Page 1

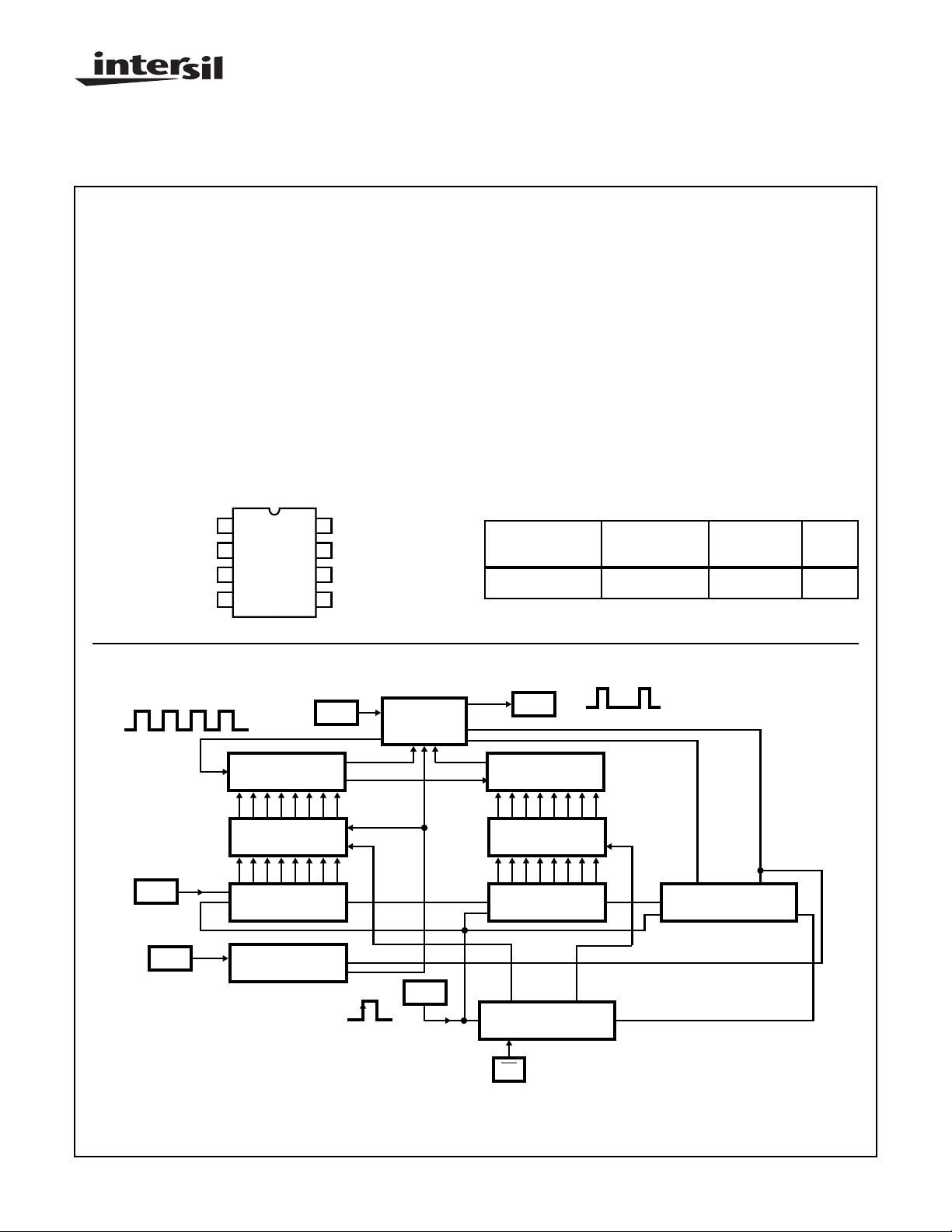

CDP68HC68W1

March 1998

Features

• Programmable Frequency and Duty Cycle Output

• Serial Bus Input; Compatible with Motorola/Intersil

SPI Bus, Simple Shift-Register Type Interface

• 8 Lead PDIP Package

• Schmitt Trigger Clock Input

o

• 4V to 6V Operation, -40

C to 85oC Temperature Range

• 8MHz Clock Input Frequency

Pinout

CDP68HC68W1

(PDIP)

TOP VIEW

CLK

1

2

CS

3

V

T

V

4

SS

8

V

DD

7

PWM

6

SCK

5

DAT A

CMOS Serial Digital Pulse Width Modulator

Description

The CDP68HC68W1 modulates a clock input to supply a

variable frequency and duty-cycle output signal. Three 8-bit

registers (pulse width, frequency and control) are accessed

serially after power is applied to initialize device operation.

The value in the pulse width register selects the high

duration of the output period. The frequency register byte

divides the clock input frequency and determines the overall

output clock period. The input clock can be further divided by

two or a low power mode may be selected by the lower two

bits in the control register. A comparator circuit allows

threshold control by setting the output low if the input at the

V

pin rises above 0.75V. The CDP68HC68W1 is supplied in

T

an 8 lead PDIP package (E suffix).

Ordering Information

TEMP. RANGE

PART NUMBER

CDP68HC68W1E -40 to 85 8 Ld PDIP E8.3

(oC) PACKAGE

PKG.

NO.

Block Diagram

DAT A

V

T

8 - STAGE RIPPLE

COUNTER

PULSE - WIDTH

DATA REGISTER

8 - STAGE SHIFT

REGISTER

V

T

COMPARATOR

CLK

RESET

LOAD

INPUT CLK

MODULATOR

LOGIC

SCK

PWM

8 - STAGE RIPPLE

COUNTER

FREQUENCY

DATA REGISTER

8 - STAGE SHIFT

REGISTER

168

5 - STAGE 24 - STATE

COMPARATOR

CS

LOAD

24

CONTROL REGISTER

2 - STAGE SHIFT

LOAD

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

http://www.intersil.com or 407-727-9207

| Copyright © Intersil Corporation 1999

1

File Number 1919.3

Page 2

CDP68HC68W1

Absolute Maximum Ratings Thermal Information

DC Supply Voltage Range, (VDD) . . . . . . . . . . . . . . . . -0.5V to +7V

(Voltage Referenced to VSS Terminal)

Input Voltage Range, All Inputs . . . . . . . . . . . . .-0.5V to VDD +0.5V

DC Input Current, Any One Input. . . . . . . . . . . . . . . . . . . . . . . . .±10mA

Operating Conditions

Temperature Range (TA) . . . . . . . . . . . . . . . . . . . . . . -40oC to 85oC

TA = Full Package Temperature Range (All Package Types)

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation

of the device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTE:

1. θJA is measured with the component mounted on an evaluation PC board in free air.

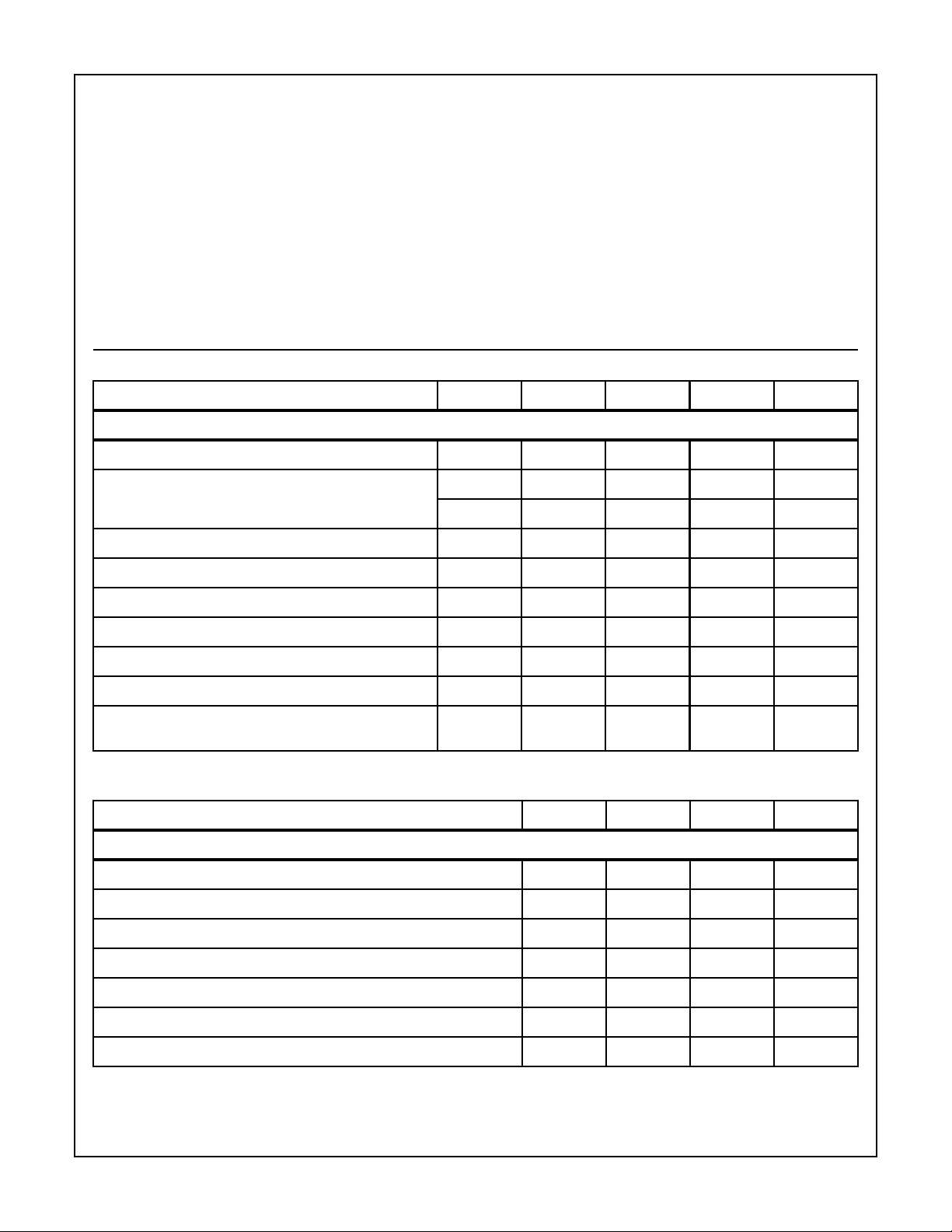

DC Electrical Specifications

PARAMETER SYMBOL MIN TYP MAX UNITS

CDP68HC68W1, VDD = 5V ±10%, VSS = 0V, TA = -40oC to 85oC

DC Operating Voltage Range - 4 - 6 V

Thermal Resistance (Typical, Note 1) θJA (oC/W)

PDIP Package. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Device Dissipation Per Output Transistor . . . . . . . . . . . . . . .100mW

Maximum Storage Temperature Range (T

) . . . .-65oC to 150oC

STG

Maximum Lead Temperature (During Soldering) . . . . . . . . . . 265oC

At Distance 1/16 ±1/32 in. (1.59 ± 0.79mm)

From Case for 10s Max

Input Voltage Range (Except VT Pin) V

VT Pin Output Voltage Threshold V

Device Current in “Power Down” Mode, Clock Disabled I

Low Level Output Voltage (IOL = 1.6mA) V

High Level Output Voltage (IOH = -1.6mA) V

Input Leakage Current I

Operating Device Current (f

= 1MHz) I

CLK

OPER

Clock Input Capacitance

(VIN = 0V, f

= 1MHz, TA = 25oC)

CLK

IH

V

IL

IT

PD

OL

OH

IN

C

IN

0.7•V

DD

-0.3 - 0.3•V

0.4 - 0.15•V

-V

+0.3V V

DD

DD

DD

--1µA

- - 0.4 V

VDD - 0.4V - - V

--±1 µA

--1mA

- - 10 pF

Control Timing

PARAMETER SYMBOL MIN MAX UNITS

CDP68HC68W1, VDD = 5V ±10%, VSS = 0V, TA = -40oC to 85oC

Clock Frequency F

Cycle Time t

Clock to PWM Out t

Clock High Time t

Clock Low Time t

Rise Time (20% VDD to 70% VDD)t

Fall Time (70% VDDto 20% VDD)t

CLK

CYC

PWMO

CLKH

CLKL

R

F

DC 8.0 MHz

--ns

- 125 ns

50 - ns

50 - ns

- 100 ns

- 100 ns

V

V

2

Page 3

CDP68HC68W1

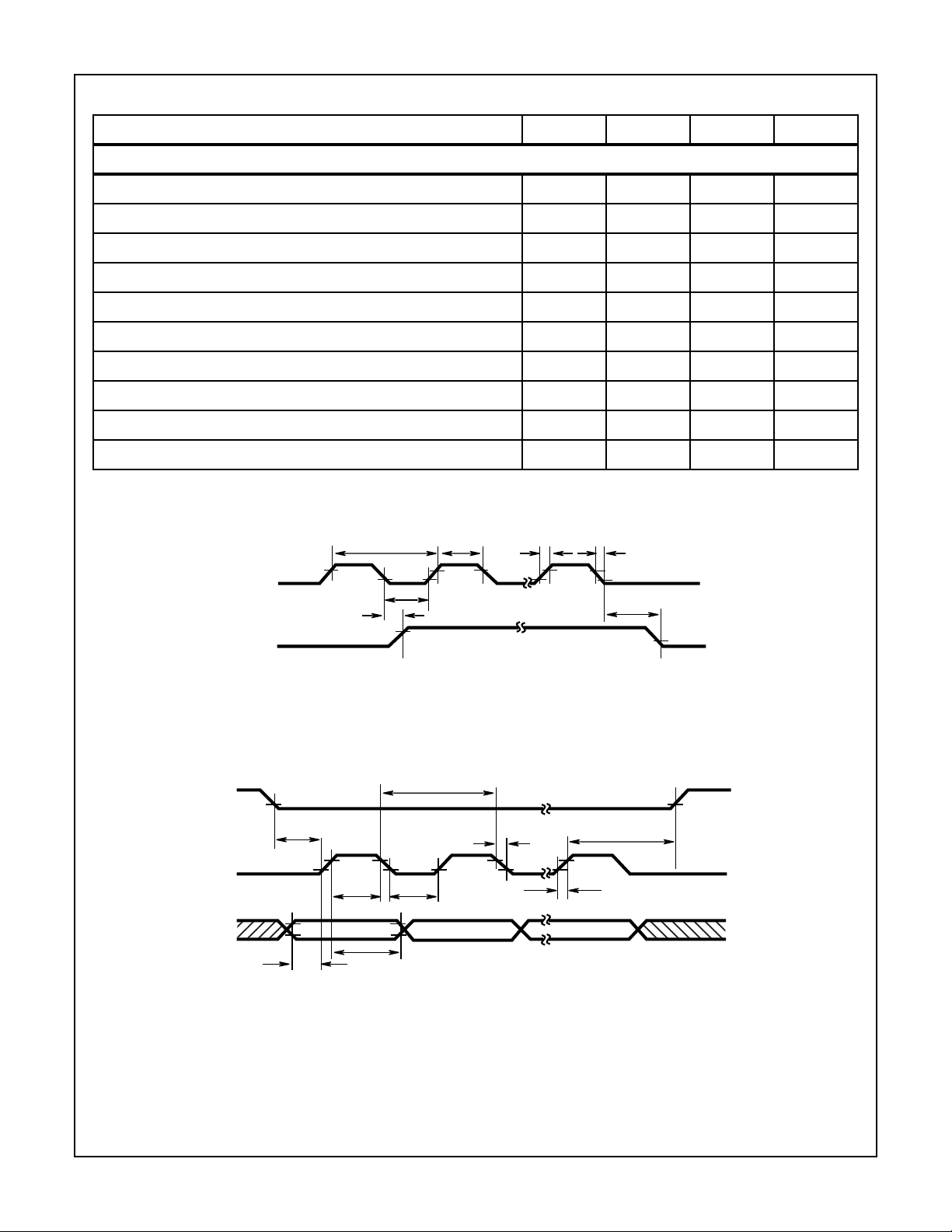

SPI Interface Timing

PARAMETER SYMBOL MIN MAX UNITS

CDP68HC68W1, VDD = 5V ±10%, VSS = 0V, TA = -40oC to 85oC

Serial Clock Frequency f

Cycle Time t

Enable Lead Time t

Enable Lag Time t

Serial Clock (SCK) High Time t

Serial Clock (SCK) Low Time t

Data Setup Time t

Data Hold Time t

Fall Time (70% VDD to 20% VDD, CL = 200pF) t

Rise Time (20% VDD to 70% VDD, CL = 200pF) t

t

CLKH

t

R

CLK

t

PWMO

t

CYC

t

CLKL

SCK

SCYC

ELD

ELG

SH

SL

DSU

DHD

SCKF

SCKR

DC 2.1 MHz

480 - ns

240 - ns

- 200 ns

190 - ns

190 - ns

100 - ns

100 - ns

- 100 ns

- 100 ns

t

F

t

PWMO

CS

(INPUT)

SCK

(INPUT)

DAT A

(INPUT)

PWM

FIGURE 1. PWM TIMING

t

SCYC

t

ELD

t

DSU

t

SH

MSB LSB

t

DHD

t

SCKF

t

SL

FIGURE 2. SERIAL PERIPHERAL INTERFACE TIMING

t

t

SCKR

ELG

3

Page 4

CDP68HC68W1

CHIP SELECT

PWM-OUT = 0

CS)

(

SERIAL CLK

(SCK)

DAT A

CLK = 0

CS)

(

SCK

DAT A

CLK

PWM-OUT

CONTROL WORD FREQUENCY WORD

DON’T

DON’T

DON’T

DON’T

DON’T

DON’T

CARE

CARE

FREQUENCY WORD PULSE WIDTH (PWM) WORD

= 0

BIT 2

= 1

= 0

BIT 1

CARE

= 0

= 0

CARE

BIT 0

= 0

= 0

BIT 7

CARE

= 0

= 0

CARE

BIT 6

= 0

PWR

COUNT

BIT 5

= 0

LSB MSBMSB

CLOCK

DIVIDE

BIT 4

= 0

BIT 7

= 0

= 0= 0= 0

BIT 2

BIT 3

= 0

= 0

BIT 6

= 0

BIT 5

BIT 1

= 0

= 0

LSBMSBLSB

BIT 4

01234567012

BIT 0

= 1

= 0

3456701234567

BIT 3

= 0

CURVES

CONTINUED

IMMEDIATELY

BELOW

CURVES

CONTINUED

BELOW

CLK

PWM

OUT

TOTAL OUTPUT PERIOD =

5 X (INPUT CLOCK PERIOD)

FIGURE 3. CDP68HC68W1 INTERFACE TIMING SPECIFICATIONS (CONTINUED)

INPUT

CLOCK (CLK)

OUTPUT

(PWM)

4

Page 5

CDP68HC68W1

Introduction

The digital pulse width modular (DPWM) divides down a

clock signal supplied via the CLK input as specified by the

control, frequency, and pulse width data registers. The

resultant output signal, with altered frequency and duty

cycle, appears at the output of the device on the PWM pin.

Functional Pin Description

VDD and V

These pins are used to supply power and establish logic levels within the PWM. V

V

SS

CLK

The CLK pin is an input only pin where the clock signal to be

altered by the PWM circuitry is supplied. This is the source

of the PWM output. This input frequency can be internally

divided by either one or two, depending on the state of the

CD bit in the control register.

CS

The CS pin is the chip select input to the PWM’s SPI interface. A high-to-low (1 to 0) transition selects the chip. A lowto-high (0 to 1) transition deselects the chip and transfers

data from the shift registers to the data registers.

VT

The VT pin is the input to the voltage threshold comparator

on the PWM. An analog voltage greater than 0.75V (at V

= 5V) on this pin will immediately cause the PWM output to

go to logic “0”. This will be the status until the V

returned to a voltage below 0.4V, the W1 is deselected, and

then one or more of the data registers is written to.

An analog voltage on this pin less than 0.75V (at V

will allow the device to operate as specified by the values in

the registers.

DAT A

Data input at this pin is clocked into the shift register (i.e.,

latched) on the rising edge of the serial clock (SCK), most

significant bits first.

SCK

The SCK pin is the serial clock input to the PWM’s SPI interface. A rising edge on this pin will shift data available at the

(DATA) pin into the shift register.

PWM

This pin provides the resultant output frequency and pulse

width. After V

a logic “0”, until the chip is selected, 24 bits of information

clocked in, and the chip deselected.

SS

(ground).

is a positive voltage with respect to

DD

input is

T

DD

power up, the output on this pin will remain

DD

DD

= 5V)

Functional Description

Serial Port

Data are entered into the three DPWM registers serially

through the DATA pin, accompanied by a clock signal applied

to the SCK. The user can supply these serial data via shift

register(s) or a microcontroller’s serial port, such as the SPI

port available on most CDP68HC05 microcontrollers. Microcontroller I/O lines can also be used to simulate a serial port.

Data are written serially, most significant bit first, in 8, 16 or

24-bit increments. Data are sampled and shifted into the

PWMs shift register on each rising edge of the SCK. The

serial clock should remain low when inactive. Therefore,

when using a 68HC05 microcontroller’s SPI port to provide

data, program the microcontroller’s SPI control register bits

CPOL, CPHA to 0, 0.

The CDP68HC68W1 latches data words after device

deselection. Therefore,

each write to the W1.

Power-Up Initialization

Upon V

at a low level (logic zero) until:

1. The chip is selected (

2. 24-bit of information are shifted in.

3. The chip is deselected (

The 24-bits of necessary information pertain to the loading

of the PWM 8-bit registers, in the following order:

1. Control register

2. Frequency register

3. Pulse width register

See section entitled

ters

specified PWM output signal will appear until the device is

reprogrammed or the voltage on the V

specified threshold. Reprogramming the device will update

the PWM output after the end of the present output clock

period.

Reprogramming Shortcuts

After the device has been fully programmed upon power up,

it is only necessary to input 8 bits of information to alter the

output pulse width, or 16 bits to alter the output frequency.

Altering the Pulse Width: The pulse width may be

changed by selecting the chip, inputting 8 bits, and deselecting the chip. By deselecting the chip, data from the first

8-bit shift register are latched into the pulse width register

(PWM register). The frequency and control registers

remain unchanged. The updated PWM information will

appear at the output only after the end of the previous total

output period.

Altering the Frequency: The frequency can be changed by

selecting the chip, inputting 16 bits (frequency information

followed by pulse width information), and deselected the

power up, the output of the PWM chip will remain

DD

for a description of each register. Once initialized, the

CS must go high (inactive) following

CS pin pulled low).

CS pin pulled high).

Pulse Width Modulator Data Regis-

pin rises above the

T

5

Page 6

CDP68HC68W1

chip. Deselection will transfer 16 bits of data from the shift

register into the frequency register and PW register. The

updated frequency and PW information will appear at the

PWM output pin only after the end of the previous total

output period.

Altering the Control Word: Changing the clock divider

and/or power control bit in the CDPHC68W1 control register

requires full 24-bit programming, as described under Power

Up Initialization.

Pulse Width Modulator Data Registers

Byte 1: Control Register

7654 3 210

0 0 0 0 0 0

B7-B2 Unused; “don’t care”.

B2, PC Power Control Bit. If this bit is a “0”, the chip will

remain in the active state. If the bit is set to a “1”,

internal clocking and the voltage comparator

(VT) circuit and voltage reference will be

disabled. Thus the chip will enter a low current

drain mode. The chip may only reenter the

active mode by clearing this bit and clocking in a

full 24 bits of information.

B0, CD Clock Divider Bit. If this bit is a “0”, the chip will

set internal clocking (CLK) at a divide-by-one

rate with respect to the (CLK). If this bit is set to

“1”, the internal clocking will be set to divide-by-2

state.

Byte 2: Frequency Data Register

765 4 3 210

PWM Frequency Register

B7-B0 This register contains the value that will deter-

mine the output frequency or total period by:

F

F

OUT

F

= resultant PWM output frequency

OUT

= the frequency of input CLK

F

IN

IN

------------------------------------------ -=

N1+()CD 1+()

n = value in frequency register

CD = value of clock divider bit in control register.

PC CD

Byte 3: Pulse Width Data Register

765 4 3 210

Pulse Width Data Register

B7-B0 This register contains the value that will

determine the pulse width or duty cycle (high

duration) of the output PWM waveform.

PW = (N+1) (CD+1)

PW = Pulse width out as measured in number of

input CLK periods.

CD = Value of clock divider bit in control register.

N = Value in PW register.

For a case of n (binary value in PW register)

equal to 3 and CD (clock divider) = 0 (divide-by-

1), the output will be 4 input clock periods of a

high level f ollo wed b y the remaining cloc ks of the

total period which will be a low level.

Assuming the frequency register contains a

value of 5, the resultant PWM output would be

high for 4 CLK periods, low for 2.

Using the CDP68HC68W1

Programming the CDP68HC68W1

1. Select chip

2. Write to control register

3. Write to frequency register

4. Write to pulse width register

5. Deselect chip

NEXT - TO then alter the pulse width

1. Select chip

2. Write to pulse width register*

3. Deselect chip

OR - To then alter the frequency (and possibly PW):

1. Select chip

2. Write to frequency register*

3. Write to pulse width register*

4. Deselect chip

NOTE: All writes use 8-bit words

Example

For a case of n (binary value in frequency

register) equal to 5, CD (clock divider) = 0

(divide-by-1), the PWM output will be a frequency 1/6 that of the input clock (CLK). Likewise, the output clock period will be equal to 6

input CLK periods.

when CD = 0,

When CD=0, frequency register = 4, pulse width register = 1;

output = high for 2 input CLK periods, low for 3;

1. Select chip

2. Then write (most significant bit first) to the control, the frequency, and pulse width registers (control = 00, frequency =

04, PW = 1)

6

Page 7

CDP68HC68W1

3. Deselect the chip

New pulse width out begins and PWM goes high when

CS is

raised after last SCK pulse (assuming no previous time-out).

PWM then toggles on falling CLK edges.

Resulting output waveform: Control = 00 = Divide-by-1,

frequency = 4;

PW = 1: (1 + 1) (0 + 1) = 2 CLKs high time.

CDP68HC68W1 Application Example

Frequency

INPCLK

------------------------------------- -

==

04 1+()0 1+()

INPCLK

----------------------- -

5

The following example was written for a system which has

the CDP68HC68W1 connected to the SPI bus of a

CDP68HC05C8B microcontroller. The program sets the W1

to run a divide by 200 frequency with a duty cycle of 30% by

and the Pulse Width Data Register. The frequency and pulse

width are then modified. Finally the pulse width is modified

without changing the frequency. The program was assembled using the Intersil HASM 3.0 assembler.

writing to the Control Register, the Frequency Data Register,

INTERSIL Corporation (c)1990 - 1997

68HC05 Assembler Version 3.0.2

Filename: W1.LST

Source Created: 01/08/98, 10:36 am

Assembled: 01/08/98, 10:36 am

00001 ***********************************************************************

00002 * File: W1.S

00003 * Example W1 routines - sets W1 to a divide by

00004 * 200 output with 30% duty cycle

00005 *

00006 * Date: Thursday, January 8, 1998

00007 ***********************************************************************

00008

00009 ***********************************************************************

00010 * Partial Map of CDP68HC05C8B Hardware Registers

00011 ***********************************************************************

00012

00013 0000 Section Registers, $0000

00014 0000 PortA ds 1 ;Port A

00015 0001 PortB ds 1 ;Port B

00016 0002 PortC ds 1 ;Port C

00017 0003 PortD ds 1 ;Port D

00018 0004 DDRA ds 1 ;Port A Data Direction Register

00019 0005 DDRB ds 1 ;Port B DDR

00020 0006 DDRC ds 1 ;Port C DDR

00021 0007 _Free1 ds 3 ;three unused locations

00022 000A SPCR ds 1 ;SPI Control Register

00023 $0006 = 6 SPE equ 6 ;SPI Enable bit

00024 $0004 = 4 MSTR equ 4 ;SPI Master Mode bit

00025 000B SPSR ds 1 ;SPI Status Register

00026 $0007 = 7 SPIF equ 7 ;SPI Flag bit for ANDs, CMPs, etc.

00027 000C SPDR ds 1 ;SPI Data Register

00028

00029 ***********************************************************************

00030 * CDP68HC68W1 Constants

00031 ***********************************************************************

00032

00033 $0000 = 0 W1 equ 0 ;W1 is connected to bit 0 of Port A

00034 $0002 = 2 W1_PC equ 2 ;Power Control: 1 = power down

00035 $0001 = 1 W1_CD equ 1 ;Clock Divider: 1 = divide by 2

00036

00037

00038 ***********************************************************************

00039 * Main Routines

00040 ***********************************************************************

00041

00042 0100 Section Code, $0100

00043

00044* [6] 0100 AD37 jsr Init_W1 ;turn on PA0

00045 Set200_30

00046 [5] 0102 1100 bclr W1,PortA ;select W1 (CE is active low)

00047* [6] 0104 AD28 jsr Set_SPI_Mode ;Setup the 68HC05 SPI control

00048 ;to talk to the W1

00049

00050 ******* Set Up Control, Frequency, and Pulse Width

00051

00052 SendCommands

00053 [2] 0106 A601 lda #W1_CD ;set divide by two clock on W1

7

Page 8

CDP68HC68W1

00054* [6] 0108 AD29 jsr SPI_xmit

00055 [2] 010A A663 lda #99 ;set frequency to divide by 2000

00056* [6] 010C AD25 jsr SPI_xmit

00057 [2] 010E A61D lda #29 ;set pulse width to 30% duty cycle

00058* [6] 0110 AD21 jsr SPI_xmit

00059

00060 DeselectW1_1

00061 [5] 0112 1000 bset W1,PortA ;deselect the W1 which loads registers

00062 ; with values transmitted

00063

00064 ;

00065 ; Here the CDP68HC05C8B would generally

00066 ; attend to other processing issues

00067 ;

00068

00069 ******* Modify Frequency and Pulse Width

00070

00071 [5] 0114 1100 bclr W1,PortA ;select W1 (CE is active low)

00072* [6] 0116 AD16 jsr Set_SPI_Mode ;Setup the CDP68HC05 SPI Control....

00073 ;to talk to the W1

00074 SendCommands2

00075 [2] 0118 A631 lda #49 ;set frequency to divide by 100 (the

00076* [6] 011A AD17 jsr SPI_xmit ;divide by 2 is still in effect)

00077 [2] 011C A609 lda #9 ;set pulse width to 20% duty cycle

00078* [6] 011E AD13 jsr SPI_xmit

00079

00080 DeselectW1_2

00081 [5] 0120 1000 bset W1,PortA ;deselect the W1 which loads registers

00082

00083 ;

00084 ; Here the CDP68HC05C8B would again

00085 ; attend to other processing issues

00086 ;

00087

00088 ******* Modify Pulse Width

00089

00090 [5] 0122 1100 bclr W1,PortA ;select W1 (CE is active low)

00091* [6] 0124 AD08 jsr Set_SPI_Mode ;Setup the 68HC05 SPI control...

00092 ;to talk to the W1

00093 SendCommands3

00094 [2] 0126 A611 lda #17 ;set pulse width to 38% duty cycle

00095* [6] 0128 AD09 jsr SPI_xmit

00096

00097 DeselectW1_3

00098 [5] 012A 1000 bset W1,PortA ;deselect the W1 which loads registers

00099 ;with values transmitted

00100 Finish

00101 [3] 012C 20FE bra * ;loop forever

00102

00103 ***********************************************************************

00104 * Common Subroutines

00105 ***********************************************************************

00106

00107 012E Section Subroutines, *

00108

00109 Set_SPI_Mode

00110 [2] 012E A650 lda #(2!SPE+2!MSTR) ;Enable SPI as a Master with....

00111 [4] 0130 B70A sta SPCR ;CPHA=CPOL=0,

00112 [6] 0132 81 rts

00113 SPI_Xmit

00114 [4] 0133 B70C sta SPDR ;send A to SPI device

00115 SPI_wait

00116 [5] 0135 0F0BFD brclr SPIF,SPSR,SPI_wait ;wait until transmit complete

00117 [6] 0138 81 rts

00118

00119 Init_W1

00120 [5] 0139 1000 bset W1,PortA ;disable the W1 (CE is active low)

00121 [5] 013B 1004 bset W1,DDRA ;by activating PA0 as a high

8

Page 9

CDP68HC68W1

Dual-In-Line Plastic Packages (PDIP)

N

D1

E1

-C-

-B-

A1

A2

A

L

e

C

S

INDEX

AREA

BASE

PLANE

SEATING

PLANE

D1

B1

1 2 3 N/2

-AD

e

B

0.010 (0.25) C AMB

NOTES:

1. Controlling Dimensions: INCH. In case of conflict between

English and Metric dimensions, the inch dimensions control.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Symbols are defined in the “MO Series Symbol List” in Section

2.2 of Publication No. 95.

4. Dimensions A, A1 and L are measured with the package seated

in JEDEC seating plane gauge GS-3.

5. D, D1, and E1 dimensions do not include mold flash or protrusions. Mold flash or protrusions shall not exceed 0.010 inch

(0.25mm).

6. E and are measured with the leads constrained to be per-

e

pendicular to datum .

A

-C-

7. eB and eC are measured at the lead tips with the leads unconstrained. eC must be zero or greater.

8. B1 maximum dimensions do not include dambar protrusions.

Dambar protrusions shall not exceed 0.010 inch (0.25mm).

9. N is the maximum number of terminal positions.

10. Corner leads (1, N, N/2 and N/2 + 1) for E8.3, E16.3, E18.3,

E28.3, E42.6 will have a B1 dimension of 0.030 - 0.045 inch

(0.76 - 1.14mm).

E8.3 (JEDEC MS-001-BA ISSUE D)

8 LEAD DUAL-IN-LINE PLASTIC PACKAGE

INCHES MILLIMETERS

SYMBOL

A - 0.210 - 5.33 4

E

A1 0.015 - 0.39 - 4

A2 0.115 0.195 2.93 4.95 -

B 0.014 0.022 0.356 0.558 -

C

L

e

A

C

e

B

B1 0.045 0.070 1.15 1.77 8, 10

C 0.008 0.014 0.204 0.355 D 0.355 0.400 9.01 10.16 5

D1 0.005 - 0.13 - 5

E 0.300 0.325 7.62 8.25 6

E1 0.240 0.280 6.10 7.11 5

e 0.100 BSC 2.54 BSC -

e

A

e

B

0.300 BSC 7.62 BSC 6

- 0.430 - 10.92 7

L 0.115 0.150 2.93 3.81 4

N8 89

NOTESMIN MAX MIN MAX

Rev. 0 12/93

All Intersil semiconductor products are manufactured, assembled and tested under ISO9000 quality systems certification.

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate

and reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which

may result from its use. No license is granted by implication or otherwise under an y patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see web site http://www.intersil.com

Sales Office Headquarters

NORTH AMERICA

Intersil Corporation

P. O. Box 883, Mail Stop 53-204

Melbourne, FL 32902

TEL: (407) 724-7000

FAX: (407) 724-7240

EUROPE

Intersil SA

Mercure Center

100, Rue de la Fusee

1130 Brussels, Belgium

TEL: (32) 2.724.2111

FAX: (32) 2.724.22.05

ASIA

Intersil (Taiwan) Ltd.

Taiwan Limited

7F-6, No. 101 Fu Hsing North Road

Taipei, Taiwan

Republic of China

TEL: (886) 2 2716 9310

FAX: (886) 2 2715 3029

9

Loading...

Loading...