Page 1

CLC016

Data Retiming PLL with Automatic Rate Selection

General Description

National’s Comlinear CLC016 is a low-cost, monolithic, data

retiming phase-locked loop (PLL) designed for high-speed

serial clock and data recovery. The CLC016 simplifies highspeed data recovery in multi-rate systems by incorporating

auto-rate select (ARS) circuitry on chip. This function allows

the user to configure the CLC016torecognize up to four different data rates and automatically adjust to provide accurate, low-jitter clock and data recovery. A single resistor is

used to set each data rate anywhere between 40 Mbps and

400 Mbps. No potentiometers, crystals, or other external ICs

are required to set the rate.

The CLC016 has output jitter of only 130 ps

pp

at a 270 Mbps

data rate and 0.25%fractional loop bandwidth. Low phase

detector output offset and low VCO injection combine to ensure that the CLC016 does not generate bit errors or large

phase transients in response to extreme fluctuations in data

transition density. The result is improved performance when

handling the pathological patterns inherent in the SMPTE

259M video industry standard.

The carrier detect and output mute functions may be used

together to automatically latch the outputs when no data is

present, preventing random transitions. The external loop filter allows the user to tailor the loop response to the specific

application needs. The CLC016 will operate with either +5V

or −5.2V power supplies. The serial data inputs and outputs,

as well as the recovered clock outputs, allow single- or

differential-ECL interfacing. The logic control inputs are TTLcompatible.

Applications

n SMPTE 259M serial digital interfaces: NTSC/PAL, 4:2:2

component, 360 Mbps wide screen

n Serial digital video routing and distribution

n Clock and data recovery for high-speed data

transmission

n Re-synchronization of serial data for SONET/SDH, ATM,

CAD networks, medical and industrial imaging

Features

n Retimed data output

n Recovered clock output

n Auto and manual rate select modes

n Four user-configurable data rates

n No potentiometers required

n External loop bandwidth control

n Frequency detector for lock acquisition

n Carrier detect output

n Output MUTE function

n Single supply operation: +5V or −5.2V

n Low cost

Key Specifications

n Low jitter: 130 ps

pp

@

270 Mbps, 0.25%fractional loop

bandwidth (0.675 MHz)

n High data rates: 40 Mbps − 400 Mbps

n Low supply current: 100 mA, including output biasing

n Flexible fractional loop bandwidth: from 0.05%to 0.5

%

Order Number Temperature Package

CLC016ACQ 0˚C to +70˚C PLCC V28A

CLC016AJQ –40˚C to +85˚C PLCC V28A

TRI-STATE®is a registered trademark of National Semiconductor Corporation.

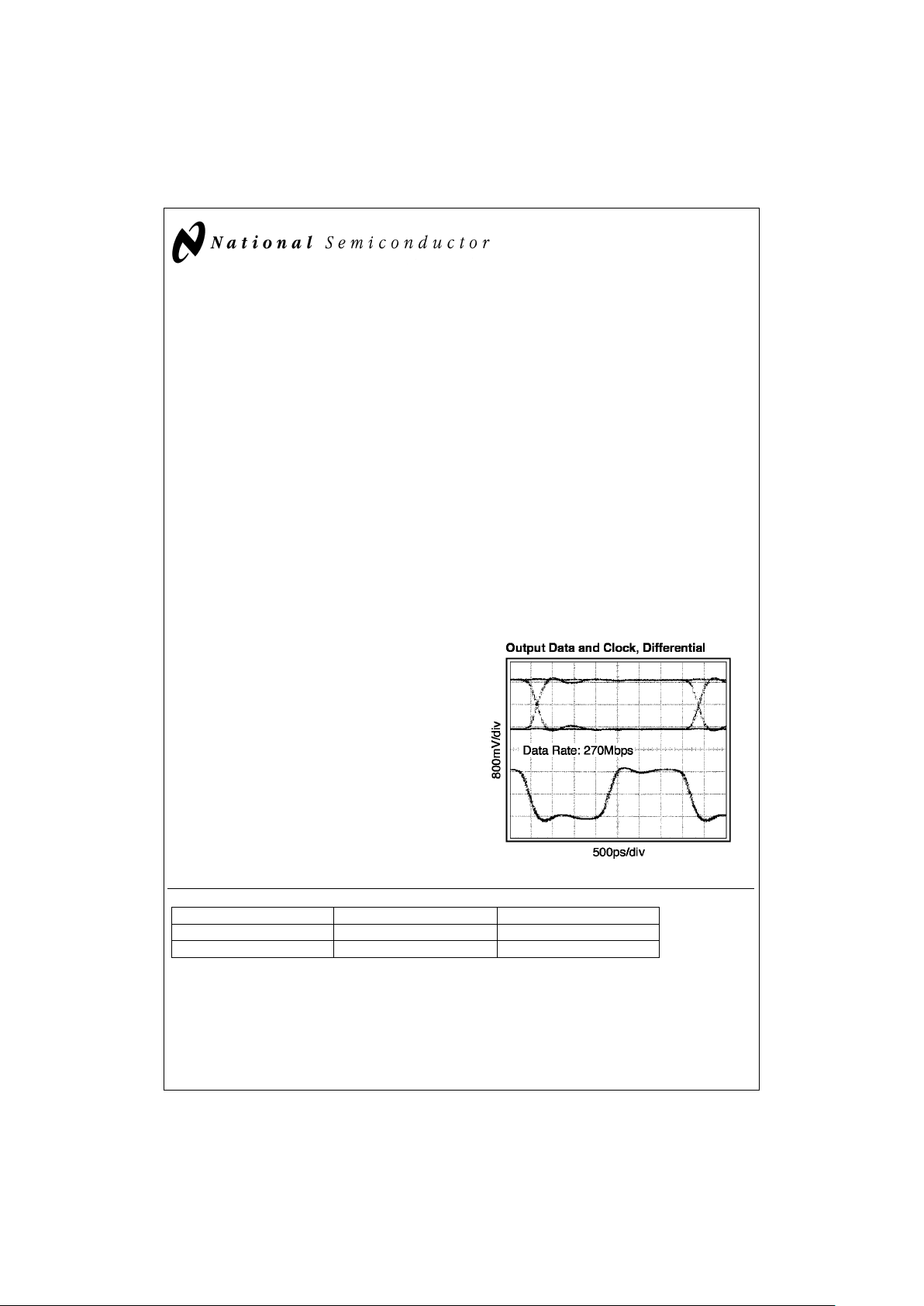

DS100087-1

July 1998

CLC016 Data Retiming PLL with Automatic Rate Selection

© 1998 National Semiconductor Corporation DS100087 www.national.com

Page 2

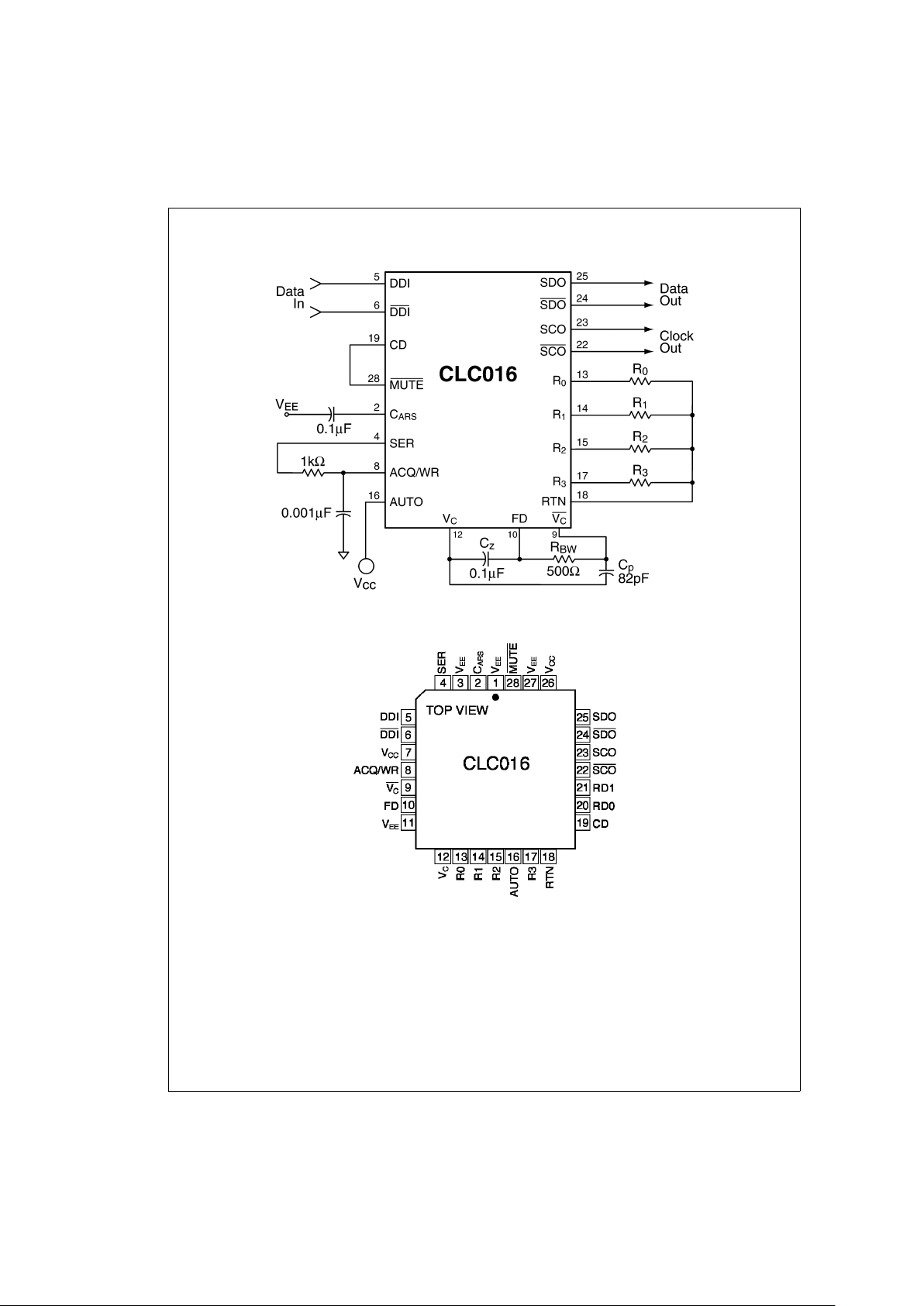

Typical Application

Four-Rate Clock and Data Recovery with Automatic Rate Selection

DS100087-2

Pinout

DS100087-3

28-pin PLCC

www.national.com 2

Page 3

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Supply Voltage (V

CC–VEE

) −0.3, +6.0V

Maximum Junction Temperature +150˚C

Storage Temperature Range −65˚C to +150˚C

Lead Temperature (Soldering 4 sec) +260˚C

ESD Rating (Note 12) 2kV

Package Thermal Resistance

θ

JA

28-Pin PLCC 85˚C/W

θ

JC

28-Pin PLCC 35˚C/W

Reliability Information

MTTF (based on limited life

test data) 2.6 x 10

7

hours

Recommended Operating

Conditions

Supply Voltage (VCC–VEE) 4.5V to 5.5V

Operating Temperature –40˚C to +85˚C

Jitter Transfer Function Fractional Loop

Bandwidth 0.05%to 0.5

%

SCO/SCO, SDO/SDO Minimum

Voltage (Note 13) VCC– 1.6V

Electrical Characteristics

(VCC= 0V, VEE= −5V, RBW= 500Ω;CZ= 0.1 µF; CP= 82 pF; Rn= 3504, C

ARS

= 0.1 µF; unless specified).

Parameter Conditions

Typ

+25˚C

Min/Max

+25˚C

Min/Max

Full Temp.

Range

Units

DYNAMIC PERFORMANCE

Residual Jitter 270 Mbps PRN sequence

(Notes 3, 4)

150 250 300 ps

pp

Acquisition Time 270 Mbps PRN sequence 6 x 10

5

bit cells

Minimum Average Data Rate, f

CLK

Full Temperature Range

4.5V ≤ (V

CC−VEE

) ≤ 5.5V

(Note 3)

100 100 Mbps

0 to 70˚ 4.5V ≤ (V

CC−VEE

) ≤ 5.5V 40 Mbps

Maximum Average Data Rate, f

CLK

4.5V ≤ (VCC−VEE) ≤ 5.5V

(Note 3)

400 400 Mbps

Tracking and Capture Range 4.5V ≤ (V

CC−VEE

) ≤ 5.5V

(Notes 3, 5)

±

8.3

±

5.0/

±

13.0

±

2.5/

±

18.0

%

f

CLK

VCO Power Supply Sensitivity (Note 3)

±

0.8

±

1.2

±

1.3

%

V

VCO Temperature Sensitivity

±

250 ppm/˚C

Jitter Transfer Function −3 dB bandwidth

(Fractional Loop Bandwidth), λ

BW

RBW= 100Ω (Notes 6, 7) 0.05

%

f

CLK

RBW= 500Ω (Notes 6, 7) 0.25

%

f

CLK

RBW= 1000Ω (Notes 6, 7) 0.5

%

f

CLK

Jitter Transfer Function Peaking RBW= 500Ω, 270 Mbps

(Note 6)

<

0.1 dB

STATIC PERFORMANCE

Power Supply Current, I

EE

(Note 3) 105 125 133 mA

Voltage on Selected R

n

Resistor (Note 8) VCC−2.2 V

Voltage on Unselected R

n

Resistor (Note 8) V

CC

V

V

C/VC

Common-Mode Voltage, V

CM

(Note 8) VCC−1.5 V

V

C/VC

Diff-Mode Voltage Range, V

DM

(Note 8)

±

300 mV

DDI/DDI

Input Range Upper Limit, V

H

V

CC

V

Input Range Lower Limit, V

L

VEE+2.5 V

Minimum Differential Input Amplitude, V

∆

200 200 mV

Input Current (Note 3) 3 6 6 µA

SCO/SCO, SDO/SDO

Output Current, I

OUT

(Note 3) 11 9.3/12 8.6/12.7 mA

Output Voltage Swing, V

OUT

R

collector

=75Ω(Note 3) 725 625/900 mV

ACQ/WR, MUTE, RDO/RD1

Voltage Input — LOW, V

IL

(Note 9)

V

EE

+ 0.8 VEE+ 0.8 V

Voltage Input — HIGH, V

IH

(Note 3) VEE+ 2.0 VEE+ 2.0 V

Input Current (I

IN

) (Note 3)

±

100

±

500 nA

3 www.national.com

Page 4

Electrical Characteristics (Continued)

(VCC= 0V, VEE= −5V, RBW= 500Ω;CZ= 0.1 µF; CP= 82 pF; Rn= 3504, C

ARS

= 0.1 µF; unless specified).

Parameter Conditions

Typ

+25˚C

Min/Max

+25˚C

Min/Max

Full Temp.

Range

Units

STATIC PERFORMANCE

CD, UNL, RDO/RD1 (Note 9)

Current Output — LOW, I

OL

VOL≤ VEE+0.5V 800 µA

Current Output — HIGH, I

OH

VOH≥ VCC−0.5V −700 µA

TIMING PERFORMANCE

Delay: SCO to SDO, t

d

200 ps

SCO Duty Cycle (Note 3) 50 44/56 44/56

%

Rise/Fall Time: SCO, SDO, t

r/tf

20%–80%,R

collector

=75Ω

(Note 10)

230 ps

SDO Duty Cycle Distortion 35 ps

Minimum Setup Time:

RDO/RD1 to ACQ/WR, t

SU

420 20 ns

Minimum Hold Time:

ACQ/WR to SS1/SS0, t

h

320 20 ns

Minimum Pulse Width:

ACQ/WR, t

w

520 20 ns

ARS Oscillator Period, t

OSC

(Note 3) 10.5 8.5/15.5 ms

CD Pulse Width, t

PW

(Note 11) 1 µs

MUTE Response Time, t

M

5ns

Note 1: “Absolute Maximum Ratings” are those values beyond which the safety of the device cannot be guaranteed. They are not meant to imply that the devices

should be operated at these limits. The table of “Electrical Characteristics” specifies conditions of device operation.

Note 2: Min/Max ratings are based on product characterization and simulation. Individual parameters are tested as noted. Outgoing quality levels are determined

from tested parameters.

Note 3: J-level spec. is 100%tested at +25˚C.

Note 4: Peak-to-peak jitter is defined as 6 times the rms jitter.

Note 5: Tracking and capture range are specified as a percentage of the input data rate f

CLK

. The minimum and maximum are guaranteed so long as Rnhas been

chosen according to the equation in

Resistor Selection for Data Rates.

Note 6: Average data transition density of 1 transition per 2 bit cells.

Note 7: When the value of R

BW

changes it is necessary to also change the values of CPand CZ. See

Loop Filter Design.

Note 8: This information is provided for system troubleshooting purposes only.

Note 9: RD0/RD1 are inputs when AUTO = 0 and outputs when AUTO = 1.

Note 10: Includes typical pc board capacitance.

Note 11: The CD circuit is a retriggerable one-shot which retriggers on every data transition.

Note 12: Human body model, 1.5 kΩ in series with 100 pF.

Note 13: To maintain specified performance, SCO/SCO and SDO/SDO should not drop below this level.

www.national.com 4

Page 5

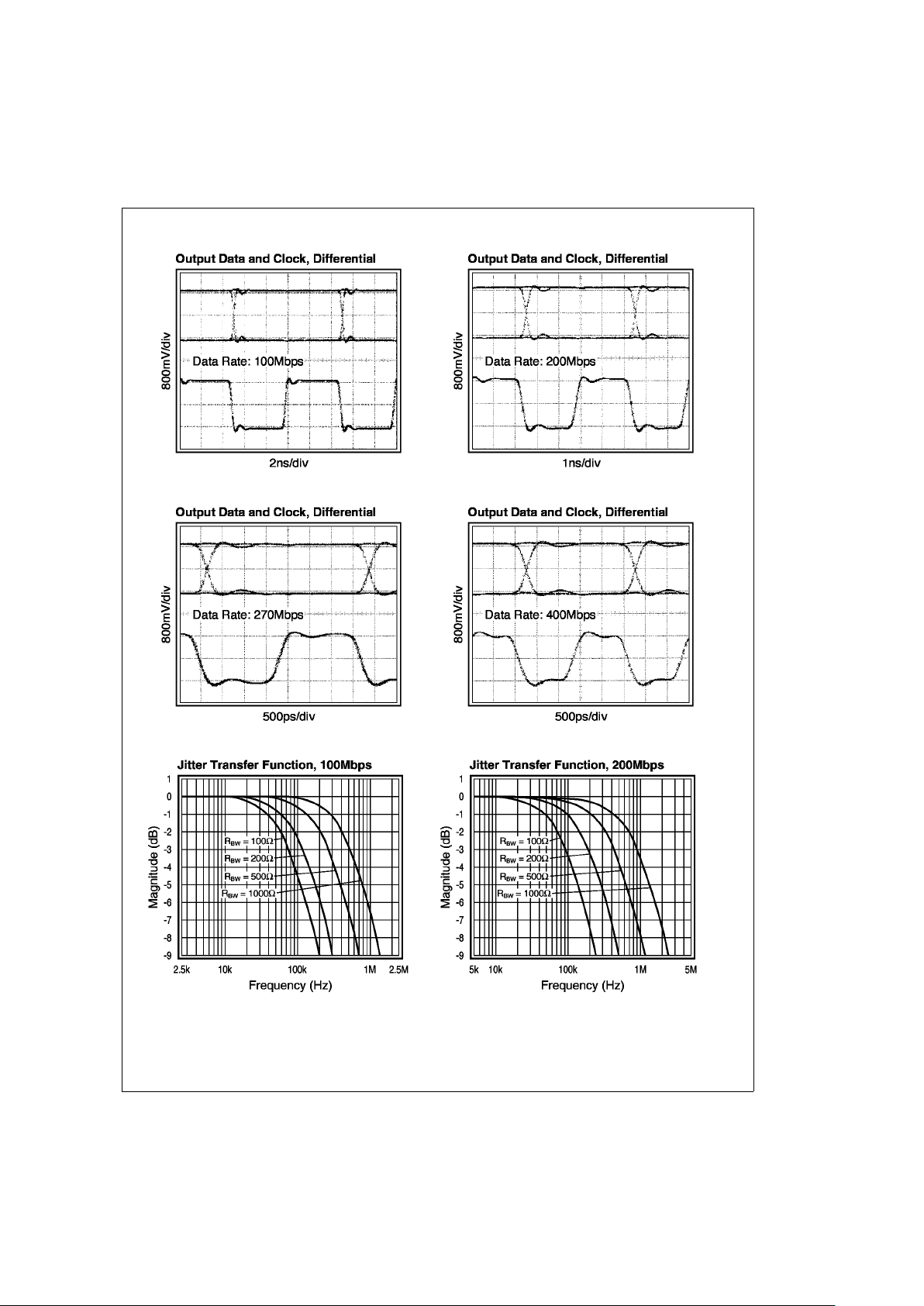

Typical Performance Characteristics

DS100087-4 DS100087-5

DS100087-6 DS100087-7

DS100087-8 DS100087-9

5 www.national.com

Page 6

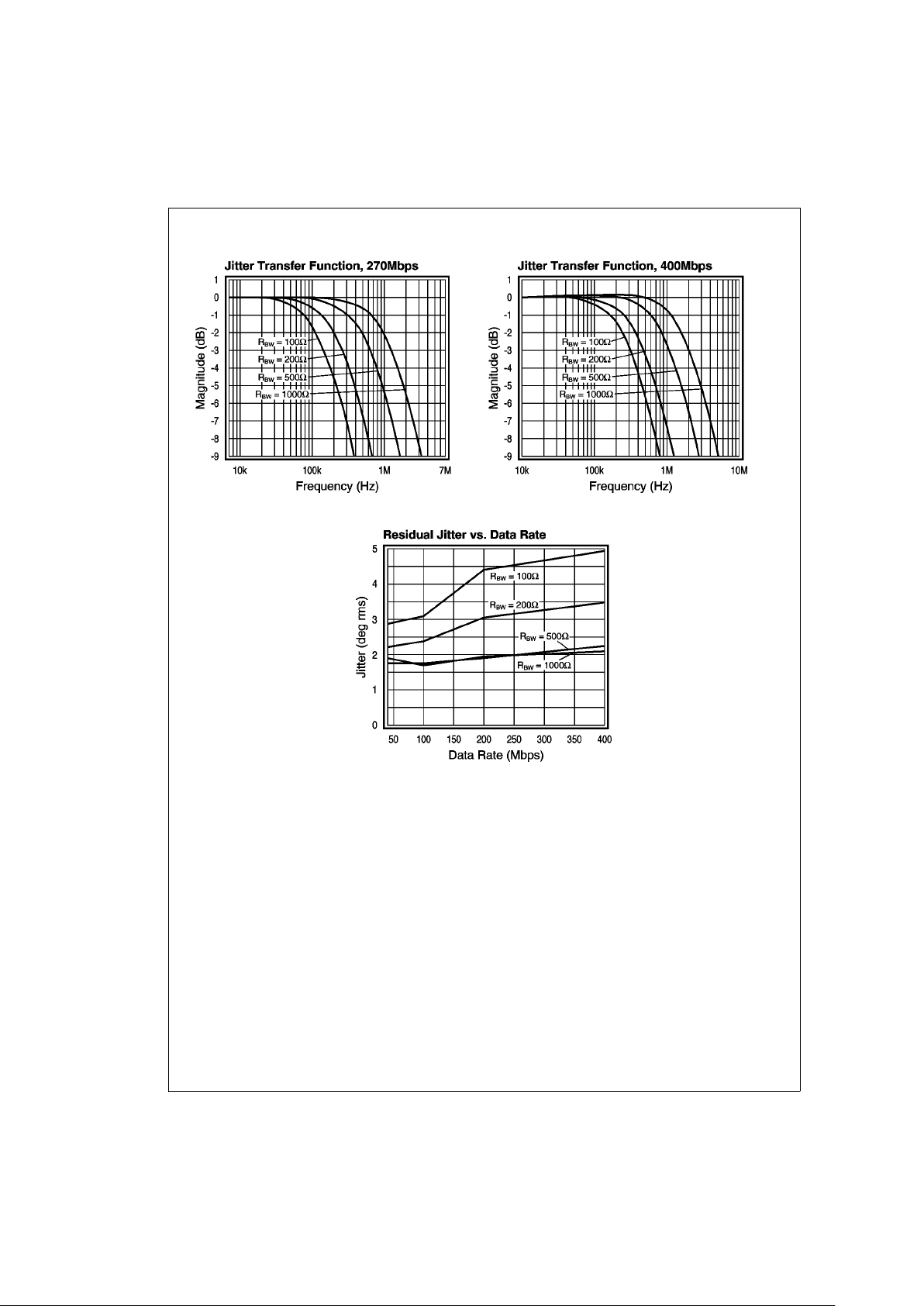

Typical Performance Characteristics (Continued)

DS100087-10 DS100087-11

DS100087-12

www.national.com 6

Page 7

Product Description

The CLC016 Data Retiming PLL is a monolithic circuit that

recovers clock and data from a serial NRZ or NRZI data

stream. The Data Retiming PLL incorporates an Auto-Rate

Selection function which automatically selects one of four

user-configurable data rates. The following outline lists the

material covered in this data sheet:

•

Typical schematics for +5V or −5.2V operation

•

Block diagram description

•

Pin definitions

•

Design guidelines

•

Interface connections

•

Measurement

•

Typical applications

•

Printed circuit layout and evaluation boards

For application assistance, refer to the list of telephone numbers on the pack page of this data sheet.

Data Retimer Typical Connections

The CLC016 schematics provided in

Figure 1

and

Figure 2

show typical +5V or −5.2V connections with Auto-Rate Selection configured for SMPTE 259M standard video data

rates: 143, 177, 270 and 360 Mbps. The section

Resistor

Selection for Data Rates

gives tables and equations for de-

termining R

n

resistor values for any data rate from 50 Mbps

to 400 Mbps. A resistor value table is also given for SONET/

SDH data rates. The schematics in

Figure 1

and

Figure 2

do

not include input termination. The high impedance inputs on

the CLC016 allow the user to define the termination. The

Interfaces

section suggests recommended terminations for

the inputs and outputs of the CLC016.

DS100087-13

FIGURE 1. Typical +5V Connection

DS100087-14

FIGURE 2. Typical −5.2V Connection

7 www.national.com

Page 8

Product Description (Continued)

Pin Definitions

Name Pin # Description

DDI, DDI

5, 6 Differential (ECL, PECL) data

inputs.

SCO,

SCO

23, 22 Differential collector (ECL,

PECL compatible) clock outputs

SDO,

SDO

25, 24 Differential collector (ECL,

PECL compatible) retimed data

outputs

RDO,

RD1

20, 21 Bi-directional (TTL, CMOS)

VCO data rate bus. See

Table 3

for state table.

R

n

13, 14,

15, 17

VCO rate configuration resistors

(n=0,1,2,3).

RTN 18 Return for R

n

SER 4 Loop unlock output (TTL,

CMOS) indicator. High when

loop is unlocked or

harmonic-locked.

CD 19 Carrier detector (TTL, CMOS)

output. Low when no signal is

present.

MUTE

28 Output mute (TTL, CMOS)

control. Connect to CD to latch

outputs when no signal is

present.

AUTO 16 Auto- or manual-rate mode

control (TTL, CMOS) input.

Assert high for auto-rate mode.

ACQ/WR 8 ARS oscillator enable and rate

latch enable (TTL, CMOS)

input. Connect to SER (see

diagrams) for auto-rate mode.

C

ARS

2 External capacitor connections

for controlling the rate of the

ARS search.

V

C,VC

12, 9 VCO control lines. Loop filter

connects across these and FD.

FD 10 Frequency detector output. C

Z

must connect from FD to VC.

V

CC

7, 26 Positive supply pins (ground or

+5V).

V

EE

1, 3, 11,27Negative supply pins (−5.2V or

ground).

Operation Description

The CLC016 Data Retiming PLL,

Figure 3

, has three main

functions: Frequency Detector (FD), Phase-Locked Loop

(PLL) and Auto-Rate Select (ARS).

The Frequency Detector detects the frequency difference

between the input data rate and the VCO frequency, and

forces a rapid change in VCO frequency to minimize that difference. As the frequency difference approaches zero, the

PLL acquires phase lock and the Frequency Detector becomes inactive. In Auto-Rate Select mode, the Frequency

Detector requests the ARS function to search for a new data

rate.

The PLL consists of a Voltage Controlled Oscillator (VCO), a

Phase Detector (PD), and an external Loop Filter (LF). The

PLL recovers a low-jitter clock for data retiming. The data is

re-synchronized (retimed) at the Data Latch. The data and

clock are buffered outputs.

TheARS block has two modes of operation:Auto-Rate Mode

(ARM) and Manual-Rate Mode (MRM). Once the ARS function is activated (ARM), it sequences through the userselected data rates until phase lock is achieved. The user

has control over the rate at which ARS steps through the

data rates (see

Auto-Rate Selection

section).

The Carrier Detect (CD) block detects the presence of input

data and is an input to the ARS block. When CD is connected to MUTE and no data is present, the clock and data

outputs are latched.

DS100087-15

FIGURE 3. Functional Block Diagram

www.national.com 8

Page 9

Product Description (Continued)

Functional Block Descriptions

Frequency Detector (FD)

The Frequency Detector detects the difference between

VCO rate and the input data rate, then forces the frequency

(rate) difference to zero. In Auto-Rate Mode, when a difference is detected, FD requests the ARS block to start a

search to match the rate. Once the PLL acquires phase lock,

the PLL takes control and the FD goes inactive.

Phase Detector (PD)

The PD compares the phase of the VCO to the phase of the

input data. The PD output is a differential current which is

proportional to the phase error. The PD gain has units of amperes per radian and is dependent upon the data transition

density (ρ). The data transition density is defined as the average number of data transitions per clock cycle, and is

bounded by 0 ≤ρ≤1. The PD output is connected to the

VCO through the external loop filter network. This network

translates the PD output current to a voltage that controls the

VCO.

Loop Filter (LF)

The external Loop Filter shown in

Figure 3

is made up of

passive components R

BW,CZ

, and CP. This external loop fil-

ter controls the PLL dynamics and acquisition time.

The Frequency Detector supplies its signal to the C

Z

capacitor, and takes control of the VCO under the condition of frequency unlock. The selection of the filter components is covered in the

Loop Filter Design

section.

Voltage Controlled Oscillator (VCO)

The VCO is a temperature-compensated, factory-trimmed

multivibrator that requires no external capacitors for tuning. It

is stable over temperature and power supply variations. This

eliminates the need for potentiometers to adjust each of the

VCO center frequencies to correspond with the input data

rates. Instead, an external resistor (R

n

) is used to set each of

four data rates in the range of 40 Mbps to 400 Mbps.

Carrier Detector (CD)

The CD circuit is a retriggerable one-shot which retriggers on

every data transition. When data transitions occur at a rate

≥1 transition per µs, CD indicates the presence of data at the

input pins DDI and DDI. CD also inputs a signal to ARS that

inhibits any rate search from occurring in the absence of input data. When CD in connected to the MUTE pin, and no

data is present, the output clock (SCO, SCO) and data

(SDO, SDO) lines are latched.

Auto-Rate Select (ARS) and Multiplexer (MUX)

The ARS, in conjunction with the MUX, sequences through

the user-configured resistor values (R

n

) in an unlocked condition. The ARS has two modes: Auto-Rate Mode (ARM) and

Manual-Rate Mode (MRM). It incorporates additional features and functions that are discussed in the section named

Auto-Rate Selection.

When ARS is in Auto-Rate Mode, its inputs are the FD (the

LHP control line), the Carrier Detect (CD), the VCO (CLK),

and Latched Data output. These input signals produce an

external Search (SER) signal that, when connected to the

ACQ/WR input, enables the ARM operation. A single capacitor, C

ARS

, sets the ARM sequence time for stepping through

the different user-configured data rates.

The timing section of the ARS block controls the digital input

analog multiplexer (MUX). Under the control of ARS, the

MUX steps through each data rate starting with the

previously-selected resistor R

n

and incrementing to R

n+1

,

etc. in order of R

0,R1,R2,R3,R0

, .... This sequence is re-

peated until lock is achieved. The 2-bit bidirectional bus,

comprised of RD0 and RD1, indicates the selected data rate.

The RD0, RD1 bidirectional bus is set to output mode when

AUTO is active (high). Therefore, RD0, RD1 can be monitored when AUTO is active. When no data is present at the

inputs, CD will inhibit the ARM.

In manual mode the RD0, RD1 lines are set to input mode.

Therefore, RD0, RD1 cannot be monitored when AUTO is inactive. The selection of external components for both modes

of operation is discussed in sections,

Resistor Selection for

Data Rates,

and

Auto-Rate Selection

.

DESIGN GUIDELINES

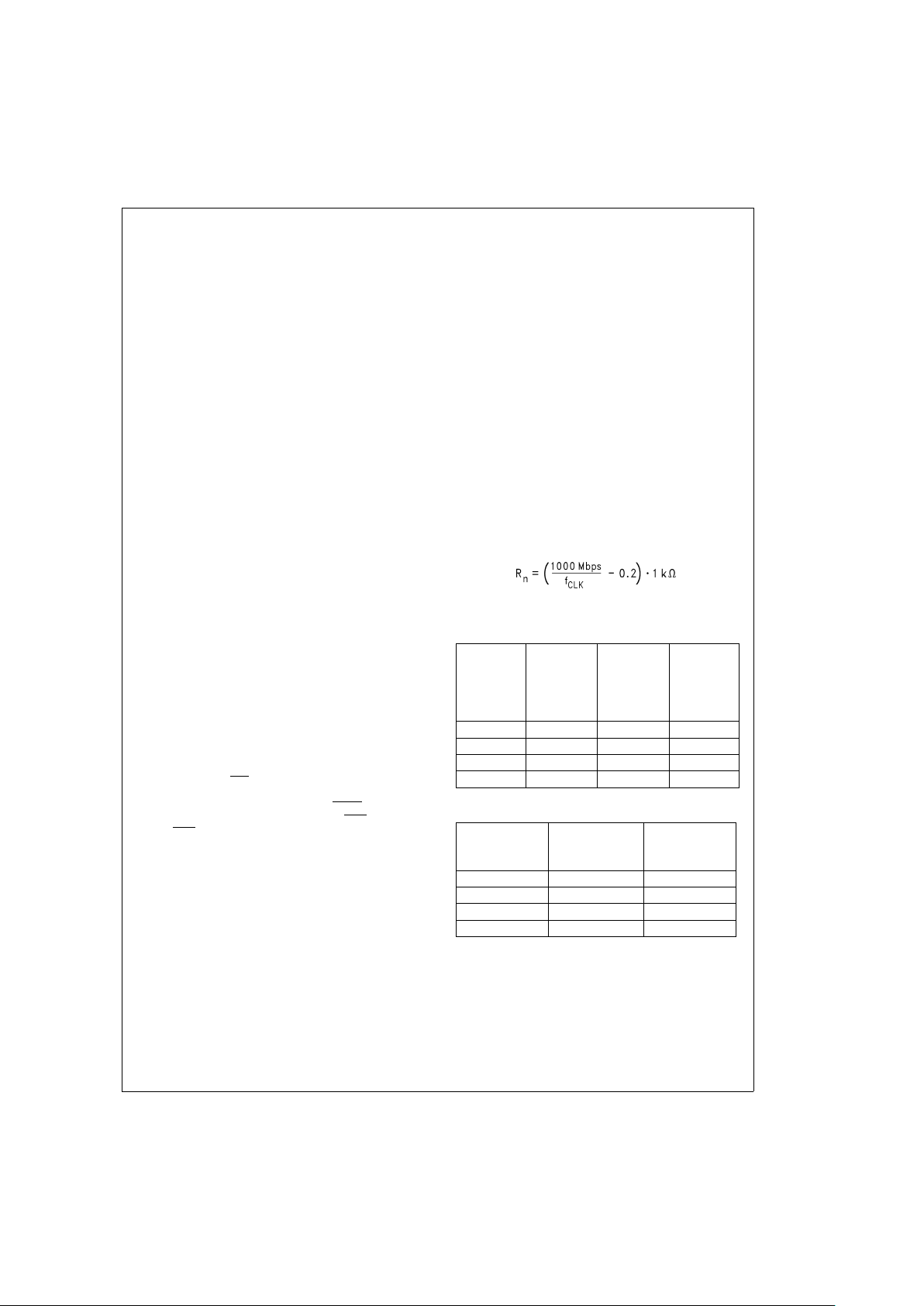

Resistor Selection for Data Rates

The CLC016 Data Retiming PPL supports 4 different data

rates using user-selected resistors that set the VCO center

frequency. The resistors found in

Figures 1, 2

are identified

by the reference designators R

n

, where n is 0, 1, 2 and 3.

It is recommended that the user select resistor values with

tolerances of 1%and temperature coefficients of ≤100 ppm/

˚C. Refer to

Table 1

and

Table 2

for calculated resistor values for SMPTE and SONET standards. Resistors for other

data rates are determined from the following equation:

wheren=0,1,2,3andf

CLK

is the desired data rate.

TABLE 1. Resistor Values for SMPTE 259M Data Rates

Data Rate

(Mbps)

Ref. Des.

(in

Figures

1, 2

)

R

n

Calculated

Resistor

(kΩ)

1

%

Resistors

(in

Figures

1, 2

)

(kΩ)

143 R

0

6.79 6.81

177 R

1

5.45 5.49

270 R

2

3.50 3.48

360 R

3

2.58 2.55

TABLE 2. DS-3 and SONET/SDH Resistor Values

Data Rate

(Mbps)

Calculated

Resistor

(kΩ)

1%Resistors

(kΩ)

44.7 22.1 22.1

51.84 19.1 19.1

155.52 6.23 6.19

311.04 3.02 3.01

Loop Filter Design

The function of the PLL is to low-pass filter the jitter of the incoming data stream. The jitter transfer function for the PLL

(or the phase transfer function) is set by the phase detector

gain, the loop filter transfer function, and the VCO gain.

These elements are shown in the small-signal block diagram,

Figure 4

.

9 www.national.com

Page 10

Product Description (Continued)

The jitter transfer function is the small signal transfer function, θ

o/θi

, and is given by:

where fBWis the PLL bandwidth and fZis a zero in the closed

loop transfer function.

The phase detector gain and VCO gain are fixed internally.

Selection of the external loop filter components defines the

overall jitter transfer function. Additionally, the filter components control the acquisition performance of the PLL.

A Bode plot for the closed loop PLL jitter transfer function is

shown in

Figure 5

.

At frequencies above f

BW

(the PLL bandwidth) the jitter is at-

tenuated. At frequencies below f

BW

the jitter is transmitted

through the PLL. A small amount of jitter peaking (δ) occurs

at frequencies below f

BW

. The amount of peaking increases

when f

Z

moves closer to fBW.

Setting the Loop Bandwidth (Selecting R

BW

)

The fractional loop bandwidth, λ

BW

, is the ratio of fBWto the

data rate. The CLC016 is specified for operation with fractional loop bandwidths ranging from 0.05%to 0.5%. For example, if the loop bandwidth is 1 MHz and the data rate is

270 Mbps, then the fractional loop bandwidth is:

The fractional loop bandwidth is set by the loop component

R

BW

:

where ρ is the data transition density in average number of

data transitions per bit cell, and ranges in value from 0 to 1.

For example, if a pseudo-random data stream is used, the

value of ρ is 1/2, and a data transition will occur once every

two bit cells on the average. The phase detector and VCO

gain set the constants in the equation.

If the value of R

BW

is 500Ω and ρ = 1/2, the fractional loop

bandwidth is:

For a data rate of 270 Mbps this corresponds to a loop bandwidth f

BW

= 644 kHz. The jitter at frequencies above 644 kHz

will be attenuated by the PLL.

The equation may be rearranged to obtain R

BW

as a function

of the desired fractional loop bandwidth:

Setting the Jitter Peaking Factor (Selecting CZ)

The jitter peaking factor, δ, is set by the ratio of the critical

frequencies f

Z

and fBW. The ratio is defined as:

Figure 6

shows how the jitter peaking factor, δ, varies with α.

For example, if the value of α is 0.1, then the jitter peaking is

about 0.6 dB.

The approximation for the required value of α to obtain a

given amount of jitter peaking is:

α

≅

δ(0.134 + 0.058δ)

The critical frequency f

Z

is:

Select CZby the following equation:

DS100087-16

FIGURE 4. PLL Loop

DS100087-17

FIGURE 5. Closed-Loop Transfer Function

www.national.com 10

Page 11

Product Description (Continued)

As an example, assume that the amount of jitter peaking that

can be tolerated is 0.05 dB. From the jitter peaking design

equation (or from

Figure 6

) the required value of α is:

α

≅

0.05[0.134 + (0.058)(0.05)] = 0.007

Now assuming that the loop bandwidth is 644 kHz and that

the value of R

BW

is 500Ω, the value of CZis:

The value of CZalso affects the acquisition performance of

the PLL. Estimate the acquisition time with the following

equation:

where t

ACQxfCLK

is the acquisition time in number of bit

cells.

Selecting C

P

Capacitor CPestablishes a high frequency pole in the loop

filter to remove high frequency spectral components from the

phase detector. The pole frequency f

P

is:

In general, the pole should be set at least a factor of 4 above

the PLL bandwidth, f

BW

. Therefore, select CPusing:

For example, if RBWis 500Ω and fBWis 644 kHz, then an appropriate value for C

P

is:

Choosing a value for CPlarger than the value recommended

by the selection equation will introduce jitter peaking. Reducing the value of C

P

below that recommended by the selection equation is acceptable, but will result in some increase

in jitter. This is most noticeable with large fractional loop

bandwidths.

In addition, C

P

can affect the ability of the PLL to acquire

lock, especially at high data rates. Because of this, it is recommended to eliminate C

P

entirely for the condition of high

data rate (

>

300 Mbps) combined with narrow loop band-

width (

<

0.1%).

Multiple Rate Considerations

R

BW

establishes the fractional loop bandwidth. For a fixed

value of R

BW,fBW

will vary with the selected data rate. The

location of the critical frequencies f

Z

and fP, however, are in-

dependent of data rate.

To control jitter peaking for all multi-rate application choose:

•

the value of CZfor the smallest value of fBW(which is obtained at the lowest data rate).

•

the value of CPfor the largest value of fBW(which is obtained at the highest data rate).

Loop Filter Element Summary Table

The table below summarizes the recommended loop filter element values for each of the four SMPTE 259M data rates

and a fractional loop bandwidth of 0.25%. The final row of

the table gives the recommended values for the multi-rate

case, where all four of the SMPTE rates are configured.

Data Rate

(Mbps)

f

BW

(kHz)

R

BW

(Ω)

C

Z

(µF)

C

P

(pF)

143 358 500 0.10 200

177 443 500 0.10 160

270 675 500 0.047 100

360 900 500 0.04 82

143–360 0.25%f

CLK

500 0.10 82

Component Types and Tolerances

It is recommended that R

BW

resistors have tolerances of 1

%

and temperature coefficients of ≤100 ppm/˚C. The recommended capacitors are ceramic surface mount with 5%tolerance or better.

AUTO-RATE SELECTION

Auto Rate Mode (ARM)

This section provides more detail on the ARS sub-system

and how to use it.

Figure 7

shows a detailed view of the ARS

portion of the

Figure 3

block diagram

The auto-rate mode is enabled by connecting AUTO to V

CC

and SER to ACQ/WR through the 1 kΩ/1 nF network. When

the VCO is not at the input data rate, SER goes high enabling the ARS oscillator and the Latch. The oscillator increments the 2-bit counter and causes the VCO to sequence

through the rates determined by resistor R

n

(beginning at the

currently selected rate and advancing the index, n, upward).

The oscillator period (T

ARS

) is determined by C

ARS

. When

the VCO rate is at the input data rate, SER goes low and

ceases to increment the counter.

DS100087-18

FIGURE 6. Jitter Peaking Curve

11 www.national.com

Page 12

Product Description (Continued)

SER goes high when CD is high and either of the following

conditions is true:

•

The FD is active, causing LHP to go high.

•

The harmonic lock detector determines that the VCO is

running at a harmonic of the input data rate, causing

HLOCK to go high.

Timing diagrams related to locking and unlocking of the PLL

and removal of the input data are given in

Figures 8, 9

and

Figure 10

. The term t

ACQ

in

Figure 8

is defined in the

Loop

Filter Design

section. Also, tSis the settling time for the

phase error to decay to less than 90˚. It is given by the following equation:

t

S=RBWxCZ

x In(2) + 20 µs

The ARS oscillator period must be greater than the sum of

t

ACQ

and tS:

t

ARS

= (140 ms/µF) x C

ARS

>

t

ACQ+tS

The harmonic lock detector senses if the VCO is locked to a

data rate harmonic (integer multiple) by looking for the presence of bit changes across 3 consecutive periods of CLK as

shown in Case 1 of

Figure 11

. This event occurs on average

25%of the time in random data. HLOCK goes low if the occurrence rate is less than 12.5%. When a harmonic lock condition occurs there is at leasta2µsdelay for HLOCK to go

high. Case 2 illustrates the situation where CLK is at the 2nd

harmonic of the input data rate and each input bit cell is

double-clocked. Bit changes across three consecutive periods are never detected and HLOCK goes high.

During intervals of sparse data transitions, the harmonic lock

detector may cause SER to go high. An example of this is

the pathological pattern associated with the SMPTE 259M

video industry standard. For an interval of 50 µs, the input

data transitions can be separated by 20-bit cells; and it appears to the harmonic lock detector as though the VCO is at

a harmonic rate. So long as these intervals do not exceed

the period of the ARS oscillator, the ARS sub-system will not

increment the 2-bit counter.

T

ARS

must be the greater of

the value calculated by the above equation of the sparse

data pattern interval. Figure 12

shows a timing diagram re-

lating to sparse data transition intervals.

In auto-rate mode the user can monitor the RD0/1 bus to de-

termine the automatically selected data rate. Refer to

Table3

for the correspondence between the data bus state and the

selected rate resistor.

DS100087-19

FIGURE 7. Auto-Rate Select

DS100087-20

FIGURE 8. Data Rate Applied or Moves

within PLL Capture

DS100087-21

FIGURE 9. Data Rate Moves beyond the

PLL Tracking Range

DS100087-22

FIGURE 10. Input Data Removed

DS100087-23

FIGURE 11. Harmonic Lock Detector Operation

www.national.com 12

Page 13

Product Description (Continued)

Minimum Data Rate Spacing in ARM

RD0 and RD1 indicate which VCO rate configuration resistor

(i.e., R

n

) is selected. For each resistor there is a range of

rates that the PLL will lock to. If two data rates fall within this

range, a given RD0/RD1 indication may correspond to either

rate. If it is desired that each incoming data rate be uniquely

reported by RD0 and RD1, then the minimum spacing between data rates must be great enough to prevent the tracking and capture range of the PLL for one rate configuration

resistor from encompassing the adjacent rate. The tracking

and capture range is given in the

Electrical Characteristic

table. In addition, the tolerance of VCO rate configuration resistor should be added to the guaranteed tracking and capture range in computing minimum data rate spacing.

Manual Rate Mode (MRM)

The Manual Rate Mode provides the user with manual control over the data rate selection. This is done by setting the

AUTO line low and shorting the C

ARS

capacitor to VEE. The

manual data rate is set by the 2-bit bus RD0/1 using the

ACQ/WR line to initiate a MUX update.

Table 3

gives the

state table for resistor selection.

TABLE 3. Rate State Table

ACQ/WR RD1 RD0 Resistor

100R

0

101R

1

110R

2

111R

3

0 X X No Change

When in the MRM, the AUTO line is set low as in

Figure 13

.

The buffer output is TRI-STATE

®

which allows the bus lines

RD0/1 to be used as inputs to the latch. The inputs RD0/1

are latched by using the ACQ/WR line.

The ACQ/WR line and bus lines RD0/1 must observe setup

and hold conditions. The minimum requirements are specified in the sub-section

Timing Performance

of the

Electri-

cal Characteristics

page. The timing diagram in

Figure 14

indicates where the measurements are made.

Fixed Rate Mode

For single data rate applications, set AUTO low, ACQ/WR

high, and tie RD0 and RD1 to the levels shown in

Table 3

.

Also, short C

ARS

to VEE.

Minimum Data Rate Spacing in MRM

If it is desired that SER goes high (due to the inability of the

PLL rate) as an indication that the incoming data rate does

not correspond to the intended rate selected by RD0 and

RD1, then the minimum spacing between data rates must be

great enough to prevent the tracking and capture range of

the PLL at one rate from encompassing the adjacent rate. If

the data rates are too close, it is possible for the PLL to lock

to either rate regardless of which was selected by RD0 and

RD1. The tracking and capture range is given in the

Electri-

cal Characteristics

table. In addition, the tolerance of VCO

rate configuration resistors should be added to the guaranteed tracking and capture range in computing minimum data

rate spacing.

Output Timing

The clock-to-output data timing has a small delay of clock-todata. This delay is specified in the

Electrical Characteris-

tics

page under the sub-section

Timing Performance.

The

delay is measured from the 50%level of the CLK to the eye

pattern 50%crossing, as shown in

Figure 15

INPUT INTERFACES

The CLC016 provides high impedance inputs which accept

differential or single-ended input drive. The detailed electrical specifications are found in the

Electrical Characteris-

tics

page. Recommended interfaces for the CLC016 follow.

Four conditions should be observed when interfacing to the

CLC016 inputs:

•

Keep input levels within specified common-mode input

range.

•

Provide a bias current path to the inputs.

•

Terminate cable in the proper impedance.

DS100087-24

FIGURE 12. Response to Sparse Patterns

DS100087-25

FIGURE 13. Manual Select Mode

DS100087-26

FIGURE 14. ACQ/WR and RD0/1 Timing Diagram

DS100087-27

FIGURE 15. Output Timing of Clock and Data

13 www.national.com

Page 14

Product Description (Continued)

•

Observe the output current requirements of the driving

device.

Figure 16

and

Figure 17

show DC and AC coupled interface

examples which meet these four conditions.

OUTPUT INTERFACES

SDO, SDO, SCO, and SCO swing at ECL logic levels when

the correct external components are used. However, the outputs are not standard emitter-coupled logic outputs. Instead,

the signals flow from the collectors of the output transistors.

The primary advantage of this architecture is lower power

dissipation. Some example interfaces follow.

Differential Load-Terminated Output Interface

Figure 18

shows an interface to drive signals differentially

over a coaxial cable. The diode establishes V

OH.

. The diode-

resistor network sets V

OL

. The resistors terminate the cable

in its characteristic impedance.

Differential Source-Terminated Output Interface

Figure 19

is similar to

Figure 18

except that the termination

is placed near the output pins.

Terminating Physically Separated Outputs

When the circuit design requires the outputs to be routed to

separate locations, the recommended interface is depicted

in

Figure 20

. Choose the resistors for an equivalent 75Ω termination of the cable impedance (or other cable characteristic impedance, as appropriate).

DS100087-28

FIGURE 16. Differential 75Ω Source

DS100087-29

FIGURE 17. AC Coupled Termination

DS100087-30

FIGURE 18. Differential Load-Terminated

Output Interface

DS100087-31

FIGURE 19. Differential Source-

Terminated Output Interface

www.national.com 14

Page 15

Product Description (Continued)

CONTROL LINE INTERFACES

The use of the CLC016 with +5V supplies allows the control

lines to interface to standard TTL logic signals. Operating the

CLC016 at −5.2V requires level-shifting circuits for the control line inputs. Refer to the

Static Performance

section of

the

Electrical Characteristics

page for required input volt-

age levels.

POWER CONSUMPTION

The power supply current given in the Electrical Characteristics table includes the current required for both the clock and

data output buffers to drive a 75Ω load to ECL swings.

TYPICAL APPLICATIONS

The CLC016 was designed as one of a series of data transmission support chips. The CLC016 is recommended for a

wide variety of clock and data recovery applications that fit

within its range of data rates.

Serial Data Transmission over Cable

Serial data transmission is common for all types of communication channels where the data is sent over coaxial or

twisted pair cable.

Figure 21

shows a typical connection using a CLC006 driver chip, CLC014 Adaptive Cable Equalizer,

and the CLC016 Data Retiming PLL. The CLC016 extracts

the clock and retimes the data from the serial bit stream.

The components recommended in

Figure 21

support the

four common data rates specified in SMPTE 259M.

ESD

The CLC016 is a

CMOS chip.

Operators are cautioned to

use grounding straps when handling.

MEASUREMENTS & EVALUATION

When evaluating the CLC016 Data Retimer, it is recommended that you solder the part to the board or use a leadless chip carrier socket. Probing with capacitive probes will

disturb the CLC016 performance. When probing the signal

levels use a

1 pF capacitance

probe with a 500Ω tip.

The block diagram below shows a simple method of measuring the clock to eye pattern jitter. Use of the CLC016 evaluation board is recommended for jitter evaluation. It also provides a good reference for a user’s circuit board design. The

plot in

Figure 23

shows a histogram of the jitter and where

the measurements were taken.

DS100087-32

FIGURE 20. Load Terminated Output Interface

DS100087-33

FIGURE 21. Typical Cable Connection

15 www.national.com

Page 16

Product Description (Continued)

PCB LAYOUT RECOMMENDATIONS

Printed circuit board layout affects the performance of the

CLC016. The following are PCB layout rules for the CLC016:

1. Use a ground plane.

2. De-couple V

CC/VEE

power pins with 0.01 µF ceramic ca-

pacitors placed ≤0.1” (3mm) from the power pins and

6.8 µF tantalum capacitors.

3. For long signal runs, match transmission lines to the desired characteristic impedance for the input and output

lines.

4. Remove ground plane 0.025” (0.06mm) from all pads.

5. Remove ground plane from the area around the loop filter and frequency selection resistors.

6. Keep digital and analog lines sufficiently away from loop

filter or frequency selection resistors.

7. Avoid the use of sockets in production boards.

8. In proto-boards use a low-profile, low impedance, type

socket.

EVALUATION BOARD

An evaluation board layout and schematic are shown on the

following page. The art work shows the board solder masks,

trace layers, and ground plane.

To order an evaluation

board, contact your local sales representative or National support center and request part number

CLC730057.

The evaluation board provides LEDs and switches to operate the PLL in various modes. The board allows the user to

select +5V or −5.2V power supplies, identified on the printed

board silk screen. Insert all tantalum capacitors as shown in

the schematic or silk screen. A complete bill of materials is

given in the following table. The components recommended

in the materials list are for SMPTE 259M standards.

DS100087-34

FIGURE 22. Jitter Measurement Setup

DS100087-35

FIGURE 23. Typical Jitter Histogram

www.national.com 16

Page 17

Product Description (Continued)

DS100087-36

Schematic for Evaluation Board CLC730057

17 www.national.com

Page 18

Product Description (Continued)

CLC730057 Retimer Evaluation Board Material List

Item

Reference

Designator

Description Qty

1 U1 CLC016AJQ Retimer Chip 1

2 U2 74HC04 Hex Inv. 14 PIN SOIC 1

3 U3 74HC00 Quad 2-Input Pos-Nand Gate 1

4V

EE/VCC

Banana Jack, Red, EF Johnson #108-0902-001 1

5 Gnd Banana Jack, Black, EF Johnson #108-0993-001 1

6 DDI, DDI, SDO,

SDO, SCO, SCO

BNC PC Amphenol #31-5329-52RFX 6

7 C6 0.001 µF SMD Cap, Size 1206 1

8 C1, C2, C3, C4, C7,

C8, C12, C13

0.01 µF SMD Cap, Size 1206 8

9 C10, C11, CX, C

Z

0.1 µF SMD Cap, Size 1206 4

10 C

P

82 pF SMD Cap, Size 1206 1

11 C5, C9 6.8 µF SMD Cap, Tantalum Cap, Size 6032 Digikey #PCT3685 2

12 SW1 5 Position Dip Switch Grayhill #GH1216 1

13 D1, D2 DL4148-ND Switching Diode (1N4148 or equivalent) 2

14 RT0, RT1, RT2,

RT3

Sub-miniature PCB Mount LED Array PC084-GL5 1

15 CD, UNL Single Sub-miniature PCB Mount LED PC080-RL5 2

16 R

BW

499Ω SMD Resistor, Size 1206 1

17 R8–R12, R18, R19 10 kΩ SMD Resistor, Size 1206 7

18 R17 1 kΩ SMD Resistor, Size 1206 1

19 R13–R16 75Ω SMD Resistor, Size 1206 4

20 R

3

2550Ω SMD 1%Resistor, Size 1206 1

21 R

2

3480Ω SMD 1%Resistor, Size 1206 1

22 R

1

5490Ω SMD 1%Resistor, Size 1206 1

23 R

0

6810Ω SMD 1%Resistor, Size 1206 1

24 R4, R5, R6, R7 Choose for input termination 4

25 Socket Digikey #A2141-ND 1

www.national.com 18

Page 19

Product Description (Continued)

The PC board plots consist of 4-layers depicting signal traces, power planes and ground planes for the CLC730057 evaluation

board. Layers not to scale.

DS100087-37 DS100087-38

DS100087-39

DS100087-40

DS100087-41

DS100087-42

19 www.national.com

Page 20

Physical Dimensions inches (millimeters) unless otherwise noted

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or systems which, (a) are intended for surgical implant into

the body, or (b) support or sustain life, and whose failure to perform when properly used in accordance

with instructions for use provided in the labeling, can

be reasonably expected to result in a significant injury

to the user.

2. A critical component in any component of a life support

device or system whose failure to perform can be reasonably expected to cause the failure of the life support

device or system, or to affect its safety or effectiveness.

National Semiconductor

Corporation

Americas

Tel: 1-800-272-9959

Fax: 1-800-737-7018

Email: support@nsc.com

www.national.com

National Semiconductor

Europe

Fax: +49 (0) 1 80-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 1 80-530 85 85

English Tel: +49 (0) 1 80-532 78 32

Français Tel: +49 (0) 1 80-532 93 58

Italiano Tel: +49 (0) 1 80-534 16 80

National Semiconductor

Asia Pacific Customer

Response Group

Tel: 65-2544466

Fax: 65-2504466

Email: sea.support@nsc.com

National Semiconductor

Japan Ltd.

Tel: 81-3-5620-6175

Fax: 81-3-5620-6179

Order Number CLC016ACQ or CLC016AJQ

NS Package Number V28A

CLC016 Data Retiming PLL with Automatic Rate Selection

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

Loading...

Loading...