M Digital Video Serializer with Integrated Cable Driver

© 2000 National Semiconductor Corporation DS100917 www.national.com

Page 2

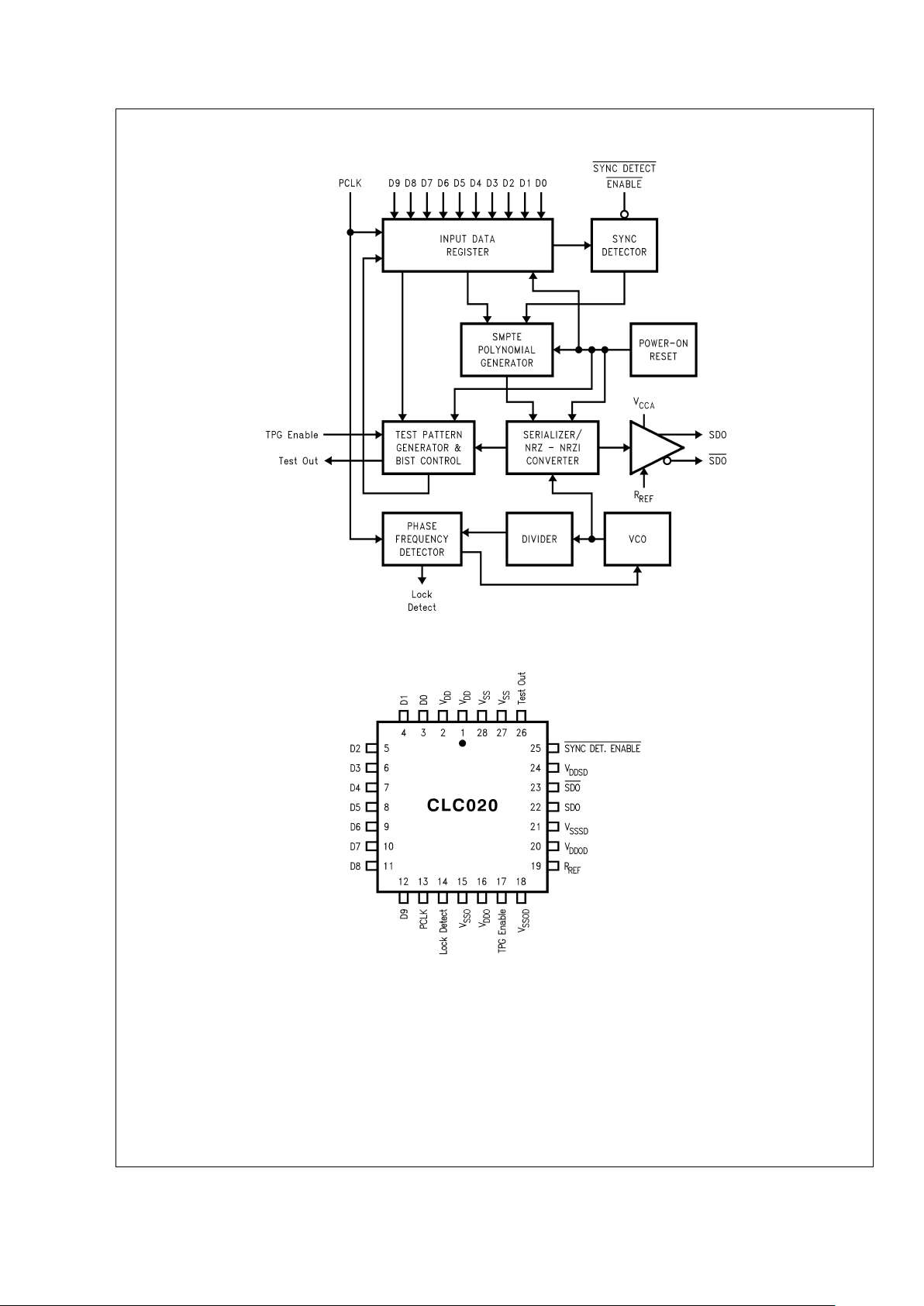

Block Diagram

Connection Diagram

DS100917-1

DS100917-2

28-Pin PLCC

Order Number CLC020ACQ

See NS Package Number V28A

CLC020

www.national.com 2

Page 3

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Supply Voltage (V

DD−VSS

) 6.0V

CMOS/TTL Input Voltage (V

I

) −0.5V to (VDD+ 0.5V)

CMOS/TTL Output Voltage (V

O

) −0.5V to (VDD+ 0.5V)

CMOS/TTL Input Current (single input)

V

I=VSS

−0.5V −5 mA

V

I=VDD

+0.5V +5 mA

Input Current, Other Inputs

±

1mA

CMOS/TTL Output Source/Sink Current

±

10 mA

SDO Output Source Current 20 mA

Package Thermal Resistance

θ

JA

28-lead PLCC 85˚C/W

θ

JC

28-lead PLCC 35˚C/W

Storage Temp. Range −65˚C to +150˚C

Junction Temperature +150˚C

Lead Temperature (Soldering 4 Sec) +260˚C

ESD Rating (HBM)

>

2.5 kV

ESD Rating (MM)

>

300 V

Transistor Count 33,400

Recommended Operating

Conditions

Supply Voltage (VDD−VSS) 5.0V±10%

CMOS/TTL Input Voltage V

SS

to V

DD

Maximum DC Bias on SDO pins 3.0V±10%

Operating Free Air Temperature (T

A

) 0˚C to +70˚C

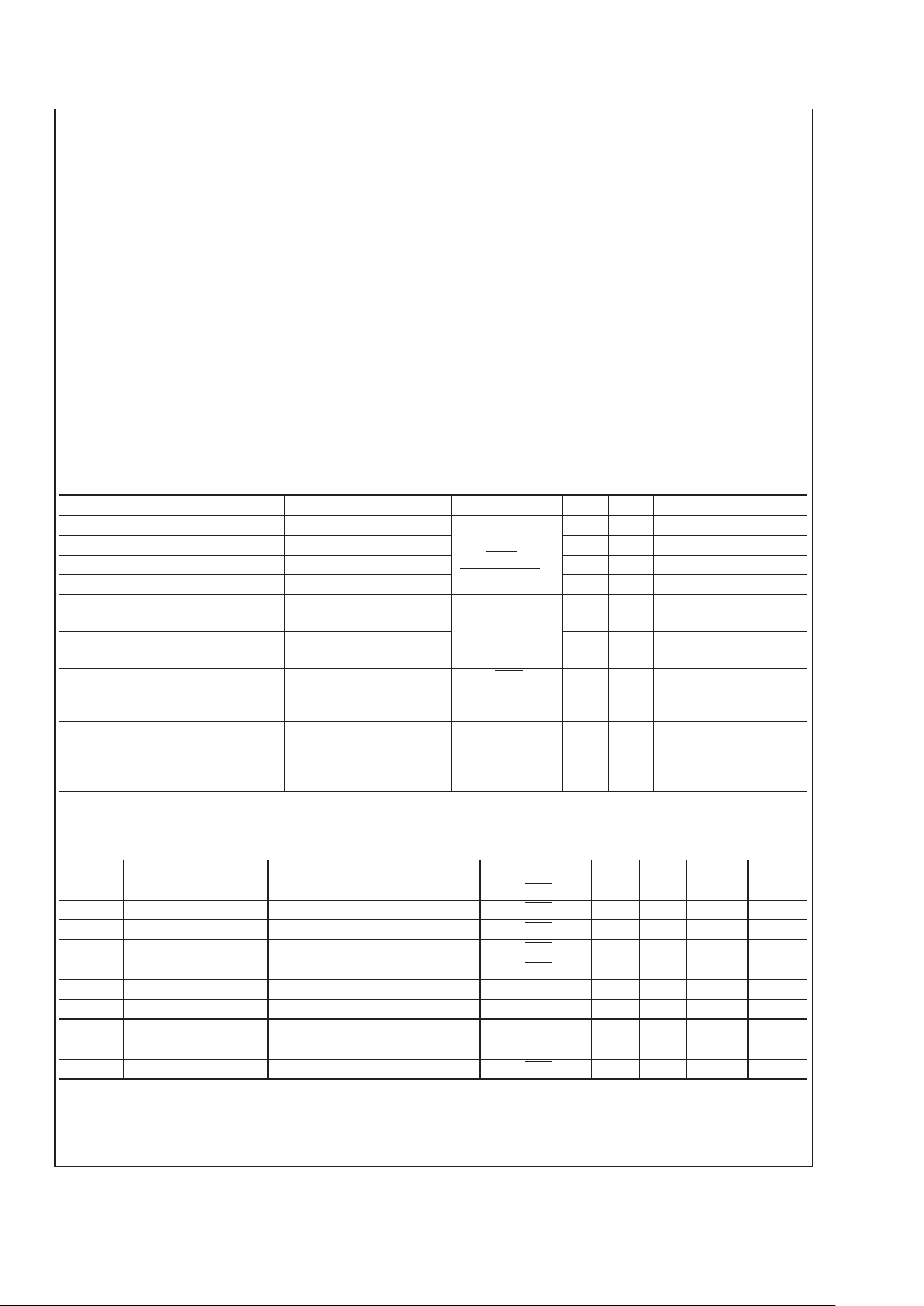

DC Electrical Characteristics

Over Supply Voltage and Operating Temperature ranges, unless otherwise specified (Notes 2, 3).

Symbol Parameter Conditions Reference Min Typ Max Units

V

IH

Input Voltage High Level D0 through D9,

P

CLK

, TPG_EN

and Sync.

Detect Enable

2.0 V

DD

V

V

IL

Input Voltage Low Level V

SS

0.8 V

I

IH

Input Current High Level VIH=V

DD

+40 +60 µA

I

IL

Input Current Low Level VIL=V

SS

-1 -20 µA

V

OH

CMOS Output Voltage

High Level

IOH= −10 mA Lock Detect,

Test Out

2.4 4.7 V

DD

V

V

OL

CMOS Output Voltage

Low Level

IOL= +10 mA 0.0 0.3 VSS+ 0.5V V

V

SDO

Serial Driver Output

Voltage

RL=75Ω1%,

R

REF

= 1.69 kΩ 1%,

Figure 2

SDO, SDO 700 800 900 mV

P-P

I

DD

Power Supply Current,

Total

RL=75Ω1%,

R

REF

= 1.69 kΩ 1%,

P

CLK

= 27 MHz,

Figure 2

,

NTSC Colour Bar Pattern

47 60 mA

AC Electrical Characteristics

Over Supply Voltage and Operating Temperature ranges, unless otherwise specified (Note 3).

Symbol Parameter Conditions Reference Min Typ Max Units

BR

SDO

Serial data rate RL=75Ω, AC coupled, (Note 5) SDO, SDO 100 400 Mbps

t

j

Serial output jitter 270 Mbps,

Figure 2

, (Note 6) SDO, SDO 220 ps

P-P

t

jit

Serial output jitter (Notes 4, 5) SDO, SDO 100 200 ps

P-P

tr,t

f

Rise time, Fall time 20%–80%, (Notes 4, 5) SDO, SDO 500 800 1500 ps

Output overshoot SDO, SDO

1%

t

LOCK

Lock time 270 Mbps, (Notes 5, 7) 75 µs

t

SU

Setup time

Figure 3

DNto P

CLK

32 ns

t

HLD

Hold time

Figure 3

DNfrom P

CLK

1.5 1 ns

L

GEN

Output inductance (Note 4) SDO, SDO 6nH

R

GEN

Output resistance (Note 4) SDO, SDO 25k Ω

CLC020

www.national.com3

Page 4

AC Electrical Characteristics (Continued)

Note 1: “Absolute Maximum Ratings” are those parameter values beyond which the life and operation of the device cannot be guaranteed. The stating herein of

these maximums shall not be construed to imply that the device can or should be operated at or beyond these values. The table of “Electrical Characteristics” specifies acceptable device operating conditions.

Note 2: Current flow into device pins is defined as positive. Current flow out of device pins is defined as negative. All voltages are stated referenced to V

SS

=0V.

Note 3: Typical values are stated for V

DD

= +5.0V and TA= +25˚C.

Note 4: Specification is guaranteed by design.

Note 5: R

L

=75Ω, AC-coupled@270 M

bps,RREF

= 1.69 kΩ 1%, See

Test Loads

and

Figure 2

.

Note 6: CLC020 mounted in the SD020EVK board, configured in BIST mode (NTSC color bars) with P

CLK

= 27MHz derived from Tektronix TG2000 black-burst ref-

erence. Timing jitter measured with Tektronix VM700T using jitter measurement FFT mode, frame rate, 1kHz filter bandwidth, Hanning window.

Note 7: Measured from rising-edge of first P

CLK

cycle until Lock Detect output goes high (true).

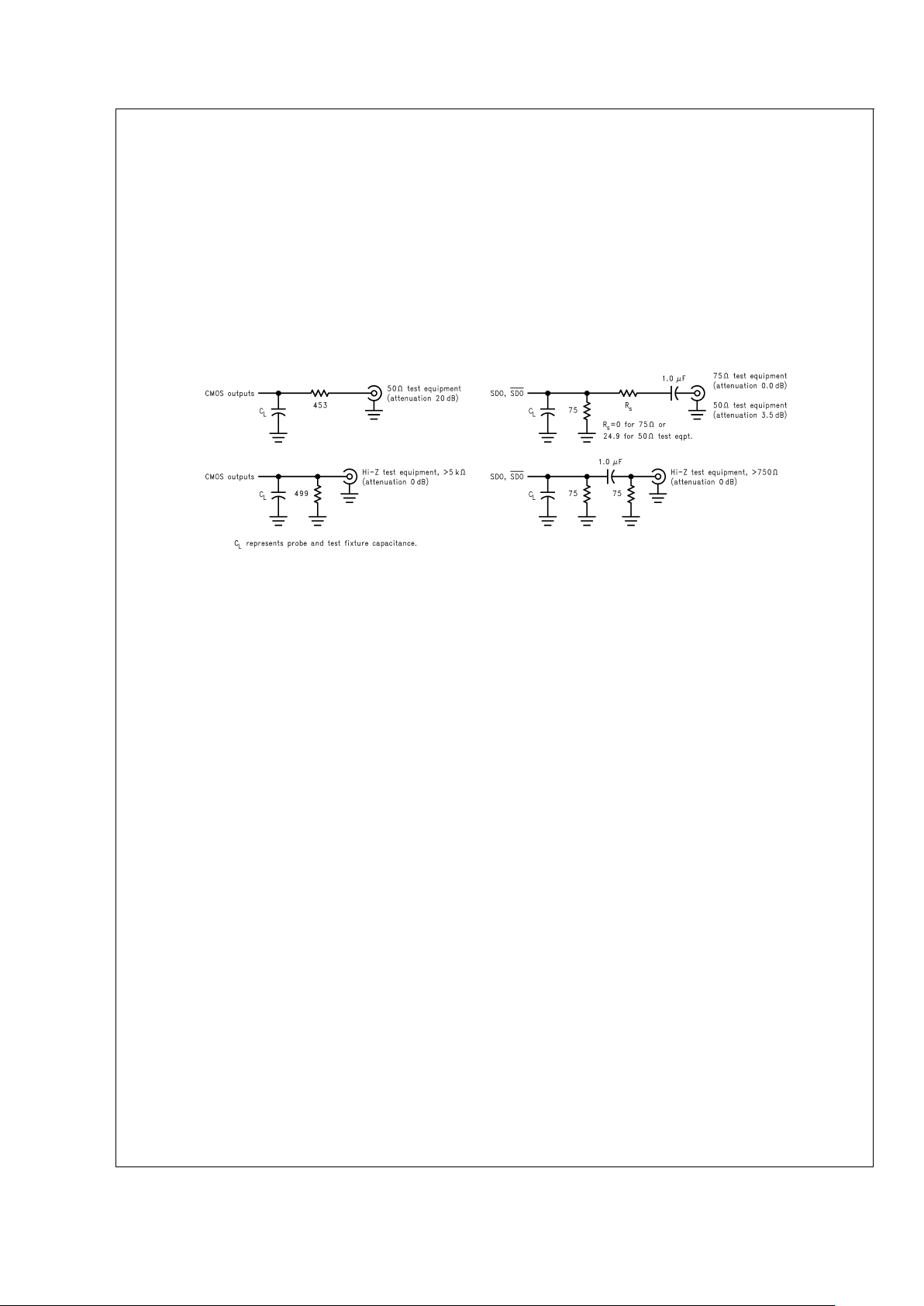

Test Loads

DS100917-3

All resistors in Ohms, 1% tolerance.

FIGURE 1. Test Loads

CLC020

www.national.com 4

Page 5

Test Loads (Continued)

Timing Diagram

Device Operation

The CLC020 SMPTE 259M Digital Video Serializer is used in

digital video signal origination and processing equipment:

cameras, video tape recorders, telecines, video test equipment and others. It converts parallel component or composite digital video signals into serial format. Logic levels within

this equipment are normally TTL-compatible as produced by

CMOS or bipolar logic devices. The encoder outputs

ECL-compatible serial digital video (SDV) signals conforming to SMPTE 259M-1997. The CLC020 operates at all standard SMPTE and ITU-R parallel data rates.

DS100917-4

FIGURE 2. Test Circuit

DS100917-5

FIGURE 3. Setup and Hold Timing

CLC020

www.national.com5

Page 6

Device Operation (Continued)

VIDEO DATA PROCESSING CIRCUITS

The input data register accepts 8 or 10-bit parallel data and

clock signals having CMOS/TTL-compatible signal levels.

Parallel data may conform to any of several standards:

SMPTE 125M, SMPTE 267M, SMPTE 244M or ITU-R

BT.601. If data is 8-bit, it is converted to a 10-bit representation according to the type of data being input: component

4:2:2 per SMPTE 259M paragraph 7.1.1, composite NTSC

per paragraph 8.1.1 or composite PAL per paragraph 9.1.1.

Output from this register feeds the SMPTE polynomial

generator/serializer and sync detector. All CMOS inputs including the P

CLK

input have internal pull-down devices.

The sync detector or TRS character detector accepts data

from the input register. The detection function is controlled

by Sync Detect Enable, a low-true, TTL-compatible, external

signal. Synchronization words, the timing reference signals

(TRS), start-of-active-video (SAV) and end-of-active-video

(EAV) are defined in SMPTE 125M-1995 and 244M. The

sync detector supplies control signals to the SMPTE polynomial generator that identify the presence of valid video data.

The sync detector performs input TRS character

LSB-clipping as prescribed in ITU-R-BT.601. LSB-clipping

causes all TRS characters with a value between 000h and

003h to be forced to 000h and all TRS characters with a

value between 3FCh and 3FFh to be forced to 3FFh. Clipping is done prior to encoding.

The SMPTE polynomial generator accepts the parallel

video data and encodes it using the polynomial X

9+X4

+1 as

specified in SMPTE 259M–1997, paragraph 5 and Annex C.

The scrambled data is then serialized for output.

The NRZ-to-NRZI converter accepts serial NRZ data from

the SMPTE polynomial genertor and converts it to NRZI using the polynomialX+1perSMPTE 259M–1997, paragraph

5.2 and Annex C. The transmission bit order is LSB first, per

paragraph 6. The converter’s output feeds the output driver

amplifier.

PHASE-LOCKED LOOP AND VCO

The phase-locked loop (PLL) system generates the output

serial data clock at 10x the parallel data clock frequency.

This system consists of a VCO, divider chain,

phase-frequency detector and internal loop filter. The VCO

free-running frequency is internally set. The PLL automatically generates the appropriate frequency for the serial clock

rate using the parallel data clock (P

CLK

) frequency as its reference. Loop filtering is internal to the CLC020. The VCO

has separate V

SSO

and V

DDO

power supply feeds, pins 15

and 16, which may be supplied power independently via an

external low-pass filter, if desired. The PLL acquisition (lock)

time is less than 75 µs

@

270 Mbps.

LOCK DETECT

The Lock Detect output of the phase-frequency detector indicates the PLL lock condition. It is a logic HIGH when the

loop is locked. The output is CMOS/TTL-compatible and is

suitable for driving other CMOS devices or a LED indicator.

SERIAL DATA OUTPUT BUFFER

The current-mode serial data outputs provide low-skew

complimentary or differential signals. The output buffer design can drive 75Ω coaxial cables (AC-coupled) or 10k/100k

ECL/PECL-compatible devices (DC-coupled). Output levels

are 800 mV

P-P

±

10% into 75Ω AC-coupled, back-matched

loads. The output level is 400 mV

P-P

±

10% when

DC-coupled into 75Ω (See Application Information for details). The 75Ω resistors connected to the SDO outputs are

back-matching resistors. No series back-matching resistors

should be used. SDO output levels are controlled by the

value of R

REF

connected to pin 19. The value of R

REF

is nor-

mally 1.69 kΩ,

±

1%. The output buffer is static when the de-

vice is in an out-of-lock condition. Separate V

SSSD

and

V

DDSD

power feeds, pins 21 and 24, are provided for the se-

rial output driver.

POWER-ON RESET

The CLC020 has an internally controlled, automatic,

power-on reset circuit. This circuit clears TRS detection circuitry,all latches, registers, counters and polynomial generators and disables the serial output. The SDO outputs are

tri-stated during power-on reset. The part will remain in the

reset condition until the parallel input clock is applied.

BUILT-IN SELF-TEST (BIST)

The CLC020 has a built-in self-test (BIST) function. The

BIST performs a comprehensive go-no-go test of the device.

The test uses either a full-field color bar for NTSC or a PLL

pathological for PALas the test data pattern. Data is input internally to the input data register, processed through the device and tested for errors.

Table 1

gives device pin functions

and

Table 2

gives the test pattern codes used for this function. The signal level at Test_Output,pin 26, indicates a pass

or fail condition.

The BIST is initiated by applying the code for the desired

BIST to D0 throught D3 (D9 through D4 are 00h) and a

27 MHz clock at the P

CLK

input. Since all parallel data inputs

are equipped with an internal pull-down device, only those

inputs D0 through D3 which require a logic-1 need be pulled

high.After the Lock_Detect output goes high (true) indicating

the VCO is locked on frequency,TPG_Enable, pin 17, is then

taken to a logic high. TPG_Enable may be temporarily connected to the Lock_Detect output to automate BIST operation. Test_Output, pin 26, is monitored for a pass/fail indication. If no errors have been detected, this output will go to a

logic high level approximately 2 field intervals after

TPG_Enable is taken high. If errors have been detected in

the internal circuitry of the CLC020, Test_Output will remain

low until the test is terminated. The BIST is terminated by

taking TPG_Enable to a logic low. Continuous serial data

output is available during the test.

TEST PATTERN GENERATOR

The CLC020 features an on-board test pattern generator

(TPG). Four full-field component video test patterns for both

NTSC and PALstandards, and 4x3 and 16x9 raster sizes are

produced. The test patterns are: flat-field black, PLL pathological, equalizer (EQ) pathological and a modified 75%,

8-color vertical bar pattern. The pathologicals follow recommendations contained in SMPTE RP 178–1996 regarding

the test data used. The color bar pattern does not incorporate bandwidth limiting coding in the chroma and luma data

when transitioning between the bars. For this reason, it may

not be suitable for use as a visual test pattern or for input to

video D-to-A conversion devices unless measures are taken

to restrict the production of out-of-band frequency components.

The TPG is operated by applying the code for the desired

test pattern to D0 through D3 (D4 through D9 are 00h). Since

all parallel data inputs are equipped with an internal

pull-down device, only those inputs D0 through D3 which require a logic-1 need be pulled high. Next, apply a 27 or

CLC020

www.national.com 6

Page 7

Device Operation (Continued)

36 MHz signal, appropriate to the raster size desired, at the

P

CLK

input and wait until the Lock_Detect output goes true

indicating the VCO is locked on-frequency. Then, take

TPG_Enable, pin 17, to a logic high. The serial test pattern

data appears on the SDO outputs. TPG_Enable may be

temporarily connected to the Lock_Detect output to automate TPG operation. The TPG mode is exited by taking

TPG_Enable to a logic low.

Table 1

gives device pin func-

tions for this mode.

Table 2

gives the available test patterns

and selection codes.

TABLE 1. BIST and Test Pattern Generator Control Functions

Pin Name Function

3 D0 TPG code input LSB

4 D1 TPG code input

5 D2 TPG code input

6 D3 TPG code input MSB

17 TPG_EN TPG Enable, active high true

26 Test_Out BIST Pass/Fail output. Pass=High

(See text for timing requirements)

DS100917-6

FIGURE 4. Built-In Self-Test Control Sequence

DS100917-7

FIGURE 5. Test Pattern Generator Control Sequence

CLC020

www.national.com7

Page 8

Device Operation (Continued)

TABLE 2. Component Video Test Pattern Selection

Standard Frame Test Pattern D3 D2 D1 D0

NTSC 4x3 Flat-field black 0000

NTSC 4x3 PLL pathological 0001

NTSC 4x3 EQ pathological 0010

NTSC 4x3 Color bars, 75%, 8-bars (modified, see text), BIST 0011

PAL 4x3 Flat-field black 0100

PAL 4x3 PLL pathological, BIST 0101

PAL 4x3 EQ pathological 0110

PAL 4x3 Color bars, 75%, 8-bars (modified, see text) 0111

NTSC 16x9 Flat-field black 1000

NTSC 16x9 PLL pathological 1001

NTSC 16x9 EQ pathological 1010

NTSC 16x9 Color bars, 75%, 8-bars (modified, see text) 1011

PAL 16x9 Flat-field black 1100

PAL 16x9 PLL pathological 1101

PAL 16x9 EQ pathological 1110

PAL 16x9 Color bars, 75%, 8-bars (modified, see text) 1111

Note: D9 through D4 = 0 (binary)

CLC020

www.national.com 8

Page 9

Pin Descriptions

Pin # Name Description

1V

DD

Positive power supply input (digital logic)

2V

DD

Positive power supply input (digital logic)

3 D0 Parallel data input/Test pattern select (LSB)

4 D1 Parallel data input/Test pattern select

5 D2 Parallel data input/Test pattern select

6 D3 Parallel data input/Test pattern select (MSB)

7 D4 Parallel data input

8 D5 Parallel data input

9 D6 Parallel data input

10 D7 Parallel data input

11 D8 Parallel data input

12 D9 Parallel data input

13 PCLK Parallel clock input

14 Lock Detect VCO Lock Detect output (high-true)

15 V

SSO

Negative power supply input (PLL supply)

16 V

DDO

Positive power supply input (PLL supply)

17 TPG_EN Test Pattern Generator (TPG) Enable input (high-true)

18 V

SSOD

Negative power supply input (PLL digital supply)

19 R

REF

Output driver level control

20 V

DDOD

Positive power supply input (PLL digital supply)

21 V

SSSD

Negative power supply input (Output driver)

22 SDO Serial data true output

23 SDO

Serial data complement output

24 V

DDSD

Positive power supply input (Output driver)

25 Sync Detect Enable

Parallel data sync detection enable input (low true)

26 Test_Out BIST Pass/Fail output

27 V

SS

Negative power supply input (digital logic)

28 V

SS

Negative power supply input (digital logic)

Note: All CMOS/TTL inputs have internal pull-down devices.

CLC020

www.national.com9

Page 10

Application Information

A typical application circuit for the CLC020 is shown in

Fig-

ure 6

. This circuit demonstrates the capabilities of the

CLC020 and allows its evaluation in a variety of configurations. An assembled demonstration board with more comprehensive evaluation options is available, part number

SD020EVK. The board may be ordered through any of Na-

tional’s sales offices. Complete circuit board layouts and

schematics, for the SD020EVK are available on National’s

WEB site in the application information for this device. For

latest information, please see:

www.national.com/appinfo/interface

APPLICATION CIRCUIT

Several different input and output drive and loading options

can be constructed on the SD020EVK application circuit

board,

Figure 7

. Pin headers are provided for input cabling

and control signal access. The appropriate value resistor

packs, 220 and 330Ω for TTL or 50Ω for signal sources requiring such loading, should be installed at RP1-4 before applying input signals. Output loading can be adapted to both

50 and 75Ω test equipment. Resistors R3 and R4, 24.9Ω,

size 1206 surface-mount, should be installed when using

50Ω test loads. Output levels at J1 and J2 will be attenuated

by 3.5 dB under these conditions. (Note: it is necessary to

cut and remove the traces shorting the mounting pads of R3

and R4 before installing these components).

The board’s outputs may be DC interfaced to PECL inputs by

first installing 124Ω resistors at R1B and R2B, changing R1A

and R2A to 187Ω and replacing C1 and C2 with short circuits. The PECL inputs should be directly connected to J1

and J2 without cabling. If 75Ω cabling is used to connect the

CLC020 to the PECL inputs, the voltage dividers used on the

CLC020 outputs must be removed and re-installed on the

circuit board where the PECL device is mounted. This will

provide correct termination for the cable and biasing for both

the CLC020’s outputs and the PECL inputs. It is most important to note that a 75Ω or equivalent DC loading (measured

with respect to the negative supply rail) must always be installed at both of the CLC020’s SDO outputs to obtain proper

signal levels from device. When using 75Ω

Thevenin-equivalent load circuits, the DC bias applied to the

SDO outputs should not exceed +3V with respect to the

negative supply rail. Serial output levels should be reduced

to 400 mV

p-p

by changing R

REF

to 3.4 kΩ.

The Test Out output circuit includes a series 453Ω resistor,

R10, which permits driving 50Ω test loads. The signal level

at J3 will be attenuated by 20 dB. For high impedance test

loads (

>

500Ω), replace R10 with a short circuit. If the Lock

Detect output is to be externally monitored, the attached

monitoring circuit should present a DC resistance greater

than 5 kΩ so as not to affect Lock Detect indicator operation.

DS100917-8

FIGURE 6. Typical Application Circuit

CLC020

www.national.com 10

Page 11

Application Information (Continued)

MEASURING JITTER

The test method used to obtain the timing jitter value given in

the AC Electrical Specification table is based on procedures

and equipment described in SMPTE RP 192-1996. The recommended practice discusses several methods and indicator devices. An FFT method performed by standard video

test equipment was used to obtain the data given in this data

sheet. As such, the jitter characteristics (or jitter floor) of the

measurement equipment, particularly the measurement analyzer, become integral to the resulting jitter value. The

method and equipment were chosen so that the test can be

easily duplicated by the design engineer using most standard digital video test equipment. In so doing, similar results

should be achieved. The intrinsic jitter floor of the CLC020’s

PLL is approximately 25% of the typical jitter given in the

electrical specifications. In production, device jitter is measured on automatic IC test equipment (ATE)using a different

method compatible with that equipment. Jitter measured using this ATE yields values approximately 50% of those obtained using the video test equipment.

The jitter test setup used to obtain values quoted in the data

sheet consists of:

•

National Semiconductor SD020EVK, CLC020 evaluation

kit

•

Tektronix TG2000 signal generation platform with DVG1

option

•

Tektronix VM700T Option 1S Video Measurement Set

•

Tektronix TDS 794D, Option C2 oscilloscope

•

Tektronix P6339A passive probe

•

75 Ohm coaxial cable, 3ft., Belden 8281 or RG59 (2 required)

•

ECL-to-TTL/CMOS level converter/amplifier,

Figure 9

Apply the black-burst reference clock from the TG2000 signal generator’s BG1 module 27MHz clock output to the level

converter input. The clock amplitude converter schematic is

shown in Figure 9. Adjust the input bias control to give a 50%

duty cycle output as measured on the oscilloscope/probe

system. Connect the level translator to the SD020EVK

board, connector P1, P

CLK

pins (the outer-most row of pins

is ground). Configure the SD020EVK to operate in the NTSC

colour bars, BIST mode. Configure the VM700T to make the

jitter measurement in the jitter FFT mode at the frame rate

DS100917-9

Connect LOCK DETECT to TPG ENABLE for test pattern generator function.

Remove RP1 & RP3 and replace RP2 & RP4 with 50Ω resistor packs for coax interfacing.

Install RP1-4 when using ribbon cable for input interfacing.

This board is designed for use with TTL power supplies only.

For optional ECL compatible load: R1A = R2A = 187; R1B = R2B = 124.

All resistances & impedances in Ohms. Values with 3 significant digits are 1%; with 2 digits 5%.

FIGURE 7. SD020EVK Schematic Diagram

CLC020

www.national.com11

Page 12

Application Information (Continued)

with 1kHz filter bandwidth and Hanning window. Configure

the setup as shown in

Figure 8

. Switch the test equipment on

(from standby mode) and allow all equipment temperatures

stabilize per manufacturer’s recommendation. Measure the

jitter value after allowing the instrument’s reading to stabilize

(about 1 minute). Consult the VM700T Video Measurement

Set Option 1S Serial Digital Measurements User Manual

(document number 071-0074-00) for details of equipment

operation.

The VM700T measurement system’s jitter floor specification

at 270Mbps is given as 200ps

±

20% (100ps±5% typical) of

actual components from 50Hz to 1MHz and 200ps +60%,

-30% of actual components from 1MHz to 10MHz. To obtain

the actual residual jitter of the CLC020, a root-sum-square

adjustment of the jitter reading must be made to compensate

for the measurement system’s jitter floor specification. For

example, if the jitter reading is 250ps, the CLC020 residual

jitter is the square root of (250

2

− 2002) = 150ps. The accu-

racy limits of the reading as given above apply.

DS100917-10

FIGURE 8. Jitter Test Circuit

DS100917-13

FIGURE 9. ECL-to-TTL/CMOS level converter/amplifer

CLC020

www.national.com 12

Page 13

Application Information (Continued)

PCB LAYOUT AND POWER SYSTEM BYPASS

RECOMMENDATIONS

Circuit board layout and stack-up for the CLC020 should be

designed to provide noise-free power to the device. Good

layout practice also will separate high frequency or high level

inputs and outputs to minimize unwanted stray noise pickup,

feedback and interference. Power system performance may

be greatly improved by using thin dielectrics (4 to 10 mils) for

power/ground sandwiches. This increases the intrinsic capacitance of the PCB power system which improves power

supply filtering, especially at high frequencies, and makes

the value and placement of external bypass capacitors less

critical. External bypass capacitors should include both RF

ceramic and tantalum electrolytic types. RF capacitors may

use values in the range 0.01 µF to 0.1 µF. Tantalum capacitors may be in the range 2.2 µF to 10 µF. Voltage rating for

tantalum capacitors should be at least 5x the power supply

voltage being used. It is recommended practice to use two

vias at each power pin of the CLC020 as well as all RF bypass capacitor terminals. Dual vias reduce the interconnect

inductance by up to half, thereby reducing interconnect inductance and extending the effective frequency range of the

bypass components.

The outer layers of the PCB may be flooded with additional

V

SS

(ground) plane. These planes will improve shielding and

isolation as well as increase the intrinsic capacitance of the

power supply plane system. Naturally, to be effective, these

planes must be tied to the V

SS

power supply plane at frequent intervals with vias. Frequent via placement also improves signal integrity on signal transmission lines by providing short paths for image currents which reduces signal

distortion. The planes should be pulled back from all transmission lines and component mounting pads a distance

equal to the width of the widest transmission line or the thickness of the dielectric separating the transmission line from

the internal power or ground plane(s) whichever is greater.

Doing so minimizes effects on transmission line impedances

and reduces unwanted parasitic capacitances at component

mounting pads.

In especially noisy power supply environments, such as is

often the case when using switching power supplies, separate filtering may be used at the CLC020’s VCO and output

driver power pins. The CLC020 was designed for this situation. The digital section, VCO and output driver power supply

feeds are independent (see pinout description table and pinout drawing for details). Supply filtering may take the form

of L-section or pi-section, L-C filters in series with these V

DD

inputs. Such filters are available in a single package from

several manufacturers. Despite being independent feeds, all

device power supplies should be applied simultaneously as

from a common source. The CLC020 is free from power supply latch-up caused by circuit-induced delays between the

device’s three separate power feed systems.

REPLACING THE GENNUM GS9022

The CLC020 is form-fit-function compatible with the Gennum

GS9022. The CLC020 can improve the performance of

GS9022 applications using the existing PCB layout with the

removal of certain components or changes to component

values. New layouts using the CLC020 will benefit from the

greatly reduced ancilliary component count and more compact layout.

The CLC020 does not require external VCO filtering components. The external VCO filtering components at pin 17 of

the GS9022 may remain connected to the CLC020 without

complications. It is suggested that these be removed from

DS100917-11

FIGURE 10. Jitter Plots

CLC020

www.national.com13

Page 14

Application Information (Continued)

the circuit board. The CLC020 uses pin 17 for its test pattern

generator enable function. You will find the TPG function

very useful when you make this change.

Remove the C

OSC

capacitor used by the GS9022 at pin 26.

The CLC020 uses pin 26 as the BIST pass/fail indicator output. You may attach a LED as an indicator to this pin, if desired. LED current should be limited to 10 mA maximum. The

same LED type and current limiting resistor shown in

Figure

7

at the Lock Detect output may be used for this indicator

function.

Remove any capacitor attached to pin 19. A capacitor at-

tached to pin 19 will cause distortion of the output V

OH

level.

The former data rate setting resistor, R

VCO

, at pin 19 now

functions as the output level setting resistor, R

REF

. It must be

changed to a 1.69 kΩ, 1% value for correct output level setting.

The input series resistors and the P

CLK

risetime filter capacitor used with the GS9022 are not needed for the CLC020.

These components should be removed from the circuit

board and the resistors replaced by short circuits (0Ω resistors). These series resistors will increase input signal rise

and fall times if left on the board.

The CLC020 has current-mode serial cable driver outputs.

These outputs have very high internal generator resistance

as one would expect of a current source. Though these

current-mode outputs can produce the equivalent drive volt-

ages into the load, it is necessary to change and simplify the

typical GS9022 output circuit normally recommended for that

device. The output load resistors at pins 22 and 23 must be

changed to 75Ω, 1% values. These resistors become the

back-matching loads across which the CLC020’s outputs develop drive voltage. The series back-matching resistors used

on the GS9022 should be removed and replaced with short

circuits. The risetime compensating capacitors across these

resistors should be removed.

Pin 28 on the CLC020 is V

SS

and must be connected to the

negative supply or ground. On layouts designed to mount

the GS9022, the series R-C network connected to this pin

should be replaced by short circuits (0Ω resistors).

The pull-up resistor connected to the Lock Detect output, pin

14, should be removed. It may be replaced by a LED and

current limiting resistor connected to V

SS

if a visual lock indi-

cator is desired.

The CLC020 has an internal pull-down at the Sync Detect

Enable input and may be left unconnected in SMPTE

video-only applications.

The CLC020 has independent power supply pins for the

VCO, V

SSO

, pin 15 and V

DDO

, pin 16. The CLC020 has an

output driver negative supply, V

SSSD

, at pin 21. The output

driver positive supply, V

DDSD

, is pin 24 (as on the GS9022).

On new layouts, additional power supply filtering may be

added at these pins, if desired.

CLC020

www.national.com 14

Page 15

Physical Dimensions inches (millimeters) unless otherwise noted

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

labeling, can be reasonably expected to result in a

significant injury to the user.

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

National Semiconductor

Corporation

Americas

Tel: 1-800-272-9959

Fax: 1-800-737-7018

Email: support@nsc.com

National Semiconductor

Europe

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Response Group

Tel: 65-2544466

Fax: 65-2504466

Email: ap.support@nsc.com

National Semiconductor

Japan Ltd.

Tel: 81-3-5639-7560

Fax: 81-3-5639-7507

www.national.com

28-Pin PLCC

Order Number CLC020ACQ

NS Package Number V28A

CLC020 SMPTE 259M Digital Video Serializer with Integrated Cable Driver

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

Loading...

Loading...