Datasheet CHFP6KE60A, CHFP6KE60, CHFP6KE43A, CHFP6KE43, CHFP6KE40A Datasheet (Microsemi Corporation)

...Page 1

8700 E. Thomas Road

• Solderable standoff tabs .040X.040X.010

Scottsdale, AZ 85251

Tel: (480) 941-6300

Fax: (480) 947-1503

FLIP-CHIP TVS DIODES

CHFP6KE5.0

thru

CHFP6KE170CA

FEATURES

• Unidirectional and Bidirectional

• Fully glass passivated

• 600 watt (10/1000 µs)

• Eliminates wire bonding

• NON Inductive Insertion

• No voltage overshoot

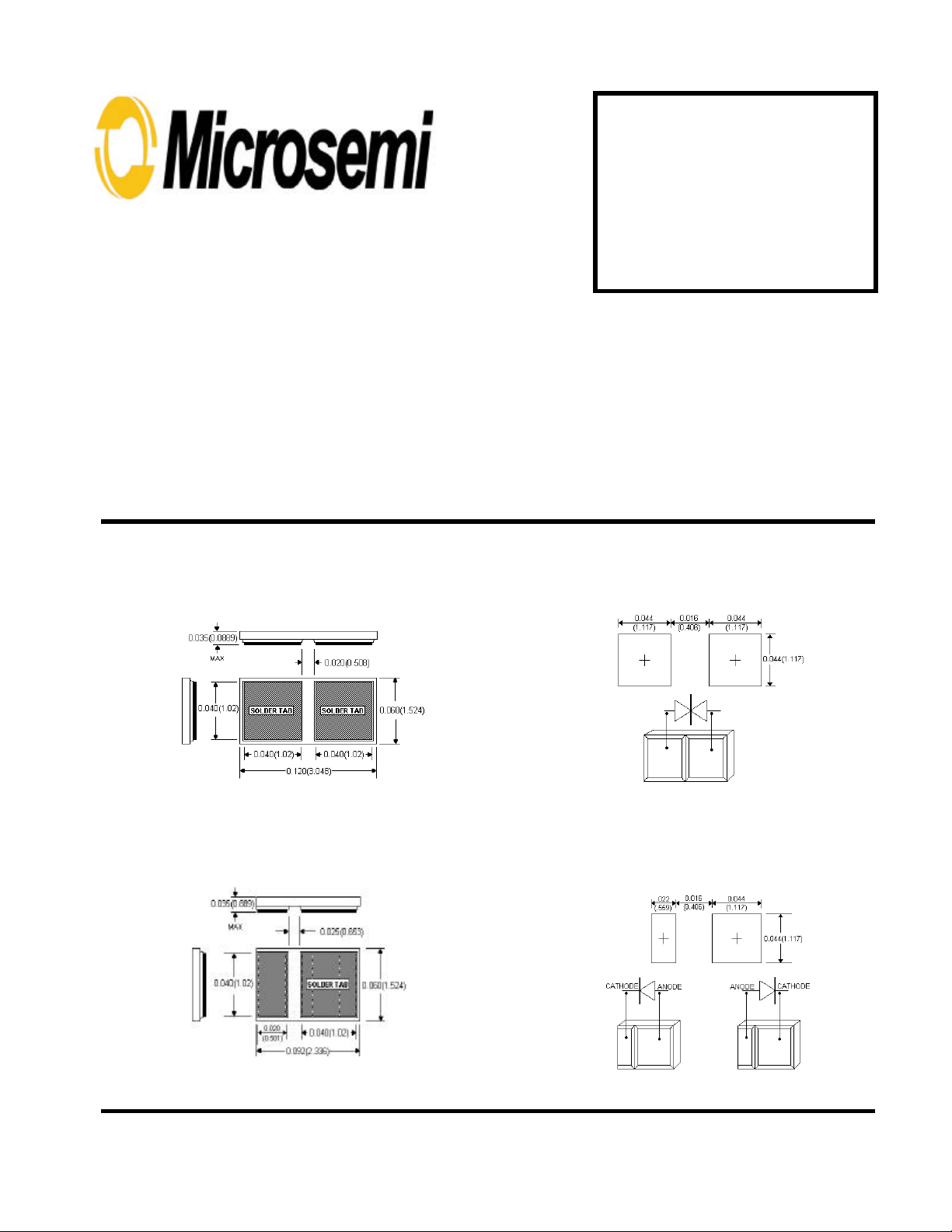

MECHANICAL

•

Weight: 0.01 grams (approximate)

PACKAGING

• Waffle package 50 pices or wafer ring 70 pieces

BIDIRECTIONAL ALL DIMENSIONS NOMINAL

FLIP-CHIP DIMENSIONS PAD SIZE & CIRCUIT

Patented Flip-Chip Series

MAXIMUM RATINGS

• Max Junction Temperature: 1500C (with conformal coating)

• Storage Temperature: -55

• Flip-Chip Peak Pulse Power: 600 Watts (10/1000 µs)

• Maximum non-repetitive peak power 600 Watts (10/1000 µs)

• Total continuous power dissipation 2.5 W (with adequate heat

sink @ 75

• Turn-on time (theoretical) unidirectional 1X10

• Turn-on time (theoretical) bidirectional 1X10

0

C)

inches (mm)

0

C to +1500C

-12

-9

FLIP-CHIP DIMENSIONS PAD SIZE & CIRCUIT

MSC1596.PDF ISO 9001 CERTIFIED REV B 3/13/2000

UNIDIRECTIONAL ALL DIMENSIONS NOMINAL

inches (mm)

VBR above 30 V VBR 30V and below

Page 2

CHFP6KE5.0 thru CHFP6KE170CA

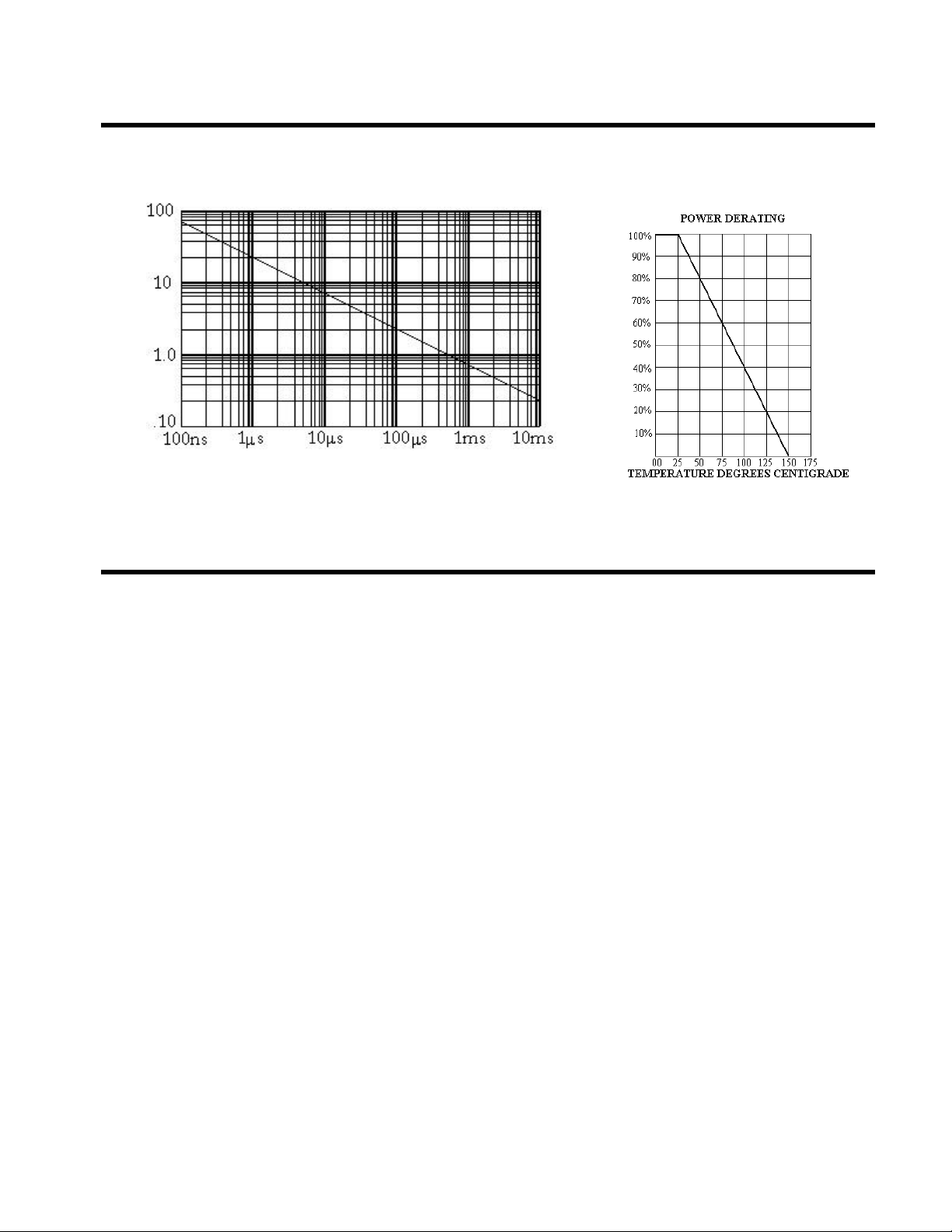

PEAK PULSE POWER Vs PULSE TIME

– PEAK PULSE POWER – kW

pp

P

TP – PULSE TIME – SEC

PEAK PULSE

POWER DERATING

)

PP

) or Current (I

PP

In percent of 25° C rating

Peak Pulse Power (P

TEMPERATURE °C

ATTACHMENT AND CONFORMAL COATING

INSTRUCTIONS

FOR Flip-Chip COMPONENTS

The .010” thick tab standoffs minimize shorting during attachment; however, minimal

solder/conductive epoxy must be used and carefully controlled to prevent excess

attachment material from wicking up the side of the tab and shorting across the junction.

Maximum recommended solder temperatures are 212 C for IR reflow and 221 C for

vapor-phase reflow. For flip-chip protection, coating material is Stycast ™ 2651-40 lowviscosity epoxy manufactured by Emerson & Cuming. Follow instructions carefully for

preparation of the epoxy to prevent entrapment of air bubbles. Make sure that Flip-Chips

have been baked at 100 C for 15 minutes minimum to out-gas any adsorbed moisture

immediately prior to coating. Epoxy-coating material should be dispensed around the

edges of the chip with an appropriately sized syringe after which epoxy is de-aired to

remove bubbles entrapped beneath the chip. Cure epoxy as instructed by the supplier.

MSC1596.PDF ISO 9001 CERTIFIED REV B 3/13/2000

Page 3

CHFP6KE5.0 thru CHFP6KE170CA

ELECTRICAL Characteristics @ 250C Unless otherwise specified

Part

Number

CHFP6KE5.0 5.0 6.4 10 9.6 800 62.5 .057

CHFP6KE5.0A 5.0 6.4 10 9.2 800 62.5 .057

CHFP6KE6.0 6.0 6.67 10 11.4 800 52.6 .059

CHFP6KE6.0A 6.0 6.67 10 10.3 800 58.3 .059

CHFP6KE6.5 6.5 7.22 10 12.3 500 48.7 .061

CHFP6KE6.5A 6.5 7.22 10 11.2 500 53.6 .061

CHFP6KE7.0 7.0 7.78 10 13.3 200 45.1 .065

CHFP6KE7.0A 7.0 7.78 10 12.0 200 50.0 .065

CHFP6KE7.5 7.5 8.33 1 14.3 100 42.0 .067

CHFP6KE7.5A 7.5 8.33 1 12.9 100 46.5 .067

CHFP6KE8.0 8.0 8.89 1 15.0 50 40.0 .070

CHFP6KE8.0A 8.0 8.89 1 13.6 50 44.1 .070

CHFP6KE8.5 8.5 9.44 1 15.9 10 37.7 .073

CHFP6KE8.5A 8.5 9.44 1 14.4 10 41.7 .073

CHFP6KE9.0 9.0 10.0 1 16.9 5 35.5 .076

CHFP6KE9.0A 9.0 10.0 1 15.4 5 59.0 .076

CHFP6KE10 10 11.1 1 18.8 5 31.9 .078

CHFP6KE10A 10 11.1 1 17.0 5 35.3 .078

CHFP6KE11 11 12.2 1 20.1 5 29.9 .081

CHFP6KE11A 11 12.2 1 18.2 5 33.0 .081

CHFP6KE12 12 13.3 1 22.0 5 27.3 .082

CHFP6KE12A 12 13.3 1 19.9 5 30.2 .082

CHFP6KE13 13 14.4 1 23.8 5 25.2 .084

CHFP6KE13A 13 14.4 1 21.5 5 27.9 .084

CHFP6KE14 14 15.6 1 25.8 5 23.3 .086

CHFP6KE14A 14 15.6 1 23.2 5 25.8 .086

CHFP6KE15 15 16.7 1 26.9 5 22.3 .087

CHFP6KE15A 15 16.7 1 24.4 5 24.0 .087

CHFP6KE16 16 17.8 1 28.8 5 20.8 .088

CHFP6KE16A 16 17.8 1 26.0 5 23.1 .088

CHFP6KE17 17 18.9 1 30.5 5 29.7 .090

CHFP6KE17A 17 18.9 1 27.6 5 21.7 .090

CHFP6KE18 18 20.0 1 32.2 5 18.6 .092

CHFP6KE18A 18 20.0 1 29.2 5 20.5 .092

CHFP6KE20 20 22.2 1 35.8 5 16.7 .093

CHFP6KE20A 20 22.2 1 32.4 5 18.5 .093

CHFP6KE22 22 24.4 1 39.4 5 15.2 .094

CHFP6KE22A 22 24.4 1 35.5 5 16.9 .094

CHFP6KE24 24 26.7 1 43.0 5 14.0 .096

CHFP6KE24A 24 26.7 1 38.9 5 15.4 .096

CHFP6KE26 26 28.9 1 46.6 5 12.4 .097

CHFP6KE26A 26 28.9 1 42.1 5 14.2 .097

CHFP6KE28 28 31.1 1 50.0 5 12.0 .098

CHFP6KE28A 28 31.1 1 45.4 5 13.2 .098

CHFP6KE30 30 33.3 1 53.5 5 11.2 .099

CHFP6KE30A 30 33.3 1 48.4 5 12.4 .099

CHFP6KE33 33 36.7 1 59.0 5 10.2 .100

CHFP6KE33A 33 36.7 1 53.3 5 11.3 .100

CHFP6KE36 36 40.0 1 64.3 5 9.3 .101

CHFP6KE36A 36 40.0 1 58.1 5 10.3 .101

CHFP6KE40 40 44.4 1 71.4 5 8.4 .101

CHFP6KE40A 40 44.4 1 64.5 5 9.3 .101

CHFP6KE43 43 47.8 1 76.7 5 7.8 .102

CHFP6KE43A 43 47.8 1 69.4 5 8.6 .102

CHFP6KE45 45 50.0 1 80.3 5 7.5 .102

CHFP6KE45A 45 50.0 1 72.7 5 8.3 .102

CHFP6KE48 48 53.3 1 85.5 5 7.0 .103

CHFP6KE48A 48 53.3 1 77.4 5 7.7 .103

CHFP6KE51 51 56.7 1 91.1 5 6.6 .103

CHFP6KE51A 51 56.7 1 82.4 5 7.3 .103

CHFP6KE54 54 60.0 1 96.3 5 6.2 .104

CHFP6KE54A 54 60.0 1 87.1 5 6.9 .104

CHFP6KE58 58 64.4 1 103 5 5.8 .104

CHFP6KE58A 58 64.4 1 93.6 5 6.4 .104

CHFP6KE60 60 66.7 1 107 5 5.6 .104

CHFP6KE60A 60 66.7 1 96.8 5 6.2 .104

CHFP6KE64 64 71.1 1 114 5 5.3 .105

CHFP6KE64A 64 71.1 1 103 5 5.8 .105

CHFP6KE70 70 77.8 1 125 5 4.8 .105

CHFP6KE70A 70 77.8 1 113 5 5.3 .105

CHFP6KE75 75 83.3 1 134 5 4.5 .105

CHFP6KE75A 75 83.3 1 121 5 4.9 .105

CHFP6KE78 78 86.7 1 139 5 4.3 .106

CHFP6KE78A 78 86.7 1 126 5 4.7 .106

CHFP6KE85 85 94.4 1 151 5 3.9 .107

CHFP6KE85A 85 94.4 1 137 5 4.4 .107

CHFP6KE90 90 100 1 160 5 3.8 .107

CHFP6KE90A 90 100 1 146 5 4.1 .107

CHFP6KE100 100 111 1 179 5 3.4 .107

CHFP6KE100A 100 111 1 162 5 3.7 .107

CHFP6KE110 110 122 1 196 5 3.0 .108

CHFP6KE110A 110 122 1 177 5 3.4 .108

CHFP6KE120 120 133 1 214 5 2.8 .108

CHFP6KE120A 120 133 1 193 5 3.1 .108

CHFP6KE130 130 144 1 231 5 2.6 .108

CHFP6KE130A 130 144 1 209 5 2.9 .108

CHFP6KE150 150 167 1 268 5 2.2 .108

CHFP6KE150A 150 167 1 243 5 2.5 .108

CHFP6KE160 160 178 1 287 5 2.1 .108

CHFP6KE160A 160 178 1 259 5 2.3 .108

Rated

Stand-off

Voltage

V

WM

VOLTS VOLTS mA VOLTS µ A AMPS %/°C

Minimum

Breakdown Voltage

V(

) @I

BR

T

Maximum Clamping

@ I

PP

VC Max

Maximum Reverse

Leakage

@ V

WM

I

D

Rated Maximum

Peak Pulse

Current

I

PP

Maximum Voltage

Temperature

Coefficient

OF V(

BR

)

Note:

For bidirectional devices

add a “C” (example

CHFP6KE5.0C thru

CHFP6KE170CA

bidirectional devices).

are

TOLERANCES

A suffix designates 5%

Plain suffix designates

10%

MSC1596.PDF ISO 9001 CERTIFIED REV B 3/13/2000

Loading...

Loading...